Comparison of NOx and Smoke Characteristics of Water-in-Oil Emulsion and Marine Diesel Oil in 400-kW Marine Generator Engine

Abstract

:1. Introduction

2. Experimental Apparatus and Methodology

2.1. Emulsion Oil Properties

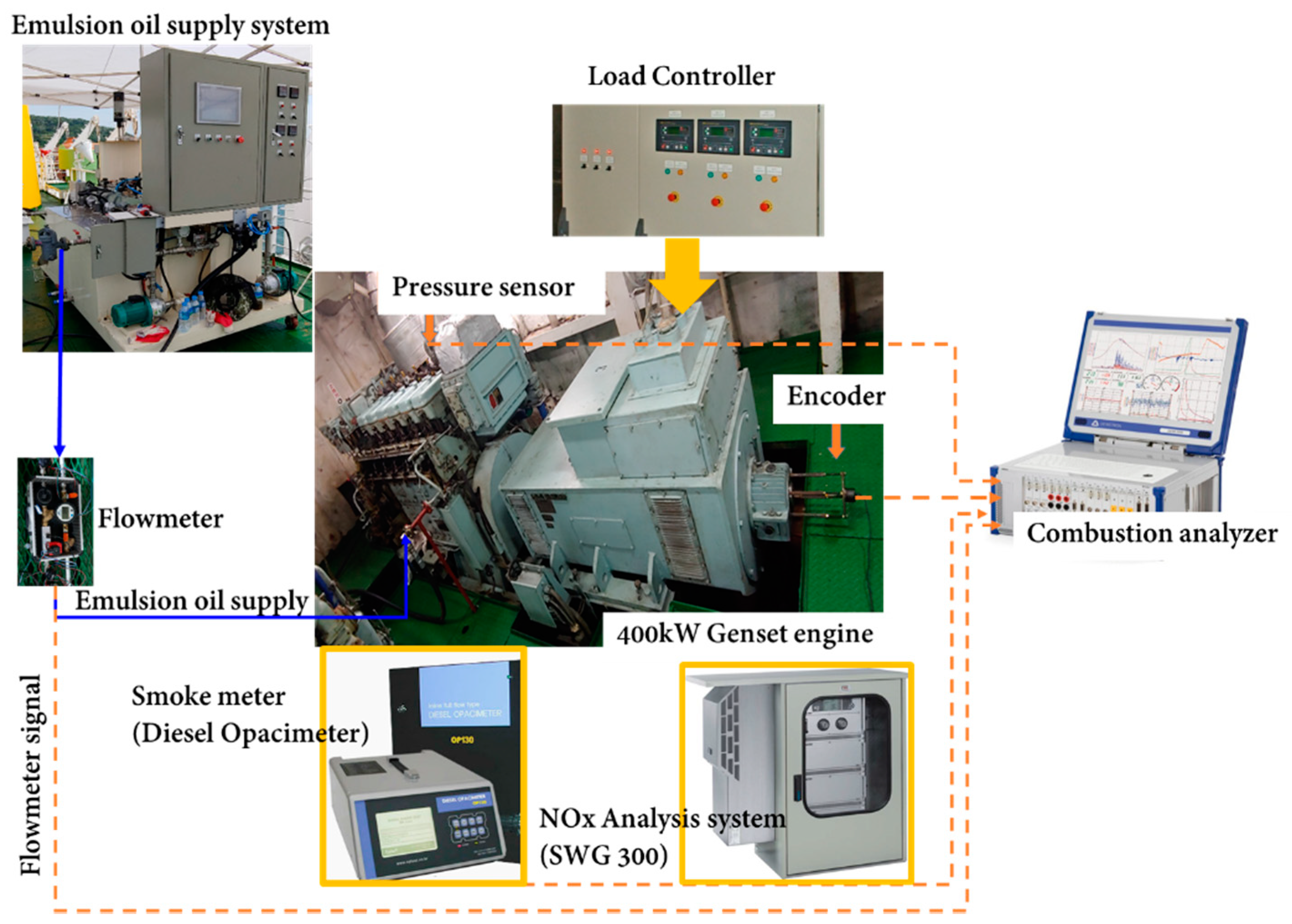

2.2. Experimental Apparatus

2.3. Experimental Conditions

3. Results and Investigations

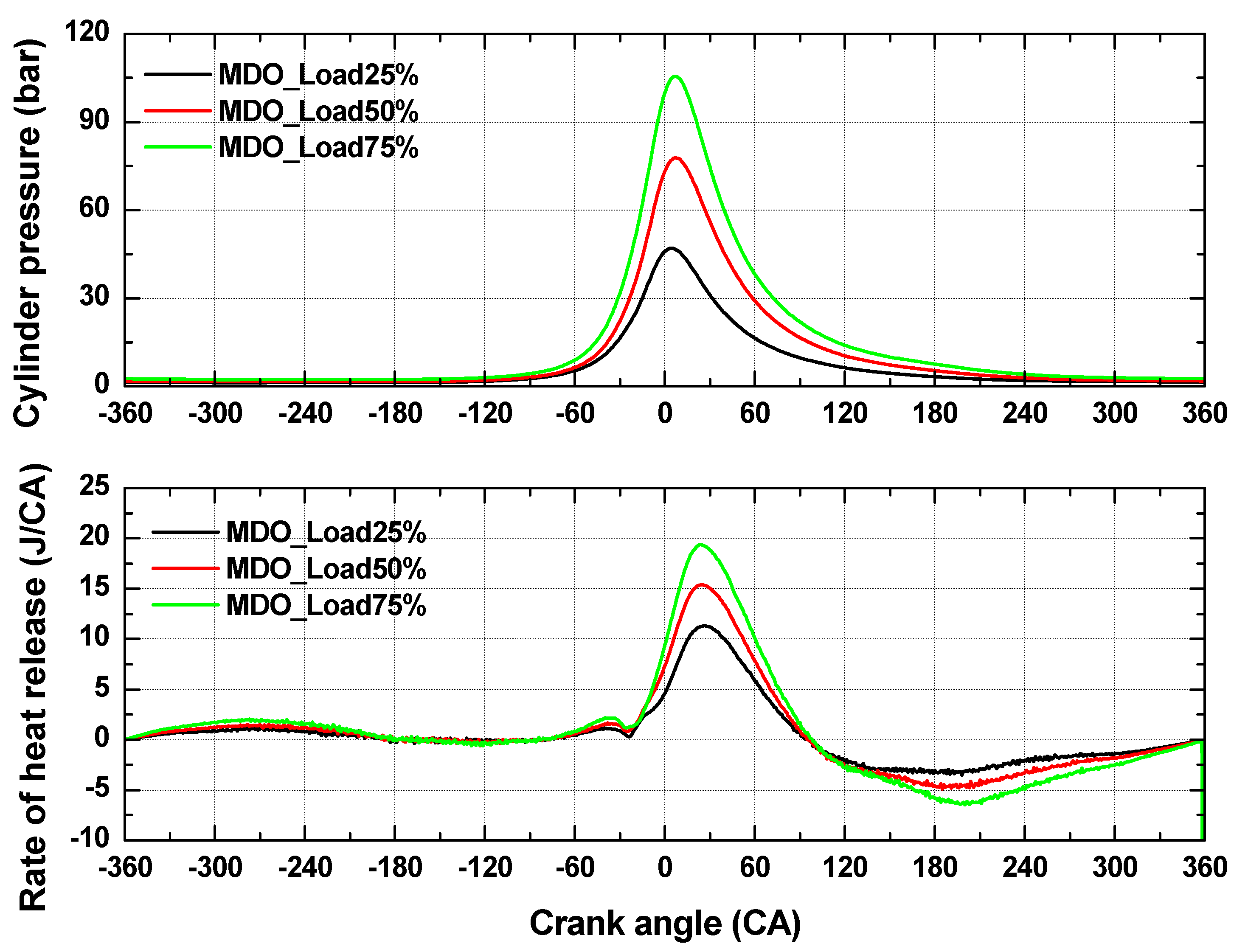

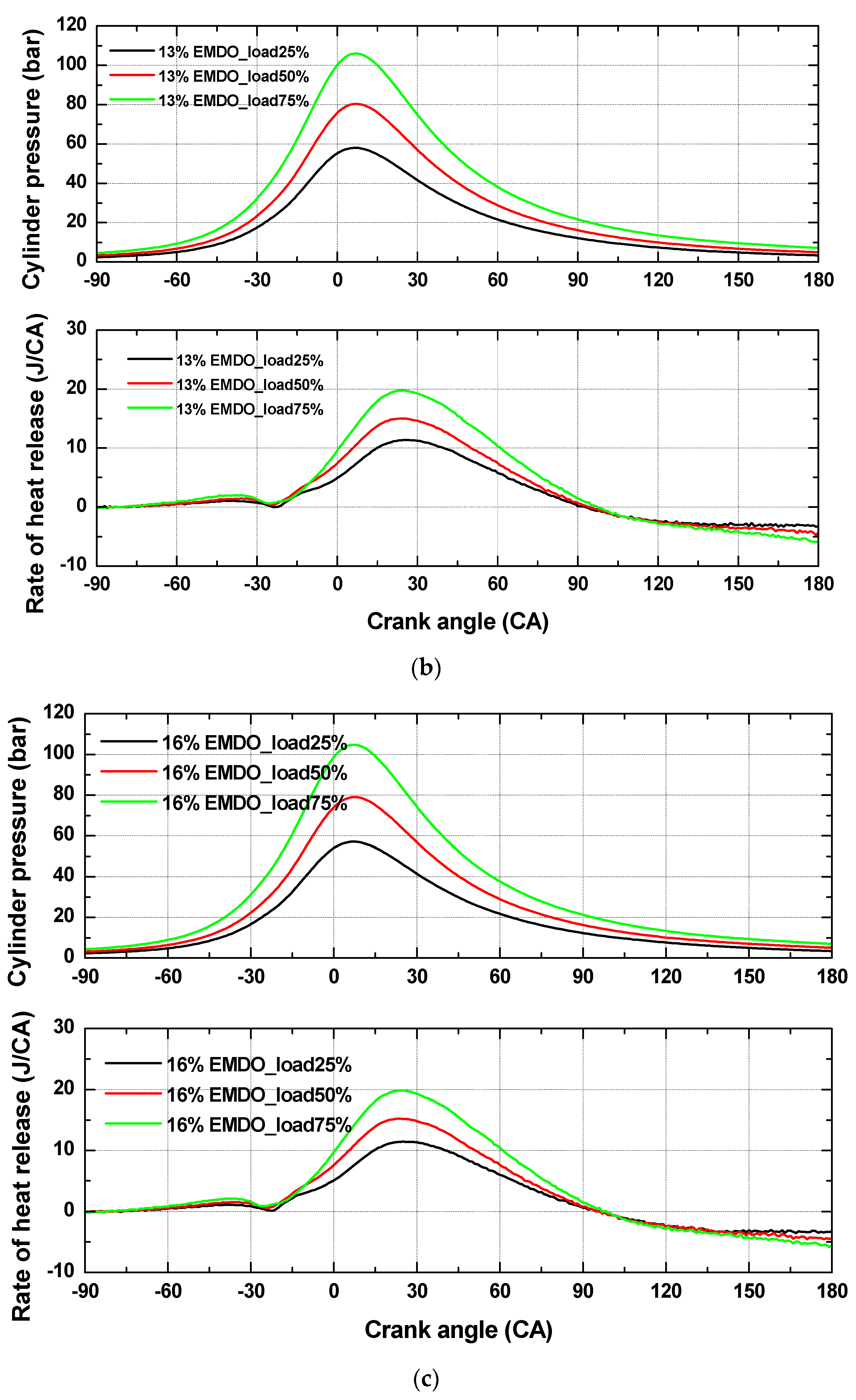

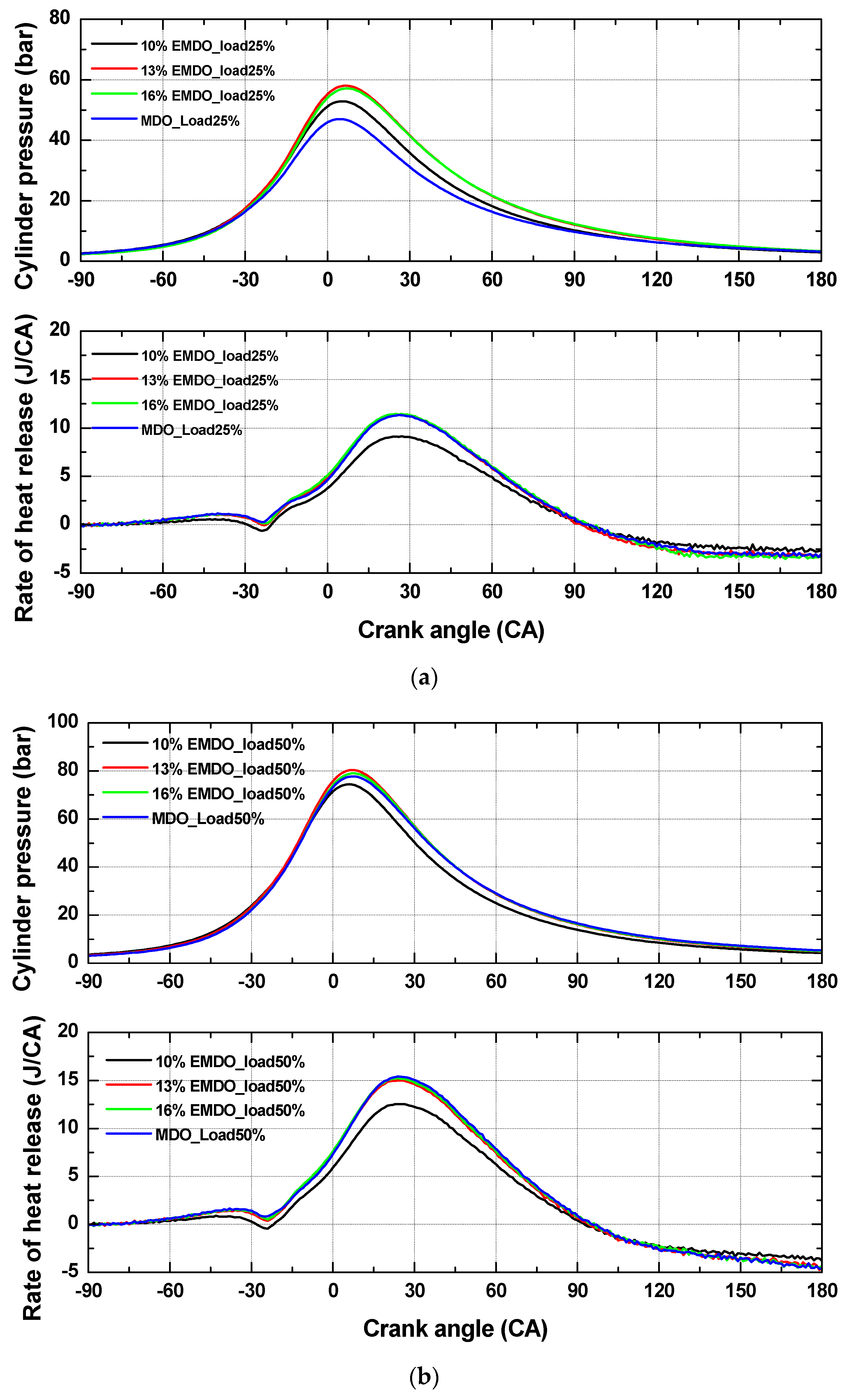

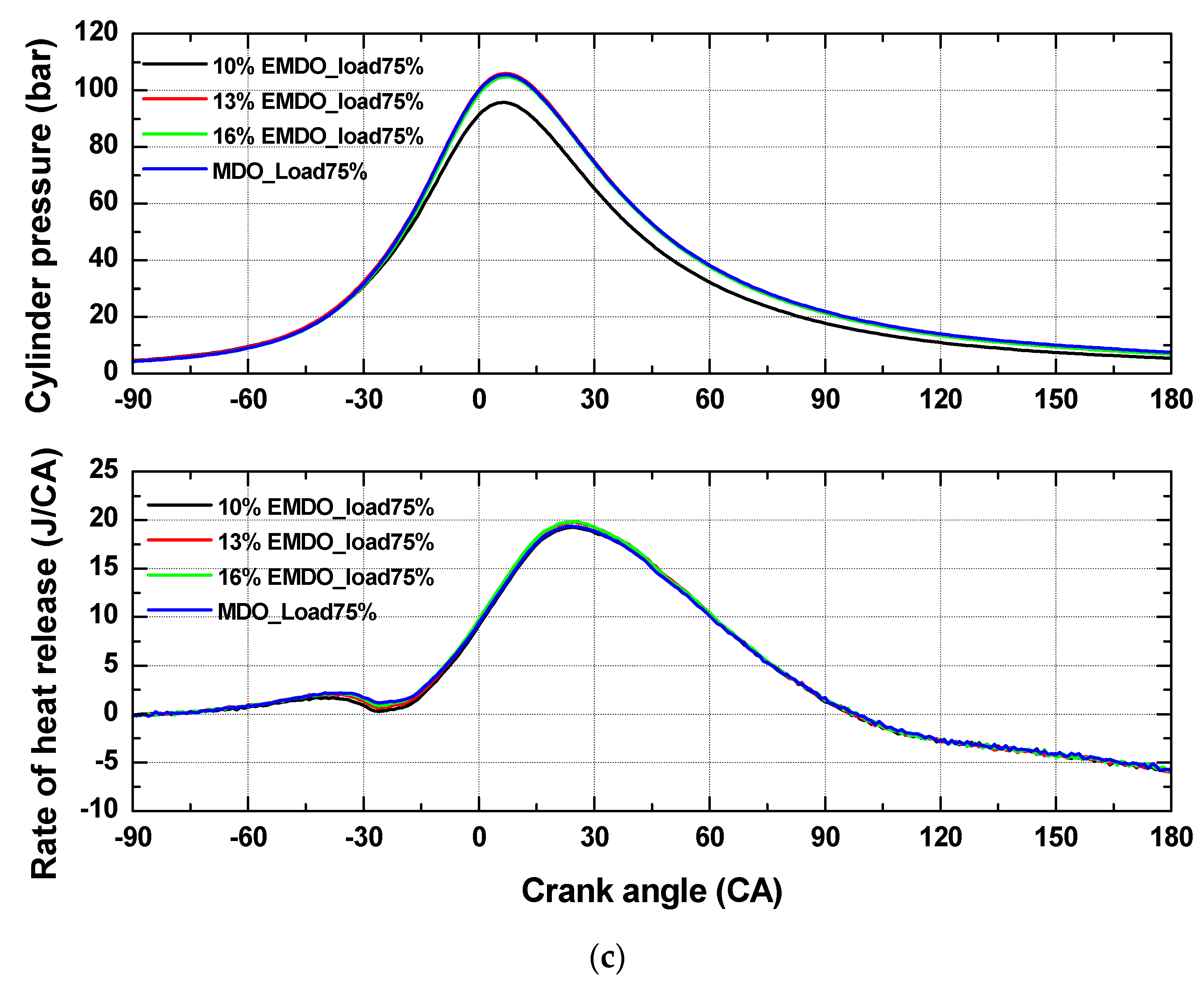

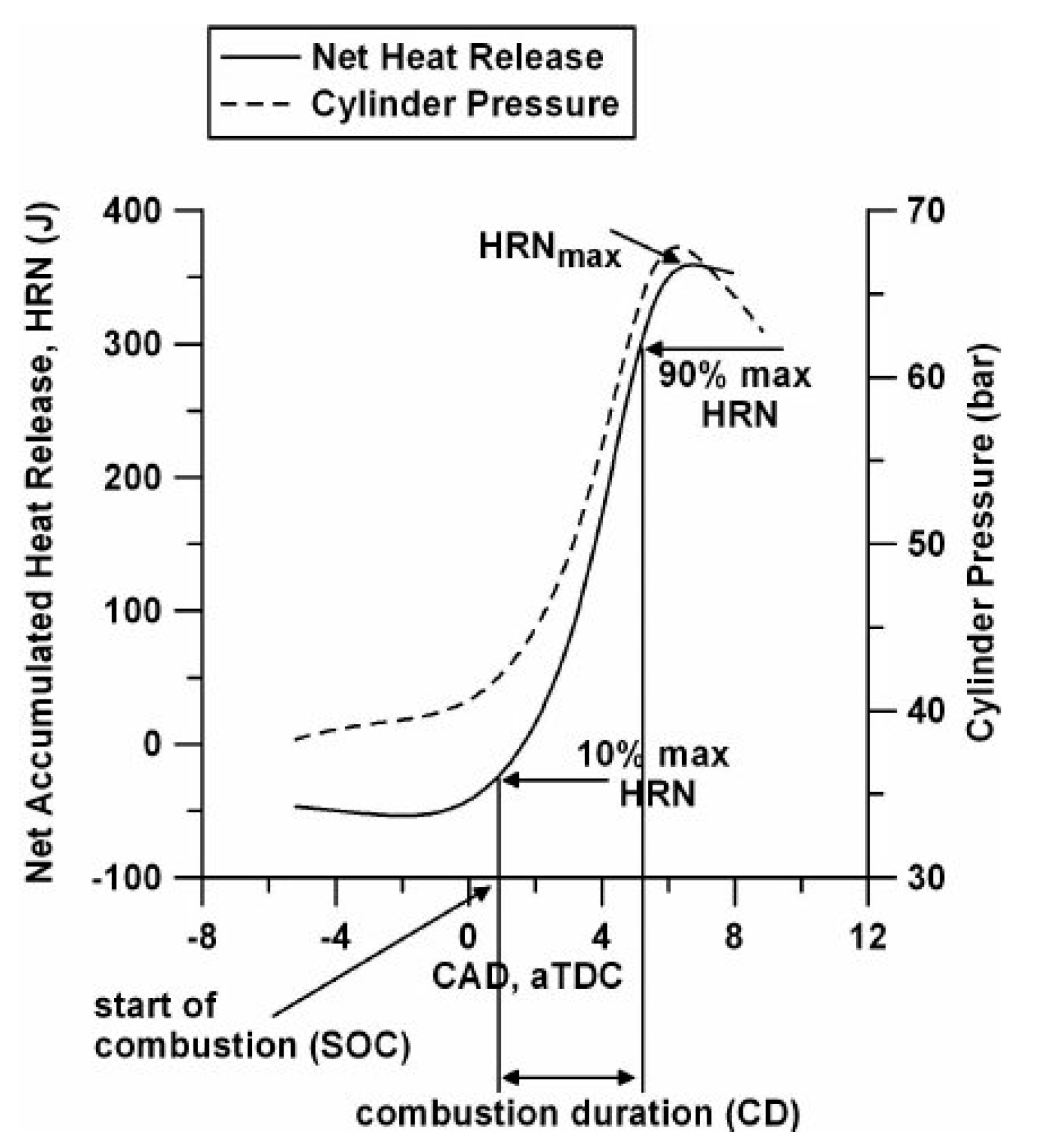

3.1. Characteristics of Combustion and Heat Release Rate of Emulsion Fuel According to Moisture Content

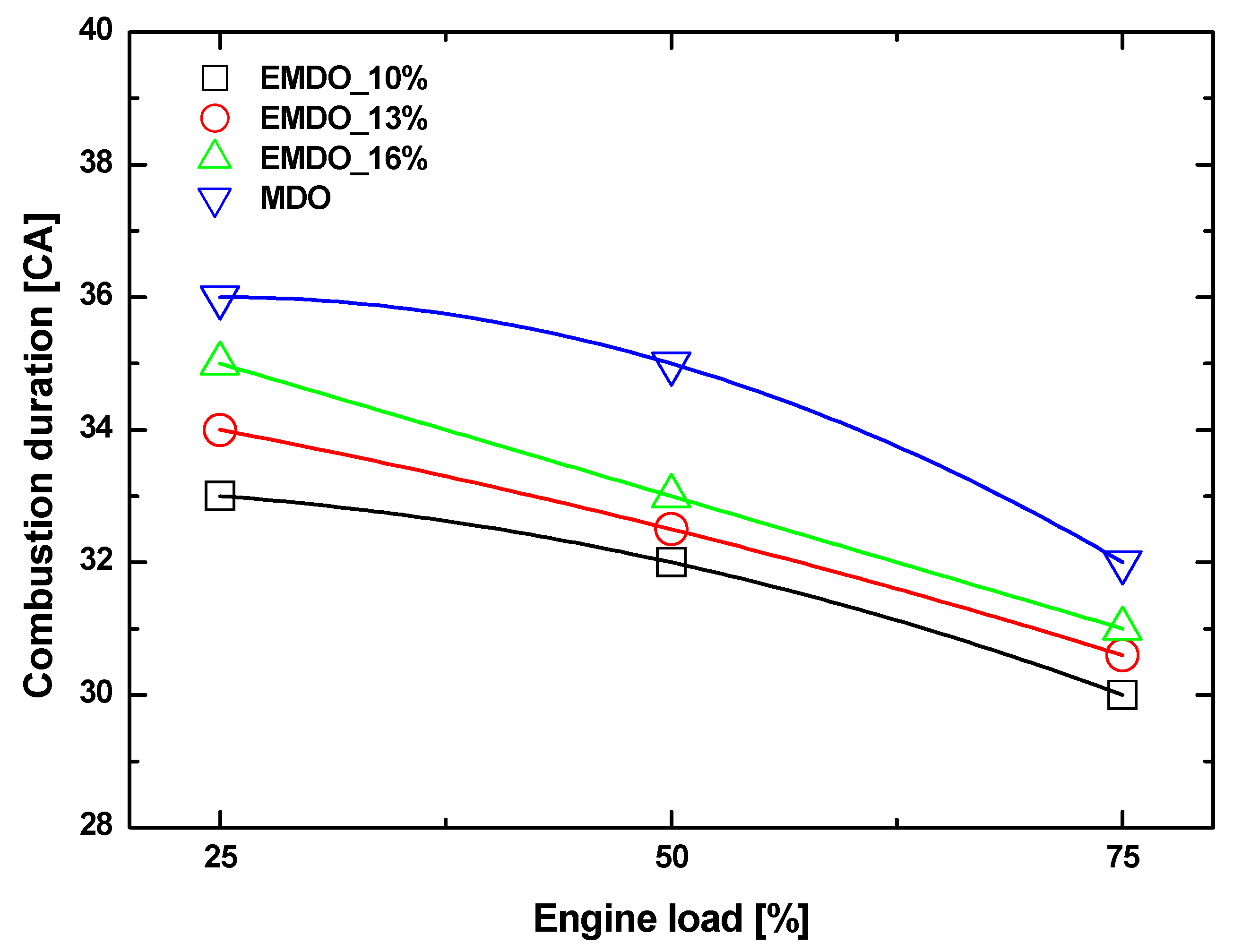

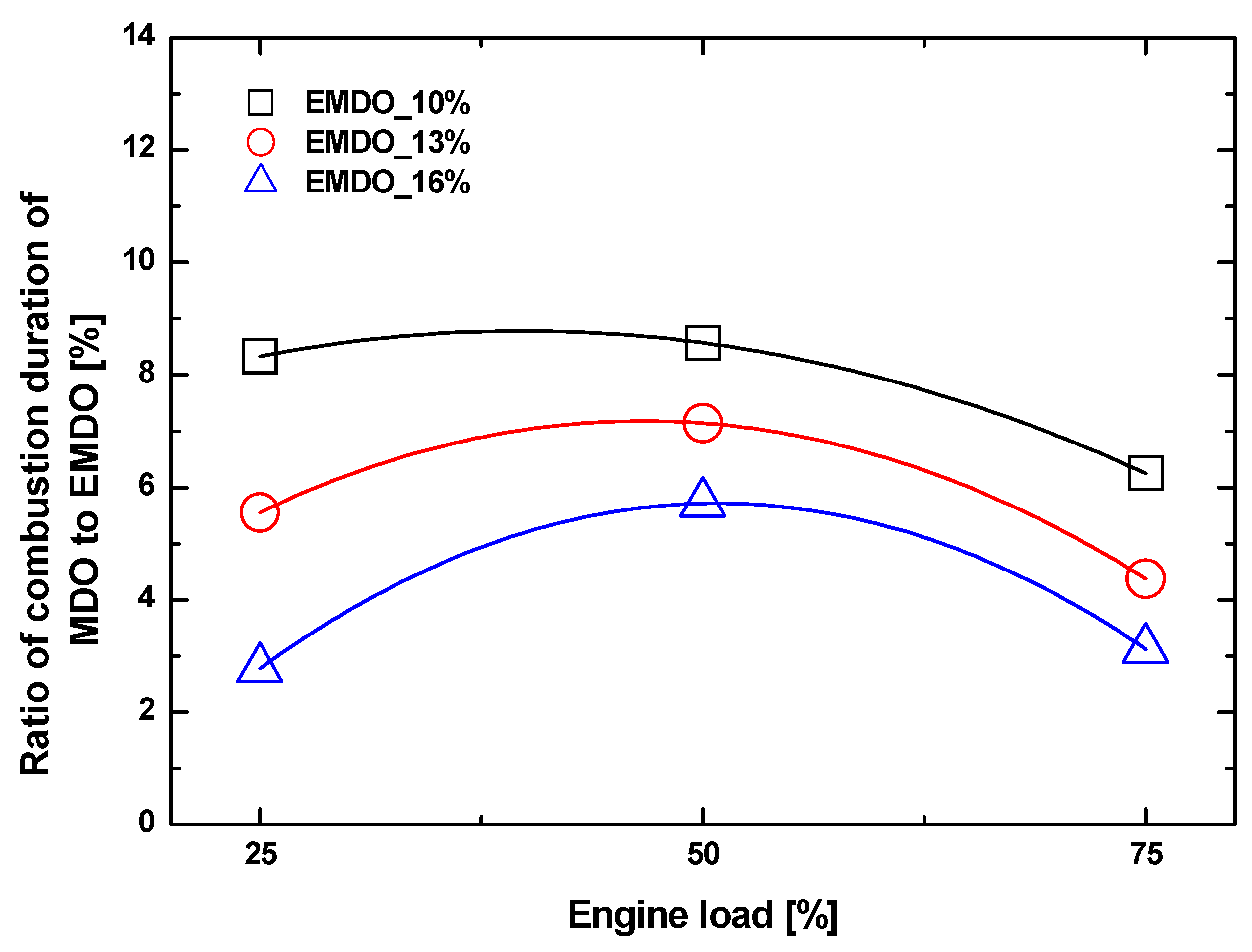

3.2. Combustion Duration Characteristics of MDO and EMDO

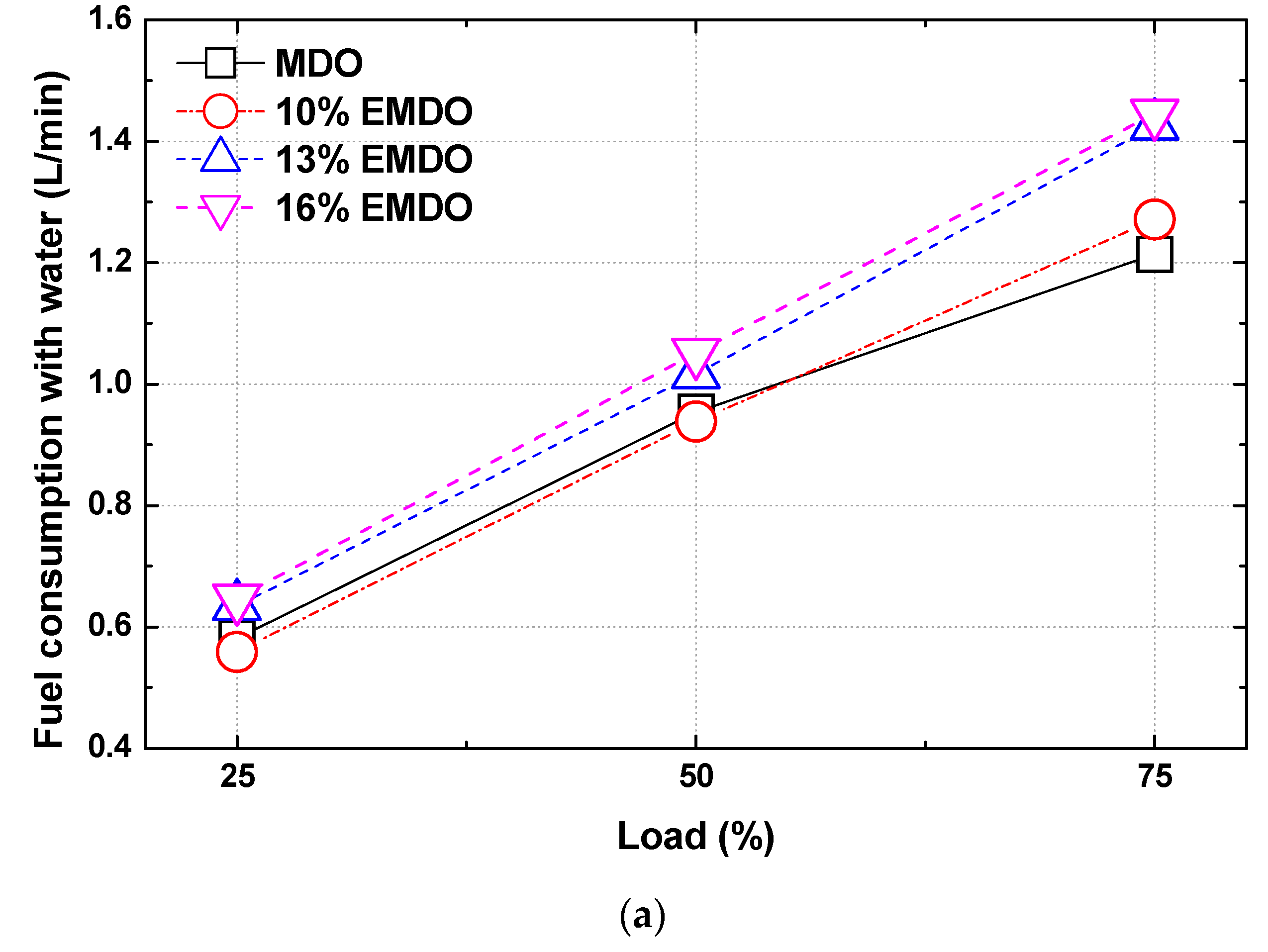

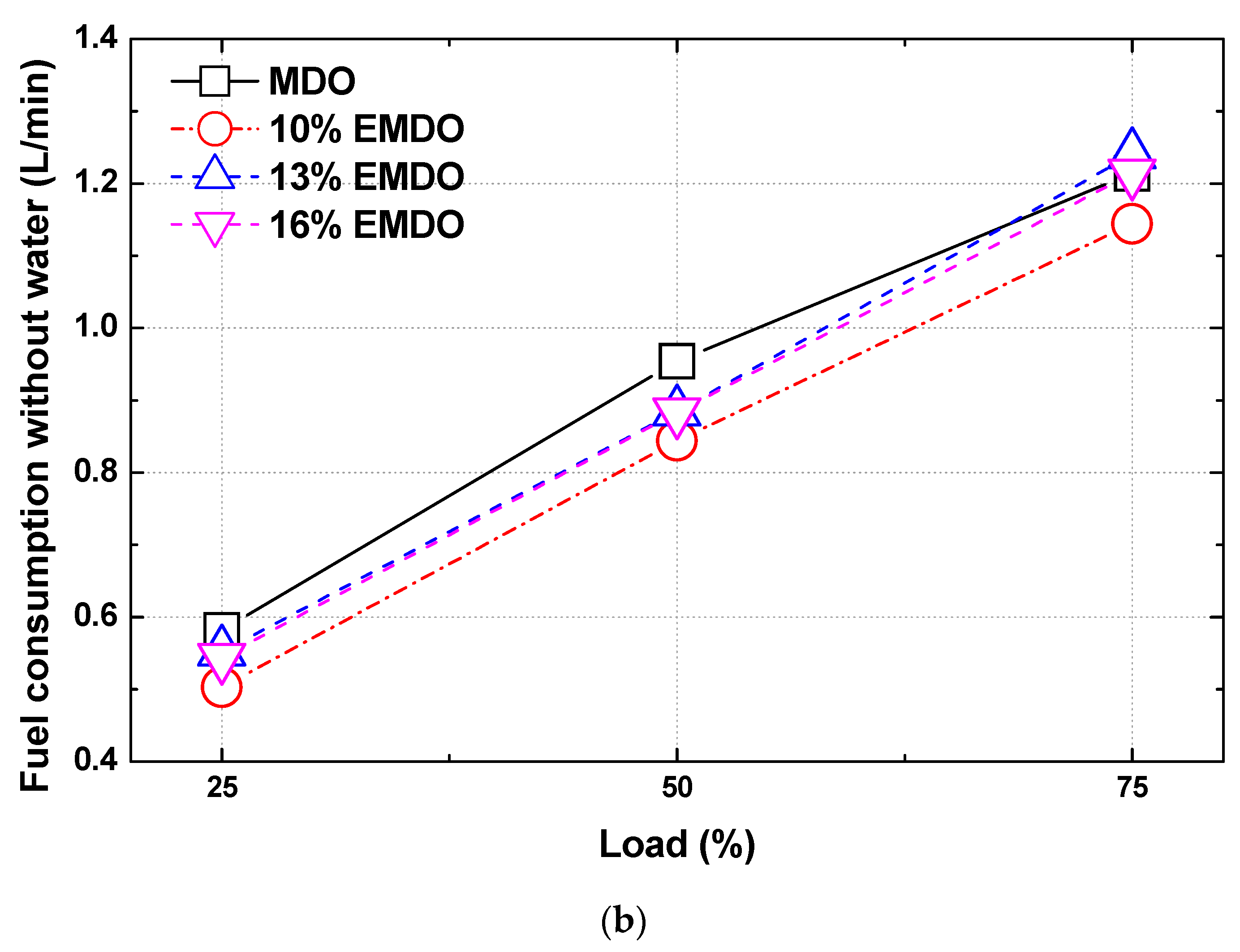

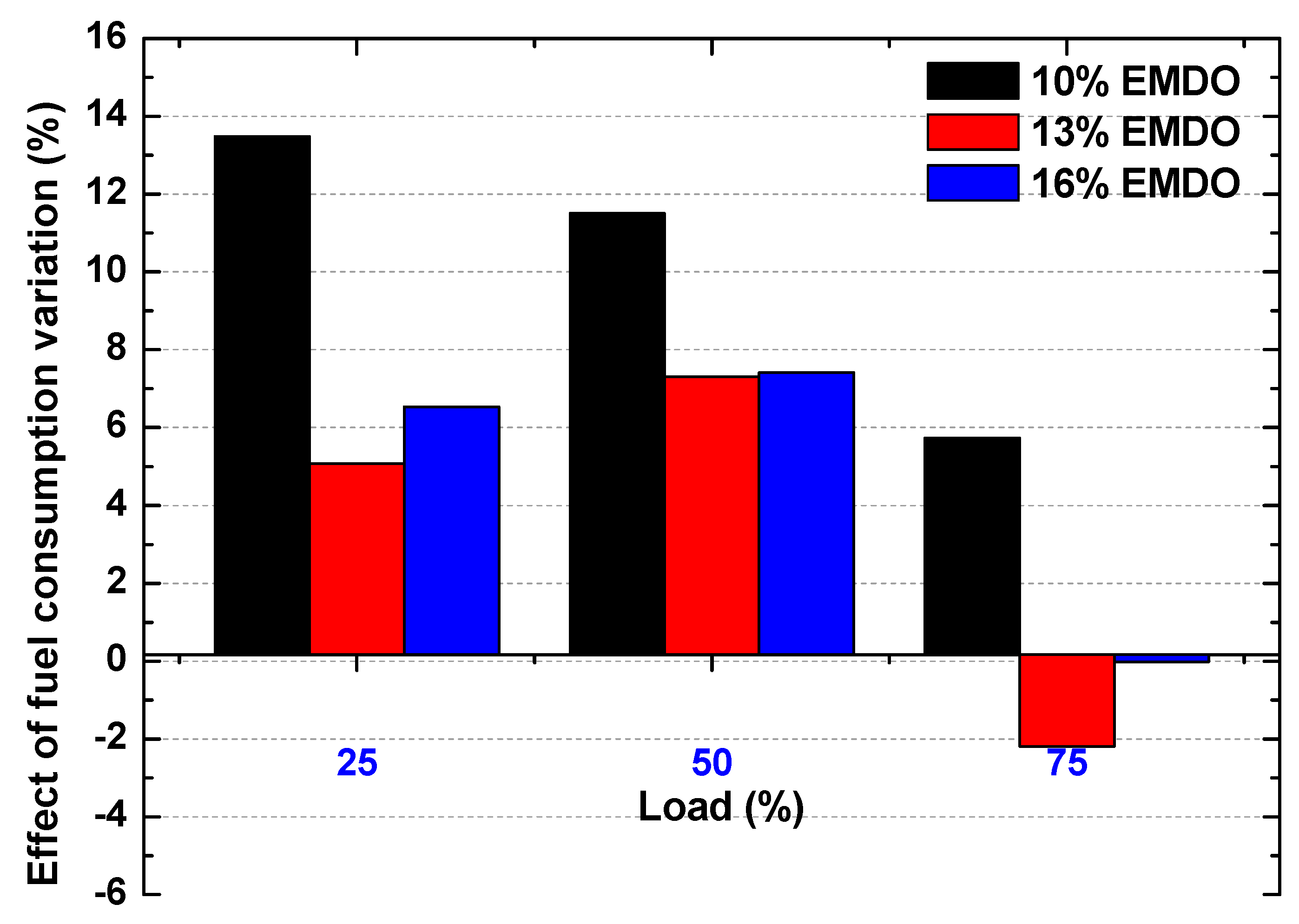

3.3. Comparison of Specific Fuel Consumption of MDO and Emulsified Fuel According to Moisture Content

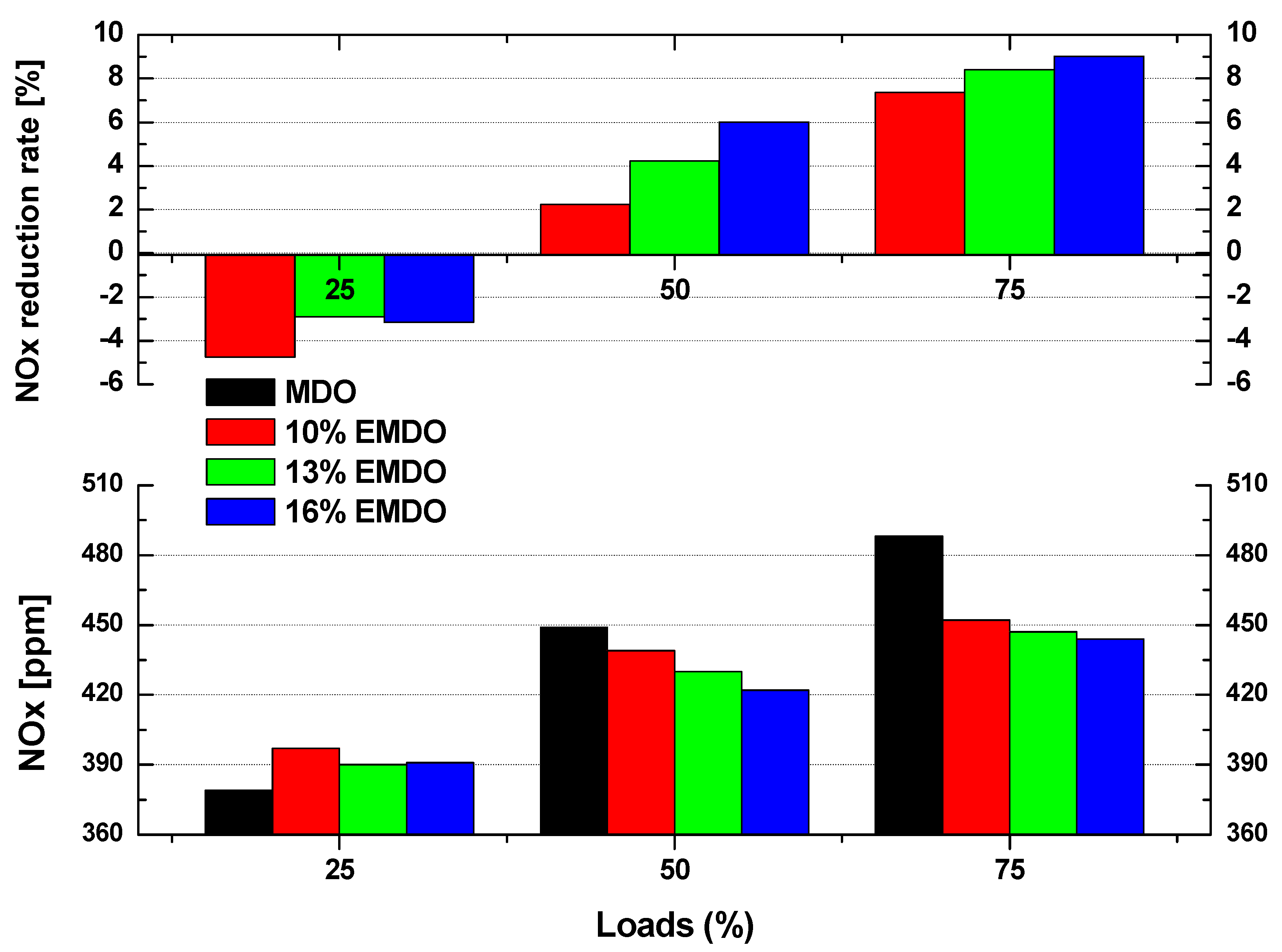

3.4. Combustion and Exhaust Characteristics of MDO and Emulsified Fuel According to Moisture Content

4. Conclusions

- (1)

- EMDO exhibited higher cylinder pressure and shorter combustion duration than MDO. The combustion durations of 10% EMDO decreased by 8.3%, 8.5% and 6.3%, those of 13% EMDO by 5.5%, 7.1% and 4.4%, and those of 16% EMDO by 2.7%, 5.7% and 3.1% with loads compared to MDO with water concentrations of 10%, 13% and 16%.

- (2)

- The pure fuel consumptions of 10% EMDO decreased by 13.5%, 11.5%, and 5.7%, those of 13% EMDO by 5.1%, 7.3%, and -2.1%r, and those of 16% EMDO by 6.5%, 7.4%, and 0% with loads compared to MDO. In the case of 75% engine load, the fuel consumption rate of 10% EMDO decreased, whereas those of 13% and 16% EMDO increased.

- (3)

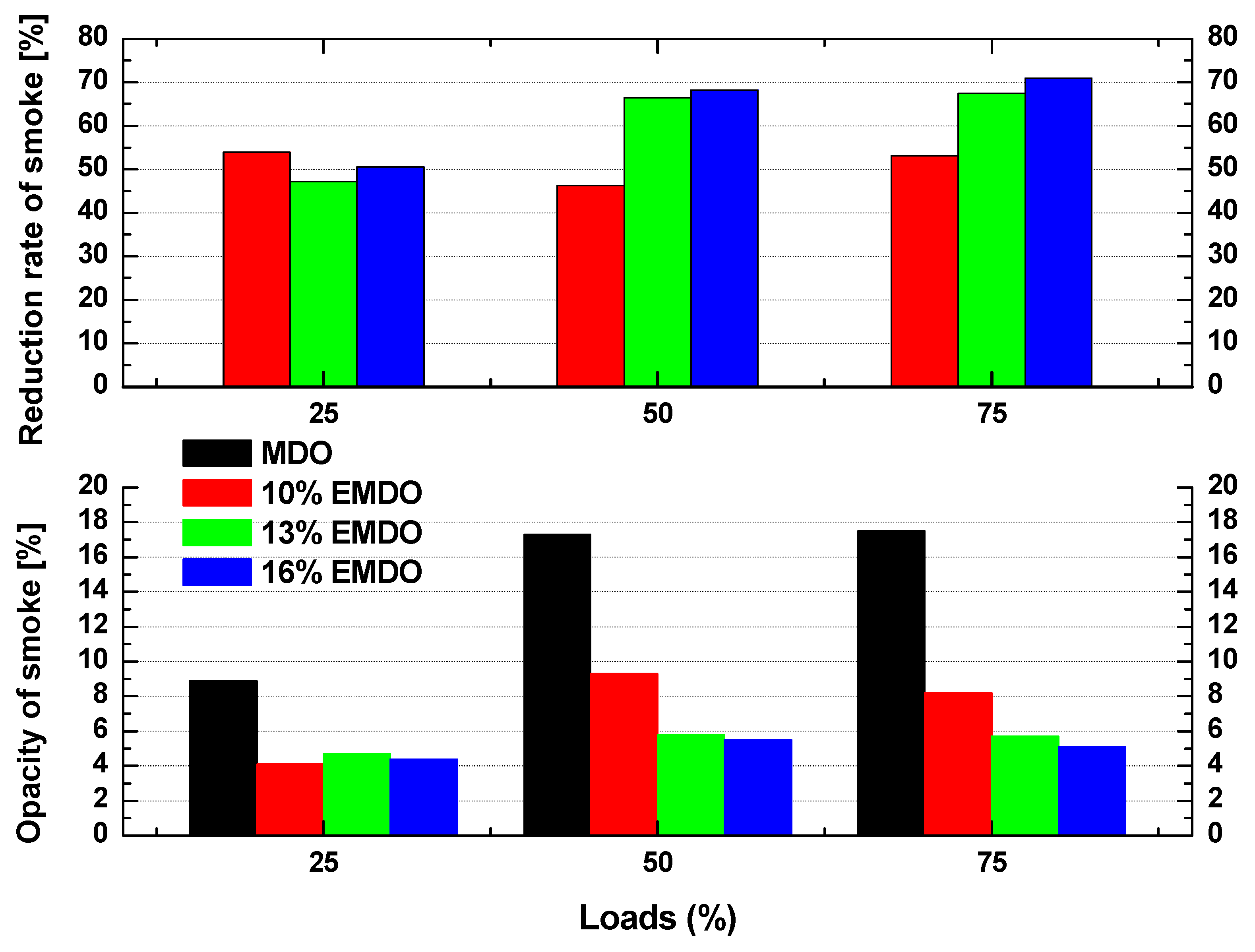

- The NOx emissions of EMDO fuel decreased by up to 8% at 75% load compared to MDO. The smoke reduction rate was 75% for 16% EMDO at 75% engine load.

- (4)

- As the water content of emulsified fuel increased, the nitrogen oxide emission and smoke exhaust decreased. The smoke density and emission also decreased with increase in the moisture content of MDO. The reduction of smoke with increasing water content could be attributed to the following factors: (1) reduction in the combustion temperature, (2) the mixture of the surrounding air and the fuel is boosted as the surface area of the droplet increases due to fine explosion of the emulsion; (3) increase in the moisture content; and (4) effect of aqueous reaction of water and carbon.

Author Contributions

Funding

Conflicts of Interest

References

- Dhinesh, B.; Lalvani, J.I.; Parthasarathy, M.; Annamalai, K. An assessment on performance, emission and combustion characteristics of single cylinder diesel engine powered by Cymbopogon flexuous biofuel. Energy Convers. Manag. 2016, 117, 466–474. [Google Scholar] [CrossRef]

- Sharma, A.; Kumar, N.; Vibhanshu, V.; Deep, A. Emission Studies on a VCR Engine Using Stable Diesel Water Emulsion; SAE Technical Paper; SAE International: Warrendale, WA, USA, 2013. [Google Scholar] [CrossRef]

- Nadeem, M.; Rangkuti, C.; Anuar, K.; Haq, M.R.; Tan, I.B.; Shah, S.S. Diesel engine performance and emission evaluation using emulsified fuels stabilized by conventional and gemini surfactants. Fuel 2006, 85, 2111–2119. [Google Scholar] [CrossRef]

- Şahin, Z.; Tuti, M.; Durgun, O. Experimental investigation of the effects of water adding to the intake air on the engine performance and exhaust emissions in a DI automotive diesel engine. Fuel 2014, 115, 884–895. [Google Scholar] [CrossRef]

- Lin, C.Y.; Wang, K.H. Effects of a combustion improver on diesel engine performance and emission characteristics when using three-phase emulsions as an alternative fuel. Energy Fuels 2004, 18, 477–484. [Google Scholar] [CrossRef]

- Lin, C.Y.; Wang, K.H. Diesel engine performance and emission characteristics using three-phase emulsions as fuel. Fuel 2004, 83, 537–545. [Google Scholar] [CrossRef]

- Subramanian, K.A. A comparison of water–diesel emulsion and timed injection of water into the intake manifold of a diesel engine for simultaneous control of NO and smoke emissions. Energy Convers. Manag. 2011, 52, 849–857. [Google Scholar] [CrossRef]

- Lin, C.Y.; Wang, K.H. Effects of diesel engine speed and water content on emission characteristics of three-phase emulsions. J. Environ. Sci Health Part A Toxic Hazard. Subst. Environ. Eng. 2006, 39, 1345–1359. [Google Scholar] [CrossRef]

- Yang, W.M.; An, H.; Chou, S.K.; Vedharaji, S.; Vallinagam, R.; Balaji, M.; Mohammad, F.E.A.; Chua, K.J.E. Emulsion fuel with novel nano-organic additives for diesel engine application. Fuel 2013, 104, 726–731. [Google Scholar] [CrossRef]

- Ogunkoya, D.; Li, S.; Rojas, O.J.; Fang, T. Performance, combustion, and emissions in a diesel engine operated with fuel-in-water emulsions based on lignin. Appl. Energy 2015, 154, 851–861. [Google Scholar] [CrossRef]

- Sadhik Basha, J.; Anand, R.B. Effects of nanoparticle additive in the water-diesel emulsion fuel on the performance, emission and combustion characteristics of a diesel engine. Int. J. Veh. Des. 2012, 59, 164–181. [Google Scholar] [CrossRef]

- Shukla, P.C.; Gupta, T.; Labhasetwar, N.K.; Khobaragade, R.; Gupta, N.K.; Agarwal, A.K. Effectiveness of non-noble metal based diesel oxidation catalysts on particle number emissions from diesel and biodiesel exhaust. Sci. Total Environ. 2016, 574, 1512–1520. [Google Scholar] [CrossRef] [PubMed]

- Saraee, H.S.; Taghavifar, H.; Jafarmadar, S. Experimental and numerical consideration of the effect of CeO2 nanoparticles on diesel engine performance and exhaust emission with the aid of artificial neural network. Appl. Therm. Eng. 2016, 113, 663–672. [Google Scholar] [CrossRef]

- Saxena, V.; Kumar, N.; Saxena, V.K. A comprehensive review on combustion and stability aspects of metal nanoparticles and its additive effect on diesel and biodiesel fuelled C.I. engine. Renew. Sustain. Energy Rev. 2017, 70, 563–588. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K.; Subbarao, R.; Johny, A.; Mohan, A.; Tamilarasu, A. Experimental studies on the effect of metal oxide and antioxidant additives with Calophyllum Inophyllum Methyl ester in compression ignition engine. J. Clean. Prod. 2017, 166, 474–484. [Google Scholar] [CrossRef]

- Mitchell, M.R.; Link, R.E.; Kao, M.J.; Ting, C.C.; Li, B.F.; Tsung, T.T. Aqueous aluminum nanofluid combustion in diesel fuel. J. Test. Eval. 2008, 36, 186–190. [Google Scholar] [CrossRef]

- Vellaiyan, S.; Amirthagadeswaran, K.S. Zinc oxide incorporated water-in-diesel emulsion fuel: Formulation, particle size measurement, and emission characteristics assessment. Pet. Sci. Technol. 2016, 34, 114–122. [Google Scholar] [CrossRef]

- Farfaletti, A.; Astorga, C.; Martini, G.; Manfredi, U.; Mueller, A.; Rey, M.; De Santi, G.; Krasenbrink, A.; Larsen, B.R. Effect of water/fuel emulsions and a cerium-based combustion improver additive on HD and LD diesel exhaust emissions. Environ. Sci. Technol. 2005, 39, 6792–6799. [Google Scholar] [CrossRef] [PubMed]

- Keskin, A.; Gürü, M.; Altıparmak, D. Influence of tall oil biodiesel with Mg and Mo based fuel additives on diesel engine performance and emission. Bioresour. Technol. 2008, 99, 6434–6438. [Google Scholar] [CrossRef]

- Kovacs, A.; Csoka, I.; Konya, M.; Csanyi, E.; Feher, A.; Istvan, E. Structural analysis of W/o/W multiple emulsions by means of DSC. J. Therm. Sci. Calori. 2005, 82, 491–497. [Google Scholar] [CrossRef]

- Dluska, E.; Hubacz, R.; Wronski, S.; Kamienshi, J.; Dylag, M.; Wojtowicz, R. The influence of helical flow on water fuel emulsion preparation. Chem. Eng. Commun. 2007, 194, 1271–1286. [Google Scholar] [CrossRef]

- Eckert, P.; Velji, A.; Spicher, U. Numerical Investigation of fuelwater emulsion combustion in DI-diesel Engines. In Proceedings of the International Council on Combustion Engines, CIMAC, Vienna, Austria, 21–24 May 2007. [Google Scholar]

- Weber, J.; Peters, N.; Bockhorn, H.; Pittermann, R. Numerical simulation of the evolution of the soot particle size distribution in a DI diesel engine using an emulsified fuel of diesel-water. SAE Trans. 2004, 113, 2217–2233. [Google Scholar]

- Kim, M.; Oh, J.; Lee, C. Study on Combustion and Emission Characteristics of Marine Diesel Oil and Water-In-Oil Emulsified Marine Diesel Oil. Energies 2018, 11, 1830. [Google Scholar] [CrossRef]

- Ismael, M.A.; Morgan, R.; Heikal, A.; Aziz, R.A.; Crua, C. The Effect of Fuel Injection Equipment of Water-In-Diesel Emulsions on Micro-Explosion Behaviour. Energies 2018, 11, 1650. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Chen, L.-W. Comparison of fuel properties and emission characteristics of two- and three-phase emulsions prepared by ultrasonically vibrating and mechanically homogenizing emulsification methods. Fuel 2008, 87, 2154–2161. [Google Scholar] [CrossRef]

- Fu, W.B.; Hou, I.Y.; Wang, L.; Ma, F.H. A unified model for the micro-explosion of emulsified droplets of oil and water. Fuel Process. Technol. 2002, 79, 107–119. [Google Scholar] [CrossRef]

- Watanabe, H.; Matsushita, Y.; Aoki, H.; Miura, T. Numerical simulation of emulsified fuel spray combustion with putting and micro-explosion. Combust. Flame 2010, 318, 21305704. [Google Scholar]

- Rashid, M.A.A.; Ithnin, A.M.; Yahya, W.J.; Ramlan, N.A.; Mazlan, N.A.; Sugeng, D.A. Integration of real-time non-surfactant emulsion fuel system on light duty lorry. In IOP Conference Series: Materials Science and Engineering; IOP: London, UK, 2017; Volume 257, p. 012051. [Google Scholar]

- Ithnin, A.M.; Yahya, W.J.; Ahmad, M.A.; Ramlan, N.A.; Kadir, H.A.; Sidik, N.A.C.; Koga, T. Emulsifier-free Water-in-Diesel emulsion fuel: Its stability behaviour engine performance and exhaust emission. Fuel 2018, 215, 454–462. [Google Scholar] [CrossRef]

- Mwangi, J.K.; Lee, W.-J.; Chang, Y.-C.; Chen, C.-Y.; Wang, L.C. An overview: Energy saving and pollution reduction by using green fuel blends in diesel engines. Appl. Energy 2015, 159, 214–236. [Google Scholar] [CrossRef]

- Jung, I.C.; Lee, K.H. Characteristics of ignition and micro-explosion for droplets of water-in-fuel emulsion. J. Korean Soc. Mar. Eng. 2013, 37, 1–8. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Hosseini, V.; Checkel, M.D. Using Reformer Gas to Enhance HCCI Combustion of CNG in a CFR Engine; SAE Technical Paper 2006-01-3247; SAE International: Warrendale, WA, USA, 2006. [Google Scholar] [CrossRef]

| Items/Classifications | MDO | 10% EMDO | 13% EMDO | 16% EMDO |

|---|---|---|---|---|

| Lower calorific value (J/g) | 41,860 | 36,760 | 34,610 | 34,430 |

| Gross calorific value (J/g) | 44,810 | 39,990 | 37,880 | 37,690 |

| Hydrogen (m/m %) | 13.06 | 13.06 | 12.87 | 12.73 |

| Carbon (m/m %) | 85.90 | 79.08 | 77.55 | 78.97 |

| Sulphur content (Weight %) | 0.19 | 0.15 | 0.14 | 0.13 |

| Density @ 20 °C (kg/m3) | 858.9 | 872.3 | 878.5 | 882.3 |

| Moisture (Volume %) | 0.3 | 11.0 | 14.5 | 15.2 |

| Flash point (°C) | 104 | 102 | 114 | 118 |

| Items/Descriptions | Specifications |

|---|---|

| Engine type | 4-stoke turbo-charged DI marine generator engine |

| Number of cylinders | 6 |

| Bore × Stroke (mm) | 165 × 210 |

| Displacement (cc) | 18,000 |

| Fuel injection system | Mechanical pumping system (Max. 1400 bar) |

| Engine’s maximum continuous rating (MCR) (kW/rpm) | 400 kW/1200 rpm |

| Items | Specification |

|---|---|

| Dynamometer | Load controller (in a marine ship) |

| Exhaust gas analyser | SWG 300 |

| Smoke meter | Diesel opacimeter (OP 130D) |

| Fuel | MDO, EMDO (10%, 13% and 16%) |

|---|---|

| Engine speed (rpm) | 1200 |

| Load (kW) | 100 (25%), 200 (50%), 300 (75%) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, J.; Im, M.; Oh, S.; Lee, C. Comparison of NOx and Smoke Characteristics of Water-in-Oil Emulsion and Marine Diesel Oil in 400-kW Marine Generator Engine. Energies 2019, 12, 228. https://doi.org/10.3390/en12020228

Oh J, Im M, Oh S, Lee C. Comparison of NOx and Smoke Characteristics of Water-in-Oil Emulsion and Marine Diesel Oil in 400-kW Marine Generator Engine. Energies. 2019; 12(2):228. https://doi.org/10.3390/en12020228

Chicago/Turabian StyleOh, Jungmo, Myeonghwan Im, Seungjin Oh, and Changhee Lee. 2019. "Comparison of NOx and Smoke Characteristics of Water-in-Oil Emulsion and Marine Diesel Oil in 400-kW Marine Generator Engine" Energies 12, no. 2: 228. https://doi.org/10.3390/en12020228

APA StyleOh, J., Im, M., Oh, S., & Lee, C. (2019). Comparison of NOx and Smoke Characteristics of Water-in-Oil Emulsion and Marine Diesel Oil in 400-kW Marine Generator Engine. Energies, 12(2), 228. https://doi.org/10.3390/en12020228