A Novel Hybrid Prognostic Approach for Remaining Useful Life Estimation of Lithium-Ion Batteries

Abstract

1. Introduction

2. Basic Condition

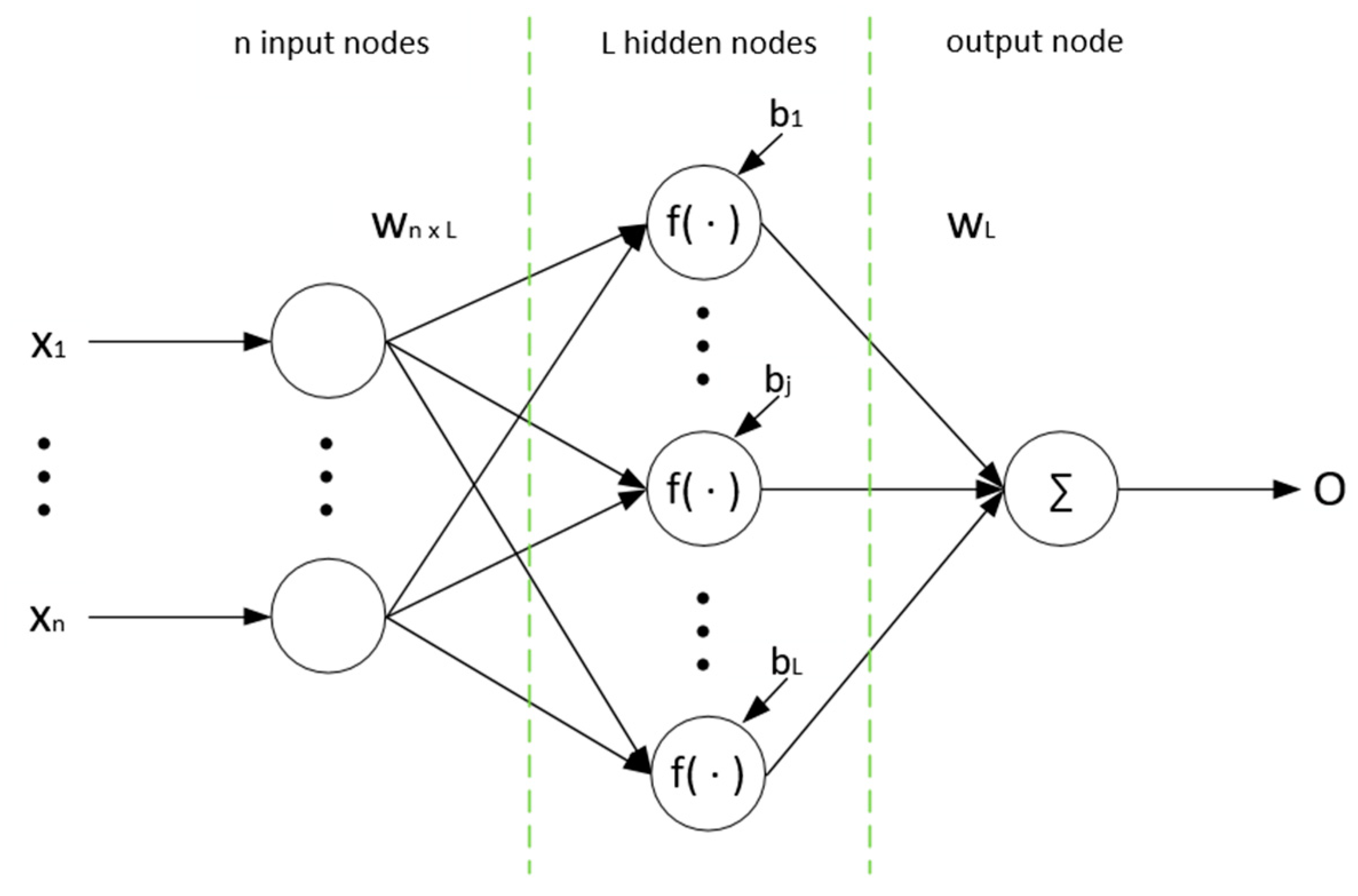

2.1. Extreme Learning Machine (ELM)

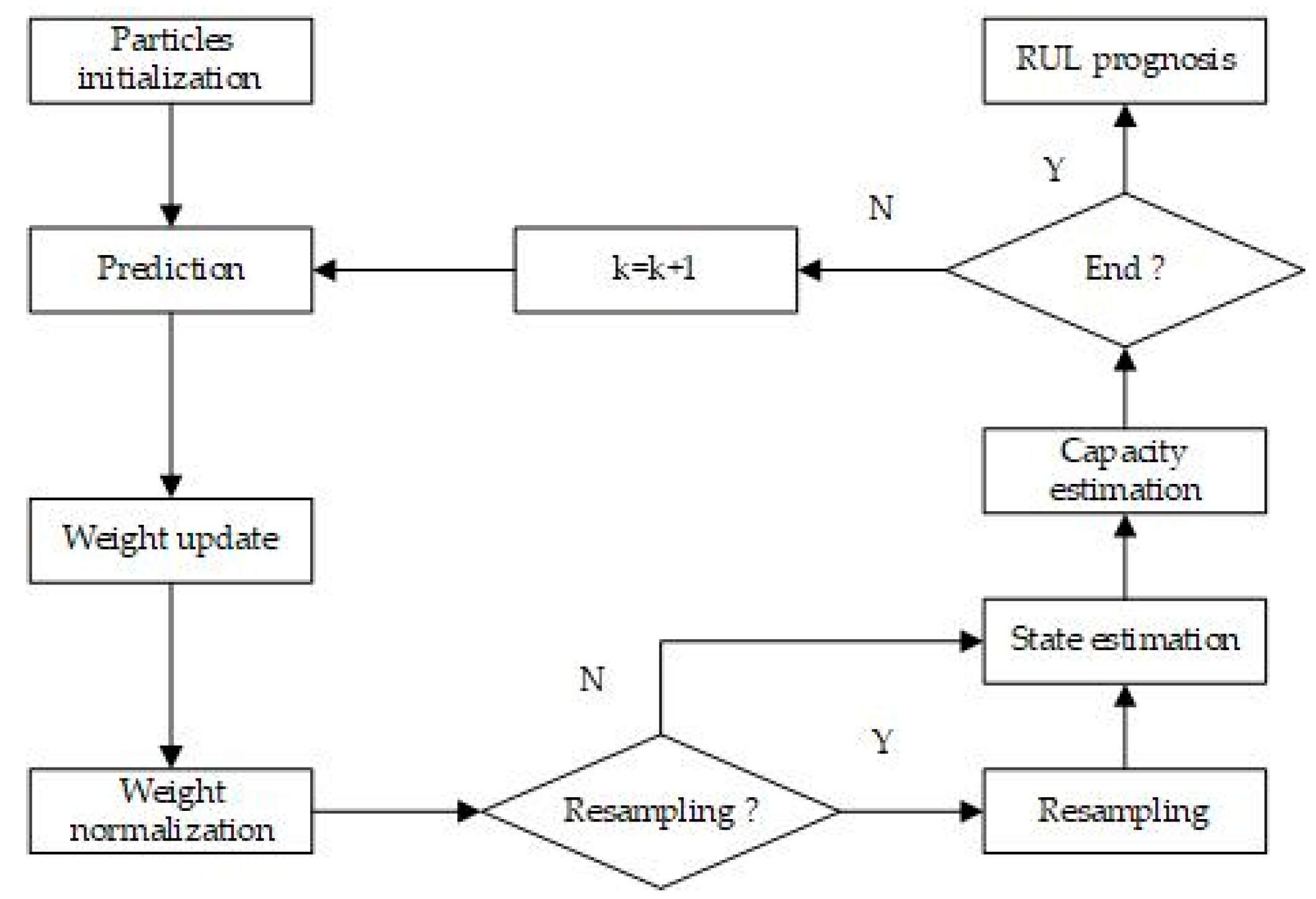

2.2. PFELM Algorithm (PFELM)

3. Experiment and Analysis

3.1. Data Description

3.2. Determination of Algorithm Parameters and Evaluation Index of Results

3.2.1. Number of Layers and Nodes in Each Layer of ELM

3.2.2. Evaluation Index of Results

3.3. Experimental Results Presentation

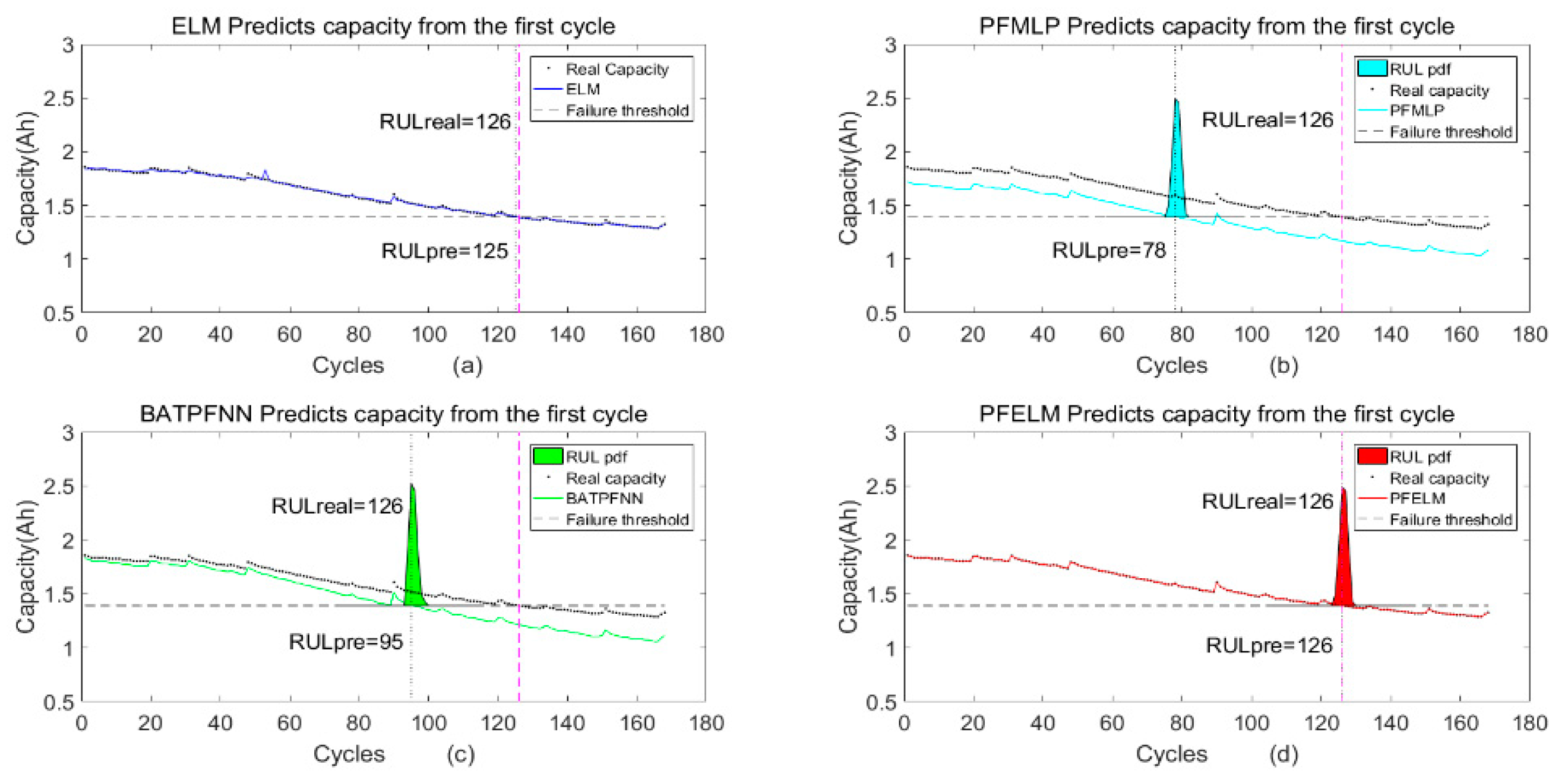

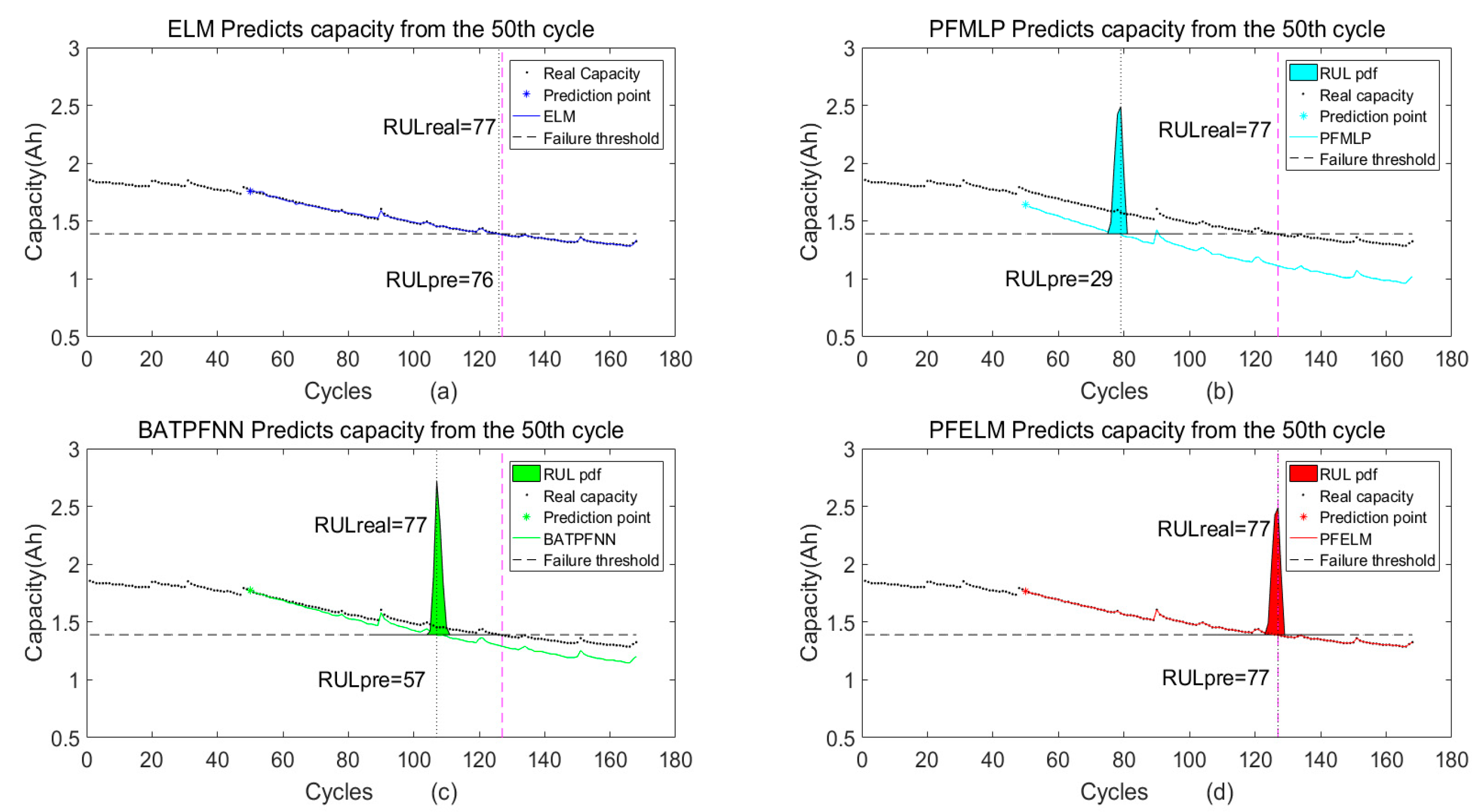

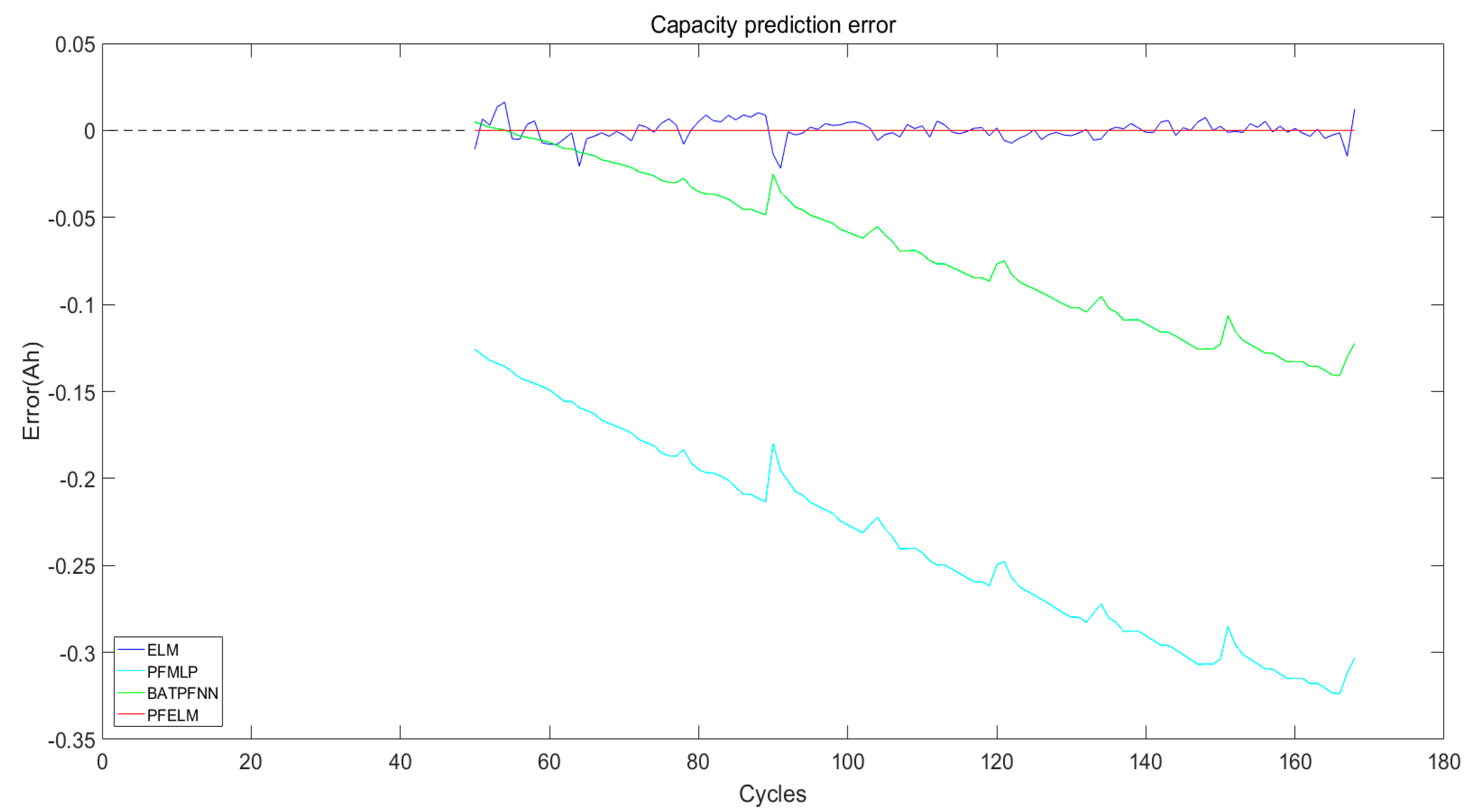

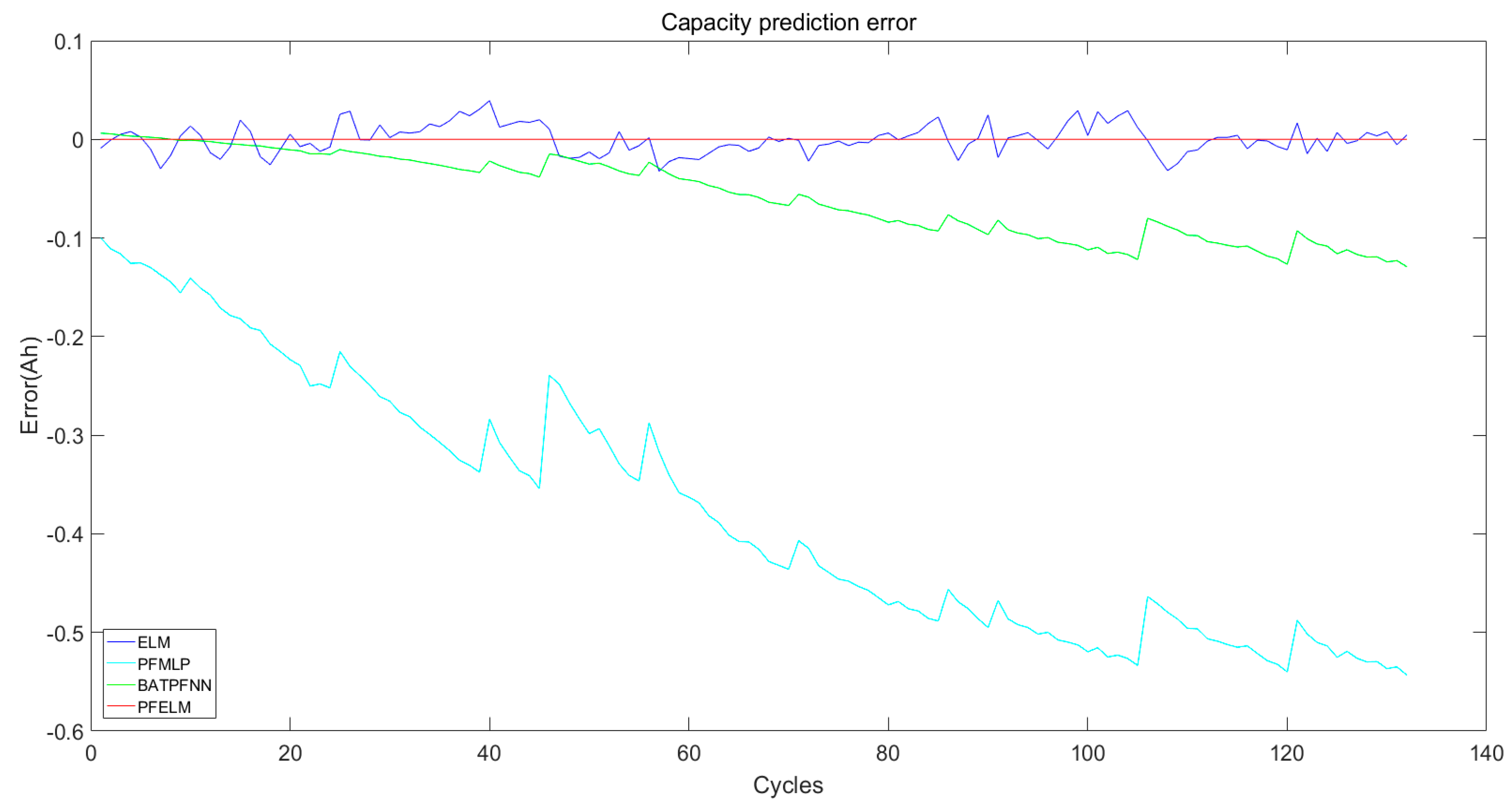

3.3.1. Comparison of Prognosis Results of B0005

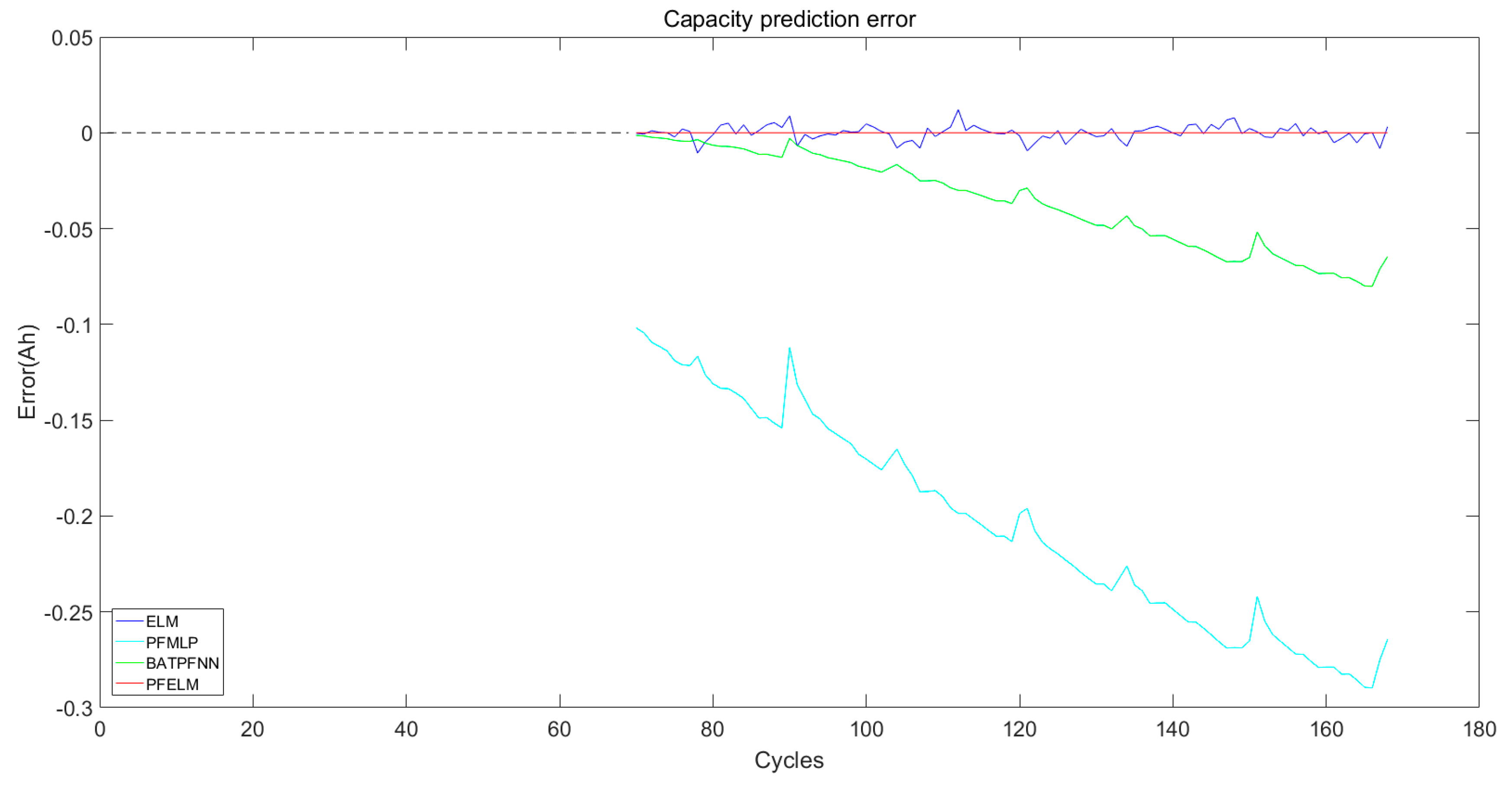

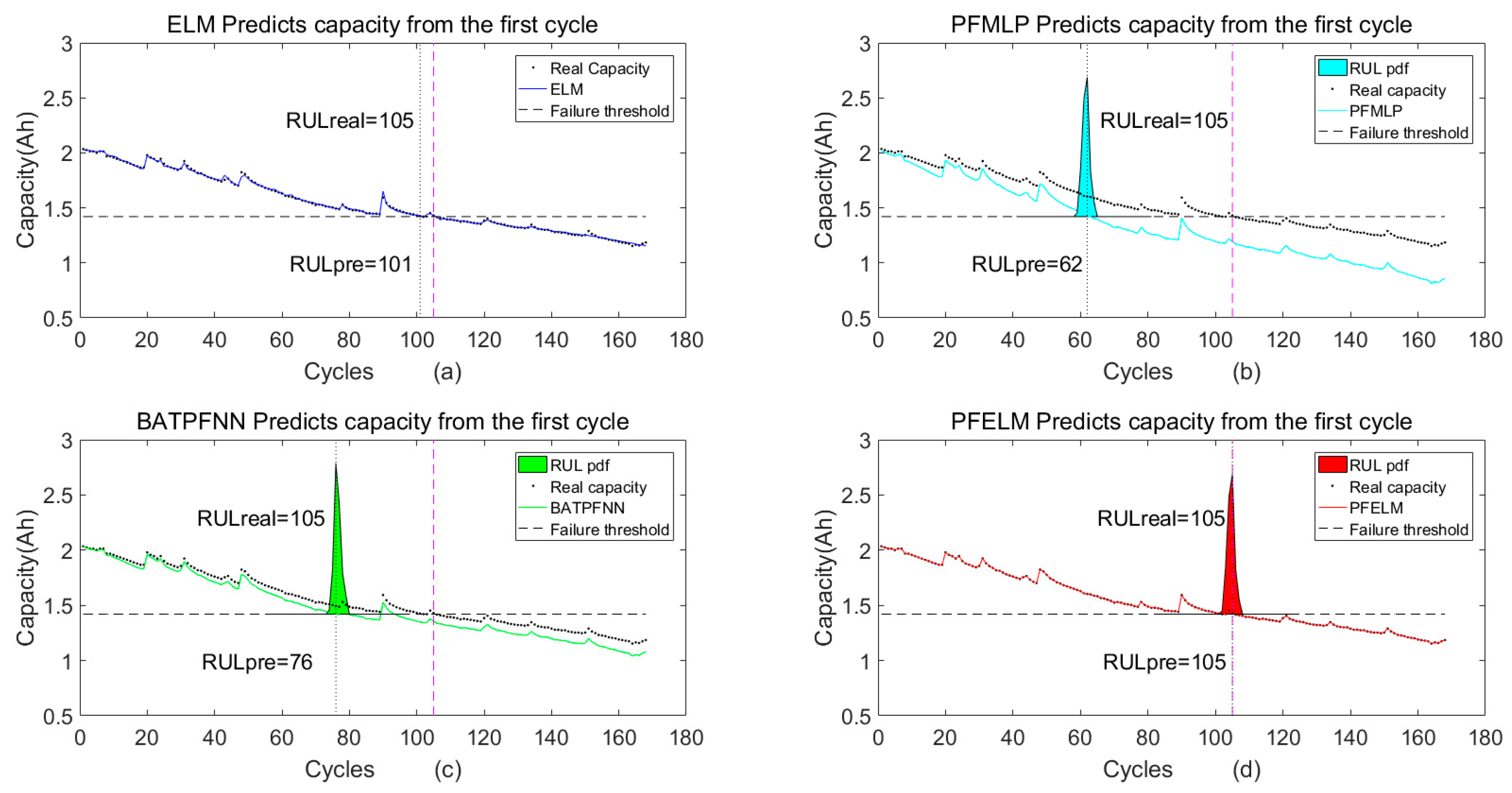

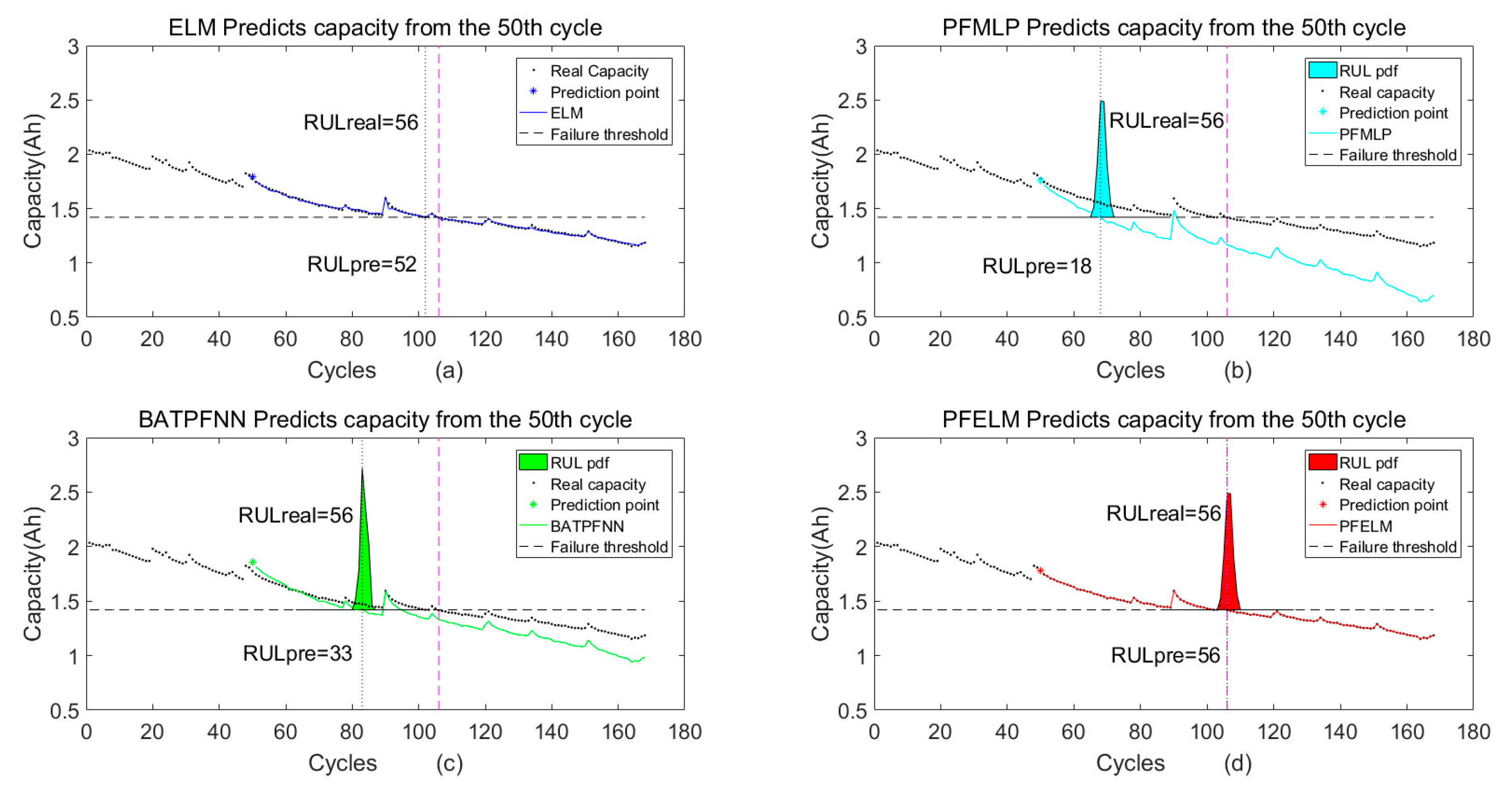

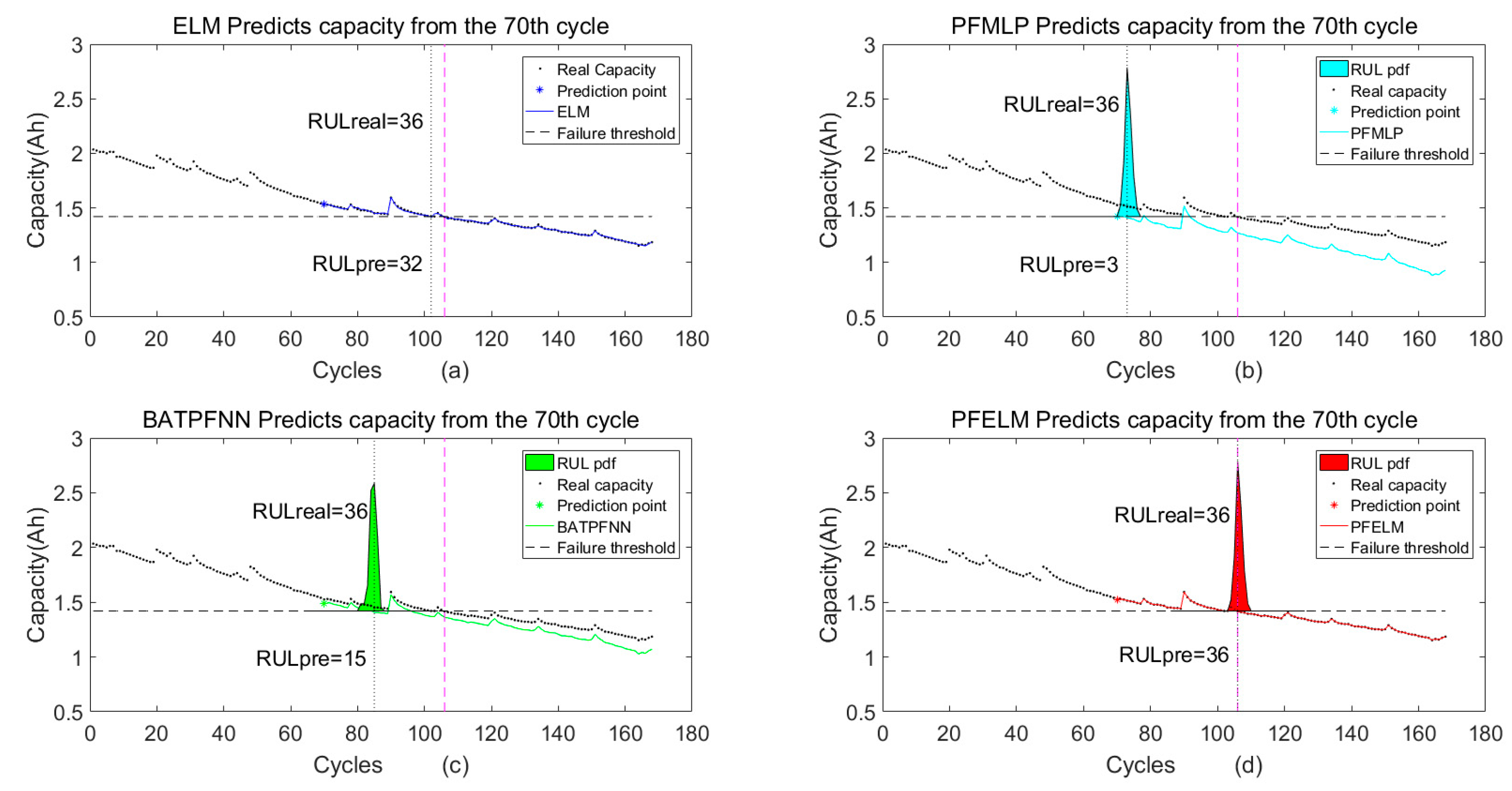

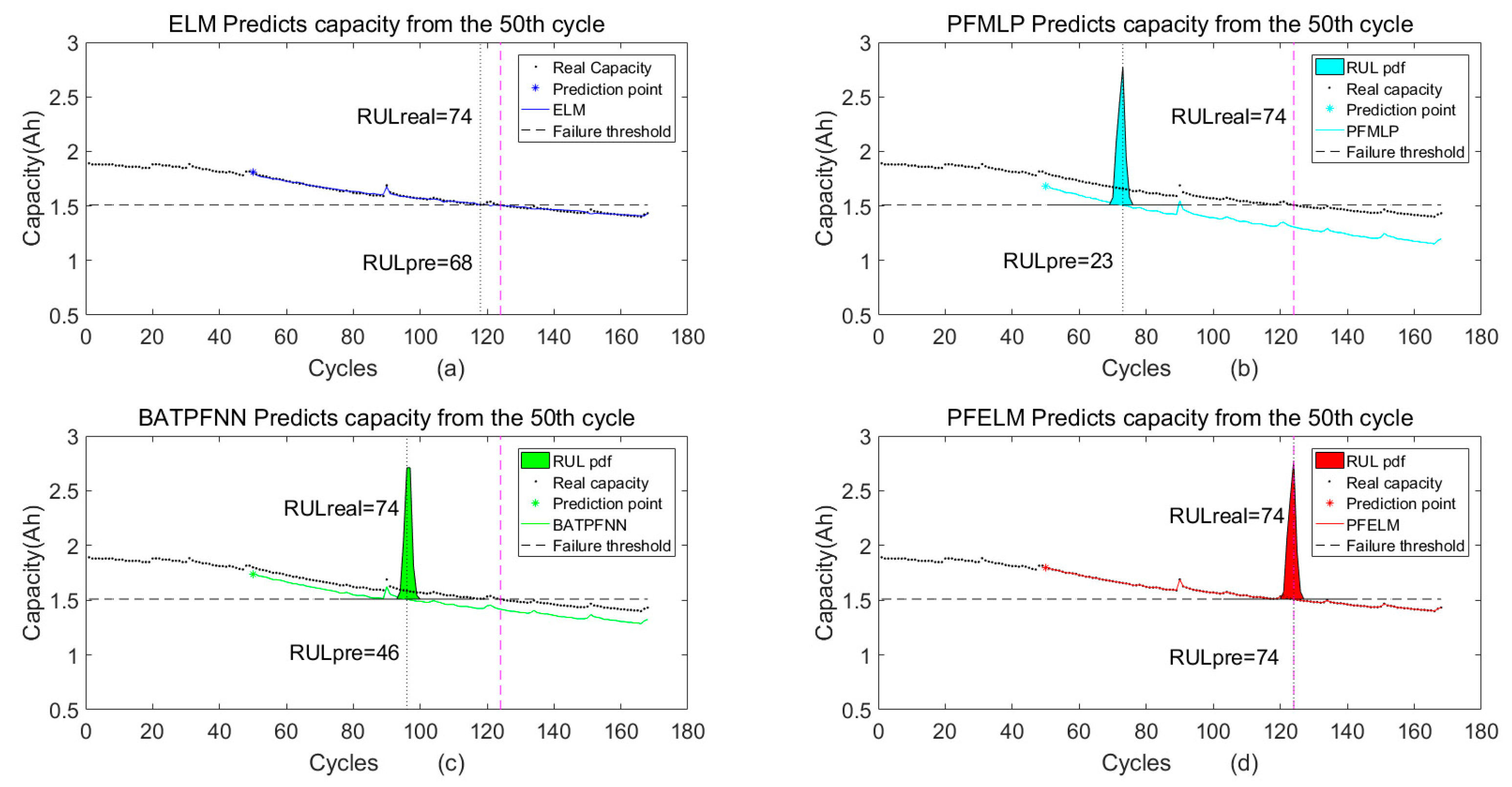

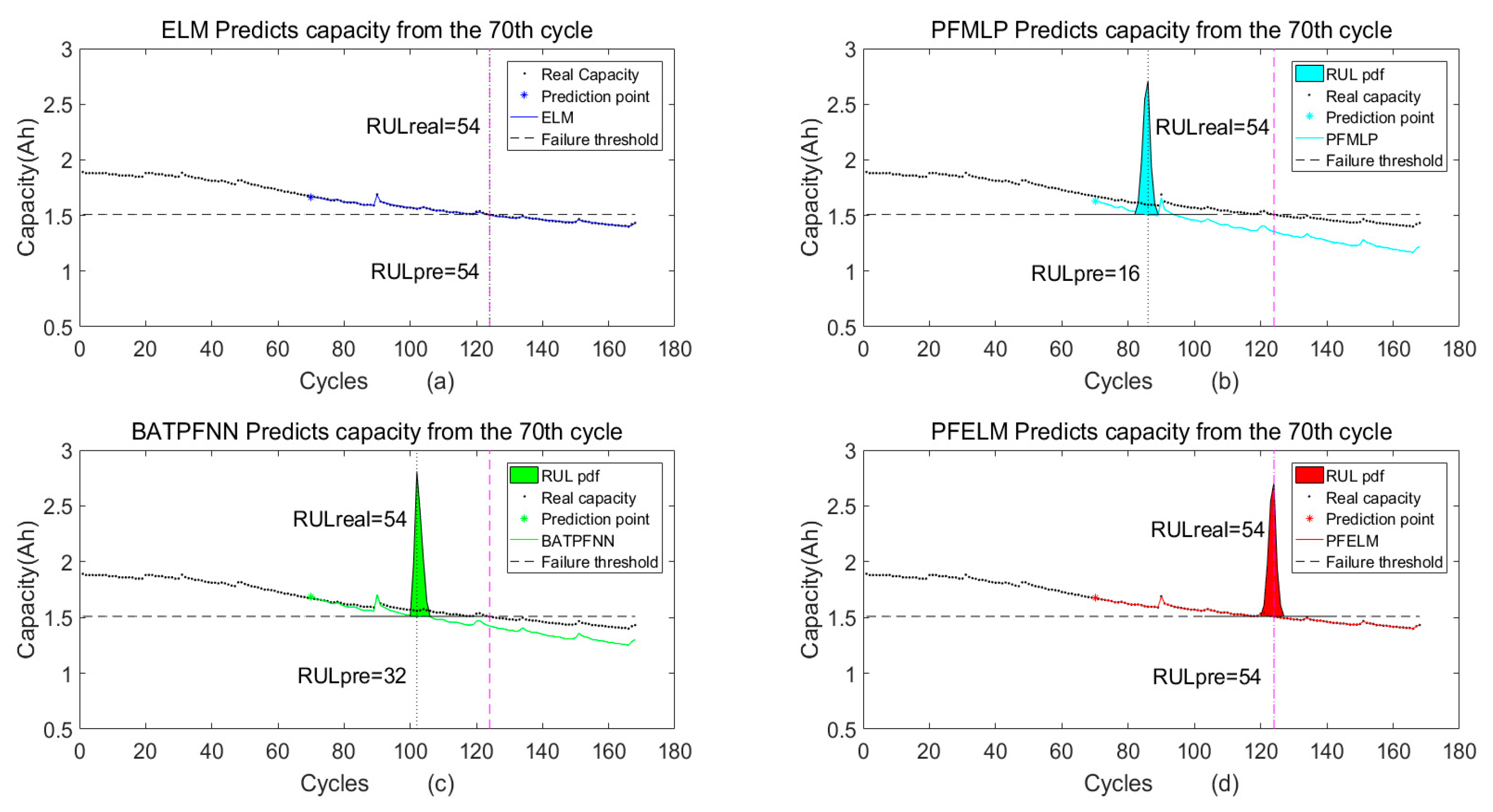

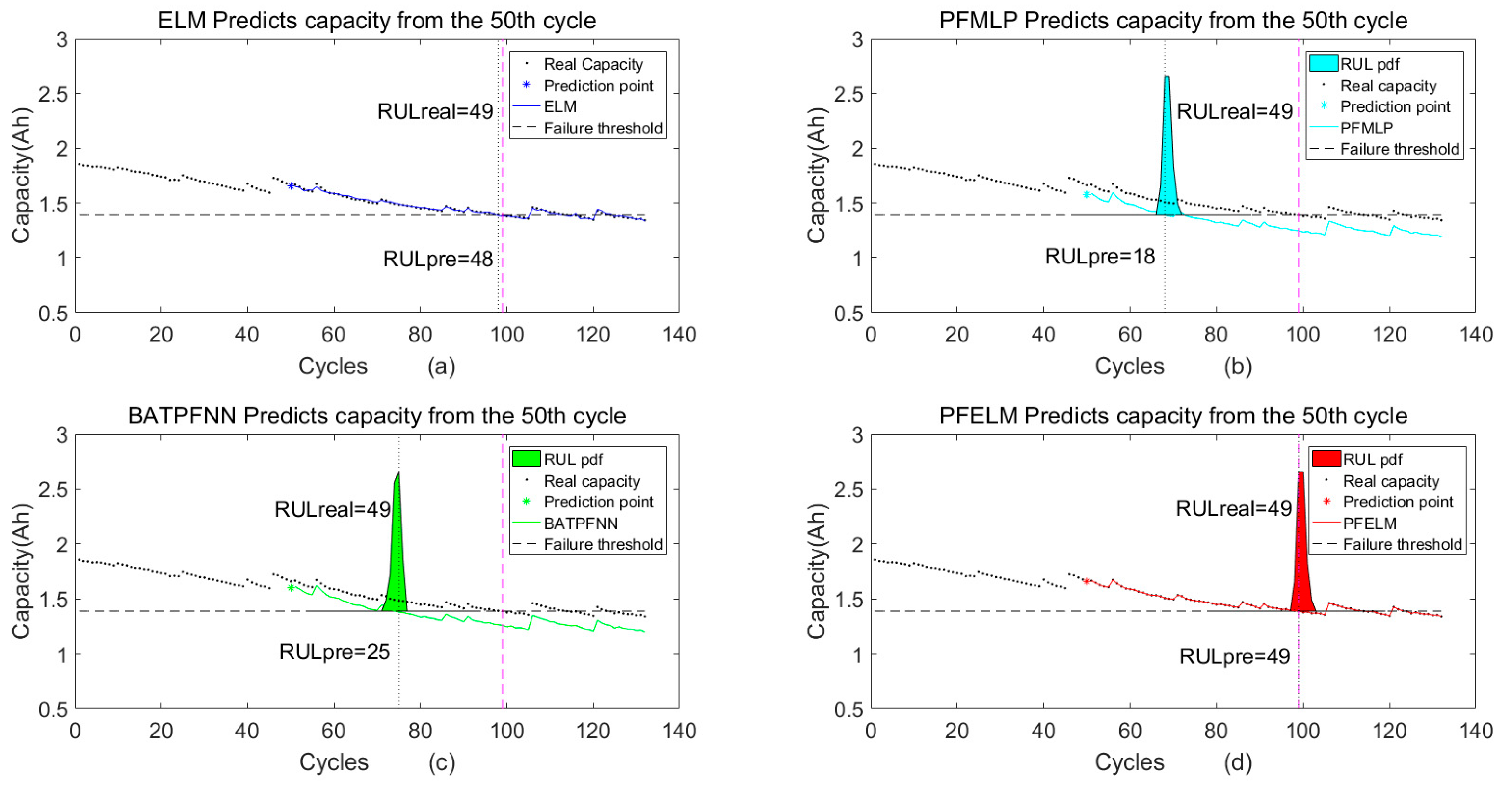

3.3.2. Comparison of Prognosis Results of B0006

3.3.3. Comparison of Prognosis Results of B0007

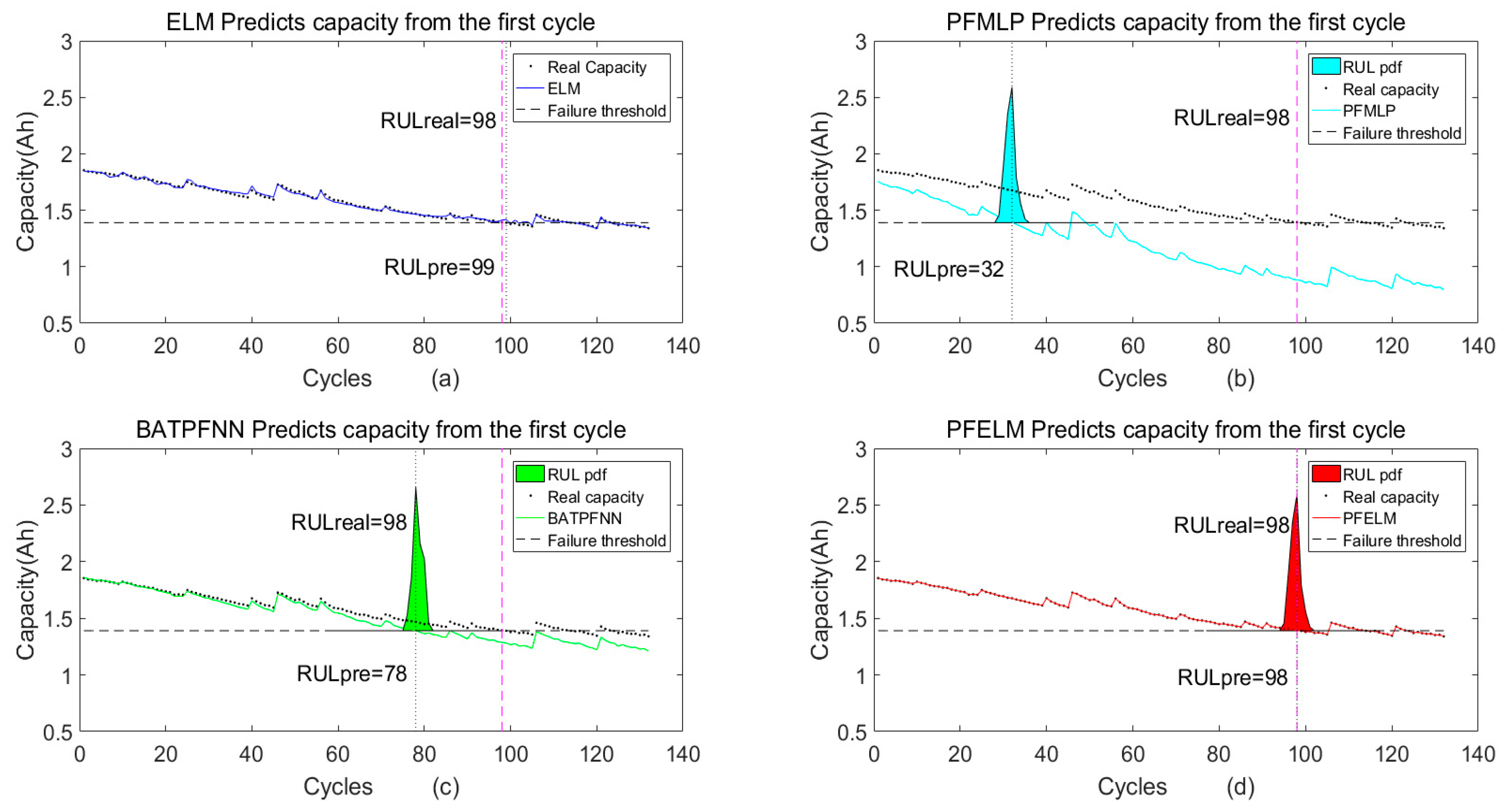

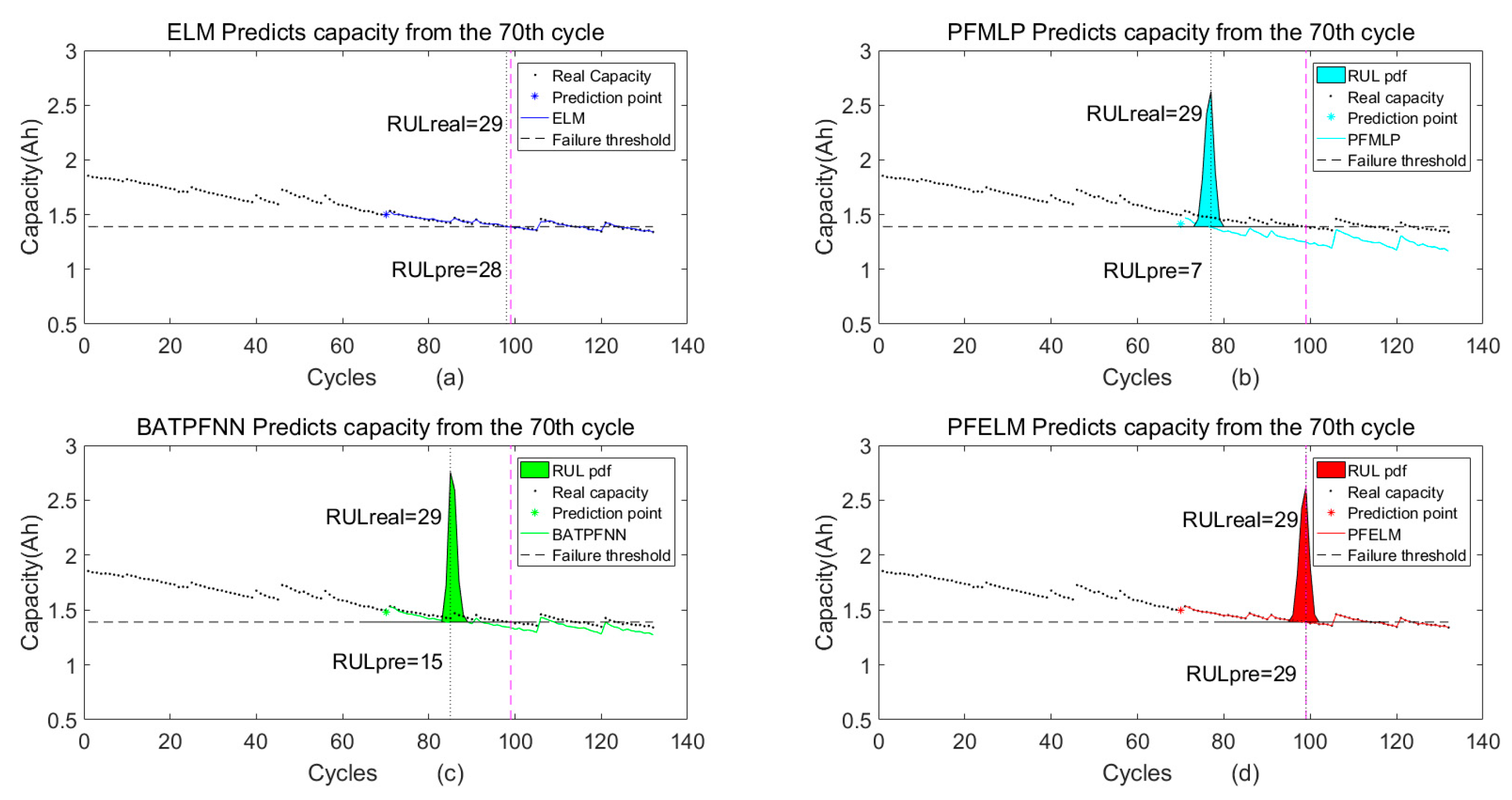

3.3.4. Comparison of Prognosis Results of B0018

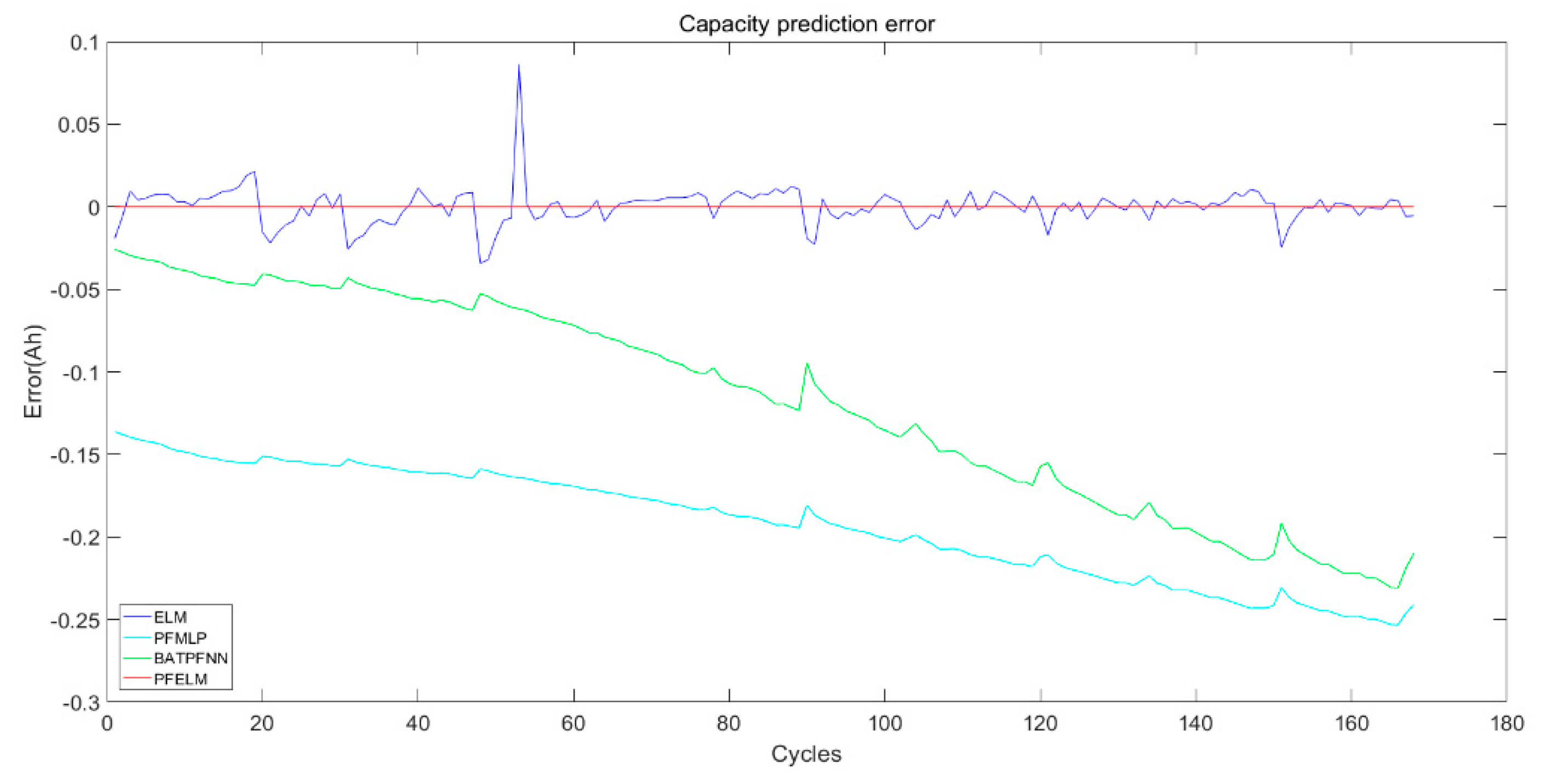

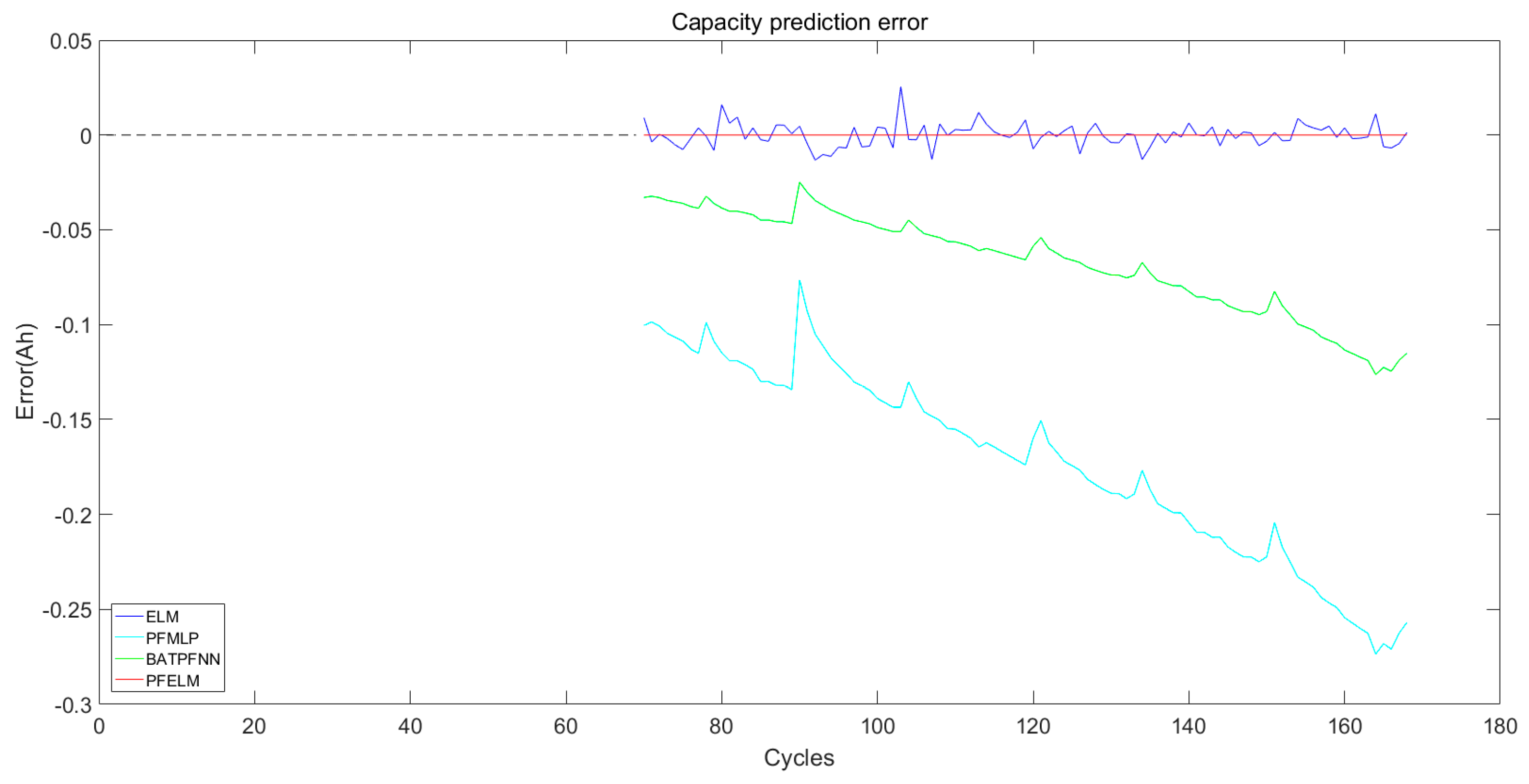

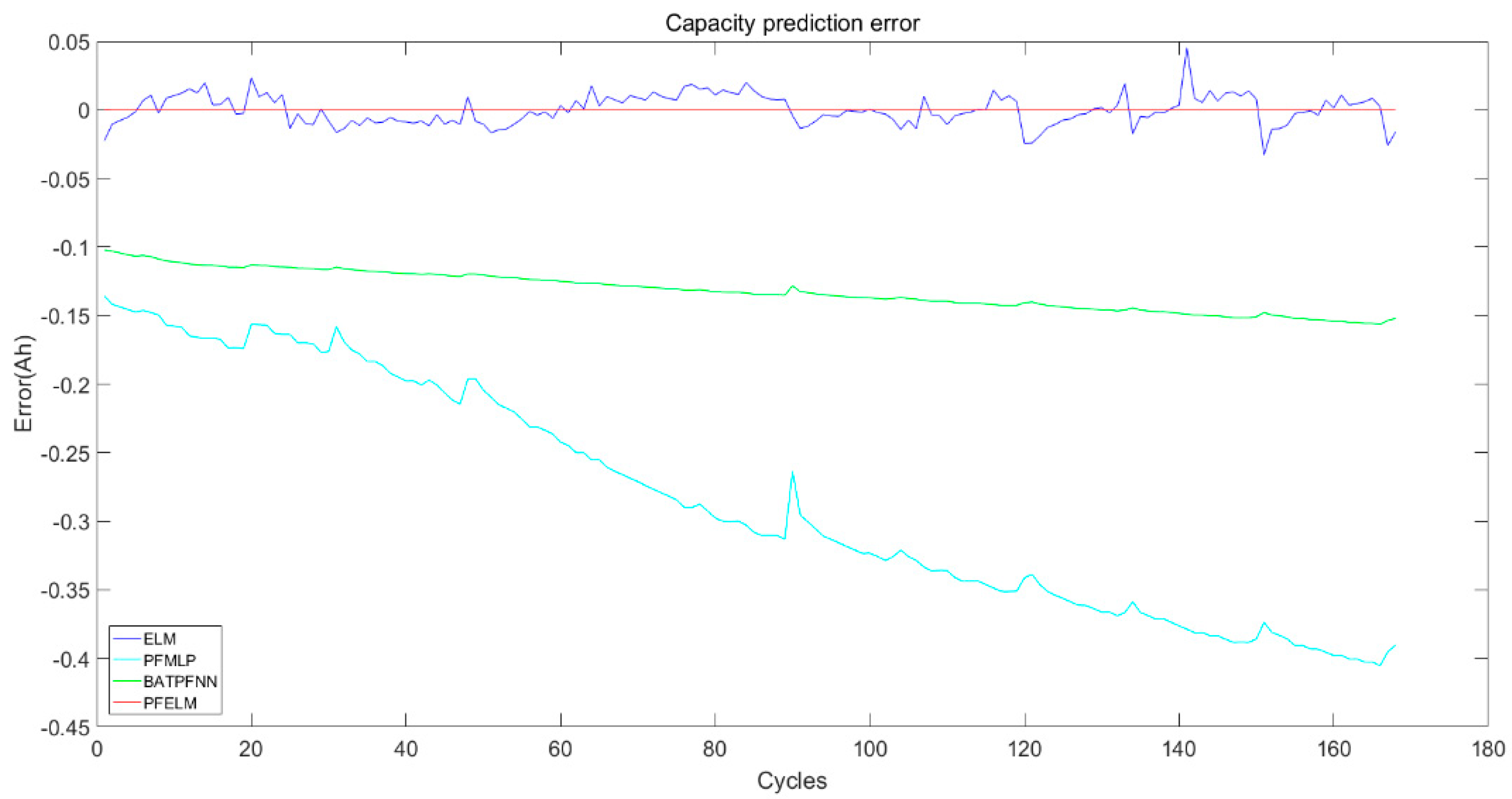

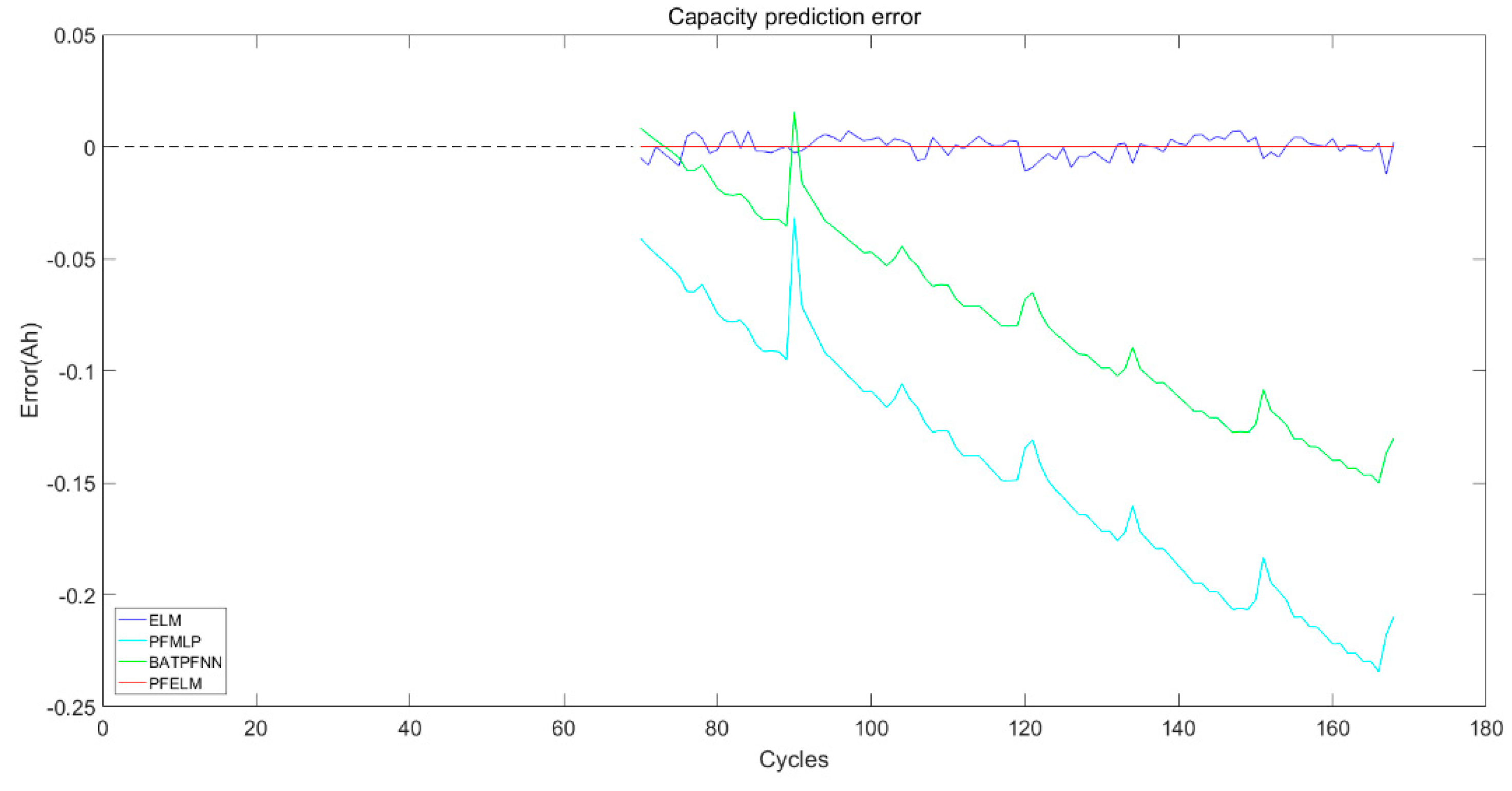

3.4. Experimental Results Comparisons and Discussion

3.4.1. RUL Prediction Accuracy Analysis

3.4.2. Robustness Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rodrigues, E.M.G.; Godina, R.; Catalao, J.P.S. Modelling electrochemical energy storage devices in insular power network applications supported on real data. Appl. Energy 2017, 188, 315–329. [Google Scholar] [CrossRef]

- Menale, C.; D’Annibale, F.; Mazzarotta, B.; Bubbico, R. Thermal management of lithium-ion batteries: An experimental investigation. Energy 2019, 182, 57–71. [Google Scholar] [CrossRef]

- Li, F.; Xu, J.P. A new prognostics method for state of health estimation of lithium-ion batteries based on a mixture of Gaussian process models and particle filter. Microelectron. Reliab. 2015, 55, 1035–1045. [Google Scholar] [CrossRef]

- Nuhic, A.; Terzimehic, T.; Soczka-Guth, T.; Buchholz, M.; Dietmayer, K. Health diagnosis and remaining useful life prognostics of lithium-ion batteries using data-driven methods. J. Power Sources 2013, 239, 680–688. [Google Scholar] [CrossRef]

- Wu, L.F.; Fu, X.H.; Guan, Y. Review of the Remaining Useful Life Prognostics of Vehicle Lithium-Ion Batteries Using Data-Driven Methodologies. Appl. Sci. 2016, 6, 166. [Google Scholar] [CrossRef]

- Barre, A.; Deguilhem, B.; Grolleau, S.; Gerard, M.; Suard, F.; Riu, D. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications. J. Power Sources 2013, 241, 680–689. [Google Scholar] [CrossRef]

- Su, C.; Chen, H.J. A review on prognostics approaches for remaining useful life of lithium-ion battery. In Proceedings of the 2017 International Conference on New Energy and Future Energy System, Kunming, China, 22–25 September 2017; Kyriakopoulos, G.L., Ed.; Iop Publishing Ltd.: Bristol, UK, 2017; Volume 93. [Google Scholar]

- Jirkof, P.; Schmutz, J.B. Social and organizational factors affecting biosafety compliance in animal facilities: An integrative analysis of safety rules within the system. Saf. Sci. 2019, 118, 538–550. [Google Scholar] [CrossRef]

- Qu, S.; Kang, Y.; Gu, P.; Zhang, C.; Duan, B. A Fast Online State of Health Estimation Method for Lithium-Ion Batteries Based on Incremental Capacity Analysis. Energies 2019, 12, 3333. [Google Scholar] [CrossRef]

- Su, X.H.; Wang, S.; Pecht, M.; Ma, P.J.; Zhao, L.L. Prognostics of lithium-ion batteries based on different dimensional state equations in the particle filtering method. Trans. Inst. Meas. Control 2017, 39, 1537–1546. [Google Scholar] [CrossRef]

- Liu, D.T.; Yin, X.H.; Song, Y.C.; Liu, W.; Peng, Y. An On-Line State of Health Estimation of Lithium-Ion Battery Using Unscented Particle Filter. IEEE Access 2018, 6, 40990–41001. [Google Scholar] [CrossRef]

- Liu, Z.B.; Fan, D.S.; Bu, S.H.; Zhang, C. Prediction of Remaining Useful Life of Battery Cell Using Logistic Regression Based on Strong Tracking Particle Filter. In Proceedings of the 2015 IEEE Conference on Prognostics and Health Management (PHM), Austin, TX, USA, 22–25 June 2015. [Google Scholar]

- Mo, B.H.; Yu, J.S.; Tang, D.Y.; Liu, H.; Yu, J.S. A remaining useful life prediction approach for lithium-ion batteries using Kalman filter and an improved particle filter. In Proceedings of the 2016 IEEE International Conference on Prognostics and Health Management (ICPHM), Ottawa, ON, Canada, 20–22 June 2016. [Google Scholar]

- He, W.; Pecht, M.; Flynn, D.; Dinmohammadi, F. A Physics-Based Electrochemical Model for Lithium-Ion Battery State-of-Charge Estimation Solved by an Optimised Projection-Based Method and Moving-Window Filtering. Energies 2018, 11, 23. [Google Scholar] [CrossRef]

- Andre, D.; Appel, C.; Soczka-Guth, T.; Sauer, D.U. Advanced mathematical methods of SOC and SOH estimation for lithium-ion batteries. J. Power Sources 2013, 224, 20–27. [Google Scholar] [CrossRef]

- Xu, X.D.; Yu, C.Q.; Tang, S.J.; Sun, X.Y.; Si, X.S.; Wu, L.F. Remaining Useful Life Prediction of Lithium-Ion Batteries Based on Wiener Processes with Considering the Relaxation Effect. Energies 2019, 12, 17. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, C.B.; Chen, Z.H. An online method for lithium-ion battery remaining useful life estimation using importance sampling and neural networks. Appl. Energy 2016, 173, 134–140. [Google Scholar] [CrossRef]

- Choi, H.S.; Cho, W.J. Investigation of Multi-Level Cell Characteristic in Amorphous Indium-Gallium-Zinc Oxide Thin-Film-Transistor Based 1T-1R Non-Volatile Memory Device. J. Nanosci. Nanotechnol. 2019, 19, 6031–6035. [Google Scholar] [CrossRef] [PubMed]

- Long, B.; Li, X.; Gao, X.; Liu, Z. Prognostics Comparison of Lithium-Ion Battery Based on the Shallow and Deep Neural Networks Model. Energies 2019, 12, 3271. [Google Scholar] [CrossRef]

- Pang, X.Q.; Huang, R.; Wen, J.; Shi, Y.H.; Jia, J.F.; Zeng, J.C. A Lithium-ion Battery RUL Prediction Method Considering the Capacity Regeneration Phenomenon. Energies 2019, 12, 14. [Google Scholar] [CrossRef]

- Li, X.Y.; Shu, X.; Shen, J.W.; Xiao, R.X.; Yan, W.S.; Chen, Z. An On-Board Remaining Useful Life Estimation Algorithm for Lithium-Ion Batteries of Electric Vehicles. Energies 2017, 10, 15. [Google Scholar] [CrossRef]

- Liu, D.T.; Zhou, J.B.; Pan, D.W.; Peng, Y.; Peng, X.Y. Lithium-ion battery remaining useful life estimation with an optimized Relevance Vector Machine algorithm with incremental learning. Measurement 2015, 63, 143–151. [Google Scholar] [CrossRef]

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.H.; Aykol, M.; Herring, P.K.; Fraggedakis, D.; et al. Data-driven prediction of battery cycle life before capacity degradation. Nat. Energy 2019, 4, 383–391. [Google Scholar] [CrossRef]

- Khumprom, P.; Yodo, N. A Data-Driven Predictive Prognostic Model for Lithium-ion Batteries based on a Deep Learning Algorithm. Energies 2019, 12, 21. [Google Scholar] [CrossRef]

- Long, B.; Xian, W.M.; Jiang, L.; Liu, Z. An improved autoregressive model by particle swarm optimization for prognostics of lithium-ion batteries. Microelectron. Reliab. 2013, 53, 821–831. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Z.Q. Remaining Useful Life Prediction of Lithium-Ion Batteries Based on Health Indicator and Gaussian Process Regression Model. IEEE Access 2019, 7, 39474–39484. [Google Scholar] [CrossRef]

- Cadini, F.; Sbarufatti, C.; Cancelliere, F.; Giglio, M. State-of-life prognosis and diagnosis of lithium-ion batteries by data-driven particle filters. Appl. Energy 2019, 235, 661–672. [Google Scholar] [CrossRef]

- Wu, Y.; Li, W.; Wang, Y.R.; Zhang, K. Remaining Useful Life Prediction of Lithium-Ion Batteries Using Neural Network and Bat-Based Particle Filter. IEEE Access 2019, 7, 54843–54854. [Google Scholar] [CrossRef]

- Wei, J.W.; Dong, G.Z.; Chen, Z.H. Remaining Useful Life Prediction and State of Health Diagnosis for Lithium-Ion Batteries Using Particle Filter and Support Vector Regression. IEEE Trans. Ind. Electron. 2018, 65, 5634–5643. [Google Scholar] [CrossRef]

- Chang, Y.; Fang, H.J. A hybrid prognostic method for system degradation based on particle filter and relevance vector machine. Reliab. Eng. Syst. Saf. 2019, 186, 51–63. [Google Scholar] [CrossRef]

- Sbarufatti, C.; Corbetta, M.; Giglio, M.; Cadini, F. Adaptive prognosis of lithium-ion batteries based on the combination of particle filters and radial basis function neural networks. J. Power Sources 2017, 344, 128–140. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, Y.P.; Cheng, J.H. A Hybrid Method for Remaining Useful Life Estimation of Lithium-Ion Battery with Regeneration Phenomena. Appl. Sci. 2019, 9, 15. [Google Scholar] [CrossRef]

- Si, X.S. An Adaptive Prognostic Approach via Nonlinear Degradation Modeling: Application to Battery Data. IEEE Trans. Ind. Electron. 2015, 62, 5082–5096. [Google Scholar] [CrossRef]

- Yang, J.; Peng, Z.; Pei, Z.D.; Guan, Y.; Yuan, H.M.; Wu, L.F. Remaining Useful Life Assessment of Lithium-ion Battery based on HKA-ELM Algorithm. Int. J. Electrochem. Sci. 2018, 13, 9257–9272. [Google Scholar] [CrossRef]

- Ma, Y.Y.; Shen, D.X.; Wu, L.F.; Guan, Y.; Zhu, H. The Remaining Useful Life Estimation of Lithium-ion Batteries Based on the HKA -ML-ELM Algorithm. Int. J. Electrochem. Sci. 2019, 14, 7737–7757. [Google Scholar] [CrossRef]

- Huang, G.B.; Zhu, Q.Y.; Siew, C.K. Extreme learning machine: A new learning scheme of feedforward neural networks. In Proceedings of the 2004 IEEE International Joint Conference on Neural Networks, Budapest, Hungary, 25–29 July 2004; Volume 1–4, pp. 985–990. [Google Scholar]

- Huang, G.B.; Chen, L.; Siew, C.K. Universal approximation using incremental constructive feedforward networks with random hidden nodes. IEEE Trans. Neural Netw. 2006, 17, 879–892. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.B.; Chen, L. Convex incremental extreme learning machine. Neurocomputing 2007, 70, 3056–3062. [Google Scholar] [CrossRef]

- Huang, G.B.; Chen, L. Enhanced random search based incremental extreme learning machine. Neurocomputing 2008, 71, 3460–3468. [Google Scholar] [CrossRef]

- Kumar, S.; Pal, S.K.; Singh, R. A novel hybrid model based on particle swarm optimisation and extreme learning machine for short-term temperature prediction using ambient sensors. Sustain. Cities Soc. 2019, 49, 12. [Google Scholar] [CrossRef]

- Li, G.Q.; Chen, B.; Qi, X.B.; Zhang, L. Circular convolution parallel extreme learning machine for modeling boiler efficiency for a 300 MW CFBB. Soft Comput. 2019, 23, 6567–6577. [Google Scholar] [CrossRef]

- Lin, P.C.; Huang, H.C.; Komorowski, M.; Lin, W.K.; Changh, C.M.; Chen, K.T.; Li, Y.C.; Lin, M.C. A machine learning approach for predicting urine output after fluid administration. Comput. Meth. Programs Biomed. 2019, 177, 155–159. [Google Scholar] [CrossRef]

- You, Z.H.; Lei, Y.K.; Zhu, L.; Xia, J.F.; Wang, B. Prediction of protein-protein interactions from amino acid sequences with ensemble extreme learning machines and principal component analysis. BMC Bioinform. 2013, 14, 11. [Google Scholar] [CrossRef]

- Huang, G.B. An Insight into Extreme Learning Machines: Random Neurons, Random Features and Kernels. Cogn. Comput. 2014, 6, 376–390. [Google Scholar] [CrossRef]

- Xia, B.Z.; Guo, S.K.; Wang, W.; Lai, Y.Z.; Wang, H.W.; Wang, M.W.; Zheng, W.W. A State of Charge Estimation Method Based on Adaptive Extended Kalman-Particle Filtering for Lithium-ion Batteries. Energies 2018, 11, 15. [Google Scholar] [CrossRef]

- Su, L.S.; Zhang, J.B.; Wang, C.J.; Zhang, Y.K.; Li, Z.; Song, Y.; Jin, T.; Ma, Z. Identifying main factors of capacity fading in lithium ion cells using orthogonal design of experiments. Appl. Energy 2016, 163, 201–210. [Google Scholar] [CrossRef]

| L | Maximum Error | Minimum Error | Average Error | Mean Square Error |

|---|---|---|---|---|

| 3 | 0.059 | −0.076 | 0 | 0.018 |

| 4 | 0.032 | −0.044 | 0 | 0.013 |

| 5 | 0.052 | −0.038 | 0 | 0.015 |

| 6 | 0.044 | −0.044 | 0 | 0.012 |

| 7 | 0.045 | −0.037 | 0 | 0.013 |

| 8 | 0.037 | −0.039 | 0 | 0.013 |

| 9 | 0.048 | −0.052 | 0 | 0.016 |

| 10 | 0.030 | −0.025 | 0 | 0.010 |

| Prediction Point | Real RUL | Method | Predicted RUL | AE | MSE | RUL Pdf Range |

|---|---|---|---|---|---|---|

| 1 | 126 | ELM | 125 | 1 | 0.0111 | None |

| PFMLP | 78 | 48 | 0.1949 | [76,81] | ||

| BATPFNN | 95 | 31 | 0.1338 | [94,99] | ||

| PFELM | 126 | 0 | 2.9424 × 10−16 | [124,129] | ||

| 50 | 77 | ELM | 76 | 1 | 0.0058 | None |

| PFMLP | 29 | 48 | 0.2431 | [76,80] | ||

| BATPFNN | 57 | 20 | 0.0818 | [105,110] | ||

| PFELM | 77 | 0 | 3.2119 × 10−16 | [124,128] | ||

| 70 | 57 | ELM | 56 | 1 | 0.0038 | None |

| PFMLP | 16 | 41 | 0.2111 | [84,89] | ||

| BATPFNN | 46 | 11 | 0.0438 | [112,118] | ||

| PFELM | 57 | 0 | 3.0353 × 10−16 | [125,130] |

| Prediction Point | Real RUL | Method | Predicted RUL | AE | MSE | RUL Pdf Range |

|---|---|---|---|---|---|---|

| 1 | 105 | ELM | 101 | 4 | 0.0110 | None |

| PFMLP | 62 | 43 | 0.2169 | [59,64] | ||

| BATPFNN | 76 | 29 | 0.0710 | [74–79] | ||

| PFELM | 105 | 0 | 3.2414 × 10−16 | [102,107] | ||

| 50 | 56 | ELM | 52 | 4 | 0.0098 | None |

| PFMLP | 18 | 38 | 0.2963 | [66,71] | ||

| BATPFNN | 33 | 23 | 0.1129 | [81,86] | ||

| PFELM | 56 | 0 | 2.4341 × 10−16 | [104,109] | ||

| 70 | 36 | ELM | 32 | 4 | 0.0061 | None |

| PFMLP | 3 | 33 | 0.1789 | [71–76] | ||

| BATPFNN | 15 | 21 | 0.0721 | [81,87] | ||

| PFELM | 36 | 0 | 2.6965 × 10−16 | [104,109] |

| Prediction Point | Real RUL | Method | Predicted RUL | AE | MSE | RUL Pdf Range |

|---|---|---|---|---|---|---|

| 1 | 123 | ELM | 119 | 4 | 0.0110 | None |

| PFMLP | 58 | 65 | 0.2946 | [68,74] | ||

| BATPFNN | 75 | 48 | 0.1328 | [86,91] | ||

| PFELM | 123 | 0 | 3.1124 × 10−16 | [119,125] | ||

| 50 | 74 | ELM | 74 | 6 | 0.0102 | None |

| PFMLP | 23 | 51 | 0.1893 | [70,75] | ||

| BATPFNN | 46 | 28 | 0.0863 | [94,99] | ||

| PFELM | 74 | 0 | 3.0464 × 10−16 | [121,126] | ||

| 70 | 54 | ELM | 0 | 0 | 0.0043 | None |

| PFMLP | 16 | 38 | 0.1532 | [83,88] | ||

| BATPFNN | 32 | 22 | 0.0877 | [101,105] | ||

| PFELM | 54 | 0 | 3.2416 × 10−16 | [121,126] |

| Prediction Point | Real RUL | Method | Predicted RUL | AE | MSE | PDF Range |

|---|---|---|---|---|---|---|

| 1 | 98 | ELM | 99 | 1 | 0.0145 | None |

| PFMLP | 32 | 66 | 0.3982 | [29,35] | ||

| BATPFNN | 78 | 20 | 0.0715 | [76,81] | ||

| PFELM | 98 | 0 | 3.3752 × 10−16 | [95,100] | ||

| 50 | 49 | ELM | 48 | 1 | 0.0103 | None |

| PFMLP | 18 | 31 | 0.1286 | [67,71] | ||

| BATPFNN | 25 | 24 | 0.1136 | [72,76] | ||

| PFELM | 49 | 0 | 2.0824 × 10−16 | [98,102] | ||

| 70 | 29 | ELM | 28 | 1 | 0.0077 | None |

| PFMLP | 7 | 22 | 0.1284 | [54,59] | ||

| BATPFNN | 15 | 14 | 0.0438 | [84,88] | ||

| PFELM | 29 | 0 | 3.2504 × 10−16 | [97,102] |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, T.; Xia, B.; Liu, Y.; Lai, Y.; Zheng, W.; Wang, H.; Wang, W.; Wang, M. A Novel Hybrid Prognostic Approach for Remaining Useful Life Estimation of Lithium-Ion Batteries. Energies 2019, 12, 3678. https://doi.org/10.3390/en12193678

Sun T, Xia B, Liu Y, Lai Y, Zheng W, Wang H, Wang W, Wang M. A Novel Hybrid Prognostic Approach for Remaining Useful Life Estimation of Lithium-Ion Batteries. Energies. 2019; 12(19):3678. https://doi.org/10.3390/en12193678

Chicago/Turabian StyleSun, Tianfei, Bizhong Xia, Yifan Liu, Yongzhi Lai, Weiwei Zheng, Huawen Wang, Wei Wang, and Mingwang Wang. 2019. "A Novel Hybrid Prognostic Approach for Remaining Useful Life Estimation of Lithium-Ion Batteries" Energies 12, no. 19: 3678. https://doi.org/10.3390/en12193678

APA StyleSun, T., Xia, B., Liu, Y., Lai, Y., Zheng, W., Wang, H., Wang, W., & Wang, M. (2019). A Novel Hybrid Prognostic Approach for Remaining Useful Life Estimation of Lithium-Ion Batteries. Energies, 12(19), 3678. https://doi.org/10.3390/en12193678