A Study on the Heating Method and Implementation of a Shrink-Fit Tool Holder

Abstract

1. Introduction

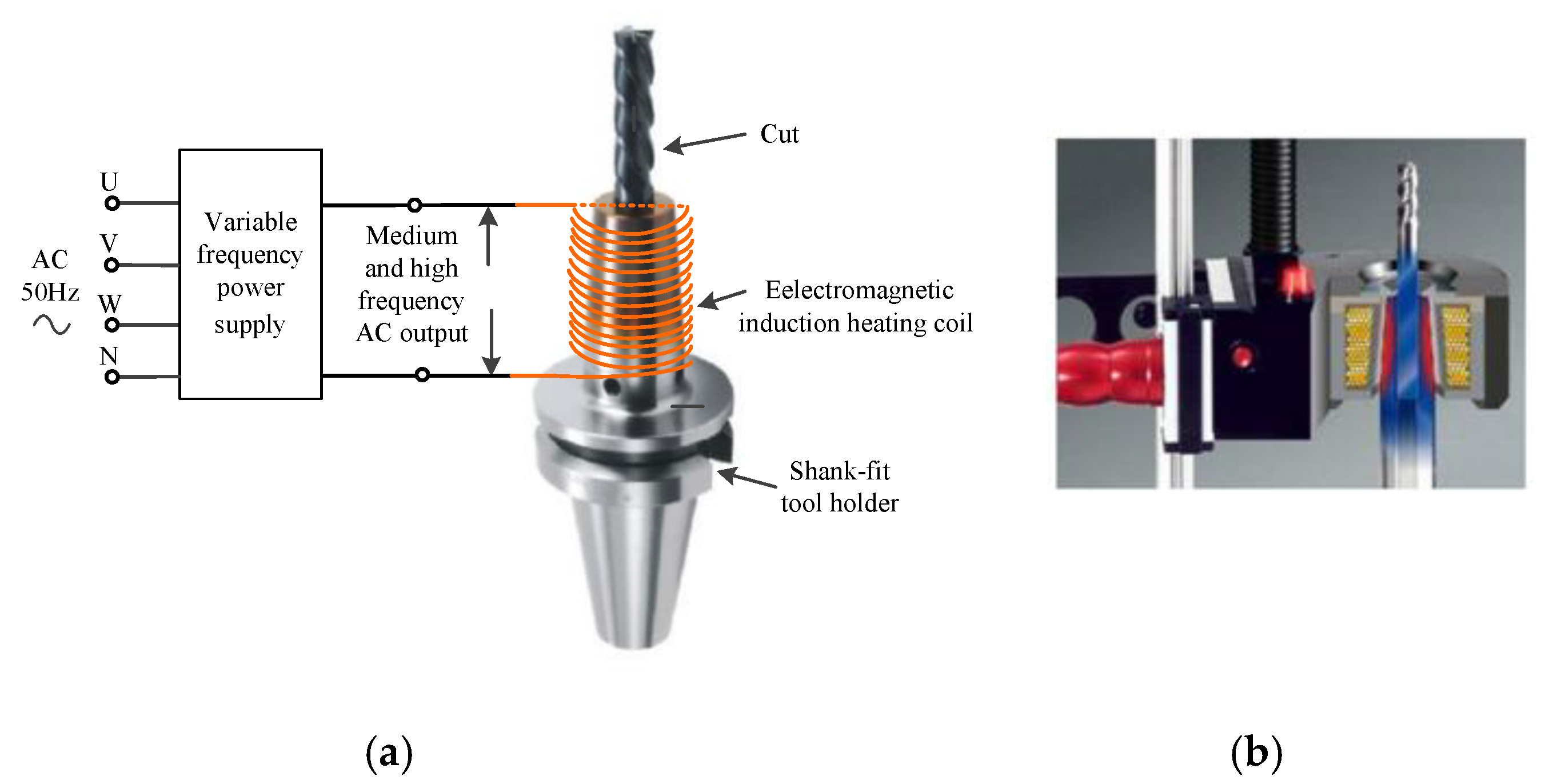

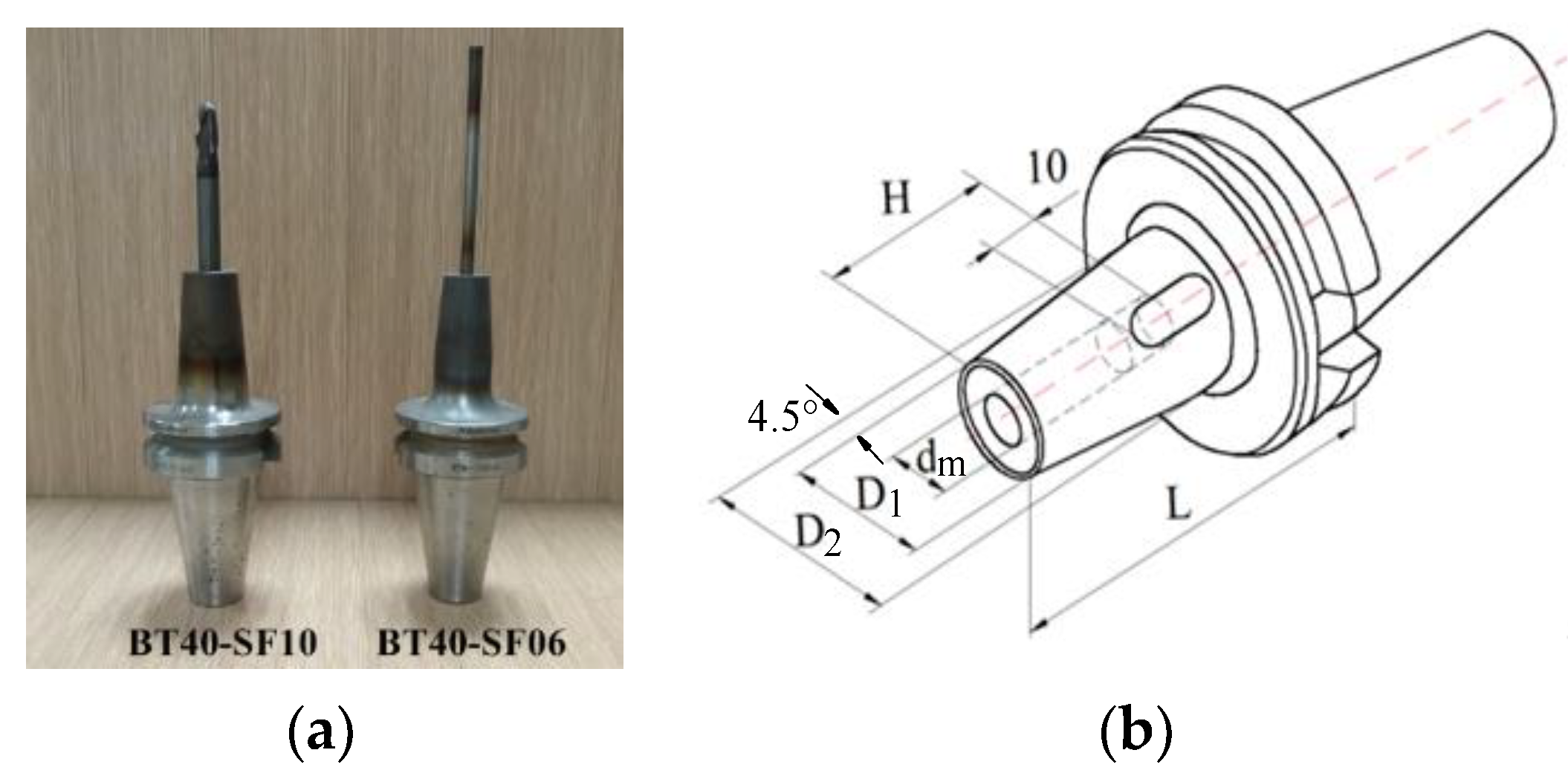

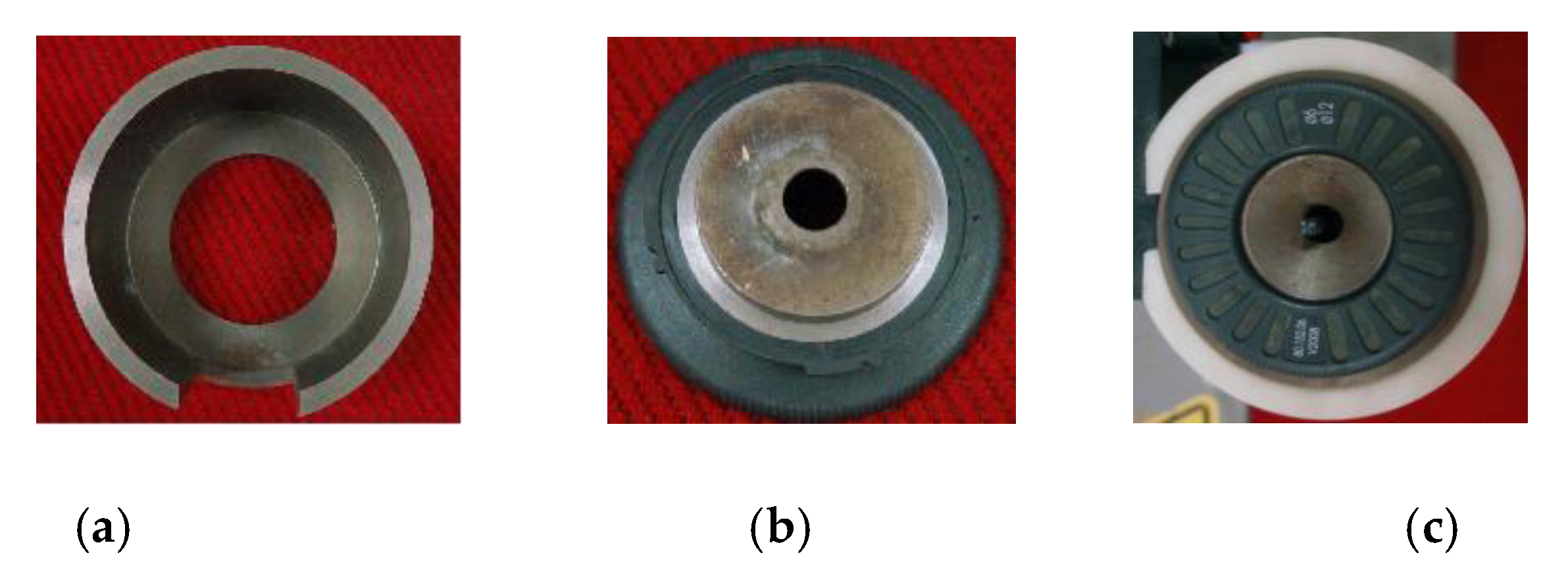

2. The Principle of the Shrink-Fit Tool Holder

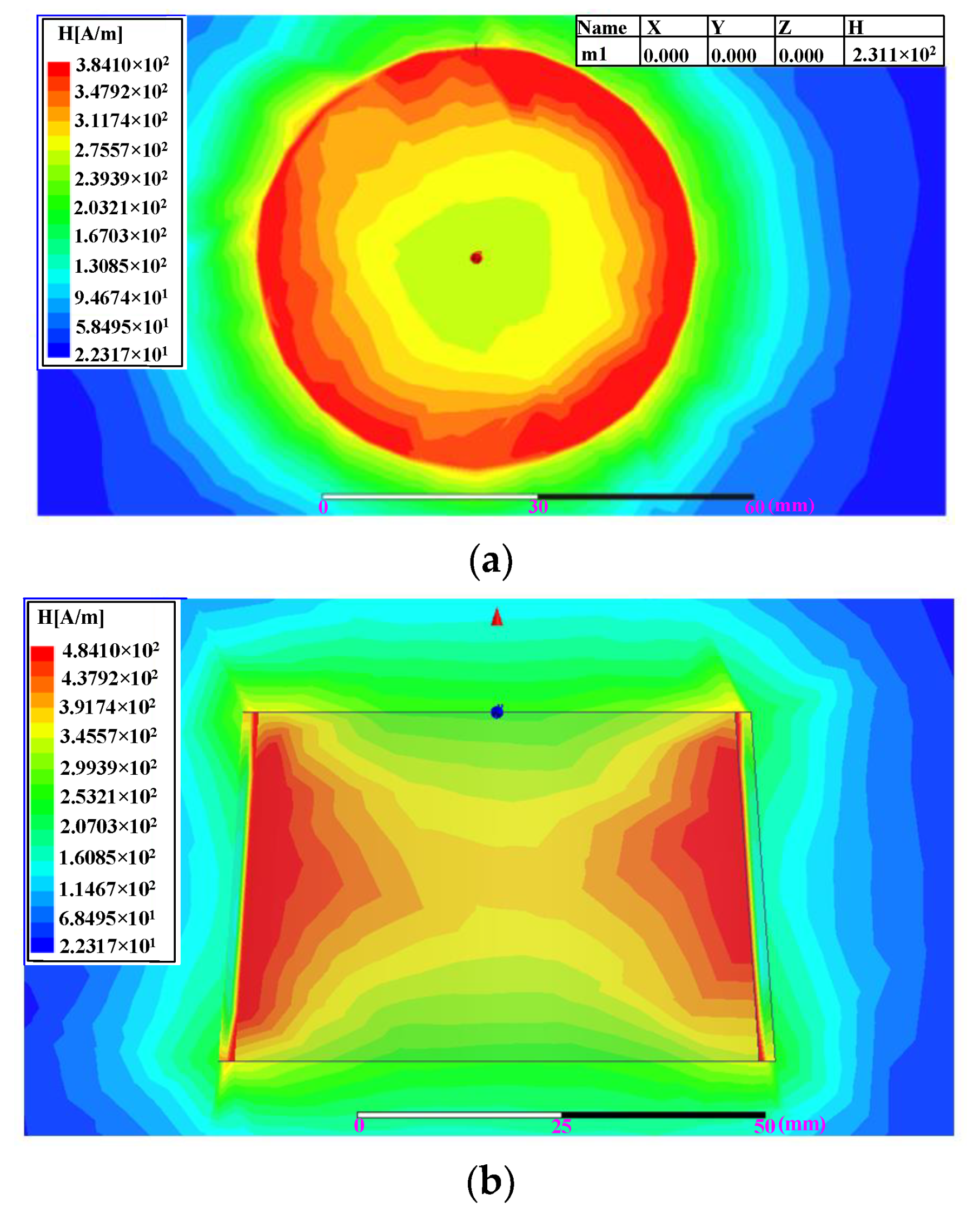

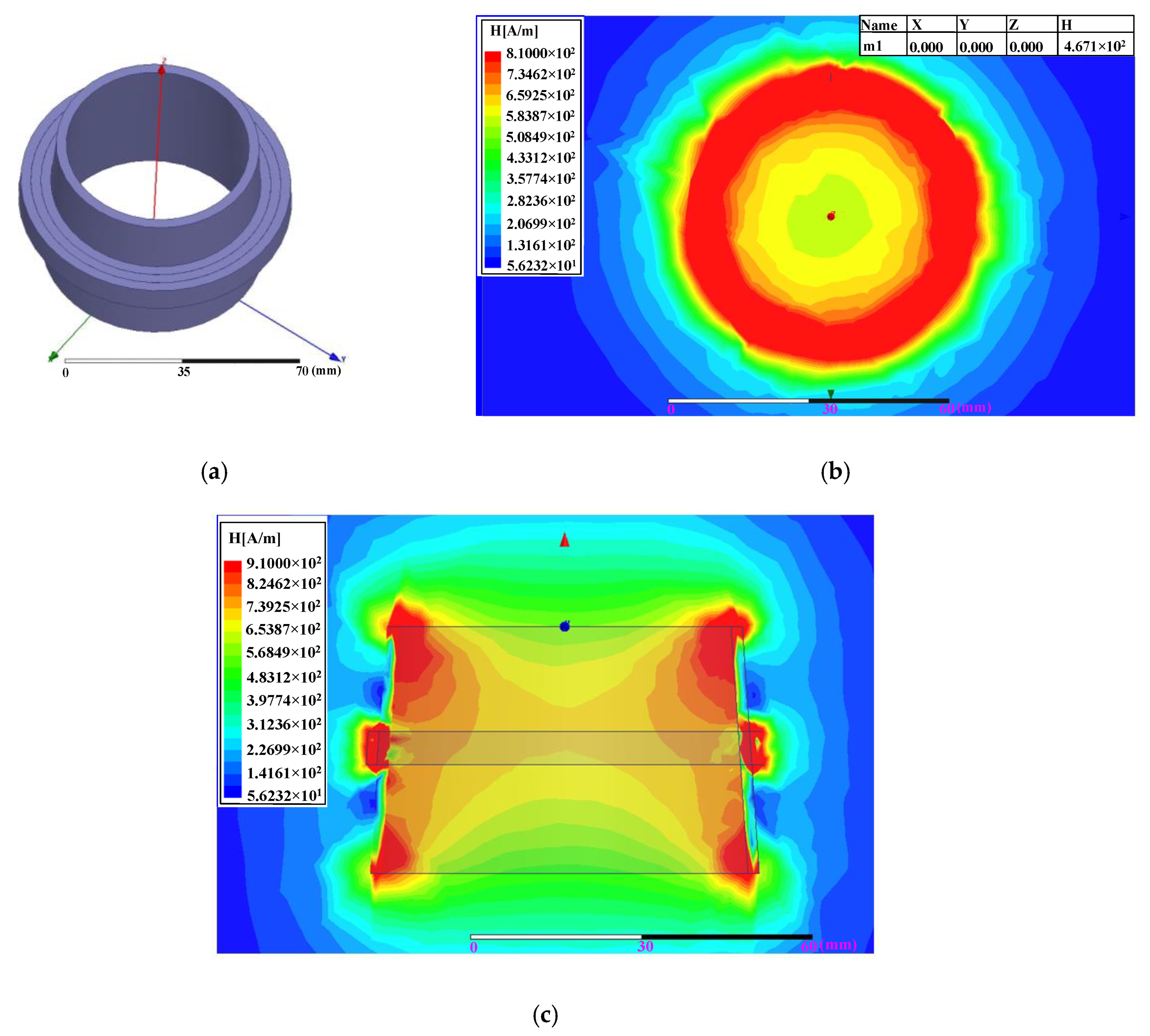

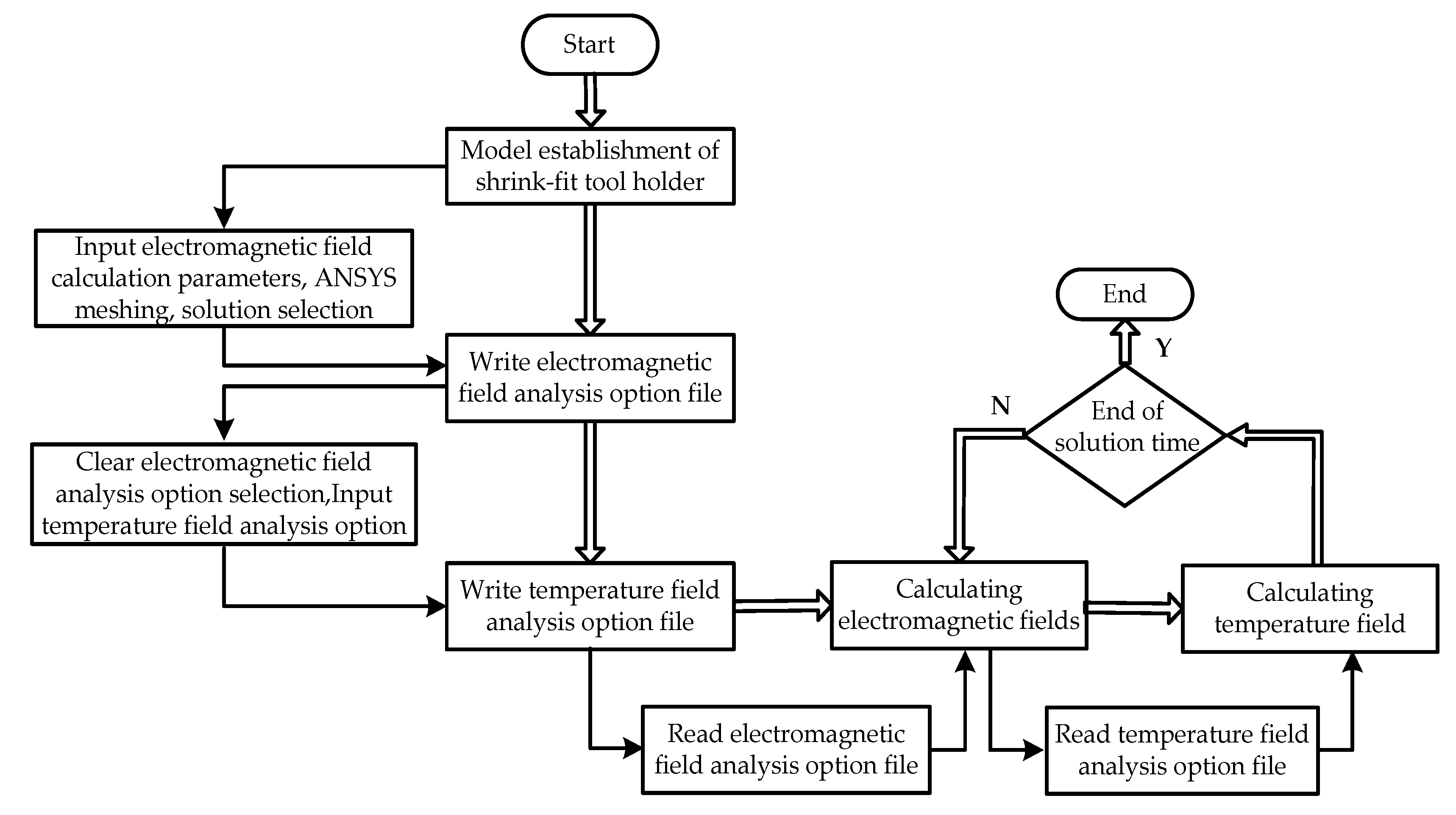

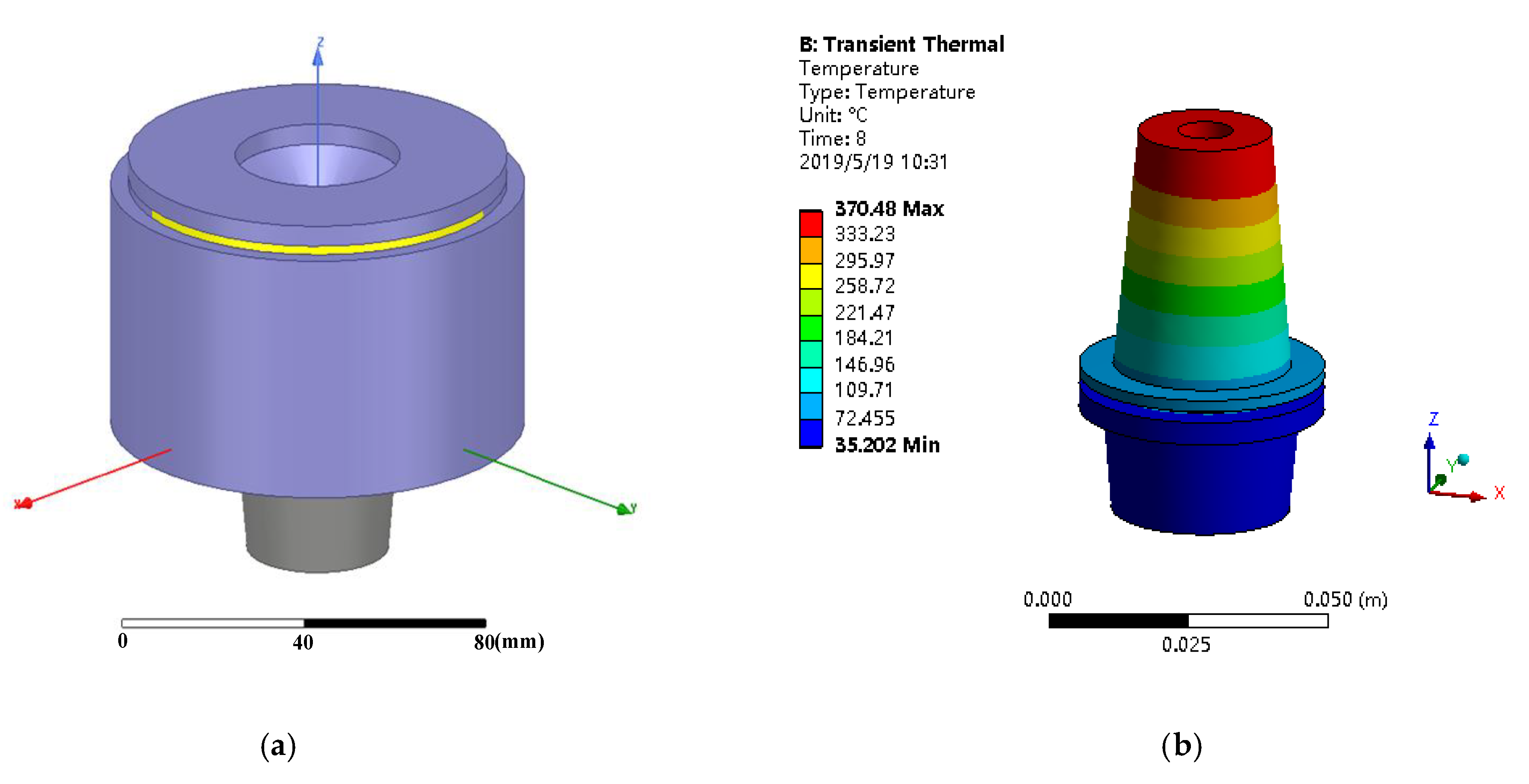

3. Establishment of Electromagnetic Field Mode and Electromagnetic Field Simulation

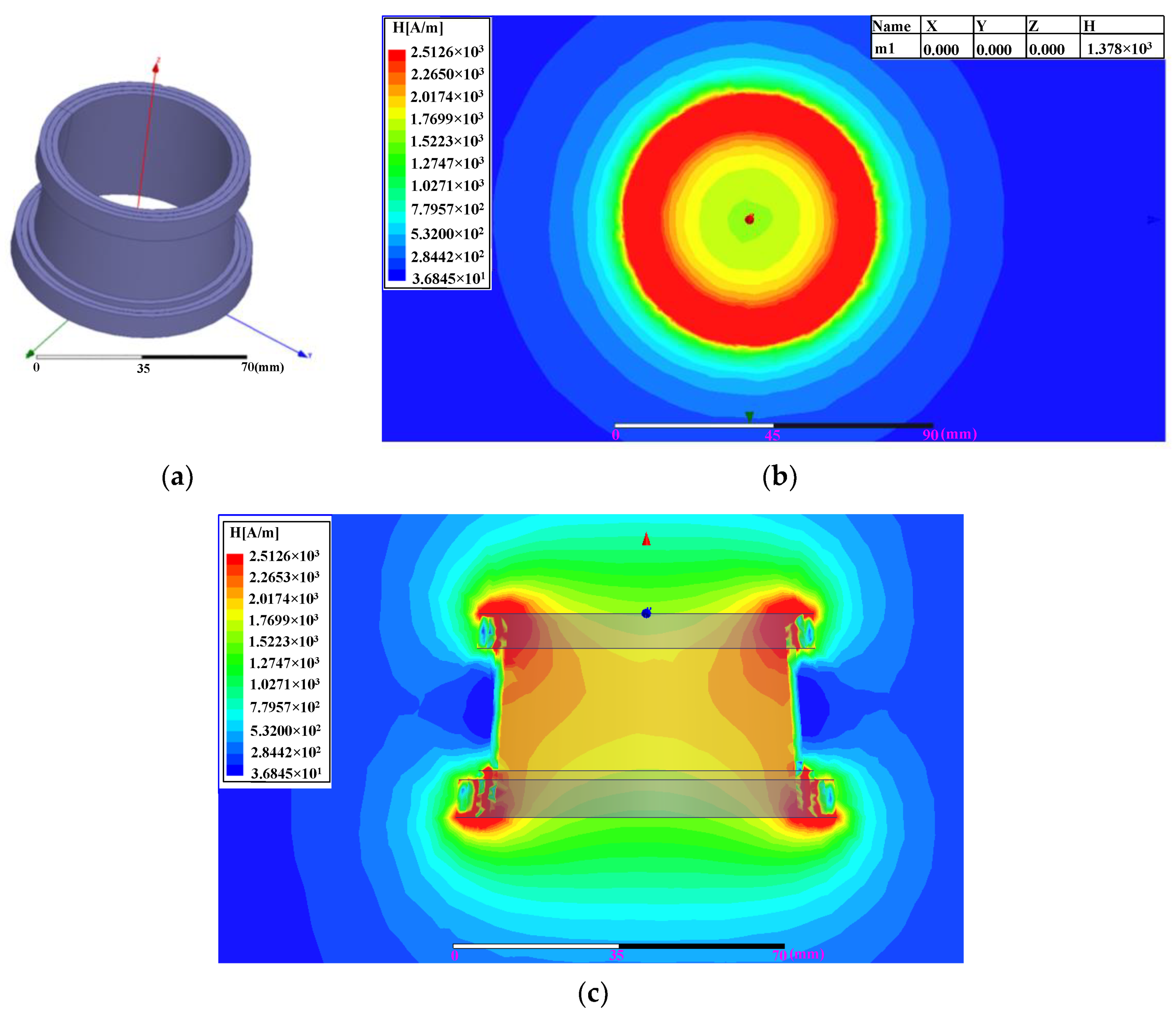

3.1. Establishment of Electromagnetic Field Model of Shrink-Fit Tool Holder

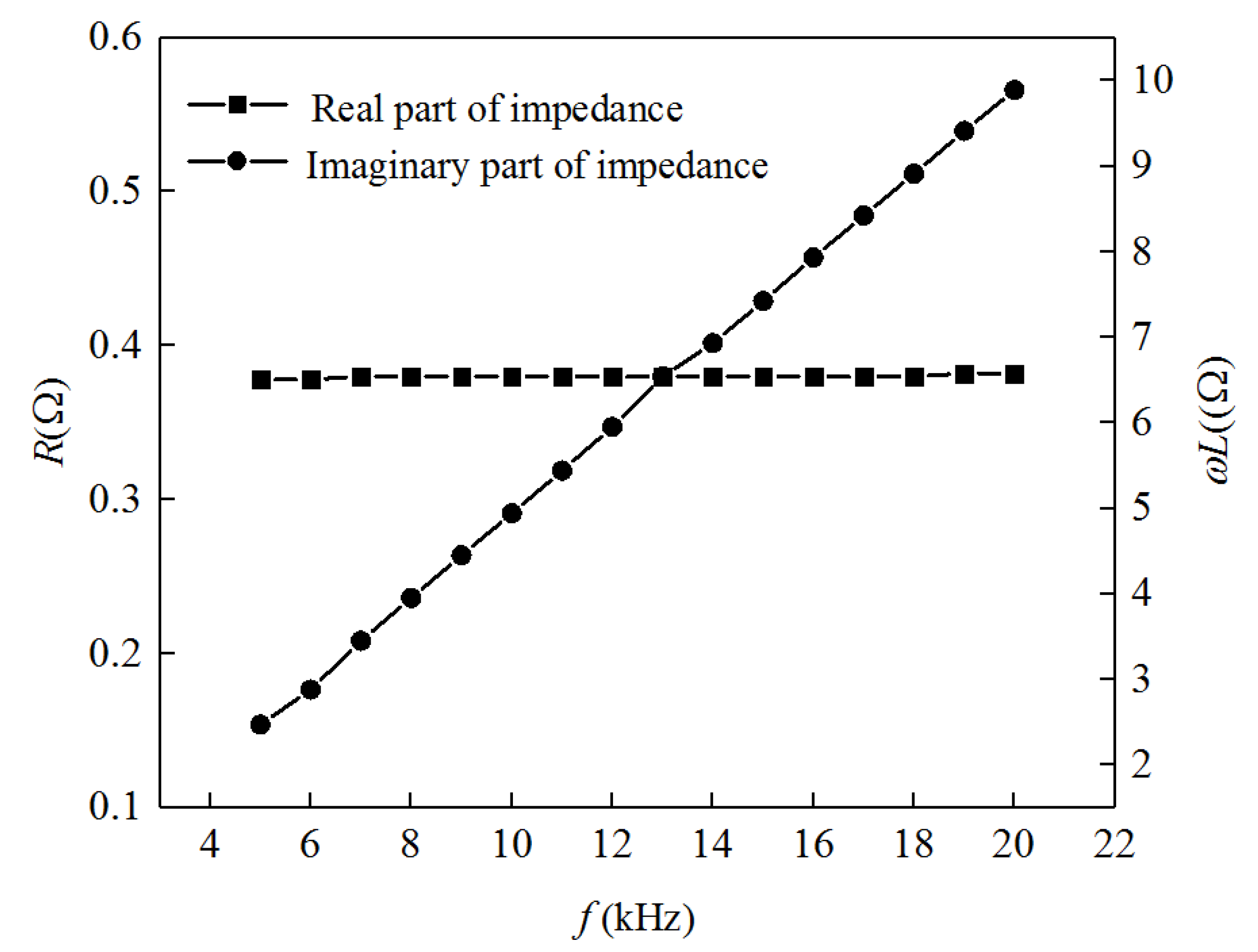

3.2. Electromagnetic Field Simulation

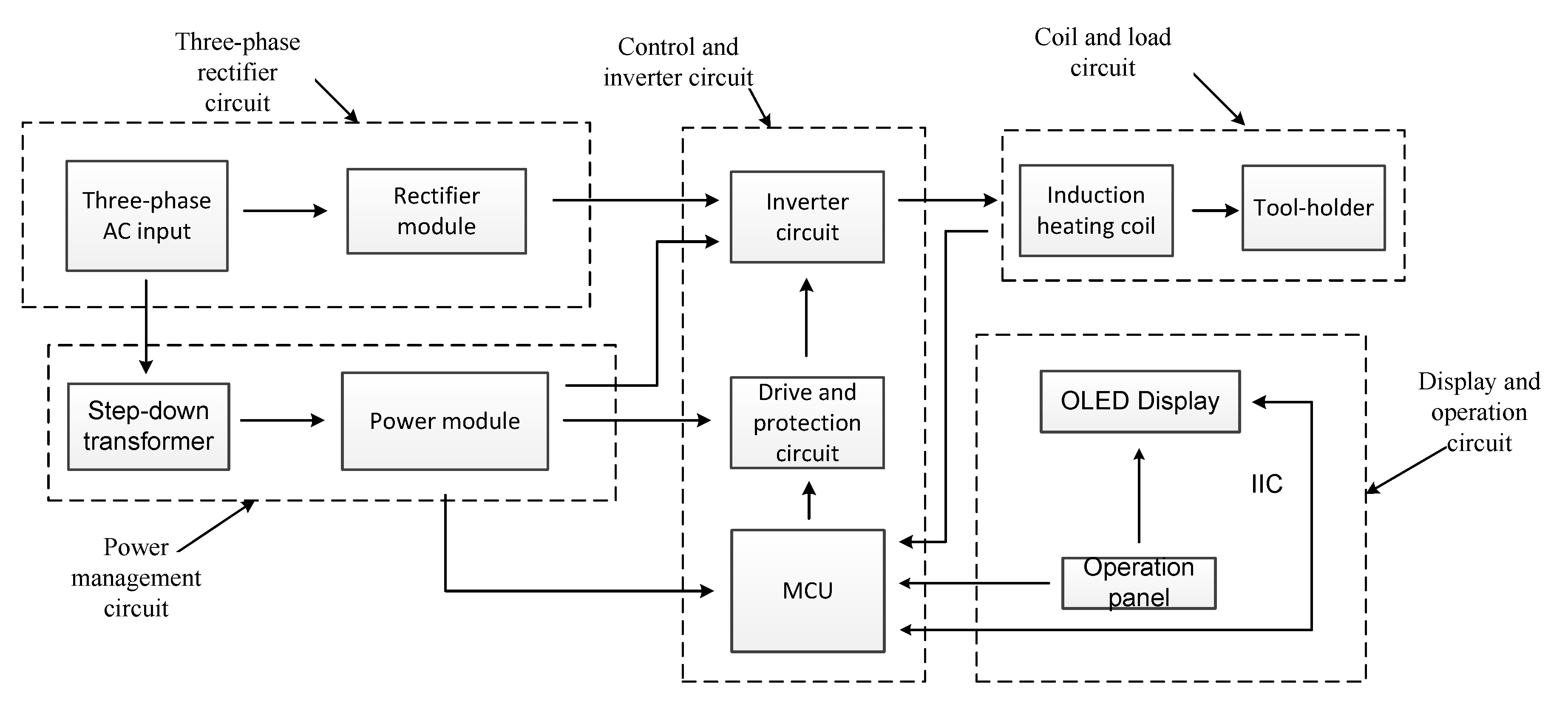

4. Design and Implementation of Tool Holder Heat-Loading Equipment

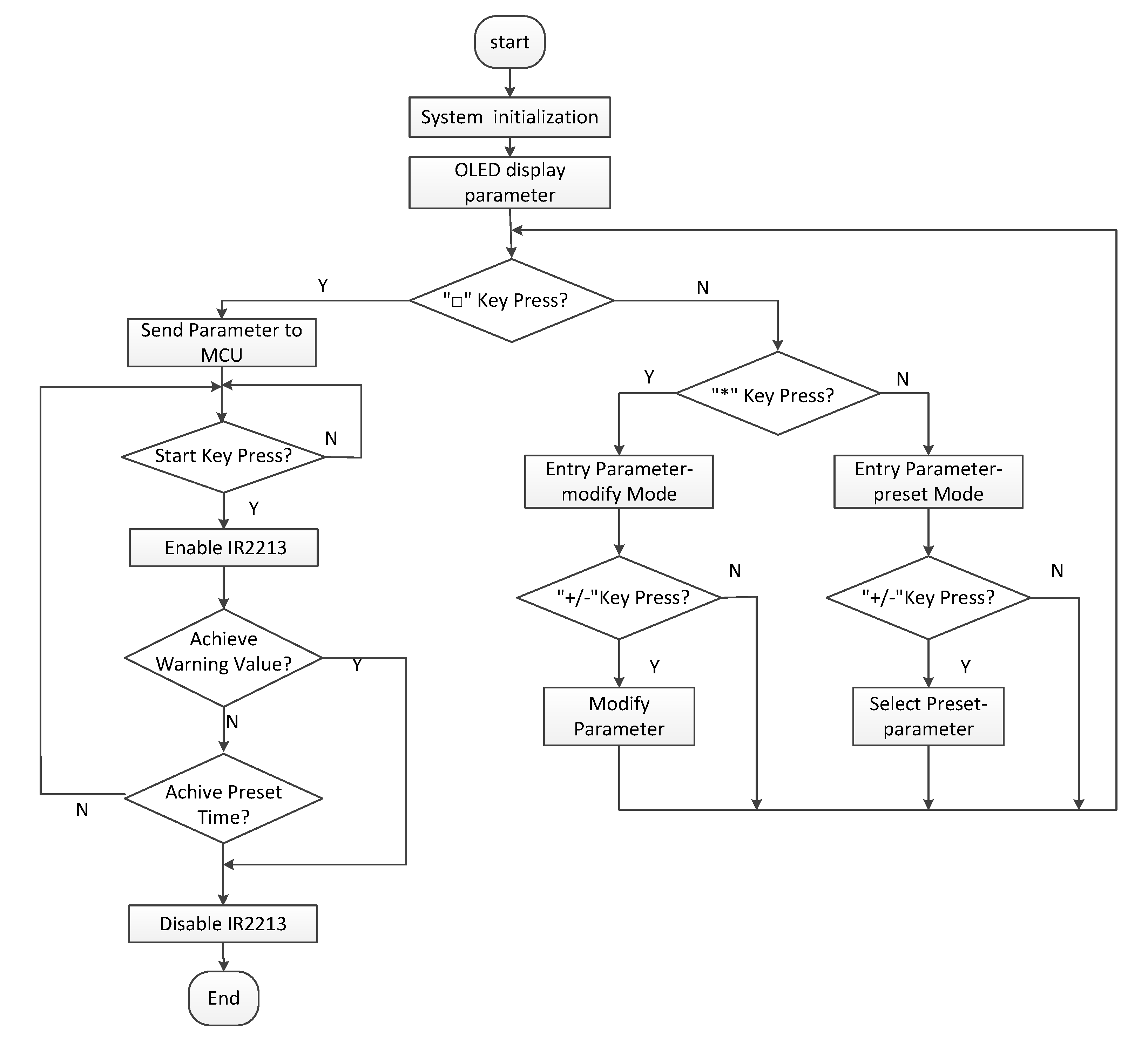

- (1)

- When the "Start" key is detected, the OLED (Organic Light-Emitting Diode) sends the parameter to the STM32 through the IIC (Inter-Integrated Circuit), thereby outputting a different PWM wave.

- (2)

- When the "*" key is first detected, the OLED enters the modified parameter mode. Then, the “*” button is pressed to modify the caliber parameter; the “*” button is pressed twice to modify the time parameter; the “*” button is pressed three times to modify the frequency parameter. When modifying the parameters, the path parameter modification step is 1.0 mm; the time parameter modification step is 0.2 s; and the frequency parameter modification step is 0.5 kHz. When the "*" key is pressed four times, the modified aperture parameter is returned.

- (3)

- When the system does not detect the "*" key press, directly detecting the "+" key press, the parameter pre-existing in the OLED is made variable, with the caliber as the variable, and a parameter larger than the currently displayed caliber size is called, if direct detection is performed. When the "-" key is pressed, the parameter pre-existing in the OLED is made variable, and a parameter smaller than the currently displayed aperture size is called. At the same time, the frequency parameter is used as a limiting condition, where the frequency is limited to between 8–20 kHz.

5. Experiment and Analysis

6. Conclusions and Future Work

- (1)

- The magnetic field in the X–Y plane generated by the proposed coil was increased by one order of magnitude around the surface of the tool holder by the addition of the magnetic slot; furthermore, the magnetic leakage was improved. The electromagnetic field strength in the middle of the coil was greatly increased, to 2.312 × 104 A/m, by the addition of a magnetic ring covering the top of the coil.

- (2)

- The simulated distribution of the three-dimensional temperature field was consistent with the electromagnetic field distribution. The highest temperature obtained by the simulation was about 370 °C, on the top of the clamping part, which was consistent with the measured result.

- (3)

- Under the same heating conditions, the heated temperatures of the BT40-SF06 were larger than those of the BT40-SF10. The inserting and pulling out temperature was about 270 °C for the BT40-SF06, but about 285 °C for the BT40-SF10, as determined experimentally. When the DC voltage was substantially the same and the heating frequency was lowered, or when the heating frequency was substantially constant and the DC voltage was increased, the heating effect was better.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hanna, I.M.; Agapiou, J.S.; Stephenson, D.A. Modeling the HSK toolholder-spindle interface. J. Manuf. Sci. Eng. 2002, 124, 734–744. [Google Scholar] [CrossRef]

- Fleischer, J.; Schulze, V.; Klaiber, M.; Bauera, J.; Zangera, F.; Boeva, N.; Leberlea, U.; Spohrera, A.; Rothaupta, B. The influence of tool holder technologies on milling performance. Procedia CIRP 2016, 46, 226–229. [Google Scholar] [CrossRef][Green Version]

- Namazi, M.; Altintas, Y.; Abe, T.; Rajapakse, N. Modeling and identification of tool holder-spindle interface dynamics. Int. J. Mach. Tools Manuf. 2007, 47, 1333–1341. [Google Scholar] [CrossRef]

- Iglesias, A.; Munoa, J.; Ciurana, J. Optimisation of face milling operations with structural chatter using a stability model based process planning methodology. Int. J. Adv. Manuf. Technol. 2014, 70, 559–571. [Google Scholar] [CrossRef]

- Karban, P.; Kotlan, V.; Dolezel, I. Numerical model of induction shrink fits in monolithic formulation. IEEE. Trans. Magn. 2012, 48, 315–318. [Google Scholar] [CrossRef]

- Yaser, M.; Milad, A.; Erhan, B. Suppressing vibration modes of spindle-holder-tool assembly through FRF modification for enhanced chatter stability. CIRP Ann. Manuf. Technol. 2018, 67, 397–400. [Google Scholar]

- Filiz, S.; Cheng, C.-H.; Powell, K.B.; Schmitz, T.L.; Ozdoganlar, O.B. An improved tool–holder model for RCSA tool-point frequency response prediction. Precis. Eng. 2009, 33, 26–36. [Google Scholar] [CrossRef]

- Lope, I.; Acero, J.; Carretero, C. Analysis and optimization of the efficiency of induction heating application with Litz-wire planar and solenoidal coils. IEEE Trans. Power Electron. 2016, 31, 5089–5101. [Google Scholar] [CrossRef]

- Chen, Y.L.; Cai, Y.; Shimizu, Y.; Ito, S.; Gao, W.; Ju, B.F. Ductile cutting of silicon microstructures with surface inclination measurement and compensation by using a force sensor integrated single point diamond tool. J. Micromech. Microeng. 2016, 26, 025002. [Google Scholar] [CrossRef]

- Yang, R.Z.; He, Y.Z.; Zhang, H.; Huang, S.D. Through coating imaging and nondestructive visualization evaluation of early marine corrosion using electromagnetic induction thermography. Ocean Eng. 2018, 147, 277–288. [Google Scholar] [CrossRef]

- Chen, S.P.; Li, L. The hot-mounted tool holder for high-speed Precision Machining. Manuf. Technol. Mach. Tool 2008, 139–141. [Google Scholar]

- Cheng, Q.; Liu, X.Y.; Zhao, Y.S.; An, G.P. Identification of dynamical contact parameters for spindle-tool holder interface based on frequency response functions. J. Univ. Sci. Technol. B 2013, 39, 1144–1148. [Google Scholar]

- Carvalho, S.R.; Silva, S.M.M.L.E.; Machado, A.R.; Guimarãesa, G. Temperature determination at the chip–tool interface using an inverse thermal model considering the tool and tool holder. J. Mater. Process Technol. 2006, 179, 97–104. [Google Scholar] [CrossRef]

- Schmitz, T.L.; Powell, K.; Won, D.; Ziegert, J.C. Shrink fit tool holder connection stiffness/damping modeling for frequency response prediction in milling. Int. J. Mach. Tool Manuf. 2007, 47, 1368–1380. [Google Scholar] [CrossRef]

- Zhou, H.; Wang, C.; Tang, D.; Peng, R. Dynamic analysis of the lengthened shrink-fit holder and cutting tool system in high-speed milling. Mach. Sci. Technol. 2012, 16, 157–172. [Google Scholar] [CrossRef]

- Chen, J.; Tian, L.; Shang, H.M.; Wang, G.C. Thermal fatigue analysis of HSK shrink toolholder. Appl. Mech. Mater. 2014, 532, 408–412. [Google Scholar] [CrossRef]

- Rezaei, M.M.; Movahhedy, M.R.; Moradi, H.; Ahmadian, M.T. Extending the inverse receptance coupling method for prediction of tool holder joint dynamics in milling. J. Manuf. Process. 2012, 14, 199–207. [Google Scholar] [CrossRef]

- Liao, J.; Zhang, J.; Feng, P.; Yu, D.; Wu, Z. Identification of contact stiffness of shrink-fit tool-holder joint based on fractal theory. Int. J. Adv. Manuf. Technol. 2017, 90, 2173–2184. [Google Scholar] [CrossRef]

- Yamazaki, K.; Yu, F. Effect of eddy-current loss reduction by magnet segmentation in synchronous motors with concentrated windings. IEEE. Trans. Ind. Appl. 2011, 47, 779–788. [Google Scholar] [CrossRef]

- Fu, X.B.; Wang, B.Y.; Tang, X.F.; Ji, H.C.; Zhu, X.X. Study on induction heating of workpiece before gear rolling process with different coilstructures. Appl. Therm. Eng. 2017, 114, 1–9. [Google Scholar] [CrossRef]

- Boglietti, A.; Cavagnino, A.; Lazzari, M. Computational algorithms for induction motor equivalent circuit parameter determination—Part II: Skin Effect and Magnetizing Characteristics. IEEE Trans. Ind. Electron. 2011, 58, 3734–3740. [Google Scholar] [CrossRef]

- Yamazaki, K.; Abe, A. Loss investigation of interior permanent-magnet motors considering carrier harmonics and magnet eddy currents. IEEE Trans. Ind. Appl. 2009, 45, 659–665. [Google Scholar] [CrossRef]

- Ebrahimi, B.; Khamesee, M.B.; Golnaraghi, M.F. Design and modeling of a magnetic shock absorber based on eddy current damping effect. J. Sound Vib. 2008, 315, 875–889. [Google Scholar] [CrossRef]

- Carr, W.J.J. Ac loss in a twisted filamentary superconducting wire. II. J. Appl. Phys. 1974, 45, 929–934. [Google Scholar] [CrossRef]

- Di Barba, P.; Forzan, M.; Sieni, E. Multiobjective design optimization of an induction heating device: A benchmark problem. Int. J. Appl. Electrom. 2015, 47, 1003–1013. [Google Scholar] [CrossRef]

- Lei, G.; Zhu, J.G.; Guo, Y.G.; Liu, C.C.; Ma, B.A. Review of design optimization methods for electrical machines. Energies 2017, 10, 1962. [Google Scholar] [CrossRef]

- Hatic, V.; Mavric, B.; Kosnik, N.; Sarler, B. Simulation of direct chill casting under the influence of a low-frequency electromagnetic field. Appl. Math. Model. 2018, 54, 170–188. [Google Scholar] [CrossRef]

- Li, Y.B.; Yan, H.B.; Massoudi, M.; Wu, W.T. Effects of anisotropic thermal conductivity and Lorentz force on the flow and heat transfer of a Ferro-Nanofluid in a magnetic field. Energies 2017, 10, 1065. [Google Scholar] [CrossRef]

- Sergeant, P.; Hectors, D.; Dupre, L.; Reusel, K.V. Thermal analysis of magnetic shields for induction heating. IET Electron. Power. Appl. 2009, 3, 543–550. [Google Scholar] [CrossRef]

- Arslan, M.A. Coupled thermal/structural contact analyses of shrink-fit tool holder. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 715–724. [Google Scholar] [CrossRef]

- Malekzadeh, P.; Golbahar Haghighi, M.R.; Heydarpour, Y. Heat transfer analysis of functionally graded hollow cylinders subjected to an axisymmetric moving boundary heat flux. Numer. Heat Transf. Part A Appl. 2012, 61, 614–632. [Google Scholar] [CrossRef]

- Ahmadi, D.; Wang, J. Online selective harmonic compensation and power generation with distributed energy resources. IEEE Trans. Power. Electron. 2014, 29, 3738–3747. [Google Scholar] [CrossRef]

| Model | TaperNo. | dm (mm) | D1 (mm) | D2 (mm) | L (mm) | H (mm) | Screw | Material |

|---|---|---|---|---|---|---|---|---|

| BT40-SF×06-90 | 40 | 6 | 20 | 27 | 90 | 36 | SO06014C | 4Cr5MoSiV1 |

| BT40-SF×10-90 | 40 | 10 | 24 | 32 | 90 | 42 | SO06014C | 4Cr5MoSiV1 |

| DC Voltage (V) | Starting Temperature (°C) | Heating Frequency (kHz) | Heating Temperature (°C) |

|---|---|---|---|

| 202.4 | 24.9 | 20 | 208.9 |

| 205.5 | 28.0 | 18 | 221.4 |

| 207.3 | 27.4 | 16 | 228.8 |

| 205.1 | 26.0 | 14 | 237.7 |

| 201.7 | 25.0 | 12 | 252.1 |

| 223.7 | 23.0 | 20 | 254.7 |

| 225.2 | 24.7 | 18 | 269.9 |

| 228.3 | 25.6 | 16 | 280.7 |

| 225.0 | 26.1 | 14 | 294.4 |

| 224.4 | 25.1 | 12 | 316.1 |

| 256.4 | 25.3 | 20 | 318.4 |

| 264.1 | 25.2 | 18 | 342.5 |

| 248.7 | 26.8 | 16 | 356.9 |

| 249.9 | 24.4 | 14 | 370.1 |

| 251.8 | 24.8 | 12 | 387.3 |

| DC Voltage (V) | Starting Temperature (°C) | Heating Frequency (kHz) | Final Temperature (°C) |

|---|---|---|---|

| 205.5 | 27.6 | 18 | 211.4 |

| 207.3 | 27.4 | 16 | 219.3 |

| 205.1 | 25.7 | 14 | 226.6 |

| 203.6 | 25.5 | 12 | 239.9 |

| 223.7 | 23.2 | 20 | 248.8 |

| 225.2 | 24.2 | 18 | 259.1 |

| 228.3 | 25.0 | 16 | 270.0 |

| 225.0 | 25.9 | 14 | 284.9 |

| 256.4 | 25.1 | 20 | 304.9 |

| 264.1 | 25.3 | 18 | 333.5 |

| 248.7 | 26.5 | 16 | 347.0 |

| 249.9 | 24.9 | 14 | 359.7 |

| 250.1 | 25.5 | 12 | 370.1 |

| Starting Temperature (°C) | Heating Frequency (kHz) | Heating Time (s) | Heating Temperature (°C) BT40-SF06 | Heating Temperature (°C) BT40-SF10 |

|---|---|---|---|---|

| 23.3 | 20 | 5 | 251.1 | 245.1 |

| 26.3 | 20 | 6 | 286.3 | 276.3 |

| 26.4 | 20 | 7 | 318.4 | 304.9 |

| 24.1 | 20 | 8 | 341.8 | 332.2 |

| 25.5 | 18 | 5 | 287.2 | 281.3 |

| 25.2 | 18 | 6 | 313.8 | 307.2 |

| 24.2 | 18 | 7 | 334.1 | 333.5 |

| 24.3 | 18 | 8 | 365.4 | 363.7 |

| 23.9 | 16 | 5 | 307.7 | 298.6 |

| 24.0 | 16 | 6 | 331.6 | 330.4 |

| 25.1 | 16 | 7 | 350.9 | 347.0 |

| 24.7 | 16 | 8 | 378.2 | 375.4 |

| 25.6 | 14 | 5 | 311.2 | 304.7 |

| 25.0 | 14 | 6 | 342.3 | 330.3 |

| 25.5 | 14 | 7 | 370.1 | 359.7 |

| 24.8 | 14 | 8 | 398.5 | 385.1 |

| 24.6 | 12 | 5 | 341.7 | 322.3 |

| 26.1 | 12 | 6 | 370.0 | 351.5 |

| 24.7 | 12 | 7 | 389.3 | 370.1 |

| 24.9 | 12 | 8 | 412.1 | 397.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Li, C.; Sun, S.; Tong, R.; Li, Q. A Study on the Heating Method and Implementation of a Shrink-Fit Tool Holder. Energies 2019, 12, 3416. https://doi.org/10.3390/en12183416

Wu X, Li C, Sun S, Tong R, Li Q. A Study on the Heating Method and Implementation of a Shrink-Fit Tool Holder. Energies. 2019; 12(18):3416. https://doi.org/10.3390/en12183416

Chicago/Turabian StyleWu, Xiushan, Can Li, Sian Sun, Renyuan Tong, and Qing Li. 2019. "A Study on the Heating Method and Implementation of a Shrink-Fit Tool Holder" Energies 12, no. 18: 3416. https://doi.org/10.3390/en12183416

APA StyleWu, X., Li, C., Sun, S., Tong, R., & Li, Q. (2019). A Study on the Heating Method and Implementation of a Shrink-Fit Tool Holder. Energies, 12(18), 3416. https://doi.org/10.3390/en12183416