Intelligent Estimation of Vitrinite Reflectance of Coal from Photomicrographs Based on Machine Learning

Abstract

1. Introduction

1.1. Background and Motivation

1.2. Related Work

- (1)

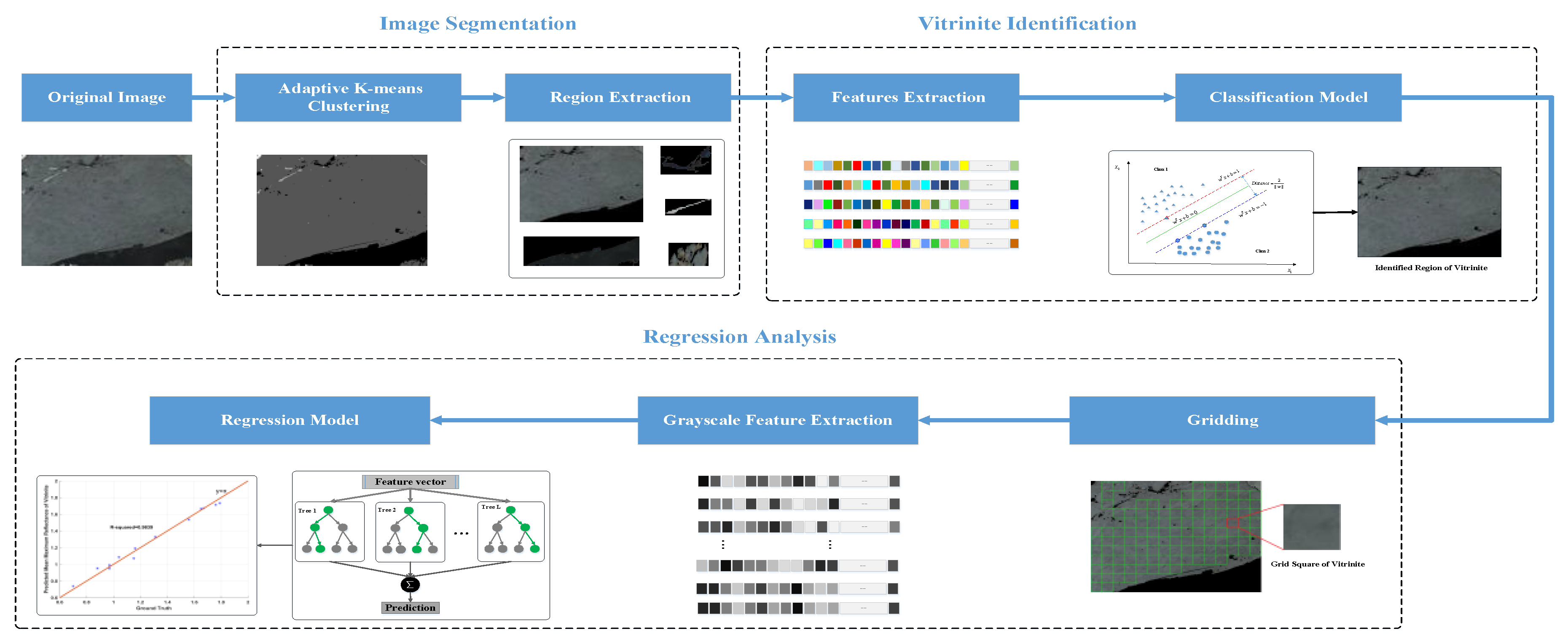

- Considering the complicated characteristics of coal photomicrographs, the number of maceral categories in one photomicrograph is uncertain. We adopted an adaptive image segmentation method to intelligently segment an entire photomicrograph into several discrete regions, where each region corresponds to one maceral group. The proposed method can be generalized in different degrees of coalification.

- (2)

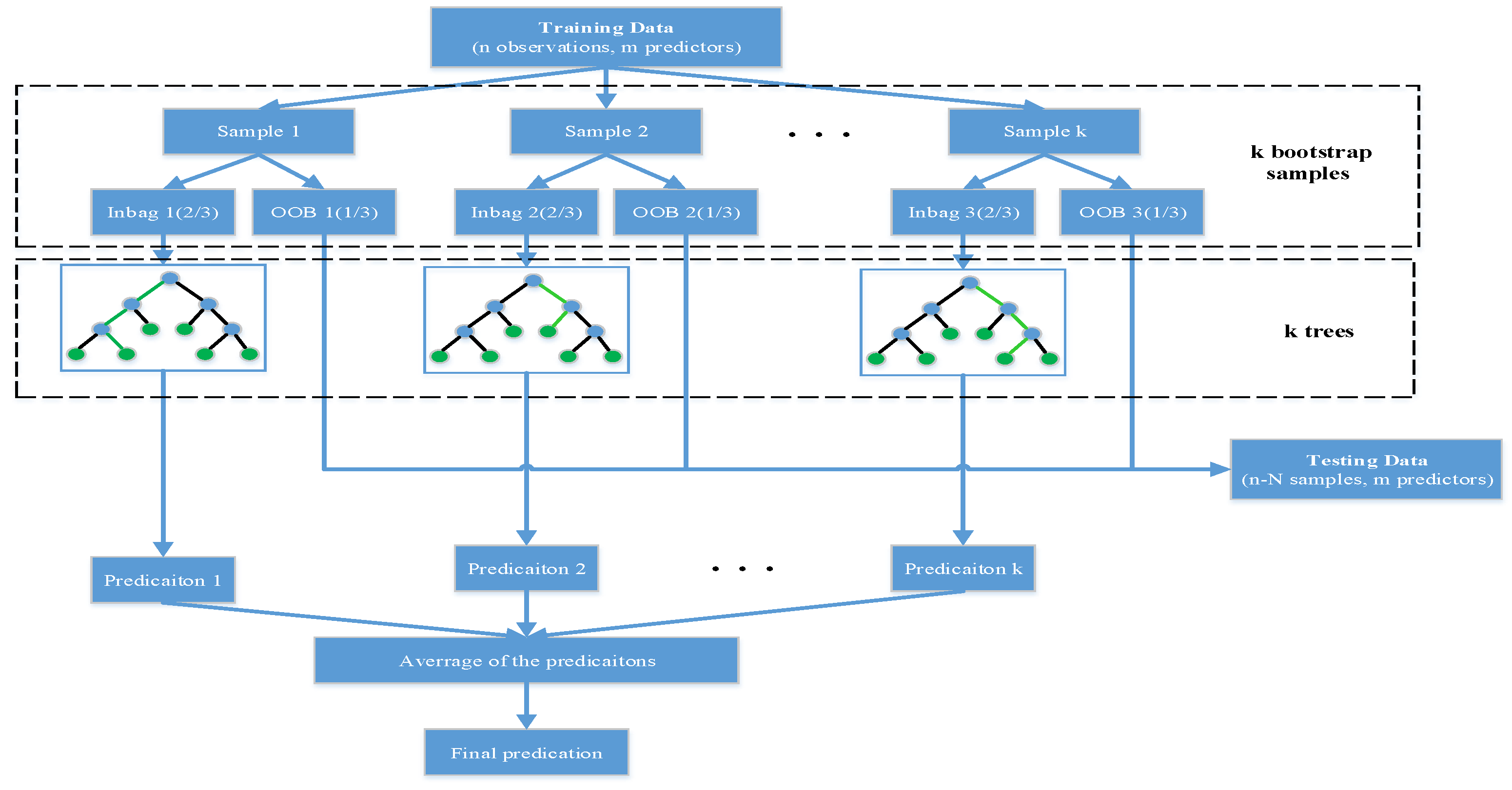

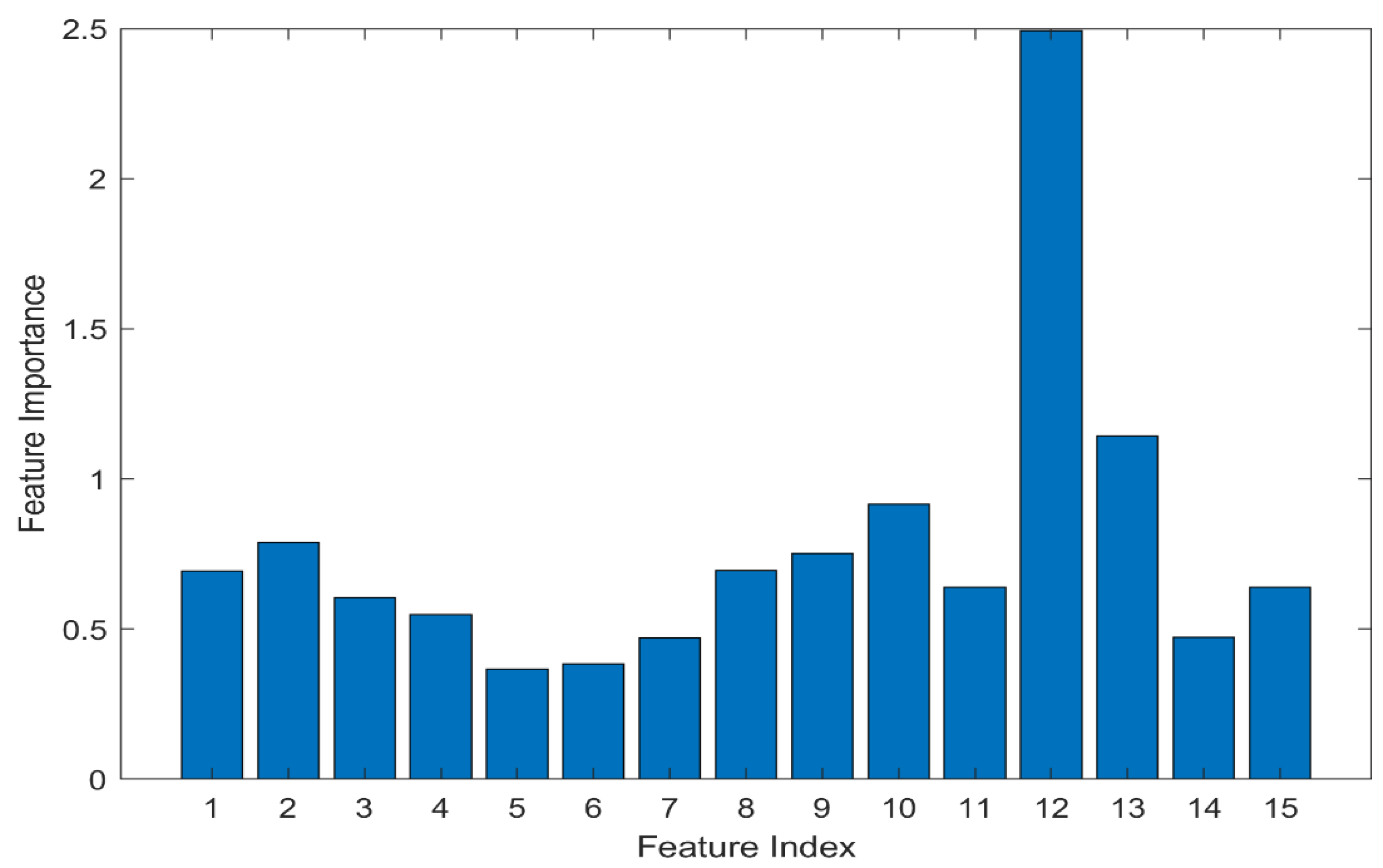

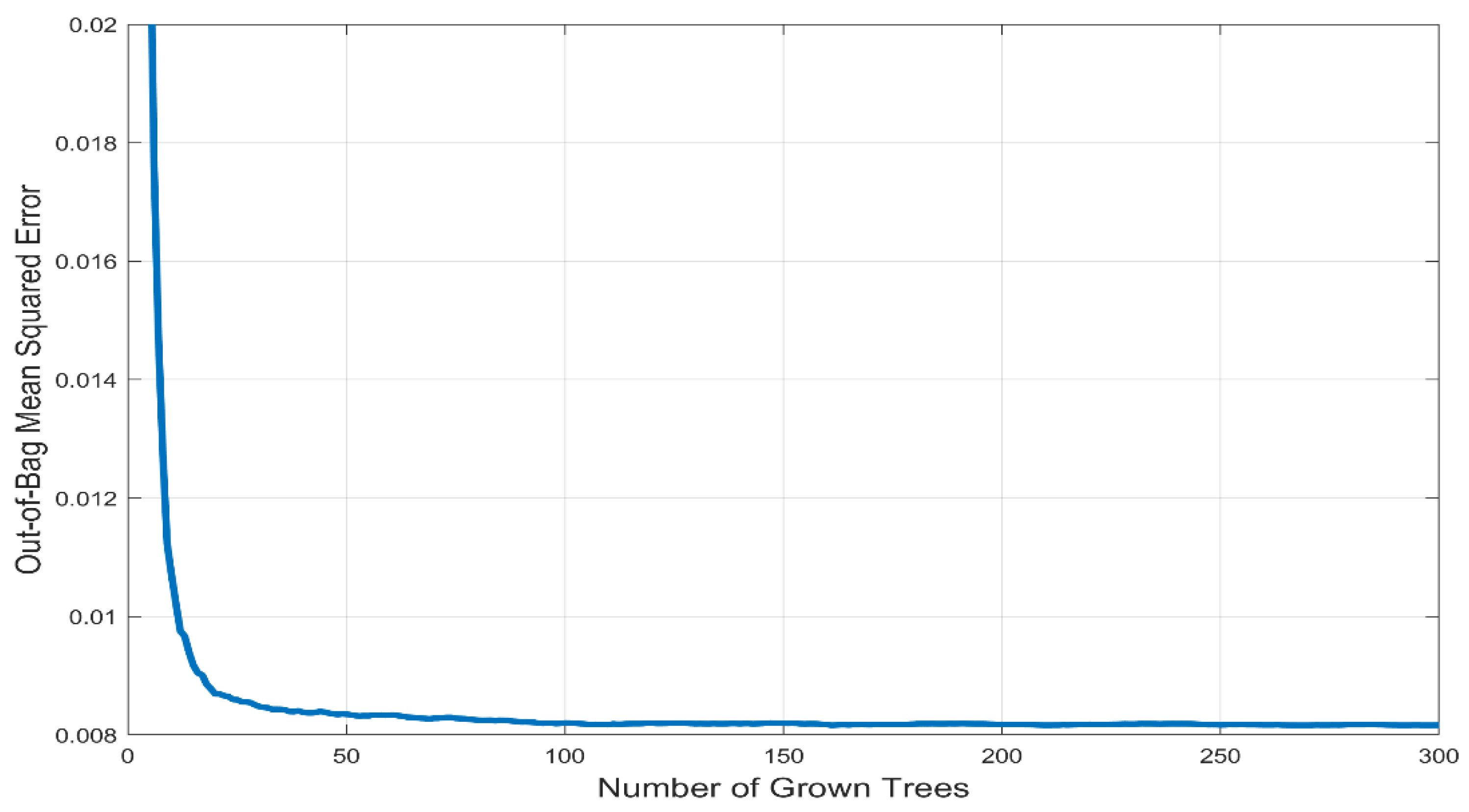

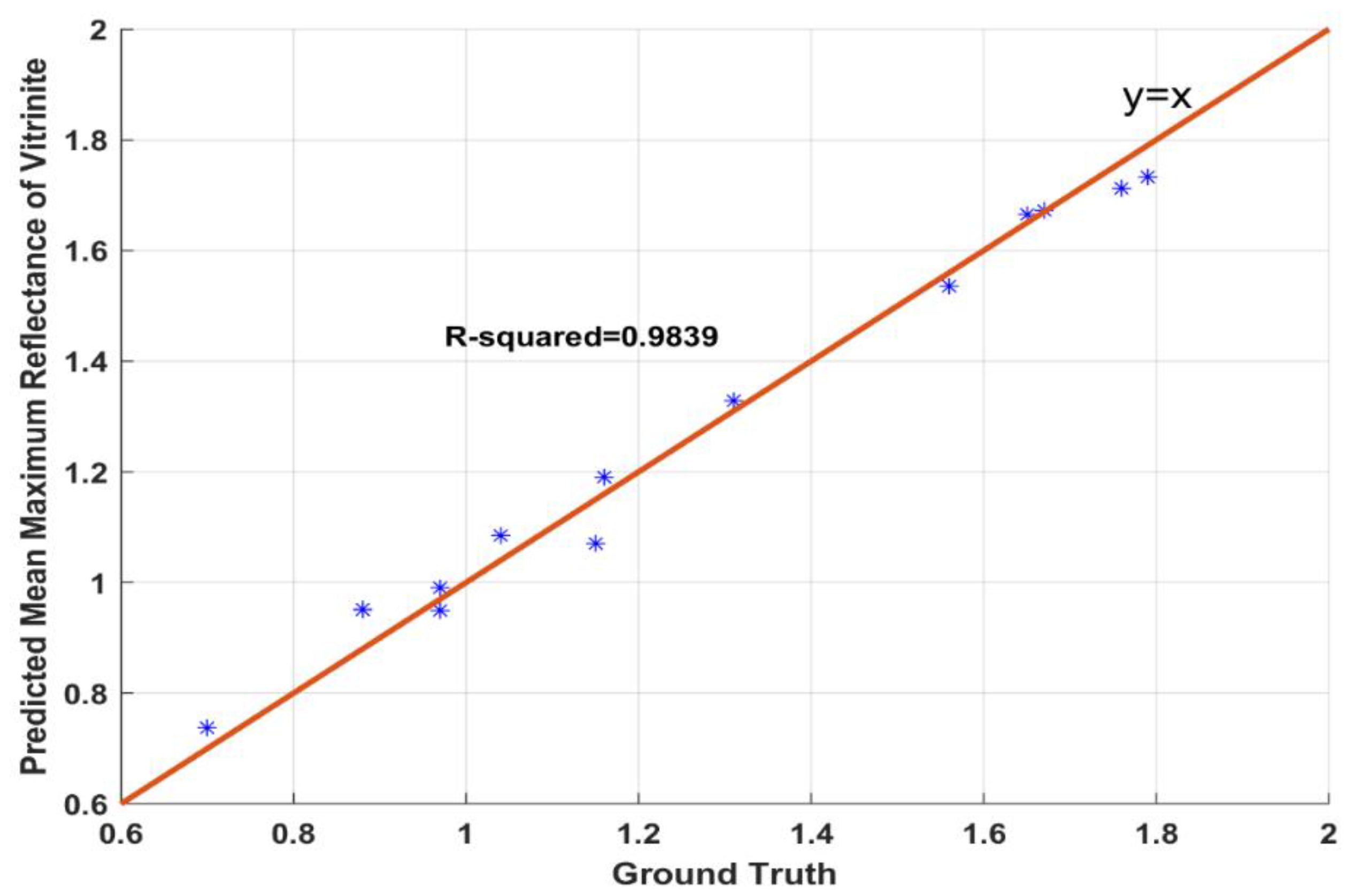

- Comprehensive and discriminative features from coal photomicrographs, including texture, grayscale, and geometric features, were employed to distinguish vitrinite from other maceral components. We evaluated four popular machine learning classifiers along with the comprehensive feature combination. The SVM with RBF kernel provides state-of-the-art performance with an average accuracy of 97.10%. In the vitrinite reflectance estimation stage, we employed 15 grayscale features to reflect the gray distribution characteristics. Finally, we evaluated seven regression methods to estimate the MMVR value, and the best regression performance was obtained by random forest (RF), with R-squared of 0.9839.

- (3)

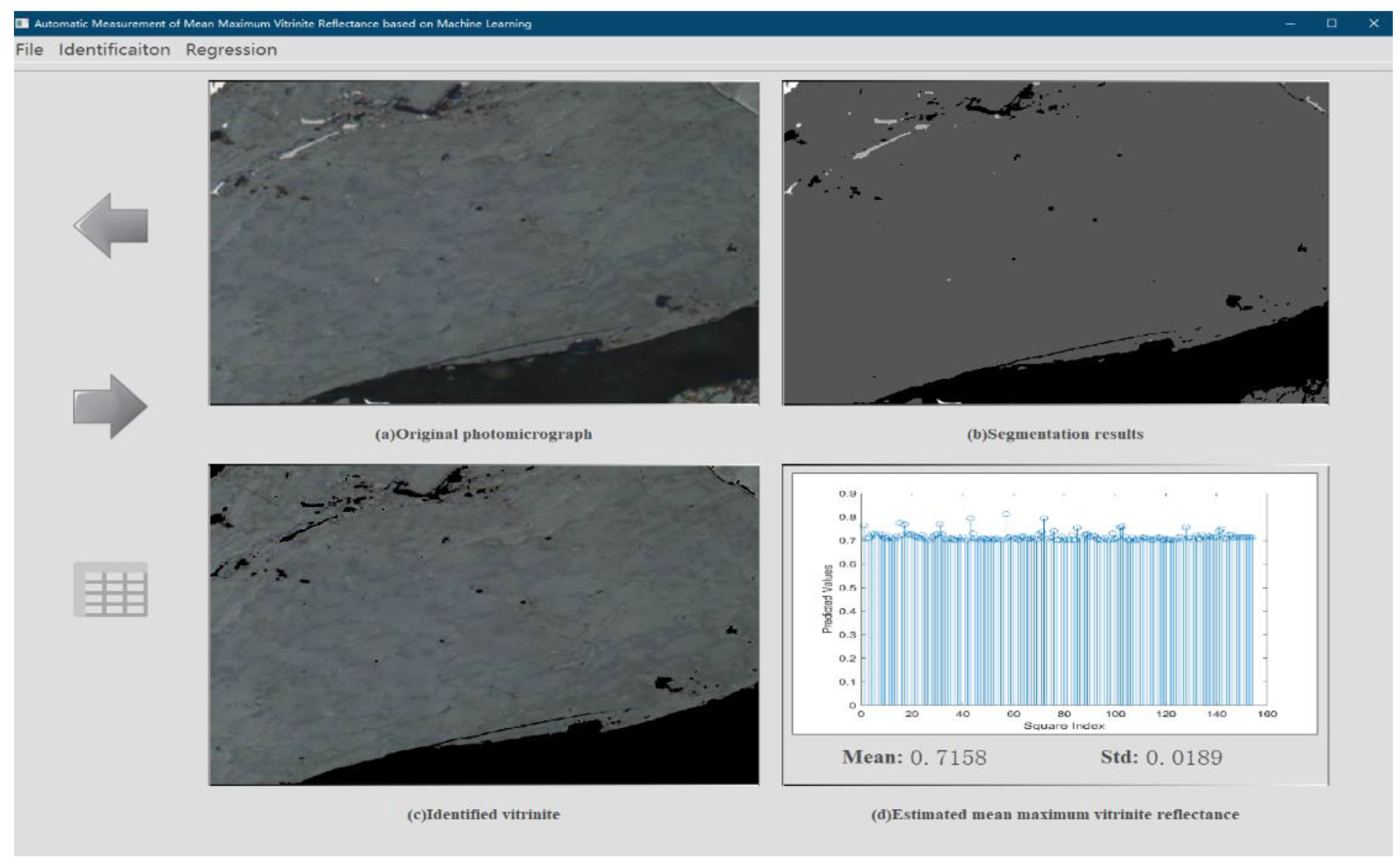

- We released a fully automatic mean maximum vitrinite reflectance estimation software, namely MMVRML, which is able to automatically estimate MMVR from photomicrographs. This tool integrates algorithms of adaptive image segmentation, vitrinite identification, and MMVR estimation. The developed software is freely available for users at the following website: https://github.com/GuyooGu/MMVRML.

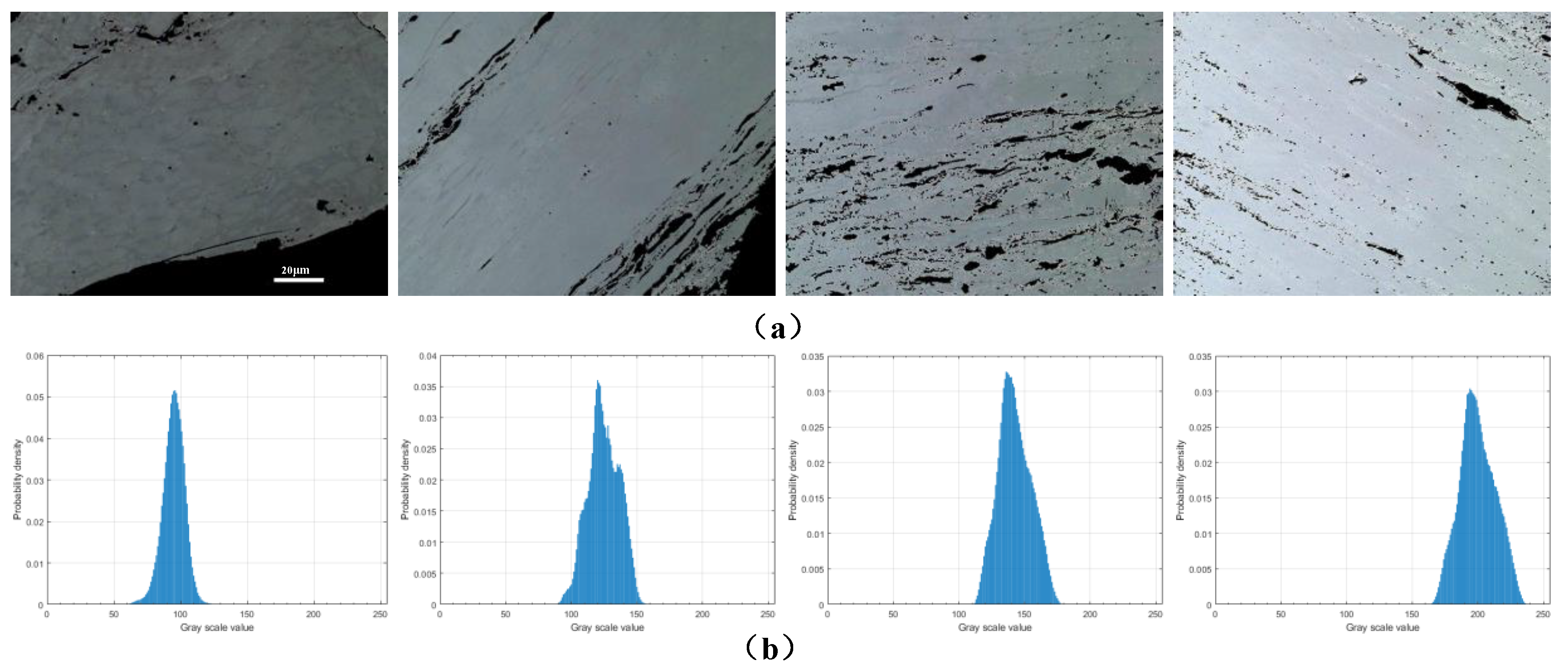

2. Materials

3. Methods

3.1. Image Segmentation Based on Adaptive K-Means Clustering

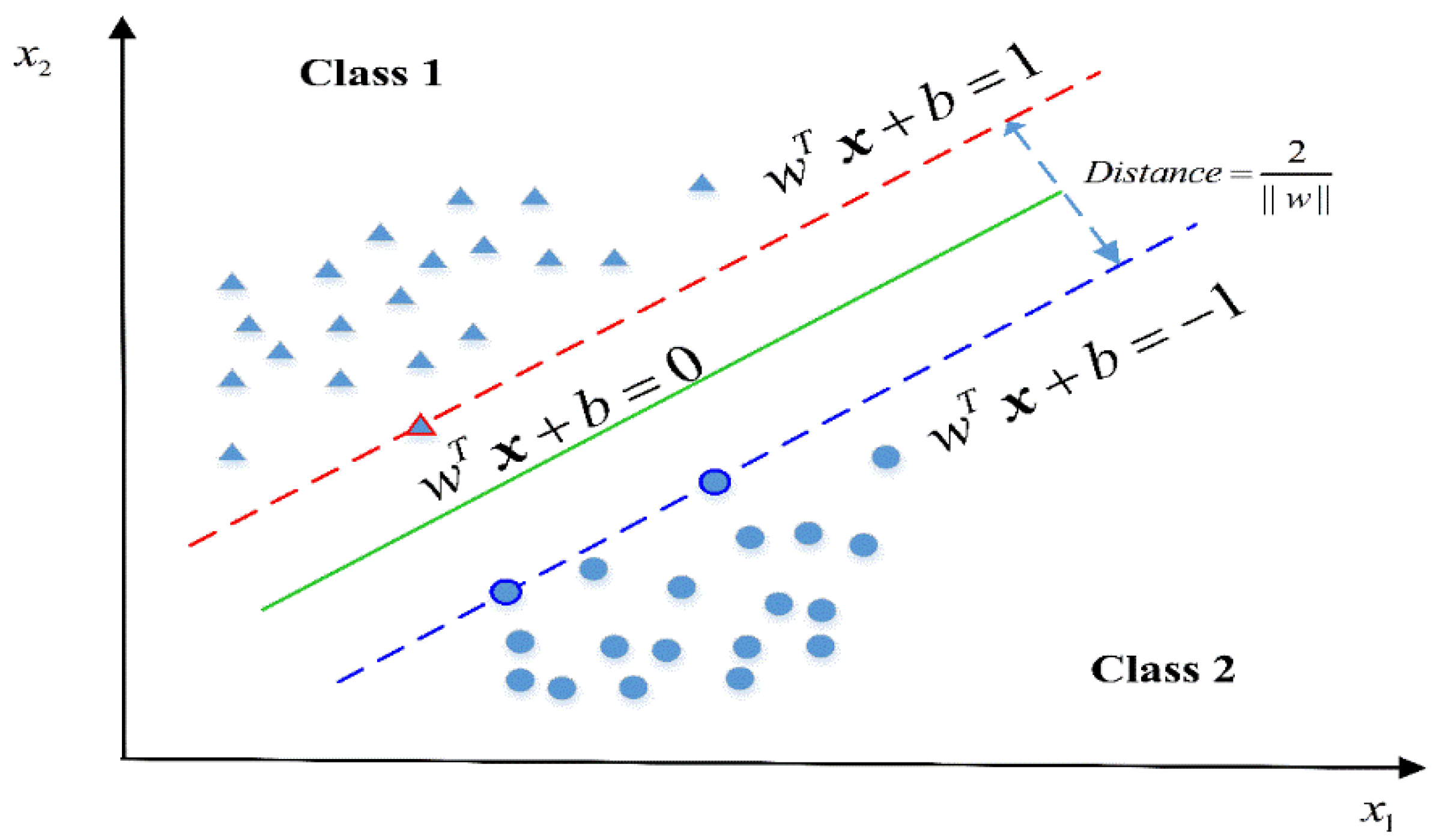

3.2. RBF SVM for Classification

| Algorithm 1. Pseudo code of the adaptive K-means clustering for image segmentation. |

| Algorithm: Image segmentation based on adaptive K-means clustering |

| Input: The photomicrograph to be clustered. |

| Output: Separated regions with different maceral components. |

| Step 1. Convert RGB (i.e., Red, Green and Blue) values of each photomicrograph into a 2-dimensional matrix, denoted as , where represents the number of pixels and each row of contains the RGB values for each pixel, . Step 2. Initialize the cluster centroid as the column-wise mean value of , denote as . Step 3. Repeat the following sub-steps until is empty or the iteration number arrives at 50: { |

| Repeat until the centroid do not change any more or the iteration number arrives at 50: { Compute the distance between each pixel and the centroid, and save the distances in vector : Compute the bandwidth of the cluster: Determine which pixels belong to this cluster, save the flag in vector : Update the centroid as: } Remove the pixels belonging to this cluster from and save the obtained centroid in matrix . } |

| Step 4. Obtain cluster centroids, denoted as . Transform cluster centroids according to the following formula, and get : Step 5. Sort the matrix and calculate the distance between two adjacent transformed centroids, discard the centroids less than a given threshold. |

| Step 6. Unmap the remaining transformed centroids in , and get the final cluster centroids. Assign each pixel to the nearest centroids. Step 7. Create a binary mask corresponding to each cluster and obtain independent regions. |

3.3. Random Forest for Regression

3.4. Feature Extraction

3.5. Evalutation Criteria

4. Experimental Results and Discussion

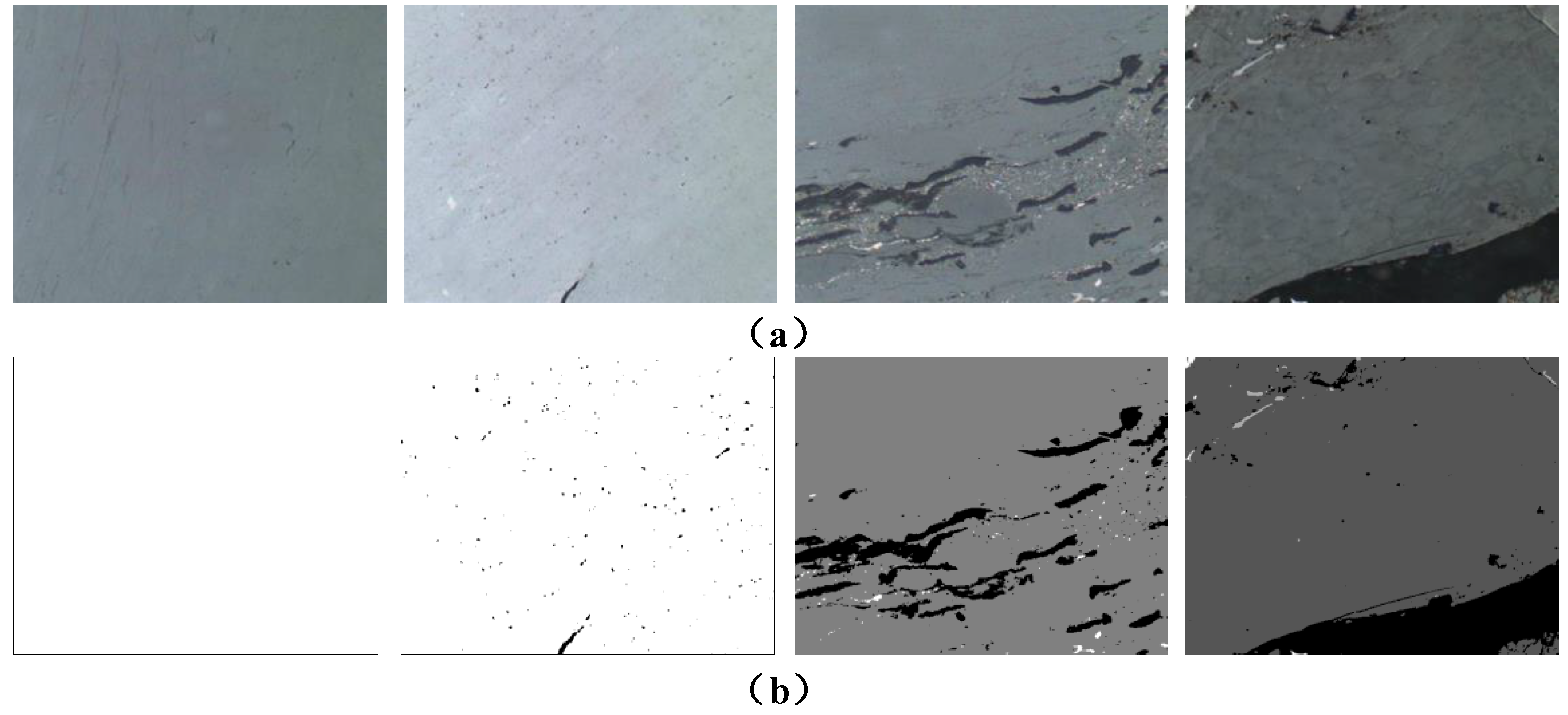

4.1. Image Segmenation Results

4.2. Vitrinite Identification Results

4.3. Vitrinite Reflectance Regression Results

4.4. The Platform of Automatic Vitrinite Reflectance Measurement

4.5. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chen, Y.; Qin, Y.; Li, Z.; Shi, Q.; Wei, C.; Wu, C.; Cao, C.; Qu, Z. Differences in desorption rate and composition of desorbed gases between undeformed and mylonitic coals in the Zhina Coalfield, Southwest China. FUEL 2019, 239, 905–916. [Google Scholar] [CrossRef]

- Mählmann, R.F.; Le Bayon, R. Vitrinite and vitrinite like solid bitumen reflectance in thermal maturity studies: Correlations from diagenesis to incipient metamorphism in different geodynamic settings. Int. J. Coal Geol. 2016, 157, 52–73. [Google Scholar] [CrossRef]

- Unsworth, J.F.; Gough, H. Characterization of coals by automated optical image analysis 2. Inertinite reflectance. J. Microsc. 1989, 156, 327–342. [Google Scholar] [CrossRef]

- Dembicki, J.H. Chapter 3—Source Rock Evaluation. In Practical Petroleum Geochemistry for Exploration and Production; Dembicki, J.H., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 61–133. [Google Scholar]

- Flores, R.M. Chapter 4—Coalification, Gasification, and Gas Storage. In Coal and Coalbed Gas; Flores, R.M., Ed.; Elsevier: Boston, MA, USA, 2014; pp. 167–233. [Google Scholar]

- Ward, C.R.; Suárez-Ruiz, I. Chapter 1—Introduction to Applied Coal Petrology. In Applied Coal Petrology; Suárez-Ruiz, I., Crelling, J.C., Eds.; Elsevier: Burlington, MA, USA, 2008; pp. 1–18. [Google Scholar]

- Chen, Y.; Qin, Y.; Wei, C.; Huang, L.; Shi, Q.; Wu, C.; Zhang, X. Porosity changes in progressively pulverized anthracite subsamples: Implications for the study of closed pore distribution in coals. FUEL 2018, 225, 612–622. [Google Scholar] [CrossRef]

- Zou, J.; Han, F.; Li, T.; Tian, H.; Li, Y. Mineralogical and Geochemical Compositions of the Lopingian Coals in the Zhongliangshan Coalfield, Southwestern China. Minerals 2018, 8, 104. [Google Scholar] [CrossRef]

- Karmakar, B.; Ghosh, T.; Ojha, K.; Pathak, A.K.; Devraju, J. Effects of chemical composition and petrography of coal for coalbed methane evaluation with special reference to in-situ gas content. In Proceedings of the 10th Biennial International Conference & Exposition, Kochi, India, 23–25 November 2013. [Google Scholar]

- International Organization for Standardization. Methods for the Petrographic Analysis of coals—Part 5: Method of Determining Microscopically the Reflectance of Vitrinite. In ISO 7404-5; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- ASTM International. Standard Test Method for Microscopical Determination of the Vitrinite Reflectance of Coal. In ASTM D2798-11a; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Fedor, F.; Hamor-Vido, M. Statistical analysis of vitrinite reflectance data—A new approach. Int. J. Coal Geol. 2003, 56, 277–294. [Google Scholar] [CrossRef]

- Van Niekerk, D.; Mitchell, G.D.; Mathews, J.P. Petrographic and reflectance analysis of solvent-swelled and solvent-extracted South African vitrinite-rich and inertinite-rich coals. Int. J. Coal Geol. 2010, 81, 45–52. [Google Scholar] [CrossRef]

- Młynarczuk, M.; Górszczyk, A.; Ślipek, B. The application of pattern recognition in the automatic classification of microscopic rock images. Comput. Geosci. 2013, 60, 126–133. [Google Scholar] [CrossRef]

- Wang, H.; Lei, M.; Chen, Y.; Li, M.; Zou, L. Intelligent Identification of Maceral Components of Coal Based on Image Segmentation and Classification. Appl. Sci. 2019, 9, 3245. [Google Scholar] [CrossRef]

- Pearson Petrography. Available online: http://www.coalpetrography.com/blog1/ (accessed on 1 August 2019).

- Coal Grain Analysis. Available online: https://www.csiro.au/en/Do-business/Commercialisation/-Marketplace/Coal-Grain-Analysis (accessed on 1 August 2019).

- England, B.M.; Mikka, R.A.; Bagnall, E.J. Petrographic characterization of coal using automatic image analysis. J. Microsc. 1979, 116, 329–336. [Google Scholar] [CrossRef]

- Fernandes, P.; Luis, J.; Rodrigues, S.; Marques, M.; Valentim, B.; Flores, D. The Measurement of Vitrinite Reflectance with MatLab; CIMP-Commission Internationale de Microflore du Paléozoique: Warsaw, Poland, 2010; pp. 11–13. [Google Scholar]

- Chen, H.; Bai, X.; Li, Z.; Zhang, Y. Working curve establishing and application of determining maceral reflectance by image analysis method. J. China Coal Soc. 2014, 39, 562–567. [Google Scholar]

- CRAIC: How to Measure Vitrinite Reflectance. Available online: http://www.microspectra.com/-support/learn/how-to-analyze-coal?tdsourcetag=s_pcqq_aiomsg (accessed on 1 August 2019).

- Lim Laboratory Imaging. Available online: http://www.limaging.cz/en/front-page/vitrinite (accessed on 1 August 2019).

- Mlynarczuk, M.; Skiba, M. The application of artificial intelligence for the identification of the maceral groups and mineral components of coal. Comput. Geosci. 2017, 103, 133–141. [Google Scholar] [CrossRef]

- Gesserman, R.M. Petrographic web atlas for metallurgical bituminous coal macerals. In Proceedings of the 2009 Portland GSA Annual Meeting, Portland, OR, USA, 18–21 October 2009. [Google Scholar]

- ASTM International. Standard practice for preparing coal samples for microscopical analysis by reflected light. In D2797/D2797M-11a; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Zhao, L.; Chen, Z.; Yang, Y.; Zou, L.; Wang, Z.J. ICFS clustering with multiple representatives for large data. IEEE T NEUR NET LEAR 2018, 30, 728–738. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Wang, H.; Huang, W.; You, Z. Plant diseased leaf segmentation and recognition by fusion of superpixel, K-means and PHOG. Optik 2018, 157, 866–872. [Google Scholar] [CrossRef]

- Bhuiyan, M.; Esmaieli, K.; Ordóñez-Calderón, J.C. Application of Data Analytics Techniques to Establish Geometallurgical Relationships to Bond Work Index at the Paracutu Mine, Minas Gerais, Brazil. Minerals 2019, 9, 302. [Google Scholar] [CrossRef]

- Zheng, B.; Myint, S.W.; Thenkabail, P.S.; Aggarwal, R.M. A support vector machine to identify irrigated crop types using time-series Landsat NDVI data. Int. J. Appl. Earth OBS 2015, 34, 103–112. [Google Scholar] [CrossRef]

- Zou, L.; Wang, M.; Shen, Y.; Liao, J.; Li, A.; Wang, M. PKIS: Computational identification of protein kinases for experimentally discovered protein phosphorylation sites. BMC Bioinform. 2013, 14, 247. [Google Scholar] [CrossRef]

- Ring, M.; Eskofier, B.M. An approximation of the Gaussian RBF kernel for efficient classification with SVMs. Pattern Recognit. Lett. 2016, 84, 107–113. [Google Scholar] [CrossRef]

- Zhou, Z.H.; Feng, J. Deep Forest: Towards An alternative to deep neural networks. In Proceedings of the Twenty-Sixth International Joint Conference on Artificial Intelligence (IJCAI-17), Melbourne, Australia, 19–25 August 2017. [Google Scholar]

- Zou, L.; Huang, Q.; Li, A.; Wang, M. A genome-wide association study of Alzheimer’s disease using random forests and enrichment analysis. Sci. China Life Sci. 2012, 55, 618–625. [Google Scholar] [CrossRef]

- Adusumilli, S.; Bhatt, D.; Wang, H.; Bhattacharya, P.; Devabhaktuni, V. A low-cost INS/GPS integration methodology based on random forest regression. Expert Syst. Appl. 2013, 40, 4653–4659. [Google Scholar] [CrossRef]

- Li, N.; Hao, H.; Gu, Q.; Wang, D.; Hu, X. A transfer learning method for automatic identification of sandstone microscopic images. Comput. Geosci. 2017, 103, 111–121. [Google Scholar] [CrossRef]

- Löfstedt, T.; Brynolfsson, P.; Asklund, T.; Nyholm, T.; Garpebring, A. Gray-level invariant Haralick texture features. PLoS ONE 2019, 14, e212110. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Yang, J.; Wang, S.; Dong, Z.; Phillips, P. Pathological brain detection in MRI scanning via Hu moment invariants and machine learning. J. Exp. Theor. Artif. Intell. 2017, 29, 299–312. [Google Scholar] [CrossRef]

- Tran, D.; Mac, H.; Tong, V.; Tran, H.A.; Nguyen, L.G. A LSTM based framework for handling multiclass imbalance in DGA botnet detection. Neurocomputing 2018, 275, 2401–2413. [Google Scholar] [CrossRef]

- Parmar, K.S.; Bhardwaj, R. Water quality management using statistical analysis and time-series prediction model. Appl. Water Sci. 2014, 4, 425–434. [Google Scholar] [CrossRef]

| Grayscale Features and Corresponding Index |

|---|

| x1–x10: the top 10 grayscale value sorting in quantity |

| x11: mean grayscale value |

| x12: maximum grayscale value |

| x13: minimum grayscale value |

| x14: median grayscale value |

| x15: mode grayscale value |

| Confusion Matrix | Predicted Label | ||

|---|---|---|---|

| True | False | ||

| True Label | True | True Positive (TP) | False Negative (FN) |

| False | False Positive (FP) | True Negative (TN) | |

| Accuracy | Precision | Recall | F1-Score | |

|---|---|---|---|---|

| KNN | 95.88% | 93.14% | 85.14% | 88.96% |

| Deep Forest | 96.10% | 91.67% | 88.00% | 89.79% |

| Random Forest | 95.59% | 92.17% | 87.43% | 89.73% |

| RBF SVM | 97.10% | 94.08% | 90.86% | 92.44% |

| Methods | MSE | RMSE | MAE | R-Squared | |

|---|---|---|---|---|---|

| Square-wise | Regression Tree | 0.0171 | 0.1308 | 0.0932 | 0.8661 |

| Gaussian Process Regression | 0.0121 | 0.1100 | 0.0828 | 0.9030 | |

| Linear Regression | 0.0140 | 0.1182 | 0.0926 | 0.8898 | |

| SVM Regression | 0.0139 | 0.1179 | 0.0944 | 0.8857 | |

| ANN Regression | 0.0183 | 0.1354 | 0.1051 | 0.8462 | |

| RBM Regression | 0.0255 | 0.1596 | 0.1213 | 0.8398 | |

| Random Forest Regression | 0.0110 | 0.1047 | 0.0760 | 0.9125 | |

| Coal Sample-wise | Regression Tree | 0.0022 | 0.0472 | 0.0398 | 0.9792 |

| Gaussian Process Regression | 0.0019 | 0.0430 | 0.0367 | 0.9832 | |

| Linear Regression | 0.0021 | 0.0463 | 0.0412 | 0.9797 | |

| SVM Regression | 0.0025 | 0.0498 | 0.0441 | 0.9765 | |

| ANN Regression | 0.0044 | 0.0662 | 0.0541 | 0.9567 | |

| RBM Regression | 0.0037 | 0.0611 | 0.0526 | 0.9709 | |

| Random Forest Regression | 0.0018 | 0.0424 | 0.0362 | 0.9839 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Lei, M.; Li, M.; Chen, Y.; Jiang, J.; Zou, L. Intelligent Estimation of Vitrinite Reflectance of Coal from Photomicrographs Based on Machine Learning. Energies 2019, 12, 3855. https://doi.org/10.3390/en12203855

Wang H, Lei M, Li M, Chen Y, Jiang J, Zou L. Intelligent Estimation of Vitrinite Reflectance of Coal from Photomicrographs Based on Machine Learning. Energies. 2019; 12(20):3855. https://doi.org/10.3390/en12203855

Chicago/Turabian StyleWang, Hongdong, Meng Lei, Ming Li, Yilin Chen, Jin Jiang, and Liang Zou. 2019. "Intelligent Estimation of Vitrinite Reflectance of Coal from Photomicrographs Based on Machine Learning" Energies 12, no. 20: 3855. https://doi.org/10.3390/en12203855

APA StyleWang, H., Lei, M., Li, M., Chen, Y., Jiang, J., & Zou, L. (2019). Intelligent Estimation of Vitrinite Reflectance of Coal from Photomicrographs Based on Machine Learning. Energies, 12(20), 3855. https://doi.org/10.3390/en12203855