1. Introduction

The Indonesian government has been putting a lot of effort into developing renewable energy sources in recent years to achieve the targeted energy mix of 23% from renewables by 2025 [

1]. Of all the renewable energy sources in Indonesia, geothermal power is arguably the most promising with a predicted total potential of 29,000 MWe, which is the biggest in the world [

2,

3]. The government has set a target of 7000 MWe of installed geothermal power plant capacity in Indonesia by 2025 [

4]. To put this target in perspective, the total installed electrical generation capacity from geothermal power plants in the country was only 1340 MWe in 2015 [

5]. This has increased to 1925 MWe in 2018 [

6]. While assuming a constant capacity growth until 2025, more than 600 MWe of new geothermal power plants must be built each year to achieve the target.

In general, there are two ways to boost power generation from geothermal power plants: (1) developing new sites and (2) enhancing existing power plants. Building new geothermal power plants typically take years from the initial study until operation in Indonesia. Experience has shown that the preliminary survey might take five to seven years to complete, the exploration three to five years, the drilling and plant development two to three years, and the Power Purchase Agreement (PPA) from two to three years [

7]. Moreover, building new geothermal power plants are usually considered a risky investment with a high capital cost at the beginning of the development, which makes the business case often not too attractive [

2]. On the other hand, enhancing an existing power plant is simpler, faster, and more economical.

Among the available options to enhance an existing geothermal power plant, recovering waste heat from the discharged geothermal brine with a binary power cycle is very attractive, because it offers the best performance and it is the most economical when compared to other methods [

8]. Currently, there is only one commercially operational geothermal binary power plant in Indonesia, which is located in Sarulla, North Sumatera [

9]. This binary system contributes as much as 49% of the total plant capacity of 110 MW [

10]. A smaller binary power plant with a capacity of 500 kW has been in development in Lahendong, North Sulawesi, since 2015, but it is not operational yet at the moment [

11]. Despite of all the promises, it is noted that there is still some reluctance to adopt binary power system technology, because the working fluids may have flammability and/or environmental issues [

3]. Another issue is the fact that binary power plants cannot contribute as much power as the main geothermal power plant, which might deter investors [

5].

To address these concerns, feasibility studies are crucial. Traditionally, such studies have been focused on working fluid selections and system architecture from a thermodynamics point of view. For example, the research by Franco and Villani [

12] found that for water-dominated, medium-temperature geothermal fields, a binary power plant could enhance the first law efficiency by up to 12% and the second law efficiency by 45%. A study by Astolfi et al. [

13] found that the optimal performance of a simple binary geothermal power plant that they studied was achieved by fluids with a ratio between its critical and inlet geofluid temperatures of 0.88 to 0.92. They also mentioned that superheating was not necessary and the optimal design adopted the saturated cycle configuration. Another research by Liu et al. [

14], which emphasized the work output and exergy analysis, found that a simple cycle with R123 as the working fluid was the optimal design for a low-temperature geothermal resource, with a temperature of 80–95 °C.

Recently, the thermo-economic approach has been increasingly popular. It gives a more comprehensive picture of both the expected technical and economical performances. Hettiarachchi et al. [

15] suggested that it is crucial to optimize the binary cycles based on the thermo-economic approach, especially in the case of utilizing low to medium temperature heat source. Such studies have been conducted in various places, including the thermo-economic investigation of a geothermal binary power plant based on typical geothermal resource conditions in New Zealand, which concluded that the most thermo-economic design for the specified brine conditions was a standard Rankine cycle while using n-Pentane as the working fluid, because it had the best payback period [

16]. A low-temperature geothermal energy analysis in Italy was carried out by Gemelli et al. [

17], which found that mountainous locations had a longer payback time than hills. Zare [

18] studied the payback periods and the net present values of three different binary geothermal systems, i.e., a simple Organic Rankine Cycle (S-ORC), an Organic Rankine Cycle with internal heat exchanger (ORC-IHE), and a Regenerative Organic Rankine Cycle (R-ORC). The research found that the S-ORC system yielded the best economic performance while the ORC-IHE was the optimum from thermodynamic point of view. Assad et al. [

8] compared the binary geothermal power plant system with single flash and double flash technology in Geneva, Switzerland while using both thermodynamics and economic approaches. The result shows that the binary power plant was the optimum system as compared to the other configurations based on the thermo-economic approach.

A number of feasibility studies in Indonesia for binary power systems have also been attempted. For example, Prananto [

19] selected Kalina cycle as the binary system for the Wayang Windu site at Pangalengan, West Java, and showed that the cycle could produce up to 1660 kW of electricity with a system efficiency of 13.2%. Pasek et al. [

20] assessed the application of a binary cycle to utilize the waste brine from the Lahendong geothermal power plant with maximum net power output as the objective. Pambudi et al. [

21] analyzed the thermodynamic performance of a single flash–binary system for the Dieng geothermal power plant. Pikra et al. [

22] assessed the implementation of Organic Rankine Cycle (ORC) for extracting energy from hot springs in Indonesia. However, none of these studies considered the economic aspect of building a binary system for a geothermal power plant in Indonesia. All of the research mentioned above only focused on the thermal efficiency and net power output as the assessment objectives.

This work aims at presenting a thermo-economic approach to study the feasibility of a binary geothermal power plant in Indonesia. The Wayang Windu geothermal plant in West Java was selected in this study due to the availability of the actual geothermal brine data. The study included the selection of the working fluid, optimization of the system performance, and financial analysis. The fluids considered included n-Pentane, Isopentane, and R245fa, which are some of the most popular fluids in binary power plants [

23]. According to Zare (2015), these working fluids have [

18]:

High latent and specific heat

High density in both liquid and gas phase

Moderate critical temperature and pressure

Moderate evaporating and condensing temperatures.

Excellent transport and heat transfer properties

Safety and chemical stability

Material capability and no corrosion

Market availability and low cost

Environmentally benign

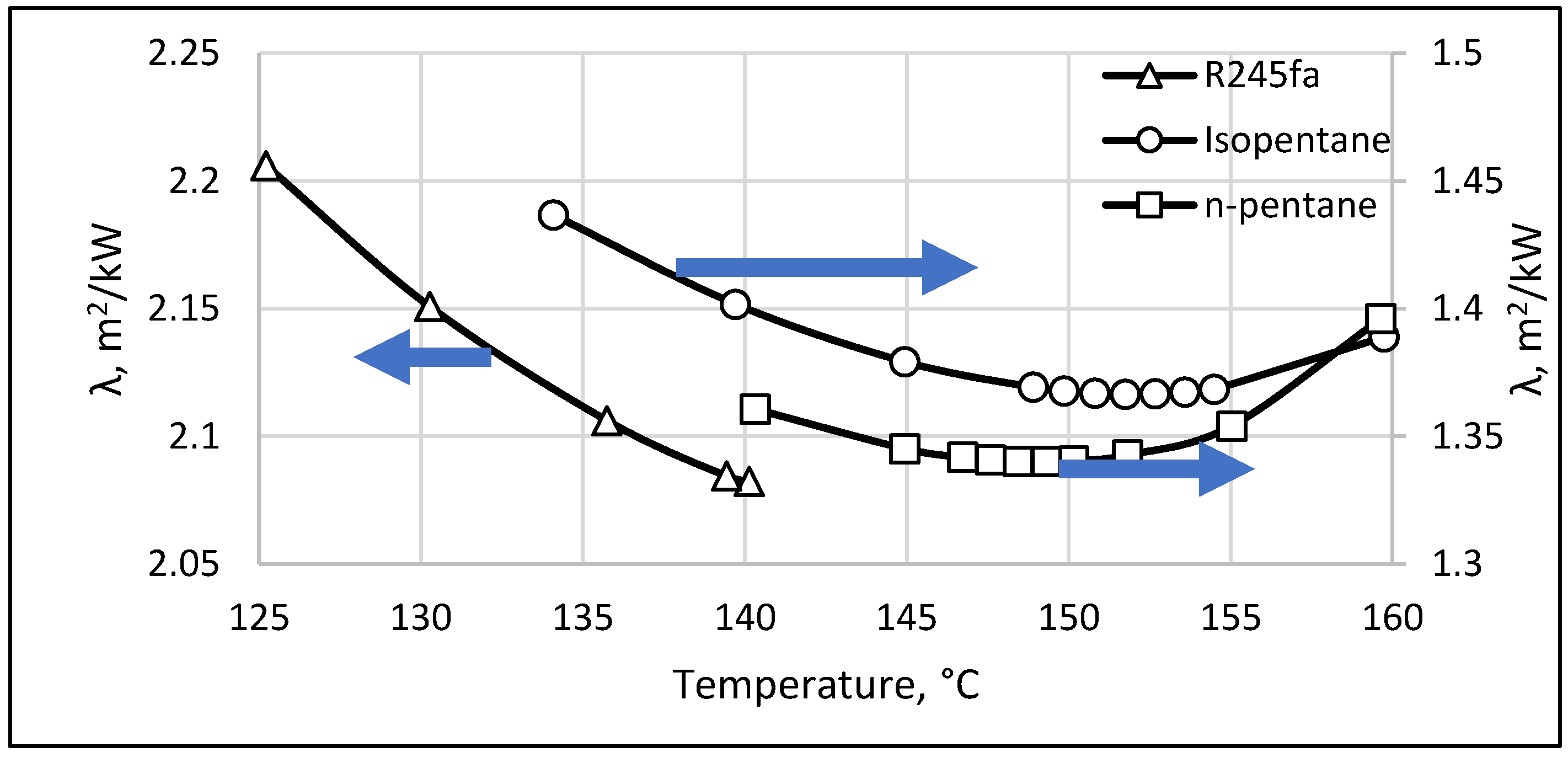

Two approaches were adopted and compared to find the optimum operating conditions: (1) maximizing the thermal efficiency and (2) minimizing the specific area of the heat exchangers to minimize the cost [

24]. It is worth noting that a larger heat exchanger is required to extract the same amount energy from a low to medium temperature heat source. Consequently, the total capital cost of the system increases. As mentioned by Toffolo et al. [

25] and Uehara et al. [

26], the main cost of an ORC system for low to medium temperature heat source comes from the heat exchanger equipment. A profitability assessment was carried out to analyze the net present value (NPV) and the internal rate of return (IRR) to investigate the financial implications. NPV is a better economic measurement when compared to the simpler payback time and return of investment analysis approach, as it gives insight into the time value of money and annual variation in revenues and expenses. The time value of money means that the value of money at the present time is worth more than its value in the future due to its potential earning capacity. In addition, the IRR gives helpful insight to compare the performances of capital investments for different projects, the project’s lifetime, or the actual dominant interest rate. The IRR is also a more suitable method than NPV when comparing projects with very different sizes [

27]. A more detailed explanation is provided in subsequent sections. The Aspen Plus version 8.6 [

28] software is employed to carry out the study.

5. Conclusions

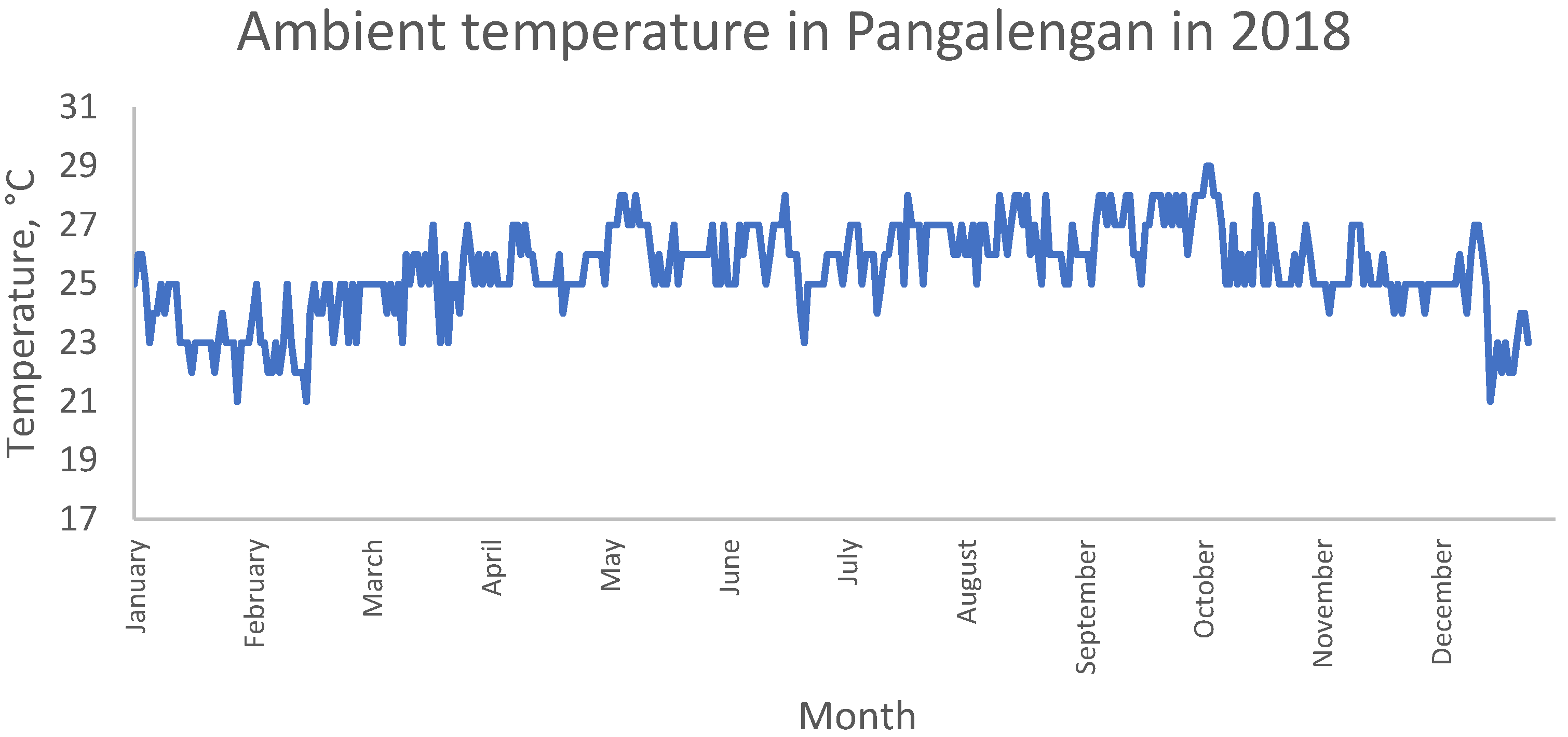

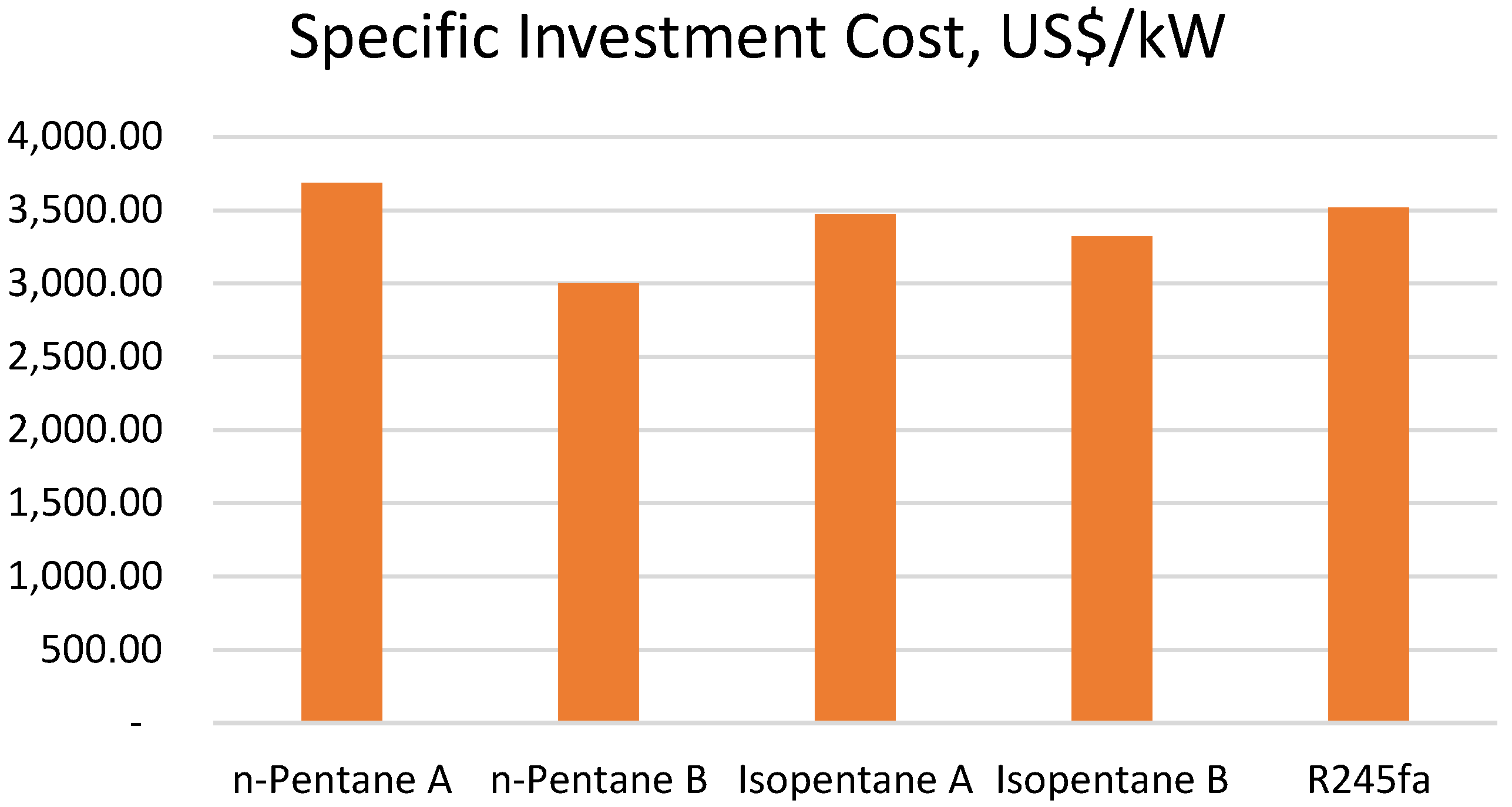

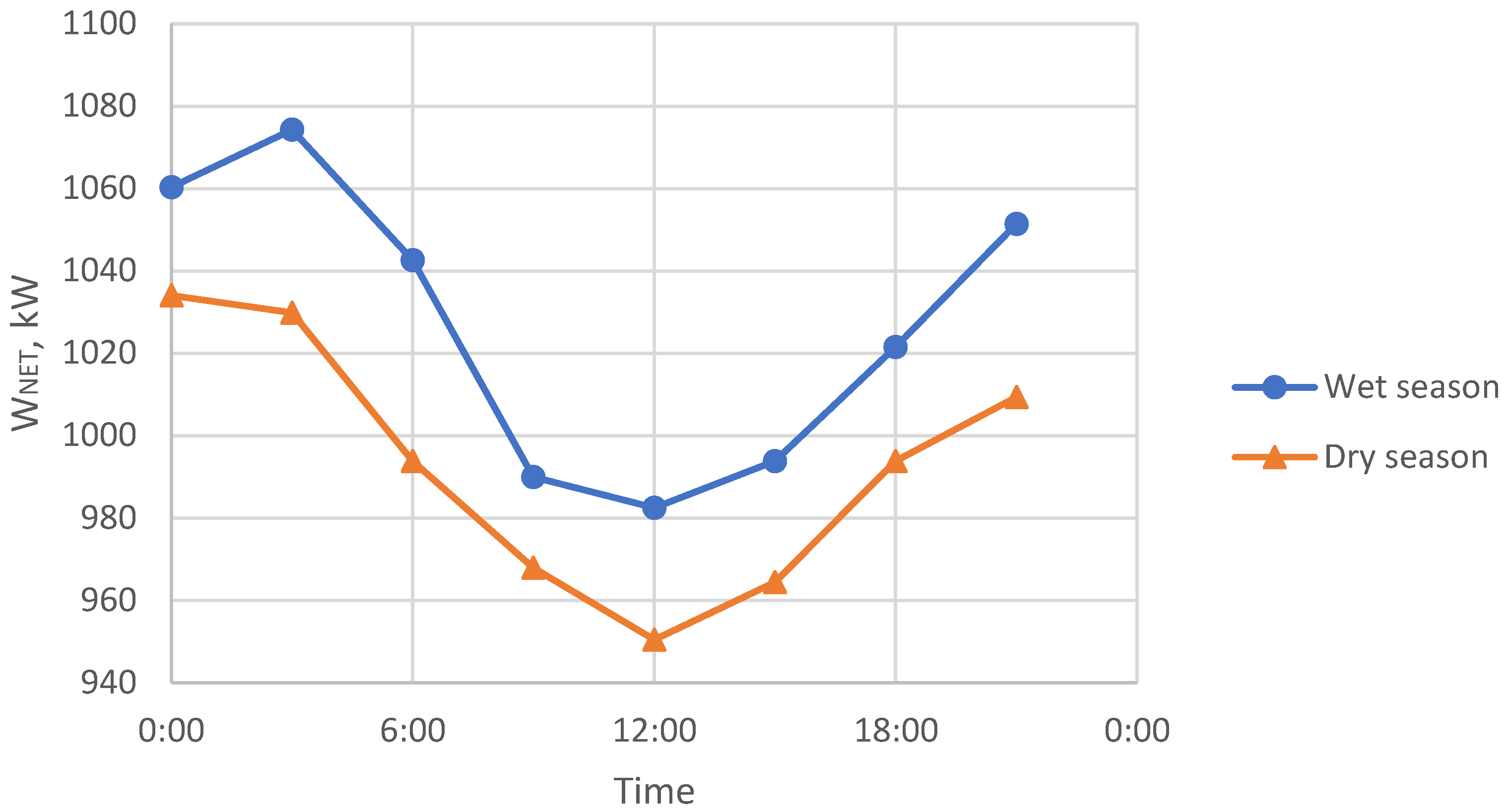

A technical and economic pre-feasibility study of a binary geothermal power plant at the Wayang Windu site, Indonesia, was carried out with various optimization approaches and working fluids. Two optimizations were executed by maximizing the thermal efficiency and minimizing the specific area of the system. Three working fluids, namely n-Pentane, Isopentane, and R-245fa, were tested. The geothermal brine from Wayang Windu geothermal power plant had a temperature of 180.7 °C, a pressure of 1.02 MPa, a mass flow rate of 48 kg/s, and a silica content of 853 ppm. The heat input for all systems was adjusted at the same level, which resulted in a constant temperature value of the brine reinjection of 142 °C.

The most economically profitable working fluid in this work was the n-Pentane, obtained with the specific area optimization approach. The system had the lowest specific investment cost of only 3003 US$/kWh and it yielded the highest net present value of US$1,879,224. Its payback period was only 13 years and the internal rate of return was 11.28%. For comparison, based on the thermal efficiency approach, the specific investment cost of the binary system using the same working fluid (n-pentane) was 3689 US$/kWh with a payback period of 17 years, and the internal rate of return was 8.85%. Thus, the result of the area optimization approach reduced the specific investment cost of the system by 687 US$/kWh and it shortened the system payback period by four years.

Generally, the specific area optimization approach resulted in better economic performance than the thermal efficiency approach. It allowed for the system to run with a higher temperature difference with the heat source and to have smaller heat exchangers areas, which affected the purchase equipment cost and the total capital investment.