The Effect of Hydration on Pores of Shale Oil Reservoirs in the Third Submember of the Triassic Chang 7 Member in Southern Ordos Basin

Abstract

1. Introduction

2. Materials and Methods

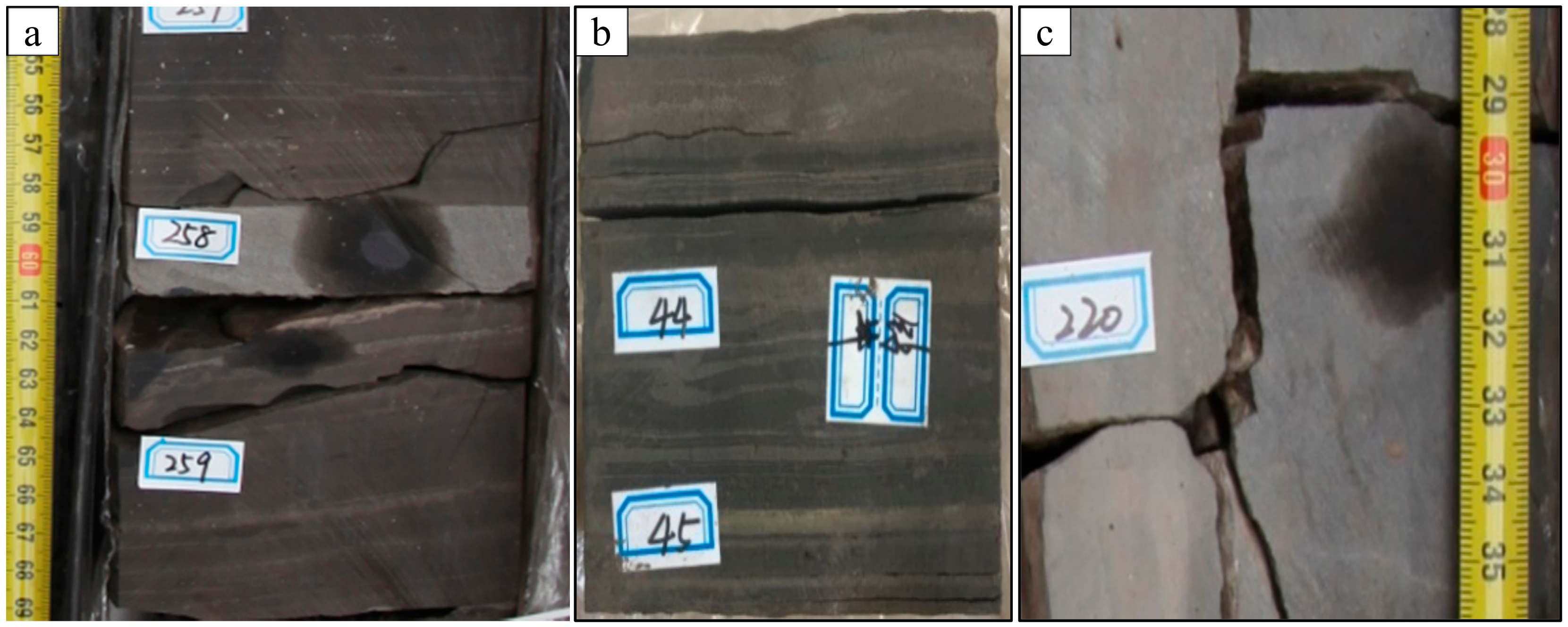

2.1. Rock Core

2.2. Drilling Fluid

2.3. Experiment Methods

2.3.1. Drilling Fluid Size

2.3.2. X-ray Diffraction

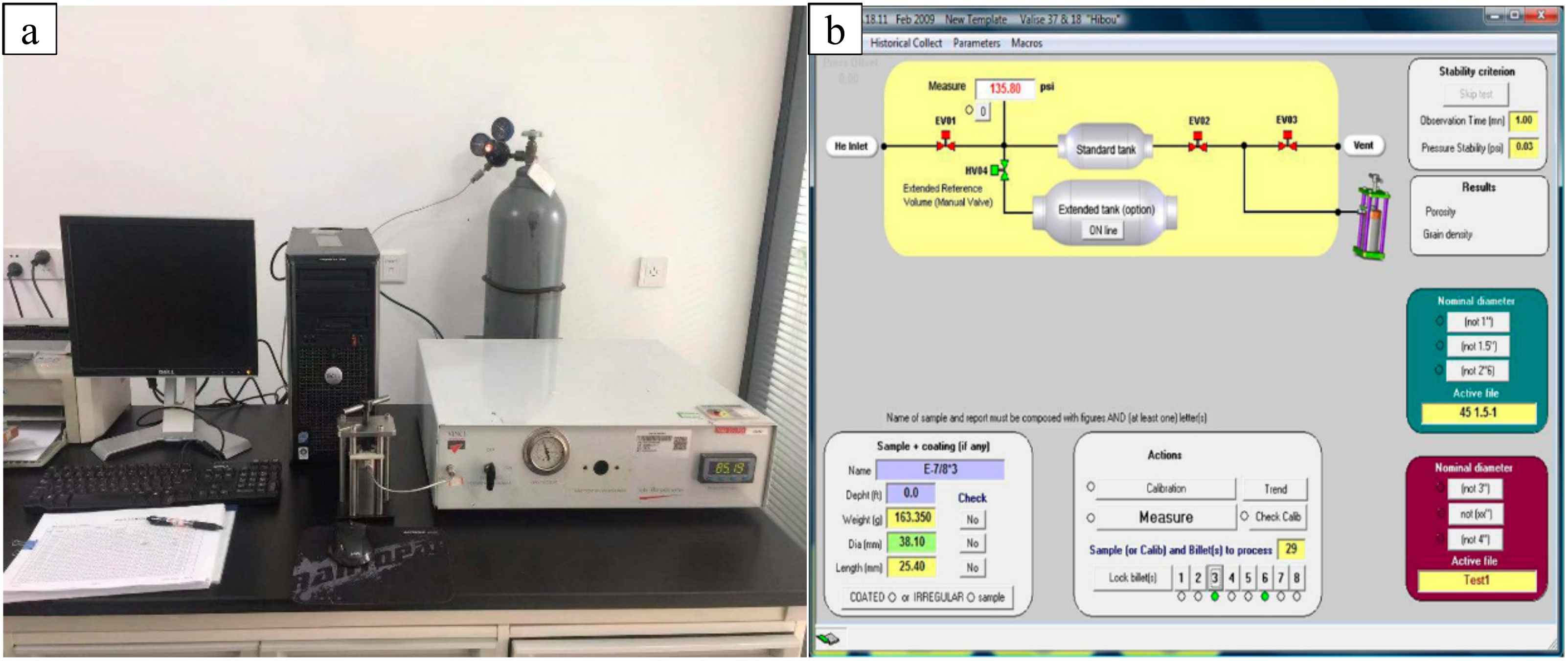

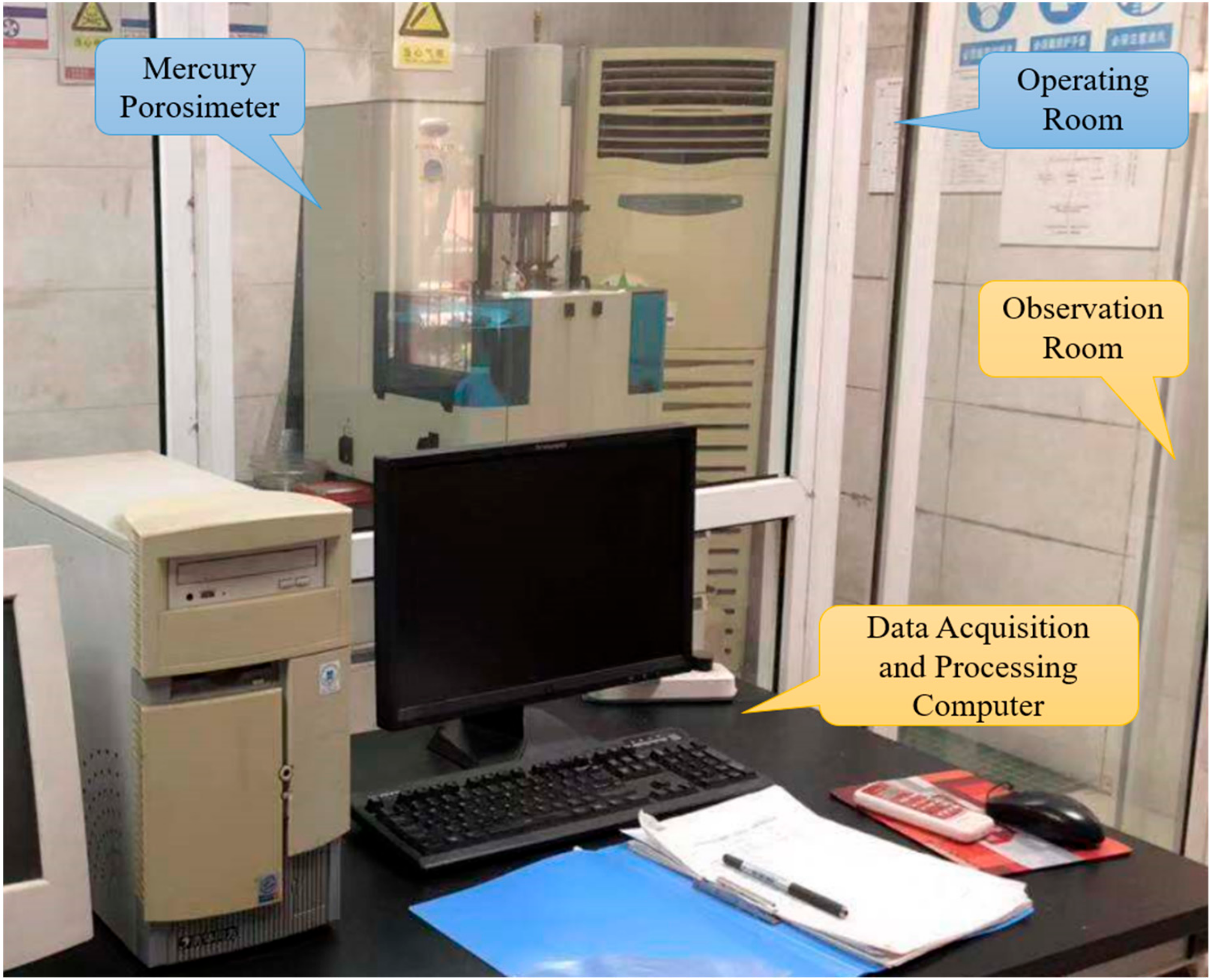

2.3.3. Porosity

2.3.4. Permeability Experiment

2.3.5. Rock Casting Thin Section

2.3.6. Scanning Electron Microscope

3. Results and Discussion

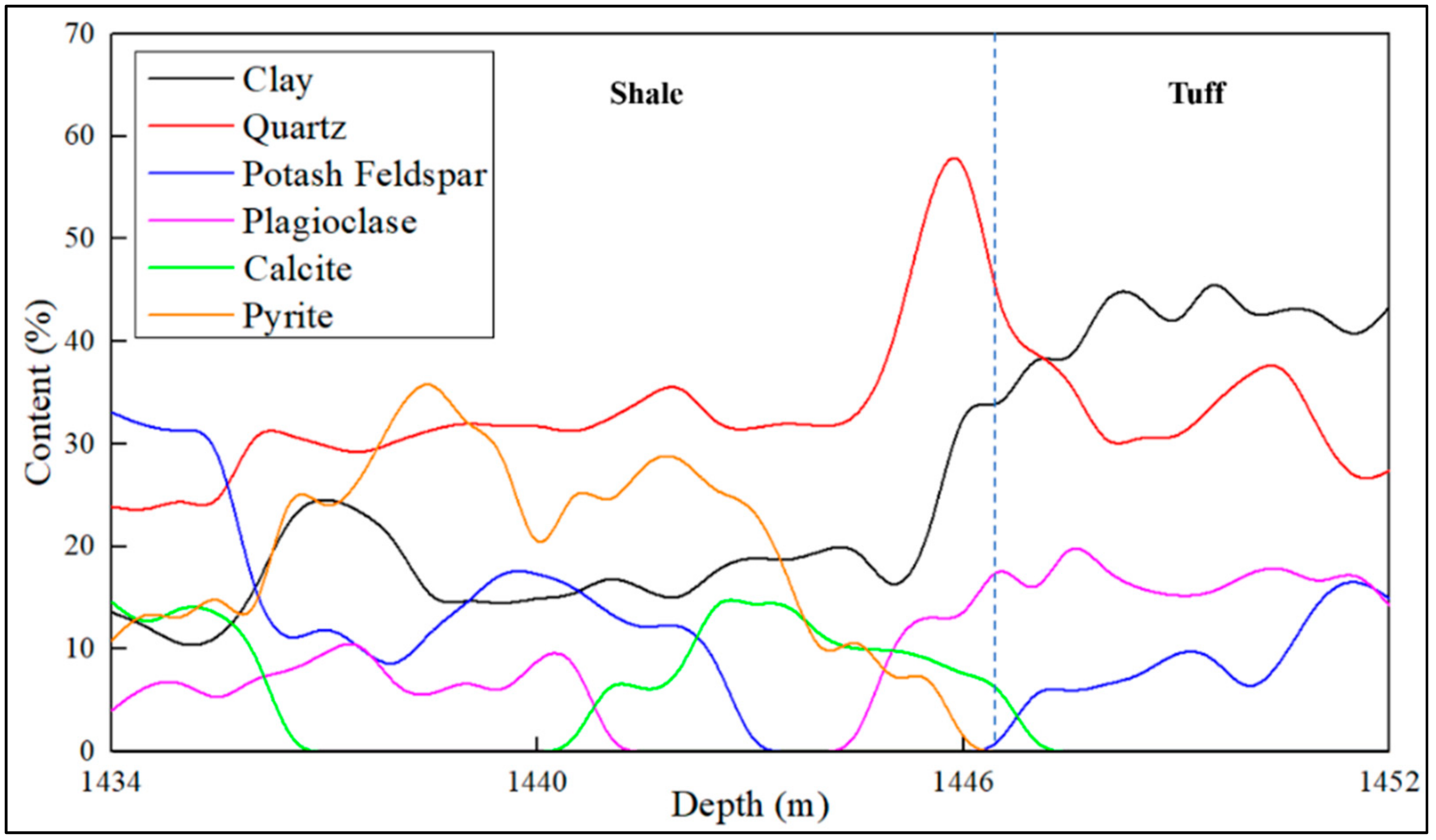

3.1. Mineralogical Compositions

3.2. Porosity and Permeability

3.3. Effect of Hydration on Pore

3.4. Pore Structure

3.5. Effect of Fluid on Pore Structures

4. Conclusions

- (1)

- The lithology of the third member of the Chang 7 members is mainly black laminated shale, and a small tuff is developed in the lower part. The whole rock contains more interbeds and microcracks, and the mineral composition of quartz and clay is higher. The complex structure and mineral composition of the rocks make rock hydration and brittle collapse easier.

- (2)

- The formation belongs to a low-porosity and low-permeability reservoir, and the density of the rock is lower than that of pure shale and tuff. Some rocks have larger porosity, but K/Φ is small, which indicates that there is more discontinuous pores in the samples. These pores may be oil storage space, but they are of little help to oil migration. Fracturing revamping is needed to break through these closed pores and cracks.

- (3)

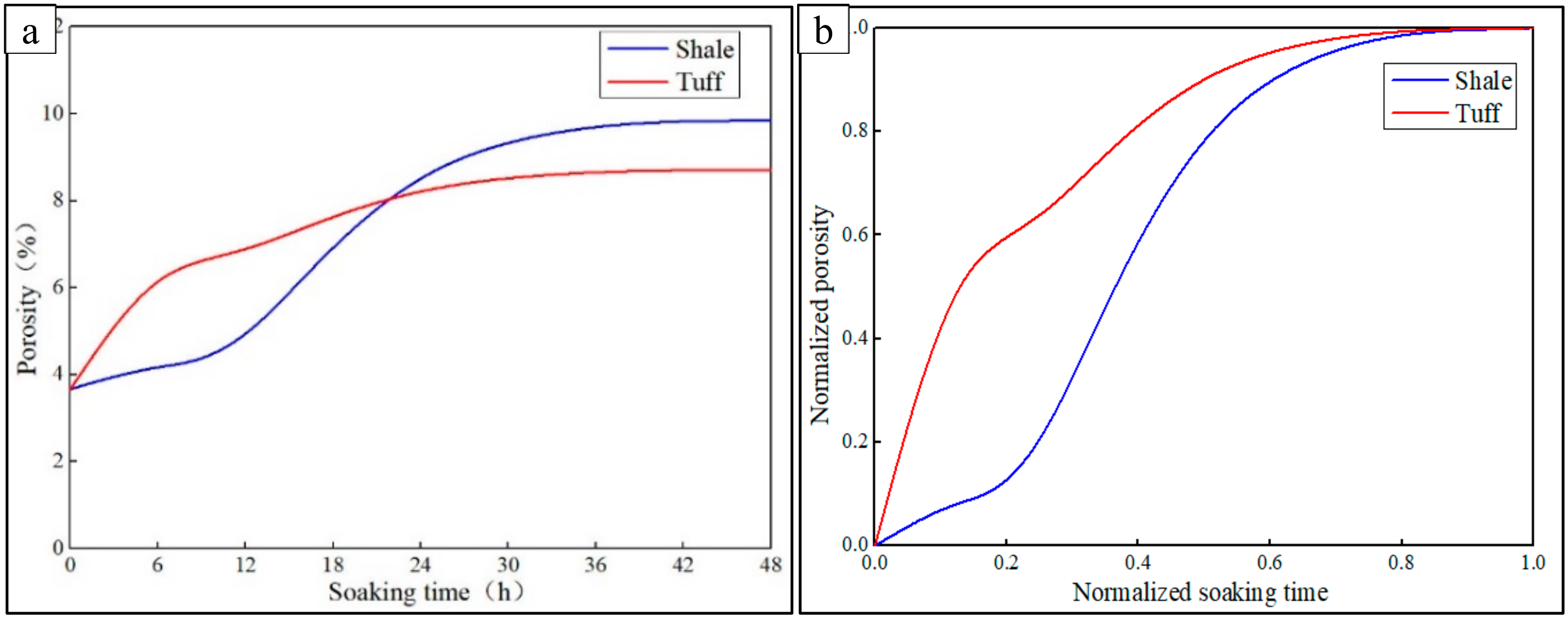

- Water soaking has a great influence on the pore characteristics of shale and tuff. The pore changes of tuff are most obvious within 6 hours of soaking, and the pore changes of shale are most obvious within 12–24 hours of soaking. Therefore, in actual construction, the tuff section requires drilling fluid to have a fast inhibition effect, and the shale section requires drilling fluid to have a long-term and stable inhibition effect.

- (4)

- Through microscopic observation, the shale bedding is obvious, and the cracks and mineral arrangement are related to the bedding direction. At high magnification, the main types of crack are dissolution cracks, shrinkage cracks of organic matter, and structural cracks. The main types of pores are intergranular pores, intragranular pores, intercrystalline pores, and organic pores. The shape and distribution of pores and cracks is influenced by the mineral type, the mineral structure, hydrocarbon expulsion of organic matter, and rock stress.

- (5)

- At formation temperatures, the effect of water and drilling fluid on rock structure can be observed; water soaking makes minerals on the rock surface fall off and disperse into the water. Stratification of rocks and expansion of cracks are easy to occur at the weak cementation between bedding. Water-based drilling fluid can plug pores and cracks and form a protective layer on the rock surface, thus effectively reducing hydration. When drilling fluids are allocated in actual construction, multisized solid particles of drilling fluids should be considered according to the actual formation pores and cracks, and the long-term stability of the protective layer formed should be guaranteed.

- (6)

- In this study, the morphological and structural characteristics of shale oil reservoir rocks are studied from the perspective of pore hydration, but the interaction between mechanical properties and bedding structure is not studied, and the corresponding evaluation theoretical model is not formed. The next step is to carry out relevant work.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jin, Z.J.; Bai, Z.R.; Gao, B.; Li, M.W. Has China ushered in the shale oil and gas revolution? Oil Gas Geol. 2019, 40, 558–570. [Google Scholar]

- Li, Z.M.; Tao, G.L.; Li, M.W.; Qian, M.H.; Xie, X.M.; Jiang, Q.G.; Liu, P.; Bao, Y.J.; Xia, D.L. Discussion on prospecting potential of shale oil in the 3rd sub-member of the Triassic Chang 7 member in Binchang block, southwestern Ordos Basin. Oil Gas Geol. 2019, 40, 451–458. [Google Scholar]

- Zou, C.N.; Yang, Z.; Cui, J.W.; Zhu, R.K.; Hou, L.H.; Tao, S.Z.; Yuan, X.J.; Wu, S.T.; Lin, S.H.; Wang, L.; et al. Formation mechanism, geological characteristics and development strategy of nonmarine shale oil in China. Pet. Explor. Dev. 2013, 40, 15–27. [Google Scholar] [CrossRef]

- Zhang, Y.; Di, Y.; Shi, Y.; Hu, J.H. Cyclic CH4 injection for enhanced oil recovery in the Eagle Ford shale reservoirs. Energies 2018, 11, 3094. [Google Scholar] [CrossRef]

- Wang, M.; Guo, Z.Q.; Jiao, C.X.; Lu, S.F.; Li, J.B.; Xue, H.T.; Li, J.J.; Li, J.Q.; Chen, G.H. Exploration progress and geochemical features of lacustrine shale oils in China. J. Pet. Sci. Eng. 2019, 178, 975–986. [Google Scholar] [CrossRef]

- Zou, C.N. Unconventional Petroleum Geology; Geological Publishing House: Beijing, China, 2014; ISBN 978-7-116-08864-1. [Google Scholar]

- Yang, Z.; Zou, C.N.; Wu, S.T.; Lin, S.H.; Pan, S.Q.; Niu, X.B.; Men, G.T.; Tang, Z.X.; Li, G.H.; Zhao, J.H.; et al. Formation, distribution and resource potential of the “sweet areas (sections)” of continental shale oil in China. Mar. Pet. Geol. 2019, 102, 48–60. [Google Scholar]

- Wang, M.; Sherwood, N.; Li, Z.S.; Lu, S.F.; Wang, W.G.; Huang, A.H.; Peng, J.; Lu, K. Shale oil occurring between salt intervals in the Dongpu Depression, Bohai Bay Basin, China. Int. J. Coal Geol. 2015, 152, 100–112. [Google Scholar] [CrossRef]

- Yin, S.L.; Chen, Y.K.; Wu, X.J. Different pore structure modalities in sandy conglomerate reservoirs and their forming mechanisms. Arab. J. Geosci. 2018, 11, 654. [Google Scholar] [CrossRef]

- Chalmers, G.R.; Bustin, R.M.; Power, I.M. Characterization of gas shale pore systems by porosimetry, pycnometry, surface area, and field emission scanning electron microscopy/transmission electron microscopy image analyses: Examples from the Barnett, Woodford, Haynesville, Marcellus, and Doig units. AAPG Bull. 2012, 96, 1099–1119. [Google Scholar]

- Wang, Z.L. Transmission electron microscopy of shape-controlled nanocrystals and their assemblies. J. Phys. Chem. B 2000, 104, 1153–1175. [Google Scholar] [CrossRef]

- Wang, X.; Hou, J.; Liu, Y.; Zhao, P.; Ma, K.; Wang, D.; Ren, X.; Yan, L. Overall PSD and fractal characteristics of tight oil reservoirs: A case study of Lucaogou Formation in Junggar Basin, China. Fractals 2019, 27, 1940005. [Google Scholar] [CrossRef]

- Gao, H.; Cao, J.; Wang, C.; He, M.Q.; Dou, L.B.; Huang, X.; Li, T.T. Comprehensive characterization of pore and throat system for tight sandstone reservoirs and associated permeability determination method using SEM, rate-controlled mercury and high pressure mercury. J. Pet. Sci. Eng. 2019, 174, 514–524. [Google Scholar] [CrossRef]

- Bai, B.; Zhu, R.; Wu, S.; Yang, W.; Gelb, J.; Gu, A.; Zhang, X.; Su, L. Multi-scale method of Nano (Micro)-CT study on microscopic pore structure of tight sandstone of Yanchang Formation, Ordos Basin. Pet. Explor. Dev. 2013, 40, 354–358. [Google Scholar] [CrossRef]

- Luo, S.; Lutkenhaus, J.L.; Nasrabadi, H. Multiscale fluid-phase-behavior simulation in shale reservoirs using a pore-size-dependent equation of state. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 9–11 October 2017; pp. 806–820. [Google Scholar]

- Wang, Y.Z.; Yuan, Y.D.; Rahman, S.S.; Arns, C. Semi-quantitative multiscale modelling and flow simulation in a nanoscale porous system of shale. Fuel 2018, 234, 1181–1192. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, C.F.; Zhu, Y.M.; Chen, S.B.; Liu, S.M.; Zhang, R. Morphology and fractal characterization of multiscale pore structures for organic-rich lacustrine shale reservoirs. Fractals 2018, 26, 1840013. [Google Scholar] [CrossRef]

- Yang, H.; Niu, X.B.; Xu, L.M.; Feng, S.B.; You, Y.; Liang, X.W.; Wang, F.; Zhang, D.D. Exploration potential of shale oil in Chang7 Member, Upper Triassic Yanchang Formation, Ordos Basin, NW China. Pet. Explor. Dev. 2016, 43, 560–569. [Google Scholar] [CrossRef]

- Fan, B.J. Oil reserves of Chang 7 Shale, Triassic Yanchang Formation, Ordos Basin. Pet. Sci. Technol. 2017, 35, 789–794. [Google Scholar]

- Cui, J.W.; Zhu, R.K.; Luo, Z.; Li, S. Sedimentary and geochemical characteristics of the Triassic Chang 7 Member shale in the Southeastern Ordos Basin, Central China. Pet. Sci. 2019, 16, 285–297. [Google Scholar] [CrossRef]

- Cao, H.S.; Shan, X.L.; Sun, P.C.; Chi, H.Z.; Du, S. Geochemical characteristics of oil shale in the Triassic Chang7 subsection, southern Ordos basin, China, and palaeo-environment reconstruction. Neues Jahrbuch für Mineralogie-Abhandlungen 2016, 193, 45–57. [Google Scholar] [CrossRef]

- Xu, Z.J.; Liu, L.F.; Liu, B.J.M.; Wang, T.G.; Zhang, Z.H.; Wu, K.J.; Feng, C.Y.; Dou, W.C.; Wang, Y.; Shu, Y. Geochemical characteristics of the Triassic Chang 7 lacustrine source rocks, Ordos Basin, China: Implications for paleoenvironment, petroleum potential and tight oil occurrence. J. Asian. Earth. Sci. 2019, 178, 112–138. [Google Scholar] [CrossRef]

- Chen, G.; Gang, W.Z.; Liu, Y.Z.; Wang, N.; Guo, Y.; Zhu, C.Z.; Cao, Q.Y. High-resolution sediment accumulation rate determined by cyclostratigraphy and its impact on the organic matter abundance of the hydrocarbon source rock in the Yanchang Formation, Ordos Basin, China. Mar. Pet. Geol. 2019, 103, 1–11. [Google Scholar] [CrossRef]

- Yuan, W.; Liu, G.D.; Xu, L.M.; Niu, X.B.; Li, C.Z. Petrographic and geochemical characteristics of organic-rich shale and tuff of the Upper Triassic Yanchang Formation, Ordos Basin, China: Implications for lacustrine fertilization by volcanic ash. Can. J. Earth Sci. 2019, 56, 47–59. [Google Scholar] [CrossRef]

- Fan, B.J.; Shi, L. Deep-lacustrine shale heterogeneity and its impact on hydrocarbon generation, expulsion, and retention: A case study from the upper triassic Yanchang formation, Ordos Basin, China. Nat. Resour. Res. 2019, 28, 241–257. [Google Scholar] [CrossRef]

- Chen, Y.H.; Zhu, Z.W.; Zhang, L. Control actions of sedimentary environments and sedimentation rates on lacustrine oil shale distribution, an example of the oil shale in the Upper Triassic Yanchang Formation, southeastern Ordos Basin (NW China). Mar. Pet. Geol. 2019, 102, 508–520. [Google Scholar] [CrossRef]

- Sun, N.Q.; Pan, J.; Zhou, S.B.; Jiao, C.B. Characteristics of faults and their significance in controlling the oil accumulations in Honghe field, Ordos Basin. Interpretation 2019, 7, T195–T206. [Google Scholar] [CrossRef]

- Han, H.; Pang, P.; Li, Z.L.; Shi, P.T.; Guo, C.; Liu, Y.; Chen, S.J.; Lu, J.G.; Gao, Y. Controls of organic and inorganic compositions on pore structure of lacustrine shales of Chang 7 member from Triassic Yanchang Formation in the Ordos Basin, China. Mar. Pet. Geol. 2019, 100, 270–284. [Google Scholar] [CrossRef]

- Li, D.L.; Li, R.X.; Xue, T.; Wang, B.P.; Liu, F.T.; Zhao, B.S.; Zhao, D. Characteristic and Geological Implications of Major Elements and Rare Earth Elements of Triassic Chang 7 Oil Shale in Tongchuan City, Southern Ordos Basin (China). Minerals 2018, 8, 157. [Google Scholar] [CrossRef]

- Li, D.L.; Li, R.X.; Zhu, Z.W.; Wu, X.L.; Zhao, B.S.; Cheng, J.H.; Liu, F.T. Rare earth elements geochemistry characteristics and their geological implications of lacustrine oil shale from Chang 7 oil layer in southern Ordos Basin, China. Geol. J. 2017, 52, 119–131. [Google Scholar] [CrossRef]

- Tan, F.Q.; Zhao, R.; Zhao, Y.Y.; Pan, Z.J.; Li, H.Q. A case study: Evaluating low-porosity and ultra-low-permeability Triassic reservoir rocks in the Ordos Basin by the integration of logs and core. Pet. Geosci. 2017, 23, 454–465. [Google Scholar] [CrossRef]

- Li, G.Z.; Qin, Y.; Wu, M.; Zhang, B.; Wu, X.; Tong, G.C.; Liu, J.B. The pore structure of the transitional shale in the Taiyuan formation, Linxing area, Ordos Basin. J. Pet. Sci. Eng. 2019, 181, 975–986. [Google Scholar] [CrossRef]

- Liu, K.Q.; Cheng, X.W.; Zhang, C.; Gao, X.S.; Zhuang, J.; Guo, X.Y. Evolution of pore structure of oil well cement slurry in suspension-solid transition stage. Constr. Build Mater. 2019, 214, 382–398. [Google Scholar] [CrossRef]

- Xu, Z.H.; Zhao, P.Q.; Wang, Z.L.; Ostadhassan, M.; Pan, Z.H. Characterization and Consecutive Prediction of Pore Structures in Tight Oil Reservoirs. Energies 2018, 11, 2705. [Google Scholar] [CrossRef]

- Huang, Z.K.; Liu, Q.Y.; Li, M.W.; Chen, J.P.; Li, P.; Zhang, R. Hydrocarbon expulsion efficiency and oil-bearing property of the shale systemin Chang 7 Member, Ordos Basin. Oil Gas Geol. 2018, 39, 513–521. [Google Scholar]

- Fan, X.Y.; Zhao, P.F.; Zhang, Q.G.; Zhang, T.; Zhu, K.; Zhou, C.H. A polymer plugging gel for the fractured strata and its application. Materials 2018, 11, 856. [Google Scholar] [CrossRef]

- Khodja, M.; Canselier, J.P.; Bergaya, F.; Fourar, K.; Khodja, M.; Cohaut, N.; Benmounah, A. Shale problems and water-based drilling fluid optimisation in the Hassi Messaoud Algerian oil field. Appl. Clay Sci. 2010, 49, 383–393. [Google Scholar] [CrossRef]

- Yu, L.; Ding, B.X.; Dong, M.Z.; Jiang, Q. Plugging ability of oil-in-water emulsions in porous media: Experimental and modeling study. Ind. Eng. Chem. Res. 2018, 57, 14795–14808. [Google Scholar] [CrossRef]

- Zolfaghari, A.; Dehghanpour, H.; Holyk, J. Water sorption behaviour of gas shales: I. Role of clays. Int. J. Coal Geol. 2017, 179, 130–138. [Google Scholar] [CrossRef]

- Borysenko, A.; Clennell, B.; Sedev, R.; Burgar, I.; Ralston, J.; Raven, M.; Dewhurst, D.; Liu, K.Y. Experimental investigations of the wettability of clays and shales. J. Geophys. Res. Solid Earth 2009, 114. [Google Scholar] [CrossRef]

- Feng, D.; Li, X.F.; Wang, X.Z.; Li, J.; Sun, F.R.; Sun, Z.; Zhang, T.; Li, P.H.; Chen, Y.; Zhang, X. Water adsorption and its impact on the pore structure characteristics of shale clay. Appl. Clay Sci. 2018, 115, 126–138. [Google Scholar] [CrossRef]

- Voorn, M.; Exner, U.; Barnhoorn, A.; Baud, P.; Reuschle, T. Porosity, permeability and 3D fracture network characterisation of dolomite reservoir rock samples. J. Pet. Sci. Eng. 2015, 127, 270–285. [Google Scholar] [CrossRef]

- Luquot, L.; Gouze, P. Experimental determination of porosity and permeability changes induced by injection of CO2 into carbonate rocks. Chem. Geol. 2009, 265, 148–159. [Google Scholar] [CrossRef]

- Mastalerz, M.; He, L.L.; Melnichenko, Y.B.; Rupp, J.A. Porosity of coal and shale: Insights from gas adsorption and SANS/USANS techniques. Energy Fuels 2012, 26, 5109–5120. [Google Scholar] [CrossRef]

- Wang, F.Y.; Yang, K.; You, J.X.; Lei, X.J. Analysis of pore size distribution and fractal dimension in tight sandstone with mercury intrusion porosimetry. Results Phys. 2019, 13, 102283. [Google Scholar] [CrossRef]

- Labani, M.M.; Rezaee, R.; Saeedi, A.; Al Hinai, A. Evaluation of pore size spectrum of gas shale reservoirs using low pressure nitrogen adsorption, gas expansion and mercury porosimetry: A case study from the Perth and Canning Basins, Western Australia. J. Pet. Sci. Eng. 2013, 112, 7–16. [Google Scholar] [CrossRef]

- Sheng, G.L.; Javadpour, F.; Su, Y.L. Dynamic porosity and apparent permeability in porous organic matter of shale gas reservoirs. Fuel 2019, 251, 341–351. [Google Scholar] [CrossRef]

- Shi, J.T.; Sun, Z.; Wu, K.L.; Wang, K.; Huang, L.; Liu, W.Y.; Li, X.F. Effect of pore shape on nanoconfined gas flow behavior: Implication for characterizing permeability of realistic shale matrix. Ind. Eng. Chem. Res. 2019, 58, 8835–8846. [Google Scholar] [CrossRef]

- Wang, R.Y.; Ding, W.L.; Zhang, Y.Q.; Wang, Z.; Wang, X.H.; He, J.H.; Zeng, W.T.; Dai, P. Analysis of developmental characteristics and dominant factors of fractures in Lower Cambrian marine shale reservoirs: A case study of Niutitang formation in Cen’gong block, southern China. J. Pet. Sci. Eng. 2016, 138, 31–49. [Google Scholar] [CrossRef]

- Fang, S.X.; He, J.; Hou, F.H.; Yang, X.Y.; Qiao, L.; Fu, S.; Yao, J.L.; Wu, Z.; Yan, R.H.; Xu, L.M. Reservoirs pore space types and evolution in M-5(5) to M-5(1) submembers of Majiagou Formation of Middle Ordovician in central gasfield area of Ordos basin. Acta Petrol. Sin. 2009, 25, 2425–2441. [Google Scholar]

- Zhu, H.H.; Zhong, D.K.; Yao, J.L.; Sun, H.T.; Niu, X.B.; Liang, X.W.; You, Y.; Li, X. Alkaline diagenesis and its effects on reservoir porosity: A case study of Upper Triassic Chang 7 Member tight sandstone in Ordos Basin, NW China. Pet. Explor. Dev. 2015, 42, 56–65. [Google Scholar] [CrossRef]

- Tang, X.; Zhu, Y.M.; Liu, Y. Investigation of shale nano-pore characteristics by scanning electron microscope and low-pressure nitrogen adsorption. J. Nanosci. Nanotechnol. 2017, 17, 6252–6261. [Google Scholar] [CrossRef]

- Ambrose, R.J.; Hartman, R.C.; Diaz-Campos, M.; Akkutlu, I.Y.; Sondergeld, C.H. Shale gas-in-place calculations part I: New pore-scale considerations. SPE J. 2012, 17, 219–229. [Google Scholar] [CrossRef]

- Bultreys, T.; De Boever, W.; Cnudde, V. Imaging and image-based fluid transport modeling at the pore scale in geological materials: A practical introduction to the current state-of-the-art. Earth-Sci. Rev. 2016, 155, 93–128. [Google Scholar] [CrossRef]

| No. | Lithology | Depth (m) | Clay Mineral Content (%) | Percentage of Smectite Layers in Interstratified Illite/Smectite (%) | |||

|---|---|---|---|---|---|---|---|

| Illite | Kaolinite | Chlorite | Illite/Smectite Mixed Layer | ||||

| 1 | Shale | 1434.6 | 26.9 | 24.5 | 10.5 | 38.1 | 35 |

| 2 | 1436.7 | 29.1 | 28.1 | 11.4 | 31.4 | 35 | |

| 3 | 1439.5 | 34.8 | 25.4 | 12.1 | 27.7 | 35 | |

| 4 | 1440.1 | 34.6 | 30.5 | 0 | 34.9 | 30 | |

| 5 | 1442.3 | 30.3 | 27.7 | 0 | 42.0 | 30 | |

| 6 | 1444.2 | 32.4 | 31.2 | 0 | 36.4 | 25 | |

| 7 | Tuff | 1447.5 | 33.0 | 0 | 24.6 | 42.4 | 25 |

| 8 | 1448.5 | 29.1 | 0 | 25.7 | 45.2 | 25 | |

| 9 | 1449.6 | 34.5 | 0 | 22.9 | 42.6 | 25 | |

| 10 | 1450.5 | 33.4 | 0 | 25.4 | 41.2 | 20 | |

| No. | Lithology | Depth (m) | Density (g/cc) | Porosity (%) | Permeability (mD) | K/Φ (mD/%) |

|---|---|---|---|---|---|---|

| 1 | Shale | 1434.6 | 2.37 | 0.66 | 0.22 | 0.33 |

| 2 | 1436.7 | 2.53 | 1.65 | 8.71 | 5.28 | |

| 3 | 1439.5 | 2.31 | 0.31 | 1.25 | 4.03 | |

| 4 | 1440.1 | 2.29 | 0.88 | 2.27 | 2.58 | |

| 5 | 1442.3 | 2.56 | 10.79 | 2.69 | 0.25 | |

| 6 | Tuff | 1446.5 | 2.42 | 8.42 | 1.51 | 0.18 |

| 7 | 1447.5 | 2.68 | 0.21 | 0.64 | 3.05 | |

| 8 | 1448.5 | 2.71 | 0.91 | 2.44 | 2.68 | |

| 9 | 1449.6 | 2.57 | 1.99 | 1.98 | 0.99 | |

| 10 | 1450.5 | 5.64 | 2.36 | 2.10 | 0.89 |

| No. | Lithology | Depth (m) | Density (g/cm3) | Mass (g) | Soaking Environment | Soaking Time (h) | Maximum Mercury Intake (cc) |

|---|---|---|---|---|---|---|---|

| 1 | Shale | 1436.7 | 2.53 | 1.696 | Non | 0 | 0.024551 |

| 2 | 1.401 | Water | 6 | 0.023511 | |||

| 3 | 1.367 | Water | 12 | 0.023418 | |||

| 4 | 1.371 | Water | 24 | 0.052754 | |||

| 5 | 1.122 | Water | 48 | 0.043689 | |||

| 6 | Tuff | 1449.6 | 2.57 | 0.983 | Non | 0 | 0.014004 |

| 7 | 0.889 | Water | 6 | 0.022914 | |||

| 8 | 1.017 | Water | 12 | 0.026382 | |||

| 9 | 0.854 | Water | 24 | 0.028782 | |||

| 10 | 0.957 | Water | 48 | 0.032433 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, P.; Fan, X.; Zhang, Q.; Wang, X.; Zhang, M.; Ran, J.; Lv, D.; Liu, J.; Shuai, J.; Wu, H. The Effect of Hydration on Pores of Shale Oil Reservoirs in the Third Submember of the Triassic Chang 7 Member in Southern Ordos Basin. Energies 2019, 12, 3932. https://doi.org/10.3390/en12203932

Zhao P, Fan X, Zhang Q, Wang X, Zhang M, Ran J, Lv D, Liu J, Shuai J, Wu H. The Effect of Hydration on Pores of Shale Oil Reservoirs in the Third Submember of the Triassic Chang 7 Member in Southern Ordos Basin. Energies. 2019; 12(20):3932. https://doi.org/10.3390/en12203932

Chicago/Turabian StyleZhao, Pengfei, Xiangyu Fan, Qiangui Zhang, Xiang Wang, Mingming Zhang, Jiawei Ran, Da Lv, Jinhua Liu, Juntian Shuai, and Hao Wu. 2019. "The Effect of Hydration on Pores of Shale Oil Reservoirs in the Third Submember of the Triassic Chang 7 Member in Southern Ordos Basin" Energies 12, no. 20: 3932. https://doi.org/10.3390/en12203932

APA StyleZhao, P., Fan, X., Zhang, Q., Wang, X., Zhang, M., Ran, J., Lv, D., Liu, J., Shuai, J., & Wu, H. (2019). The Effect of Hydration on Pores of Shale Oil Reservoirs in the Third Submember of the Triassic Chang 7 Member in Southern Ordos Basin. Energies, 12(20), 3932. https://doi.org/10.3390/en12203932