Contribution to the Energy Situation in Tajikistan by Using Residual Apricot Branches after Pruning as an Alternative Fuel

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- World Bank. Agriculture, Forestry, and Fishing, Value Added (% of GDP). Available online: https://data.worldbank.org/indicator/NV.AGR.TOTL.ZS?locations=TJ (accessed on 28 January 2019).

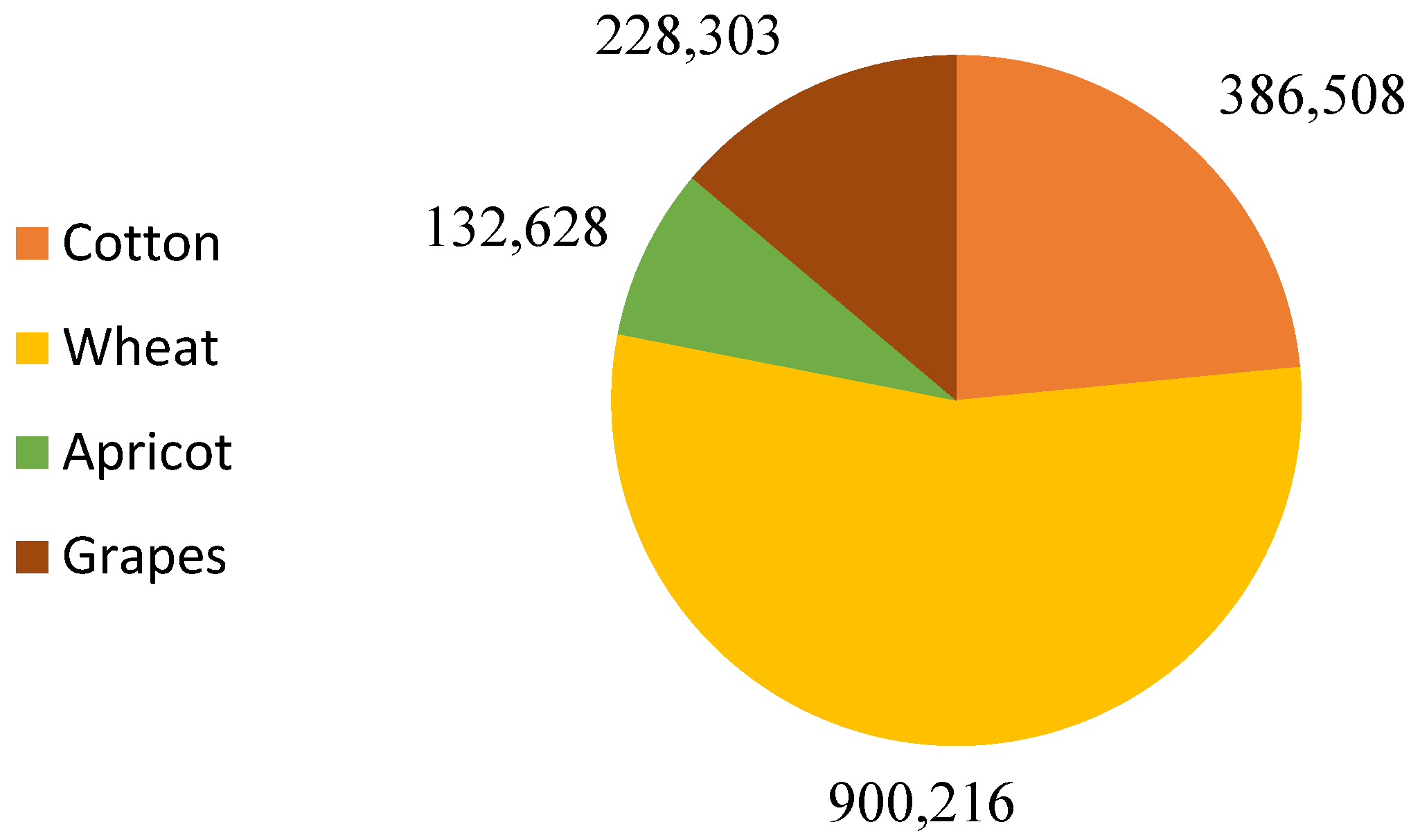

- TAJSTAT. Socio-Economic Situation of the Republic of Tajikistan; TAJSTAT: Dushanbe, Tajikistan, 2017; pp. 1–144. [Google Scholar]

- Ministry of Agriculture Republic of Tajikistan. Gardening. Available online: http://moa.tj/bo-parvar/ (accessed on 19 January 2019).

- Roussos, P.A.; Sefferou, V.; Denaxa, N.-K.; Tsantili, E.; Stathis, V. Apricot (Prunus armeniaca L.) Fruit Quality Attributes and Phytochemicals under Different Crop Load. Sci. Hortic. 2011, 129, 472–478. [Google Scholar] [CrossRef]

- FAO. Apricot Production. Available online: http://www.fao.org/faostat/en/#data/QC/ (accessed on 18 December 2018).

- Open Asia Online. Soghd—Apricot Paradise. 2016. Available online: https://news.tj/ru/node/227525 (accessed on 19 June 2019).

- Kamolov, N.; Akhmedov, T.A.; Nazirov, H.N. Apricot Growing Technology (Study Case Tajikistan); Institute of Horticulture and Vegetable Growing of Tajik Academy of Agricultural Sciences: Dushanbe, Tajikistan, 2010; pp. 1–28. [Google Scholar]

- Demirtas, N.; Bolat, I.; Ercisli, S.; Ikinci, A.; Olmez, H.A.; Sahin, M.; Altindag, M.; Celik, B. The Effects of Different Pruning Treatments on the Growth, Fruit Quality and Yield of ‘Hacihaliloglu’apricot. Acta Sci. Pol. 2010, 9, 183–192. [Google Scholar]

- Walser, R.H.; Wright, W.A.; Hamson, A.R. Pruning the Orchard; Utah State University: Logan, UT, USA, 1994; pp. 1–21. [Google Scholar]

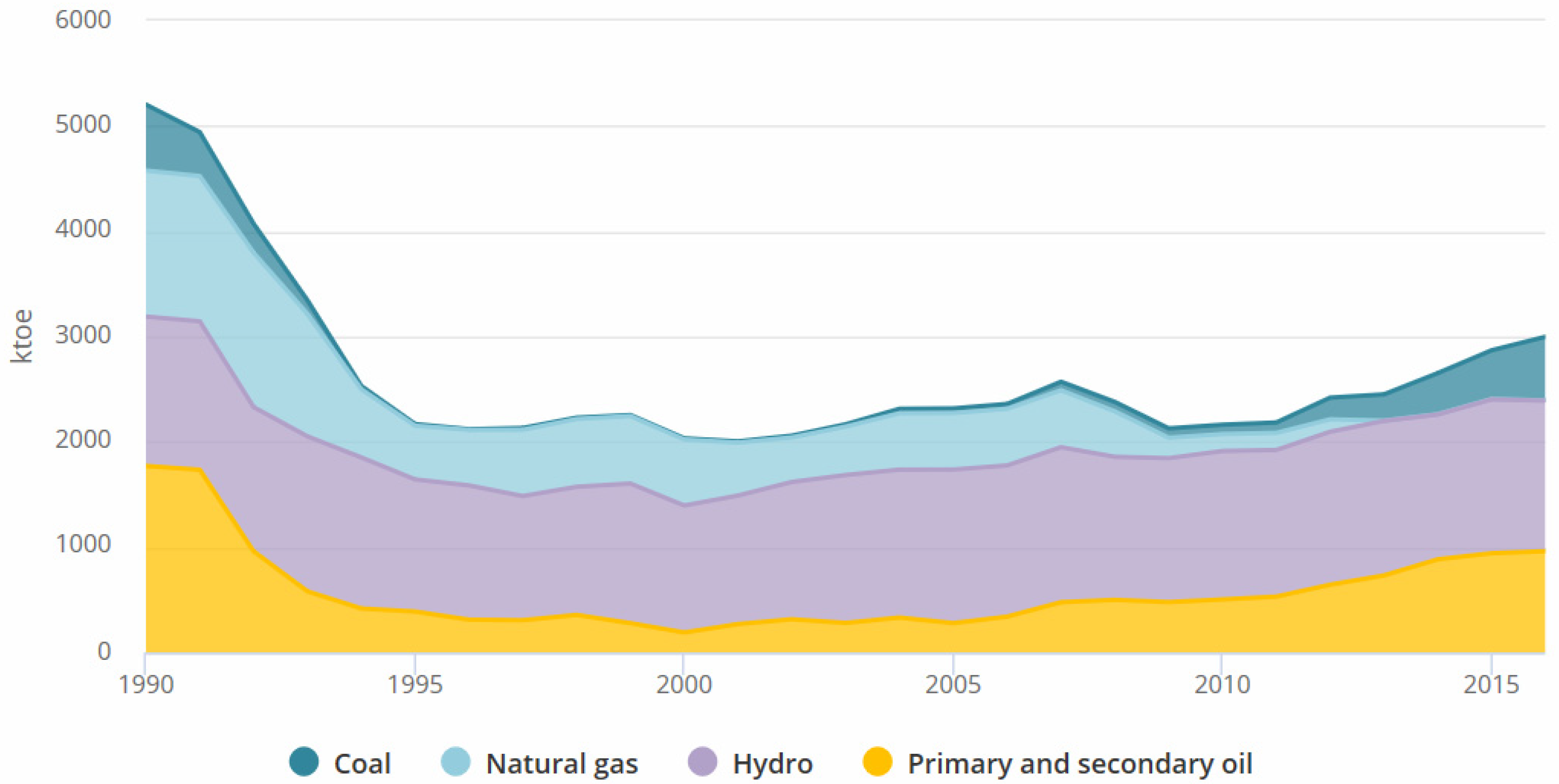

- Laldjebaev, M.; Morreale, S.J.; Sovacool, B.K.; Kassam, K.A.S. Rethinking Energy Security and Services in Practice: National Vulnerability and Three Energy Pathways in Tajikistan. Energy Policy 2018, 114, 39–50. [Google Scholar] [CrossRef]

- International Energy Agency. IEA World Energy Balances 2018. Statistics. Tajikistan—Total Primary Energy Supply (TPES) by Source. Available online: https://www.iea.org/statistics/?country=TAJIKISTAN&year=2016&category=Energysupply&indicator= TPESbySource&mode=chart&dataTable=BALANCES. All rights reserved (accessed on 5 June 2019).

- Besant-Jones, J.E.; Fields, D.; Kochnakyan, A.; Mukhamedova, T.; Stuggins, G. Tajikistan’s Winter Energy Crisis: Electricity Supply and Demand Alternatives; A World Bank study; World Bank: Washington DC, USA, 2012; pp. 1–77. [Google Scholar]

- Doukas, H.; Marinakis, V.; Karakosta, C.; Psarras, J. Promoting Renewables in the Energy Sector of Tajikistan. Renew. Energy 2012, 39, 411–418. [Google Scholar] [CrossRef]

- Karimov, K.S.; Akhmedov, K.M.; Abid, M.; Petrov, G.N. Effective Management of Combined Renewable Energy Resources in Tajikistan. Sci. Total Environ. 2013, 461–462, 835–838. [Google Scholar] [CrossRef] [PubMed]

- Laldjebaev, M. Energy Poverty in Rural Areas of Tajikistan. In Proceedings of the BEHAVE 2018 5th European Conference on Behaviour and Energy Efficiency, Zürich, Switzerland, 5–7 September 2018; pp. 5–7. [Google Scholar]

- Galaktion, V.S.; Sirojiddin, R.C.; Alexey, G.V. Analysis and Evaluation of Potential of Renewable Energy Resources of Republic of Tajikistan. In Proceedings of the International Ural Conference on Green Energy (UralCon), Chelyabinsk, Russia, 4–6 October 2018; IEEE: Chelyanbinsk, Russia, 2018; pp. 26–33. [Google Scholar]

- FAO. Forage Harvesting and Farm Animals Feeding in Conditions of Pamir; FAO: Horog, Tajikistan, 2013; pp. 1–17. [Google Scholar]

- Akhmedov, S.; Ivanova, T.; Krepl, V.; Muntean, A. Research on Solid Biofuels from Cotton Waste Biomass—Alternative for Tajikistan’s Energy Sector Development. Agron. Res. 2017, 15, 1846–1855. [Google Scholar] [CrossRef]

- Stavjarská, M. Use of Cotton Plant Waste Biomass for Solid Biofuel Production. Master’s Thesis, Czech University of Life Sciences Prague, Prague, Czech Republic, 2016. [Google Scholar]

- Pizzi, A.; Pedretti, E.F.; Duca, D.; Rossini, G.; Mengarelli, C.; Ilari, A.; Mancini, M.; Toscano, G. Emissions of Heating Appliances Fuelled with Agropellet Produced from Vine Pruning Residues and Environmental Aspects. Renew. Energy 2018, 121, 513–520. [Google Scholar] [CrossRef]

- Zanetti, M.; Brandelet, B.; Marini, D.; Sgarbossa, A.; Giorio, C.; Badocco, D.; Tapparo, A.; Grigolato, S.; Rogaume, C.; Rogaume, Y.; et al. Vineyard Pruning Residues Pellets for Use in Domestic Appliances: A Quality Assessment according to the EN ISO 17225. J. Agric. Eng. 2017, 48, 99–108. [Google Scholar] [CrossRef]

- Royo, J.; Canalis, P.; Quintana, D.; Diaz-Ramirez, M.; Sin, A.; Rezeau, A. Experimental Study on the Ash Behaviour in Combustion of Pelletized Residual Agricultural Biomass. Fuel 2019, 239, 991–1000. [Google Scholar] [CrossRef]

- Manzone, M.; Paravidino, E.; Bonifacino, G.; Balsari, P. Biomass Availability and Quality Produced by Vineyard Management during a Period of 15 Years. Renew. Energy 2016, 99, 465–471. [Google Scholar] [CrossRef]

- Fernandez-Puratich, H.; Hernandez, D.; Tenreiro, C. Analysis of Energetic Performance of Vine Biomass Residues as an Alternative Fuel for Chilean Wine Industry. Renew. Energy 2015, 83, 1260–1267. [Google Scholar] [CrossRef]

- Mendivil, M.A.; Munoz, P.; Morales, M.P.; Juarez, M.C.; Garcia-Escudero, E. Chemical Characterization of Pruned Vine Shoots from La Rioja (Spain) for Obtaining Solid Bio-fuels. J. Renew. Sustain. Energy 2013, 5, 033113. [Google Scholar] [CrossRef]

- Muzikant, M.; Havrland, B.; Hutla, P.; Věchetová, S. Properties of Heat Briquettes Produced from Vine Cane Waste–Case Study Republic of Moldova. Agric. Trop. Subtrop. 2010, 43, 277–284. [Google Scholar]

- Vacek, T. Energy Use of Vineyard Waste Biomass—Potential for the Republic of Moldova. Master’s Thesis, Czech University of Life Sciences Prague, Prague, Czech Republic, 2015. [Google Scholar]

- Cichy, W.; Witczak, M.; Walkowiak, M. Fuel Properties of Woody Biomass from Pruning Operations in Fruit Orchards. BioResources 2017, 12, 6458–6470. [Google Scholar] [CrossRef]

- BSI EN 14780. Solid Biofuels—Sample Preparation; British Standards Institution: Bonn, Germany, 2011; pp. 1–24. [Google Scholar]

- BS EN ISO 18134-3. Solid Biofuel—Determination in Moisture Content—Oven Dry Method: Part 3: Moisture in General Analysis Sample; British Standards Institution: Bonn, Germany, 2015; pp. 1–14. [Google Scholar]

- BS EN ISO 18122. Solid Biofuels—Determination of Ash Content; British Standards Institution: Bonn, Germany, 2015; pp. 1–18. [Google Scholar]

- BS EN 14918. Solid Biofuels—Determination of Calorific Value; British Standards Institution: Bonn, Germany, 2009; pp. 1–64. [Google Scholar]

- BS EN ISO 16948. Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen; British Standards Institution: Bonn, Germany, 2015; pp. 1–18. [Google Scholar]

- BS EN ISO 17831-1. Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes–Part 1: Pellets; British Standards Institution: Bonn, Germany, 2015; pp. 1–18. [Google Scholar]

- BS EN ISO 17831-2. Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes–Part 2: Briquettes; British Standards Institution: Bonn, Germany, 2015; pp. 1–18. [Google Scholar]

- Ivanova, T.; Kolarikova, M.; Havrland, B.; Passian, L. Mechanical Durability of Briquettes Made of Energy Crops and Wood Residues. In Proceedings of the Engineering for Rural Development, Jelgava, Latvia, 29–30 May 2014; Volume 13, pp. 131–136. [Google Scholar]

- BSI EN ISO 17225-2. Solid Biofuels—Fuel Specifications and Classes Part 2: Graded wood pellets; BS EN ISO; British Standards Institution: Bonn, Germany, 2014; pp. 1–18. [Google Scholar]

- BSI EN ISO 17225-3. Solid Biofuels—Fuel Specifications and Classes Part 3: Graded wood briquettes; British Standards Institution: Bonn, Germany, 2014; pp. 1–16. [Google Scholar]

- Ivanova, T.; Mendoza Hernández, A.H.; Bradna, J.; Cusimamani, E.F.; Montoya, J.C.G.; Espinel, D.A.A. Assessment of Guava (Psidium guajava L.) Wood Biomass for Briquettes’ Production. Forests 2018, 9, 613. [Google Scholar] [CrossRef]

- Brožek, M. The Effect of Moisture of the Raw Material on the Properties Briquettes for Energy Use. Acta Univ. Agric. Silvic. Mendel. Brun. 2016, 64, 1453–1458. [Google Scholar] [CrossRef]

- Vyas, D.; Sayyad, F.; Khardiwar, M.; Kumar, S. Physicochemical Properties of Briquettes from Different Feed Stock. Curr. World Environ. 2015, 10, 263–269. [Google Scholar] [CrossRef]

- Kamperidou, V.; Lykidis, C.; Barmpoutis, P. Assessment of the Thermal Characteristics of Pellets Made of Agricultural Crop Residues Mixed with Wood. BioResources 2017, 12, 9263–9272. [Google Scholar] [CrossRef]

- Lunguleasa, A.; Spirchez, C. An Aggregated Property of Wheat Straw Briquettes. Wood Res. 2015, 60, 845–856. [Google Scholar]

- Tang, J.P.; Lama, H.L.; Azizb, M.K.A.; Morad, N.A. Enhanced biomass characteristics index in palm biomass calorific value estimation. Appl. Therm. Eng. 2016, 105, 941–949. [Google Scholar] [CrossRef]

- Bradna, J.; Malat’ák, J.; Hájek, D. The Properties of Wheat Straw Combustion and Use of Fly Ash as a Soil Amendment. Agron. Res. 2016, 14, 1257–1265. [Google Scholar]

- Cosereanu, C.; Lica, D.; Lunguleasa, A. Investigation on the Quality of Briquettes Made from Rarely Used Wood Species, Agro-Wastes and Forest Biomass. Pro Ligno 2015, 11, 32–39. [Google Scholar]

- Spinelli, R.; Nati, C.; Pari, L.; Mescalchin, E.; Magagnotti, N. Production and Quality of Biomass Fuels from Mechanized Collection and Processing of Vineyard Pruning Residues. Appl. Energy 2012, 89, 374–379. [Google Scholar] [CrossRef]

- Erisman, J.W.; van Grinsven, H.; Leip, A.; Mosier, A.; Bleeker, A. Nitrogen and Biofuels; an Overview of the Current State of Knowledge. Nutr. Cycl. Agroecosyst. 2010, 86, 211–223. [Google Scholar] [CrossRef]

- Zabava, B.-S.; Voicu, G.; Dinca, M.-N.; Ungureanu, N.; Ferdes, M. Durability of Pellets Obtained from Energy Plants: Review. In Proceedings of the Engineering for Rural Development, Jelgava, Latvia, 23–25 May 2018; Volume 17, pp. 1838–1843. [Google Scholar] [CrossRef]

- Alakangas, E. New European Pellets Standards; Eubionet III: Jyväskylä, Finland, 2011; pp. 1–17. [Google Scholar]

- Guo, L.; Tabil, L.G.; Wang, D.; Wang, G. Influence of Moisture Content and Hammer Mill Screen Size on the Physical Quality of Barley, Oat, Canola and Wheat Straw Briquettes. Biomass Bioenergy 2016, 94, 201–208. [Google Scholar] [CrossRef]

- Brožek, M.; Nováková, A.; Kolářová, M. Quality Evaluation of Briquettes Made from Wood Waste. Res. Agric. Eng. 2012, 58, 30–35. [Google Scholar] [CrossRef]

- Muntean, A.; Ivanova, T.; Hutla, P.; Havrland, B. Influence of Raw Material Properties on the Quality of Solid Biofuel and Energy Consumption in Briquetting Process. Agron. Res. 2017, 15, 1708–1715. [Google Scholar] [CrossRef]

- Brunerová, A.; Pecen, J.; Brožek, M.; Ivanova, T. Mechanical Durability of Briquettes from Digestate in Different Storage Conditions. Agron. Res. 2016, 14, 327–336. [Google Scholar]

- Brožek, M. Study of Briquette Properties at their Long-time Storage. J. For. Sci. 2013, 59, 101–106. [Google Scholar] [CrossRef]

- Brožek, M. Influence of storage on Briquettes Mechanical Properties. Sci. Agric. Bohem. 2014, 45, 175–179. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Factors Affecting Strength and Durability of Densified Biomass Products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

| Parameter | Apricot Tree Wood | Cotton Stalks | Wheat Straw | Vine Wood Wastes |

|---|---|---|---|---|

| Ash content, (wt% d) | 1.71 | 3.22 1 | 5.20 2 | 3.46 3 |

| Parameter | Apricot Tree Wood | Cotton Stalks | Wheat Straw | Vine Wood Wastes |

|---|---|---|---|---|

| Gross calorific value, (MJ kg−1 d) | 20.47 | 18.93 1 | 16.86 2 | 19.47 3 |

| Net calorific value, (MJ kg−1 d) | 19.29 | 17.69 1 | 15.55 2 | 18.87 4 |

| Parameter | Apricot Tree Wood | Cotton Stalks | Wheat Straw | Vine Wood Wastes |

|---|---|---|---|---|

| Carbon, (wt% d) | 47.28 | 48.56 1 | 42.67 2 | 43.88 3 |

| Nitrogen, (wt% d) | 0.36 | 0.90 1 | 0.50 2 | 0.61 4 |

| Hydrogen, (wt% d) | 6.27 | 5.69 1 | 5.34 2 | 6.22 4 |

| Parameter | Apricot Tree Wood | Cotton Stalks | Wheat Straw | Vine Wood Wastes |

|---|---|---|---|---|

| Mechanical durability of pellets, (%) | 94.37 | 97.82 1 | 94.40 2 | - |

| Mechanical durability of briquettes, (%) | 96.15 | 97.63 1 | 95.65 3 | 91.6 4 |

| Waste | Amount of Waste per Hectare (t) | Total Amount of Waste (t Year−1) | Total Energy Yield of Apricot Wooden Wastes (TJ) |

|---|---|---|---|

| Residual wood obtained after pruning of apricot orchard | 2.73 | 168,214.41 | 3244.86 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akhmedov, S.; Ivanova, T.; Abdulloeva, S.; Muntean, A.; Krepl, V. Contribution to the Energy Situation in Tajikistan by Using Residual Apricot Branches after Pruning as an Alternative Fuel. Energies 2019, 12, 3169. https://doi.org/10.3390/en12163169

Akhmedov S, Ivanova T, Abdulloeva S, Muntean A, Krepl V. Contribution to the Energy Situation in Tajikistan by Using Residual Apricot Branches after Pruning as an Alternative Fuel. Energies. 2019; 12(16):3169. https://doi.org/10.3390/en12163169

Chicago/Turabian StyleAkhmedov, Sayfullo, Tatiana Ivanova, Surayyo Abdulloeva, Alexandru Muntean, and Vladimír Krepl. 2019. "Contribution to the Energy Situation in Tajikistan by Using Residual Apricot Branches after Pruning as an Alternative Fuel" Energies 12, no. 16: 3169. https://doi.org/10.3390/en12163169

APA StyleAkhmedov, S., Ivanova, T., Abdulloeva, S., Muntean, A., & Krepl, V. (2019). Contribution to the Energy Situation in Tajikistan by Using Residual Apricot Branches after Pruning as an Alternative Fuel. Energies, 12(16), 3169. https://doi.org/10.3390/en12163169