1. Introduction

In recent years, with the depletion of fossil fuel reserves, the search for alternative energy sources has continued rapidly. Various power plants are being established to meet the increasing energy demand. However, as a transport sector, which plays a major role in the consumption of fossil fuels, developments on the electric vehicles’ (EVs) technology will minimize the need for fossil fuels or eliminate dependence on fossil fuels completely. In addition, zero-emission electric vehicles (ZEVs) take over the role in reducing carbon emissions due to fossil fuel consumption. Although the cheapness of internal combustion engines encourages consumers, there will be an excessive increase in costs due to the decline in the supply of fossil fuels in the future. Nowadays, many vehicle manufacturers have turned to hybrid and fully EVs for the future [

1].

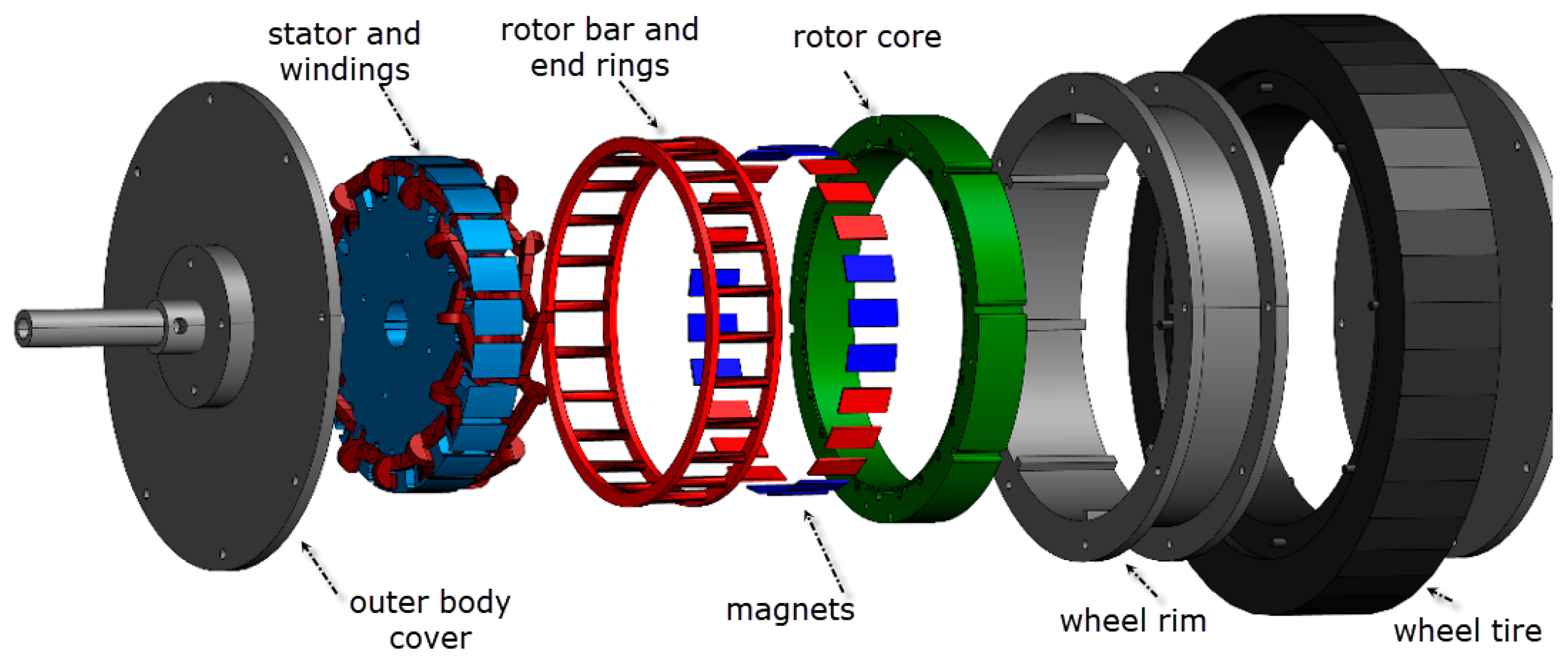

Modern EVs consist of three main parts: the battery used as an energy source, the electric motor converting the stored electrical energy into the motion and other part is the powertrain. Depending on the six types of EV configurations in the literature, electric motors used in EVs can be classified as inner rotor and outer rotor. In the configurations where the preferred motors with inner rotor are used, mechanical differentials and gears must be commonly used. But, if the selected motors with outer rotor are placed in the wheels, it does not require additional mechanical transmission parts. Since the electric motors with outer rotor transfer the needed power directly to the wheels, an efficiency increase can be achieved compared to that of inner rotor for the same power. On the other hand, the lack of transmission components reduces the rotational inertia of the vehicle. Moreover, the direct placement of the electric motors on the wheels reduces the center of gravity of the motor and reduces the number of moving parts. It is another advantage to place the electric motor on each wheel if desired [

2].

The electric motors directly determine the torque-speed and power-speed characteristics of EVs. Furthermore, the electric motors are suitable for the high torque and acceleration at any low speed. Typical electric motor characteristics are examined in constant torque and constant power region. The selection of the most suitable electric motors for the EVs were declared in the literature [

3,

4,

5]. DC motor, induction motor, synchronous motor, reluctance motor and hybrid motors types with inner rotor have been investigated for EVs. In the early years, DC motors were used in EVs because of controlling easy. However, the interest in DC motors has been decreased because of the maintenance of the brushes. In addition, developments of technology on the AC drives, induction motors (IMs) with simple structure and having relatively higher efficiency have been preferred. Furthermore, lots of studies have been conducted with permanent magnet and reluctance motor by the researchers and manufacturers. In a comparative study using the finite element method (FEM) on a few electrical motors, such as the interior permanent magnet synchronous motor (IPMSMs), the synchronous reluctance motor (SynRMs) and IMs, which are designed for EVs, it is concluded that the SMs are more efficient than others, especially at low speeds. However, the core losses of the IPMSMs at high speeds are higher than the IMs. In terms of the vibration, the switching reluctance motors (SRMs) have disadvantages with respect to the others [

6]. In another study, an IPMSM, a surface-mount permanent magnet SM (SMPMSM) and an IM were compared with each other. The results of this research showed that the PMs are more efficient than the IMs because of no cage losses. On the other hand, the SMPMSMs have not always more torque density [

7].

In recent years, works on the motors with outer rotor have been intensified to get rid of efficiency reducing components such as clutch, gearbox and mechanical differentials in the EVs. At the same times, the brushless DC motor (BLDC) has been most commonly used in the outer rotor applications. In a study using finite element method (FEM) to design a direct-drive BLDC motor for the EVs, the torque fluctuations were reduced from 17.58% to 8.4% [

8]. The BLDC motors, dual-stator and dual-field-excitation permanent magnet motors (DDPM), permanent magnet Vernier motors (PMVM), permanent magnet (PM) motors, permanent magnet flux switching (PMFS) motors and axial-flux (AF) motors with an outer rotor structure have been designed to be used in electric vehicles. The AF motor with radial active part designed for the range-extended electric vehicle has sufficient torque density [

9]. In the FS Motor topology with a different number of slots and poles, the magnet ratio of the motors was reduced to 54%. In addition to that, the cogging torque was decreased by 20% while the average torque was decreased by only 1.80% [

10]. The IPM type, SPM type, PMFS type and PMVM type with six-phase were compared in a study [

11]. The results of these studies show that PMVM is suitable for the EVs because of its high torque density and efficiency. Another way to get higher torque, better efficiency and power factor is to design a motor with outer rotor. However, the limited stator area causes overheating, flux saturation and demagnetization. Therefore, thermal analysis is required to determine the demagnetization at different temperatures as it was emphasized in Shu et al. [

12]. Especially, the maximum torque improved, sufficient mechanical power and more efficiency can be obtained by proper alignment of the magnets for an outer rotor PM Synchronous Motor (OR-PMSM) while keeping the minimum value of cogging torque and low torque ripples [

13].

Neither the IMs nor the SMs can meet the needs of the EVs up to now. As a different solution to provide these needs, a new line-start synchronous motor (LSSM) was designed to combine the advantages of IM and PMSM. For this purpose, many studies have been carried out in the literature on inner rotor LSSM. It was reported that the power factor and efficiency of LSSM are higher than the IM’s [

14]. Also, the opportunities and design challenges of the motor have been covered. Despite higher cost and synchronization problems, LSSM has a high efficiency, high power factor and high-power density when compared to other motors [

15]. Better performance at the startup and rapid synchronization have been achieved with the low magnetizing inductance [

16]. The impact of the structure of the squirrel cage on the motor synchronization showed that the asymmetrical cage is useful to improve the startup performance [

17]. Research has been conducted on motor efficiency and production cost by using different magnet materials [

18]. Another solution for initial synchronization problem is to take deep bar replacement into account [

19]. In a recent study, the effect of the skew angle on synchronization performance and torque ripples was also presented [

20]. In the literature, to handle with the LSSM problems, several design studies have been carried out on inner rotor LSSM, and different methods for the magnet alignments to improve the design have been examined. In these studies, the simplest method is to add magnets to the inner rotors of the conventional induction motors. The other method is to implant a squirrel cage on the rotor of the SM [

21]. Unlike the modification of existing motor types, a new design can be made. In general, to design a new motor, it is necessary to determine the geometry, calculate the stator parameters, and define the rotor type and their design parameters. However, the motor designed with initial design parameters may have a bad performance. Therefore, optimization of the parameters is required for the desired performance. There are several studies done for this objective in the literature related to the line start PMSM with inner rotor. In ref [

22], torque density was increased by performing an optimization technique involved response surface methodology on the magnets size. Another study employed the genetic algorithm to improve the efficiency, power factor and starting performance [

23]. Preferring a neural network based imperialist competitive algorithm is one of the other options to achieve optimum values of the rotor-slot parameters, such a study was presented in ref [

24]. Design procedure and optimal guidelines for overall enhancement of steady-state and transient performances of line start permanent magnet motors with inner rotor were presented successfully in ref [

25]. Proposed rotor type in that study includes embedded four-magnet and conventional rotor bar cage. The study was introduced with wholly parametrical analysis. On the other hand, stochastic optimization considering both steady state and dynamic capability of the designed motor was used to improve the maximum synchronous torque capacity [

26]. One of the recent studies published on this issue declared that Taguchi-based regression rate method improved the steady-state and the transient synchronization performance [

27].

Another option for improving the design is to figure out effects of the design parameters on the motor characteristics by the parametrical analysis. The first study on the line start PMSM with an outer hybrid rotor was presented in ref [

28]. Where, this type motor called as outer rotor LSSM (OR-LSSM) by the authors, and introduced the synchronization performance of the OR-LSSM with three different hybrid rotor types under the unloaded condition. The results of the study showed that most of the line start inner rotor structures can be applied on the outer-rotor LSSM on condition optimizing the magnet size and the rotor bar with different alignments yielding better performance.

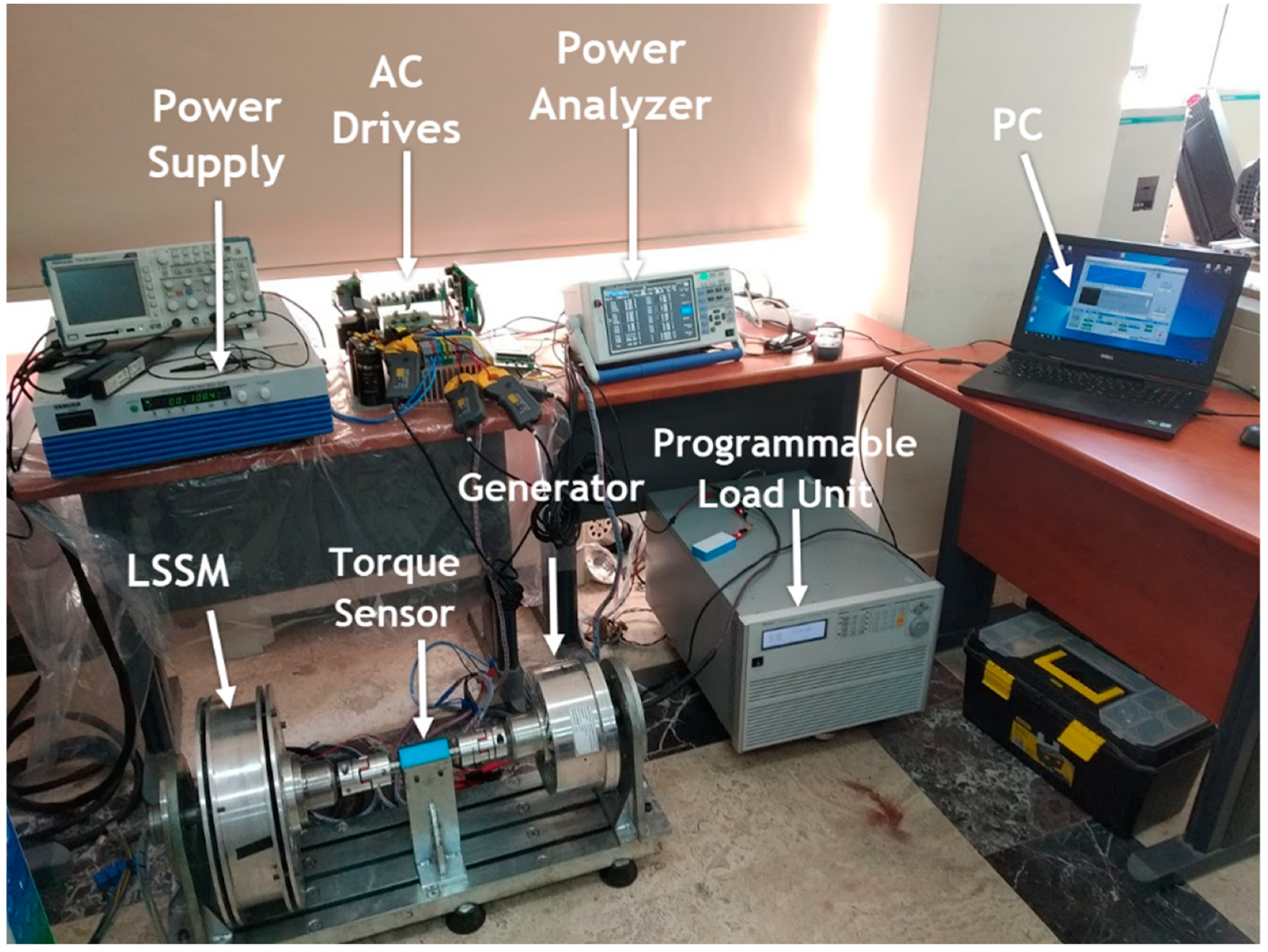

Importance of the outer hybrid rotor is that while the outer rotor maintains desired torque at synchronous speed, embedded rotor bars provides a soft starting to the motor and holding the motor stable in variable load-up system. In this study, a novel outer hybrid rotor configuration for the permanent magnet synchronous motors was presented. Considered comparison in introduction section of this study explains the differences between the others. All of the existing studies are on the inner rotor and their different configurations. Nevertheless, using in electrical vehicle, axial length of the tires and wheel rims are short and radial diameter is large. Therefore, outer rotor structure must be taken into account to provide necessary torque for the EV according to the tire dimensions. For this purpose, in this study four different outer hybrid rotor types were design and analyzed by FEM. The first three configuration introduced in this study (magnet alignments and bar replacements in Type-A, B and C) have been already processed for the inner hybrid rotors in the literature. In addition to these configurations a new hybrid outer rotor type (Type-D) was proposed and analyzed together with the others. One of these configurations, Type-D was selected to implement for the experiments because of its better performance. All of the experimental results validate the simulations for the proposed configuration in every aspect.

The paper is structured as follows. Firstly,

Section 2 describes the design of inner stator and outer hybrid rotor, alignment of the magnets and replacement of the rotor bars.

Section 3 presents the performance analysis of the designed motor types by FEM. Prototype implementation and experimental studies are given in

Section 4. Finally, the conclusions are summarized in

Section 5.

2. OR-LSSM Design

In the research, IM and PM motors have been used as the basis for hybrid motor design. Many analytical calculations related to IM design are available in the literature, and their structures are almost identical to the LSSMs. However, in this study, since the motor was designed to be completely non-standard main dimensions for the electric vehicle, stator, a rotor bar with several magnet configurations and their parameters (dimension, alignment types, the skew angle of the rotor-bar together with rotor laminations) were considered respectively.

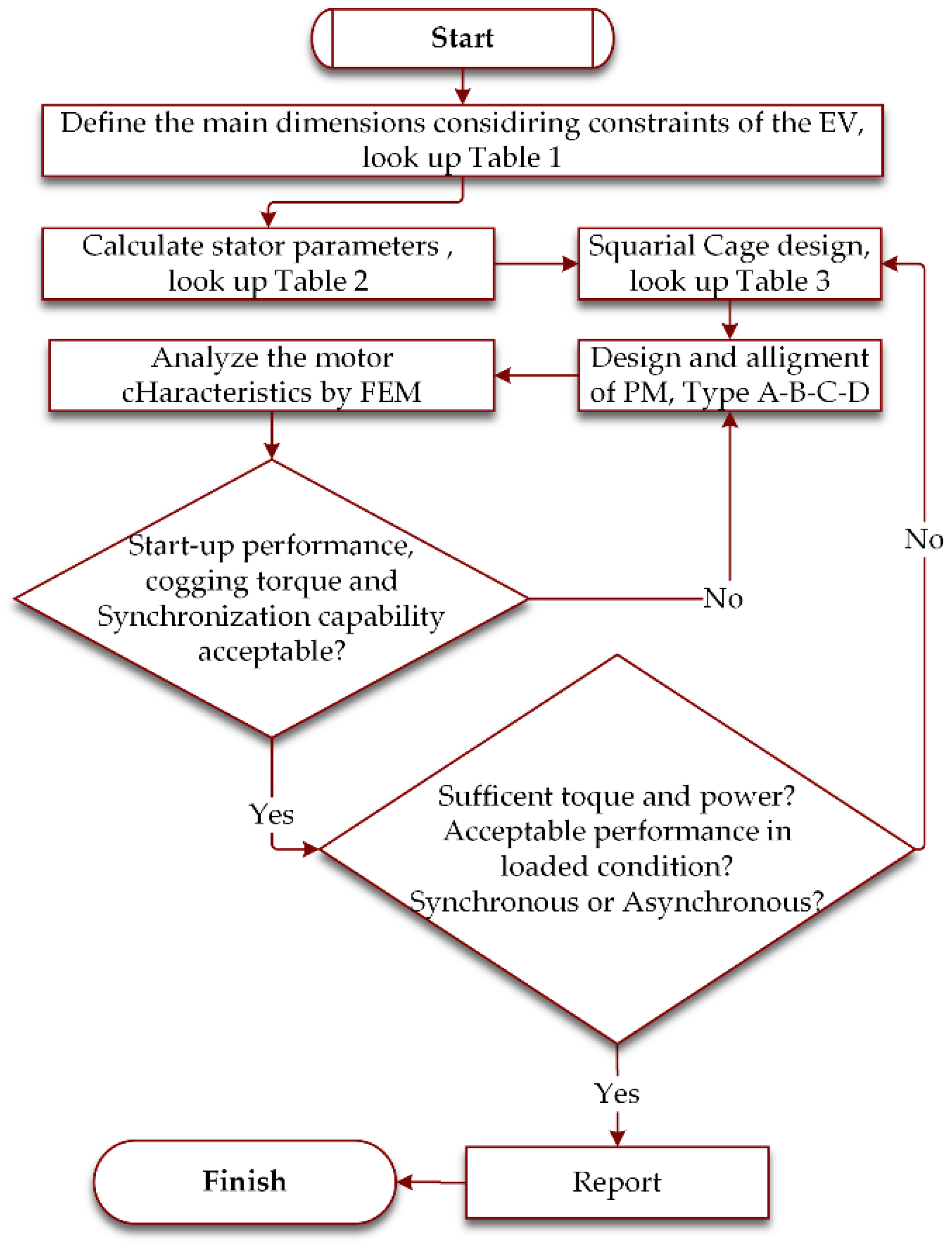

In general, to design and implement a motor, sufficient volume is firstly calculated for the desired power by taking the limitations into account. Then, the motor length is determined in accordance with the wheel diameter of an electric vehicle to be used. After calculating the length and diameter of the motor, the air gap is determined according to these dimensions to reduce unloaded speed oscillations and torque ripples. The conductors’ material, slot types and numbers in the stator and rotor as considering their configurations are identified depending on the pole-pair and motor power. In addition to that, cross-sectional area and number of turns of the conductors are estimated by some equations considering fill factor in the slots and saturation in the core due to stator winding and rotor bar current. Finally, the magnets are configured to insert into the outer rotor as to provide synchronization and minimize the losses in the steady-state operation. The design procedure is shown in

Figure 1 as a flowchart.

After determination of the initial motor dimensions, optimization and parametric analysis by FEM is used to define the best parameters to achieve better efficiency, sufficient torque and good synchronization performance at low and high speed. If the motor does not produce sufficient torque, it is necessary to change the motor dimensions. In addition, it is essential to determine the proper magnet parameters to provide optimum synchronization.

One of the goals of these configurations, if any abandoning of synchronization occurs, asynchronous mode holds the motor at sub-synchronous speed without collapse for high load angle of PMSM in case of overload operation. The other goal is that, under conditions of nominal load transition, magnets in the rotor recovers the speed up to the synchronous.

2.1. Main Dimensions of the Machine

In general, the initial value of

is selected in the interval of 0.35–0.6 Tesla [

29]. Selecting a higher value of

gives some benefits such as reducing the size of the motor, decreasing the cost and increasing overload capacity. The flux in the air gap per pole,

is given depending on the motor parameters and

, as given in

Table 1.

Where, is the average flux density in the air gap, is the motor diameter, is the motor axial length, is synchronous speed (rps), is phase current, is winding factor and is the number of poles.

The highest current capacity, as reducing the motor mass, results in more copper losses and increase the temperature. The proper value of current carrying capacity per square meter of conductor,

, can be selected in the interval of 1000–4500. In addition, the number of turns per phase,

is defined by Equation (3) in

Table 1.

The relationship between D and L has great importance in terms of the characteristic behavior of the motor. The considered EV determines the most accurate detections for these parameters.

2.2. Inner Stator Design

The stator of the motors with both inner and outer rotor consists of a core and slots. Types of the slots, such as open slot and semi-closed slot, have an impact on the power factor and manufacturing. Assembly of semi-closed slots has some difficulties compared to the open slots. However, the motor characteristic behavior is better than the other one.

In

Table 2, M is the number of phases,

is the supply voltage per phase,

is number of slots per pole per phase and

is current density of a conductor (about 3–5 A/mm

2).

2.3. Outer Rotor Design

Considering the placements of the magnets in the rotor laminations for the studied models, the core slots are determined according to the slot pitch and number of slots per phase, by Equations (12) and (13) respectively, as given

Table 3. In this table, the

parameter is the number of the slots on the rotor.

It is assumed that the rotor magneto-motor force (MMF) on the flux route is accepted about 0.85 times to that of the stator. In addition, rotor current per conductor bar is calculated by Equation (15). Related to the current density in the rotor bar,

, which is about 4–7 A/mm

2, cross-sectional area of the rotor bar is obtained by Equation (16). End ring current per pole is calculated by Equation (17). After that, the cross-sectional area of the rotor end ring is obtained by Equation (18) corresponding to the current density in the rotor end ring,

, which is about 5–8 A/mm

2. For detailed information about the equations in

Table 1,

Table 2 and

Table 3 was referred to ref [

30], the closely related references therein.

2.4. Orientation of the Magnets

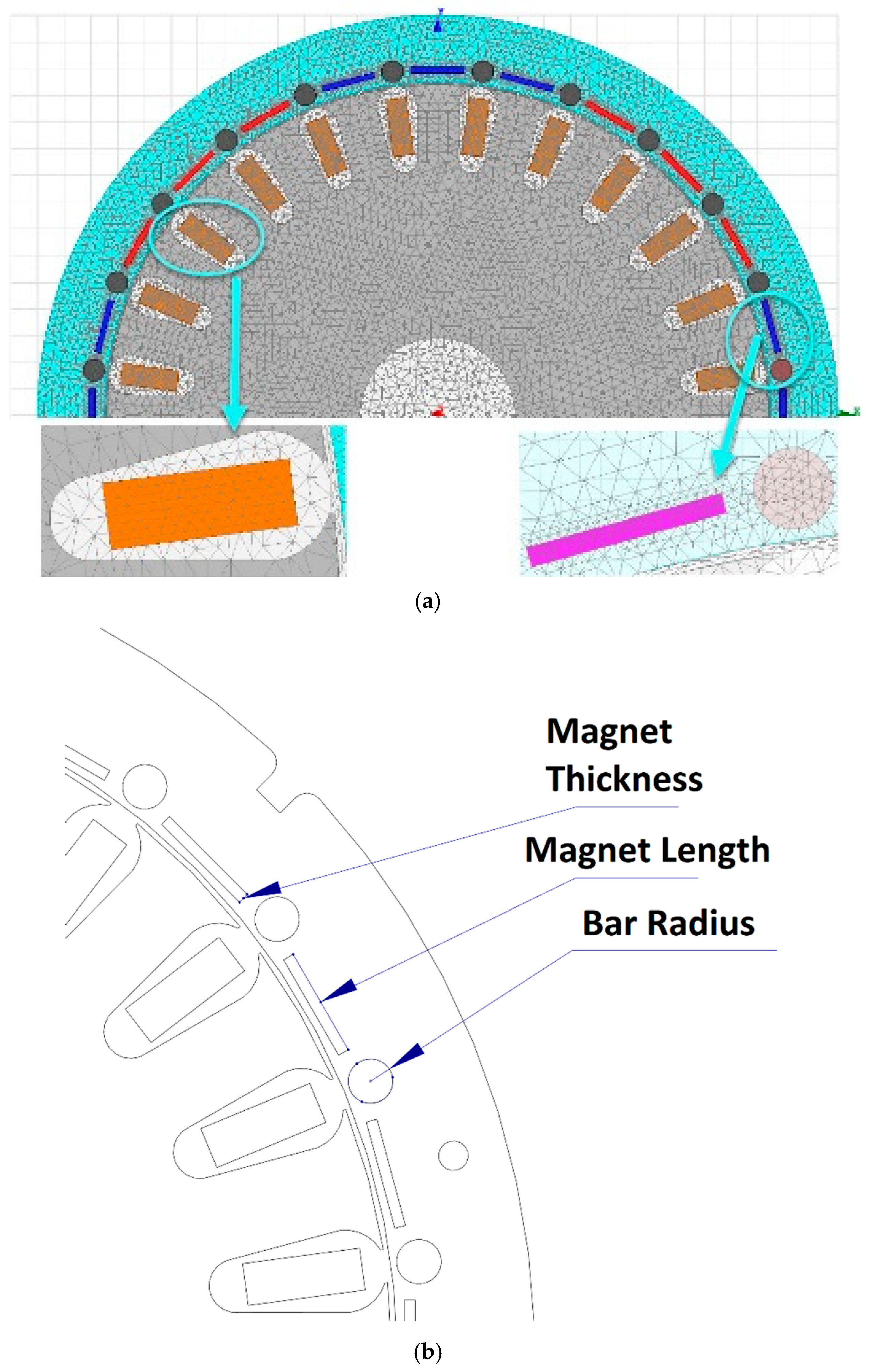

All research introduced to date, although many magnet alignment types have been proposed for the LSSM including inner rotor, only a few of them are suitable for outer rotor design as well because of the limited structural area of the rotor. In this study, LSSM models with 4 different types of magnet alignments for a medium voltage, low power electric vehicles were analyzed in the same inner stator configuration. All of these types analyzed by FEM are shown in

Figure 2. Results obtained by the FEM analysis are evaluated and discussed in the next section.

5. Conclusions

In this paper, instead of commonly used motors in electric vehicles, four different types of the outer rotor LSSM, which do not require any sensor and have no trouble in startup like a PMSM, have been designed and analyzed by FEM. The proposed novel motor model prototype which is the best model was implemented and experimental studies are presented.

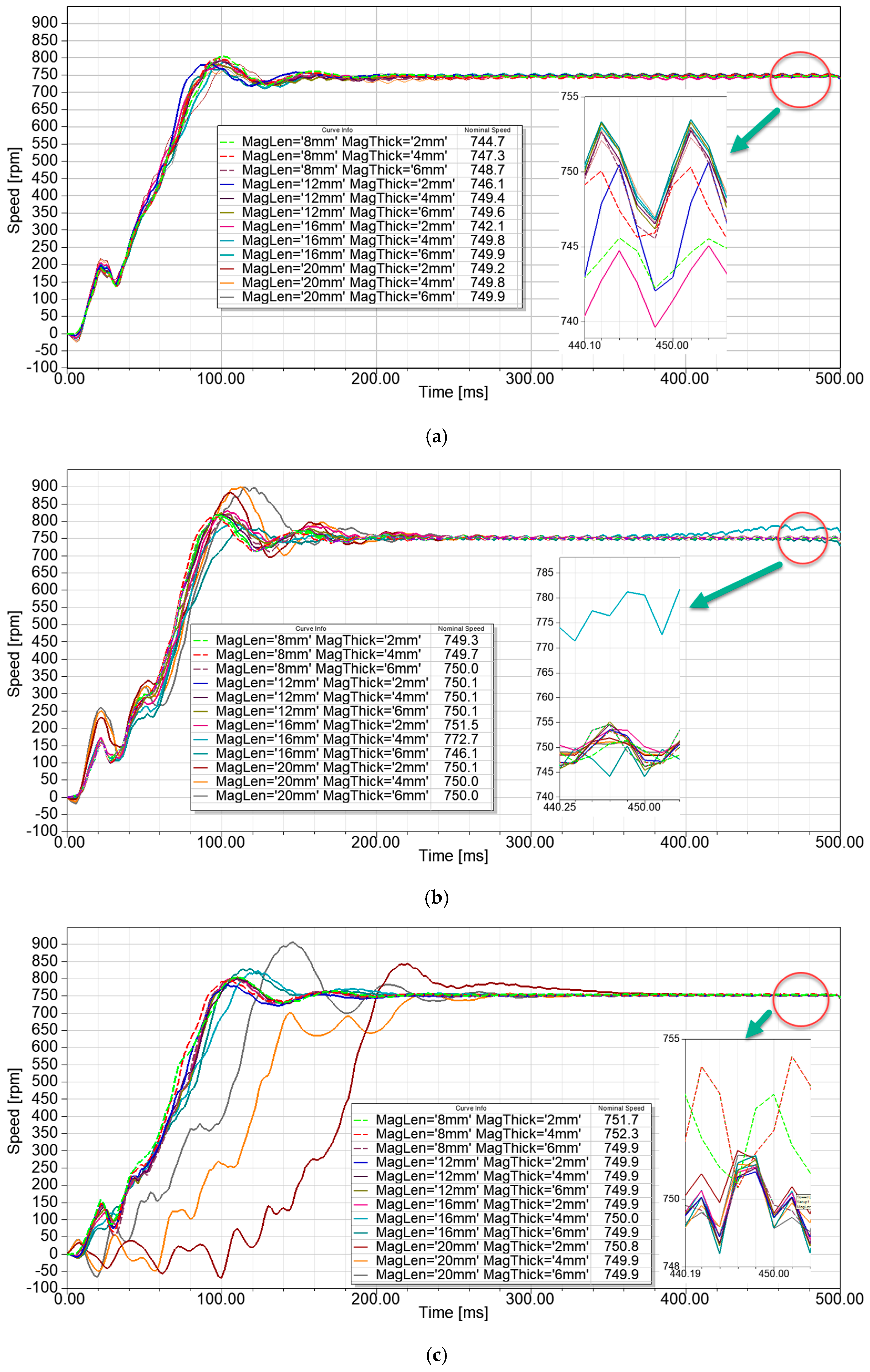

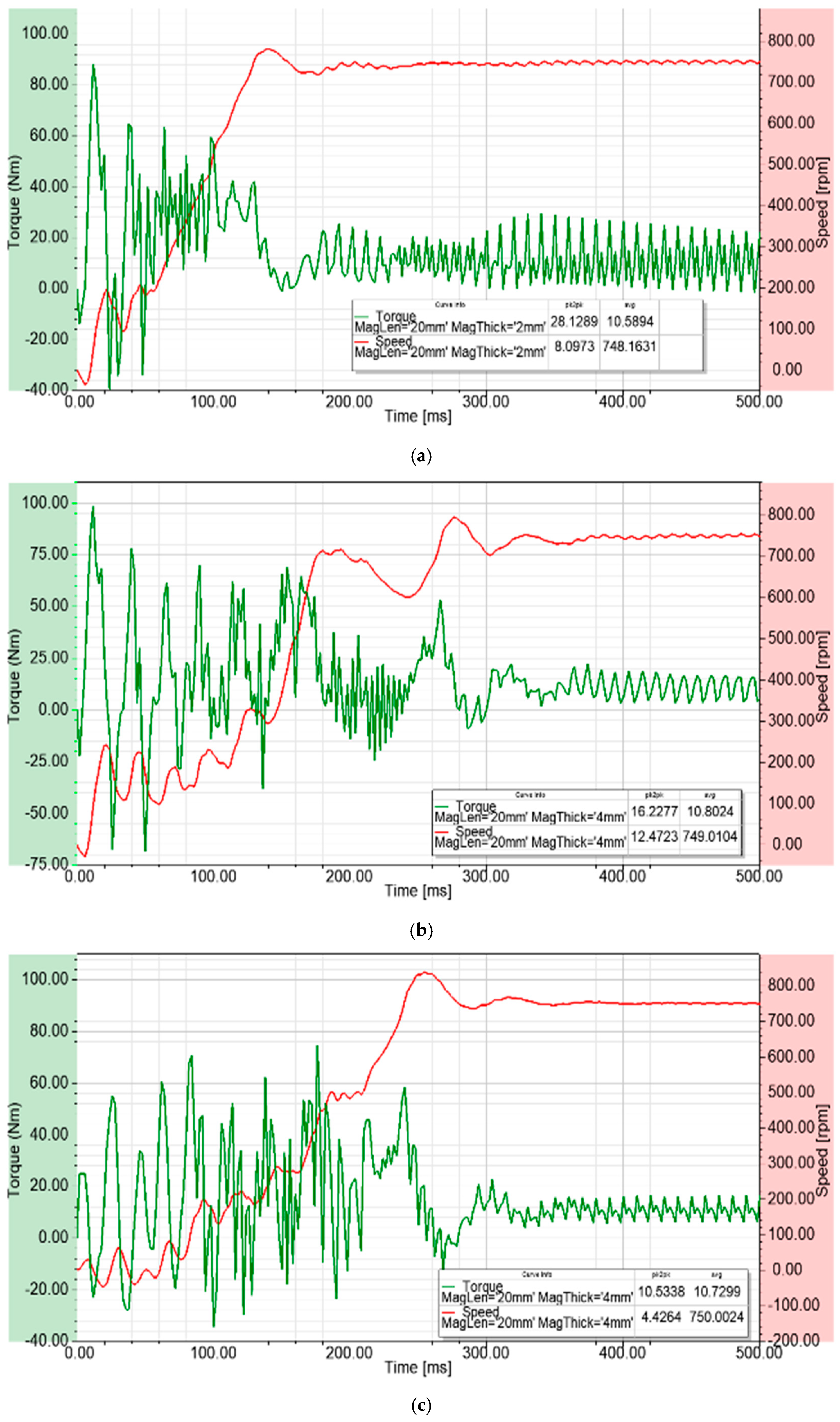

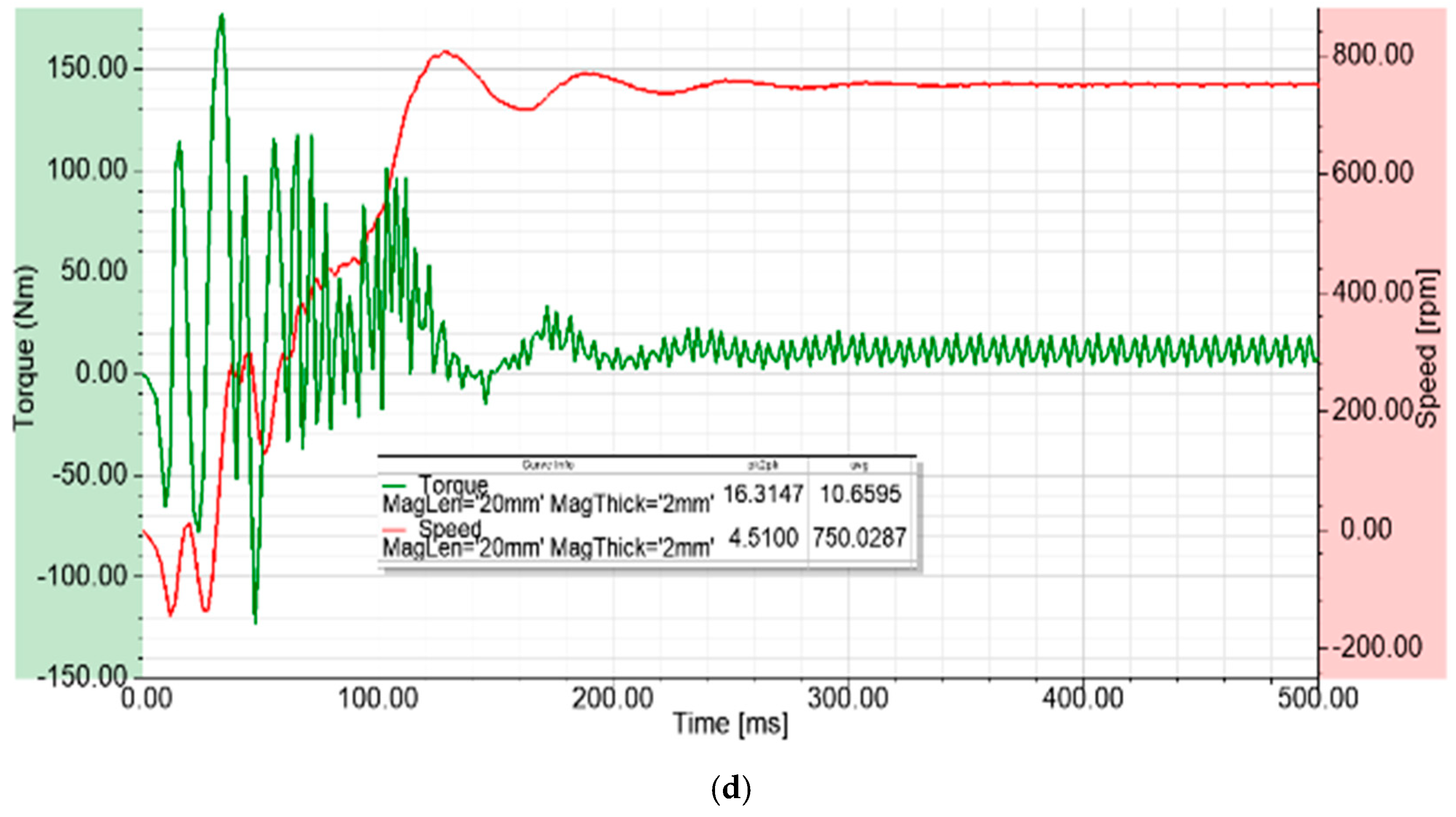

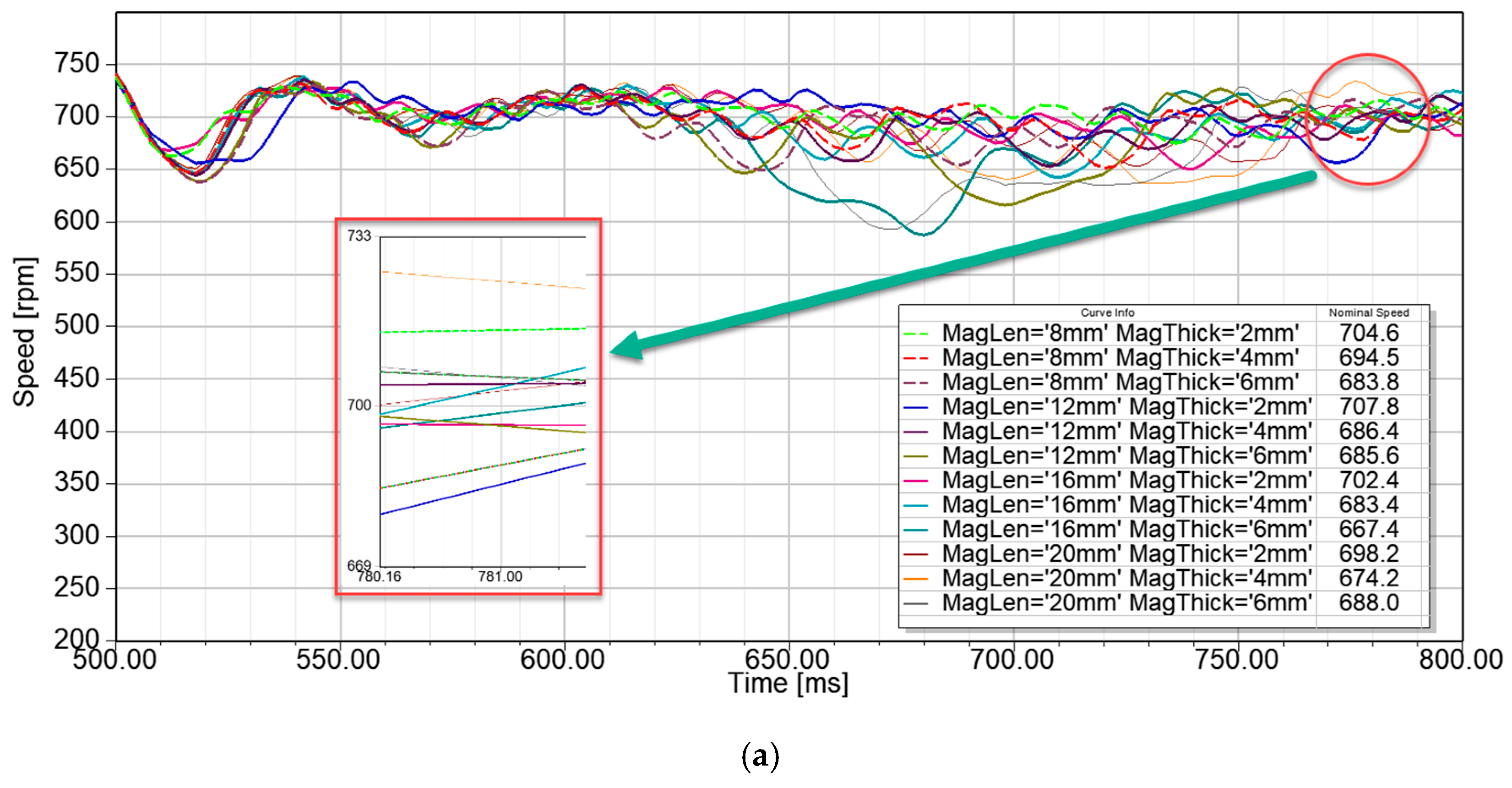

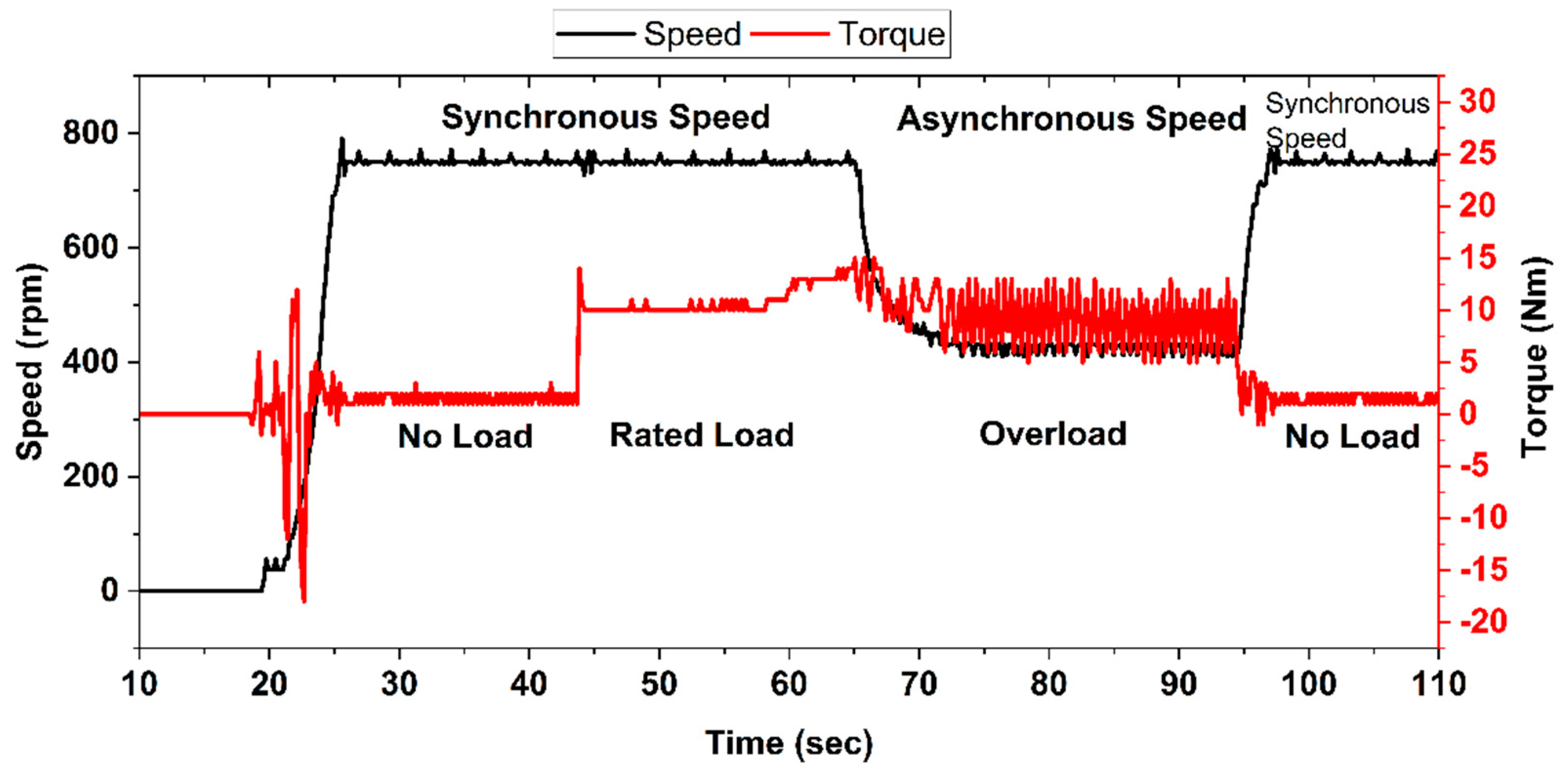

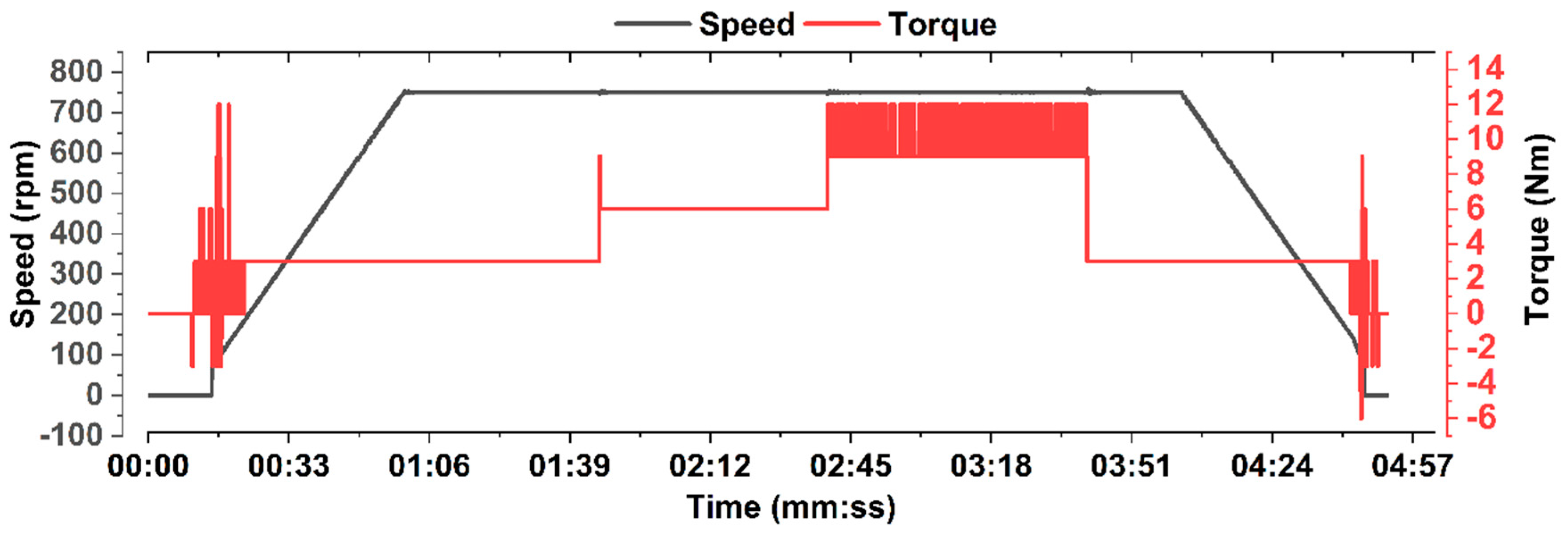

All motor types have been analyzed in terms of synchronization performance, starting performance and torque ripples with no load and under load. According to the findings obtained in this study, with no load, in terms of starting performance, the Type-D motor was 20% faster than the Type-B and C, but the same as the Type-A. When the motors were running under load, although the Type-D motor was the same as the Type-A, it was twice as fast as the B and C types, in terms of the settling time. Based on the torque ripple amplitude in steady-state, the Type-D motor had the lowest ripple amplitude with a low frequency. Although the Type-A motor was not stable, the torque ripple amplitude and frequency were three times higher than the Type-D. The Type-B and Type-C motors produced 70% lower torque ripple amplitude and frequency than the Type-A when continuously operating under load.

The obtained results from both the simulations and the experiments show that the proposed Type-D motor gives good performance at startup and produces fewer torque ripples by keeping the speed at the synchronous in case of working at the rated power. Under overload, the motor remained in asynchronous mode, thus ensuring the continuity of the system. This study demonstrated that the newly proposed outer rotor LSSM has the advantages of both synchronous motors and asynchronous motors. Thus, based on the above analysis and discussion, the proposed model can be used for EVs applications.