Environmental and Efficiency Analysis of Simulated Application of the Solid Oxide Fuel Cell Co-Generation System in a Dormitory Building

Abstract

1. Introduction

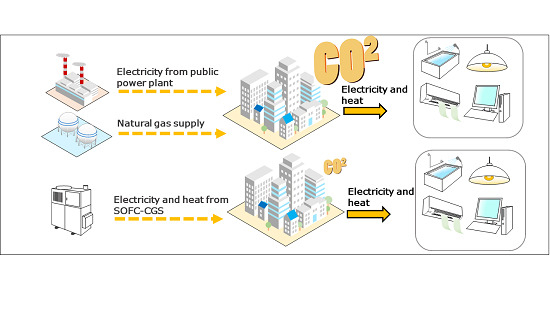

1.1. Research Background

1.2. Research Methodology

2. Energy and Environmental Analysis of the Dormitory Building

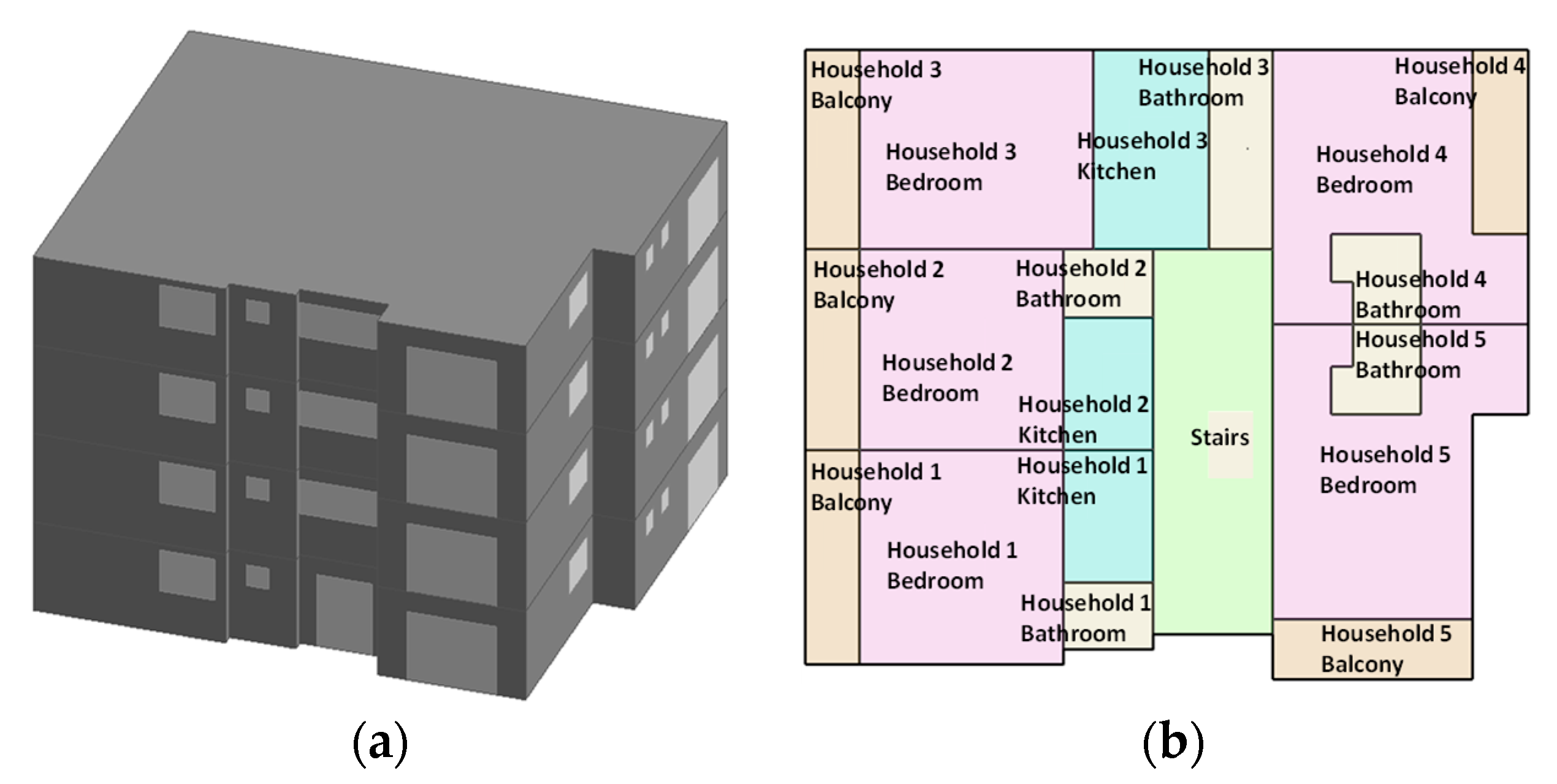

2.1. Modeling of the Dormitory Building

2.2. Energy and Environmental Analyses

3. Modeling of SOFC–CGS

3.1. Explanation of SOFC–CGS

3.2. Mathemetical Model of SOFC–CGS

4. Simulation of Operating SOFC–CGS in the Dormitory Building

5. Analysis of Efficiency and Environmental Impact of SOFC–CGS

5.1. Analysis of SOFC–CGS Efficiency

5.2. Analysis of Environmental Impact of SOFC–CGS

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| SOFC | Solid oxide fuel cell |

| SOFC–CGS | Solid oxide fuel cell cogeneration system |

| LNG | Liquefied Natural Gas |

| CHP | Combined heat and power |

| DC | Direct current |

| AC | Alternating current |

| EV | Electric vehicle |

| SOFC–CHP | Solid oxide fuel cell combined heat and power |

| GHG | Greenhouse gas |

| HVAC | Heating, Ventilation and Air Conditioning |

| ASHRAE | American Society of Heating, Refrigerating and Air-Conditioning Engineers |

| PEMFC–CHP | Proton exchange membrane fuel cell combined heat and power |

| Nomenclatures | |

| EFFElSup | Efficiency of electricity generation |

| LF | Load factor of electricity generation |

| PSupmax | Maximum electricity supply capability |

| PElSup | Amount of electricity supplication |

| VElSupSp | Electricity generation tracking speed |

| Itint | Time interval |

| PElMax | Maximum electricity generation capacity of SOFC |

| PEhCell | Amount of natural gas consumption of SOFC |

| PHtSup | Amount of heat output from SOFC |

| EFFHtSup | Heat output efficiency of SOFC |

| VwCell | Water flow rate in the water tube |

| Tout | Target output water temperature from the SOFC |

| Tin | Input water temperature to the radiator unit |

| Cw | Specific heat of water |

| PRad | Heat dissipation from the radiator unit |

| PBBSup | Amount of heat output from the backup boiler |

| PBBUse | Amount of gas used in the backup boiler |

| TDmd | Water temperature demand from the household |

| TBBin | Input water temperature to the backup boiler |

| VolHwDmd | Amount of hot water demand |

| EFFBB | Working efficiency of the backup boiler |

References

- Doosoon, L. An Analysis of the Effect of Relative Prices between Electricity and Gas on the Sectoral Demand of City Gas. Master’s Thesis, Public Administration of Seoul National University, Seoul, Korea, 2014. [Google Scholar]

- Korea Electric Power Corporation. Sustainable Report. 2016. Available online: www.kepco.co.kr (accessed on 6 August 2018).

- Wang, Y.; Zhao, Q.; Borup, U.; Choi, S. Stack and converter-integrated design for efficient residential fuel cell system. Int. J. Hydrogen Energy 2009, 34, 7316–7322. [Google Scholar] [CrossRef]

- Yuqing, W.; Yixiang, S.; Meng, N.; Ningsheng, C. A micro tri-generation system based on direct flame fuel cells for residential applications. Int. J. Hydrogen Energy 2014, 39, 5996–6005. [Google Scholar]

- Hirohisa, A.; Tetsuya, W.; Ryohei, Y. Development of an energy management system for optimal operation of fuel cell based residential energy systems. Int. J. Hydrogen Energy 2016, 41, 20314–20325. [Google Scholar]

- Alexandros, A.; Eric, S.F.; Dan, J.L.B. Options for residential building services design using fuel cell based micro-CHP and the potential for heat integration. Appl. Energy 2015, 138, 685–694. [Google Scholar]

- Mohammad, H.-M. Transient performance improvement of a stand-alone fuel cell for residential applications. Sustain. Cities Soc. 2019, 50, 101650. [Google Scholar]

- Hong, B.; Qiong, W.; Weijun, G.; Weisheng, Z. Optimal operation of a grid-connected hybrid PV/fuel cell/battery energy system for residential applications. Energy 2016, 113, 702–712. [Google Scholar]

- Yasuhiro, H.; Kiyotaka, T.; Ryuichirao, G.; Hideki, K. Hybrid utilization of renewable energy and fuel cells for residential energy systems. Energy Build. 2011, 43, 3680–3684. [Google Scholar]

- Marco, S.; Marta, G.; Massimo, S. Modeling and techno-economic analysis of the integration of a FC based micro-CHP system for residential application with a heat pump. Energy 2017, 120, 262–275. [Google Scholar]

- Ramadhani, F.; Hussain, M.A.; Mokhlis, H.; Fazly, M.; Ali, J.M. Evaluation of solid oxide fuel cell based polygeneration system in residential areas integrating with electric charging and hydrogen fueling stations for vehicles. Appl. Energy 2019, 238, 1373–1388. [Google Scholar] [CrossRef]

- Takahide, H.; Yusuke, O.; Takashi, I.; Atsushi, A. Technological assessment of residential fuel cells using hydrogen supply systems for fuel cell vehicles. Int. J. Hydrogen Energy 2017, 42, 26377–26388. [Google Scholar]

- Kazunori, N.; Joshua, D.; Michael, E.W. Assessment of primary energy consumption, carbon dioxide emissions, and peak electric load for a residential fuel cell using empirical natural gas and electricity use profiles. Energy Build. 2018, 178, 242–253. [Google Scholar]

- Van Biert, L.; Godjevac, M.; Visser, K.; Aravind, P.V. Dynamic modelling of a direct internal reforming solid oxide fuel cell stack based on single cell experiments. Appl. Energy 2019, 250, 976–990. [Google Scholar] [CrossRef]

- Marco, G.; Dario, M.; Marco, S.; Cesare, P.; Siu, F.A. A versatile computational tool for model-based design, control and diagnosis of a generic Solid Oxide Fuel Cell Integrated Stack Module. Energy Convers. Manag. 2018, 171, 1514–1528. [Google Scholar]

- Weidner, E.; Ortiz, C.R.; Davies, J. Global Development of Large Capacity Stationary Fuel Cells; JCR Technical Reports; Publications Office of the European Union: Brussels, Belgium, 2019. [Google Scholar]

- Kim, J.H.; Kim, H.J.; Yoo, S.H. Willingness to pay fuel-cell electric vehicles in South Korea. Energy 2019, 174, 497–502. [Google Scholar] [CrossRef]

- Eunji, Y.; Myoung, K.; Han, H.S. Well-to-wheel analysis of hydrogen fuel-cell electric vehicle in Korea. Int. J. Hydrogen Energy 2018, 43, 9267–9278. [Google Scholar]

- Lim, S.Y.; Kim, H.J.; Yoo, S.H. Household willingness to pay for expanding fuel cell power generation in Korea: A view from CO2 emissions reduction. Renew. Sustain. Energy Rev. 2018, 81, 242–249. [Google Scholar] [CrossRef]

- Giuseppe, D.; Piero, B.; Erasmo, M.; Francesco, P.; Fabio, M.; Dawid, P.H.; Vasilije, M. Feasibility of CaO/CuO/NiO sorption-enhanced steam methane reforming integrated with solid-oxide fuel cell for near-zero-CO2 emissions cogeneration system. Appl. Energy 2018, 230, 241–256. [Google Scholar]

- Rao, M.; Fernandes, A.; Pronk, P.; Aravind, P.V. Design, modelling and techno-economic analysis of a solid oxide fuel cell-gas turbine system with CO2 capture fueled by gases from steel industry. Appl. Therm. Eng. 2019, 148, 1258–1270. [Google Scholar] [CrossRef]

- Koki, Y.; Akihito, O. Study on Performance Evaluation of Residential SOFC Co-Generation Systems Part 2 Equipment characteristics and installation effect. Soc. Heat. Air-Cond. Sanit. Eng. Jpn. 2013, 70, 281–284. [Google Scholar]

- Koki, Y.; Akihito, O.; Myonghyang, L. Study on Performance Evaluation of Residential SOFC Co-Generation Systems. Soc. Heat. Air-Cond. Sanit. Eng. Jpn. 2014, 203, 25–33. [Google Scholar]

- Akito, O.; Yuki, K. Performance of residential fuel-cell-combined heat and power systems for various household types in Japan. Int. J. Hydrogen Energy 2018, 43, 15412–15422. [Google Scholar]

- Sumiyoshi, D. The examination for suitable spec of solid oxide fuel cell co-generation system and the proposal of tank minimization by using Bas-Tab in collective housing. J. Environ. Eng. 2015, 80, 441–450. [Google Scholar] [CrossRef][Green Version]

- Takahiro, Y.; Koshiro, A.; Daisuke, S. Estimation energy saving effects of sharing fuel cell with two households by simulation program: Study on effective usage of the home fuel cell in the apartment housing. J. Environ. Eng. 2018, 83, 365–374. [Google Scholar]

- Takahiro, Y. Analysis of Impact to Applying Residential Fuel Cell by Different Lifestyle. Ph.D. Thesis, Department of Architecture of Kyushu University, Fukuoka, Japan, 2018. [Google Scholar]

- Taehee, L.; JinHyeok, C.; TaeSung, P. Development and Performance Test of SOFC Co-generation System for RPG. In Proceedings of the Korean Society for New and Renewable Energy, Seoul, Korea, 25 June 2009; pp. 361–364. [Google Scholar]

- Zhou, X.; Hong, T.; Yan, D. Comparison of Building Energy Modeling Programs: HVAC Systems; Lawrence Berkeley National Lab. (LBNL): Berkeley, CA, USA, 2013.

- Han, C.; Inhee, L. A case study of decreasing environment pollution caused by energy consumption of a dormitory building which only using electricity by efficiently simulating applying residential SOFC (solid oxide fuel cell). J. Archit. Res. Archit. Inst. Korea 2019, 21, 21–29. [Google Scholar]

- American Society of Heating, Refrigeration, and Air-Conditioning Engineers. Energy Efficient Design for Low-Rise Residential Buildings; ASHRAE: Atlanta, GA, USA, 2010. [Google Scholar]

- Jehean, S. The Analysis of Environmental Impact Index Using Life Cycle Assessment for Korean Traditional Building. Ph.D. Thesis, Department of Architecture of the Pusan National University, Busan, Korea, 2017. [Google Scholar]

- Cheolyong, J.; Byunglip, A.; Chihoon, K.; Wonhwa, H. A Study on the insulation performance of the super window considering the evaluation of building energy rating. J. Korean Sol. Energy Soc. 2009, 29, 1598–6411. [Google Scholar]

- Kim, C.; Ahn, B.; Kim, J.; Jang, C. A Study on the Evaluation of Building Energy Rating Considering the Insulation Performance of the Window and Wall in Apartment Houses. In Proceedings of the Conference of The Society of Air-conditioning and Refrigerating Engineers of Korea, Seoul, Korea, 25 June 2009. [Google Scholar]

- Korea Environmental Industry & Technology Institute. Available online: www.epd.or.kr (accessed on 6 August 2018).

- Arata, N.; Zacharie, W.; Patrick, M.; Stefan, D.; Gunter, S.; Jan, V.; Daniel, F. Electrochemical model of solid oxide fuel cell for simulation at the stack scale. Part I: Calibration procedure on experimental data. J. Electrochem. Soc. 2011, 158, B1102–B1118. [Google Scholar]

- Marcin, M.; Katarzyna, B.; Shinji, K.; Janusz, S.S.; Grzegorz, B. A Multiscale Approach to the Numerical Simulation of the Solid Oxide Fuel Cell. Catalysts 2019, 253, 1–28. [Google Scholar]

- Kwang, H.L.; Richard, K.S.; Shinji, K. SOFC cogeneration system for building applications, part 1: Development of SOFC system-level model and the parametric study. Renew. Energy 2009, 34, 2831–2838. [Google Scholar]

| Parameter | Specific Characteristic |

|---|---|

| Area | 172.3 m2 |

| Structure | Steel–concrete |

| Envelop | Concrete |

| Aboveground Stories | 4 |

| Underground Stories | 0 |

| Story height | 2.6 m |

| Height | 10.4 m |

| Width | 12.6 m |

| Length | 14.5 m |

| Service life | 50 years |

| Climate Specification | Value |

|---|---|

| Latitude | 35°32′ N |

| Longitude | 129°19′ E |

| Average annual temperature | 14.05 °C |

| Average max annual temperature | 35.4 °C |

| Average min annual temperature | –8.8 °C |

| Average annual relative humidity | 63.40% |

| Average solar radiation | 106.15 Wh/m2 |

| Average annual wind speed | 1.93 m/s |

| Elevation above sea level | 33 m |

| Parameter | Specific Characteristic |

|---|---|

| Orientation | West to East |

| External wall | 0.58 W/m2K |

| Internal wall | 2.92 W/m2K |

| Roof | 0.27 W/m2K |

| Glazing | 3.12 W/m2K |

| Infiltration rate | 0.3 ac/h |

| Ventilation rate | 3 ac/h |

| Equipment | 5.38 W/m2 |

| Lighting | 3.88 W/m2 |

| Occupancy | 0.054 people/m2 |

| HVAC/Heating | Dedicated hot water boiler (electricity) |

| HVAC/Cooling | Electricity from grid |

| Set point temperature | Summer 26 °C, Winter 22 °C |

| Air Pollutant | Electricity (kg/kWh) | Natural Gas (kg/kWh) |

|---|---|---|

| CO2 | 4.87 × 10−1 | 3.94 × 10−2 |

| CH4 | 3.50 × 10−4 | 2.01 × 10−4 |

| N2O | 1.35 × 10−6 | 1.72 × 10−7 |

| SO2 | 0.00 × 100 | 4.22 × 10−4 |

| CO | 5.00 × 10−5 | 9.91 × 10−5 |

| NOX | 1.20 × 10−4 | 5.67 × 10−4 |

| NMVOC | 2.00 × 10−5 | 1.04 × 10−6 |

| System | System Application | Model Application | Main Design Variables |

|---|---|---|---|

| SOFC [36] | Cell stack | Electrochemical model | Volumetric rate generated thermal energy, rate of production of species, area specific resistance |

| SOFC–CGS [37] | Stationary | Electrochemical model | Partial pressure of methane, reaction rate of steam reforming, cell temperature |

| SOFC [38] | Cell Stack | Electrochemical model | Partial pressure of species, anodic and cathodic charge-transfer coefficients, exchange current density |

| SOFC–CGS [22] | Stationary | Device efficiency | Efficiency of electricity generation, efficiency of heat collection, water temperature |

| SOFC–CGS [11] | Stationary/Transportation | Device efficiency | Electric demand of cafeteria, required electricity for EV charging, electric power generated by SOFC–CGS |

| SOFC–CHP/PEMFC–CHP [24] | Stationary | Device efficiency | Power generation efficiency of the fuel cell, heat recovery efficiency of the fuel cell, heat loss rate of the tank |

| Type of Cell Stack | SOFC (Solid Oxide Fuel Cell) |

|---|---|

| Rated electrical output | 700 W |

| Max running time | 26 days |

| Standby time for start | 1 day |

| Water tank volume | 28 L |

| Reaction to overheating | Heat dissipation by radiator |

| Efficiency of heat collection | 31% |

| Water temperature from tank to backup boiler | 40 °C |

| Efficiency of electricity generation | 46.4% |

| Input Data | Unit/Value |

|---|---|

| Electricity demand | W |

| Hot water demand | L/Time unit |

| Setting temperature of backup boiler | 40 °C |

| Outside temperature | Data from ASHRAE |

| Temperature of city water | 15 °C |

| Temperature of hot water demand | 40 °C |

| Case Number | Case Name | Energy for Heating/Hot Water | Energy for Other Needs in Household |

|---|---|---|---|

| 1 | Using only electricity | Purchased electricity from power plant | Purchased electricity from power plant |

| 2 | Using natural gas and electricity | Direct natural gas (heating and hot water) | Purchased electricity from power plant |

| 3 | One SOFC–CGS for one household | Direct natural gas (heating) | Individual SOFC–CGS for one household and purchased electricity from power plant |

| 4 | One SOFC–CGS to multi-households | Direct natural gas (heating) | Shared SOFC–CGS for multi-households and purchased electricity from power plant |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, H.; Lee, I.-H. Environmental and Efficiency Analysis of Simulated Application of the Solid Oxide Fuel Cell Co-Generation System in a Dormitory Building. Energies 2019, 12, 3893. https://doi.org/10.3390/en12203893

Chang H, Lee I-H. Environmental and Efficiency Analysis of Simulated Application of the Solid Oxide Fuel Cell Co-Generation System in a Dormitory Building. Energies. 2019; 12(20):3893. https://doi.org/10.3390/en12203893

Chicago/Turabian StyleChang, Han, and In-Hee Lee. 2019. "Environmental and Efficiency Analysis of Simulated Application of the Solid Oxide Fuel Cell Co-Generation System in a Dormitory Building" Energies 12, no. 20: 3893. https://doi.org/10.3390/en12203893

APA StyleChang, H., & Lee, I.-H. (2019). Environmental and Efficiency Analysis of Simulated Application of the Solid Oxide Fuel Cell Co-Generation System in a Dormitory Building. Energies, 12(20), 3893. https://doi.org/10.3390/en12203893