Biodiesel Production from Reutealis Trisperma Oil Using KOH Impregnated Eggshell as a Heterogeneous Catalyst

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Catalyst Preparation and Characterization

2.3. Transesterification of Reutalism Trisperma Oil

3. Results and Discussion

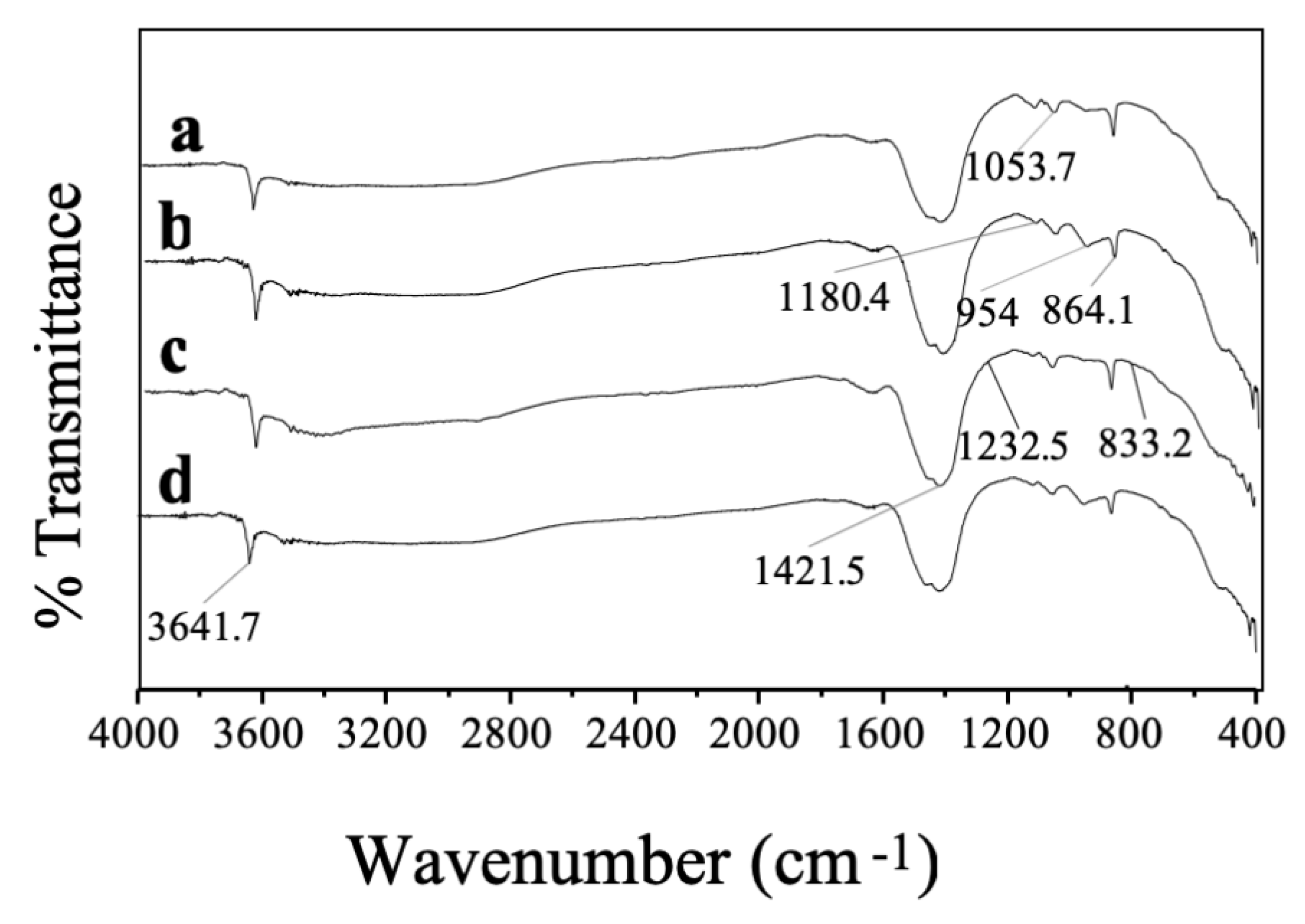

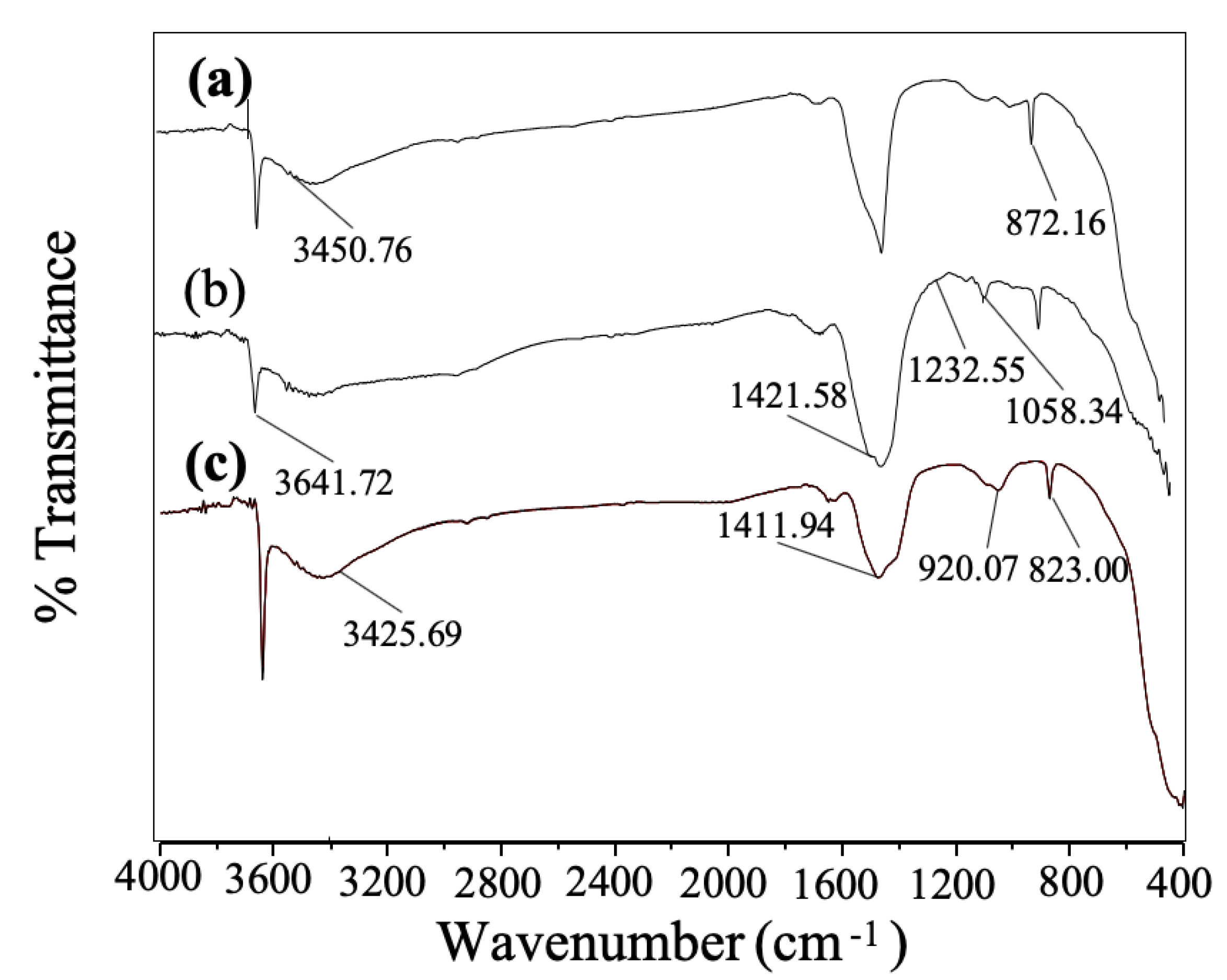

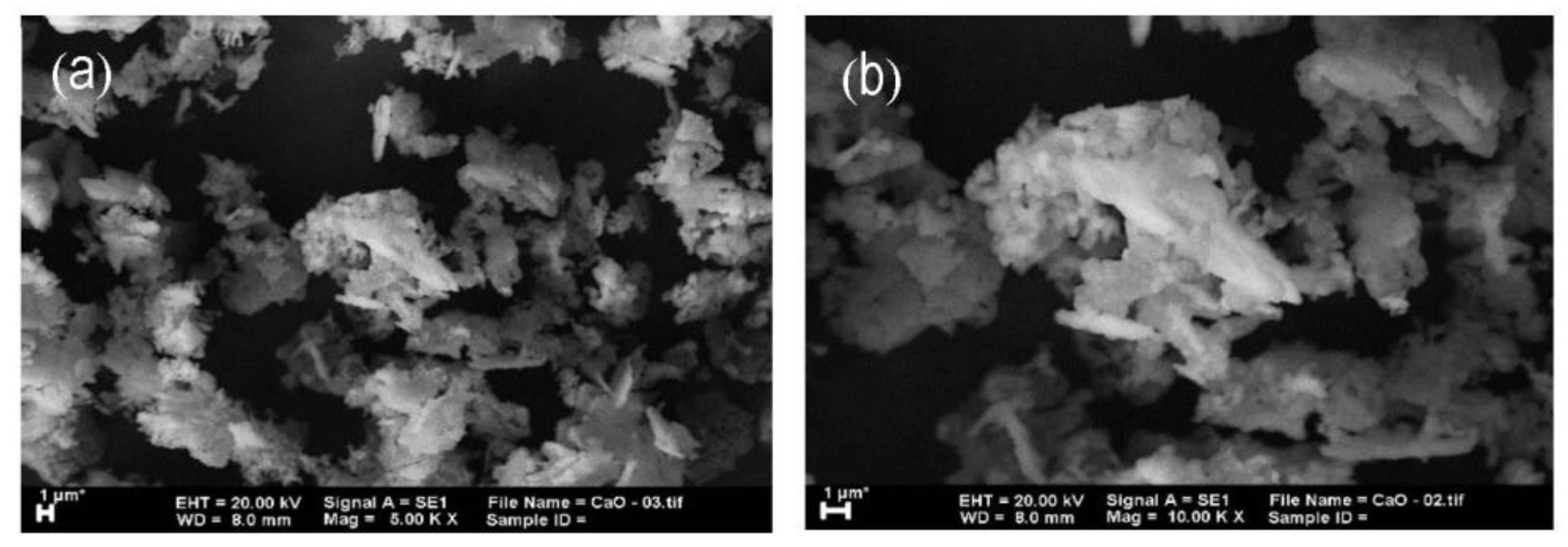

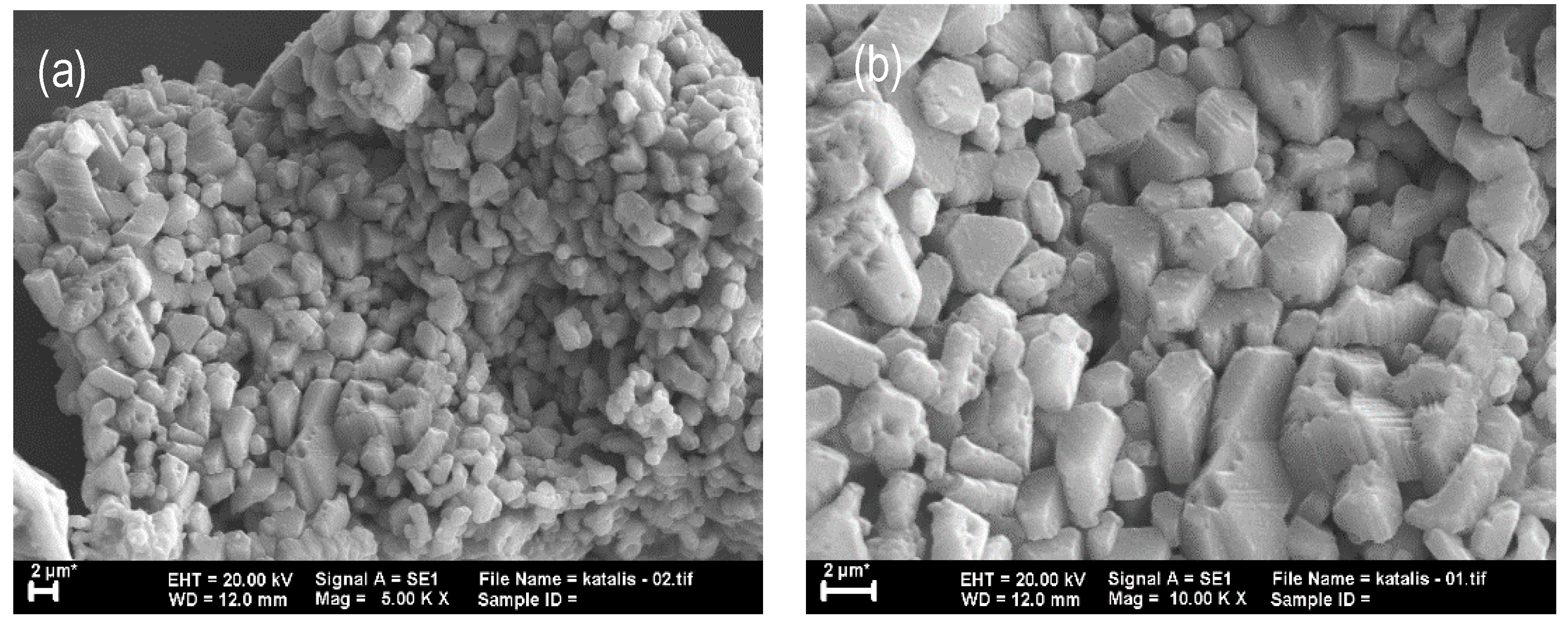

3.1. Characterization of the Catalyst

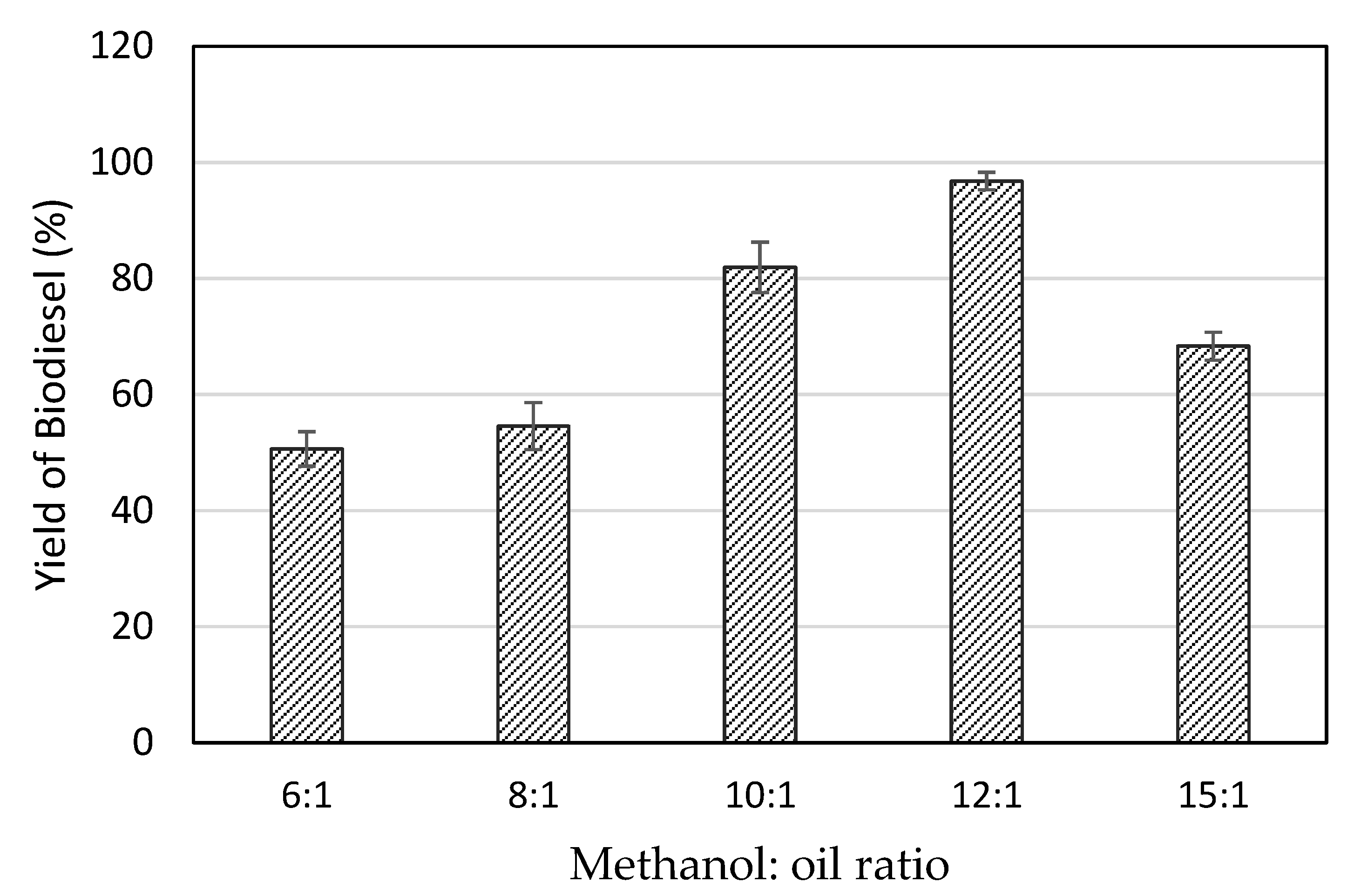

3.2. Effect of Methanol to Oil Molar Ratio

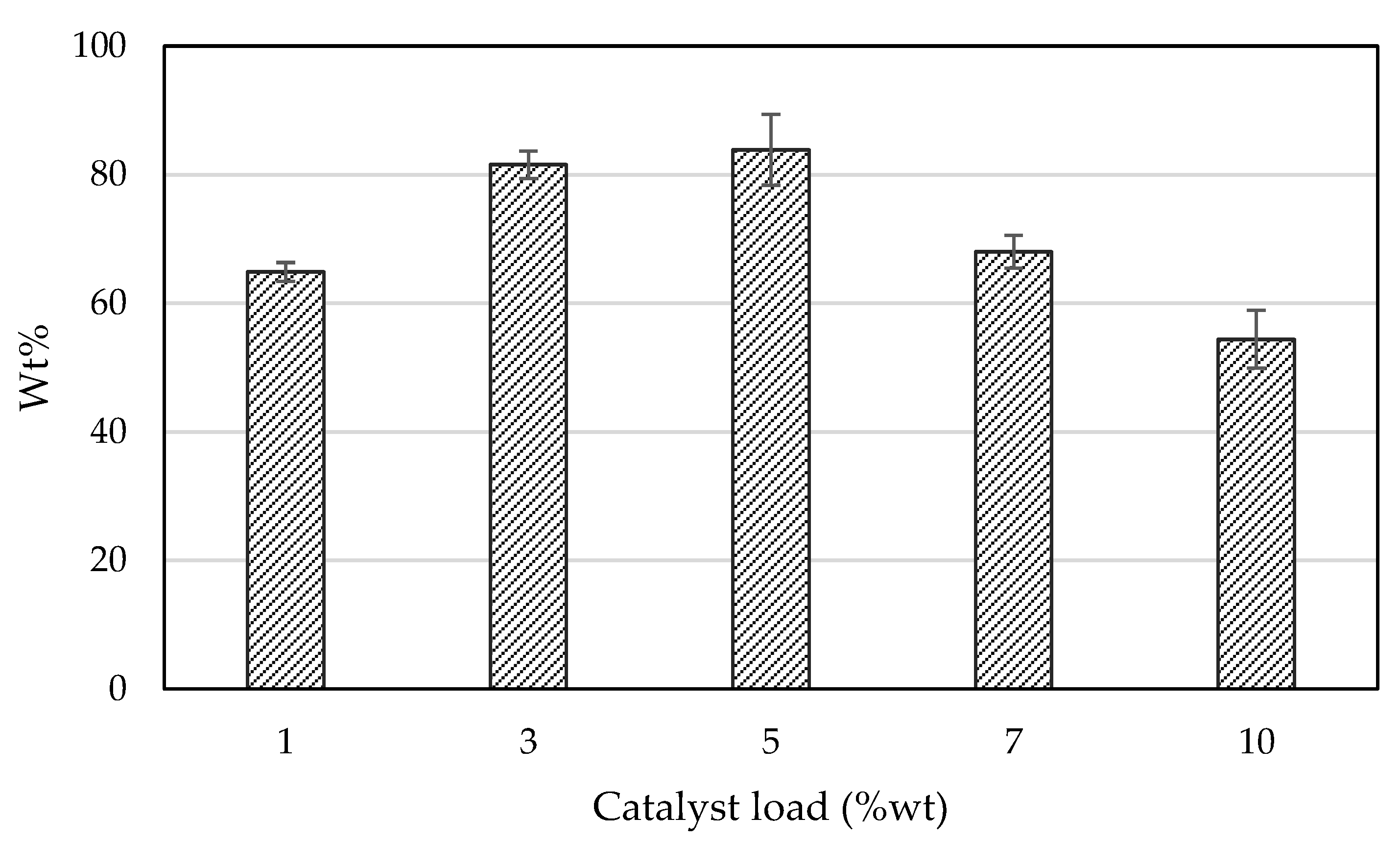

3.3. Effect of Catalyst Loading

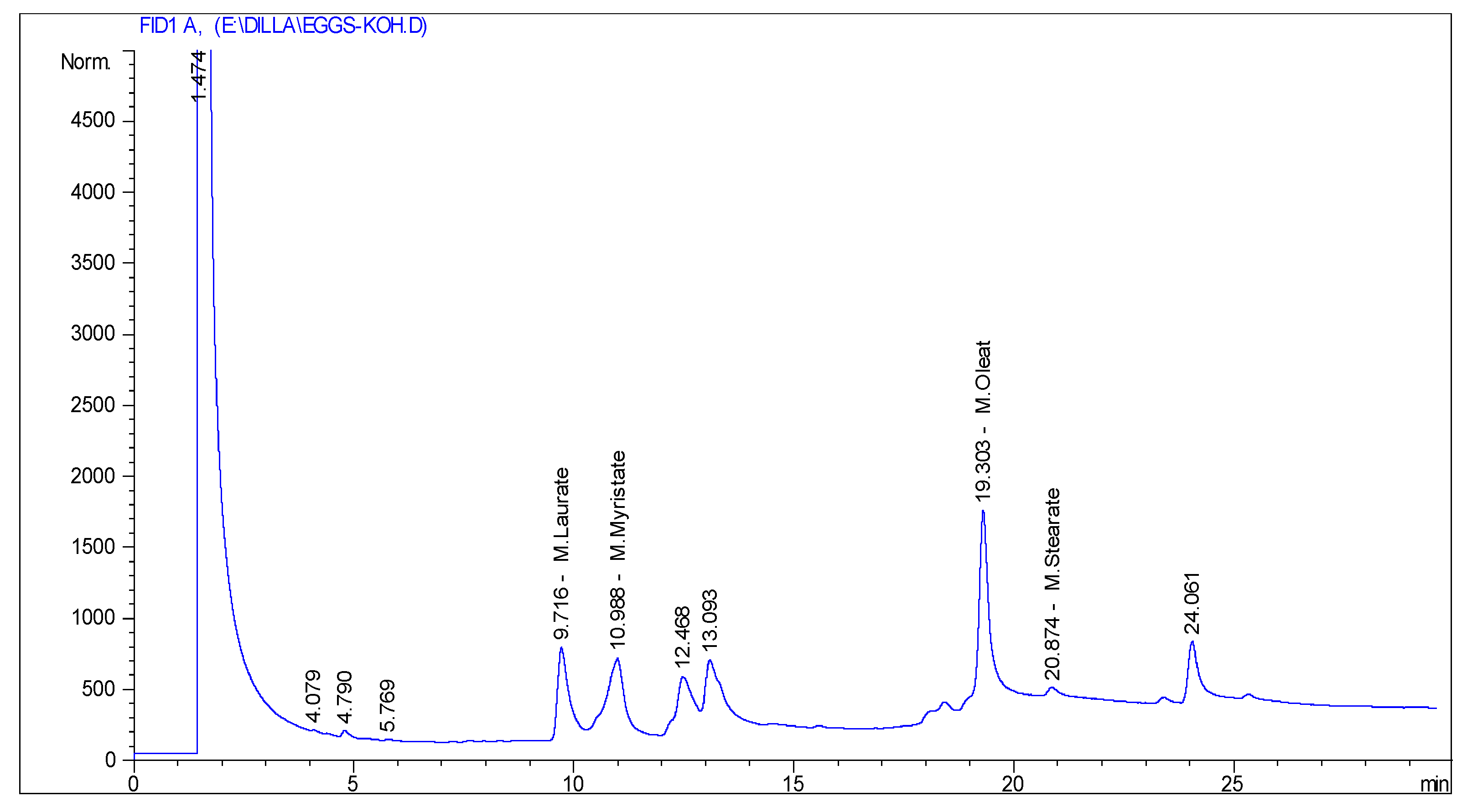

3.4. Properties of Biodiesel

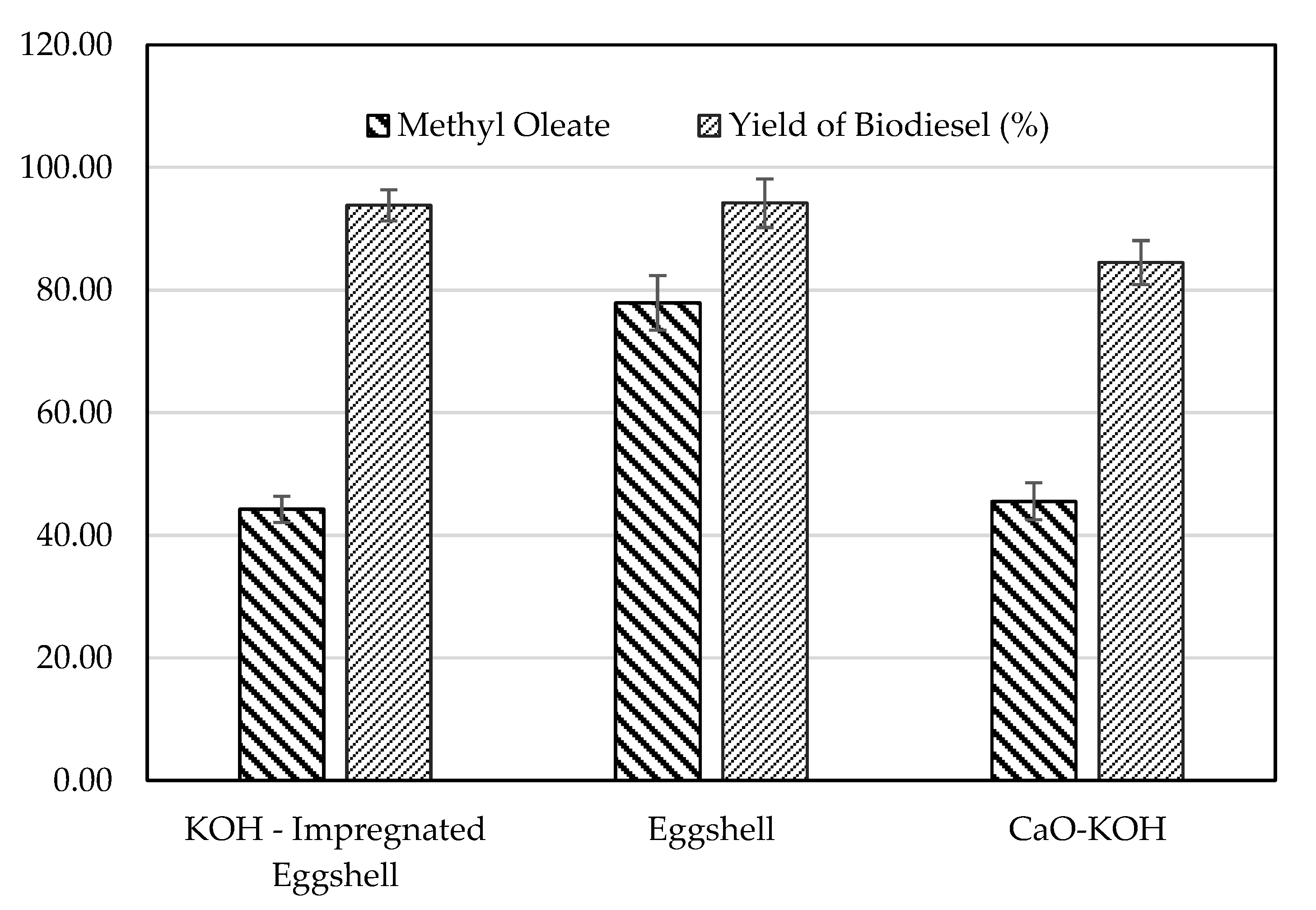

3.5. Catalytic Activity

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yadav, M.; Singh, V.; Sharma, Y.C. Methyl Transesterification of Waste Cooking Oil Using a Laboratory Synthesized Reusable Heterogeneous Base Catalyst: Process Optimization and Homogeneity Study of Catalyst. Energy Convers. Manag. 2017, 148, 1438–1452. [Google Scholar] [CrossRef]

- Farooq, M.; Ramli, A. Biodiesel Production from Low FFA Waste Cooking Oil Using Heterogeneous Catalyst Derived from Chicken Bones. Renew. Energy 2015, 76, 362–368. [Google Scholar] [CrossRef]

- Pasupulety, N.; Gunda, K.; Liu, Y.; Rempel, G.L.; Ng, F.T.T. Production of Biodiesel from Soybean Oil on CaO/Al2O3 Solid Base Catalysts. Appl. Catal. A Gen. 2013, 452, 189–202. [Google Scholar] [CrossRef]

- Kusmiyati, K.; Pratiwi, T.R.; Wulandari, T. Waste Fish Oil Biodiesel Production and Its Performance in Diesel Engine. ARPN J. Eng. Appl. Sci. 2016, 11, 1040–1044. [Google Scholar]

- Holilah, H.; Prasetyoko, D.; Oetami, T.P.; Santosa, E.B.; Zein, Y.M.; Bahruji, H.; Ediati, R.; Juwari, J. The Potential of Reutealis Trisperma Seed as a New Non-Edible Source for Biodiesel Production. Biomass Convers. Biorefin. 2014, 5, 347–353. [Google Scholar] [CrossRef]

- Kumar, K.R.; Chandrika, K. Biodiesel Production and Characterization from Non-Edible Oil Tree Species Aleurites Trisperma Blanco. Biomass Convers. Biorefin. 2014, 5, 287–294. [Google Scholar] [CrossRef]

- Hadiyanto, H.; Lestari, S.P.; Widayat, W. Preparation and Characterization of Anadara Granosa Shells and CaCO3 as Heterogeneous Catalyst for Biodiesel Production. Bull. Chem. React. Eng. Catal. 2016, 11, 21–26. [Google Scholar] [CrossRef]

- Sanjay, B. Heterogeneous Catalyst Derived from Natural Resources for Biodiesel Production: A Review. Res. J. Chem. Sci. 2013, 3, 95–101. [Google Scholar]

- Sneha, E.M.; Ramanathan, A.; Begum, K.M.M.S.; Narayanan, A. Biodiesel Production from Waste Cooking Oil Using KBr Impregnated CaO as Catalyst. Energy Convers. Manag. 2015, 91, 442–450. [Google Scholar]

- Lesbani, A.; Tamba, P.; Mohadi, R. Preparation Of Calcium Oxide From Achatina Fulica As Catalyst For Production Of Biodiesel From Waste Cooking Oil. Indones. J. Chem 2013, 13, 176–180. [Google Scholar] [CrossRef]

- Wei, Z.; Xu, C.; Li, B. Application of Waste Eggshell as Low-Cost Solid Catalyst for Biodiesel Production. Bioresour. Technol. 2009, 100, 2883–2885. [Google Scholar] [CrossRef] [PubMed]

- Zeng, D.; Zhang, Q.; Chen, S.; Liu, S.; Chen, Y.; Tian, Y.; Wang, G. Preparation and Characterization of a Strong Solid Base from Waste Eggshell for Biodiesel Production. J. Environ. Chem. Eng. 2015, 3, 560–564. [Google Scholar] [CrossRef]

- Suprapto, S.; Fauziah, T.R.; Sangi, M.S.; Oetami, T.P.; Qoniah, I.; Prasetyoko, D. Calcium Oxide from Limestone as Solid Base Catalyst in Transesterification of Reutealis Trisperma Oil. Indones. J. Chem. 2016, 16, 208–213. [Google Scholar] [CrossRef]

- Liao, C.C.; Chung, T.W. Optimization of Process Conditions Using Response Surface Methodology for the Microwave-Assisted Transesterification of Jatropha Oil with KOH Impregnated CaO as Catalyst. Chem. Eng. Res. Des. 2013, 91, 2457–2464. [Google Scholar] [CrossRef]

- Turco, F.; Davit, P.; Cossio, R.; Agostino, A.; Operti, L. Accuracy Improvement by Means of Porosity Assessment and Standards Optimization in SEM-EDS and XRF Elemental Analyses on Archaeological and Historical Pottery and Porcelain. J. Archaeol. Sci. Rep. 2017, 12, 54–65. [Google Scholar] [CrossRef]

- Bahadur, S.; Goyal, P.; Sudhakar, K. Ultrasonic Assisted Transesterification of Neem Oil for Biodiesel Production. Energy Sources Part A Recovery Util. Environ. Eff. 2015, 37, 1921–1927. [Google Scholar] [CrossRef]

- Mar, W.W.; Somsook, E. Methanolysis of Soybean Oil over KCl/CaO Solid Base Catalyst for Biodiesel Production. Sci. Asia 2012, 38, 90–94. [Google Scholar] [CrossRef]

- Granados, L.M.; Poves, Z.M.D.; Alonso, M.D.; Mariscal, R.; Galisteo, C.F.; Tost, M.R.; Santamaria, J.; Fierro, G.L.J. Biodiesel from Sunflower Oil by Using Activated Calcium Oxide. Appl. Catal. B Environ. 2007, 73, 317–326. [Google Scholar] [CrossRef]

- Correia, L.M.; Cecilia, J.A.; Castellón, E.R.; Cavalcante, C.L., Jr.; Vieira, R.S. Relevance of the Physicochemical Properties of Calcined Quail Eggshell (CaO) as a Catalyst for Biodiesel Production. J. Chem. 2017, 2017, 1–12. [Google Scholar] [CrossRef]

- Meher, L.C.; Kulkarni, M.G.; Dalai, A.K.; Naik, S.N. Transesterification of Karanja (Pongamia Pinnata). Eur. J. Lipid Sci. Technol. 2006, 108, 389–397. [Google Scholar] [CrossRef]

- Padhi, S.K.; Singh, R.K. Non-Edible Oils as the Potential Source for the Production of Biodiesel in India: A Review. J. Chem. Pharm. Res. 2011, 3, 39–49. [Google Scholar]

- Dehkordi, A.M.; Ghasemi, M. Transesterification of Waste Cooking Oil to Biodiesel Using Ca and Zr Mixed Oxides as Heterogeneous Base Catalysts. Fuel Process. Technol. 2012, 97, 45–51. [Google Scholar] [CrossRef]

- Obadiah, A.; Swaroopa, G.A.; Kumar, S.V.; Jeganathan, K.R. Biodiesel Production from Palm Oil Using Calcined Waste Animal Bone as Catalyst. Bioresour. Technol. 2012, 116, 512–516. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Fu, Y.J.; Qu, X.J.; Wang, W.; Luo, M.; Zhao, C.J.; Zu, Y.G. Biodiesel Production from Yellow Horn (Xanthoceras Sorbifolia Bunge.) Seed Oil Using Ion Exchange Resin as Heterogeneous Catalyst. Bioresour. Technol. 2012, 108, 112–118. [Google Scholar] [CrossRef] [PubMed]

- Fadhil, A.B.; Ahmed, K.M.; Dheyab, M.M. Silybum Marianum L. seed Oil: A Novel Feedstock for Biodiesel Production. Arab. J. Chem. 2012, 10, 683–690. [Google Scholar] [CrossRef]

| Material | Oxide (%) | |||||

|---|---|---|---|---|---|---|

| SO3 | K2O | CaO | Fe2O3 | CuO | SrO | |

| KOH-impregnated Eggshell (10 wt%) | 0.060 | 4.280 | 95.080 | 0.430 | 0.088 | 0.067 |

| KOH-impregnated Eggshell (15 wt%) | 0.000 | 4.300 | 95.000 | 0.290 | 0.240 | 0.180 |

| KOH-impregnated Eggshell (20 wt%) | 0.040 | 5.060 | 94.420 | 0.310 | 0.110 | 0.063 |

| KOH-impregnated Eggshell (25 wt%) | 0.000 | 12.000 | 87.600 | 0.130 | 0.170 | 0.120 |

| Eggshell | 0.010 | 0.400 | 99.390 | 0.130 | 0.048 | 0.026 |

| CaO-KOH (20 wt%) | 0.000 | 2.920 | 96.840 | 0.170 | 0.049 | 0.024 |

| Properties | Method | Unit | ASTM D56751 | R. Trisperma | Yellow Horn Seeda | Silyburn Maranumb |

|---|---|---|---|---|---|---|

| Density | ASTM D-1298 | kg/m3 | 860–900 | 890 | - | 914 |

| Viscosity | ASTM D-445 | mm2/s (cst) | 1.9–6.0 | 6.0 | 4.4 | 4.61 |

| Acid Value | ASTM D-664 | mg KOH/g | Max 0.8 | 0.5 | 0.06 | 0.08 |

| Flash Point | ASTM D-93 | °C | Min 130 | 148 | 165 | 230 |

| Cetane Number | ASTM D-613 | - | Min 47 | 62.5 | 56.1 | 34.04 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kusmiyati, K.; Prasetyoko, D.; Murwani, S.; Nur Fadhilah, M.; Oetami, T.P.; Hadiyanto, H.; Widayat, W.; Budiman, A.; Roesyadi, A. Biodiesel Production from Reutealis Trisperma Oil Using KOH Impregnated Eggshell as a Heterogeneous Catalyst. Energies 2019, 12, 3714. https://doi.org/10.3390/en12193714

Kusmiyati K, Prasetyoko D, Murwani S, Nur Fadhilah M, Oetami TP, Hadiyanto H, Widayat W, Budiman A, Roesyadi A. Biodiesel Production from Reutealis Trisperma Oil Using KOH Impregnated Eggshell as a Heterogeneous Catalyst. Energies. 2019; 12(19):3714. https://doi.org/10.3390/en12193714

Chicago/Turabian StyleKusmiyati, Kusmiyati, Didik Prasetyoko, Siwi Murwani, Muthiah Nur Fadhilah, Titie Prapti Oetami, Hadiyanto Hadiyanto, Widayat Widayat, Arief Budiman, and Achmad Roesyadi. 2019. "Biodiesel Production from Reutealis Trisperma Oil Using KOH Impregnated Eggshell as a Heterogeneous Catalyst" Energies 12, no. 19: 3714. https://doi.org/10.3390/en12193714

APA StyleKusmiyati, K., Prasetyoko, D., Murwani, S., Nur Fadhilah, M., Oetami, T. P., Hadiyanto, H., Widayat, W., Budiman, A., & Roesyadi, A. (2019). Biodiesel Production from Reutealis Trisperma Oil Using KOH Impregnated Eggshell as a Heterogeneous Catalyst. Energies, 12(19), 3714. https://doi.org/10.3390/en12193714