Smart Battery Pack for Electric Vehicles Based on Active Balancing with Wireless Communication Feedback

Abstract

1. Introduction

- Communicate wirelessly with the battery pack controller providing advanced cell balancing, monitoring, and fault tolerant operation;

- Estimate its own SOC and the possibility to evaluate SOH;

- Be easily integrated in a very large battery pack by enhancing the scalability.

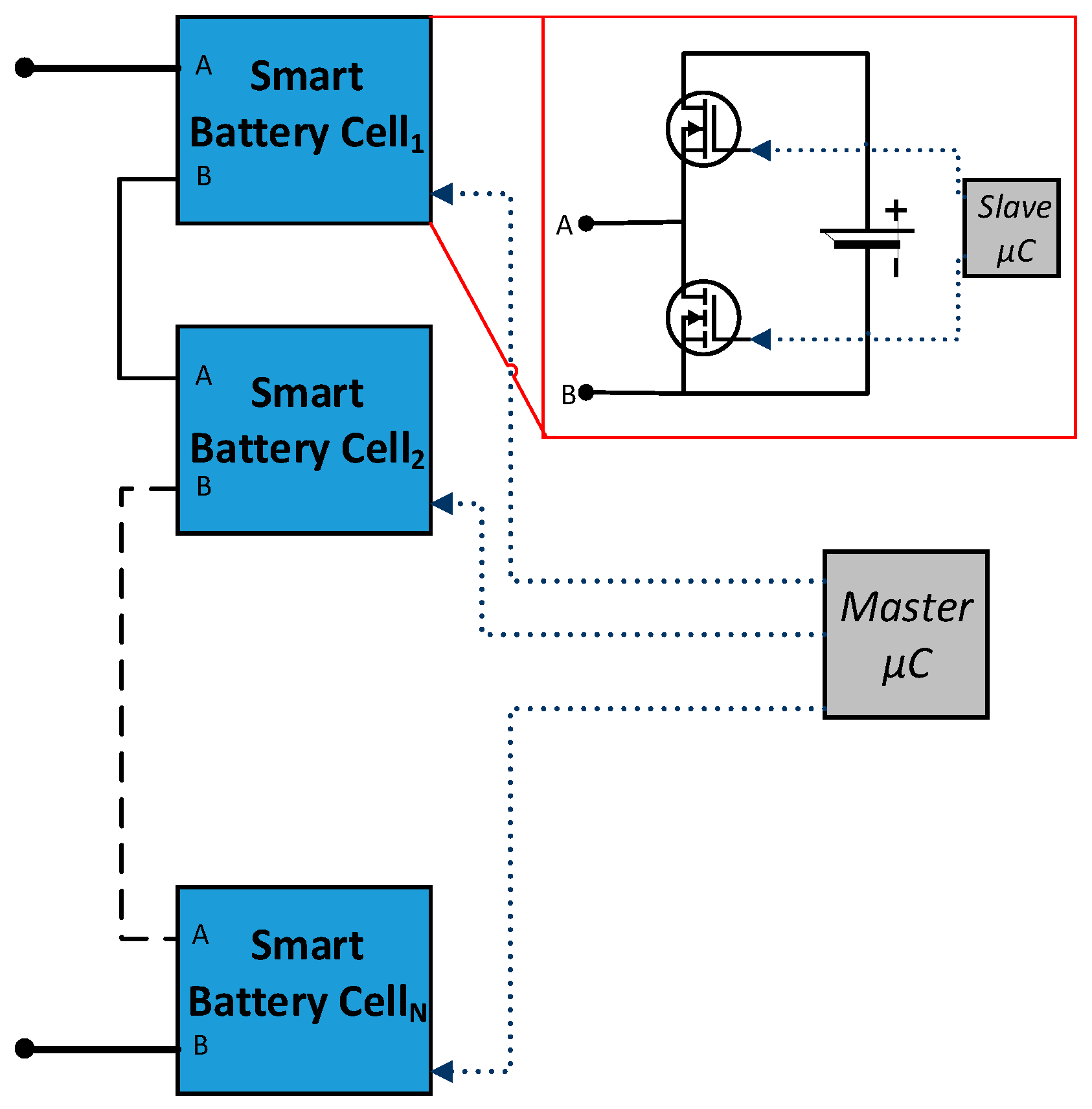

2. Smart Battery Pack

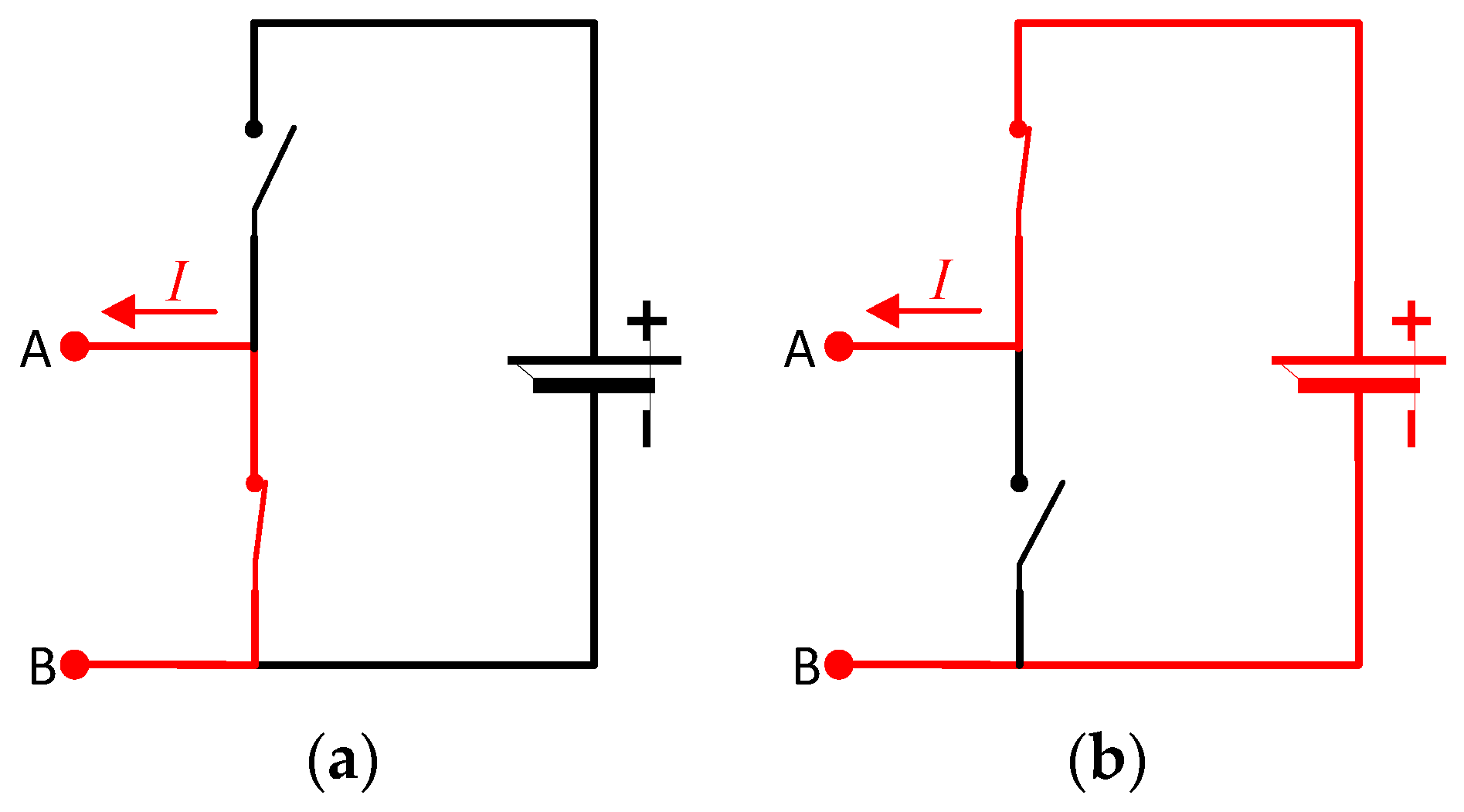

2.1. Basic Concept

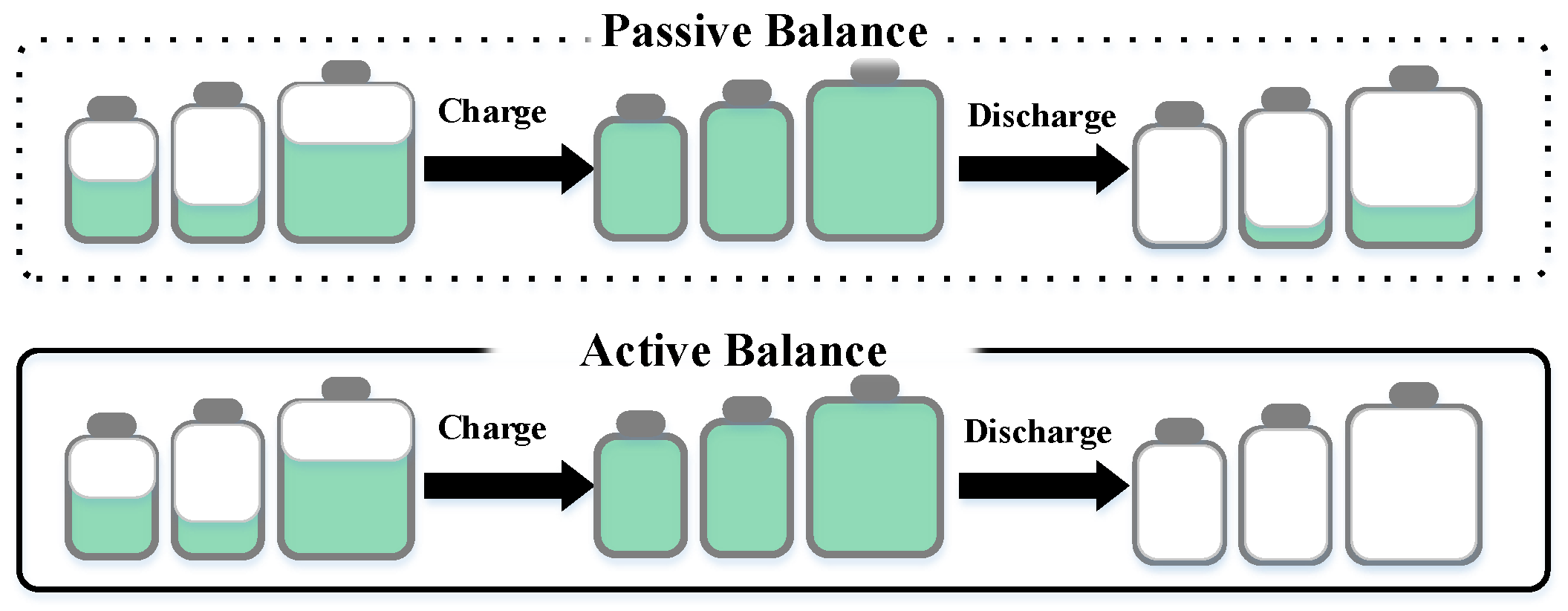

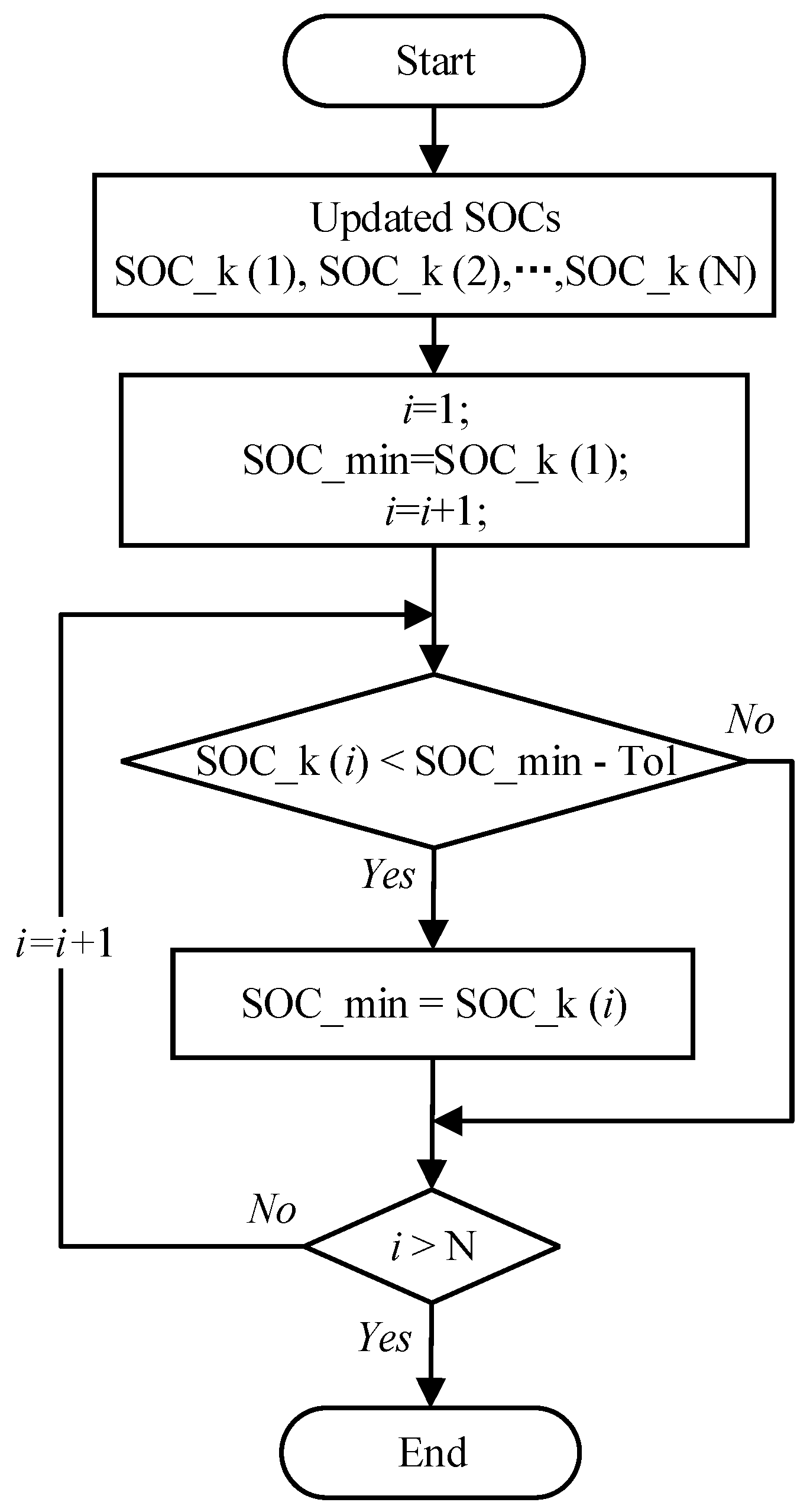

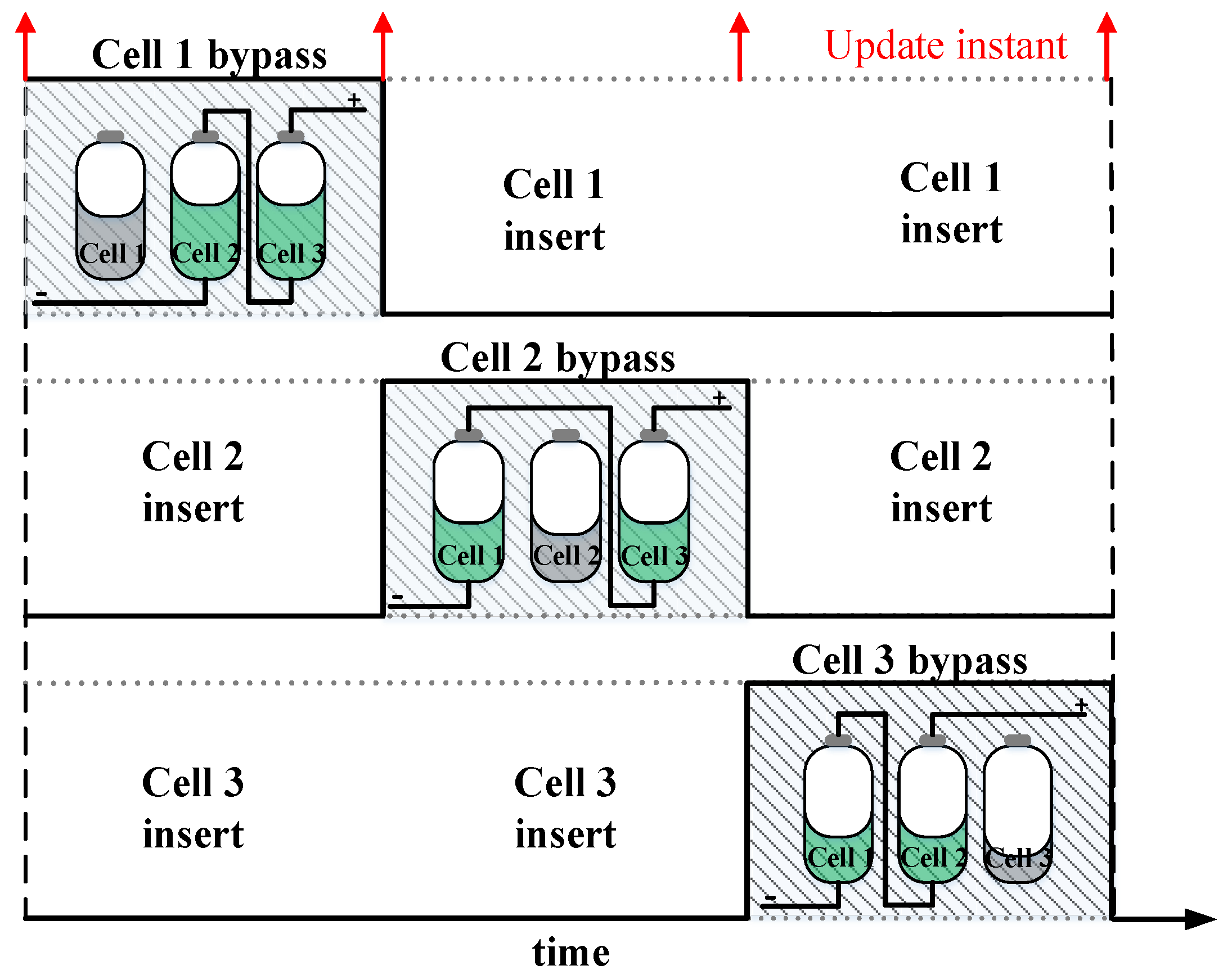

2.2. Balancing Algorithm

2.2.1. SOC Estimation

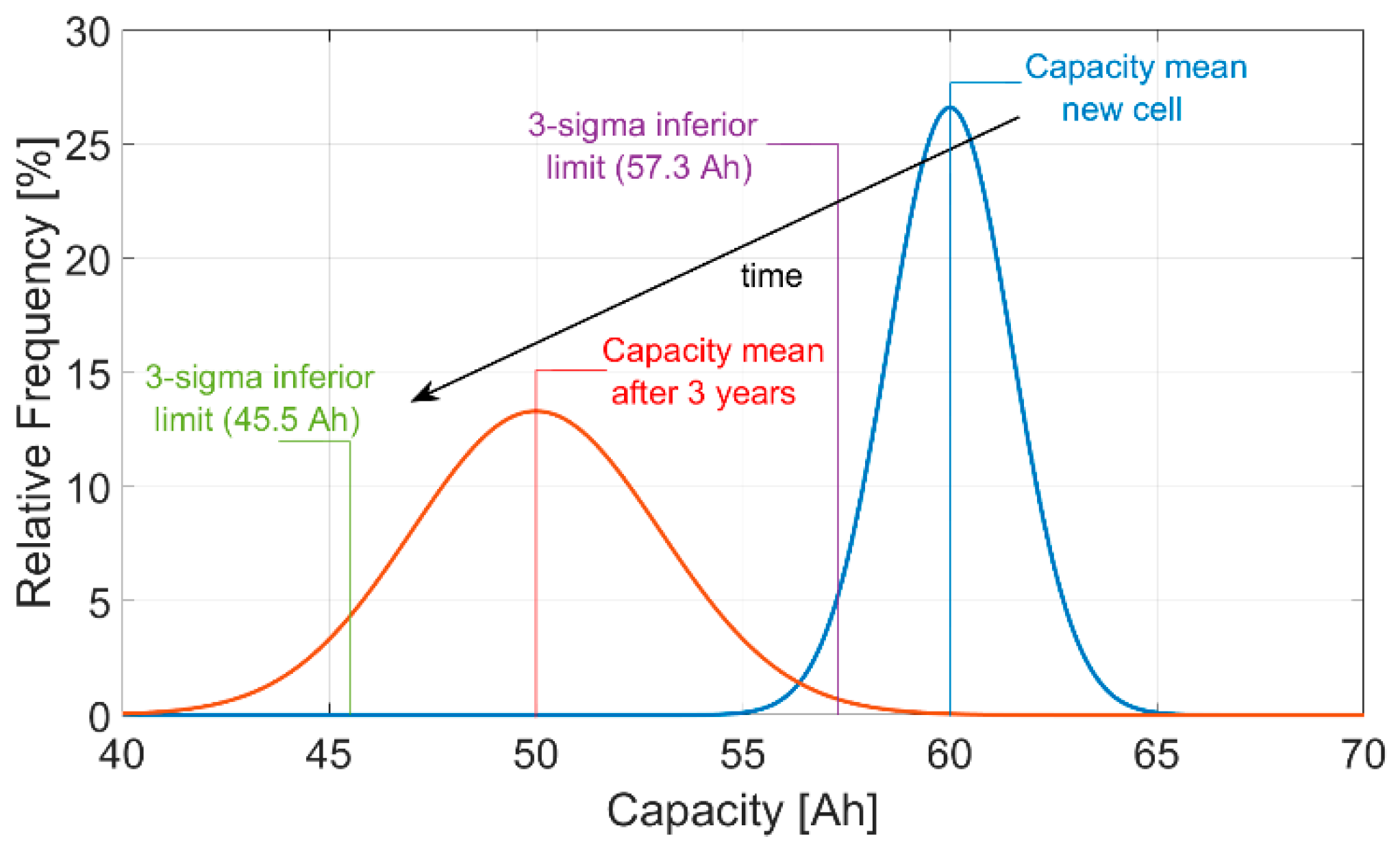

2.2.2. Capacity Gain Evaluation

2.3. Wireless Protocol Stack

2.3.1. Master

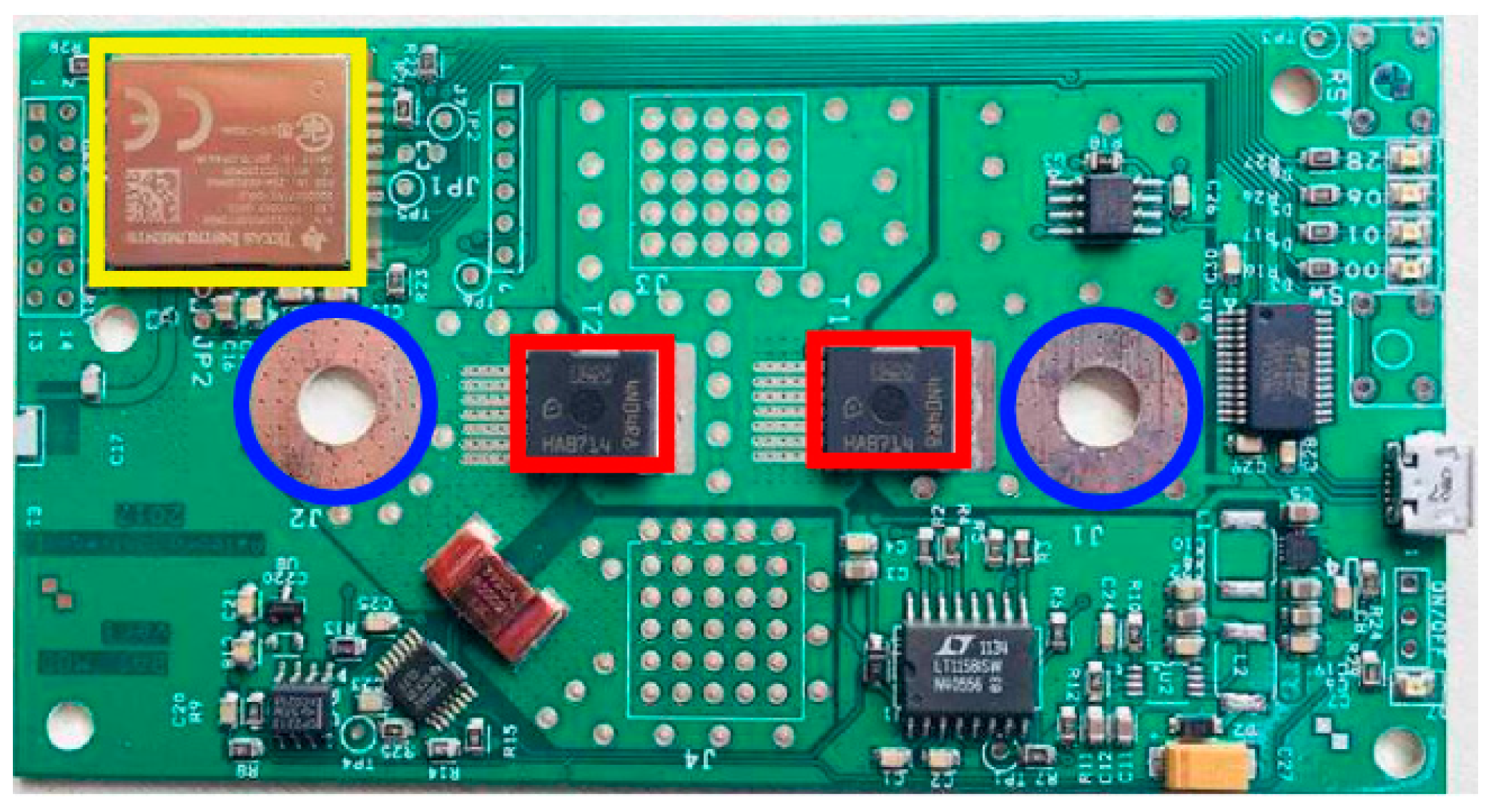

2.3.2. Slave

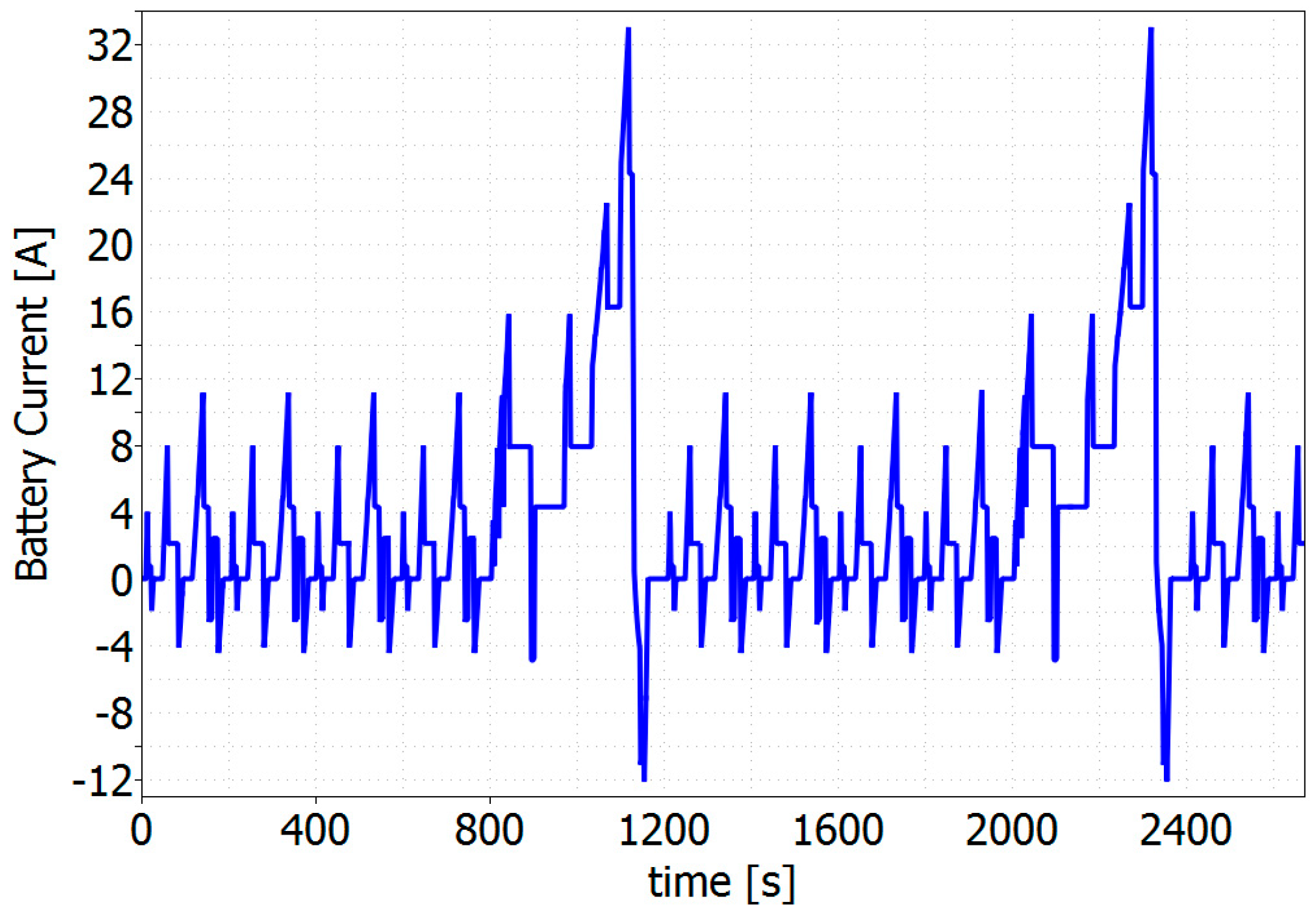

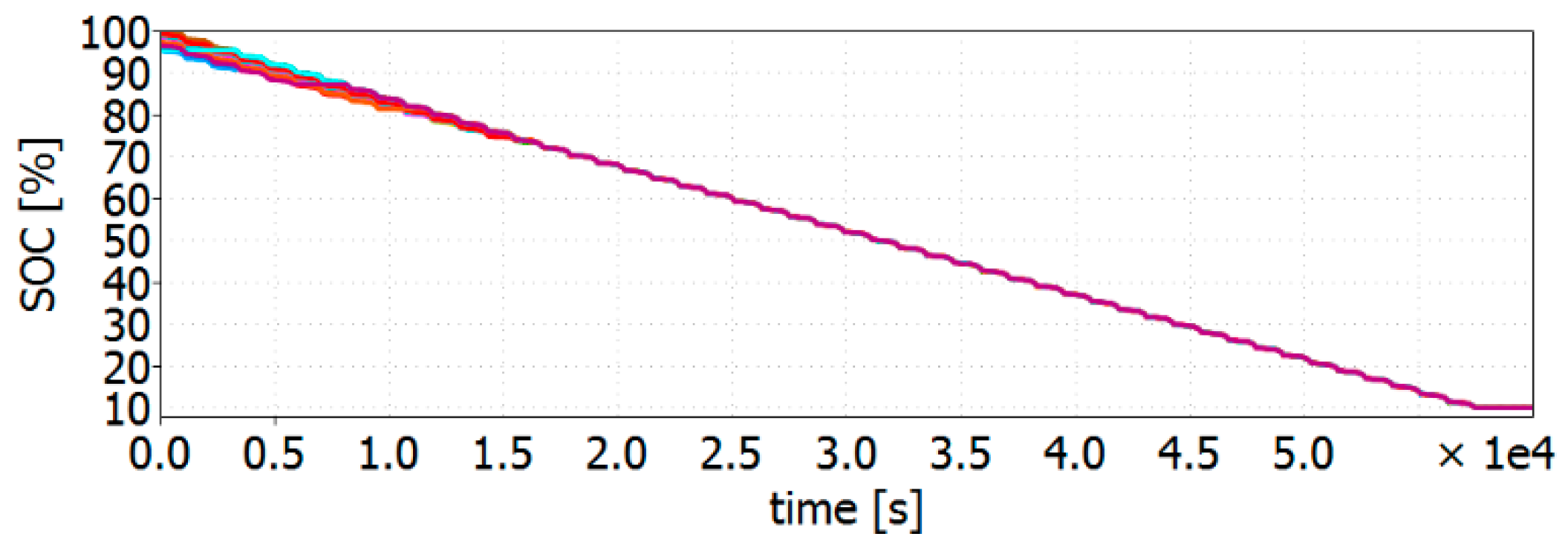

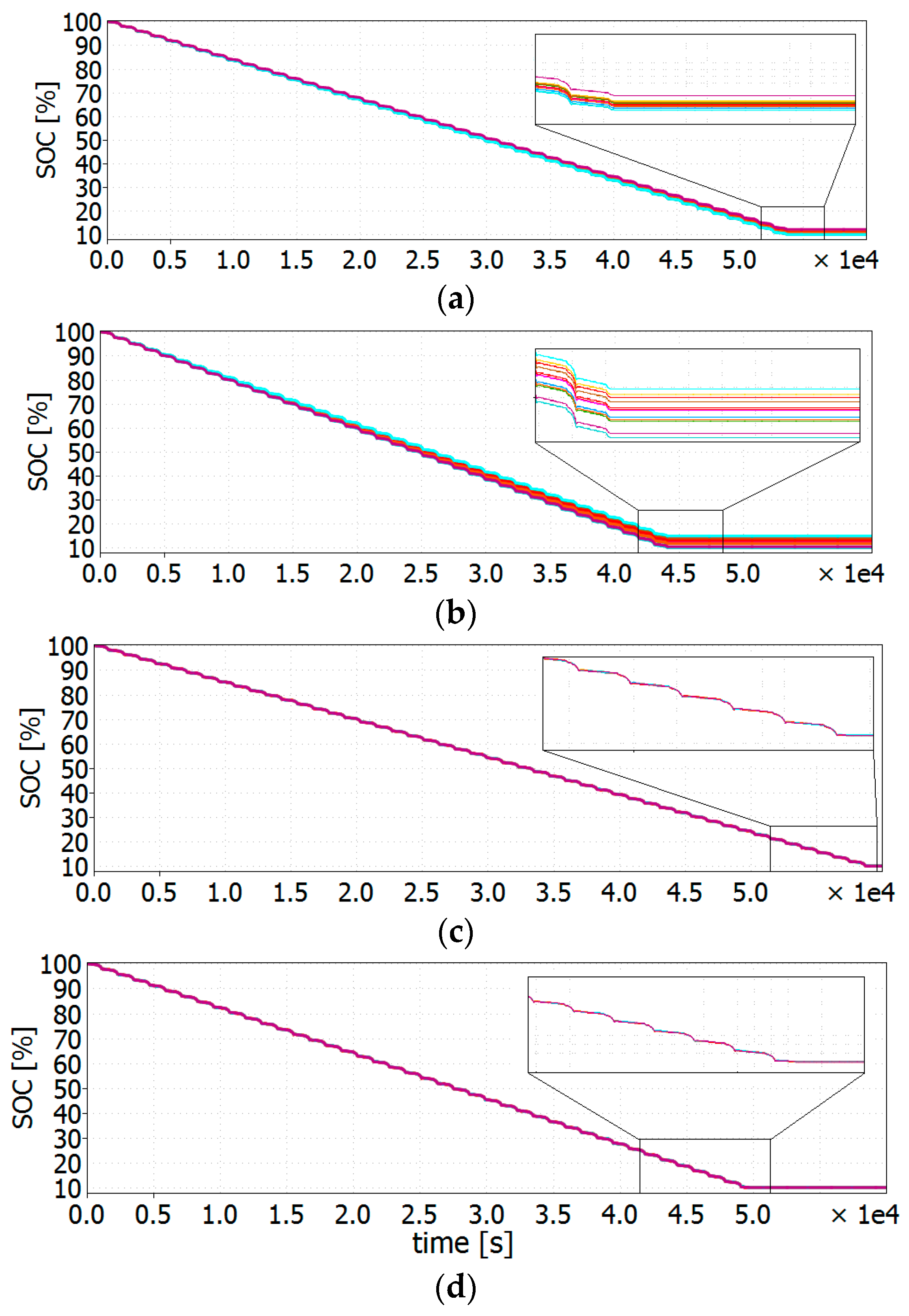

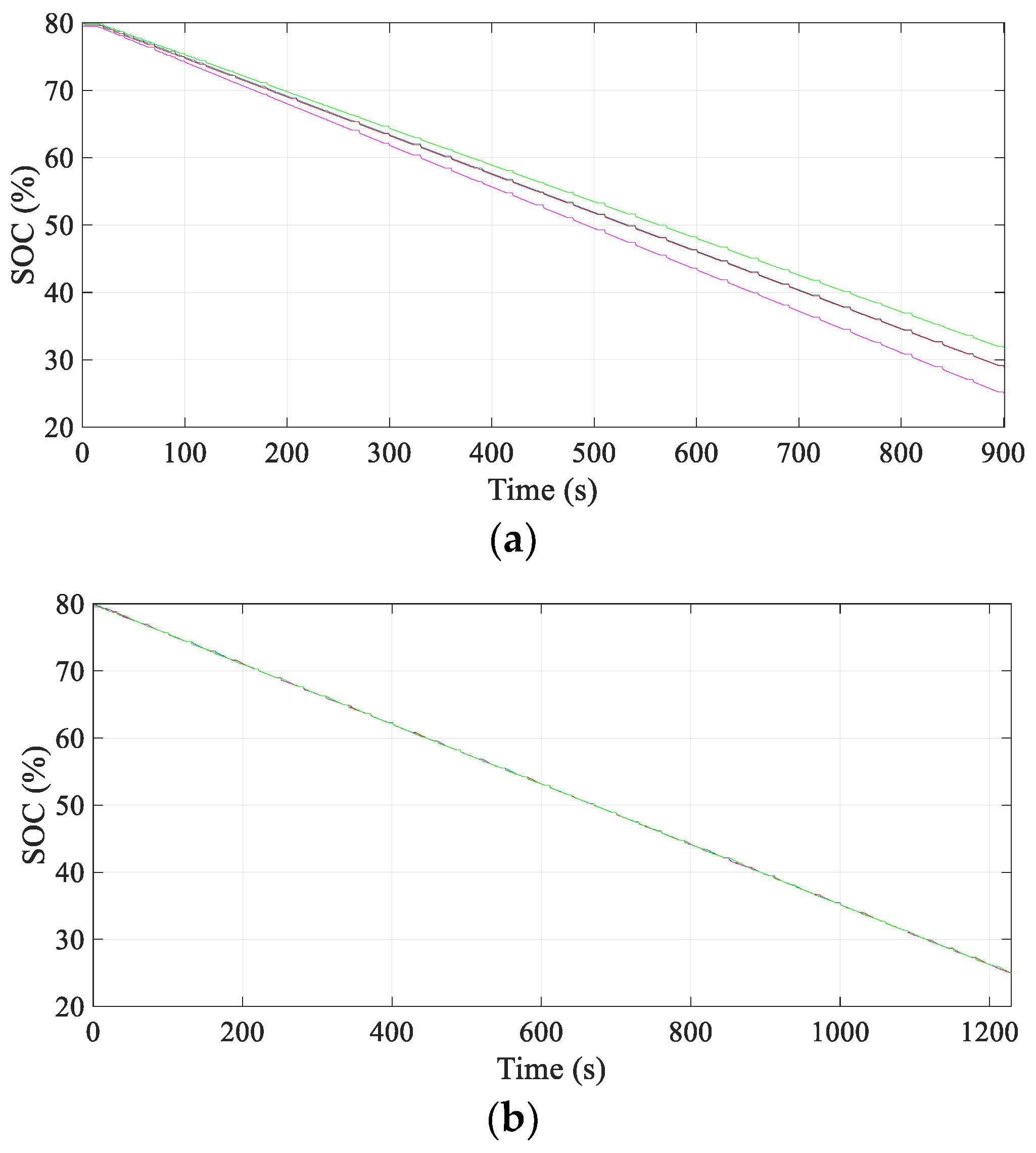

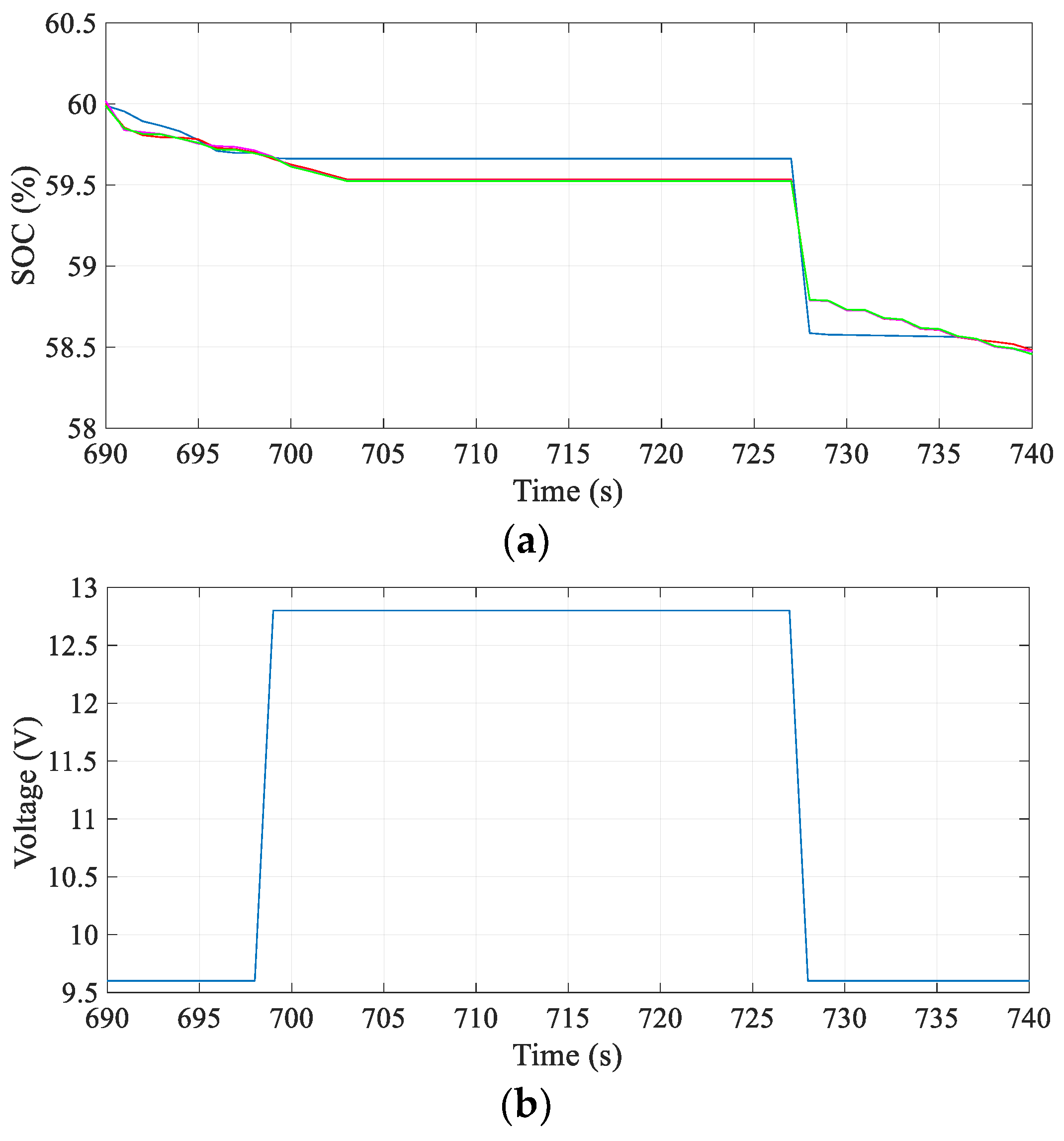

3. Simulation Results

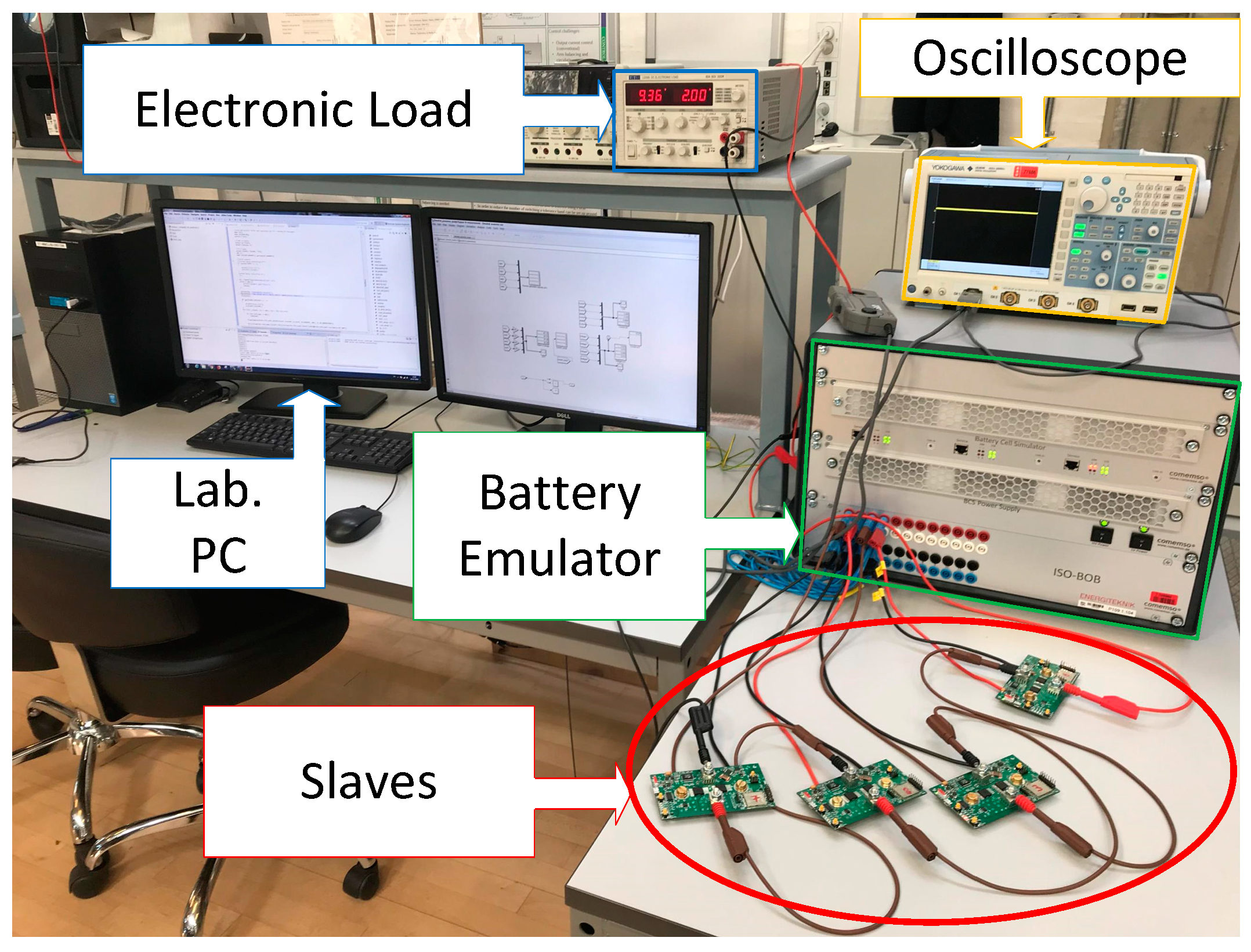

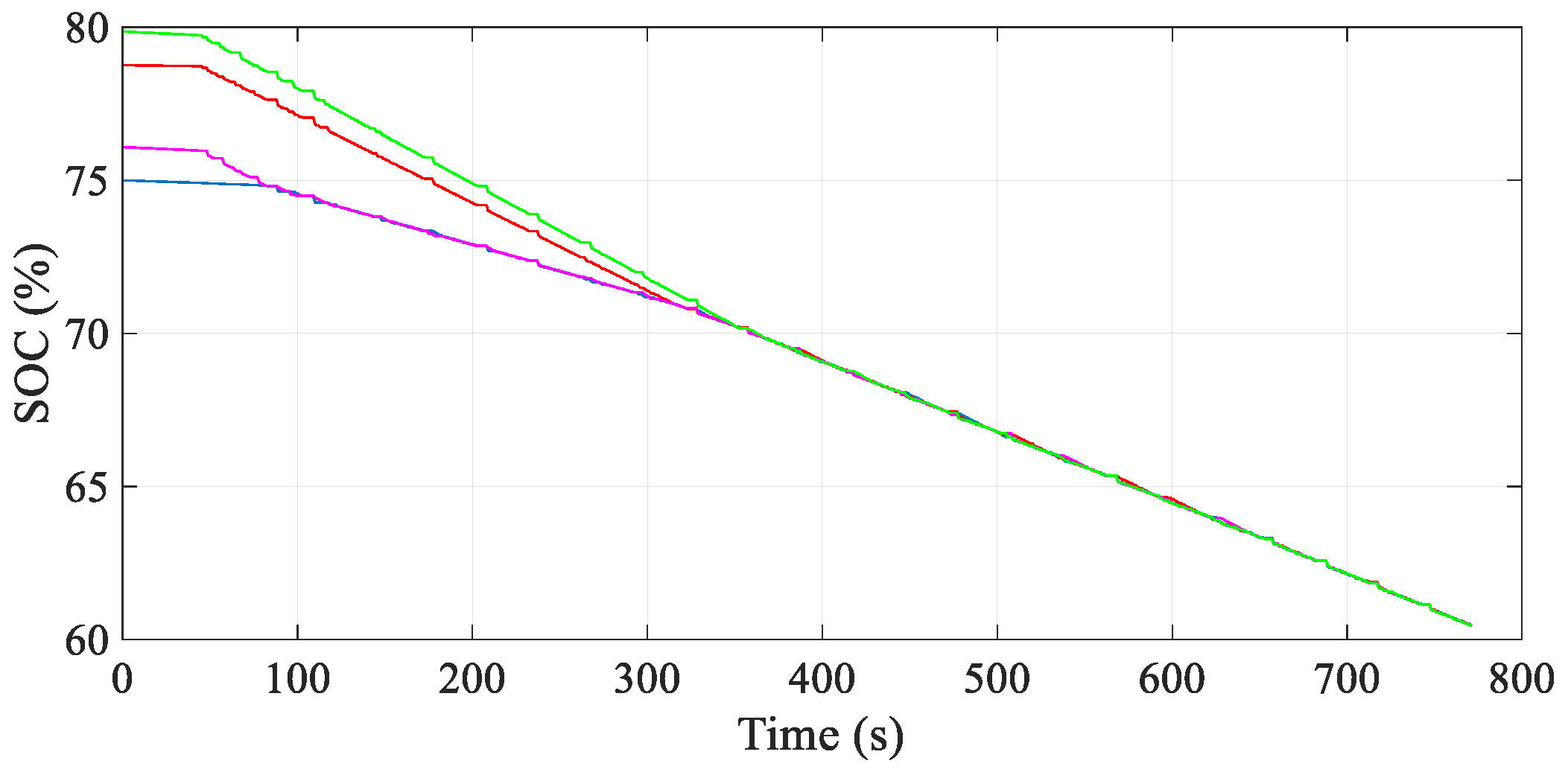

4. Experimental Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Andwari, A.M.; Pesiridis, A.; Rajoo, S.; Martinez-Botas, R.; Esfahanian, V. A review of Battery Electric Vehicle technology and readiness levels. Renew. Sustain. Energy Rev. 2017, 78, 414–430. [Google Scholar] [CrossRef]

- Cano, Z.P.; Banham, D.; Ye, S.; Hintennach, A.; Lu, J.; Fowler, M.; Chen, Z. Batteries and fuel cells for emerging electric vehicle markets. Nat. Energy 2018, 3, 279–289. [Google Scholar] [CrossRef]

- Saw, L.H.; Ye, Y.; Tay, A.A. Integration issues of lithium-ion battery into electric vehicles battery pack. J. Clean. Prod. 2016, 113, 1032–1045. [Google Scholar] [CrossRef]

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sourc. 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Lelie, M.; Braun, T.; Knips, M.; Nordmann, H.; Ringbeck, F.; Zappen, H.; Sauer, D. Battery Management System Hardware Concepts: An Overview. Appl. Sci. 2018, 8, 534. [Google Scholar] [CrossRef]

- Shen, P.; Ouyang, M.; Lu, L.; Li, J.; Feng, X. The Co-estimation of State of Charge, State of Health and State of Function for Lithium-ion Batteries in Electric Vehicles. IEEE Trans. Veh. Technol. 2018, 67, 92–103. [Google Scholar] [CrossRef]

- Naha, A.; Khandelwal, A.; Hariharan, K.S.; Kaushik, A.; Yadu, A.; Kolake, S.M. On-Board Short-Circuit Detection of Li-ion Batteries Undergoing Fixed Charging Profile as in Smartphone Applications. IEEE Trans. Ind. Electron. 2019, 66, 8782–8791. [Google Scholar] [CrossRef]

- Zhou, L.; Zheng, Y.; Ouyang, M.; Lu, L. A study on parameter variation effects on battery packs for electric vehicles. J. Power Sourc. 2017, 364, 242–252. [Google Scholar] [CrossRef]

- Ye, M.; Song, X.; Xiong, R.; Sun, F. A Novel Dynamic Performance Analysis and Evaluation Model of Series-Parallel Connected Battery Pack for Electric Vehicles. IEEE Access 2019, 7, 14256–14265. [Google Scholar] [CrossRef]

- Daowd, M.; Omar, N.; Van Den Bossche, P.; Van Mierlo, J. Passive and active battery balancing comparison based on MATLAB simulation. In Proceedings of the 2011 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 6–9 September 2011; pp. 1–7. [Google Scholar]

- Lee, S.W.; Choi, Y.G.; Kang, B. Active Charge Equalizer of Li-Ion Battery Cells Using Double Energy Carriers. Energies 2019, 12, 2290. [Google Scholar] [CrossRef]

- Baronti, F.; Roncella, R.; Saletti, R. Performance comparison of active balancing techniques for lithium-ion batteries. J. Power Sour. 2014, 267, 603–609. [Google Scholar] [CrossRef]

- Caspar, M.; Eiler, T.; Hohmann, S. Systematic Comparison of Active Balancing: A Model-Based Quantitative Analysis. IEEE Trans. Veh. Technol. 2018, 67, 920–934. [Google Scholar] [CrossRef]

- Li, Y.; Han, Y. A Module-Integrated Distributed Battery Energy Storage and Management System. IEEE Trans. Power Electron. 2016, 31, 8260–8270. [Google Scholar] [CrossRef]

- Einhorn, M.; Roessler, W.; Fleig, J. Improved Performance of Serially Connected Li-Ion Batteries With Active Cell Balancing in Electric Vehicles. IEEE Trans. Veh. Technol. 2011, 60, 2448–2457. [Google Scholar] [CrossRef]

- Narayanaswamy, S.; Kauer, M.; Steinhorst, S.; Lukasiewycz, M.; Chakraborty, S. Modular Active Charge Balancing for Scalable Battery Packs. IEEE Trans. Very Large Scale Integr. Syst. 2017, 25, 974–987. [Google Scholar] [CrossRef]

- Lukasiewycz, M.; Kauer, M.; Steinhorst, S. Synthesis of Active Cell Balancing Architectures for Battery Packs. IEEE Trans. Comput. Des. Integr. Circuits Syst. 2016, 35, 1876–1889. [Google Scholar] [CrossRef]

- Baronti, F.; Fantechi, G.; Roncella, R.; Saletti, R. High-efficiency digitally controlled charge equalizer for series-connected cells based on switching converter and super-capacitor. IEEE Trans. Ind. Inf. 2013, 9, 1139–1147. [Google Scholar] [CrossRef]

- Zhang, C.; Shang, Y.; Li, Z.; Cui, N. An interleaved equalization architecture with self-learning fuzzy logic control for series-connected battery strings. IEEE Trans. Veh. Technol. 2017, 66, 10923–10934. [Google Scholar] [CrossRef]

- Manenti, A.; Abba, A.; Merati, A.; Savaresi, S.M.; Geraci, A. A new BMS architecture based on cell redundancy. IEEE Trans. Ind. Electron. 2011, 58, 4314–4322. [Google Scholar] [CrossRef]

- Gunlu, G. Dynamically Reconfigurable Independent Cellular Switching Circuits for Managing Battery Modules. IEEE Trans. Energy Convers. 2017, 32, 194–201. [Google Scholar] [CrossRef]

- Cao, X.; Zhong, Q.C.; Qiao, Y.C.; Deng, Z.Q. Multilayer Modular Balancing Strategy for Individual Cells in a Battery Pack. IEEE Trans. Energy Convers. 2018, 33, 526–536. [Google Scholar] [CrossRef]

- Lin, N.; Ci, S.; Wu, D.; Guo, H. An Optimization Framework for Dynamically Reconfigurable Battery Systems. IEEE Trans. Energy Convers. 2018, 33, 1669–1676. [Google Scholar] [CrossRef]

- Otto, A.; Rzepka, S.; Mager, T.; Michel, B.; Lanciotti, C.; Günther, T.; Kanoun, O. Battery Management Network for Fully Electrical Vehicles Featuring Smart Systems at Cell and Pack Level; Meyer, G., Ed.; Advanced Microsystems for Automotive Applications 2012; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Mathew, S.A.; Prakash, R.; John, P.C. A smart wireless battery monitoring system for electric vehicles. In Proceedings of the 2012 12th International Conference on Intelligent Systems Design and Applications (ISDA), Kochi, India, 27–29 November 2012; pp. 189–193. [Google Scholar]

- Qahouq, J.A.A.; Cao, Y. Distributed battery system with wireless control and power transfer—A concept introduction. Conf. Proc. IEEE Appl. Power Electron. Conf. Expo. 2018, 2018, 344–347. [Google Scholar]

- Majmunovic, B.; Sarda, R.; Teodorescu, R.; Lascu, C.; Ricco, M. Highly efficient smart battery pack for EV drivetrains. In Proceedings of the 2017 IEEE Vehicle Power and Propulsion Conference (VPPC), Belfort, France, 11–14 December 2017; pp. 1–5. [Google Scholar]

- Jiang, Y.; Jiang, J.; Zhang, C.; Zhang, W.; Gao, Y.; Guo, Q. Recognition of battery aging variations for LiFePO4 batteries in 2nd use applications combining incremental capacity analysis and statistical approaches. J. Power Sourc. 2017, 360, 180–188. [Google Scholar] [CrossRef]

- Lafrenz, J.L.; Scheff, P.; Ricco, M.; Kerekes, T.; Olsen, R.L.; Teodorescu, R.; Liserre, M. Application Layer Design for Smart Battery Pack Control with Wi-Fi ® Feedback. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 Septemeber 2018. [Google Scholar]

| Battery Pack with New Cells | Battery Pack With 3-Year-Old Cells | |

|---|---|---|

| Passive balancing | 51.57 Ah | 40.95 Ah |

| Active balancing | 54 Ah | 45 Ah |

| Status | Status Code Description |

|---|---|

| 000 | Not all slaves respond with the requested state of charge (SOC) |

| 001 | All slaves respond with the requested SOC |

| 010 | Not all slaves respond after 5 REQUEST_SOC or CMD packets broadcasted |

| 011 | Not all slaves reply with valid data to a CMD packet |

| 100 | All slaves reply with valid data to a CMD packet |

| 101 | Not all slaves reply with valid data to an EXE packet |

| 110 | All slaves reply with valid data to an EXE packet |

| Battery Pack with New Cells | Battery Pack with 3-Year-Old Cells | |

|---|---|---|

| Passive balancing | 14.9 h | 12.2 h |

| Active balancing | 16.3 h | 13.8 h |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ricco, M.; Meng, J.; Gherman, T.; Grandi, G.; Teodorescu, R. Smart Battery Pack for Electric Vehicles Based on Active Balancing with Wireless Communication Feedback. Energies 2019, 12, 3862. https://doi.org/10.3390/en12203862

Ricco M, Meng J, Gherman T, Grandi G, Teodorescu R. Smart Battery Pack for Electric Vehicles Based on Active Balancing with Wireless Communication Feedback. Energies. 2019; 12(20):3862. https://doi.org/10.3390/en12203862

Chicago/Turabian StyleRicco, Mattia, Jinhao Meng, Tudor Gherman, Gabriele Grandi, and Remus Teodorescu. 2019. "Smart Battery Pack for Electric Vehicles Based on Active Balancing with Wireless Communication Feedback" Energies 12, no. 20: 3862. https://doi.org/10.3390/en12203862

APA StyleRicco, M., Meng, J., Gherman, T., Grandi, G., & Teodorescu, R. (2019). Smart Battery Pack for Electric Vehicles Based on Active Balancing with Wireless Communication Feedback. Energies, 12(20), 3862. https://doi.org/10.3390/en12203862