Vehicle Optimal Control Design to Meet the 1.5 °C Target: A Control Design Framework for Vehicle Subsystems

Abstract

1. Introduction

1.1. Literature Review

1.2. Contribution of This Work

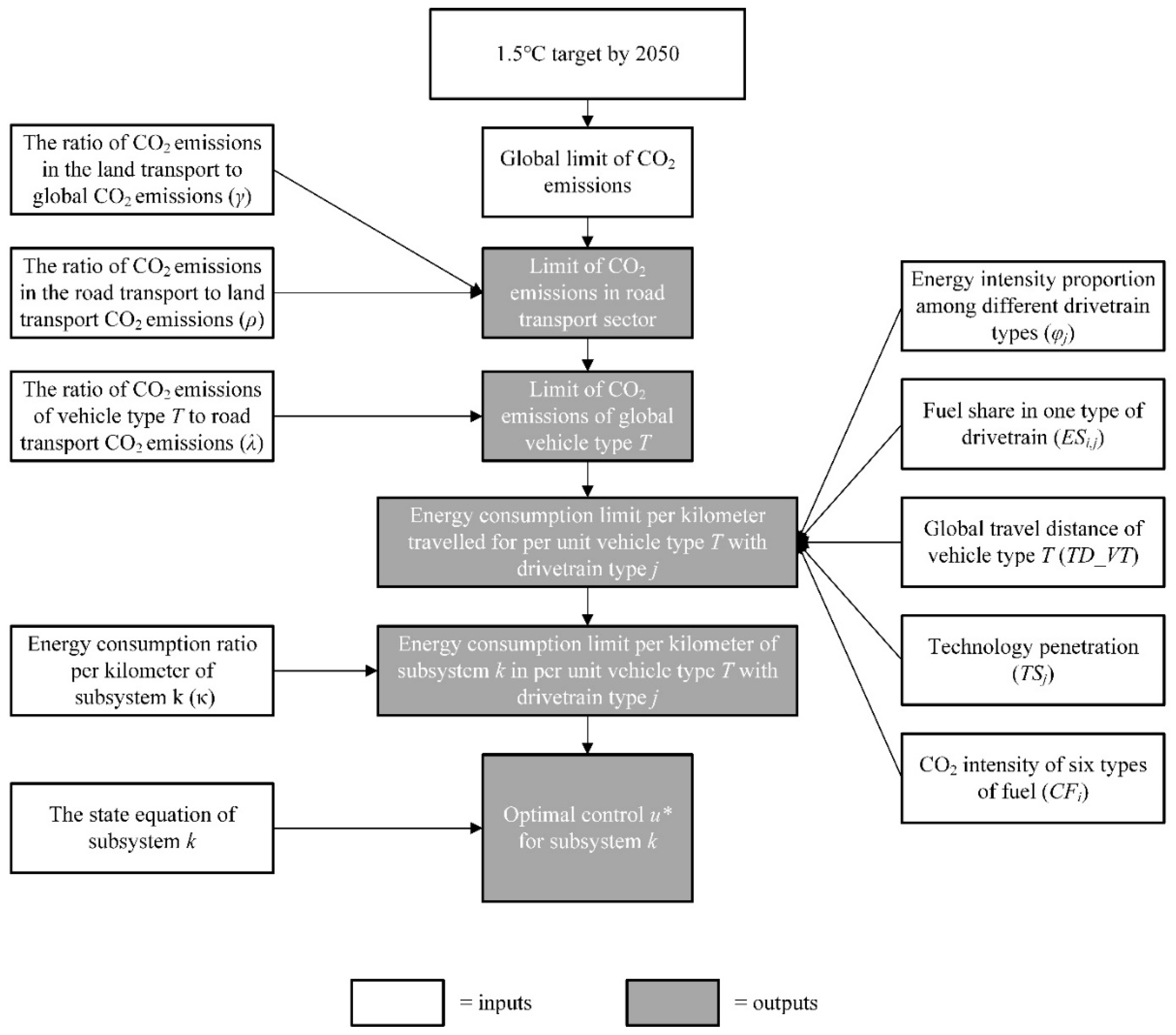

2. Methods

2.1. Overarching Methods

2.2. Assumptions and Data

2.2.1. CO2 Emission Limits

2.2.2. Travel Distance

2.2.3. Technology Penetration

2.2.4. Energy Intensity

2.2.5. CO2 Intensity

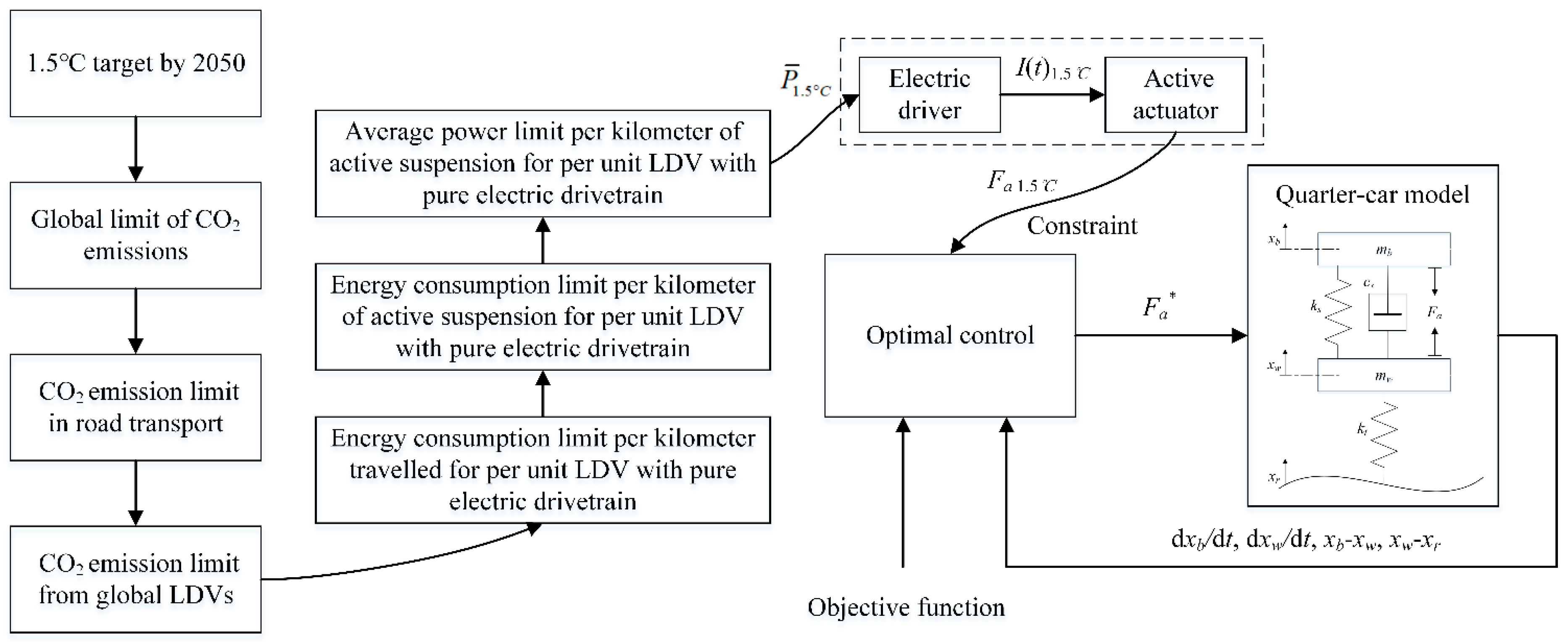

3. Case Study: Active Suspension Control for a BELDV

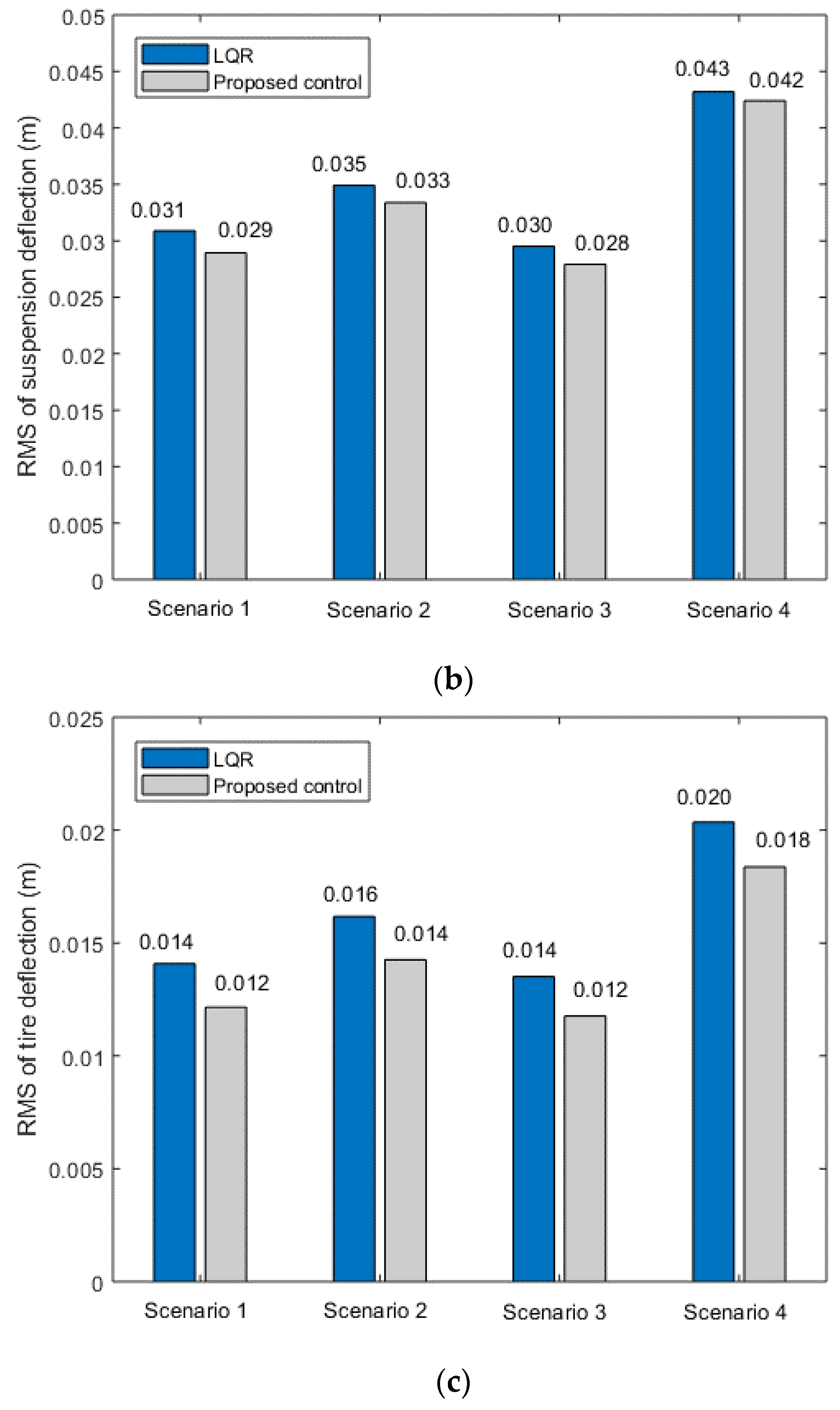

3.1. Energy Consumption Limit of Active Suspension

3.1.1. Step1: CO2Emissions_Global1.5 °C

3.1.2. Step2: CO2Emissions_RoadTransport1.5 °C

3.1.3. Step3: EC1_VLDV1.5 °C

3.1.4. Step4: EC1_Subactive-sus1.5 °C

3.2. Control Design

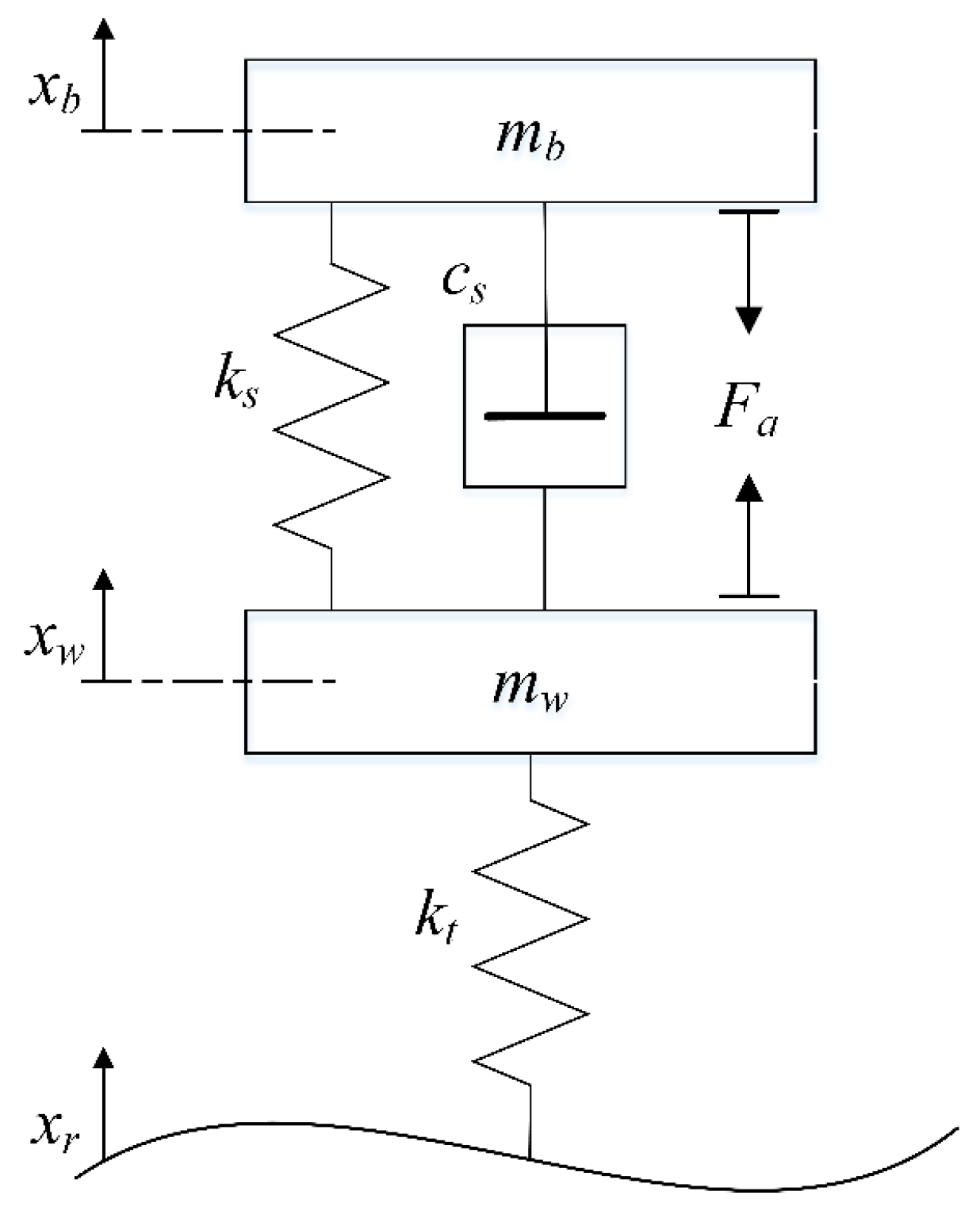

3.2.1. Vertical Quarter-Car Model

3.2.2. Design of Optimal Control

3.3. Evaluation

3.3.1. A Widely Used LQR Optimal Control for Comparison

3.3.2. Road Disturbance Model

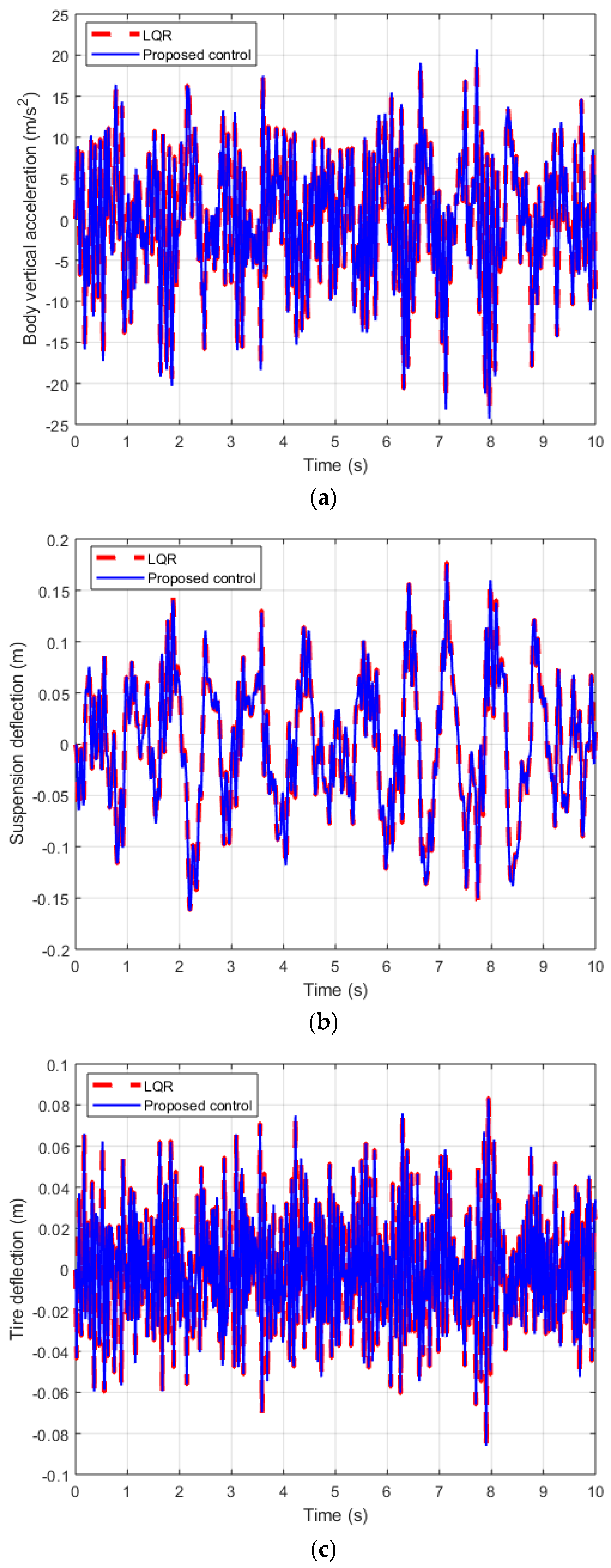

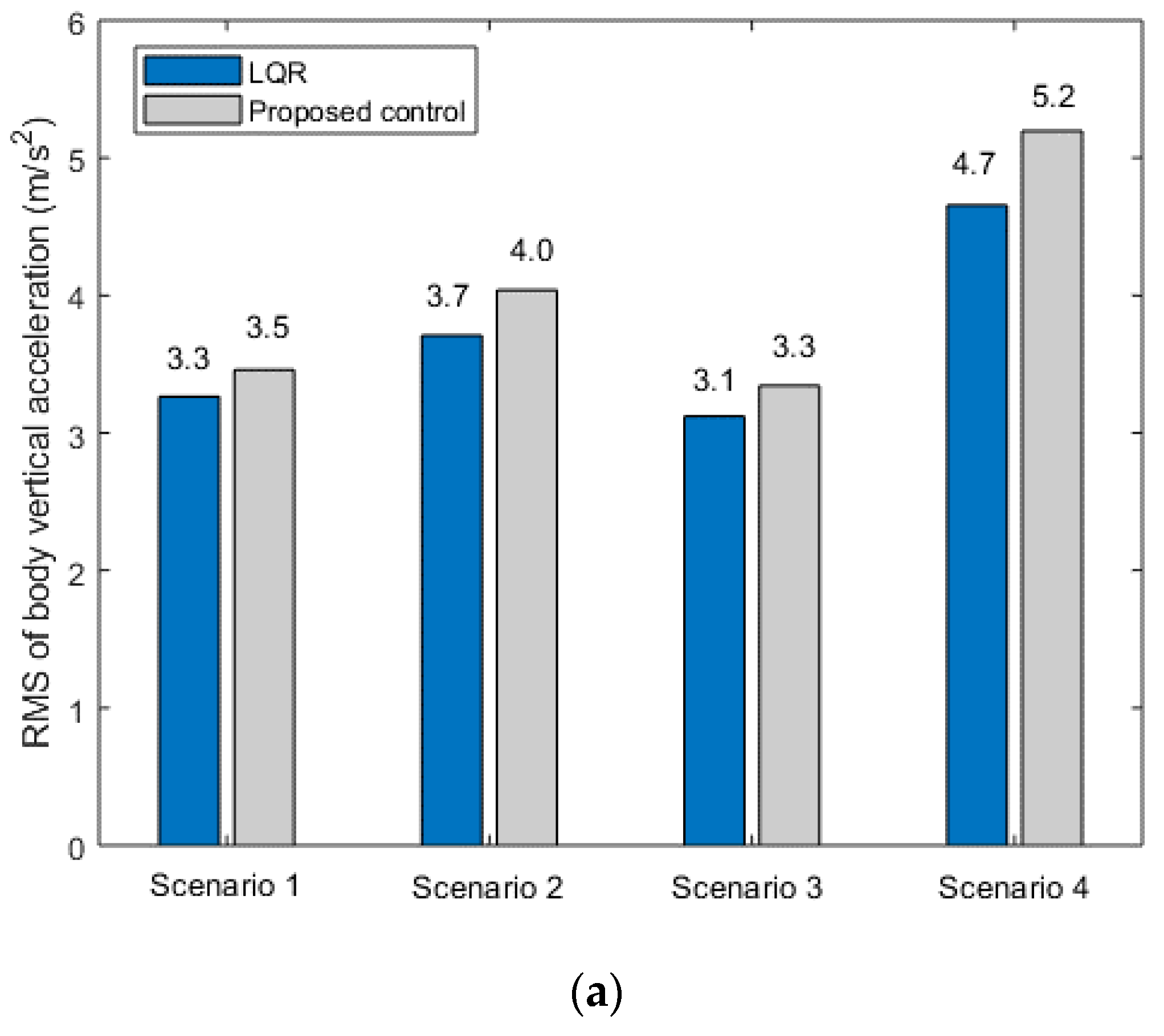

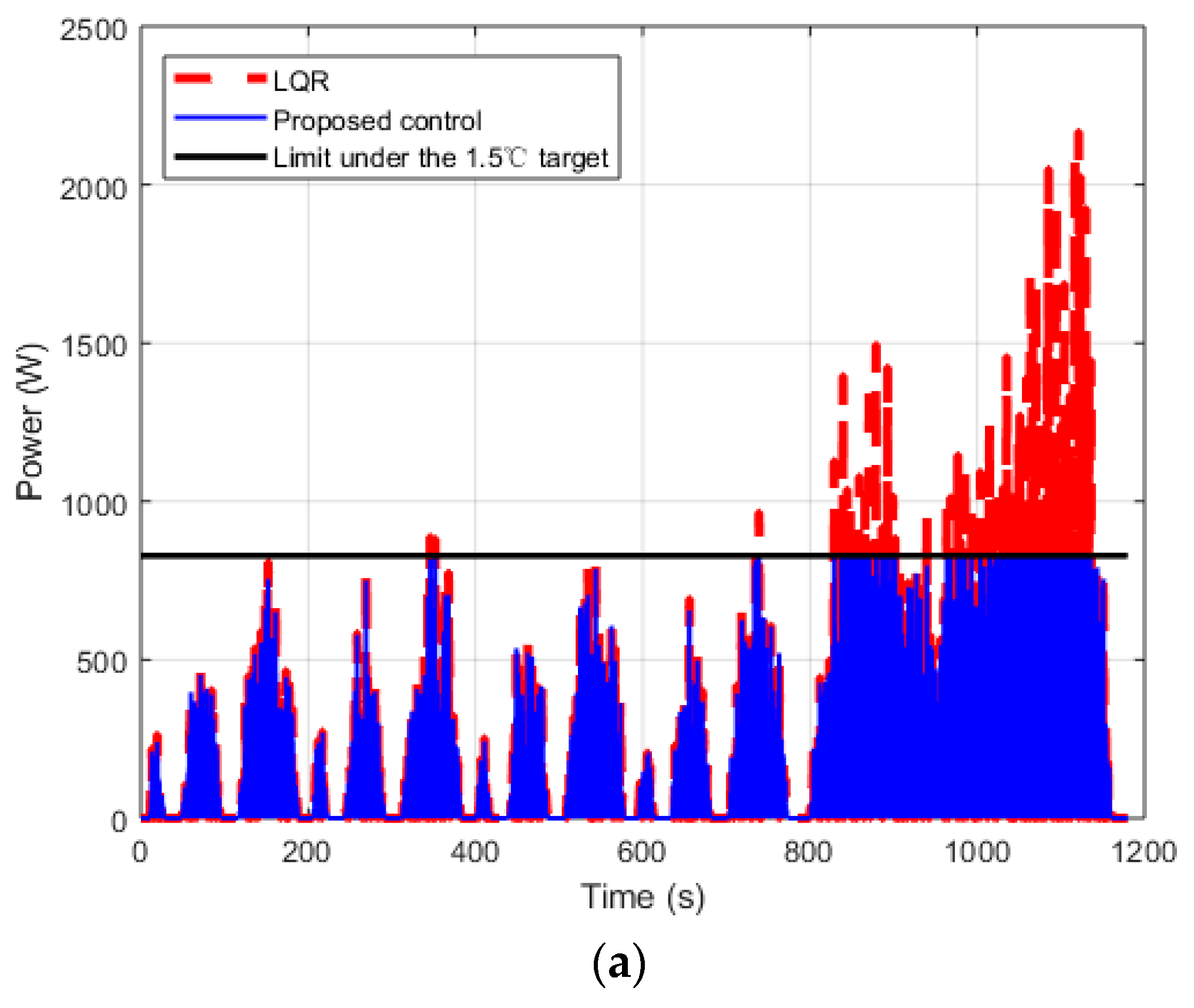

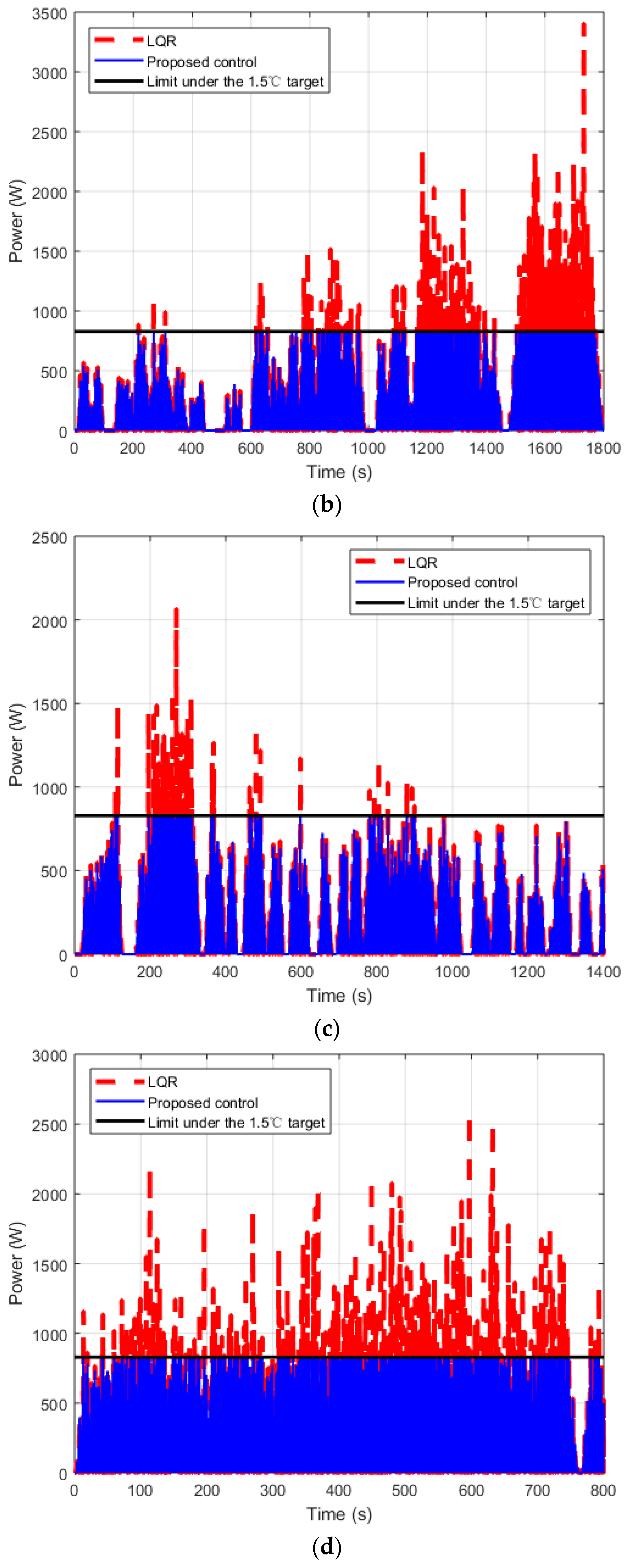

3.3.3. Results

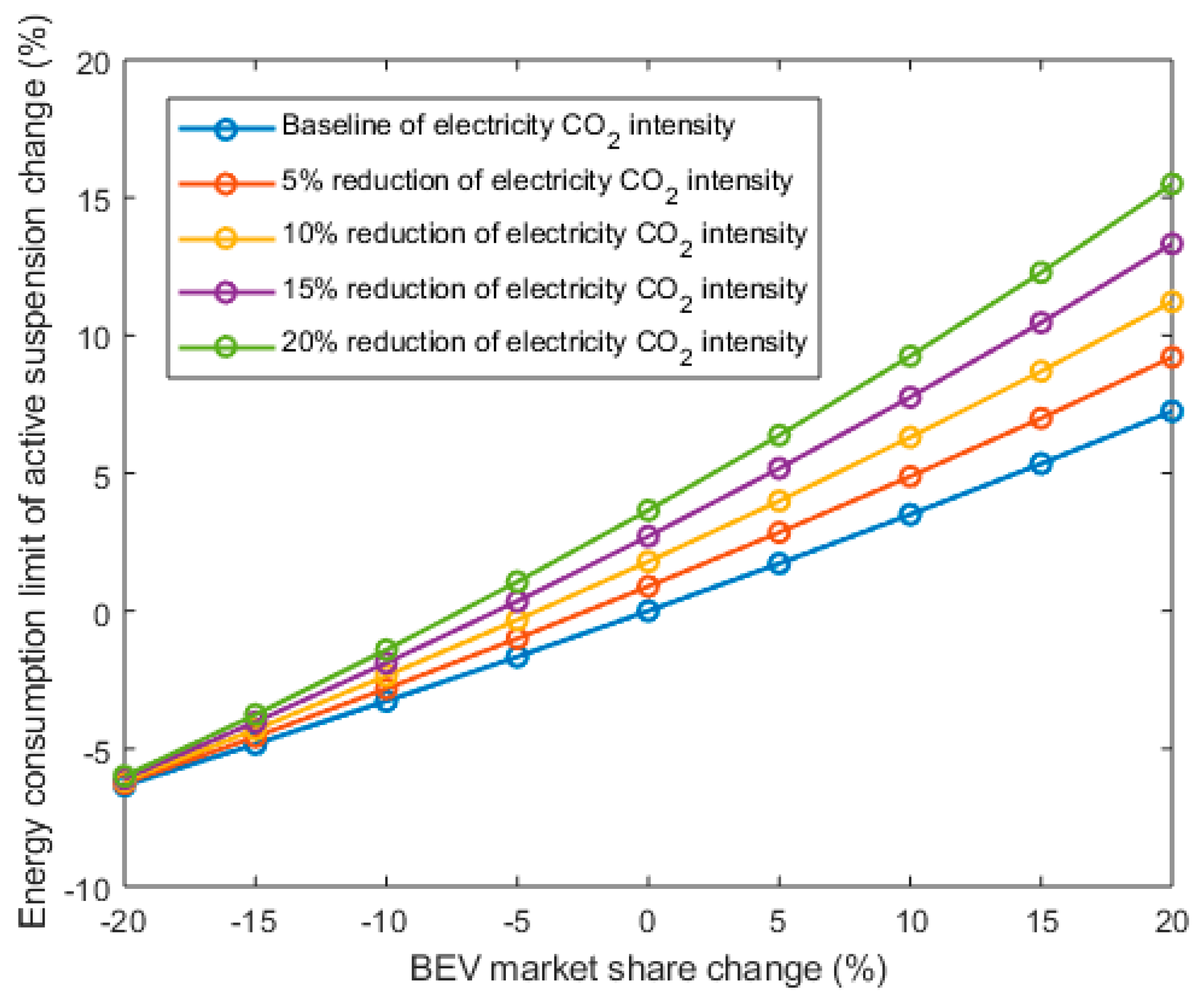

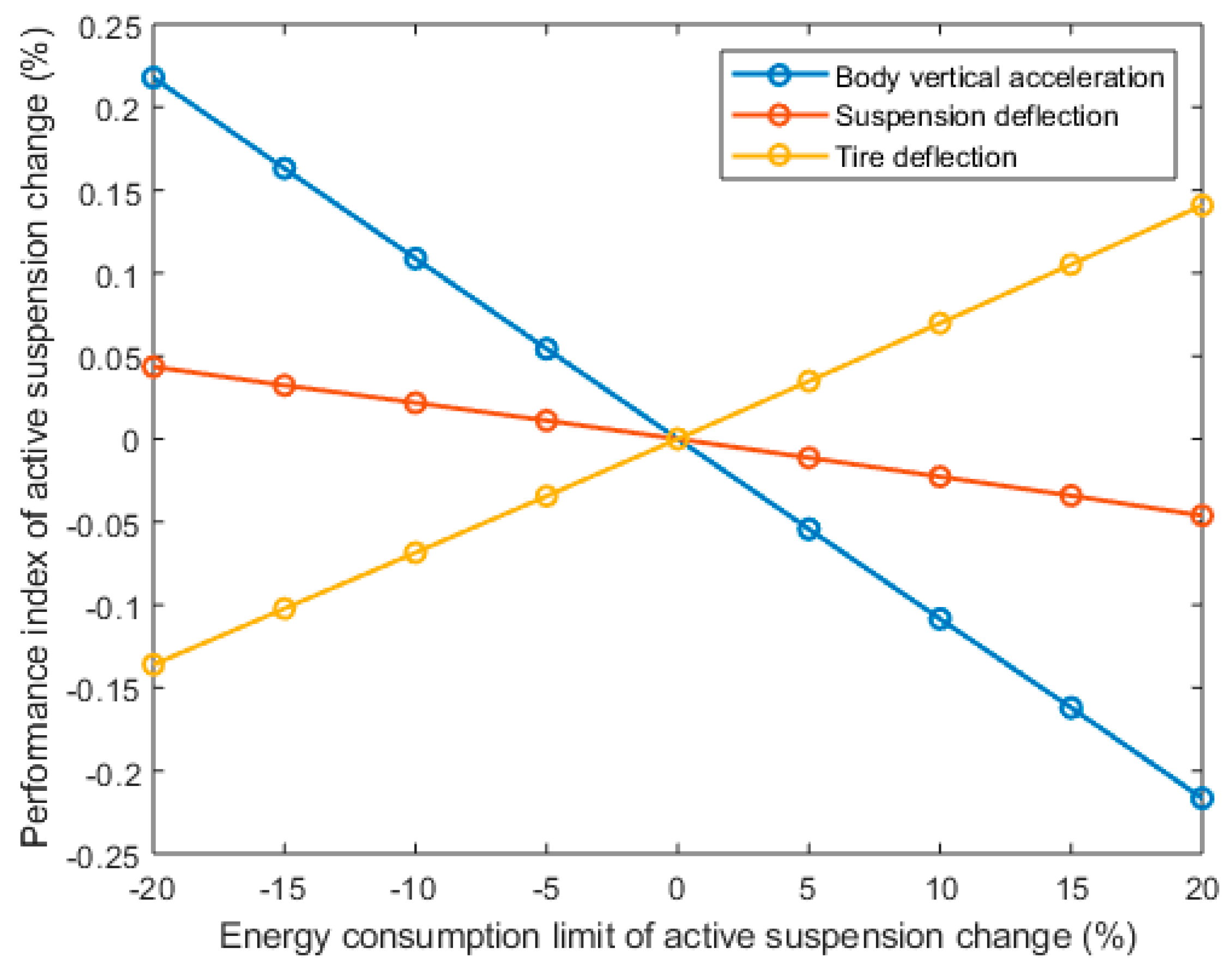

3.4. Sensitivity Analysis

4. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| BAU | business-as-usual |

| BELDV | battery electric light-duty vehicle |

| BEV | battery electric vehicle |

| CNG | compressed natural gas |

| EVs | electric vehicles |

| FCVs | fuel cell vehicles |

| GHG | greenhouse gas |

| HWFET | Highway Fuel Economy Test Cycle |

| ICEVs | internal combustion engine vehicles |

| LDV | light-duty vehicle |

| LQR | linear quadratic regulator |

| NEDC | New European Driving Cycle |

| PHEVs | plug-in hybrid electric vehicles |

| RMS | root mean square |

| UDDS | Urban Dynamometer Driving Schedule |

| WLTC | Worldwide Harmonized Light-Duty Driving Test Cycle |

| CFi | CO2 intensity of type i fuel in one year |

| CLDV | capacity per unit LDV |

| global limit of CO2 emissions at 1.5 °C target in 2050 | |

| CO2 emission limit in road transport sector at 1.5 °C target in 2050 | |

| CO2 emission limit from global LDVs under 1.5 °C target in 2050 | |

| CO2 emission limit of global vehicle type T at 1.5 °C target in 2050 | |

| cs | suspension damping coefficient |

| CT | capacity per unit vehicle type T when vehicle type T belongs to passenger transport |

| DLDVs | global transport demand of LDVs in 2050 |

| DT | global transport demand of vehicle type T in 2050 |

| ECactive-sus | energy consumed by active suspension per kilometer |

| EC1_Subactive-sus1.5°C | energy consumption limit of active suspension for per unit LDV with a pure electric drivetrain |

| ECj_Subk1.5°C | energy consumption limit per kilometer of subsystem k in per unit vehicle type T with drivetrain type j |

| ECj_VLDV1.5°C | energy consumption per kilometer traveled for per unit LDV with a pure electric drivetrain |

| energy consumption limit per kilometer traveled for per unit vehicle type T with drivetrain type j | |

| ESi,j | share of energy consumption of type i fuel out of total energy consumption by type T vehicles with type j drivetrain technology in one year |

| Fa | active actuator force |

| Gq (n0) | road roughness coefficient |

| ks | suspension stiffness |

| kt | tire stiffness |

| LT | load per unit vehicle type T when vehicle type T belongs to freight transport |

| mb | sprung mass |

| mw | unsprung mass |

| n0 | spatial frequency value |

| 1.5 °C | average power limit of active suspension in quarter car under 1.5 °C target |

| P(t) | power consumed by active suspension |

| 1 km | average period taken by a BELDV traveling one kilometer under an NEDC |

| vehicle body displacement | |

| vehicle body vertical velocity | |

| xr | road vertical displacement |

| road vertical velocity | |

| wheel displacement | |

| wheel vertical velocity | |

| TD_VT | global travel distance of vehicle type T in 2050 |

| TSj | share of type T vehicles with type j drivetrain out of all type T vehicles in 2050 |

| v(t) | vehicle speed |

| proportion of the energy consumption per kilometer among different drivetrain types | |

| κ | ratio of the energy consumption per kilometer of subsystem k to the energy consumption per kilometer of per unit vehicle type T with drivetrain type j |

| ρ | ratio of CO2 emissions in road transport to land transport CO2 emissions |

| λ | ratio of CO2 emissions of vehicle type T to road transport CO2 emissions |

| γ | ratio of CO2 emissions in land transport to global CO2 emissions |

| w0(t) | Gaussian white noise with zero mean value |

Appendix A

References

- PricewaterhouseCoopers LLP. The World in 2050: Can Rapid Global Growth Be Reconciled with Moving to a Low Carbon Economy. 2008. Available online: https://www.pwc.com/gx/en/psrc/pdf/world_in_2050_carbon_emissions_psrc.pdf (accessed on 29 May 2019).

- United Nations Framework Convention on Climate Change (UNFCCC). Paris Agreement–Pre 2020 Action. 2016. Available online: www.ec.europa.eu/clima/policies/international/negotiations/paris/index_en.htm (accessed on 10 June 2019).

- Paris Process on Mobility and Climate (PPMC). Implications of 2DS and 1.5DS for Land Transport Carbon Emissions in 2050. 2016. Available online: http://www.ppmc-transport.org/implications-of-2ds-and-1-5ds-for-land-transport-carbon-emissions-in-2050/ (accessed on 31 May 2019).

- World Energy Council (WEC). Global Transport Scenarios 2050. 2012. Available online: https://www.worldenergy.org/wp-content/uploads/2012/09/wec_transport_scenarios_2050.pdf (accessed on 31 May 2019).

- Geng, G.; Shen, Q.; Jiang, H. ANFTS Mode Control for an Electronically Controlled Hydraulic Power Steering System on a Permanent Magnet Slip Clutch. Energies 2019, 12, 1739. [Google Scholar] [CrossRef]

- Hanifah, R.A.; Toha, S.F.; Hassan, M.K.; Ahmad, S. Power reduction optimization with swarm based technique in electric power assist steering system. Energy 2016, 102, 444–452. [Google Scholar] [CrossRef]

- Edrén, J.; Jonasson, M.; Jerrelind, J.; Trigell, A.S.; Drugge, L. Energy efficient cornering using over-actuation. Mechatronics 2019, 59, 69–81. [Google Scholar] [CrossRef]

- Han, Z.; Xu, N.; Chen, H.; Huang, Y.; Zhao, B. Energy-efficient control of electric vehicles based on linear quadratic regulator and phase plane analysis. Appl. Energy 2018, 213, 639–657. [Google Scholar] [CrossRef]

- Khayyam, H. Adaptive intelligent control of vehicle air conditioning system. Appl. Therm. Eng. 2013, 51, 1154–1161. [Google Scholar] [CrossRef]

- Lim, T.H.; Shin, Y.; Kim, S.; Kwon, C. Predictive control of car refrigeration cycle with an electric compressor. Appl. Therm. Eng. 2017, 127, 1223–1232. [Google Scholar] [CrossRef]

- Huang, Y.; Khajepour, A.; Ding, H.; Bagheri, F.; Bahrami, M. An energy-saving set-point optimizer with a sliding mode controller for automotive air-conditioning/refrigeration systems. Appl. Energy 2017, 188, 576–585. [Google Scholar] [CrossRef]

- Li, L.; Li, X.; Wang, X.; Song, J.; He, K.; Li, C. Analysis of downshift’s improvement to energy efficiency of an electric vehicle during regenerative braking. Appl. Energy 2016, 176, 125–137. [Google Scholar] [CrossRef]

- Ruan, J.; Walker, P.D.; Watterson, P.A.; Zhang, N. The dynamic performance and economic benefit of a blended braking system in a multi-speed battery electric vehicle. Appl. Energy 2016, 183, 1240–1258. [Google Scholar] [CrossRef]

- Casavola, A.; Iorio, F.D.; Tedesco, F. A multiobjective H∞ control strategy for energy harvesting in regenerative vehicle suspension systems. Int. J. Control 2018, 91, 741–754. [Google Scholar] [CrossRef]

- Hsieh, C.; Huang, B.; Golnaraghi, F.; Moallem, M. Regenerative Skyhook Control for an Electromechanical Suspension System Using a Switch-Mode Rectifier. IEEE Trans. Veh. Technol. 2016, 65, 9642–9650. [Google Scholar] [CrossRef]

- Hao, H.; Geng, Y.; Sarkis, J. Carbon footprint of global passenger cars: Scenarios through 2050. Energy 2016, 101, 121–131. [Google Scholar] [CrossRef]

- Gambhir, A.; Tse, L.; Tong, D.; Martinez-Botas, R. Reducing China’s road transport sector CO2 emissions to 2050: Technologies, costs and decomposition analysis. Appl. Energy 2015, 157, 905–917. [Google Scholar] [CrossRef]

- Dhar, S.; Pathak, M.; Shukla, P.R. Transformation of India’s transport sector under global warming of 2 °C and 1.5 °C scenario. J. Clean. Prod. 2018, 172, 417–427. [Google Scholar] [CrossRef]

- Mora, C.; Rollins, R.; Taladay, K.; Kantar, M.B.; Chock, M.K.; Shimada, M.; Franklin, E.C. Bitcoin emissions alone could push global warming above 2 °C. Nat. Clim. Change 2018, 8, 931–933. [Google Scholar] [CrossRef]

- Savaresi, S.M.; Poussot-Vassal, C.; Spelta, C.; Sename, O.; Dugard, L. Semi-Active Suspension Control Design for Vehicles; Butterworth-Heinemann: Boston, MA, USA, 2010; pp. 23–25. [Google Scholar]

- Fiori, C.; Ahn, K.; Rakha, H.A. Power-based electric vehicle energy consumption model: Model development and validation. Appl. Energy 2016, 168, 257–268. [Google Scholar] [CrossRef]

- United Nations Framework Convention on Climate Change (UNFCC). Greenhouse Gas Inventory Data–Detailed Data by Party. 2016. Available online: https://di.unfccc.int/detailed_data_by_party (accessed on 10 June 2019).

- Takeshita, T. Global Scenarios of Air Pollutant Emissions from Road Transport through to 2050. Int. J. Environ. Res. Public Health 2011, 8, 3032–3062. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Xia, Q. Automobile Theory, 5th ed.; China Machine Press: Beijing, China, 2009; pp. 212–213. [Google Scholar]

- Čorić, M.; Deur, J.; Xu, L.; Tseng, H.E.; Hrovat, D. Optimisation of active suspension control inputs for improved vehicle ride performance. Veh. Syst. Dyn. 2016, 54, 1004–1030. [Google Scholar] [CrossRef]

- Wu, Z.; Chen, S.; Yang, L.; Zhang, B. Model of road roughness in time domain based on rational function. Trans. Beijing Inst. Technol. 2009, 29, 795–798. [Google Scholar]

- GB/T 7031-2005/ISO 8086. Mechanical Vibration-Road Surface Profiles—Reporting of Measured Data. Available online: https://www.iso.org/obp/ui/#iso:std:iso:8608:ed-2:v1:en (accessed on 2 August 2019).

| Variable | Value | Scenario/Year | Source/Note |

|---|---|---|---|

| CO2Emissions_Global1.5 °C (GtCO2) | 10.9 | 1.5 °C | [3] |

| (%) | 19 | 1.5 °C | [3] |

| (%) | 98 | 2016 | [22] |

| (%) | 46 | BAU | [18] |

| DLDVs (passenger km) | 6.56 × 1012 | BAU | [18] |

| CLDV (passenger/vehicle) | 1 | Assumption that one LDV is used by only one passenger | |

| TS1 (%) | 22.5 | BAU | [16] |

| TS2 (%) | 67.5 | BAU | [16] |

| TS3 (%) | 10 | BAU | [16] |

| ES1,1 (%) | 100 | BAU | - |

| ES2,2 (%) | 82.15 | BAU | [23] |

| ES3,2 (%) | 8.01 | BAU | [23] |

| ES4,2 (%) | 5.01 | BAU | [23] |

| ES5,2 (%) | 4.83 | BAU | [23] |

| ES6,3 (%) | 100 | BAU | - |

| 0.54:1.5:0.74 | 2017 | [16] | |

| CF1 (g/kWh) | 573.86 | 2017 | [19] |

| CF2 (g/MJ) | 83.16 | 2016 | [16] |

| CF3 (g/MJ) | 88.92 | 2016 | [16] |

| CF4 (g/MJ) | 70 | 2000 | [16] |

| CF5 (g/MJ) | 67.32 | 2016 | [16] |

| CF6 (g/MJ) | 100 | 2020 | [16] |

| (%) | 50 | 2010, 2016 | [20,21] |

| Level | Degree of Roughness Gq(n0) (10−6 m2/m−1) n0 = 0.1 m−1 | ||

|---|---|---|---|

| Lower Limit | Geometric Mean | Upper Limit | |

| A | 8 | 16 | 32 |

| B | 32 | 64 | 128 |

| C | 128 | 256 | 512 |

| D | 512 | 1024 | 2048 |

| E | 2048 | 4096 | 8192 |

| F | 8192 | 16,384 | 32,768 |

| G | 32,768 | 65,536 | 131,072 |

| H | 131,072 | 262,144 | 524,288 |

| Performance Index | LQR | Proposed Control |

|---|---|---|

| Body vertical acceleration (m/s2) | 7.29 | 7.32 |

| Suspension deflection (m) | 0.0644 | 0.0645 |

| Tire deflection (m) | 0.0247 | 0.0247 |

| Scenario | Road Level | Driving Cycle |

|---|---|---|

| 1 | E | New European Driving Cycle (NEDC) |

| 2 | E | Worldwide Harmonized Light-Duty Driving Test Cycle (WLTC) |

| 3 | E | Urban Dynamometer Driving Schedule (UDDS) |

| 4 | E | Highway Fuel Economy Test Cycle (HWFET) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, X.; Chen, Y.; Ding, Z.; Gu, L. Vehicle Optimal Control Design to Meet the 1.5 °C Target: A Control Design Framework for Vehicle Subsystems. Energies 2019, 12, 3170. https://doi.org/10.3390/en12163170

Hu X, Chen Y, Ding Z, Gu L. Vehicle Optimal Control Design to Meet the 1.5 °C Target: A Control Design Framework for Vehicle Subsystems. Energies. 2019; 12(16):3170. https://doi.org/10.3390/en12163170

Chicago/Turabian StyleHu, Xu, Yisong Chen, Zhensen Ding, and Liang Gu. 2019. "Vehicle Optimal Control Design to Meet the 1.5 °C Target: A Control Design Framework for Vehicle Subsystems" Energies 12, no. 16: 3170. https://doi.org/10.3390/en12163170

APA StyleHu, X., Chen, Y., Ding, Z., & Gu, L. (2019). Vehicle Optimal Control Design to Meet the 1.5 °C Target: A Control Design Framework for Vehicle Subsystems. Energies, 12(16), 3170. https://doi.org/10.3390/en12163170