1. Introduction

As wind energy becomes a prevailing source of power generation, grid codes for interconnection of wind energy conversion systems (WECS), in order to ensure the reliable and safe operation of the electricity grid, have become more and more demanding. As a result, wind turbine technology must be developed accordingly.

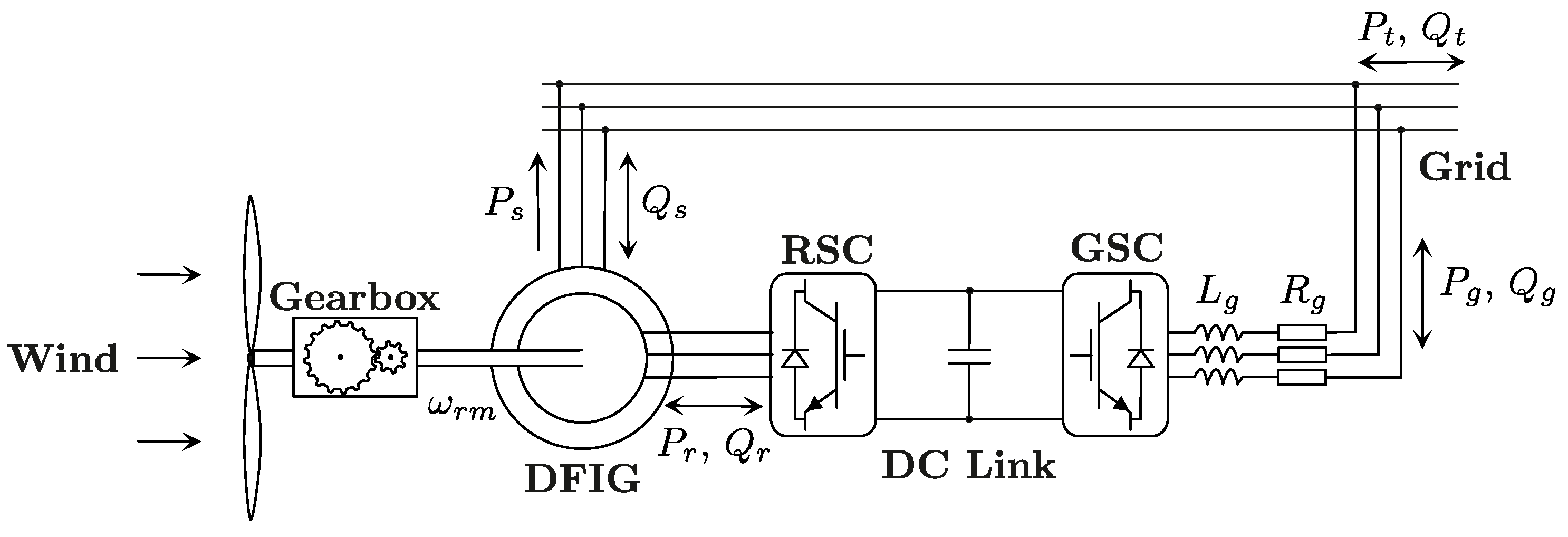

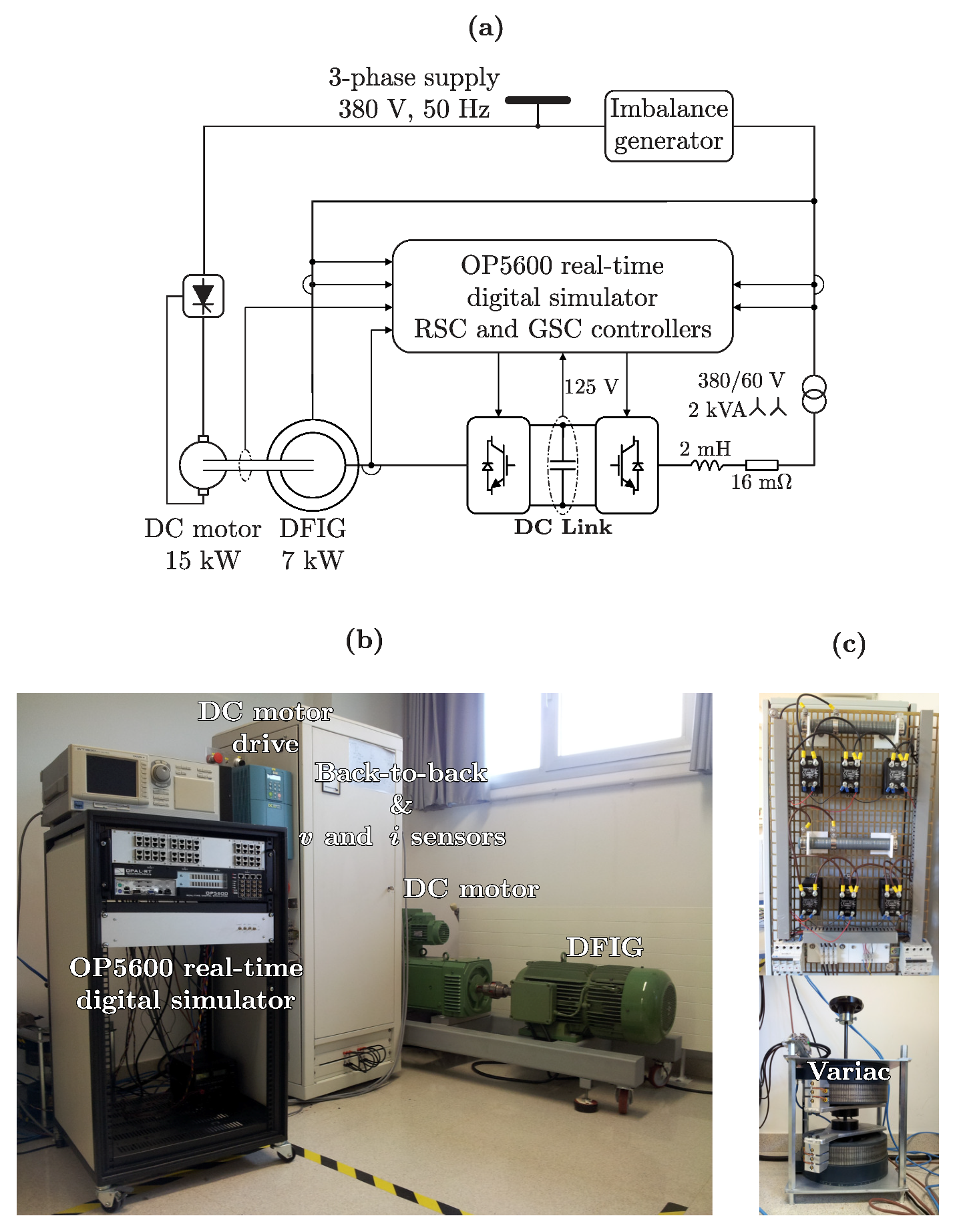

The doubly-fed induction generator (DFIG) (refer to

Figure 1) and the so-called full-scale converter wind generator are the dominating technologies in the present wind industry [

1]. Both wind turbine configurations contain a power converter stage, which is usually comprised of two identical (three-phase, two-level) voltage source converters (VSCs). Thereby, the control system associated to the grid-side power converter (GSC) plays a critical role in the accomplishment of different grid codes, such as the capability to tolerate voltage and frequency deviations, control of active and reactive powers, fault ride-through (FRT) operation, and power quality-related requirements, such as low total harmonic distortion (THD) of the current fed into the grid.

At present, to satisfy such demands, control systems of grid-connected VSCs must have the ability to control not only the fundamental component of their current positive sequence, but also other current components, such as the negative sequence, harmonics of any order, and subharmonics, that may arise due to grid disturbances.

In this context, proportional-integral (PI)- and PI+resonant (PI+R)-based control algorithms were, at first, predominant in the literature [

2,

3,

4]. However, the main drawback of those kinds of solutions consists in the lack of versatility against uncertainties in the type of grid voltage disturbance. That is, said solutions require particularising at the beginning of the design phase, which are the specific disturbed grid voltage scenarios they are intended to cope with. Therefore, if a particular type of disturbance arises which was not contemplated in advance, it is more than likely that the control algorithm does not have enough bandwidth to perform well.

Hence, a less grid voltage-dependent solution, which is capable of dealing with diverse non-ideal grid voltage profiles, is desirable. In this sense, the high-performance dynamic response and robustness naturally conferred by the different variants of sliding-mode control (SMC)-based algorithms make them excellent candidates. The constant switching frequency imposed on the commanded power converter, as well as the ability to mitigate the chattering phenomenon, are probably the two main strengths of second-order SMC (2-SMC) algorithms and, therefore, they have become a reasonable choice for addressing the design of the GSC controller.

The following handicaps, however, arise with 2-SMC:

It is complex to predict the expressions for the switching functions that lead to the best system performance; that is, to the best possible control of the active and reactive powers.

They have a considerable number of parameters to be adjusted, whose tuning is not yet as intuitive as, for example, that of proportional-integral-derivative (PID)-type controllers.

Simulation results obtained by running an empirically tuned controller have shown that, for each specific operation mode of the GSC (i.e., amount of active and reactive powers, wind turbine speed, degree and type of grid voltage disturbance, transient and steady-state of said grid voltage perturbation, and so on), there exists a different set of controller parameters giving rise to better performance, in terms of active and reactive power control.

Tuning of a specific parameter may lead to improved behaviour of a given controlled variable (e.g., active power), while negatively affecting others (e.g., reactive power).

Thus, far from trial-and-error tuning methods, a more scientific adjustment procedure for 2-SMC-based algorithms needs to be approached, such that a unique set of controller parameters remains valid for a good number of representative GSC operating regimes. Certainly, this requirement can be met by posing a multi-objective optimisation problem (MOOP).

In this sense, there are few works published, at present, in the literature (which have been oriented towards very disparate applications) focused on optimally tuning a SMC-based algorithm under a multi-objective (MO) approach [

5,

6,

7,

8,

9,

10]. However, the MOOPs tackled by those papers considered between two and (at most) five objectives to be minimised, which may not cover all the possible operating regimes of the system under study. Moreover, the SMC variant adopted by practically all papers in the literature was the first-order SMC (1-SMC) in its different versions (i.e., combining every possibility: With/without equivalent control term and with/without boundary layer), whereas there has been a lack of solutions focused on the 2-SMC. In addition, most, though not all, have validated their results by simulation, while only a few proved that results derived from experimental tests were consistent with those obtained through simulation [

8,

9].

As a consequence, throughout this paper, a tuning analysis based on multi-objective optimisation (MOO) is tackled for a 2-SMC algorithm. The parameter tuning derived in [

11] for the same system without applying any MOO approach, as well as the results to which such tuning leads, are adopted as baseline.

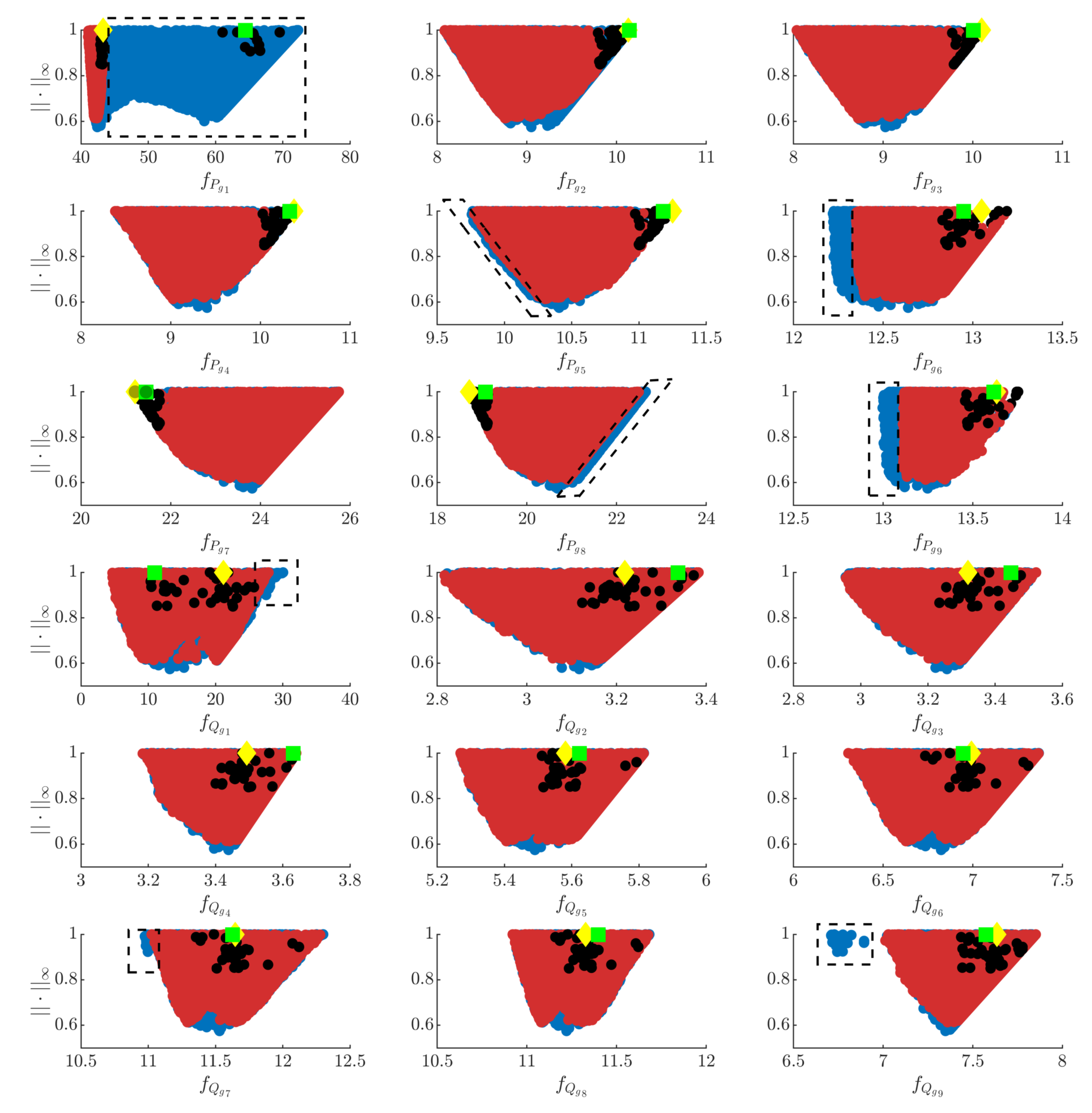

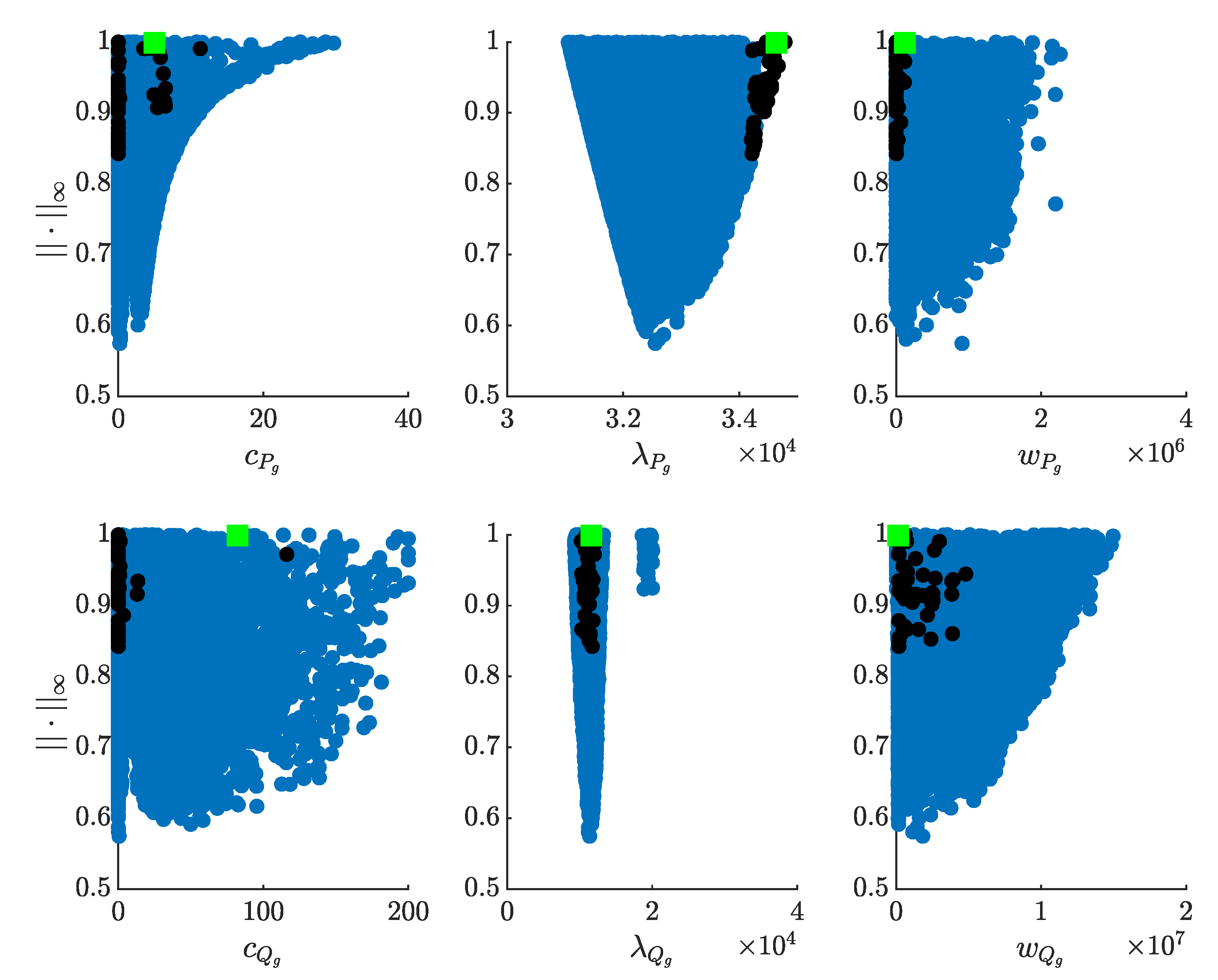

In particular, two versions (i.e., design concepts) of the same 2-SMC-based algorithm are compared under a MO approach: The first one containing six parameters to be tuned, including integral terms in its switching functions; whereas these integral terms have been removed from the second one, which contains just four parameters to adjust. To set the MOOP, two measures of the control performance, the integral of the absolute value of the error (IAE) for the active power and the standard deviation (SD) for the reactive power, in nine different operating regimes of the DFIG are taken into account. Therefore, 18 objectives are simultaneously considered.

An a posteriori MOO approach [

12] is employed. First, both the Pareto front and set are obtained in the MOO stage and, second, the final solution is chosen in the decision-making stage. Under this approach, it is not necessary to aggregate objectives and, as a result, the designer avoids weighting them a priori. Furthermore, obtaining the Pareto front can help the designer to grasp the trade-off among objectives, as well as to select the final solution in a more informed way.

The MOO stage is solved by making use of the ev-MOGA algorithm [

13], which is a multi-objective evolutionary algorithm (EA) capable of handling complex optimisation problems with non-convex and disjoint Pareto fronts. Thanks to the population nature of EAs, ev-MOGA obtains the Pareto front in a single run, as well as the majority of EAs [

14].

Dealing with MOOPs with high number of objectives (18, in this particular case) makes the Pareto front analysis more difficult. In order to assist the designer in this task, the interactive tool of level diagrams (LDs) [

15,

16] is employed. LDs are a powerful graphical tool, allowing comparison of design concepts—for this paper, the two 2-SMC-based algorithms with four and six parameters, respectively—in a synchronised

m-dimensional objective space. They have been successfully applied in a number of MOOPs, helping to analyse Pareto fronts in a more understandable way, such as multi-loop PI controller design [

17], non-linear model identification [

18], or for the tuning of biological synthetic devices [

19].

The posed results of the MOOP corroborate that it is possible to tune the aforementioned 2-SMC algorithms for both of the proposed design concepts, such that they improve upon the performance of the reference 2-SMC scheme proposed in [

11], in each and every one of the 18 objectives proposed. In addition, it is observed that the four-parameter variant of the 2-SMC algorithm exhibits similar behaviour to that of six-parameter version in practically all the objectives, hence leading us to conclude that the four-parameter version may be more suitable than its six-parameter counterpart, due to its greater simplicity.

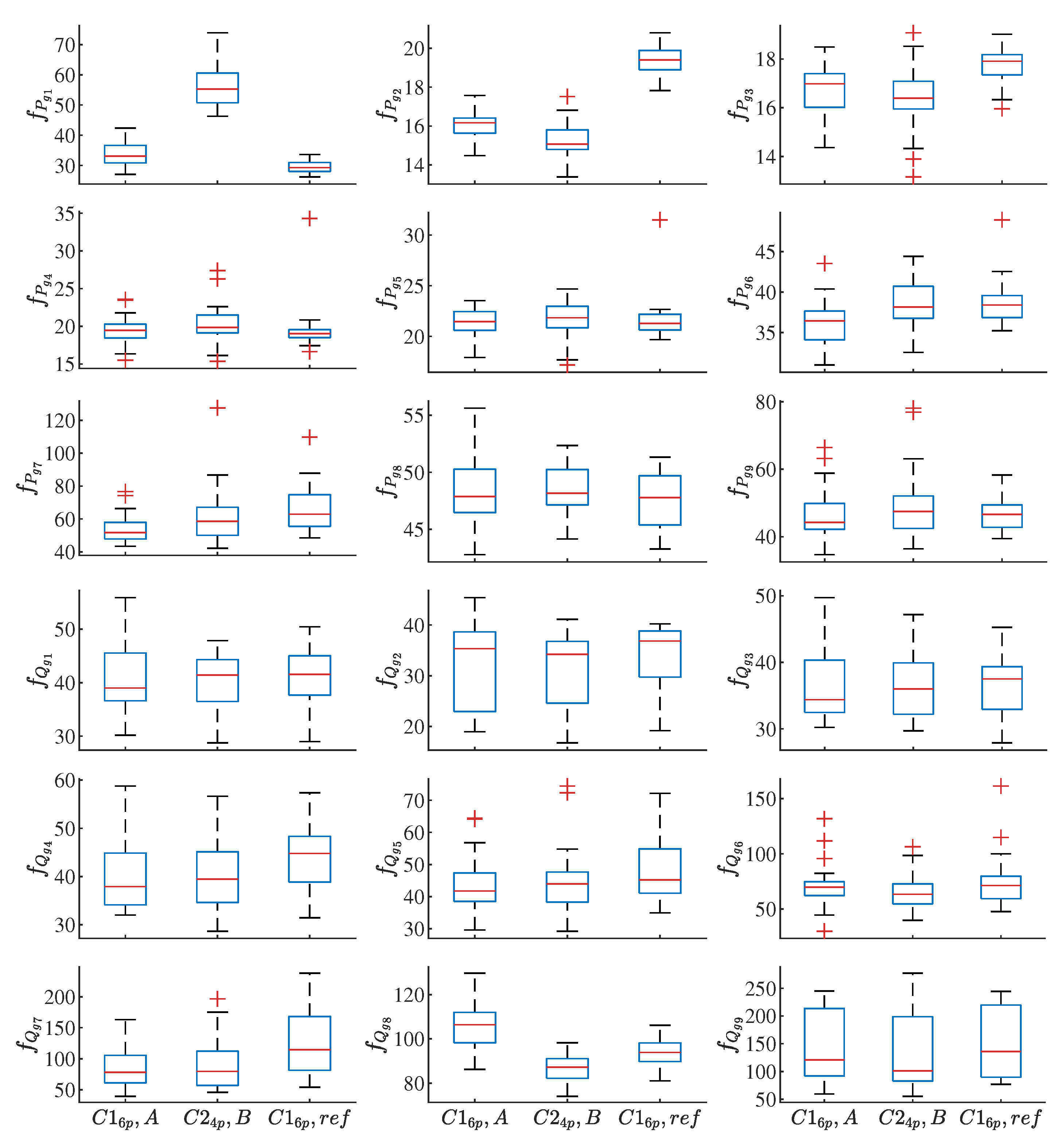

With the aim of experimentally verifying these conclusions on a physical prototype, two specific controllers (one for each design concept) are selected, which present similar performances in simulation. These controllers, as well as the reference 2-SMC one, are tested 30 times each in the physical prototype. A statistical analysis of the obtained results is carried out, which confirms the conclusions derived from the simulation.

The rest of the paper is structured as follows:

Section 2 is devoted to presenting the two variants of the 2-SMC algorithm adopted to command the GSCs of DFIGs, as well as the MOO tools to be used in order to tune their respective parameters. In

Section 3, the framework designed to tackle the MOO-based tuning of said parameters is described in depth. Both simulation and experimental results derived from such MOO-assisted parameter tuning are provided and interpreted in

Section 4. Finally,

Section 5 draws the conclusions.

2. Theoretical Considerations

2.1. DFIG-Based Wind Turbine

Figure 1 shows the general structure of a DFIG-based wind turbine. Like any other wind turbine topology able to operate at variable speed, in addition to the electric generator, it is equipped with a power converter stage which, when adequately commanded, enables full control of the active and reactive powers interchanged with the electricity grid. Thereby, the stator of the generator is directly connected to the grid, whereas its rotor is linked to the power converter stage. Essentially, the latter comprises two identical three-phase, two-level VSCs—named the rotor-side converter (RSC) and the GSC—linked to each other by means of a DC bus. Likewise, the GSC is connected to the electricity grid through an L-type filter.

Although each power converter possesses its own control algorithm, certain co-ordination between them is required to satisfy the specific control targets, related to the overall wind turbine performance, that arise during electricity network disturbances.

Even if the present study is solely focused on the GSC control algorithm, the control goals of both converters are detailed next, aiming at providing a clear insight into the task of controller parameter tuning that is to be faced.

2.1.1. RSC and GSC Control Targets

The RSC control system is in charge of governing the active and reactive powers interchanged between the stator of the generator and the grid (

and

, respectively). According to the maximum power point tracking (MPPT) curve [

20], the higher the speed of rotation of the wind turbine, the higher the average value of the stator active power set-point,

, should be.

During grid disturbances (e.g., imbalances, harmonics, or both) though, in order to prevent harmful fluctuations in the electromagnetic torque of the generator, it is necessary to add an oscillating active power component to the aforementioned set-point average value. Accordingly, the reference value of the stator active power can be expressed as the sum of two terms; that is, .

In contrast, the stator reactive power set-point, , does not fluctuate and, unless the system operator asks for a different value, it is kept near to zero most of the time. This guarantees a power factor close to unity.

With regard to the GSC control system, it is designed to command the instantaneous active and reactive powers flowing between the GSC and the grid (

and

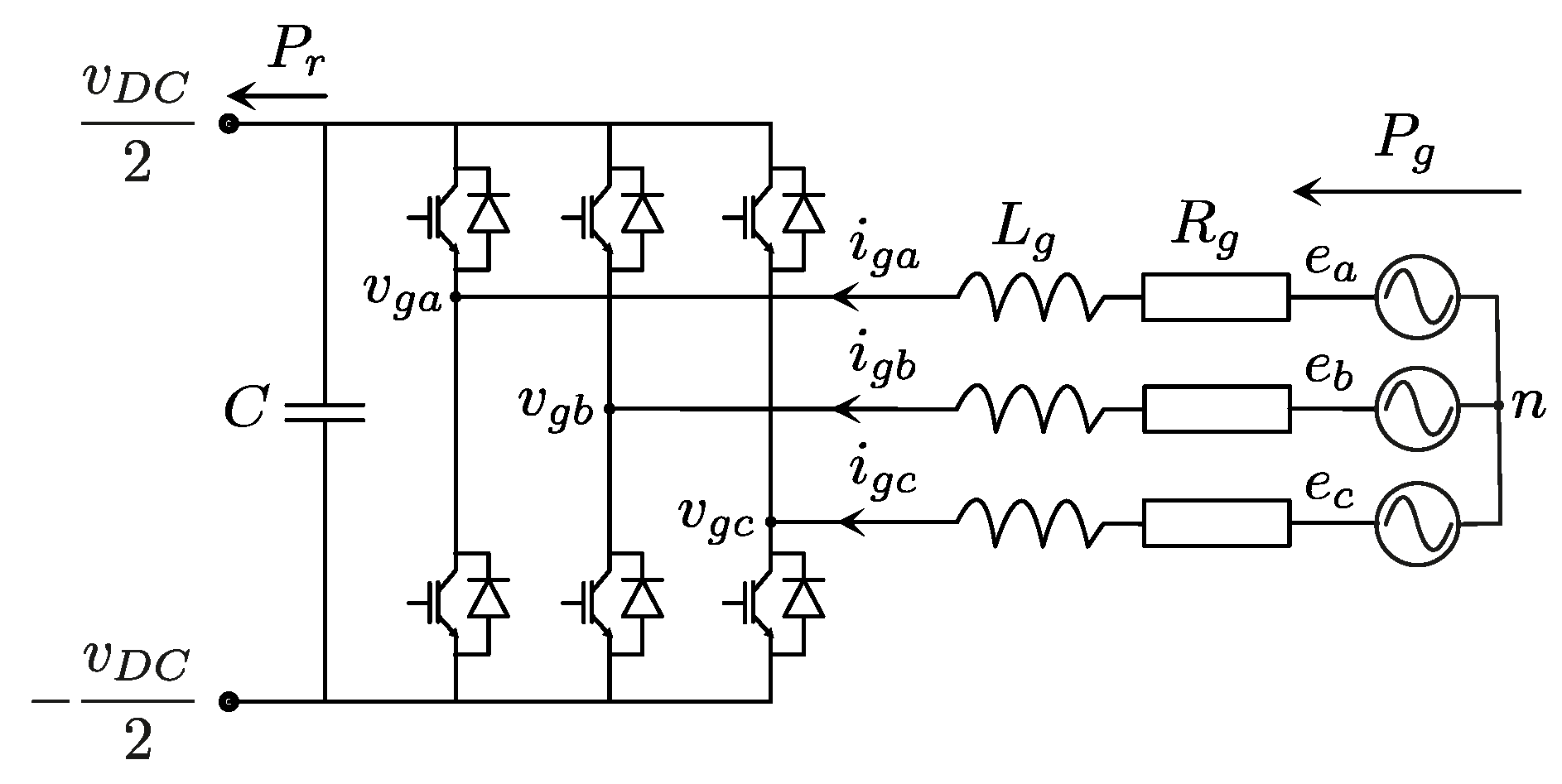

, respectively). In particular, the functional diagram displayed in

Figure 2 corresponds to the GSC control algorithm adopted in this work, where “CLARKE” and “CLARKE

” stand for the Clarke’s and inverse Clarke’s transforms, respectively [

21]. This algorithm must be implemented from the outer to the inner layer of the diagram; labelled, respectively, as “1st Step” and “3rd Step” at their bottom left-hand corners. In coherence with the latter, it is assumed that any variable present in a given layer of the diagram is also available to the layers inside.

As in many other works [

11], the active power set-point,

, is established by an integral-proportional (I-P) controller aimed at keeping the DC-link voltage steady at its rated value. Again, the reactive power set-point,

, is usually fixed to zero under non-faulty conditions.

Pushed by increasingly demanding grid codes, during grid voltages subject to imbalances or harmonic pollution, the GSC control system accomplishes additional control targets, the following two being the most common, as well as incompatible with each other [

11,

22,

23]:

To add on an oscillating active power term, , that compensates for the above-mentioned oscillatory component of the stator active power, , at the point where the DFIG is connected to the grid. As a result, a non-fluctuating total active power, , is achieved by the whole wind turbine.

To compensate the stator current imbalance and/or harmonic distortion, if any, thus balancing the overall current injected by the wind turbine into the grid and/or decreasing its THD as far as possible, respectively.

The first strategy is precisely the one adopted throughout this paper. As a result, not only the total active and reactive powers, and , remain free of fluctuations, but also DC-link voltage oscillations are avoided (which is not possible with the second strategy). In return, in comparison with the approach numbered above as 2, the THD of the overall current injected into the grid turns out to be higher.

Thereby, for the selected strategy, the reference value of the grid-side active power is computed as follows [

11]:

where

depends on variables related to the electric generator, and may be estimated as

with

and

being the generator electromagnetic torque and rotational speed, respectively.

The output of each power converter’s control system is the three-phase voltage, to be applied by said converter at its AC side. Thus, fixing the appropriate three-phase AC voltage, the aforementioned active and reactive powers can be governed. However, as is usual in three-phase AC power systems, both the RSC and GSC control algorithms are designed, as well as run, in the so-called vector space.

Thus, it is important to clarify that, in the case at hand, the control signals generated by the 2-SMC algorithm under study correspond to the stationary-frame d-q components of the GSC output voltage.

2.1.2. GSC and Grid Filter Modelling

According to

Figure 3, adopting the rectifier convention and expressing all variables in the stationary reference frame, the grid-side active and reactive powers can be derived as follows:

with

,

, and

,

being, respectively, the direct- and quadrature-axis components of the grid voltage and current. The dynamics of the latter have been provided, in [

11], as

where

and

denote the outputs of the GSC control algorithm, while

and

represent the equivalent resistance and inductance of the grid filter, respectively. Given that such filter is assumed to be of type L,

is typically close to zero.

2.2. 2-SMC Scheme Adopted for the GSC

2.2.1. Switching Functions Selected

Considering that

and

are the variables to be controlled, the following two switching functions are defined:

where the integral terms are aimed at steering possible steady-state errors to zero [

24]. Regarding the weighting constants

and

, which need to be tuned, two alternatives will be explored in this paper; namely:

To assume they both can take any strictly positive value. Specifically, MOO is applied in this work in order to select and from within a wide range of possible values.

To force them to zero, hence simplifying both switching functions and, in turn, the global control scheme for the GSC.

2.2.2. Control Laws

Taking the time derivatives of Equations (

7) and (

8), and making use of Equations (

3)–(

6), the following dynamics arise for the switching functions

and

:

where

As proposed in [

11], the control signals

and

are computed as a summation of two terms; namely:

The “super-twisting” (ST) control term, intended to attain high-performance closed-loop dynamics, ability for disturbance rejection, and robustness in the face of uncertainties, both structured and unstructured.

The equivalent control term, incorporated with the main purpose of reducing the control effort to be made by the ST algorithm.

The preceding approach may be mathematically expressed as

After forcing

in Equation (

9), the equivalent control term is derived by simply solving for

and

in said expression, which gives rise to

where the matrix

is invertible, except for the case in which

, corresponding to a null grid voltage. Assuming that the sliding regime is reached (i.e.,

),

would allow for preserving it in the absence of disturbances, as well as under both parametric and modelling uncertainties.

However, depending on the specific shapes of both

and

, their respective

and

time derivatives, present in

by virtue of Equations (

10) and (

11), are likely to bring noise, and even derivative kicks, into the

equivalent control term. Therefore, in order to elude such a jeopardy,

is considered in Equation (

13) [

22].

In any case, the inaccuracies made due to that design simplification, as well as the high parameter dependency evidenced by the equivalent control in Equation (

13), do not compromise the robustness of the global control algorithm in Equation (

12), as said robustness relies on the ST control term that follows:

with

The terms of the form , where or , are responsible for ensuring the achievement of the sliding regime in finite time.

It should be noted that there are six parameters to be tuned; namely:

,

,

,

,

, and

. Nonetheless, as already stated at the end of

Section 2.2.1, the option of forcing

will also be explored, which leads to a simplified version of the GSC control algorithm with just four parameters:

,

,

, and

.

2.3. Multi-Objective Optimisation

A MOOP with

m objectives to minimise can be stated as follows [

25]:

subject to

where

is the decision vector, with

;

is the objective vector;

and

are the inequality and equality constraint vectors, respectively; and

and

are the lower and upper bounds in the

D decision space, respectively.

As the objectives of a MOOP are usually in opposition, there is typically no single solution that minimises all the objectives. Instead, there will exist a set of Pareto optimal solutions (i.e., non-dominated solutions).

Definition 1. (Pareto optimality [25]): An objective vector is Pareto optimal if there is no other objective vector such that for all and , for at least one j, . Definition 2. (Dominance [26]): An objective vector is dominated by another objective vector iff for all and , for at least one j, . This is denoted as . Therefore, the set of solutions (the Pareto set) is defined as follows:

Definition 3. (Pareto set, ): The Pareto set is the set of all solutions in D that are not dominated by any other solution in D: Each solution in the Pareto set defines an objective vector in the Pareto front.

Definition 4. (Pareto front, ): Given a set of Pareto optimal solutions , the Pareto front is defined as Usually,

contains an infinite number of solutions and, for this reason, it is not possible to completely obtain it. The way to proceed is to obtain a discrete set

, in such a way that

characterises

. Note that the set

is not unique. In this work, the ev-MOGA algorithm (Available at

https://es.mathworks.com/matlabcentral/fileexchange/31080-ev-moga-multiobjective-evolutionary-algorithm) [

13] will be used to obtain the Pareto front approximations.

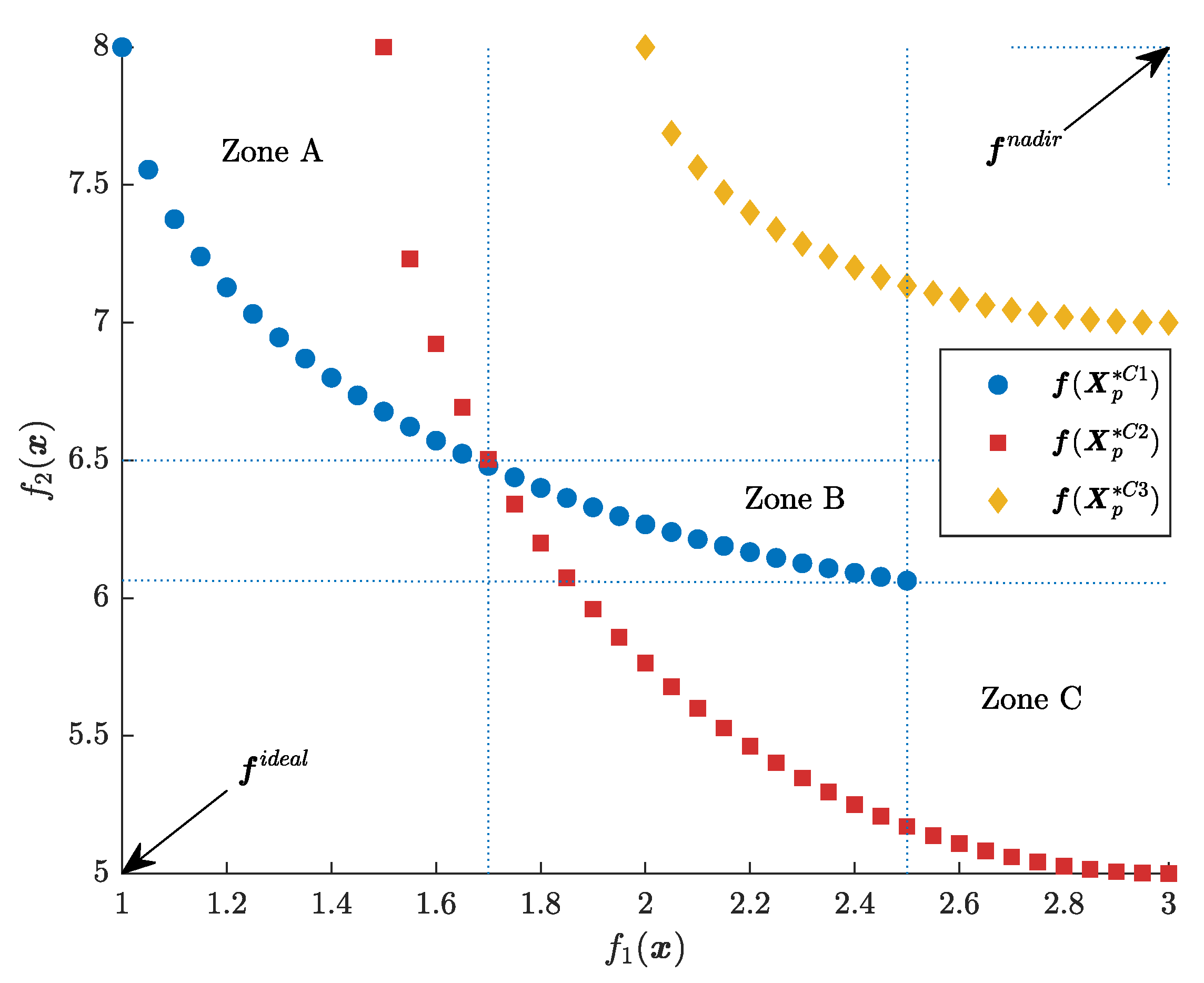

Figure 4 shows an example of characterisation of a bi-objective Pareto front and its corresponding Pareto set.

2.4. Comparison of Design Concepts Under MOO Approach

It is very common that several design alternatives (i.e., design concepts),

C, are proposed, in order to solve a specific problem. Each design concept might, for example, represent a different control structure. Comparing the different concepts in a multi-objective scenario allows for differentiating the strengths and weaknesses of each of them, in relation to the chosen objectives [

25,

27]. To do so, a MOOP is set for each design concept,

, such that all MOOPs share the same objectives,

, but each of them has its own decision vector,

, related to the parameterisation of its corresponding design concept. Therefore, if

s design concepts need to be compared, the MOOPs can be stated as

subject to

with

. For each design concept,

is the decision vector;

and

are the inequality and equality constraint vectors, respectively; and

and

are the lower and upper bounds delimiting the searching space, respectively. In contrast, the objective vector

is common to the

s MOOPs.

After optimising each multi-objective problem, a discrete Pareto set,

, and its corresponding Pareto front,

, are obtained for each design concept. Thanks to the fact that all of the MOOPs share the same objectives, a comparison in the

m-objective space can be made. This idea is illustrated in

Figure 5, where the Pareto fronts of three design concepts are depicted in a bi-objective optimisation problem. By analysing the figure, it is possible to notice the following:

Design concept 3 is dominated by design concepts 1 and 2. Therefore, the latter two will be preferred.

Depending on designer preferences, design concept 1 or 2 may be preferred.

Zone C (values of ) is only reachable by design concept 2. Consequently, if the designer demands such a trade-off, design concept 2 would be the right one.

In Zone B (), design concept 2 dominates design concept 1. As a result, design concept 2 will be preferred over design concept 1.

The opposite to what occurs in Zone B is observable in Zone A (). Design concept 2 is dominated by design concept 1 and, thus, the latter will be preferred.

2.5. LDs for Design Concept Comparison

In order to efficiently compare design concepts in an

m-dimensional objective space, an adequate visualisation method is required. Among the several methods provided in the literature [

28], the interactive tool referred to as LDs [

15,

16,

29] is employed in this work.

Second, the p-norm is applied to each normalised point. Typical norms are: (1) Taxicab norm—also called Manhattan norm—, ; (2) Euclidean norm, ; and (3) infinity norm—also known as maximum norm—, .

After that, the LD tool provides a two-dimensional graph for each objective and decision variable. On the abscissa axis of each graph, the values for each objective or decision variable are represented, while the ordinate axes of all graphs display the p-norm previously calculated for each solution. The latter allows graphics to stay synchronised, by means of their ordinate axes (meaning that each given solution of a design concept presents identical ordinate value in every graph) and, therefore, helps to compare solutions according to the selected norm.

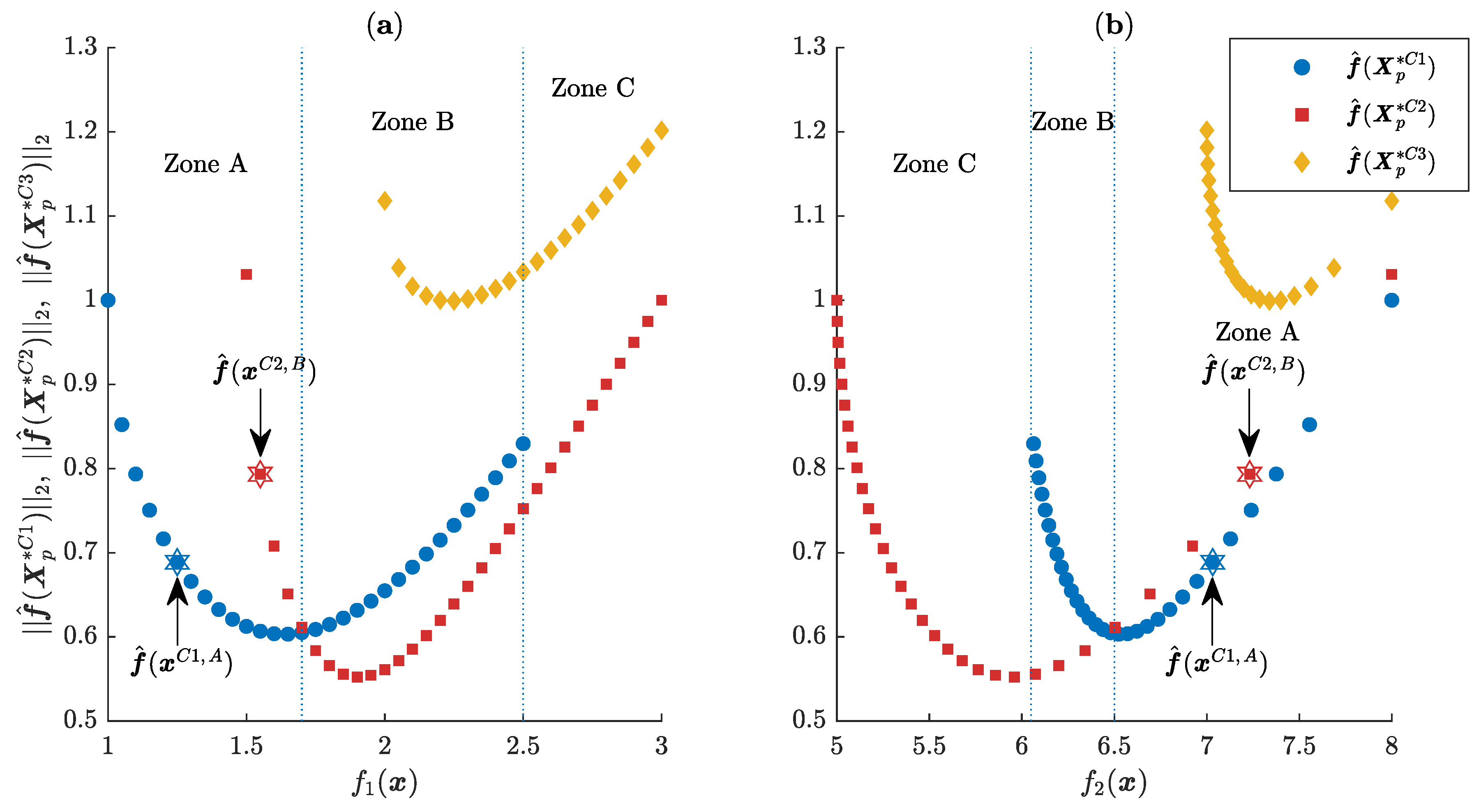

Adopting the Euclidean norm,

Figure 6 shows the LD corresponding to the same three design concepts presented in

Figure 5. Given that, similarly to

Figure 5, the search space is not contemplated, only two graphs associated to the objective space are provided, which corresponds to the bi-objective problem considered. The A, B, and C zones have been marked, in order to demonstrate their correspondence with the same zones displayed in

Figure 5. It can be noticed that the solutions of design concept 2 are the closest to

, as they present lower values of

.

Two solutions, from design concept 1 and from design concept 2, have been highlighted. Although they both present low values of and high values of , it is clearly observable that dominates . It should be noted that, when more than three objectives are considered, it becomes difficult to appreciate such relations using classical visualisation tools.

5. Conclusions

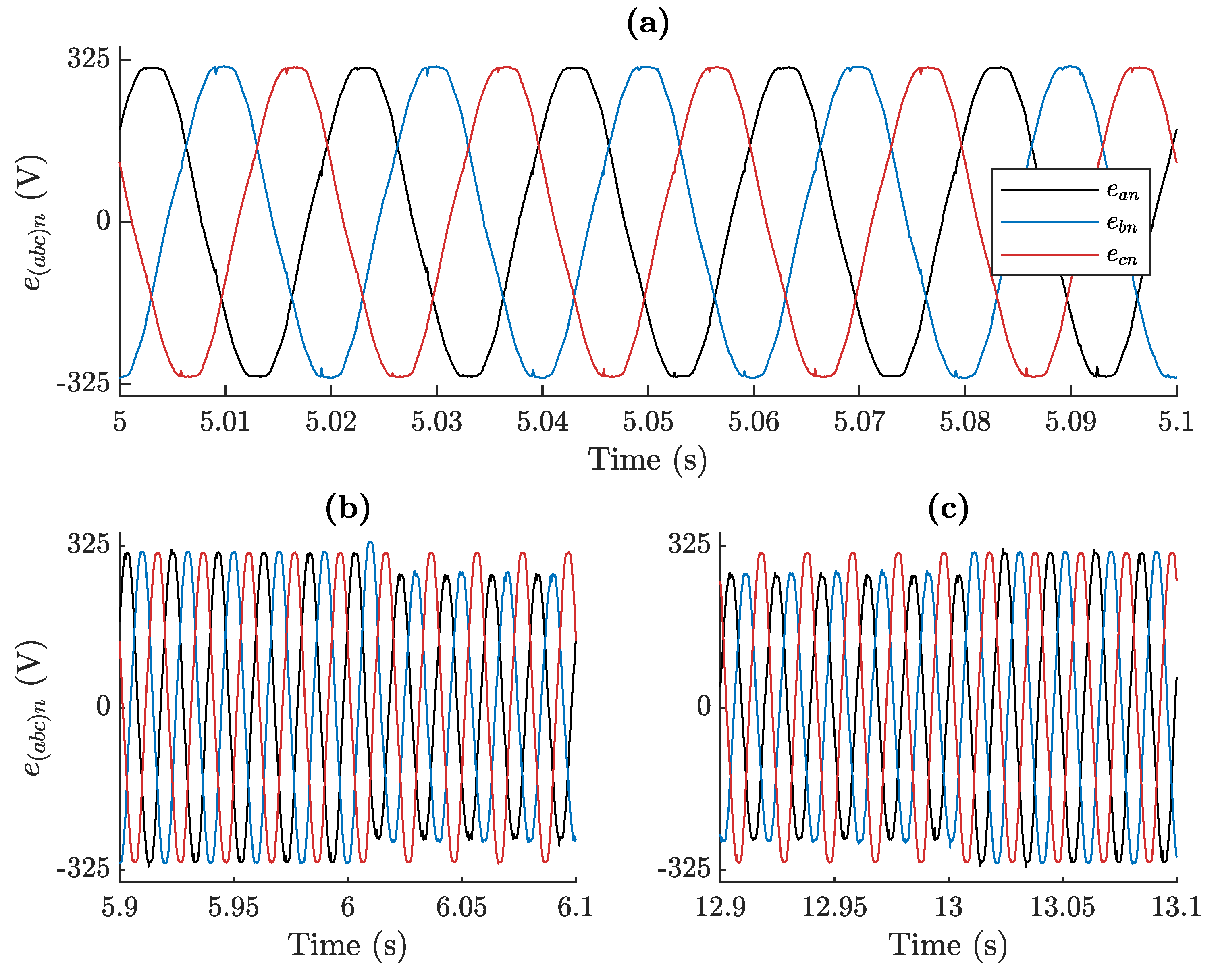

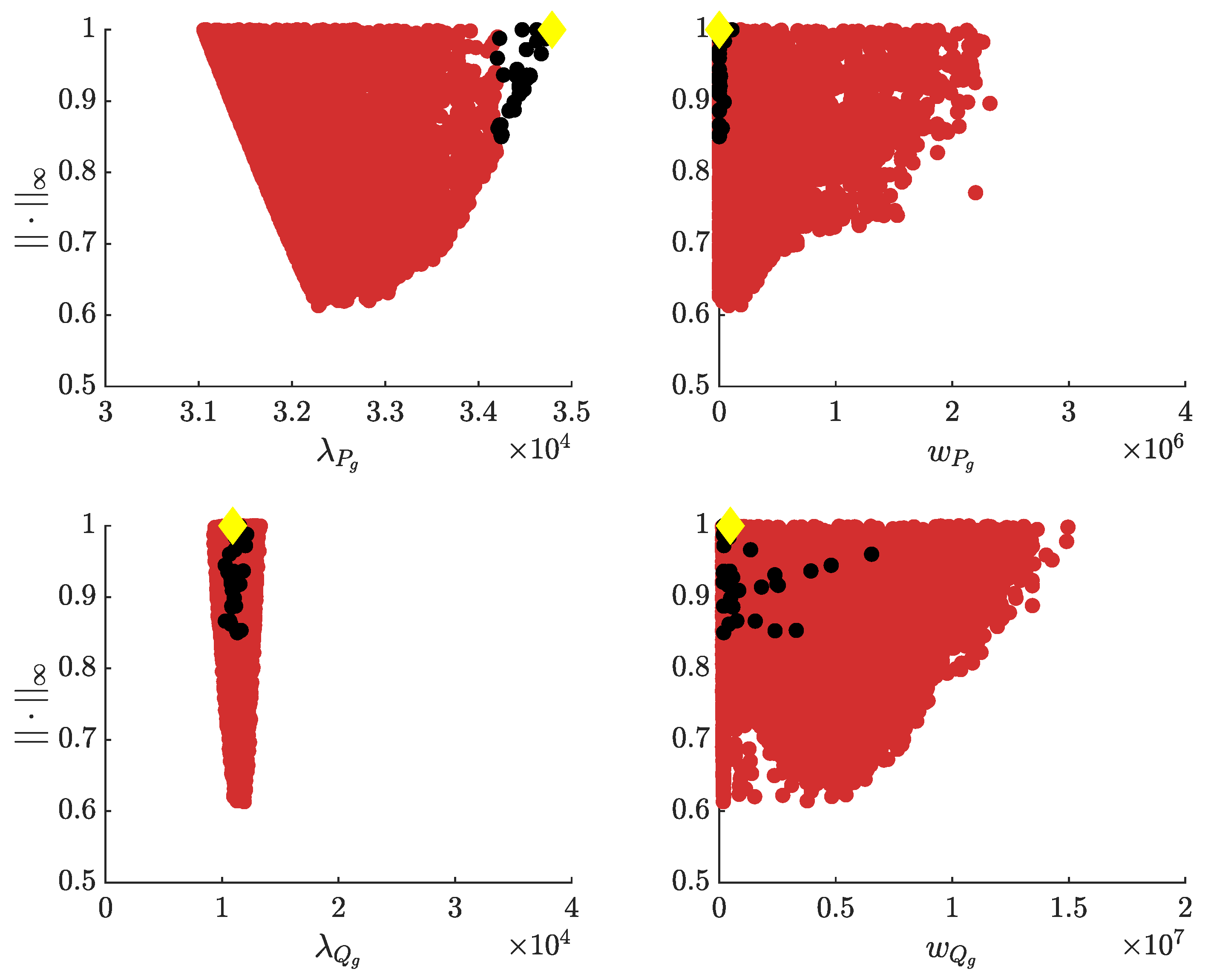

With the aim of tuning the parameters of a 2-SMC scheme commanding the GSC of a DFIG, an a posteriori MOO approach has been presented and successfully applied in this paper, both in simulation and experimentally. Two variants (i.e., design concepts) of the same 2-SMC algorithm, which only differed in the switching functions adopted, were tuned and their respective performances were compared to each other. The first algorithm contained six parameters to be tuned, while the second, whose switching functions were simplified versions of those defined for the first one, contained just four. The grid voltage was assumed to be continuously harmonically polluted, as well as subject to imbalances. In this context, the tuning process was carried out in such a way that a single set of controller parameters was valid for nine possible operating regimes of the DFIG, three of which were directly related to the appearance of imbalances in the grid voltage.

In particular, two performance indices, and , were defined for each of those nine operating regimes, which, respectively, quantify to what extent the reference values set for the grid active and reactive powers were complied with. As a result, the MOOP, on which the tuning is based, was set out by considering 18 indices in total. Driven by the high number of indices to be accounted for, the interactive tool of LDs was employed during the decision-making stage, with the purpose of facilitating analysis of the Pareto fronts (trade-off among objectives) and assisting selection of the preferred parameter sets.

The optimisation process gave rise to a Pareto front for each of the two design concepts considered. Analysis of those two Pareto fronts led to the following conclusions:

Taking a set of experimentally validated parameters as starting point, multiple solutions to the MOO-based tuning problem were found, through simulation, by demanding that each and every one of the 18 performance indices they lead to were better than those obtained when applying the baseline parameter set.

As expected, trade-offs among some of the performance indices, with , became evident. In contrast, the compromise between indices and was found to be not as marked as intuitively thought beforehand.

Although a number of solutions for the six-parameter 2-SMC algorithm behaved slightly better than those corresponding to the four-parameter variant for five of the performance indices, they also gave poorer values for another three. In summary, the six-parameter variant of the 2-SMC algorithm does not dominate that of four-parameter variant.

Considering the designer preferences, two sets of parameters (one from each design concept) were selected and compared experimentally to each other, as well as to the baseline parameter set. To that end, aiming at reducing the impact that the variability of the harmonic distortion present in the grid voltage can have on the performance indices, each of those three parameter sets underwent the same test 30 times.

A statistical analysis of the results derived from the total of 90 experimental tests carried out allows us to draw the following main conclusions:

In good logic, it has been corroborated that the two solutions selected globally improve the performance of the parameter set adopted as a baseline solution.

Performances comparable to those resulting from application of the six-parameter 2-SMC algorithm are achievable by using its simplified four-parameter version.