Experimental Study of Sand Production during Depressurization Exploitation in Hydrate Silty-Clay Sediments

Abstract

:1. Introduction

2. Experimental Introduction

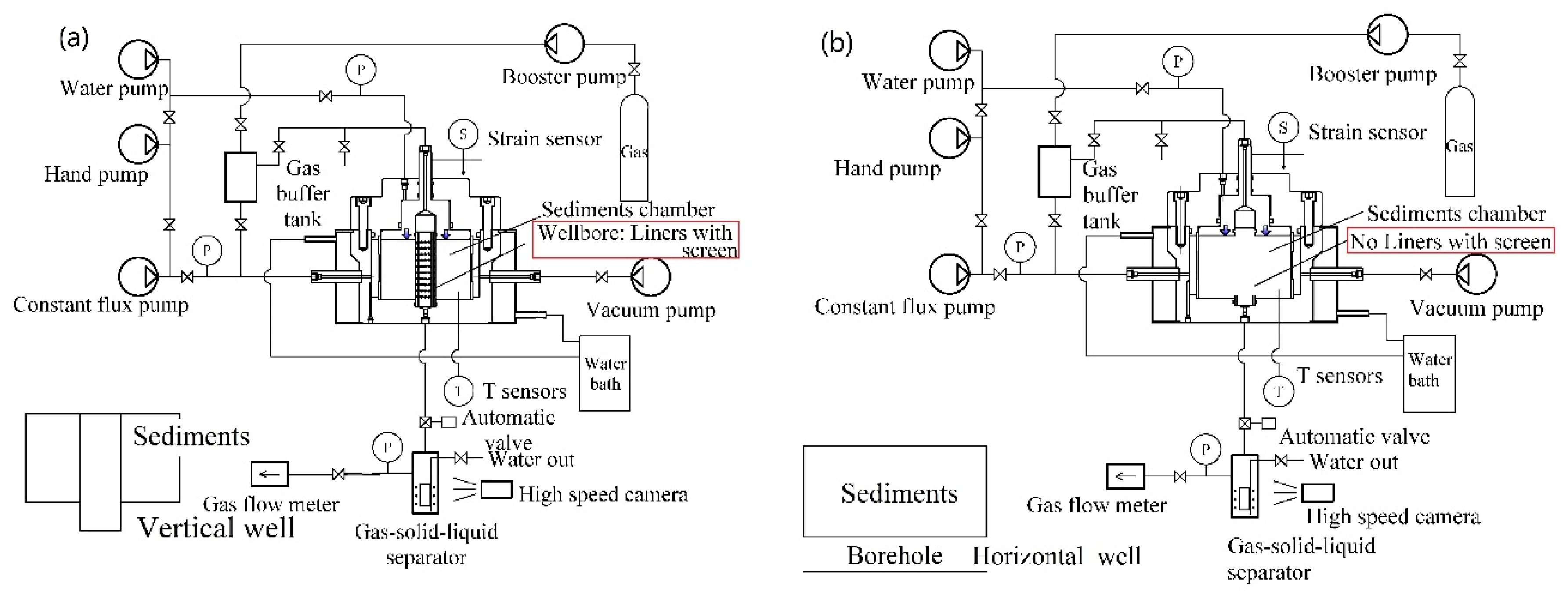

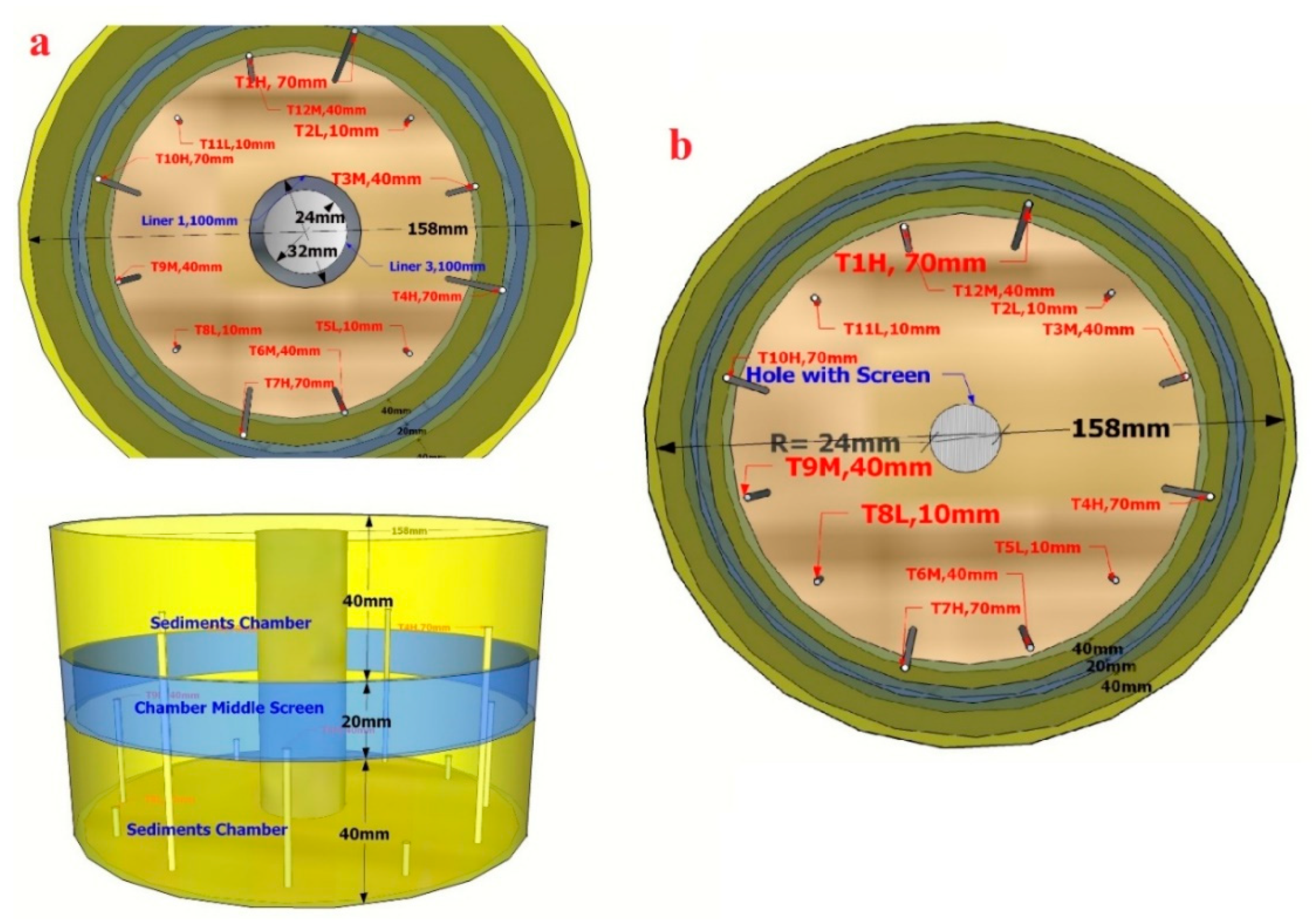

2.1. Experimental System

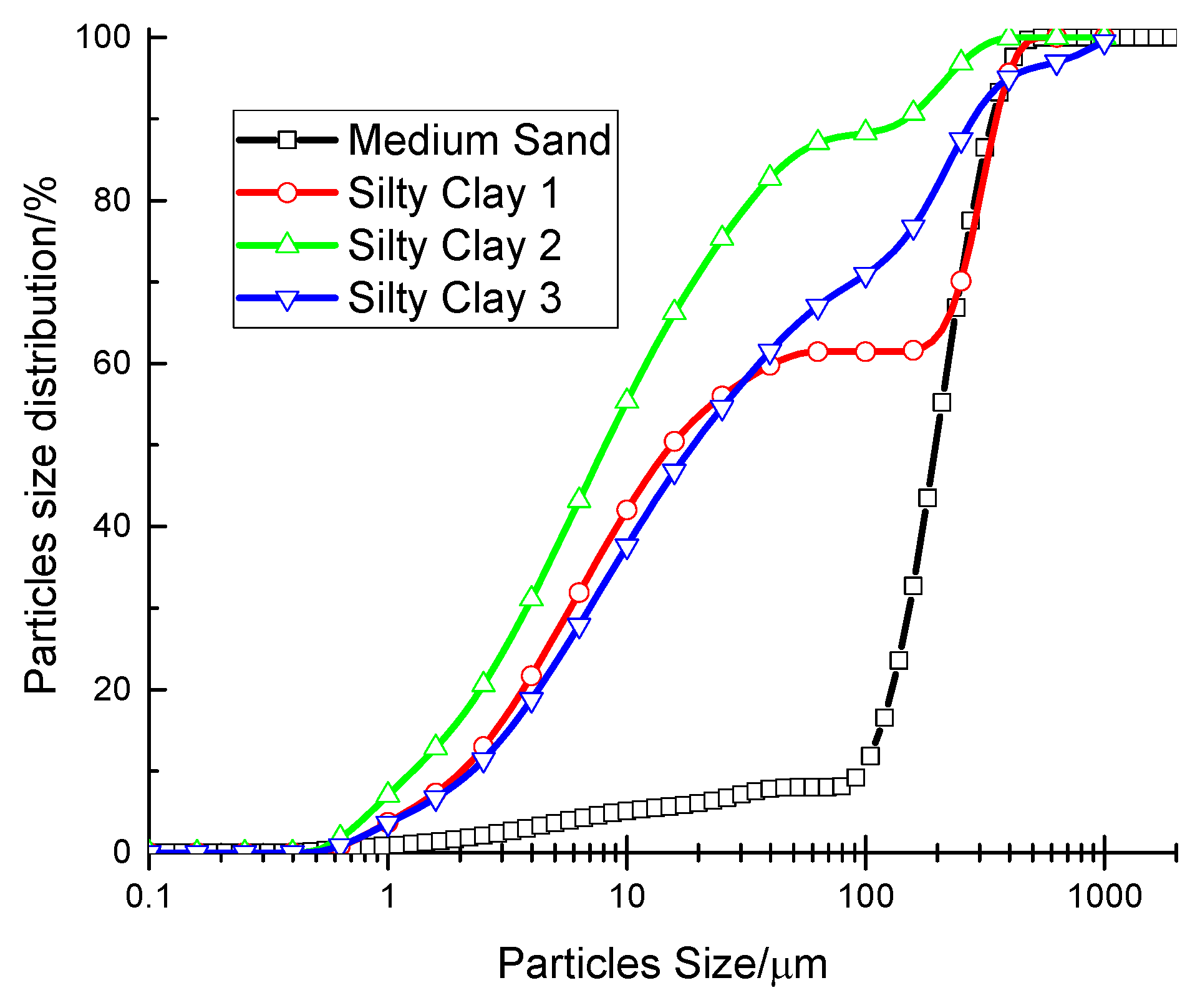

2.2. Experimental Materials

2.3. Experimental Procedure

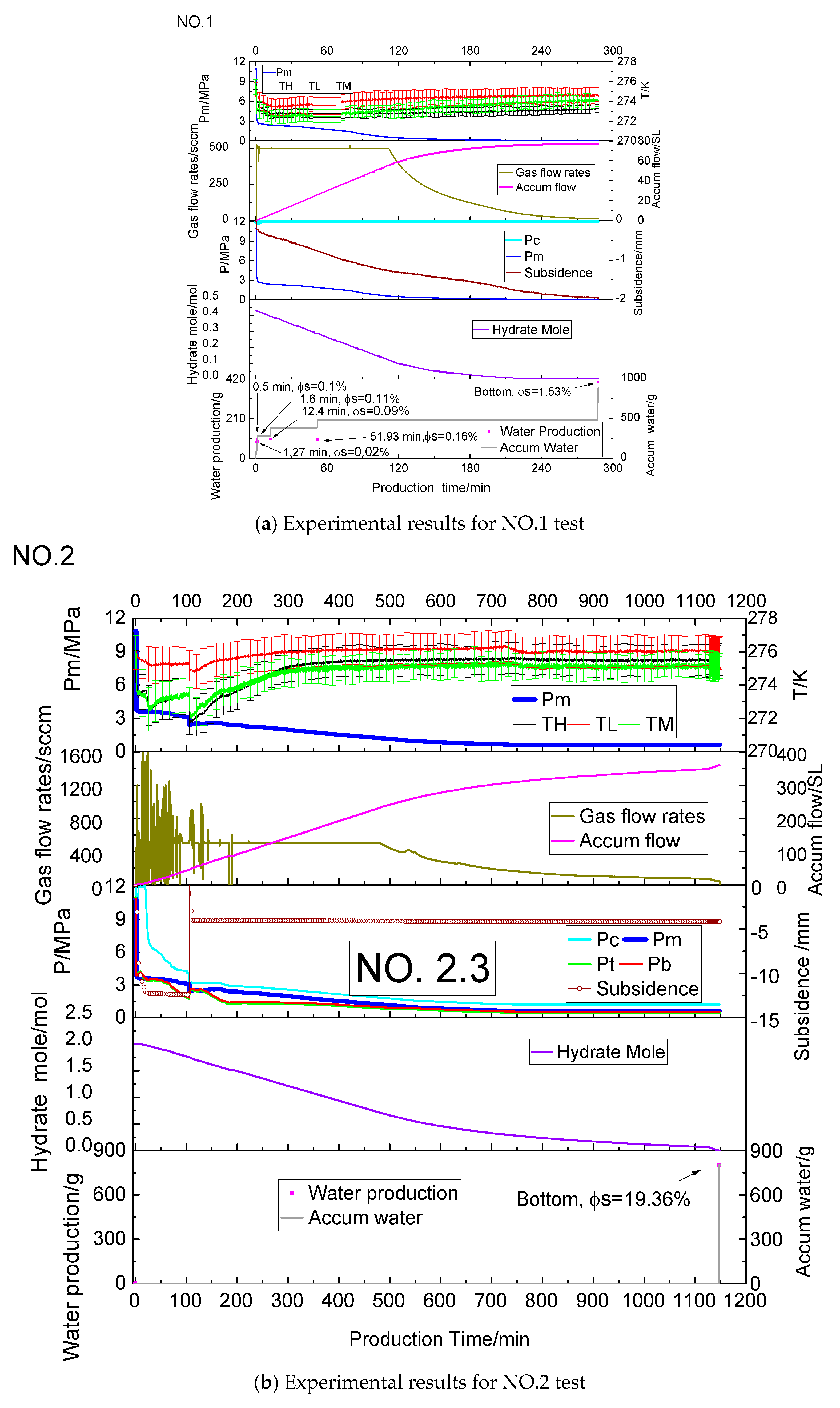

3. Experimental Results and Discussion

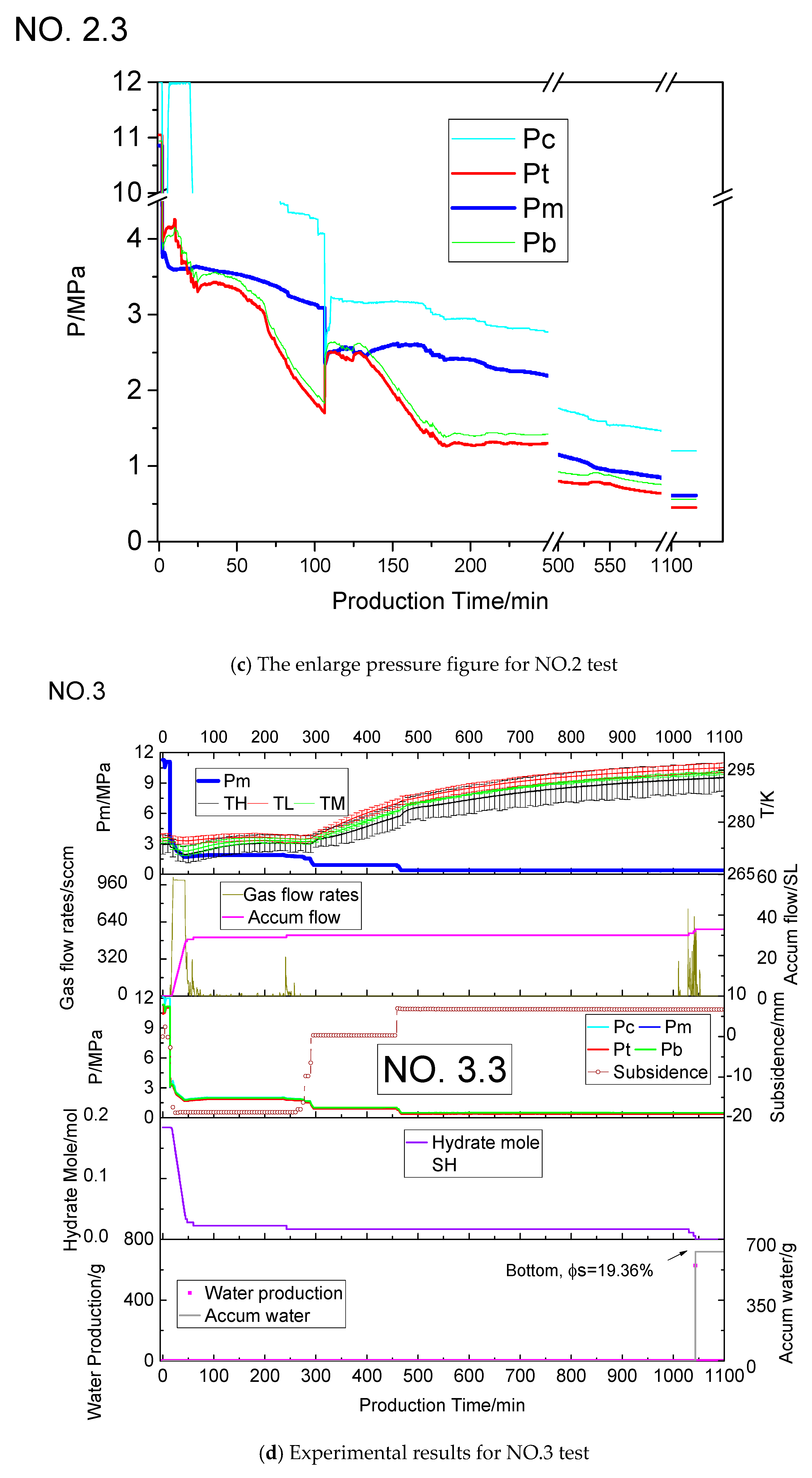

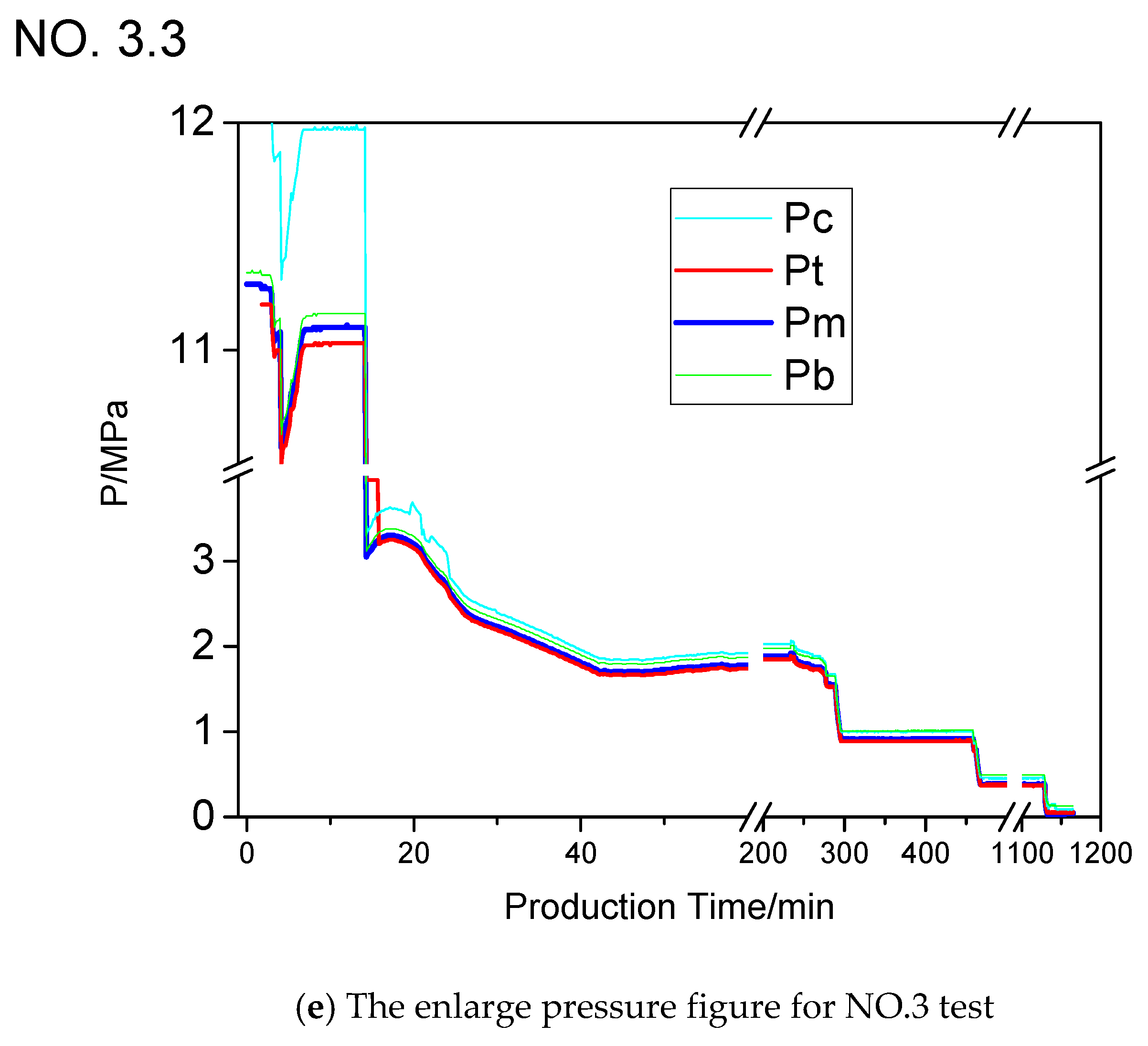

3.1. Characteristics Relating to Pressure

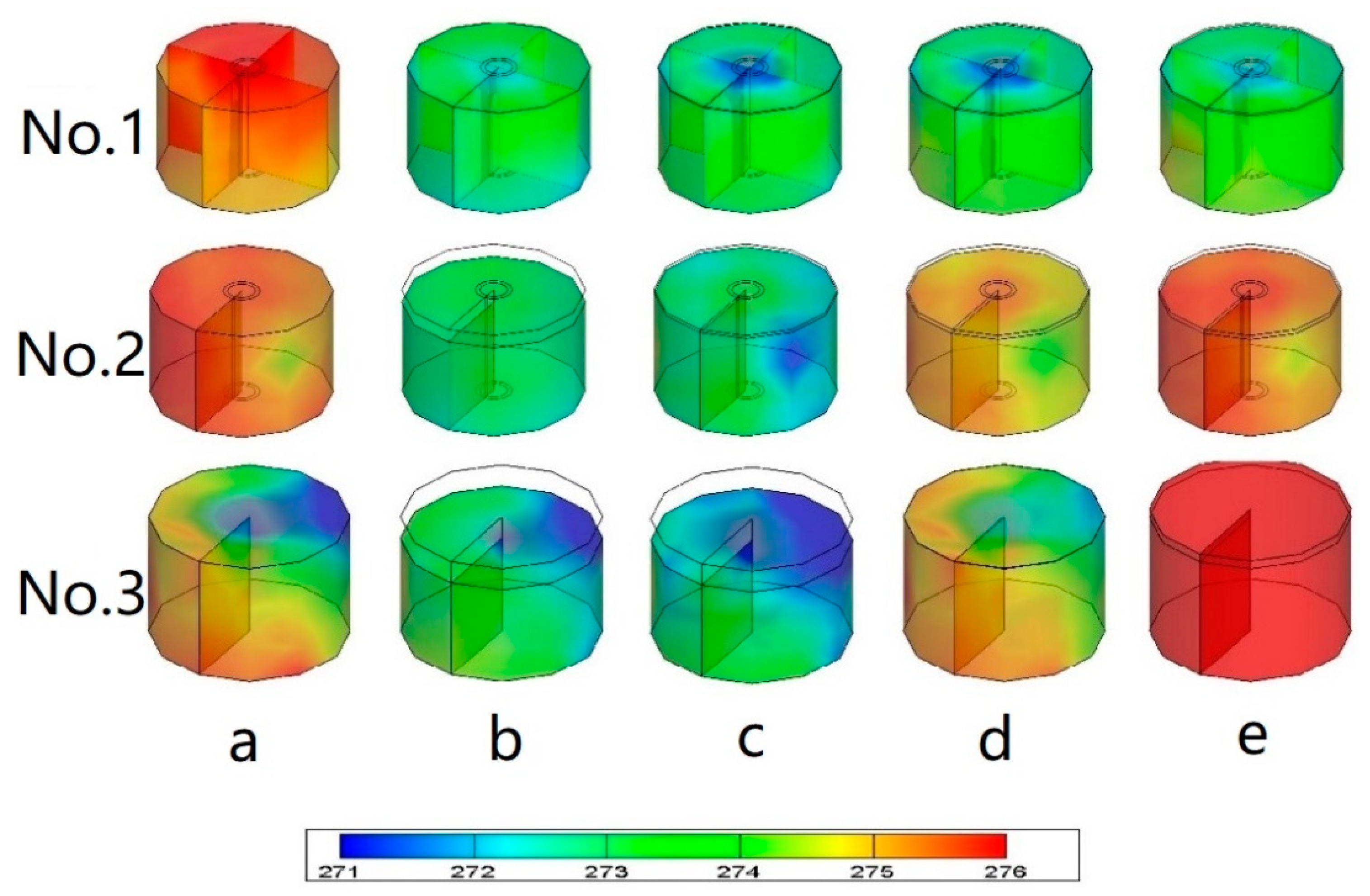

3.2. Characteristics Relating to Temperature

3.3. Characteristics Relating to Sand Production and Subsidence

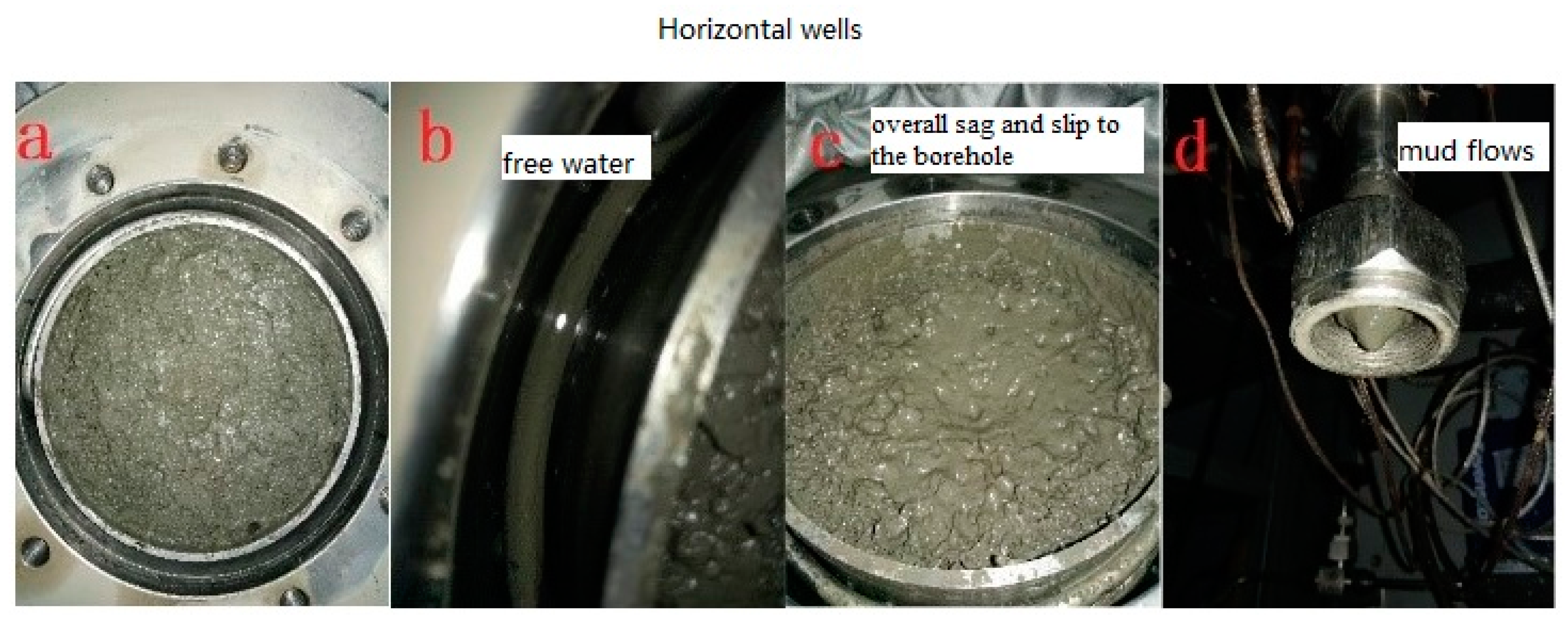

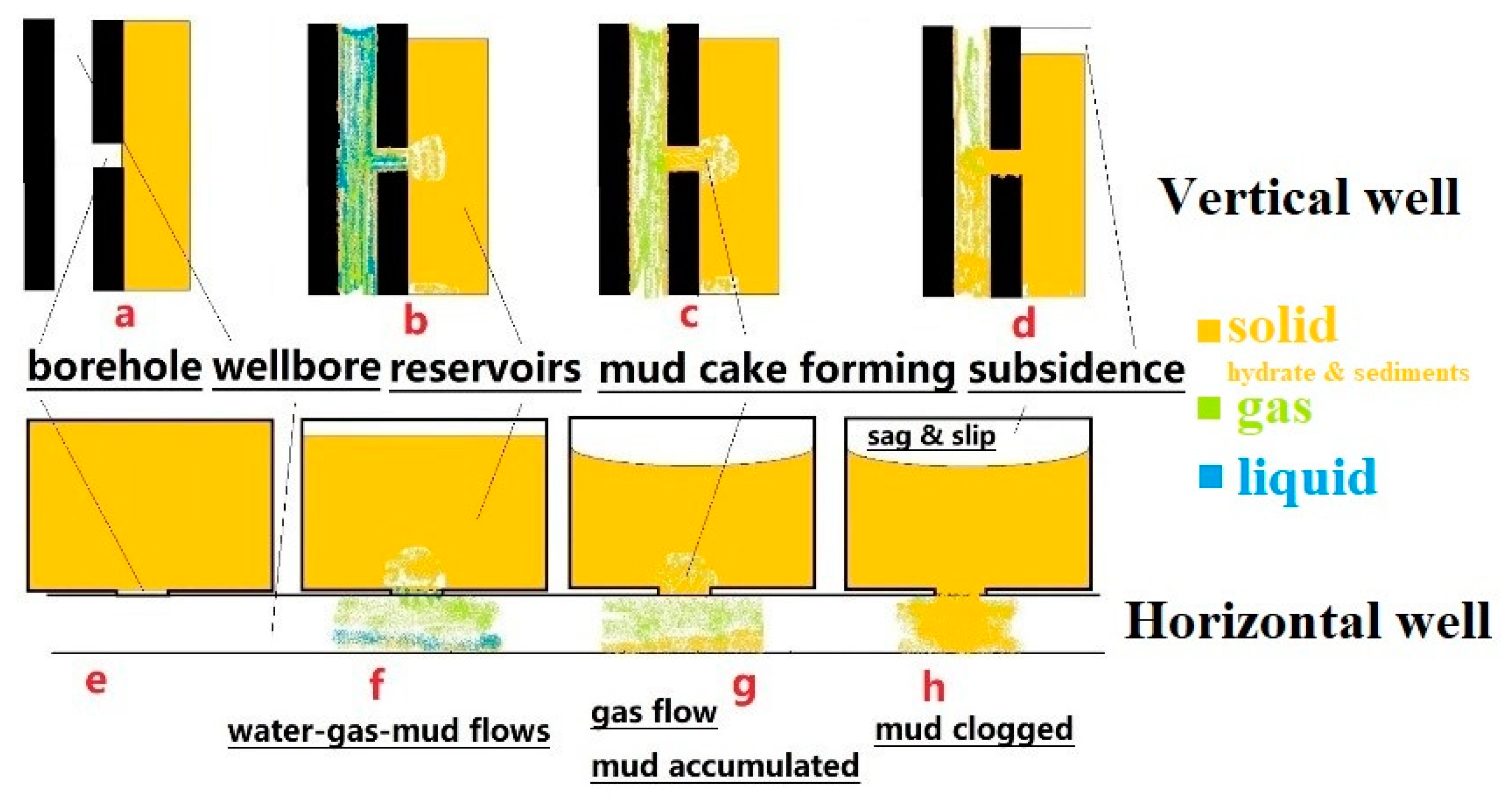

3.3.1. Sand Production and Subsidence Characteristics in a Horizontal Well

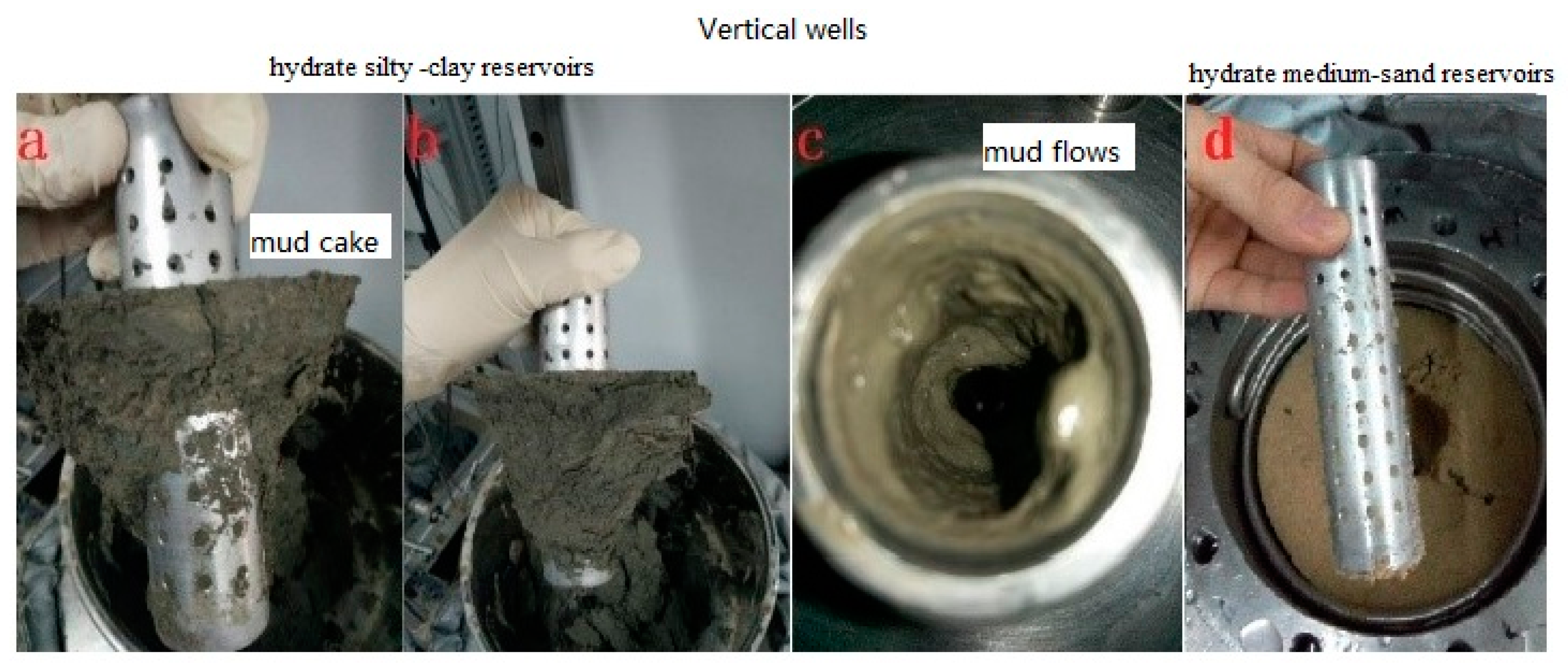

3.3.2. Sand Production and Subsidence Characteristics in a Vertical Well

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sloan, E.D.; Koh, C.A. Clathrate Hydrates of Natural Gases; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Milkov, A.V.; Sassen, R. Economic geology of offshore gas hydrate accumulations and provinces. Mar. Pet. Geol. 2002, 19, 1–11. [Google Scholar] [CrossRef]

- Milkov, A.V.; Sassen, R. Preliminary assessment of resources and economic potential of individual gas hydrate accumulations in the Gulf of Mexico continental slope. Mar. Pet. Geol. 2003, 20, 111–128. [Google Scholar] [CrossRef]

- Collett, T.; Bahk, J.-J.; Baker, R.; Boswell, R.; Divins, D.; Frye, M.; Goldberg, D.; Husebø, J.; Koh, C.; Malone, M. Methane Hydrates in Nature-Current Knowledge and Challenges. J. Chem. Eng. Data 2014, 60, 319–329. [Google Scholar] [CrossRef]

- Moridis, G.J.; Collett, T.S.; Pooladi-Darvish, M.; Hancock, S.; Santamarina, C.; Boswell, R.; Kneafsey, T.; Rutqvist, J.; Kowalsky, M.; Reagan, M.T. Challenges, Uncertainties and Issues Facing Gas Production from Gas Hydrate Deposits; Ernest Orlando Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2010.

- Hyodo, M.; Li, Y.; Yoneda, J.; Nakata, Y.; Yoshimoto, N.; Nishimura, A. Effects of dissociation on the shear strength and deformation behavior of methane hydrate-bearing sediments. Mar. Pet. Geol. 2014, 51, 52–62. [Google Scholar] [CrossRef]

- Li, D.; Wu, Q.; Wang, Z.; Lu, J.; Liang, D.; Li, X. Tri-Axial Shear Tests on Hydrate-Bearing Sediments during Hydrate Dissociation with Depressurization. Energies 2018, 11, 1819. [Google Scholar] [CrossRef]

- Grover, T.; Moridis, G.J.; Holditch, S.A. Analysis of Reservoir performance of messoyakha gas hydrate reservoir. In Proceedings of the Eighteenth International Offshore and Polar Engineering Conference, Vancouver, BC, Canada, 6–11 July 2008. [Google Scholar]

- Yamamoto, K.; Dallimore, S. Aurora-JOGMEC-NRCan Mallik 2006–2008 gas hydrate research project progress. Nat. Gas Oil 2008, 304, 285–4541. [Google Scholar]

- Haberer, R.M.; Mangelsdorf, K.; Wilkes, H.; Horsfield, B. Occurrence and palaeoenvironmental significance of aromatic hydrocarbon biomarkers in Oligocene sediments from the Mallik 5L-38 Gas Hydrate Production Research Well (Canada). Org. Geochem. 2006, 37, 519–538. [Google Scholar] [CrossRef]

- Lu, H.; Lorenson, T.D.; Moudrakovski, I.L.; Ripmeester, J.A.; Collett, T.S.; Hunter, R.B.; Ratcliffe, C.I. The characteristics of gas hydrates recovered from the Mount Elbert gas hydrate stratigraphic test well, Alaska North Slope. Mar. Pet. Geol. 2011, 28, 411–418. [Google Scholar] [CrossRef]

- Saeki, T. Road to Offshore Gas Production Test—from Mallik to Nankai Trough. In Offshore Technology Conference; Offshore Technology Conference: Houston, TX, USA, 2014. [Google Scholar]

- Zhou, S.; Chen, W.; Li, Q.; Zhou, J.; Shi, H. Research on the solid fluidization well testing and production for shallow non-diagenetic natural gas hydrate in deep water area. China Offshore Oil Gas 2017, 29, 1–8. [Google Scholar]

- Li, J.-F.; Ye, J.-L.; Qin, X.-W.; Qiu, H.-J.; Wu, N.-Y.; Lu, H.-L.; Xie, W.-W.; Lu, J.-A.; Peng, F.; Xu, Z.-Q.; et al. The first offshore natural gas hydrate production test in South China Sea. China Geol. 2018, 1, 5–16. [Google Scholar] [CrossRef]

- Wu, N.; Huang, L.; Hu, G.; Li, Y.; Chen, Q.; Liu, C. Geological control factors and scientific challenges for offshore gas hydrate exploitation. Mar. Geol. Quat. Geol. 2017, 37, 1–11. [Google Scholar]

- Lu, J.; Li, D.; He, Y.; Liang, D.; Xiong, Y. Research Status of Sand Production during the Gas Hydrate Exploitation Process. Adv. New Renew. Energy 2017, 5, 394–402. [Google Scholar]

- Uchida, S.; Klar, A.; Yamamoto, K. Sand production model in gas hydrate-bearing sediments. Int. J. Rock Mech. Min. Sci. 2016, 86, 303–316. [Google Scholar] [CrossRef]

- Boswell, R. Engineering. Is gas hydrate energy within reach? Science 2009, 325, 957. [Google Scholar] [CrossRef]

- Oyama, H.; Nagao, J.; Suzuki, K.; Narita, H. Experimental analysis of sand production from methane hydrate bearing sediments applying depressurization method. J. MMIJ 2010, 126, 497–502. [Google Scholar] [CrossRef]

- Jung, J.W.; Jang, J.; Santamarina, J.C.; Tsouris, C.; Phelps, T.J.; Rawn, C.J. Gas Production from Hydrate-Bearing Sediments: The Role of Fine Particles. Energy Fuels 2011, 26, 480–487. [Google Scholar] [CrossRef]

- Suzuki, S.; Kuwano, R. Evaluation on stability of sand control in mining methane hydrate. Seisan Kenkyu 2016, 68, 311–314. [Google Scholar]

- Murphy, A.; Soga, K.; Yamamoto, K. A laboratory investigation of sand production simulating the 2013 Daini- Atsumi Knoll gas hydrate production trial using a high pressure plane strain testing apparatus. In Proceedings of the 9th International Conferences on Gas Hydrate, Denver, CO, USA, 25–30 June 2017. [Google Scholar]

- Murphy, A.J. Sediment Heterogeneity and Sand Production in Gas Hydrate Extraction: Daini-Atsumi Knoll, Nankai Trough, Japan. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 2017. [Google Scholar]

- Lee, J.; Ahn, T.; Lee, J.Y.; Kim, S.J. Laboratory test to evaluate the performance of sand control screens during hydrate dissociation process by depressurization. In Proceedings of the Tenth ISOPE Ocean Mining and Gas Hydrates Symposium, Szczecin, Poland, 22–26 September 2013. [Google Scholar]

- Uchida, S.; Klar, A.; Yamamoto, K. Sand production modeling of the 2013 Nankai offshore gas production test. Energy Geotech. 2016, 1, 451–458. [Google Scholar]

- Yan, C.; Li, Y.; Cheng, Y.; Wang, W.; Song, B.; Deng, F.; Feng, Y. Sand production evaluation during gas production from natural gas hydrates. J. Nat. Gas Sci. Eng. 2018, 57, 77–88. [Google Scholar] [CrossRef]

- Lu, J.; Xiong, Y.; Li, D.; Shen, X.; Wu, Q.; Liang, D. Experimental Investigation of Characteristics of Sand Production in Wellbore during Hydrate Exploitation by the Depressurization Method. Energies 2018, 11, 1673. [Google Scholar] [CrossRef]

- Lu, J.; Xiong, Y.; Li, D.; Liang, D.; Jin, G.; He, Y.; Shen, X. Experimental study on sand production and sea bottom subsidence of non-diagenetic hydrate sediments in depressurization production. Mar. Geol. Quat. Geol. 2019, 39, 13. [Google Scholar]

- Li, X.-S.; Yang, B.; Zhang, Y.; Li, G.; Duan, L.-P.; Wang, Y.; Chen, Z.-Y.; Huang, N.-S.; Wu, H.-J. Experimental investigation into gas production from methane hydrate in sediment by depressurization in a novel pilot-scale hydrate simulator. Appl. Energy 2012, 93, 722–732. [Google Scholar] [CrossRef]

| No | Dry Sand Weight (kg) | Formation Water (g) | Amount of Water Substitution (mL) | Gas Production (SL) | Hydrate Mole (mol) | Water-Sand-Production (g) | Dried Sand Production (g) | Water-Gas-Sand Mix Conditions | Formation Conditions |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Medium sand, 2 | 250 | 653.86 | 77 | 0.43 | 887.39 | 6.63 | T = 293.15 K; P = 11 MPa; t = 24 h. | T = 275.15 K; P = 11 MPa; t = 48 h. Tw = 273.15 K. |

| 2 | silty-clay, 2.2 | 200 | 978.24 | 360 | 2.01 | 803.67 | 155.58 | ||

| 3 | silty-clay, 2.2 | 200 | 1215.39 | 33 * | 0.184 * | 669.09 * | 404.5 * |

| No | a | b | c | d | e |

|---|---|---|---|---|---|

| 1 | 0 m, S = 0% | 10.17 m, S = −0.38% | 110.83 m, S = −1.26% | 200 m, S = −1.66% | 287.17 m, S = −1.96% |

| 2 | 0 m, S = 0% | 40 m, S = −12.26% | 110 m, S = −2.97% | 250 m, S = −4.04% | 400 m, S = −4.08% |

| 3 | 0 m, S = 0% | 25 m, S = −18.78% | 50 m, S = −18.67% | 294 m, S = 0.35% | 494 m, S = 6.79% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, J.; Li, D.; He, Y.; Shi, L.; Liang, D.; Xiong, Y. Experimental Study of Sand Production during Depressurization Exploitation in Hydrate Silty-Clay Sediments. Energies 2019, 12, 4268. https://doi.org/10.3390/en12224268

Lu J, Li D, He Y, Shi L, Liang D, Xiong Y. Experimental Study of Sand Production during Depressurization Exploitation in Hydrate Silty-Clay Sediments. Energies. 2019; 12(22):4268. https://doi.org/10.3390/en12224268

Chicago/Turabian StyleLu, Jingsheng, Dongliang Li, Yong He, Lingli Shi, Deqing Liang, and Youming Xiong. 2019. "Experimental Study of Sand Production during Depressurization Exploitation in Hydrate Silty-Clay Sediments" Energies 12, no. 22: 4268. https://doi.org/10.3390/en12224268

APA StyleLu, J., Li, D., He, Y., Shi, L., Liang, D., & Xiong, Y. (2019). Experimental Study of Sand Production during Depressurization Exploitation in Hydrate Silty-Clay Sediments. Energies, 12(22), 4268. https://doi.org/10.3390/en12224268