Hierarchical Fault-Tolerant Control using Model Predictive Control for Wind Turbine Pitch Actuator Faults

Abstract

:1. Introduction

2. Statement of Wind Turbine Problem

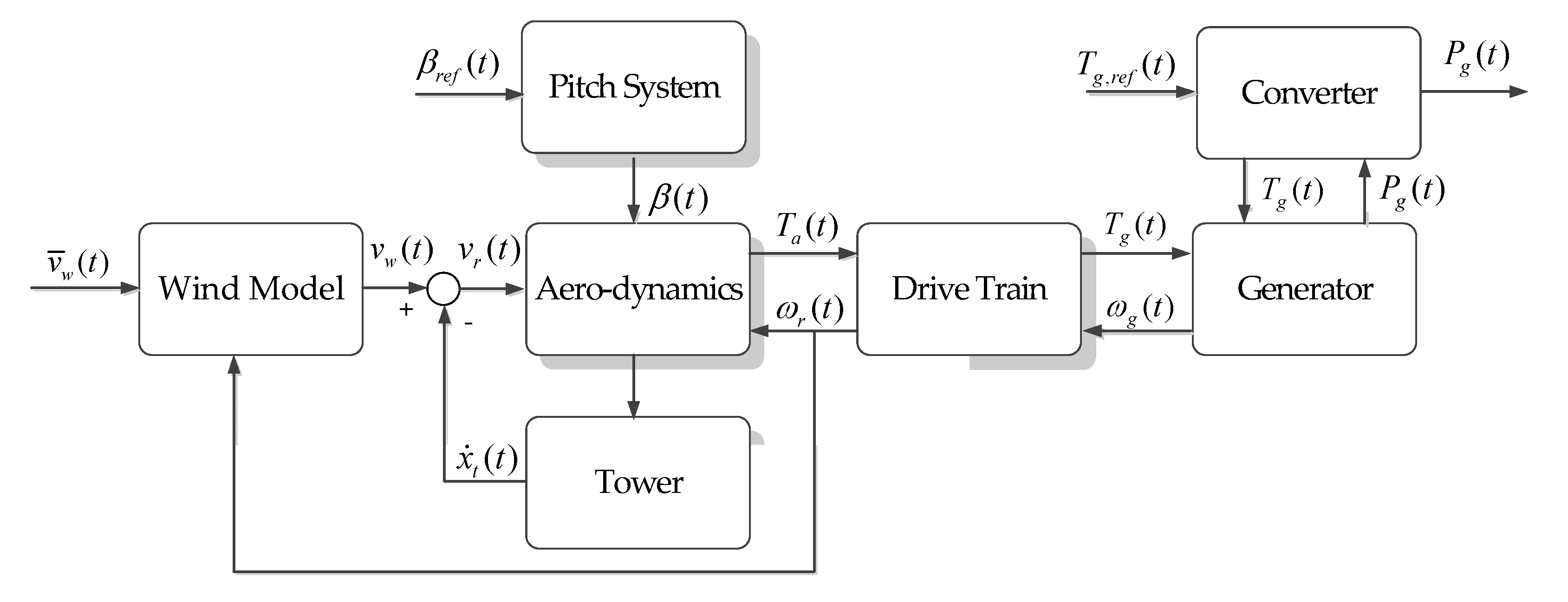

2.1. Description of Wind Turbine Aerodynamics Model

2.2. Model of Pitch Actuator System Fault

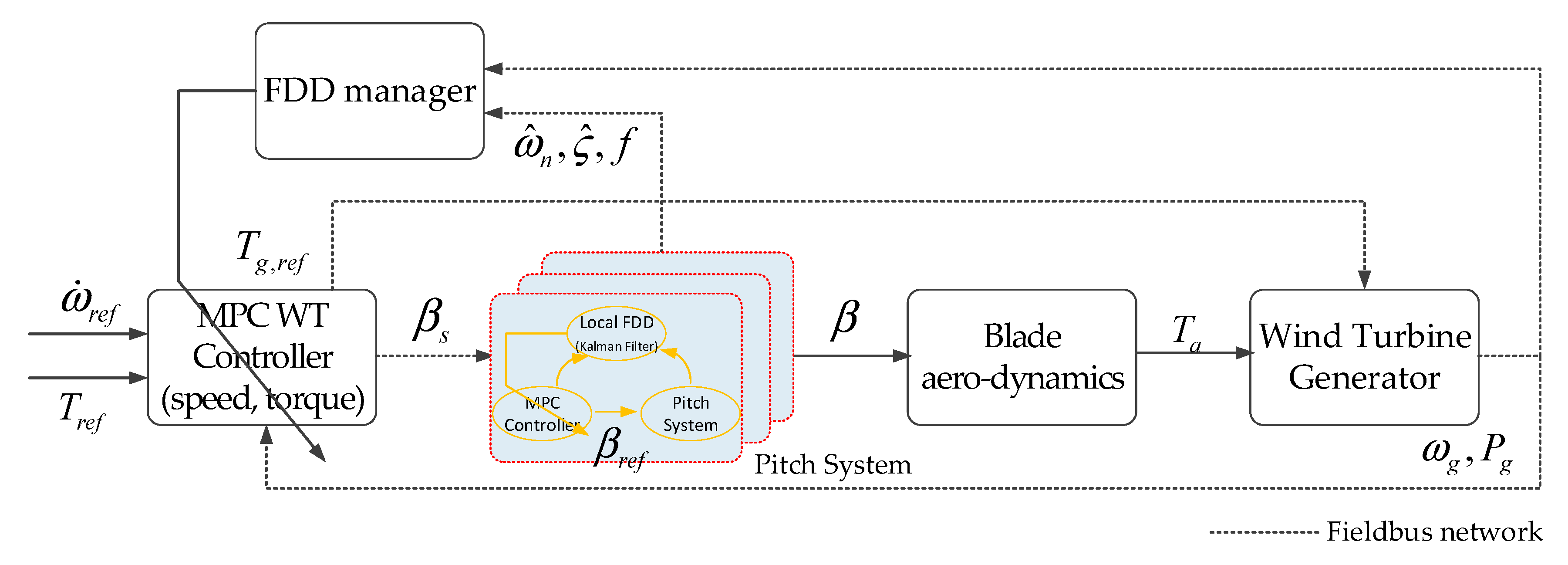

3. Design of Hierarchical Fault-Tolerant Model Predictive Control

3.1. Control Principle for Wind Turbines

3.2. Fault-Tolerant Model Predictive Control for Wind Turbines

3.2.1. Design of Fault-Tolerant MPC for the Pitch System

3.2.2. Design of Fault-Tolerant MPC for the Wind Turbine System

4. Simulation Results

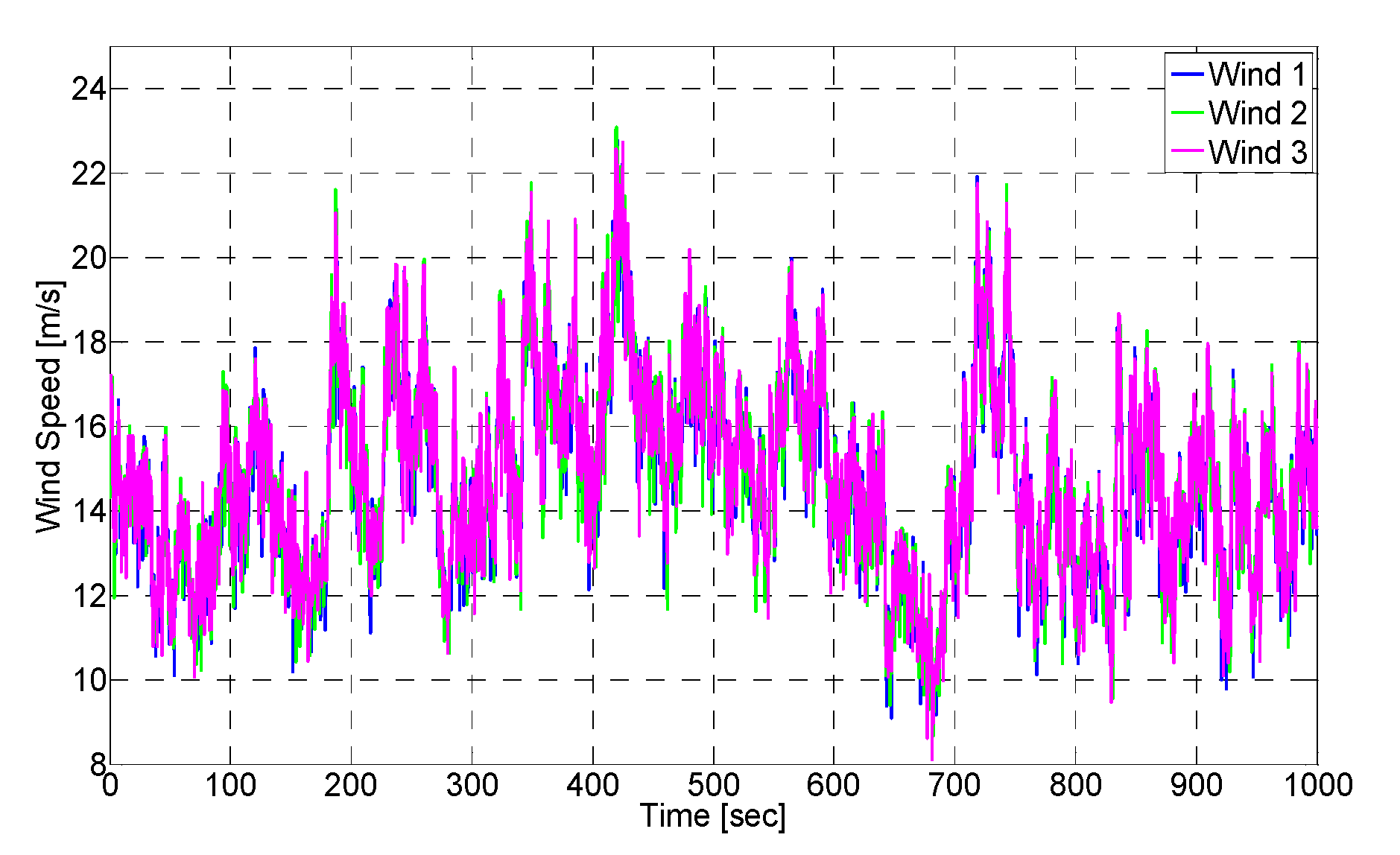

4.1. Wind Turbine Benchmark Model

| Symbol | Description |

| blade pitch angle for [°] | |

| change of pitch angle [°/s] | |

| set-point of pitch angle for pitch controller [°] | |

| reference of pitch angle for pitch system [°] | |

| estimation of pitch angle [°] | |

| estimation of natural frequency pitch system [rad/s] | |

| estimation of damping factor pitch system [rad/s] | |

| estimation of fault index for pitch system [rad/s] | |

| rated power generation (4.8 × 106) [W] | |

| rated generator torque [Nm] | |

| rated generator angular speed (162) [rad/s] | |

| current generated power [W] | |

| error of generated power (−) [w] | |

| current generator angular speed [rad/s] | |

| error of generator angular speed (−) [rad/s] |

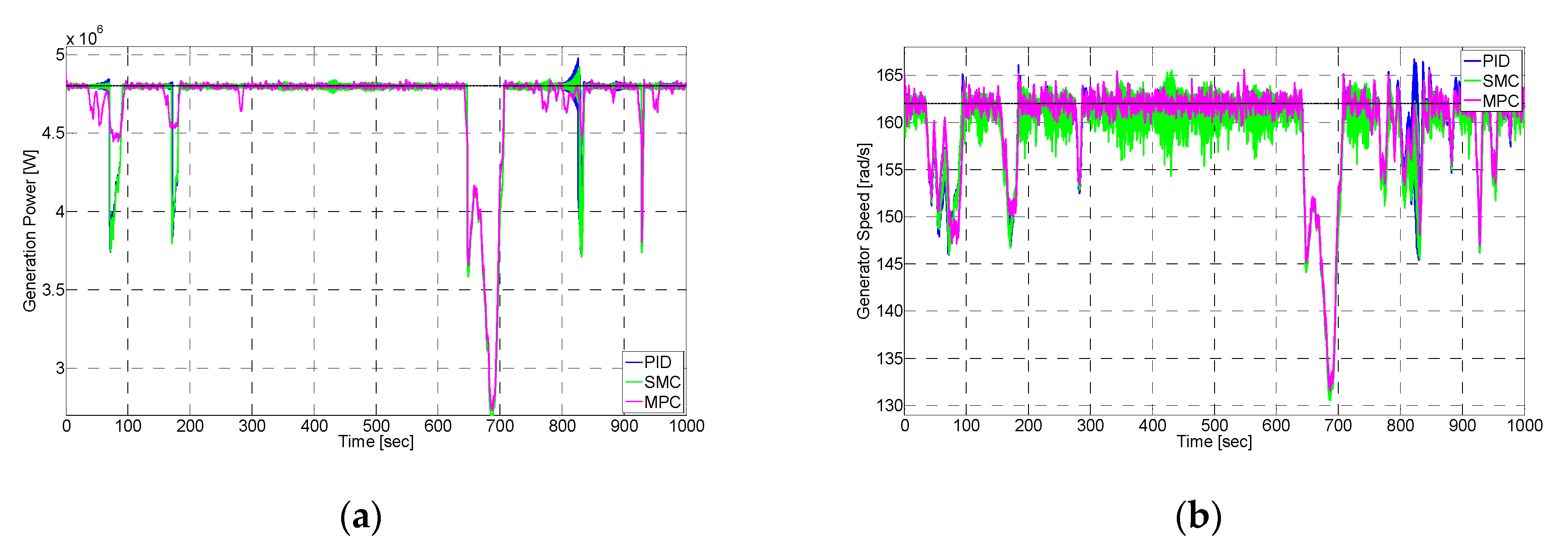

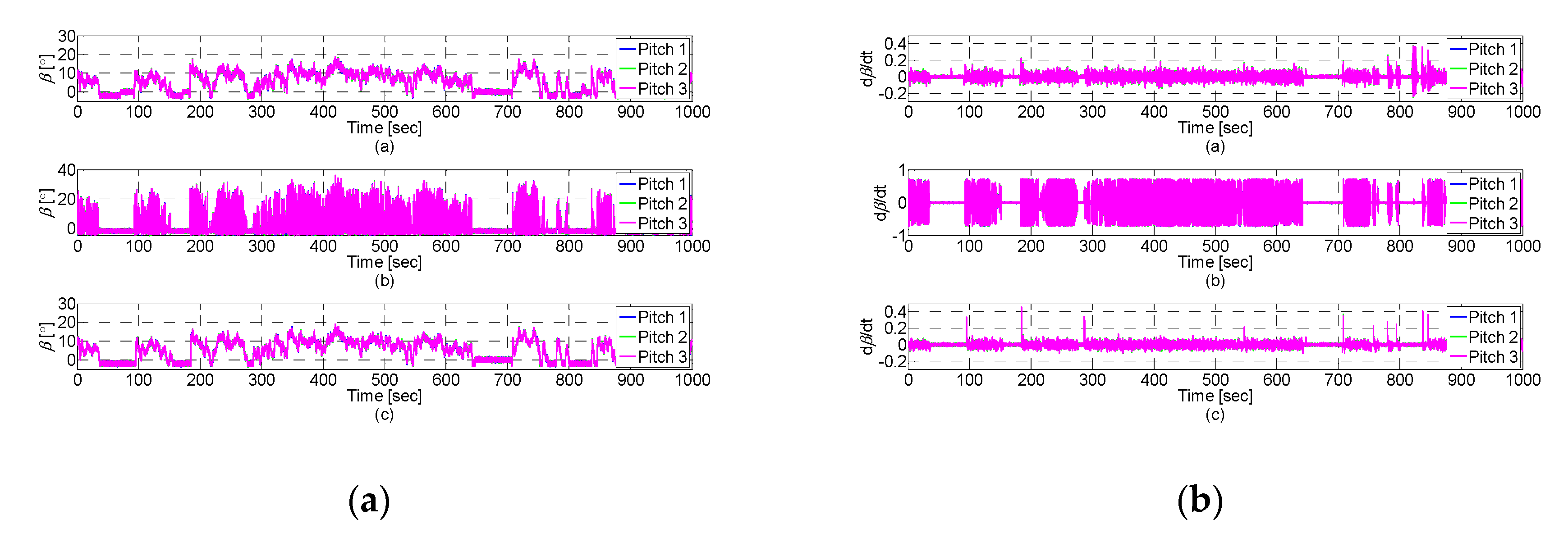

4.2. Simulations for Healthy/Fault-Free Condtion

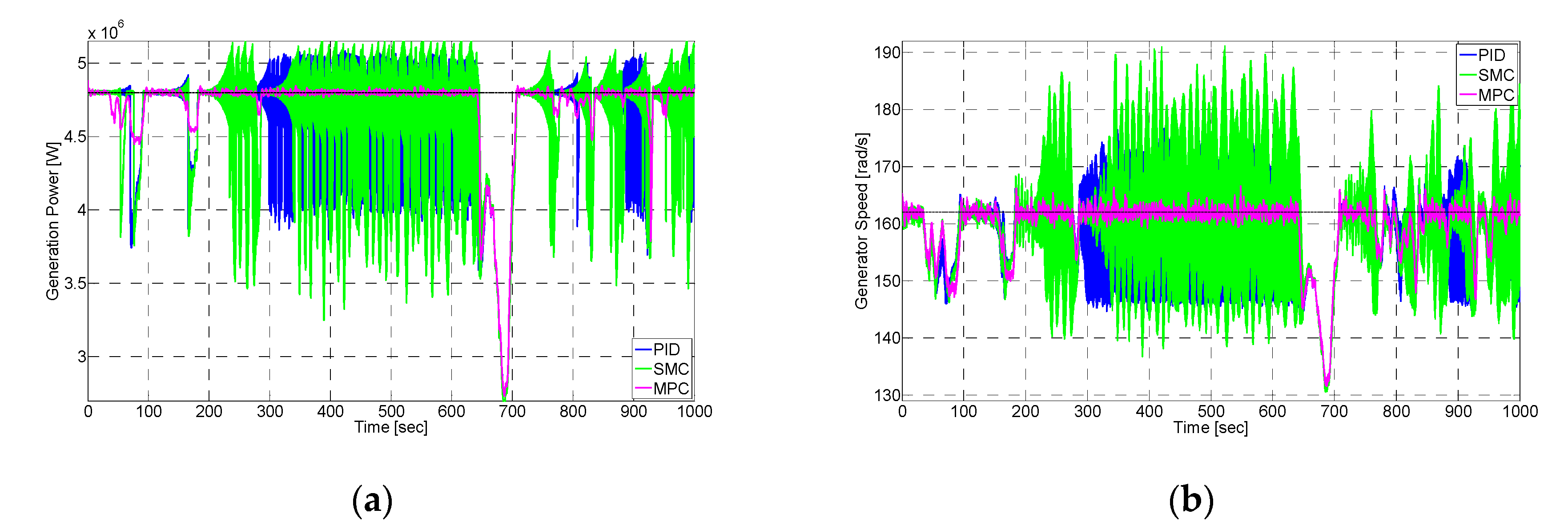

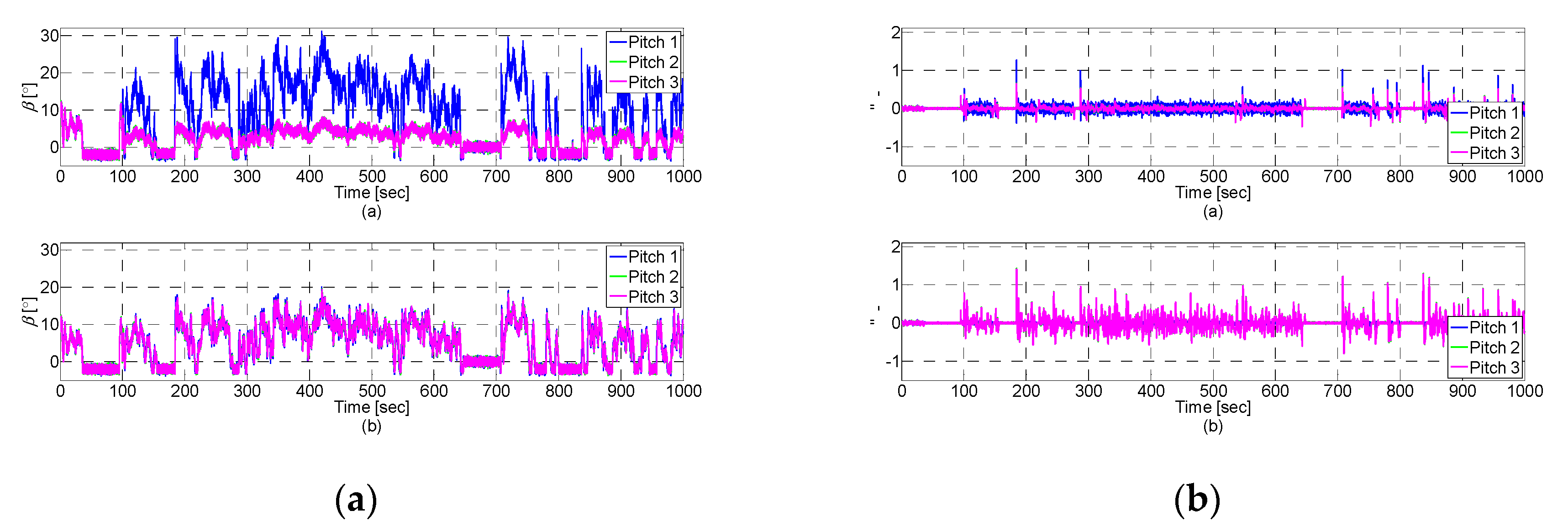

4.3. Simulations for Faulty Condtion

4.4. Simulations with Fault-Tolerant Control in Faulty Condtions

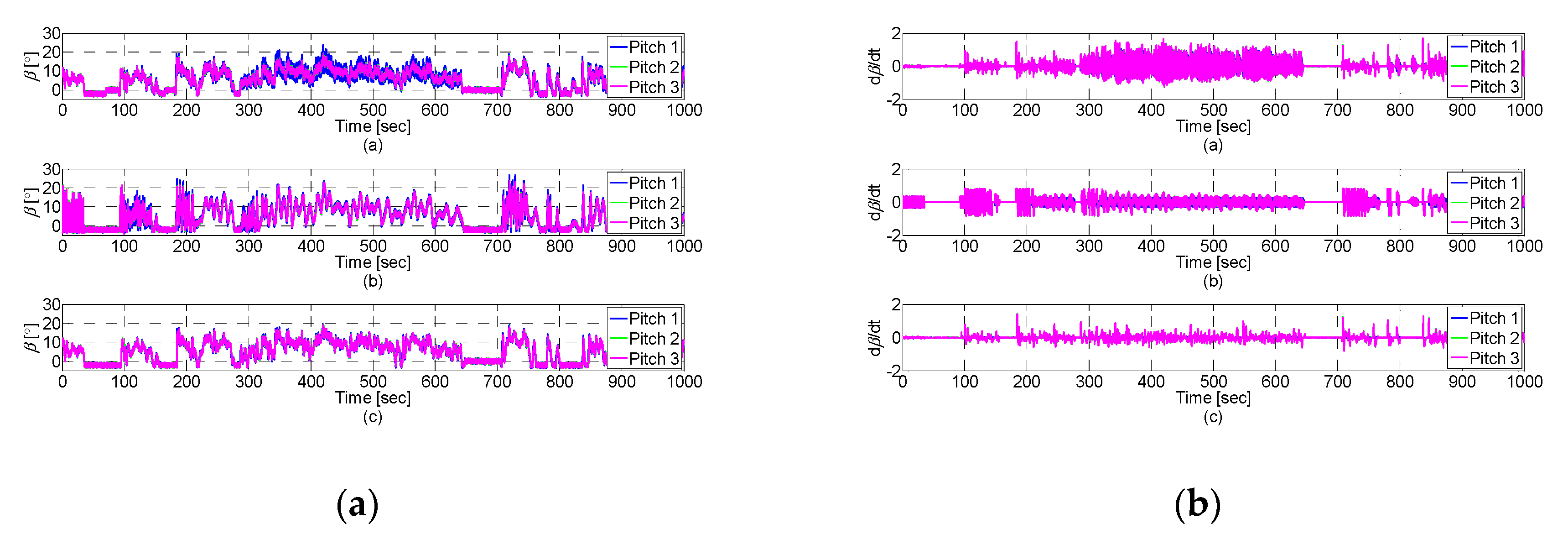

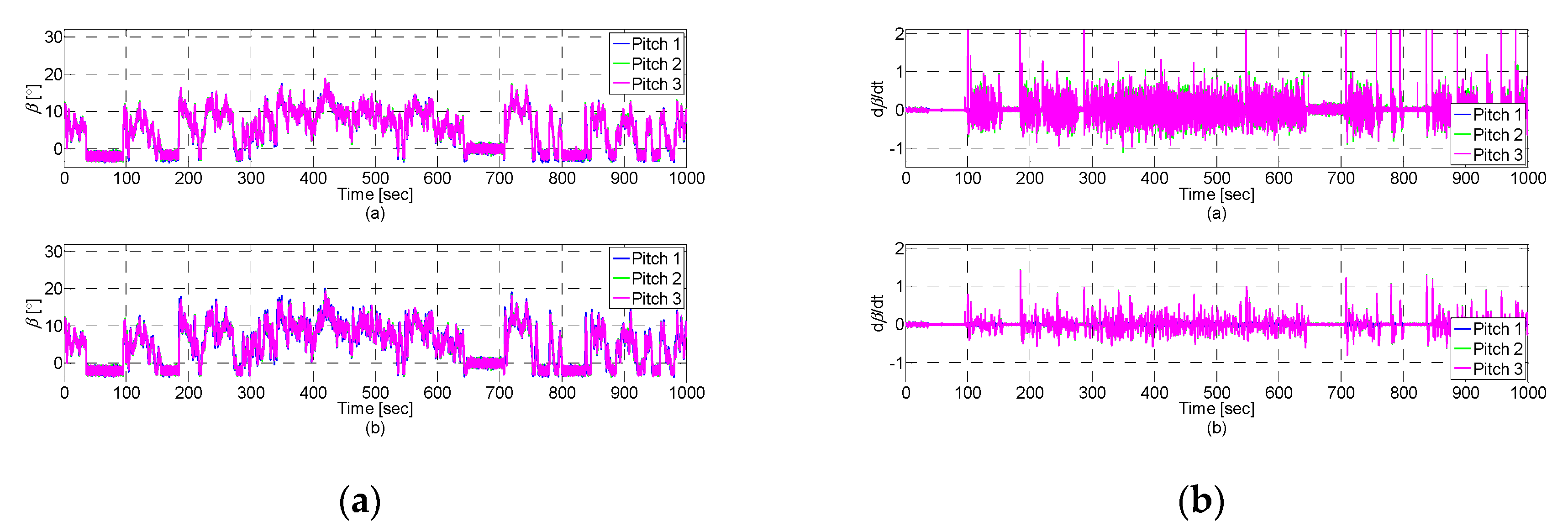

4.4.1. Fault-Tolerant Control with Pitch System Only

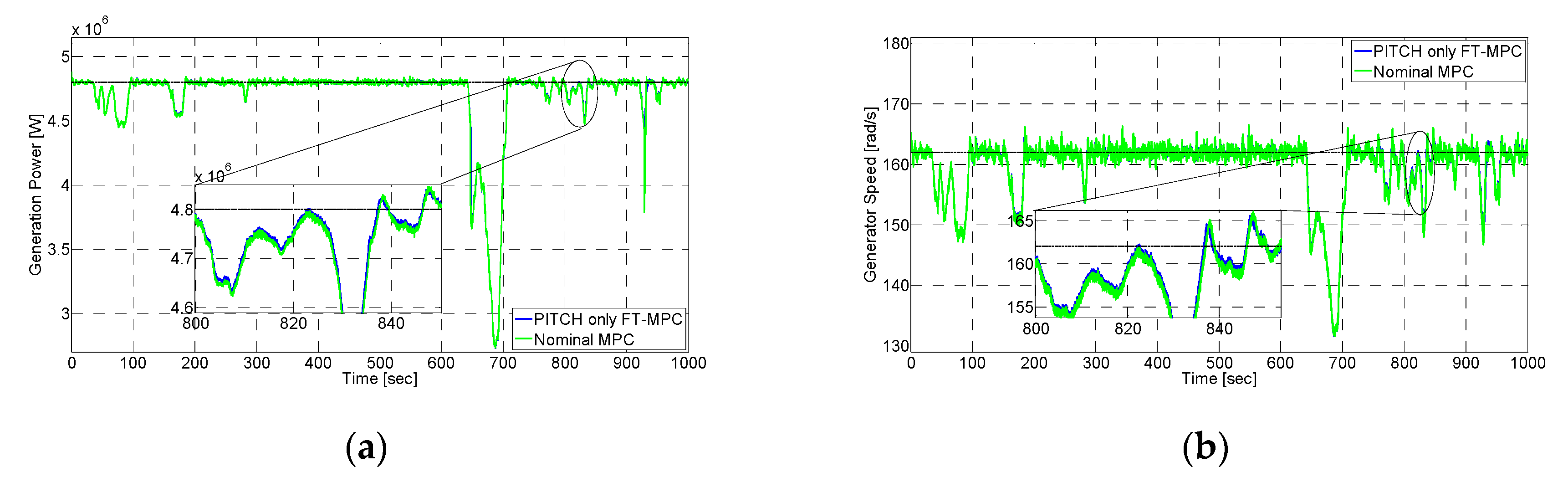

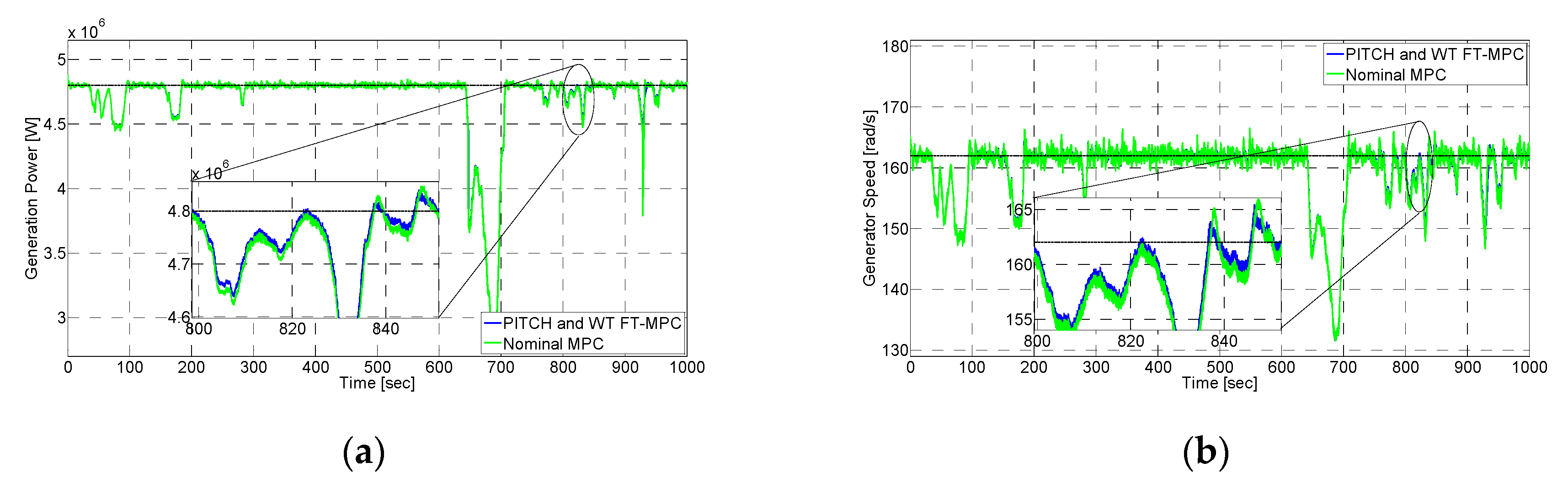

4.4.2. Fault-Tolerant Control with Pitch and Wind Turbine System

4.5. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- WindEuripe. Available online: https://windeurope.org/ (accessed on 10 June 2019).

- Kaldellis, J.K.; Zafirakis, D. The wind energy (r) evolution: A short review of a long history. Renew. Energy 2011, 36, 1887–1901. [Google Scholar] [CrossRef]

- Njiri, J.G.; Söffker, D. State-of-the-art in wind turbine control: Trends and challenges. Renew. Sustain. Energy Rev. 2016, 60, 377–393. [Google Scholar] [CrossRef]

- Burton, T.; Jenkins, N.; Sharpe, D.; Bossanyi, E. Wind Energy Handbook; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Ribrant, J.; Bertling, L. Survey of failures in wind power systems with focus on Swedish wind power plants during 1997–2005. IEEE Trans. Energy Convers. 2007, 22, 1–8. [Google Scholar] [CrossRef]

- Odgaard, P.F.; Stoustrup, J.; Kinnaert, M. Fault-tolerant control of wind turbines: A benchmark model. IEEE Trans. Control Syst. Technol. 2013, 21, 1168–1182. [Google Scholar] [CrossRef]

- Sloth, C.; Esbensen, T.; Stoustrup, J. Robust and fault-tolerant linear parameter varying control of wind turbines. Mechatronics 2011, 21, 645–659. [Google Scholar] [CrossRef]

- Lan, J.; Patton, R.; Zhu, X. Fault-tolerant wind turbine pitch control using adaptive sliding mode estimation. Renew. Energy 2018, 116, 219–231. [Google Scholar] [CrossRef]

- Badihi, H.; Zhang, Y.; Hong, H. Wind turbine fault diagnosis and fault-tolerant torque load control against actuator faults. IEEE Trans. Control Syst. Technol. 2015, 23, 1351–1372. [Google Scholar] [CrossRef]

- Badihi, H.; Zhang, Y.; Hong, H. Fuzzy Gain-Scheduled Active Fault-Tolerant Control of a Wind Turbine. J. Frankl. Inst. 2014, 351, 3677–3706. [Google Scholar] [CrossRef]

- Simani, S.; Castaldi, P. Active Actuator Fault-Tolerant Control of a Wind Turbine Benchmark Model. Int. J. Robust Nonlinear Control 2014, 24, 1283–1303. [Google Scholar] [CrossRef]

- Maciejowski, J. Predictive Control with Constraints; Prentice Hall: Upper Saddle River, NJ, USA, 2000. [Google Scholar]

- Maciejowski, J. The Implicit Daisy-Chaining Property of Constrained Predictive Control. Appl. Math. Comput. Sci. 1998, 8, 101–117. [Google Scholar]

- Yang, X.; Maciejowski, J. Fault-tolerant model predictive control of a wind turbine benchmark. In Proceedings of the 8th IFAC Symposium on Fault Detection, Supervision and Safety of Technical Processes (SAFEPROCESS), Mexico City, Mexico, 29–31 August 2012; pp. 337–342. [Google Scholar]

- Benlahrache, M.A.; Othman, S.; Sheibat-Othman, N. Faults Tolerant Control of Wind Turbine Based On Laguerre Model Predictive Compensator. In Proceedings of the 2015 European Control Conference (ECC), Linz, Austria, 15–17 July 2015; pp. 3653–3658. [Google Scholar]

- Shi, T.; Xiang, X.; Wang, L.; Zhang, Y.; Sun, D. Stochastic Model Predictive Fault Tolerant Control Based on Conditional Value at Risk for Wind Energy Conversion System. Energies 2018, 11, 193. [Google Scholar] [Green Version]

- Odgaard, P.; Stoustrup, J.; Kinnaert, M. Fault tolerant control of wind turbines—A benchmark model. IFAC Proc. Vol. 2009, 42, 155–160. [Google Scholar] [CrossRef]

- Esbensen, T.; Sloth, C. Fault Diagnosis and Fault-tolerant Control of Wind Turbines. Master’s Thesis, Faculty of Engineering, Aalborg University, Aalborg, Danmark, 2009. [Google Scholar]

- Bianchi, F.D.; Battista, H.; Mantz, R.J. Wind Turbine Control Systems: Principles, Modelling and Gain Scheduling Design; Springer: London, UK, 2007. [Google Scholar]

- Kim, J.; Kiss, B.; Lee, D. An adaptive unscented Kalman filtering approach using selective scaling. In Proceedings of the IEEE International Conference on Systems, Man and Cybernetics (SMC), Budapest, Hungary, 9–12 October 2016; pp. 784–789. [Google Scholar]

- Kim, K.; Lee, J.; Park, C. Adaptive Two-Stage Extended Kalman Filter for Fault-Tolerant INS-GPS Loosely Coupled System. IEEE Trans. Aerosp. Electron. Syst. 2009, 45, 125–137. [Google Scholar]

- Gao, Z.; Cecati, C.; Ding, S. A Survey of Fault Diagnosis and Fault-Tolerant Techniques-Part I: Fault Diagnosis with Model-Based and Signal-Based Approaches. IEEE Trans. Ind. Electron. 2015, 62, 3757–3767. [Google Scholar] [CrossRef]

- Lee, S.; Joo, Y.; Back, J.; Seo, J.; Choy, I. Sliding mode controller for torque and pitch control of PMSG wind power systems. J. Power Electron. 2011, 11, 342–349. [Google Scholar] [CrossRef]

- Liu, Y.; Patton, R.; Lan, J. Fault-tolerant Individual Pitch Control using Adaptive Sliding Mode Observer. In Proceedings of the 10th IFAC Symposium on Fault Detection, Supervision and Safety of Technical Processes (SAFEPROCESS), Warsaw, Poland, 29–31 August 2018; pp. 1127–1132. [Google Scholar]

| Parameters | Notation | Value |

|---|---|---|

| Sampling Period | - | 0.01 |

| Prediction Horizon | Np | 20 |

| Control Horizon | Nu | 2 |

| Output Constraint Min/Max | −2/90 | |

| Output Constraint Rate Up/Down | 8/−8 | |

| Input/Output Weight | R/Q | 0.1/1 |

| Controller | |||

|---|---|---|---|

| PI | 1.0380 (1) | 2.6868 (1) | 1.2618 (1) |

| SMC | 1.1479 (1.11) | 3.0746 (1.14) | 79.2850 (62.8) |

| MPC | 0.97361 (0.938) | 2.5886 (0.963) | 0.5745 (0.455) |

| Controller | |||

|---|---|---|---|

| PI | 1.3809 (1) | 5.7436 (1) | 1.0195 (1) |

| SMC | 1.7812 (1.29) | 8.4175 (1.47) | 0.8687 (0.852) |

| MPC | 0.9736 (0.705) | 2.6120 (0.455) | 0.3444 (0.338) |

| Controller | |||

|---|---|---|---|

| Nominal MPC | 9.7363 (1) | 2.6120 (1) | 3.4449 (1) |

| FTC with pitch system only | 9.7085 (0.997) | 2.5649 (0.982) | 6.2457 (1.81) |

| FTC with pitch and wind turbine systems | 9.6849 (0.995) | 2.5407 (0.973) | 1.6201 (0.470) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.; Lee, D. Hierarchical Fault-Tolerant Control using Model Predictive Control for Wind Turbine Pitch Actuator Faults. Energies 2019, 12, 3097. https://doi.org/10.3390/en12163097

Kim D, Lee D. Hierarchical Fault-Tolerant Control using Model Predictive Control for Wind Turbine Pitch Actuator Faults. Energies. 2019; 12(16):3097. https://doi.org/10.3390/en12163097

Chicago/Turabian StyleKim, Donggil, and Dongik Lee. 2019. "Hierarchical Fault-Tolerant Control using Model Predictive Control for Wind Turbine Pitch Actuator Faults" Energies 12, no. 16: 3097. https://doi.org/10.3390/en12163097

APA StyleKim, D., & Lee, D. (2019). Hierarchical Fault-Tolerant Control using Model Predictive Control for Wind Turbine Pitch Actuator Faults. Energies, 12(16), 3097. https://doi.org/10.3390/en12163097