Experimental Investigation on the Effects of CO2 Displacement Methods on Petrophysical Property Changes of Ultra-Low Permeability Sandstone Reservoirs Near Injection Wells

Abstract

:1. Introduction

2. Experimental Section

2.1. Experimental Materials

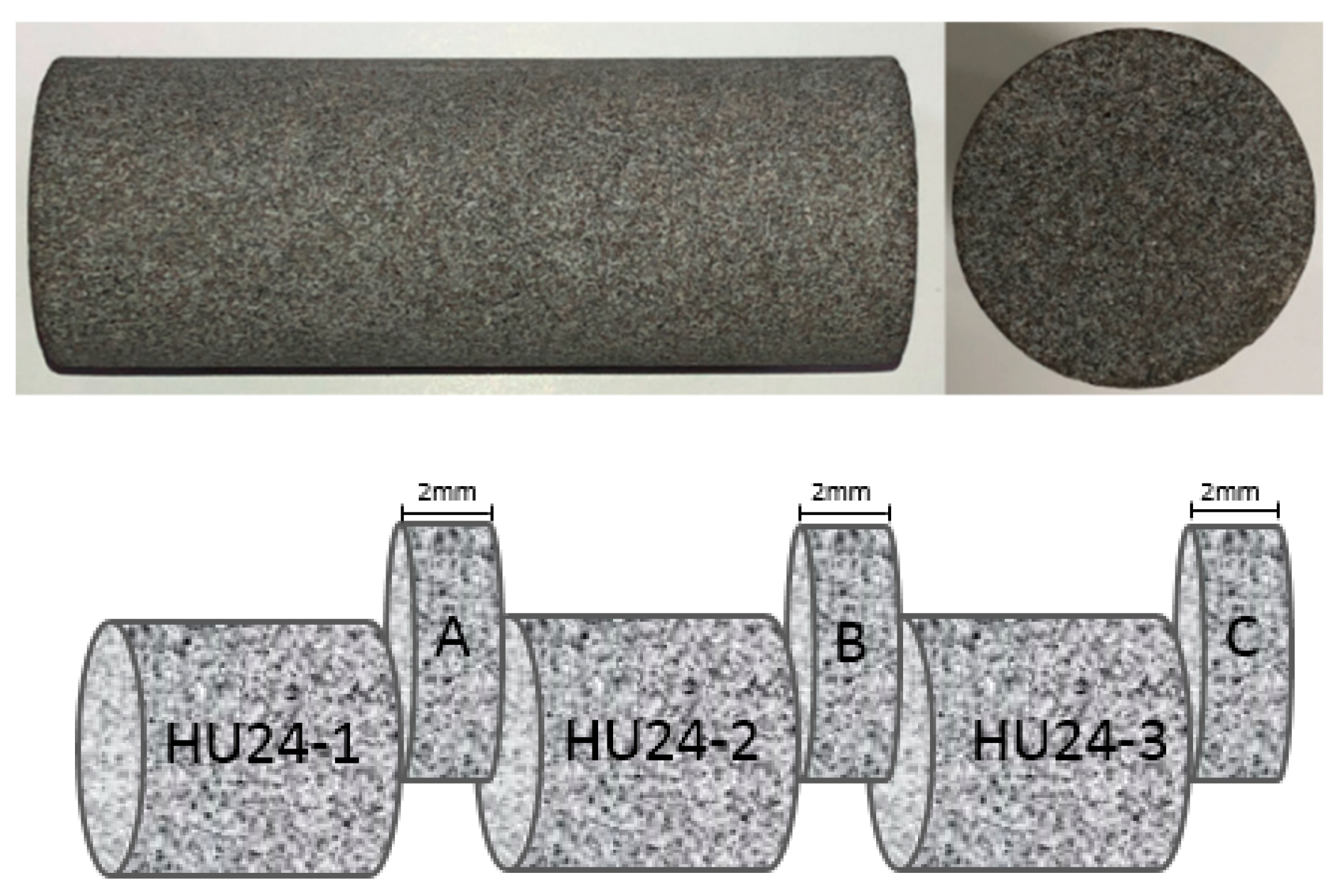

2.2. Core Segmentation and Analysis

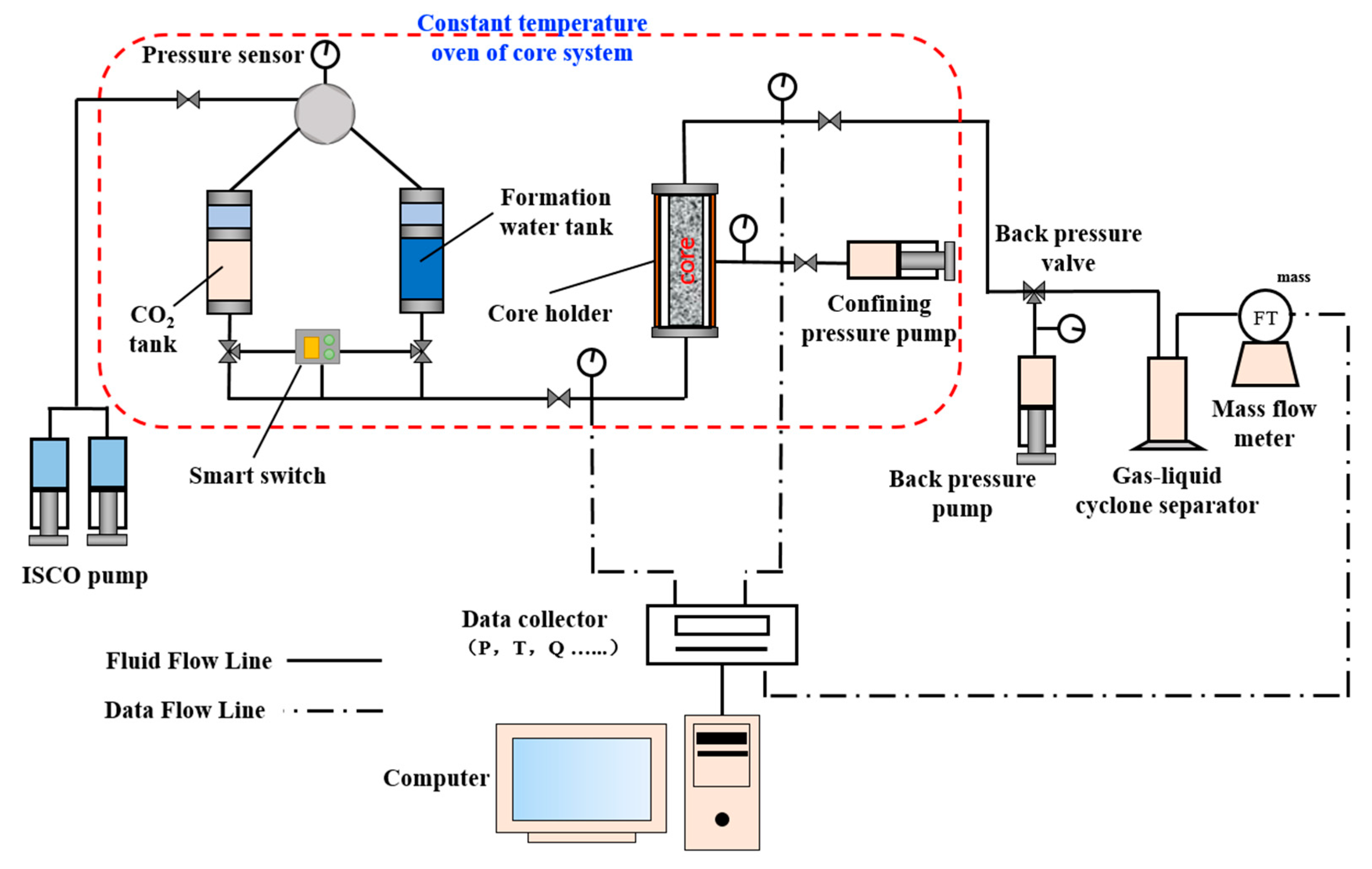

2.3. Experimental Equipment

2.4. Experimental Procedure

2.4.1. Experimental Preparation

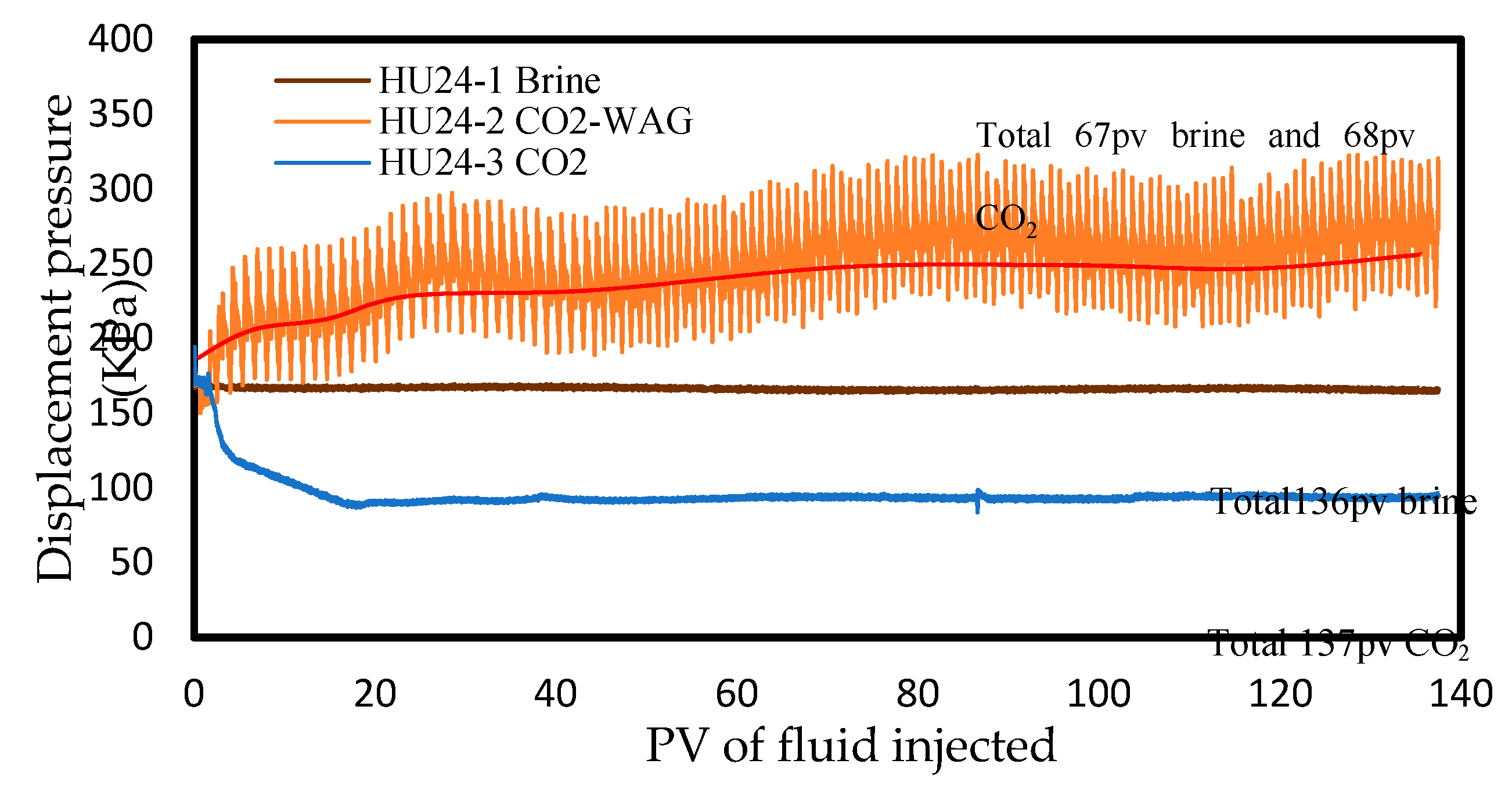

2.4.2. Core-Flooding

2.4.3. Measurements after Flooding

3. Results

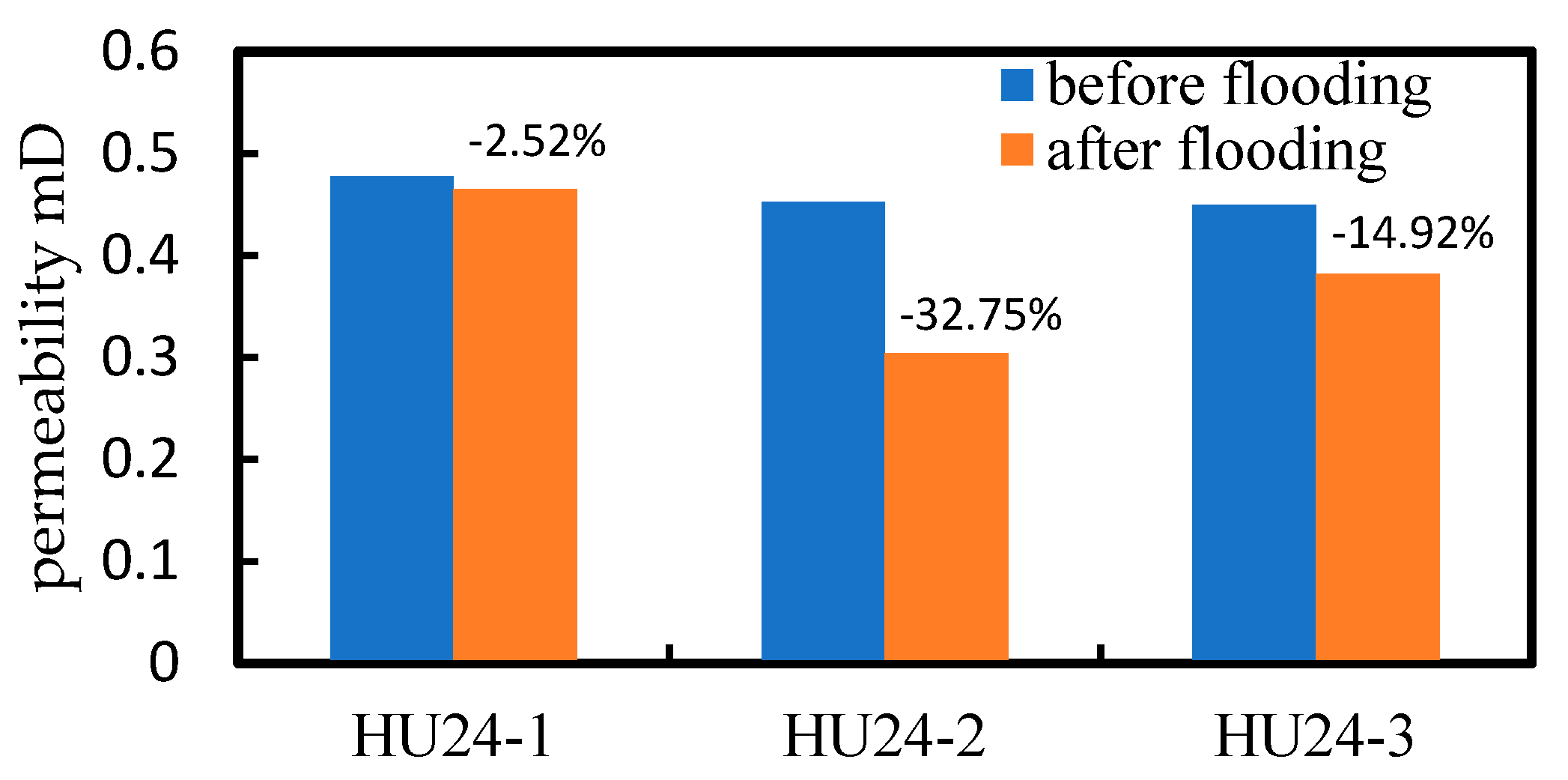

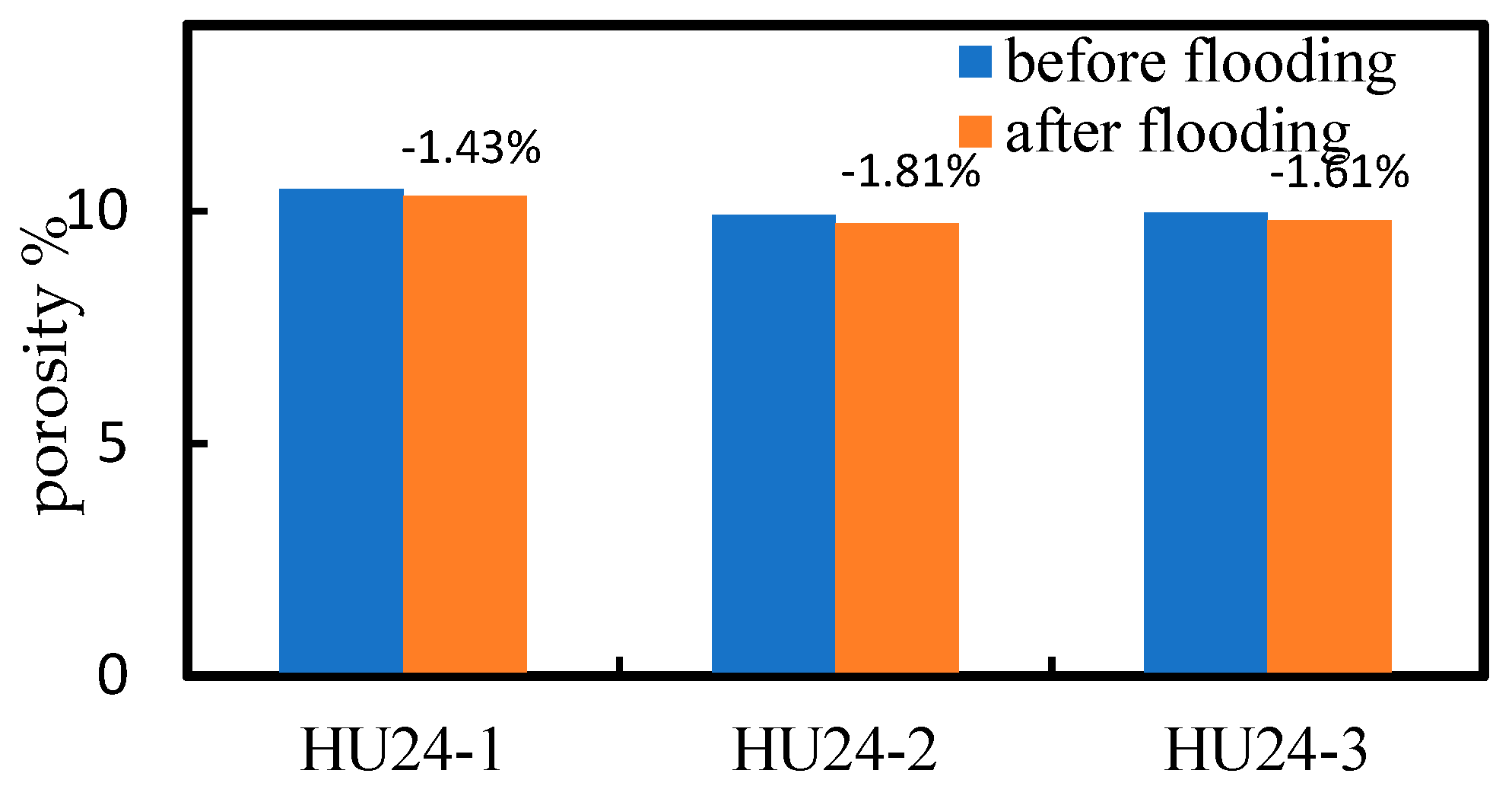

3.1. Porosity and Permeability

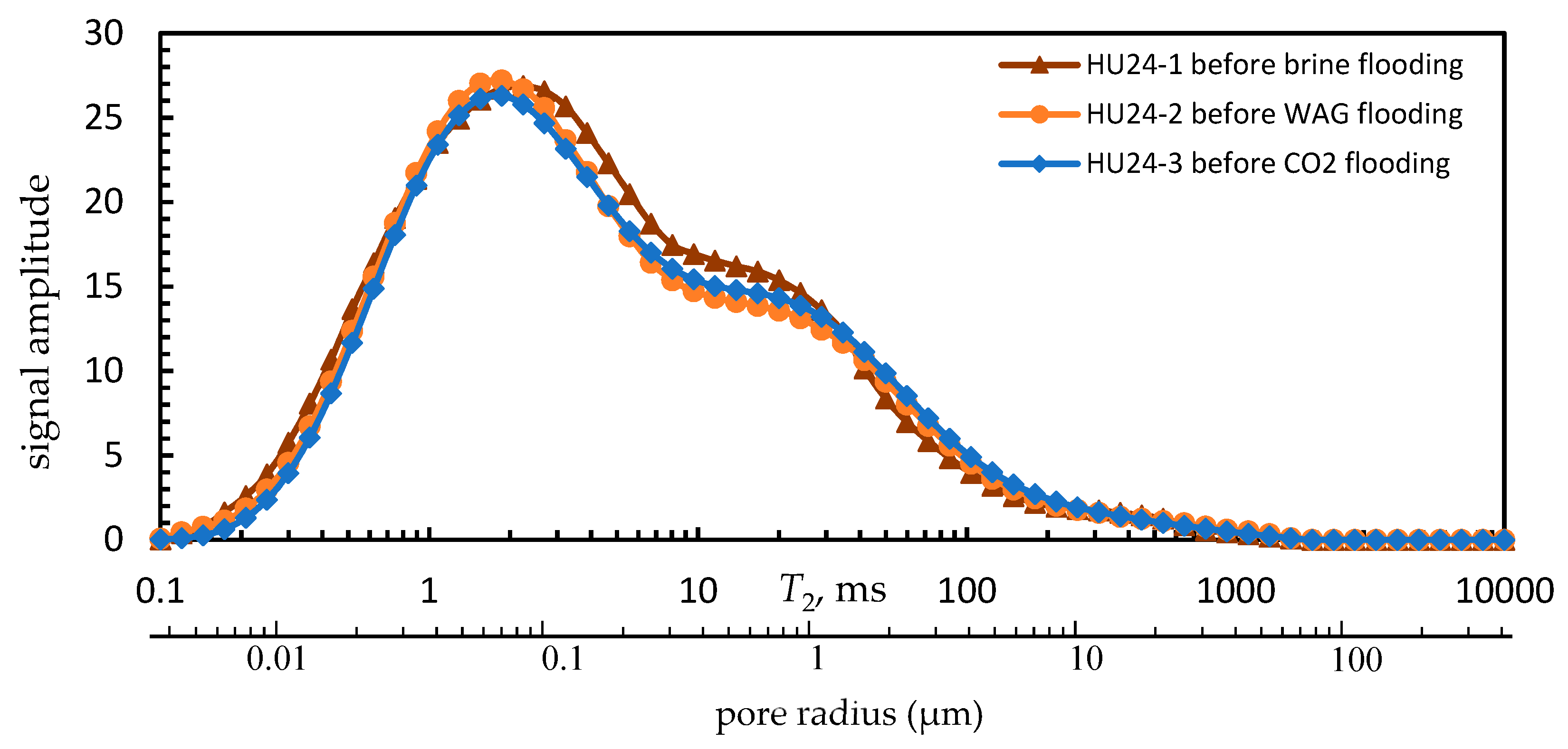

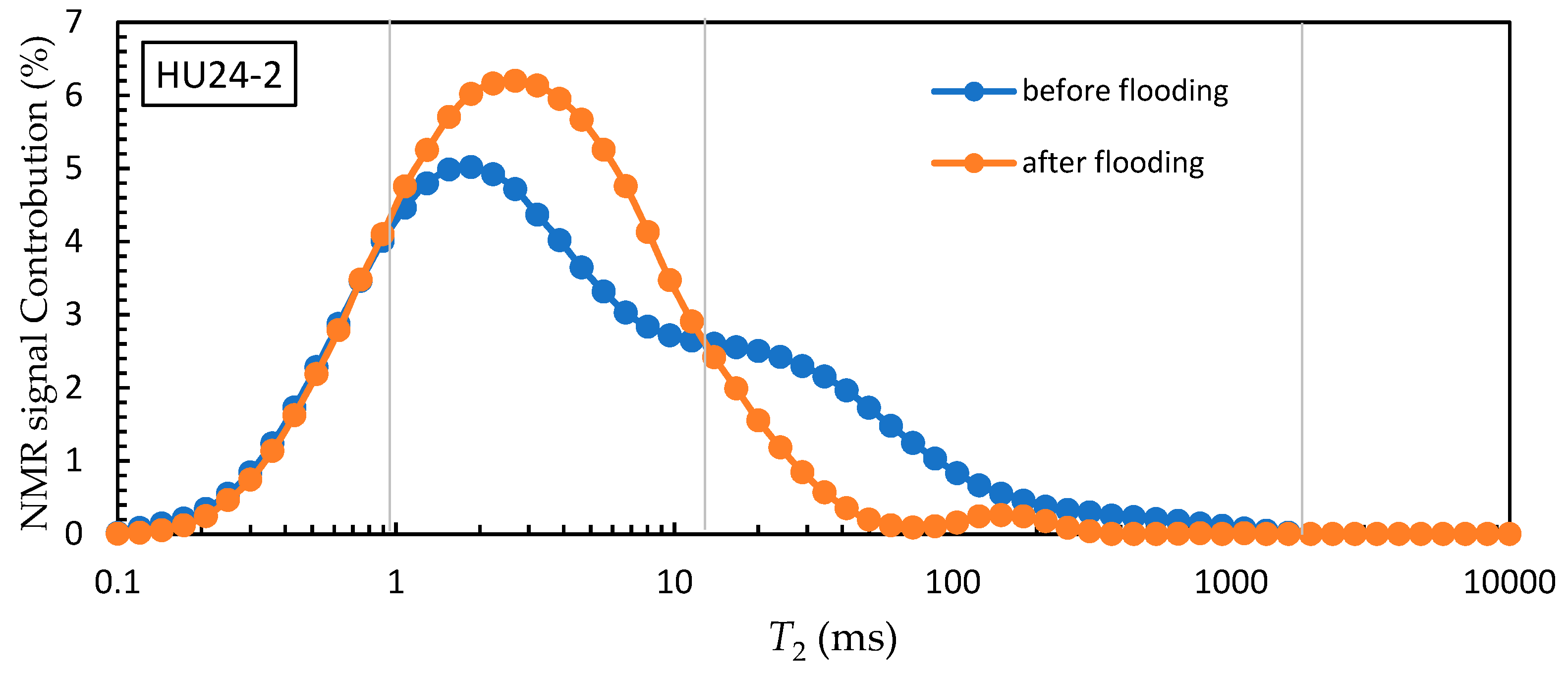

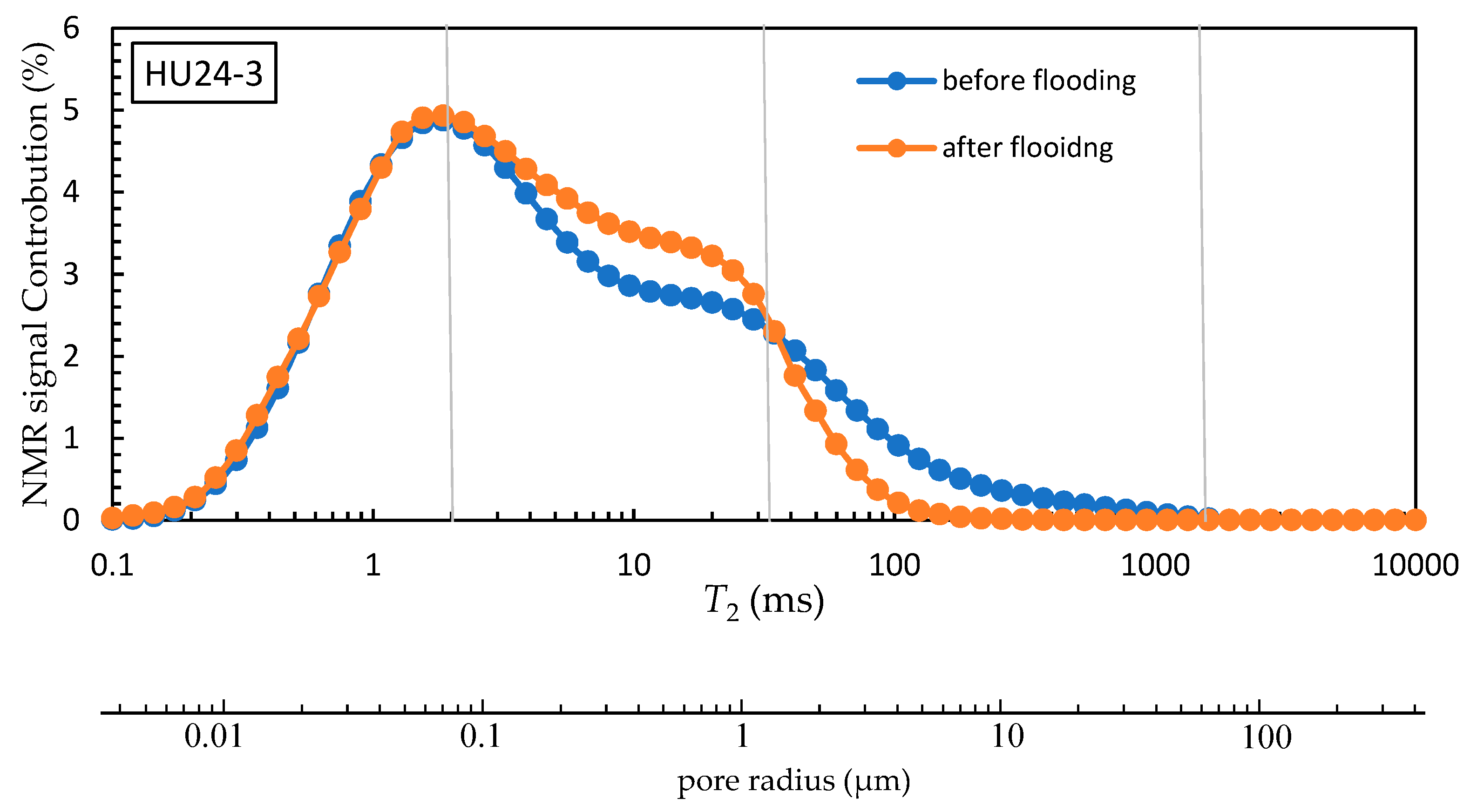

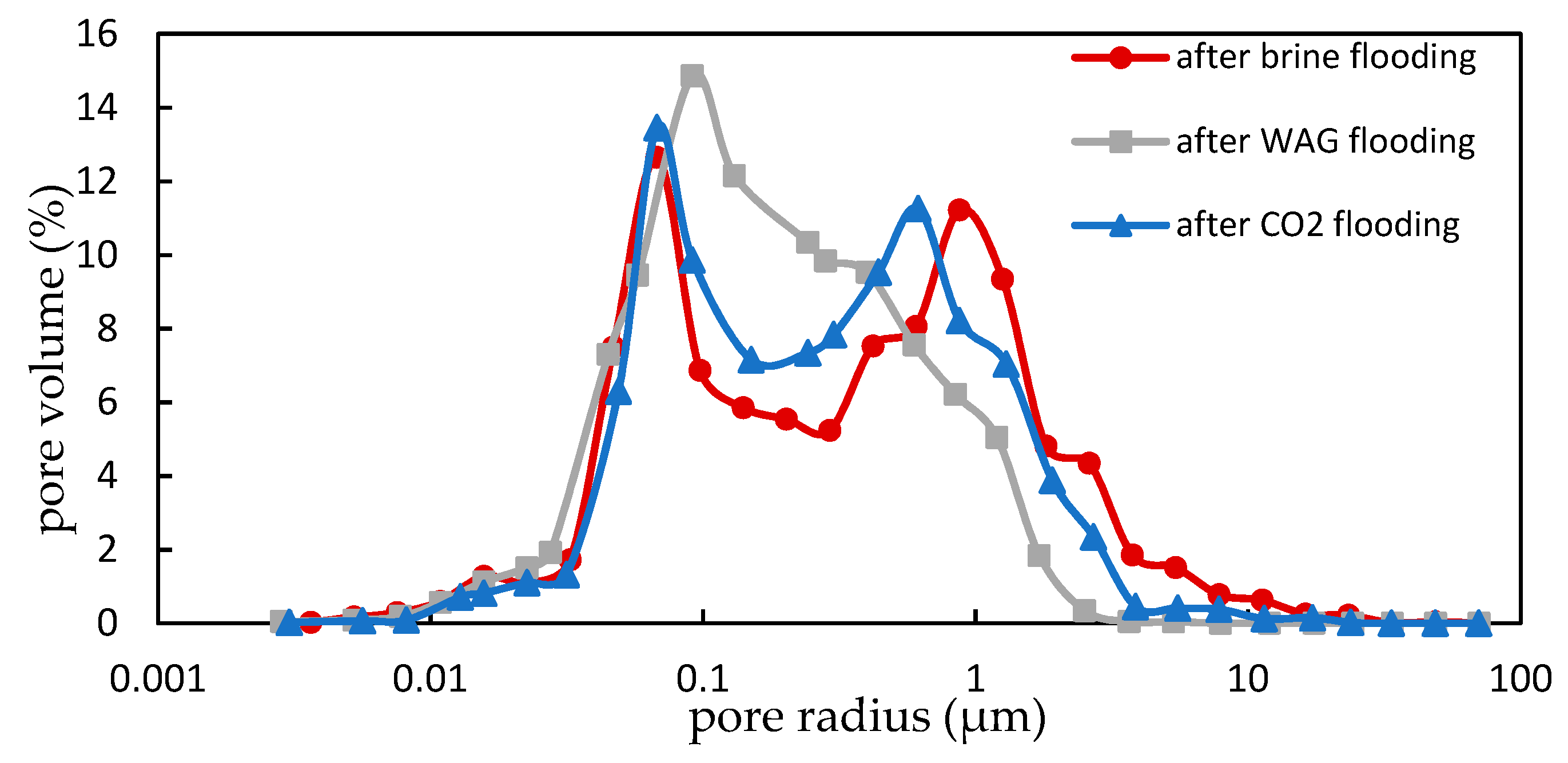

3.2. Pore Size Distribution

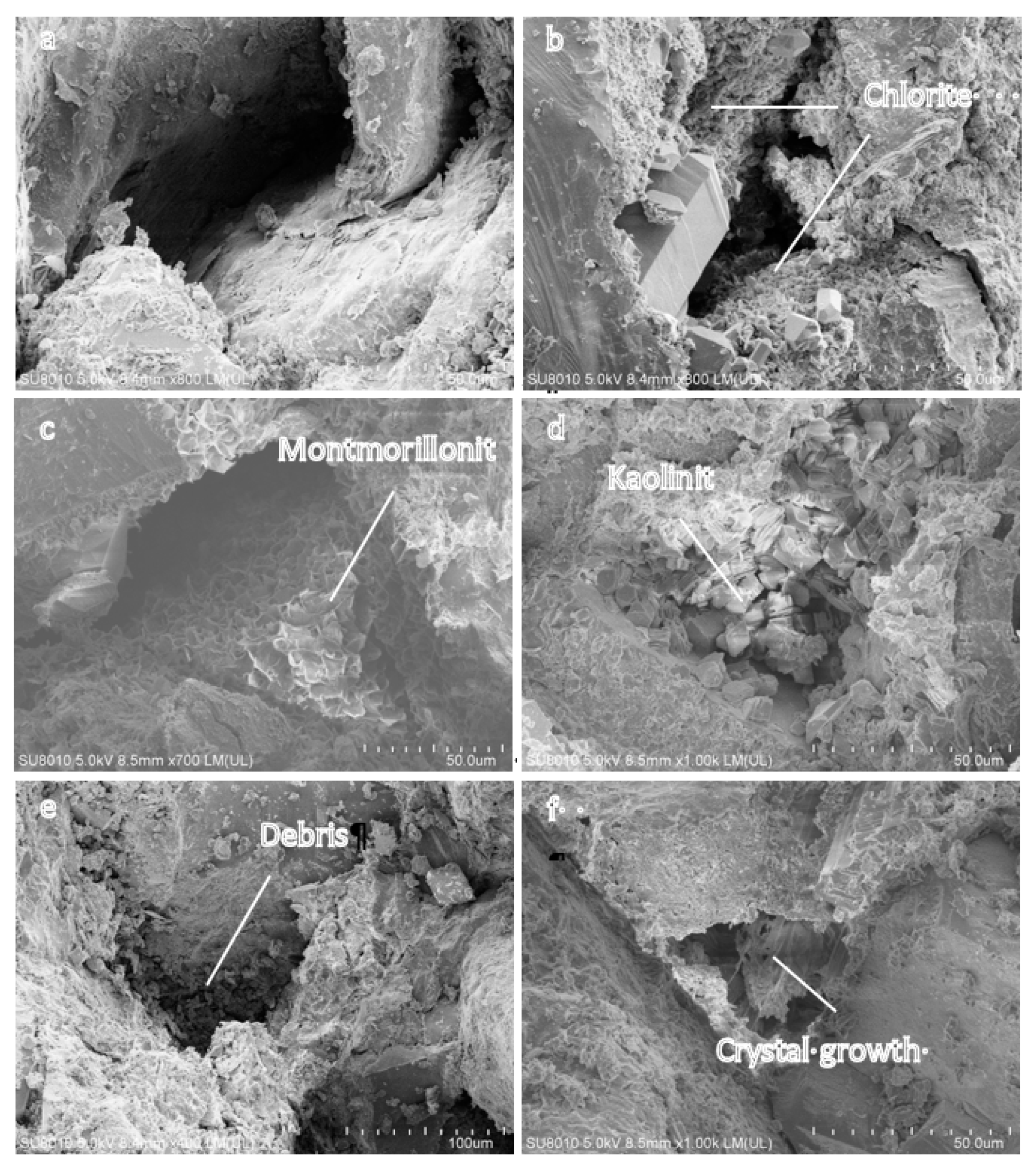

3.3. Pore Microstructure and Rock Minerals

4. Discussion

4.1. Physical Property Changes

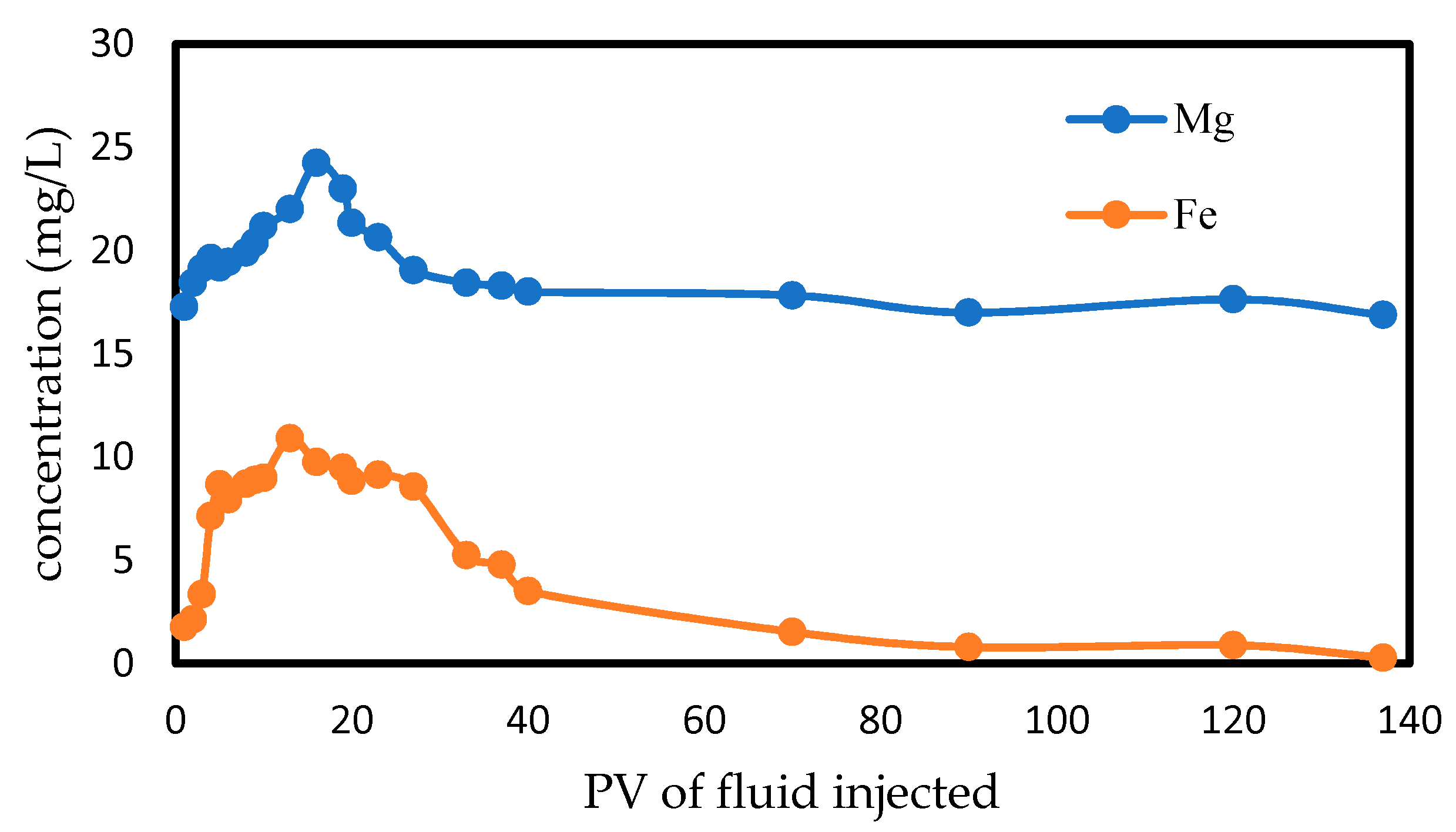

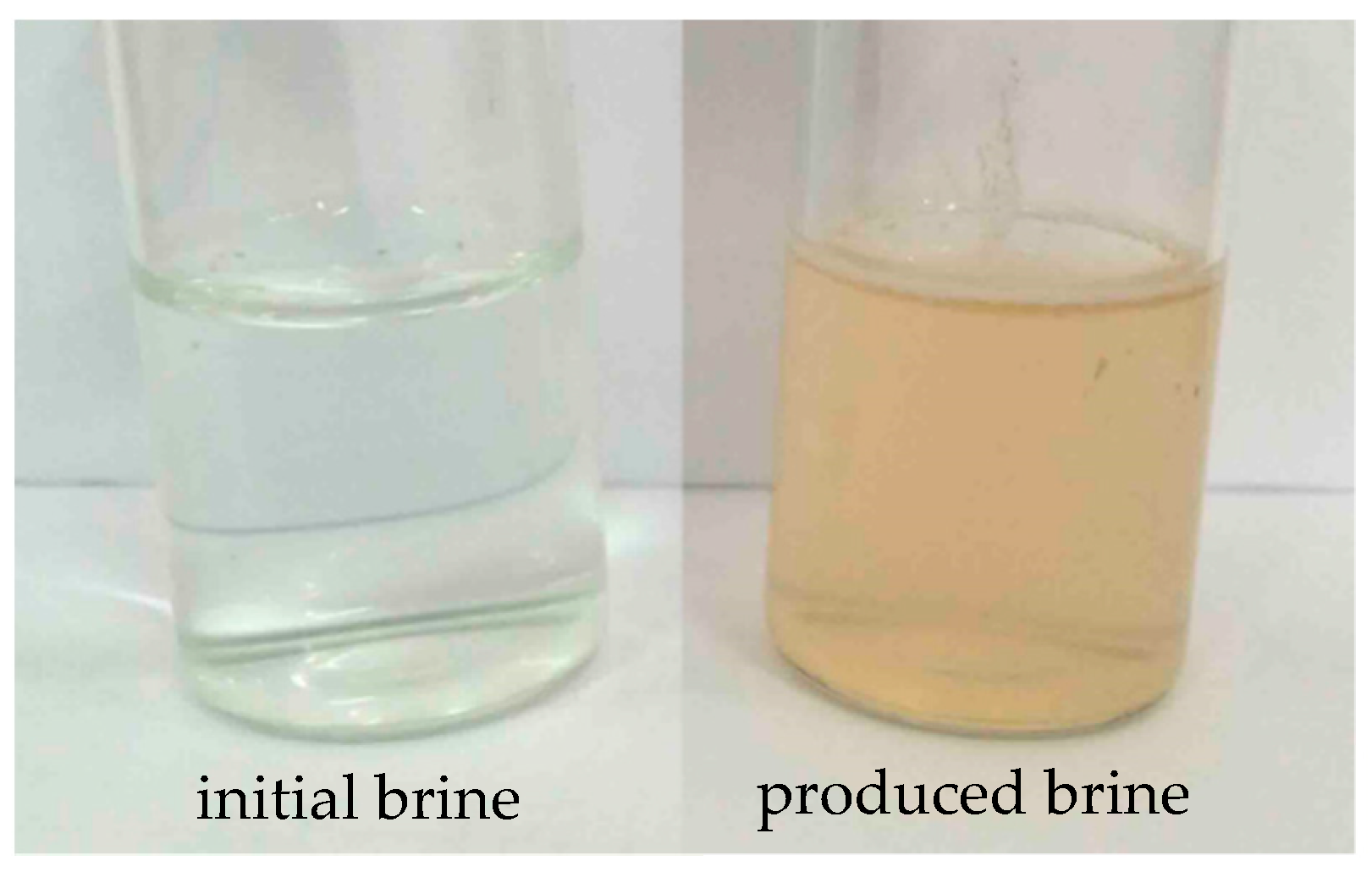

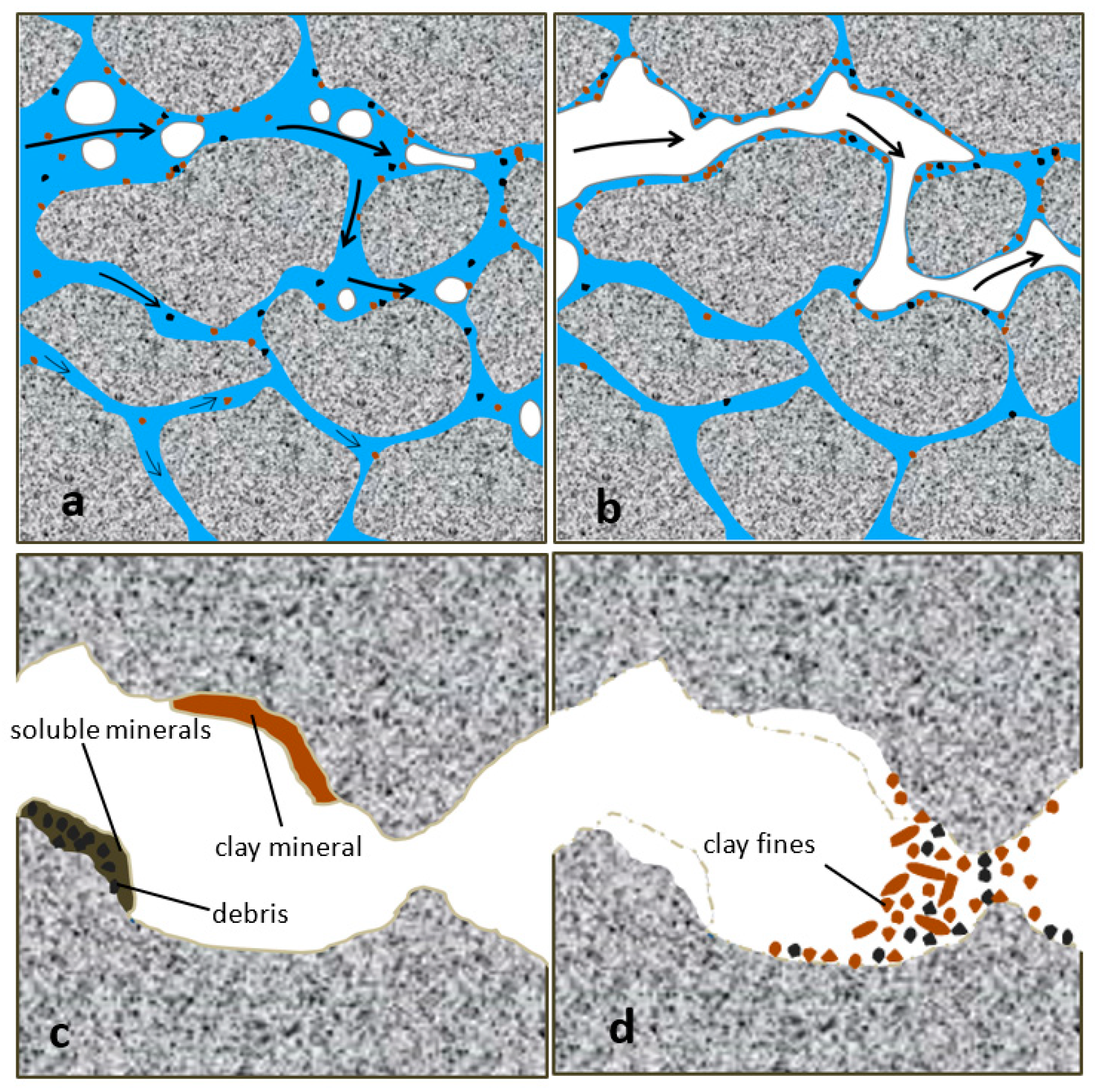

4.1.1. Permeability Decline and Fines Migration

4.1.2. CO2-Brine-Rock Interactions

4.1.3. Pore Size Transformation

4.2. Differences in Physical Property Changes

5. Conclusions

6. Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- IPCC. Climate Change 2013: The Physical Science Basis; Stocker, T., Ed.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013. [Google Scholar]

- Goodman, A.; Bromhal, G.; Strazisar, B.; Rodosta, T.; Guthrie, W.F.; Allen, D.; Guthrie, G. Comparison of methods for geologic storage of carbon dioxide in saline formations. Int. J. Greenhouse Gas Control 2013, 18, 329–342. [Google Scholar] [CrossRef]

- Lacy, R.; Serralde, C.; Climent, M.; Vaca, M. Initial assessment of the potential for future CCUS with EOR projects in Mexico using CO2 captured from fossil fuel industrial plants. Int. J. Greenhouse Gas Control 2013, 19, 212–219. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, J.T.; Jia, L.; Chen, Z.A. How to “capture the future by utilization of the past” in the coming revision of China CO2 technology roadmap. Energy Procedia 2014, 63, 6912–6916. [Google Scholar] [CrossRef]

- Zhang, L.; Ren, B.; Huang, H.; Li, Y.; Ren, S.; Chen, G.; Zhang, H. CO2 EOR and storage in Jilin oilfield China: Monitoring program and preliminary results. J. Pet. Sci. Eng. 2015, 125, 1–12. [Google Scholar] [CrossRef]

- Gong, Y.; Gu, Y. Miscible CO2 simultaneous water-and-gas (CO2-SWAG) injection in the Bakken formation. Energy Fuels 2015, 29, 5655–5665. [Google Scholar] [CrossRef]

- Lei, H.; Yang, S.; Zu, L.; Wang, Z.; Li, Y. Oil recovery performance and CO2 storage potential of CO2 water-alternating-gas injection after continuous CO2 injection in a multilayer formation. Energy Fuels 2016, 30, 8922–8931. [Google Scholar] [CrossRef]

- Zhang, L.; Soong, Y.; Dilmore, R.M. Numerical investigation of Lower Tuscaloosa Sandstone and Selma Chalk caprock under geological CO2 sequestration conditions: Mineral precipitation and permeability evolution. Greenhouse Gases: Sci. Technol. 2017, 7, 988–1007. [Google Scholar] [CrossRef]

- Zhang, L.; Dilmore, R.; Huerta, N.; Soong, Y.; Vasylkivska, V.; Namhata, A.; Li, X. Application of a new reduced-complexity assessment tool to estimate CO2 and brine leakage from reservoir and above-zone monitoring interval (AZMI) through an abandoned well under geologic carbon storage conditions. Greenhouse Gases: Sci. Technol. 2018, 8, 839–853. [Google Scholar] [CrossRef]

- Baines, S.J.; Worden, R.H. The long-term fate of CO2 in the subsurface: Natural analogues for CO2 storage. Geol. Soc. 2004, 233, 59–85. [Google Scholar] [CrossRef]

- Fischer, S.; Liebscher, A.; Wandrey, M.; the CO2 SINK Group. CO2-brine-rockinteraction-first results of long-term exposure experiments at in situ P-T conditions of the Ketzin CO2 reservoir. Chem. Erde 2010, 70, 155–164. [Google Scholar] [CrossRef]

- Gaus, I. Role and impact of CO2-rock interactions during CO2 storage in sedimentary rocks. Int. J. Greenhouse Gas Control 2010, 4, 73–89. [Google Scholar] [CrossRef]

- Hu, Y.; Jun, Y.S. Biotite dissolution in brine at varied temperatures and CO2 pressures: Its activation energy and potential CO2 intercalation. Langmuir 2012, 28, 14633–14641. [Google Scholar] [CrossRef] [PubMed]

- Rathnaweera, T.D.; Ranjith, P.G.; Perera, M.S.A.; Haque, A. Influence of CO2-brine co-injection on CO2 storage capacity enhancement in deep saline aquifers: An experimental study on Hawkesbury sandstone formation. Energy Fuels 2016, 30, 4229–4243. [Google Scholar] [CrossRef]

- Soong, Y.; Crandall, D.; Howard, B.H.; Haljasmaa, I.; Dalton, L.E.; Zhang, L.; Mclendon, T.R. Permeability and Mineral Composition Evolution of Primary Seal and Reservoir Rocks in Geologic Carbon Storage Conditions. Environ. Eng. Sci. 2018, 35, 391–400. [Google Scholar] [CrossRef]

- Doughty, C.; Pruess, K. Modeling supercritical carbon dioxide injection in heterogeneous porous media. Vadose Zone J. 2004, 3, 837–847. [Google Scholar] [CrossRef]

- Kopp, A.; Class, H.; Helmig, R. Investigations on CO2 storage capacity in saline aquifers Part 1. Dimensional analysis of flow processes and reservoir characteristics. Int. J. Greenhouse Gas Control 2009, 3, 263–276. [Google Scholar] [CrossRef]

- Yu, M.; Liu, L.; Yang, S.; Yu, Z.; Li, S. Experimental identification of CO2-oil-brine-rock interactions: Implications for CO2 sequestration after termination of a CO2-EOR project. Appl. Geochem. 2016, 75, 137–151. [Google Scholar] [CrossRef]

- Soong, Y.; Howard, B.H.; Dilmore, R.M.; Haljasmaa, I.; Crandall, D.M.; Zhang, L.; Mclendon, T.R. CO2/brine/rock interactions in Lower Tuscaloosa formation. Greenhouse Gases: Sci. Technol. 2016, 1–14. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, S.; Lei, H.; Yang, M.; Li, L.; Yang, S. Oil recovery performance and permeability reduction mechanisms in miscible CO2 water-alternative-gas (WAG) injection after continuous CO2 injection: An experimental investigation and modeling approach. J. Pet. Sci. Eng. 2017, 150, 376–385. [Google Scholar] [CrossRef]

- Assayag, N.; Matter, J.; Ader, M. Water–rock interactions during a CO2 injection field-test: Implications on host rock dissolution and alteration effects. Chem. Geol. 2009, 265, 227–235. [Google Scholar] [CrossRef]

- Yu, Z.; Liu, L.; Yang, S.; Li, S.; Yang, Y. An experimental study of CO2-brine-rock interaction at in situ pressure-temperature reservoir conditions. Chem. Geol. 2012, 326, 88–101. [Google Scholar] [CrossRef]

- Zhao, D.F.; Liao, X.W.; Yin, D.D. An experimental study for the effect of CO2-brine-rock interaction on reservoir physical properties. J. Energy Inst. 2015, 88, 27–35. [Google Scholar] [CrossRef]

- Krukowski, E.G.; Goodman, A.; Rother, G.; Ilton, E.S.; Guthrie, G.; Bodnar, R.J. FT-IR study of CO2 interaction with Na+ exchanged montmorillonite. Appl. Clay Sci. 2015, 114, 61–68. [Google Scholar] [CrossRef]

- Saeedi, A.; Delle, P.C.; Esteban, L. Flood characteristic and fluid rock interactions of a supercritical CO2, brine, rock system: South West Hub, Western Australia. Int. J. Greenhouse Gas Control 2016, 54, 309–321. [Google Scholar] [CrossRef]

- Khather, M.; Saeedi, A.; Rezaee, R. Experimental investigation of changes in petrophysical properties during CO2 injection into dolomite-rich rocks. Int. J. Greenhouse Gas Control 2017, 59, 74–90. [Google Scholar] [CrossRef]

- Zou, Y.; Li, S.; Ma, X. Effects of CO2-brine-rock interaction on porosity/permeability and mechanical properties during supercritical-CO2 fracturing in shale reservoirs. J. Nat. Gas Sci. Eng. 2018, 49, 157–168. [Google Scholar] [CrossRef]

- Sanguinito, S.; Goodman, A.; Tkach, M.; Kutchko, B.; Culp, J.; Natesakhawat, S.; Crandall, D. Quantifying dry supercritical CO2-induced changes of the Utica Shale. Fuel 2018, 226, 54–64. [Google Scholar] [CrossRef]

- Yang, P.; Guo, H.; Yang, D. Determination of residual oil distribution during waterflooding in tight oil formations with NMR relaxometry measurements. Energy Fuels 2013, 27, 5750–5756. [Google Scholar] [CrossRef]

- Fang, T.; Zhang, L.; Liu, N. Quantitative characterization of pore structure of the Carboniferous-Permian tight sandstone gas reservoirs in eastern Linqing depression by using NMR technique. Pet. Res. 2018, 3, 110–123. [Google Scholar] [CrossRef]

- Chen, S.; Li, H.; Yang, D. Optimal parametric design for water-alternating-gas (WAG) process in a CO2-miscible flooding reservoir. J. Can. Pet. Technol. 2010, 49, 75–82. [Google Scholar] [CrossRef]

- Han, L.; Gu, Y. Optimization of miscible CO2 water-alternating-gas injection in the Bakken formation. Energy Fuels 2014, 28, 6811–6819. [Google Scholar] [CrossRef]

- Le van, S.; Chon, B.H. Effects of salinity and slug size in miscible CO2 water-alternating-gas core flooding experiments. J. Ind. Eng. Chem. 2017, 52, 99–107. [Google Scholar] [CrossRef]

- Huang, H.; Sun, W.; Ji, W.; Zhang, R.; Du, K.; Zhang, S. Effects of pore-throat structure on gas permeability in the tight sandstone reservoirs of the Upper Triassic Yanchang formation in the Western Ordos Basin, China. J. Pet. Sci. Eng. 2018, 162, 602–616. [Google Scholar] [CrossRef]

- Ross, G.D.; Todd, A.C.; Tweedie, J.A.; Will, A.G.S. The dissolution effects of CO2-brine systems on the permeability of U.K. and North Sea Calcareous Sandstones. In Proceedings of the 3rd Joint SPE/DOE Symposium, Tulsa, OK, USA, 4–7 April 1982; pp. 149–162. [Google Scholar]

- Sayegh, S.G.; Krause, F.F.; Girard, M.; DeBree, C. Rock/fluid interactions of carbonated brines in a sandstone reservoir: Pembina Cardium, Alberta, Canada. SPE Formation Eval. 1990, 5, 399–405. [Google Scholar] [CrossRef]

- Shiraki, R.; Dunn, T.L. Experimental study on water–rock interactions during CO2 flooding in the Tensleep Formation, Wyoming, USA. Appl. Geochem. 2000, 15, 265–279. [Google Scholar] [CrossRef]

- Fogden, A.; Kumar, M.; Morrow, N.R.; Buckley, J.S. Mobilization of fine particles during flooding of sandstones and possible relations to enhanced oil recovery. Energy Fuels 2011, 25, 1605–1616. [Google Scholar] [CrossRef]

- Luquot, L.; Andreani, M.; Gouze, P.; Camps, P. CO2 percolation experiment through chlorite/zeolite-rich sandstone (Pretty Hill Formation-Otway Basin-Australia). Chem. Geol. 2012, 294, 75–88. [Google Scholar] [CrossRef]

- Pudlo, D.; Henkel, S.; Reitenbach, V. The chemical dissolution and physical migration of minerals induced during CO2 laboratory experiments: Their relevance for reservoir quality. Environ. Earth Sci. 2015, 73, 7029–7042. [Google Scholar] [CrossRef]

- Lemon, P.E.; Zeinijahromi, A.; Bedrikovetsky, P.G.; Shahin, I. Effects of injected water chemistry on waterflood sweep efficiency via induced fines migration. In Proceedings of the SPE International Symposium on Oilfield Chemistry, the Woodlands, TX, USA, 11–13 April 2011. [Google Scholar]

- Wilson, M.J.; Wilson, L.; Patey, I. The influence of individual clay minerals on formation damage of reservoir sandstones: a critical review with some new insights. Clay Miner. 2014, 49, 147–164. [Google Scholar] [CrossRef]

- Pearce, J.M.; Holloway, S.; Wacker, H.; Nelis, M.K.; Rochelle, C. Natural occurrences as analogues for the geological disposal of carbon dioxide. Energy Convers. Manag. 1996, 37, 1123–1128. [Google Scholar] [CrossRef]

- Al-Yaseri, A.; Zhang, Y.; Ghasemiziarani, M.; Sarmadivaleh, M.; Lebedev, M.; Roshan, H.; Iglauer, S. Permeability evolution in sandstone due to CO2 injection. Energy Fuels 2017, 31, 12390–12398. [Google Scholar] [CrossRef]

- Xie, Q.; Saeedi, A.; Delle, P.C. Fines migration during CO2 injection: Experimental results interpreted using surface forces. Int. J. Greenhouse Gas Control 2017, 65, 32–39. [Google Scholar] [CrossRef]

- Feng, Q.; Di, L.; Tang, G. A visual micro-model study: The mechanism of water alternative gas displacement in porous media. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 17–21 April 2004. [Google Scholar]

- Yamamoto, J.; Satoh, T.; Ishii, H. An Analysis of CO2-WAG Core flood by Use of X-ray CT. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Kuala Lumpur, Malaysia, 14–16 April 1997. [Google Scholar]

- Seyyedi, M.; Mehran, S. Assessing the feasibility of improving the performance of CO2 and CO2-WAG injection scenarios by CWI. Ind. Eng. Chem. Res. 2018, 34, 11617–11624. [Google Scholar] [CrossRef]

- Sohrabi, M.T.D.H.; Tehrani, D.H.; Danesh, A. Visualization of oil recovery by water-alternating-gas injection using high-pressure micromodels. SPE J. 2004, 9, 290–301. [Google Scholar] [CrossRef]

- Li, Z.; Gu, Y. Optimum timing for miscible CO2-EOR after waterflooding in a tight sandstone formation. Energy Fuels 2014, 28, 488–499. [Google Scholar] [CrossRef]

| Reservoir Parameter | Value |

|---|---|

| Depth (m) | 2137.6 |

| Reservoir thickness (m) | 10–20 |

| Average porosity (%) | 9.4 |

| Average permeability (mD) | 0.45 |

| Pore pressure (MPa) | 18.1 |

| Overburden pressure (MPa) | 48.3 |

| Reservoir temperature (°C) | 78.2 |

| Formation water salinity (ppm) | 51,200 |

| Items | Value |

|---|---|

| Density (g/cm3) | 1.04 |

| pH | 7.03 |

| K+ (mg/L) | 509.8 |

| Na+ (mg/L) | 7250 |

| Ca2+ (mg/L) | 11,400 |

| Mg2+ (mg/L) | 15.2 |

| Cl− (mg/L) | 31,900 |

| SO42−(mg/L) | 122 |

| Core No. | Length (cm) | Diameter (cm) | Permeability (mD) | Porosity (%) |

|---|---|---|---|---|

| HU24 | 7.56 | 2.52 | 0.463 | 10.13 |

| HU24-1 | 2.13 | 2.52 | 0.477 | 10.47 |

| HU24-2 | 2.19 | 2.52 | 0.452 | 9.91 |

| HU24-3 | 2.17 | 2.52 | 0.449 | 9.96 |

| Core No. | Mineral Types and Content (wt.%) | ||||||

|---|---|---|---|---|---|---|---|

| Quartz | K-Feldspar | Plagioclase | Calcite | Dolomite | Clay Minerals | Others | |

| HU24-1 | 39.9 | 13.1 | 37.8 | 3.5 | 0.9 | 3.9 | 0.9 |

| HU24-2 | 40.2 | 12.8 | 36.6 | 4.3 | 1.1 | 4.3 | 0.7 |

| HU24-3 | 39.6 | 11.2 | 39.2 | 4.1 | 1.2 | 4.2 | 0.5 |

| Core No. | Displacement Method | Kb | Ka | Variation (%) | Φb | Φa | Variation (%) |

|---|---|---|---|---|---|---|---|

| (Kb−Ka)/Kb | (Φb−Φa)/Φb | ||||||

| HU24-1 | brine | 0.477 | 0.465 | −2.52 | 10.47 | 10.32 | −1.43 |

| HU24-2 | CO2-WAG | 0.452 | 0.304 | −32.75 | 9.91 | 9.73 | −1.81 |

| HU24-3 | CO2 | 0.449 | 0.382 | −14.92 | 9.96 | 9.80 | −1.61 |

| Core No. | Before Flooding | After Flooding | ||||

|---|---|---|---|---|---|---|

| Φb | Vp | Sw | Φa | Vp | Sw | |

| HU24-1 | 10.47 | 1.11 | 99.2 | 10.32 | 1.10 | 98.3 |

| HU24-2 | 9.91 | 1.08 | 98.1 | 9.73 | 1.06 | 97.7 |

| HU24-3 | 9.96 | 1.08 | 98.6 | 9.80 | 1.06 | 97.5 |

| Core No. | Displacement Method | Variation Range of Pore Size Distribution, μm | ||

|---|---|---|---|---|

| Unchanged | Increase | Decrease | ||

| HU24-2 | CO2-WAG | r < 0.036 | 0.036 < r <0.51 | r > 0.51 |

| HU24-3 | CO2 | r < 0.12 | 0.12 < r < 1.26 | r > 1.26 |

| Core No. | Mineral Types and Content (wt.%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Quartz | K-Feldspar | Plagioclase | Calcite | Dolomite | Clay Minerals | Others | ||

| HU24-1 | b.f. | 39.9 | 13.1 | 37.8 | 3.5 | 0.9 | 3.9 | 0.9 |

| a.f. | 39.5 | 13.3 | 37.6 | 3.7 | 0.9 | 4.0 | 1.0 | |

| HU24-2 | b.f. | 40.2 | 12.8 | 36.6 | 4.3 | 1.1 | 4.3 | 0.7 |

| a.f. | 42.4 | 10.6 | 36.2 | 1.8 | 0.7 | 7.4 | 0.9 | |

| HU24-3 | b.f. | 39.6 | 11.2 | 39.2 | 4.1 | 1.2 | 4.2 | 0.5 |

| a.f. | 41.9 | 10.2 | 38.8 | 2.5 | 0.9 | 5.1 | 0.6 | |

| Core No. | Mineral Types and Content (wt.%) | ||||

|---|---|---|---|---|---|

| K-Feldspar | Calcite | Dolomite | Kaolinite | ||

| HU24-2 | b.f. | 12.8 | 4.3 | 1.1 | 0.4 |

| a.f. | 10.1 | 1.5 | 0.7 | 2.5 | |

| HU24-3 | b.f. | 11.2 | 4.1 | 1.2 | 0.6 |

| a.f. | 10.2 | 2.4 | 0.9 | 1.8 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Yang, S.; Han, H.; Wang, L.; Qian, K.; Pang, J. Experimental Investigation on the Effects of CO2 Displacement Methods on Petrophysical Property Changes of Ultra-Low Permeability Sandstone Reservoirs Near Injection Wells. Energies 2019, 12, 327. https://doi.org/10.3390/en12020327

Wang Q, Yang S, Han H, Wang L, Qian K, Pang J. Experimental Investigation on the Effects of CO2 Displacement Methods on Petrophysical Property Changes of Ultra-Low Permeability Sandstone Reservoirs Near Injection Wells. Energies. 2019; 12(2):327. https://doi.org/10.3390/en12020327

Chicago/Turabian StyleWang, Qian, Shenglai Yang, Haishui Han, Lu Wang, Kun Qian, and Jieqiong Pang. 2019. "Experimental Investigation on the Effects of CO2 Displacement Methods on Petrophysical Property Changes of Ultra-Low Permeability Sandstone Reservoirs Near Injection Wells" Energies 12, no. 2: 327. https://doi.org/10.3390/en12020327

APA StyleWang, Q., Yang, S., Han, H., Wang, L., Qian, K., & Pang, J. (2019). Experimental Investigation on the Effects of CO2 Displacement Methods on Petrophysical Property Changes of Ultra-Low Permeability Sandstone Reservoirs Near Injection Wells. Energies, 12(2), 327. https://doi.org/10.3390/en12020327