Abstract

Small hydropower plants are usually run-of-river with a poor adjustment capacity, and, therefore, large tail water fluctuation may be induced during flood discharge. Meanwhile, the turbine units need to be quickly started-up due to the regulation requirements of the power grid. However, failures of the start-up and grid connection are often encountered because of severe tail water fluctuation. In order to achieve the rapid and stable start-up under tail water fluctuations and to reduce the negative effect of start-up on turbine runner blades, the fluctuation law of the tail water from flood discharge model test is introduced as the boundary condition. A multi-objective comprehensive (MOC) index is proposed to optimize the parameters of the governor. Then the impacts of the tail water amplitude and frequency on the start-up are simulated and analyzed. Moreover, the start-up characteristics under the Integral Time Absolute Error (ITAE) index and the MOC index are compared through particle swarm optimization (PSO). The results show that both indices can ensure the rapidity of start-up under tail water fluctuation, whereas the MOC index can achieve a more stable start-up process. Therefore, the MOC index has a better stability and a less negative effect on the turbine runner blades.

1. Introduction

Nowadays, ever-increasing environment concerns and electricity demands have greatly promoted the penetration of the renewable energy [1]. Hydropower, considered as the most common of cost-effective and renewable resources, has been vigorously deployed and developed all over the word [2,3,4,5]. Among the hydropower energy types, small hydropower is very important to push forward farmers’ livelihood and improve rural energy structures [6,7,8,9]. Therefore, it is widely used in China. As is well known, most small hydropower stations are usually runoff with poor adjustment capacities [10,11]. These small hydropower stations are built on the rivers in rural mountains, and they usually have a complex topography and narrow upstream river channel. If the flood breaks out quickly and the flood peaks are large, the task of flood discharge and energy dissipation of a small hydropower station is heavy. When small hydropower station discharges floods, the tail water of the station has a huge fluctuation. Then, the working head of the turbine must be directly affected by the tail water fluctuation [12]. Therefore, in order to achieve a stable and quick start-up process under fluctuated tail water, there is an urgent need to study the impact of the tail water fluctuation caused by flood discharge on the start-up of small hydropower stations.

A reference survey has shown that the start-up strategies of hydroelectric power plant have been extensively studied. It is generally accepted that the open-loop control strategy (OLCS), the closed-loop control strategy (CLCS), and the open-loop + closed-loop control strategy (OLCLCS) are the main start-up control strategies commonly adopted in turbine governing systems [13,14]. The OLCS directly controls the guide vane without considering unit frequency feedback, so that the unit speed increases rapidly [15]. When the unit speed reaches a threshold value, this strategy then utilizes proportional integral derivative (PID) adjustment to stabilize units at the rated rotational speed. The advantage of OLCS is that guide vane control is relatively straightforward, so it will take less time before the rotational speed reaches the threshold. Its shortcoming is also obvious. The ratio between the start-up and no-load wicket gate opening is difficult to determine, which makes the selection of the start-up opening a blind and arbitrary act. As for CLCS, PID adjustment is input immediately after the governor receives the start-up order, and the speed of the unit is stabilized at the rated value through frequency feedback [16]. The CLCS is beneficial in avoiding the selection of frequency when PID adjustment and the start-up opening are switched in [14,17]. The OLCLCS combines the advantages of both OLCS and OLCS, but it is also blind and arbitrary upon start-up opening and the selection of frequency when the PID adjustment is input. In spite of the wide use of these traditional strategies, there still exists one shortcoming. The water level is considered as constant when conducting the above studies, and, as such, the impact of water fluctuation on the start-up process is ignored.

In the last few decades, a large number of publications have focused on governor parameters and start-up strategy optimization. Li et al. [18] applied a novel improved gravitational search algorithm to design and optimize a fuzzy-PID controller. The tuning of PID gains for turbine-governor was optimized by Fang et al. [19], who employed an improved particle swarm optimization (PSO) algorithm. Wang et al. [20] proposed the Artificial Sheep Algorithm, a kind of meta-heuristic method, to solve the optimization of start-up strategy. Focusing on minimizing the Integral Time Absolute Error (ITAE) criterion, Maiti et al. [21] optimized a one fractional-order PID controller. Zhou et al. [22] optimized the governor parameters based on the ITAE index by setting the objective of a rational constant to increase the rate of speed. Hou et al. [23] proposed a multi-objective optimization method for pumped storage plant start-up in which both the rising time and overshoot of speed were considered. However, it was noticed that the previous studies about start-up parameter optimization are concentrated mainly on the integration of product of time and frequency deviation while the time for start-up, the head deviation integral, and the maximum water head deviation, as well as the impact of turbine start on turbine runner blades, are ignored,.

Traditionally, for hydropower stations with large reservoirs, the upstream and downstream water levels can normally be assumed constant during a short-duration transient. As such, the water level has no effect on the unit’s start-up process and can thereby be ignored. However, most small hydropower stations are usually runoff with poor adjustment capacities, and when small hydropower stations discharge floods, the tail water of these stations has a large fluctuation [24]. Thus, the impact of tail water level fluctuation on start-up cannot be ignored for such small hydropower stations. Moreover, if a small hydropower station undertakes the functions of peak load and frequency regulation, the start-up must be rapid. It should avoid the huge fluctuation of pressure in the water diversion pipeline and reduce the negative effect on turbine runner blades during the start-up process. Therefore, motivated by the above discussions, the water level fluctuations in the star-up processes of small hydroelectric power plants are here comprehensively investigated for the first time, in a way which is more consistent with engineering practices. A multi-objective optimization approach is employed to optimize the parameters of the governor for the optimized regulation.

The present paper is organized as follows: Section 2 establishes the mathematical model of the turbine regulation system and tail water fluctuation. In Section 3, the start-up strategies are analyzed and a multi-objective comprehensive (MOC) index is presented. In Section 4, the impacts of the tail water fluctuation on the start-up are investigated, and the start-up characteristics under the ITAE index and the MOC index are compared through PSO. Section 5 is a discussion of the results, and Section 6 draws some Conclusions.

2. Mathematic Model

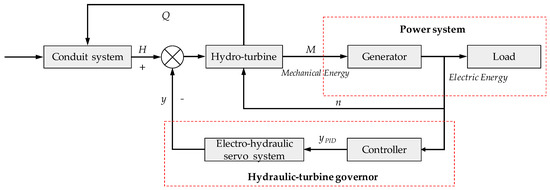

The turbine governing system of a small hydropower station is a complex nonlinear coupling system which mainly undertakes power output modulation and frequency regulation. The start-up process of a small hydroelectric power plant is closely related to the turbine governing system, which is composed of a hydraulic-turbine governor, a hydro-turbine, a generator, and a conduit system (seen in Figure 1) [20,25,26]. In this section, the mathematical model of turbine regulation system is introduced. The boundary conditions of the tail water fluctuation caused by flood discharge are established and analyzed.

Figure 1.

Structure of small hydropower station turbine governing system.

2.1. Model of Turbine Governor

A hydraulic turbine governor is one of the most important pieces of core equipment of small hydropower stations. The hydraulic turbine governor has three stages based on governor structure features, including the micro, electrical, and mechanical governor. Nowadays, the micro governor has become the main choice due to its high-performance, and it consists of an actuator and controller [27,28,29].

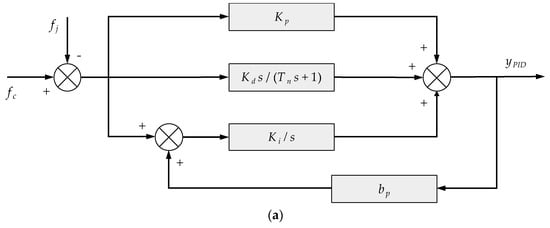

A controller can be classified into many categories, which include the proportional integration (PI) controller, the series PID controller, and the parallel PID controller. According to the performances of robustness and practicability, a parallel PID controller is applied herein. Figure 2a gives the structure of the parallel PID controller, and the transfer function is described by Equation (1).

where , and are the differential gain, integral gain and proportional gain of parallel PID controller, respectively; is the permanent slip coefficient; and s is the Laplace operator.

Figure 2.

Structure of a hydraulic turbine governor: (a) Structure of a parallel proportional integral derivative (PID) controller; (b) block diagram of electro–hydraulic servo system.

The actuator is the actuating mechanism of the hydraulic turbine governor. Here, the nonlinear characteristics are considered in the model of an electro–hydraulic servo actuator. Figure 2b presents its structure, and the expression of the electro–hydraulic servo actuator is expressed by:

where and are the auxiliary and main servomotor reaction time constants, respectively.

2.2. Model of Hydro-Turbine and Power System

2.2.1. Hydro-Turbine

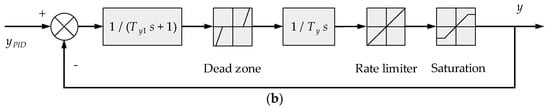

The hydro-turbine is a vital and complex piece of equipment in the hydroelectric power plant, and the parameters of the turbine are characterized by a strong nonlinearity. Currently, the comprehensive characteristic curve based model is commonly used, since it can truly express the dynamic behavior of hydro-turbine [18,30]. It can be described as:

where , , and are the relative deviations of the discharge, torque, head and speed, respectively; , and are unit speed, unit discharge and unit torque, respectively; and are the characteristic functions of unit discharge and torque, respectively; is the guide vane opening; the subscripts ‘r’ and ‘0’ indicates the rated and initial values, respectively; and is the transfer function. Figure 3 shows the mathematical calculation block diagram of the nonlinear hydro-turbine model.

Figure 3.

Block diagram of hydro-turbine model.

2.2.2. Power System

The generator and load are key electrical components of the energy conversion for small hydropower stations. The first-order generator model is applied to simplify the simulation [20] and given by:

where is the hydro-turbine unit inertia time constant and is load disturbance torque.

2.3. Model of Conduit System

According to the moment equations and continuity equations, the head and flow equations for two adjacent reaches of the pipelines are given by [31,32]:

where subscript ‘’ and ‘’ represent the upstream and downstream pipeline reaches, respectively; is length of the pipeline; and and are the conduit parameters, which can be described by Equation (6).

with

where D, and A are the pipeline diameter, head loss coefficient and discharge coefficient, respectively; and are initial head and discharge, respectively; and is wavespeed.

The substitution of Equation (7) into Equation (6) yields:

where , and .

Generally, a headrace tunnel connects with an upstream reservoir directly, that is, . Thus, according to Equation (5), one can obtain:

where , and .

Different n represents a different water hammer model. Equation (9) is a rigid water hammer model for n = 0, but it is an elastic water hammer model when . Neglecting the term of that is high order, Equation (9) can be transformed into a three order elastic water hammer equation that yields:

2.4. Model of Tail Water Fluctuation

Most small hydropower stations are built on the rivers in rural mountains and usually are located in complex topographies with narrow upstream river channels. If a flood breaks out quickly and the flood peaks are large, the task of a small hydropower station regarding flood discharge and energy dissipation is a heavy one. When a small hydropower station discharges floods, the tail water of the station will have huge fluctuations. Eventually, the working head of the turbine must be directly affected by the tail water fluctuation. According to the hydraulic model test, the tail water fluctuation caused by the flood discharge is a cyclical fluctuation [24]. Therefore, the tail water fluctuation formula can be expressed as:

where is relative amplitude of the tail water fluctuation, is fluctuation frequency of the tail water, and is the initial phase.

In order to investigate the most critical operation condition of turbine start-up process, it is assumed that the effect of the tail water fluctuation is directly imposed on the turbine.

3. Start-Up Strategy and Multi-Objective Optimization

3.1. Start-Up Strategy

To achieve a rapid and stable start-up for a small hydropower station, an optimal start-up strategy should satisfy the following four principles. (1) When the start-up order is received, the speed should be able reach the rated speed in the shortest possible time. (2) Turbine torque fluctuation should be small. (3) Axial water thrust and fluctuation should be low. (4) The pressure fluctuation of the pressurized water conduit should be as small as possible.

As mentioned previously, commonly used start-up strategies mainly include the OLCS, the CLCS and the OLCLCS. The OLCLCS and the OLCS are similar during the start-up process. The successful application of these two start-up strategies is greatly dependent on frequency when a PID adjustment is input and the start-up opening of the guide vane. However, selecting these parameters is still a blind and arbitrary process. Empirically, the start-up opening is double the no-load opening, which is the function of water head. A small no-load opening will generate a slow speed for start-up, while a large one may produce an over-speed. Therefore, both the OLCS and the OLCLCS cannot be adapted to various water head changes.

Since small hydropower stations are mostly influenced by run-off, the operating water head fluctuations during flood discharge are usually very great. Meanwhile, considering that the no-load opening strongly depends on the operating water head and easily influences the OLCS and the OLCLCS, the CLCS is employed to avoid the effect of a no-load opening and water head fluctuations on start-up processes.

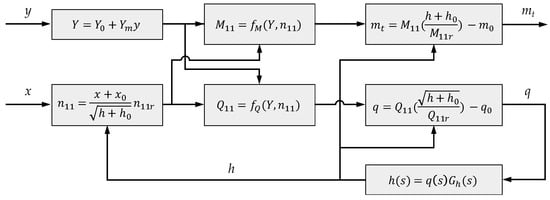

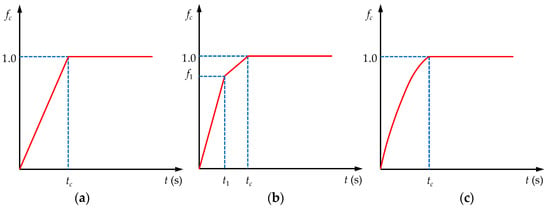

Compared with the OLCS and the OLCLCS, determining a reasonable desired rise curve of the rotating speed is a key issue for the CLCS. As depicted in Figure 4, three kinds of desired rotating speed rise curves are commonly used, and these are the linear opening scheme, the two-phase opening scheme and the exponential opening scheme.

Figure 4.

Desired rise curves of rotating speed for the closed-loop control strategy (CLCS): (a) Linear opening scheme; (b) two-phase opening scheme; and (c) exponential opening scheme, where is the time rising from 0 to rated speed at the desired speed and and are the switching time and frequency of the turning point of the two straight lines, respectively.

According to Figure 4a, the speed rising rate keeps constant for the linear opening scheme. The closed-loop control strategy with a linear law is adapted in this paper can be described as:

where is the slope.

3.2. Multi-Objective Optimization

The optimization of parameters during the start-up process in a small hydropower station is studied in this section. A previous analysis indicates that the control quality and rapidity are contradictory. Therefore, the start-up parameters’ optimization for a small hydropower station is a multi-objective coordination problem, and an appropriate algorithm and optimization method is of great importance. Recently, popular optimization methods for the governor parameters have been determined as the orthogonal experiment, the genetic algorithm and PSO. Among them, PSO has unique advantages for complex, multi-objective problem solving systems. Therefore, PSO was applied for the optimization of the start-up process.

The parameters of a hydraulic turbine governor system have a great influence on the start-up process. When PSO is used for the parameter optimization of the governor, the control performance should be evaluated by corresponding performance indices. Commonly used performance indices include the Integral Time Squared Error (ISTE), the Integral Absolute Error (IAE), the Integral Squared Error (ISE), and the ITAE. The ITAE is defined as the integral of the product of time and absolute error, which is a comprehensive index integrating the rapidity, stability and accuracy of the system. Therefore, it has been broadly applied in PID parameter optimization for turbine governor systems. The ITAE can be given as:

where is the integral upper limit time and is the signal of error.

Usually, a deviation of frequency is considered as the signal of error in previous studies for preferred frequency stability. However, start-up time has not been considered, and its impact on runner blades of turbine has also been ignored. Moreover, the working head of the turbine may have great fluctuation during flood discharge. Therefore, an MOC index is put forward in this paper which includes the time for start-up, the head deviation integral, and the maximum deviation of the water head. The expression can be described as:

in which is the speed overshoot, is deviation value between initial head and head at any instant, and is deviation between expected and actual speed. , , , and are the weight coefficients, and the corresponding values are , , , , .

4. Case Study and Results

4.1. Case Study

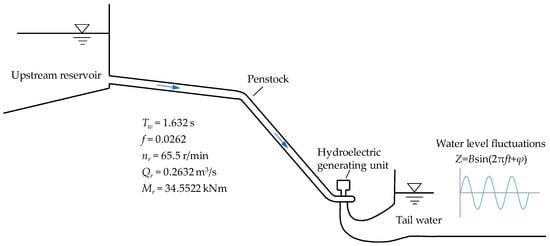

The impact of tail water fluctuation generated by flood discharge on the start-up process was studied based on a practical project which can be seen in Figure 5. The relevant parameters of a small hydroelectric power plant are shown as follows. The water inertial time constant was 1.632 s, and the friction loss coefficient was 0.0262. The rated unit speed, torque and discharge were 65.5 r/min, 34.5522 kNm, and 0.2632 m3/s, respectively. The inertia time constant and load disturbance torque of the hydro-turbine units were 5.9 and 0 s. The differential filter time constant was 0.02 s, and the permanent slip coefficient was 0.02. The reaction time constant of auxiliary and main servomotor were 0.05 s and 0.2 s, respectively. The maximum travel of the servo was 16 mm. The servomotor opening speed limit and servomotor closing speed limit were 15 and 10 s, respectively. The dead-zone nonlinearity was 0.0002.

Figure 5.

Schematic diagram of a small hydroelectric power plant.

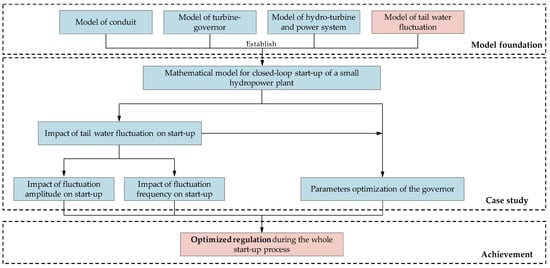

Employing the mathematical model as specified above, the CLCS for starting-up under the tail water fluctuation was simulated based on the technical parameters of the above small hydroelectric power plant. The amplitude and frequency of the tail water fluctuations were the two important factors influencing the start-up process. Therefore, the impacts of fluctuation of amplitude and frequency on start-up were numerically investigated. According to the influence results, the parameters of the governor were optimized to achieve an optimized regulation during the whole start-up process, and the technical route can be seen in Figure 6.

Figure 6.

Technical route for the case study.

4.2. Results and Analysis

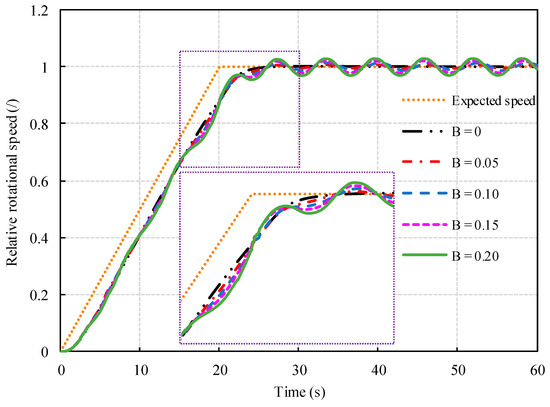

4.2.1. Impact of Tail Water Fluctuation on Start-Up

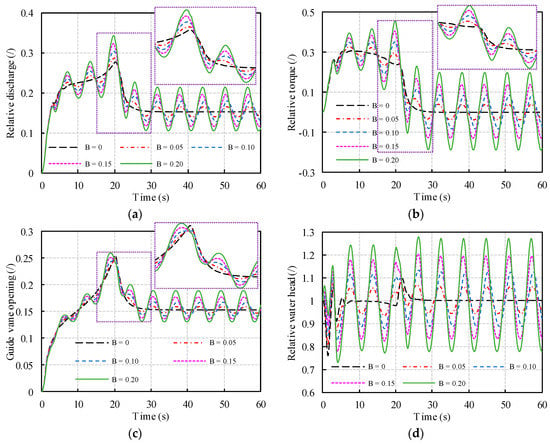

The initial water head was 1.0, and the parameters of the governor were , and . The closed-loop control strategy with a straight-line speed rise curve was adopted during start-up. The tail water fluctuation frequency was fixed at 0.17 Hz. The fluctuation amplitudes of the tail water were found to be 0, 0.05, 0.10, 0.15 and 0.20. Comparisons of the start-up characteristics of the units are presented in Figure 7 and Figure 8.

Figure 7.

Comparison of closed-loop start-up speed characteristics of different tail water fluctuation amplitudes under a fixed frequency.

Figure 8.

Comparison of closed-loop start-up characteristics of different tail water fluctuation amplitudes under a fixed frequency: (a) Time history of discharge; (b) time history of torque; (c) time history of guide vane opening; and (d) time history of water head.

Figure 7 gives the speed characteristics of different tail water fluctuation amplitudes under a fixed frequency during closed-loop start-up. When the tail water fluctuation frequency was fixed at 0.17 Hz, the unit could rapidly reach the rated rotational speed within 25 s under the different tail water fluctuation amplitudes. Secondly, with the increase of the tail water fluctuation amplitude, the speed characteristic curve had different oscillations in the rising stage, and the larger the amplitude of the tail water fluctuation, the larger the oscillation was in the rising stage. In addition, the greater the amplitude of the tail water fluctuation, the longer the unit took to get to the rated speed.

Under a fixed frequency, the characteristics of other parameters under different tail water fluctuation amplitudes are presented in Figure 8. The results show that different amplitudes of tail water fluctuation had little effect on the discharge, turbine torque, guide vane opening and water head within 0–5 s at the initial stage of the unit start-up. Five seconds later, however, the fluctuations of the discharge, turbine torque, guide vane opening and water head were greatly increased as the rotational speed increased, and, the greater the tail water fluctuation amplitude was, the larger the fluctuation of each above parameter was. Moreover, when the rotational speed stabilized at the rated speed, these parameters presented a constant amplitude oscillation without attenuation, and the amplitude of the oscillation increased as the tail water fluctuation amplitude increases.

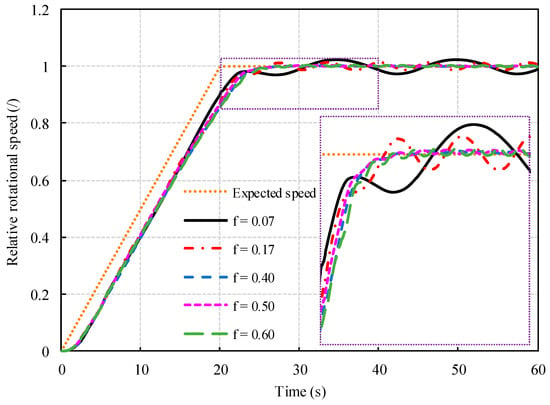

A similar simulation was conducted for the impact of fluctuation frequency on start-up. The tail water fluctuation amplitude was fixed at 0.10. The fluctuation frequencies of the tail water were 0.07, 0.17, 0.4, 0.50 and 0.60 Hz. Other parameters were the same as that used in previous calculation. The comparisons of the start-up characteristics of the unit are presented in Figure 9 and Figure 10.

Figure 9.

Comparison of closed-loop start-up speed characteristics of different tail water fluctuation frequencies under a fixed fluctuation amplitude.

Figure 10.

Comparison of closed-loop start-up characteristics of different tail water fluctuation frequencies under a fixed fluctuation amplitude: (a) Time history of discharge; (b) time history of torque; (c) time history of guide vane opening; and (d) time history of water head.

Figure 9 gives the speed characteristics of different tail water fluctuation frequencies under a fixed amplitude during a closed-loop start-up. When the tail water fluctuation amplitude was fixed at 0.10, the unit could rapidly reach the rated rotational speed within 23 s under the different tail water fluctuation frequencies. Next, the rotational speed characteristic curves were almost the same in the rising stage with the increasing fluctuation frequencies. However, when reaching the rated speed, the rotational speed exhibited different fluctuation processes under the different fluctuation frequencies. Compared with other fluctuation frequencies, the frequency of 0.07 Hz could induce a larger fluctuation amplitude of the rotational speed, which is obviously adverse for grid connection. Moreover, with the increasing tail water fluctuation frequency, the amplitude of the rotational speed fluctuation first decreased and then increased. For the frequency of 0.40 Hz, the fluctuation amplitude of the speed was the smallest during the whole start-up process.

Figure 10 presents the characteristics of other parameters under different fluctuation frequencies for a fixed fluctuation amplitude. As shown in Figure 10, the tail water fluctuation frequency had a greater influence on the demand discharge, turbine rotational torque, guide vane opening and head for the start-up process. Especially if the fluctuation frequency was too small, 0.07 Hz for instance, the guide vane opening greatly fluctuated, making the guide vane swing back and forth. This phenomenon is extremely dangerous and should be avoided.

From the above results and analysis, it can be suggested that tail water fluctuation caused by flood discharge has little effect at a speed rising stage from 0 s to a rated speed during a closed-loop start-up process. However, as soon as a rotational speed reaches a rated speed, the fluctuation of the frequency or amplitude of a tail water will cause different degrees of fluctuation oscillation of speed. Moreover, large fluctuations on some other parameters, such as demand discharge, turbine rotational torque, guide vane opening and water head, will also be caused by tail water fluctuation. More importantly, at a specific fluctuation frequency (0.07 Hz for instance), excessive fluctuations of the guide vane opening can be generated. This is obviously adverse for grid connection and sometimes may result in failure of a start-up and connection to a grid. Therefore, it is necessary to optimize the parameters of a governor to achieve a rapid and stable start-up under tail water fluctuations.

4.2.2. Optimization of Start-Up Under Tail Water Fluctuation

In Section 4.2.1, the impact of tail water fluctuations on the parameters, including the rotational speed, discharge, turbine torque, guide vane opening and work head, were discussed. It can be concluded that these parameters will be influenced in different degree because of tail water fluctuation. Especially, for some specific fluctuation frequencies, the large fluctuations may result in a failure of a start-up and connection to a grid. Therefore, the optimization of a start-up control strategy under tail water fluctuation is discussed based on the proposed MOC index in this section.

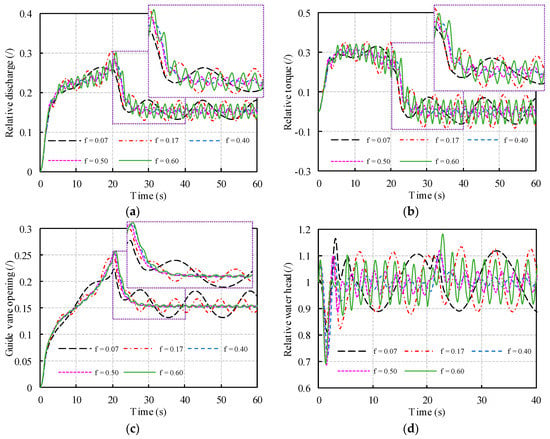

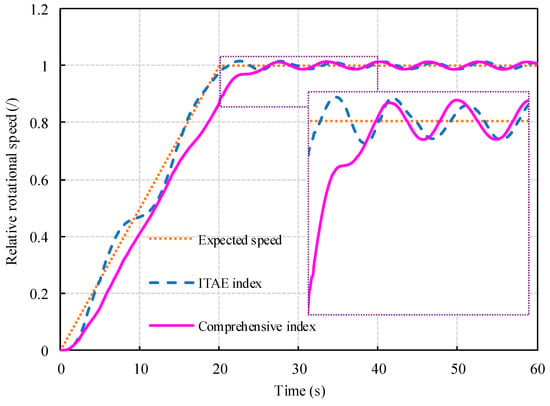

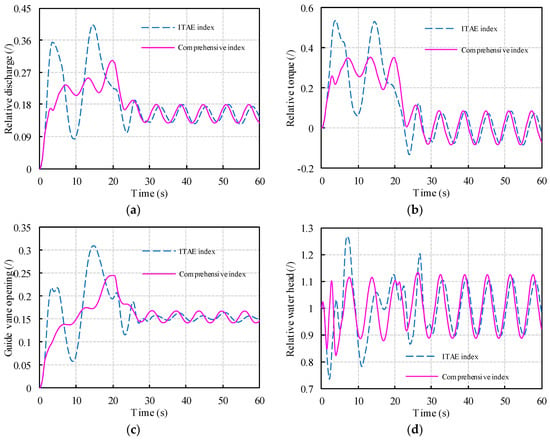

Similarly, the initial water head was 1.0, and the CLCS with a linear speed rise curve was adopted. PSO was employed to optimize the parameters of the governor under tail water fluctuation, and the MOC index was selected as the optimization function. The amplitude and frequencies were 0.1 and 0.17 Hz. In addition, the start-up characteristics of the MOC index were compared with the ITAE index. The contrast curves of the start-up are presented in Figure 11 and Figure 12, and the corresponding PID parameters and performance indices are given in Table 1.

Figure 11.

Optimization contrast curve of start-up speed characteristics.

Figure 12.

Optimization contrast curve of start-up characteristics: (a) Time history of discharge; (b) time history of torque; (c) time history of guide vane opening; and (d) time history of water head.

Table 1.

Comparison of PID parameters and performance indexes.

According to the corresponding PID parameters, the performance indices were calculated and are presented in Table 1 and Figure 11. The results indicate that the start-up times for the multi-objective comprehensive index and the ITAE were 23.85 and 19.42 s, respectively. Thus, both of these two indices can ensure start-up rapidity. Additionally, the start-up time of the MOC index was only 4.43 s more than that of the ITAE index. Secondly, the value of the product of time and absolute error was 19.19 under the ITAE index, which was much lower than that of the MOC index—35.80. However, the overshoot, the maximum deviation of water head, and the head deviation integral under the MOC index were smaller than that of the ITAE index, reduced by 9.5%, 33.3% and 5.6%, respectively.

Figure 12 gives the start-up characteristics of both the multi-objective comprehensive index and the ITAE. As shown in Figure 12a, the discharge fluctuation in the water diversion pipeline under the MOC index was more stable, achieving a better dynamic performance during the start-up process. Moreover, from Figure 12b, it can be seen that the fluctuation of the torque during the start-up process was smaller than that under the ITAE index. Therefore, if the comprehensive index is adopted, the start-up under the tail water fluctuation can achieve a better dynamic performance of the runner, thereby reducing the impact of the start-up on the runner crack. In general, the start-up under the comprehensive performance index proposed in this paper has a better stability.

5. Discussion

In order to investigate the effect of tail water fluctuation on the start-up of small hydropower stations, tail water fluctuation was simulated and taken as the boundary condition according to the model test results of flood discharge. On this basis, an MOC index, considering the start-up time, the maximum deviation of water head, and the head deviation integral, was proposed. The multi-objective comprehensive index for start-up optimization was verified by employing numerical simulations based on a practical project. In this section, the impact of tail water fluctuation frequency and amplitude on the start-up, as well as the start-up characteristics under the ITAE index and the multi-objective comprehensive index, are discussed.

(1) The impact of tail water fluctuation frequency and amplitude on the start-up of small hydropower stations were studied. The start-up speed characteristic curves under different tail water fluctuation frequencies and amplitudes are presented in Figure 7 and Figure 9. As shown in Figure 7 and Figure 9, the units can quickly reach the rated speed under different tail water fluctuation frequencies or amplitudes if the CLCS is adopted. Additionally, less speed fluctuation is induced during the speed rising stage. However, large fluctuations will be generated as soon as the units reache the rated speed. For a fluctuation frequency of 0.17 Hz, the larger the tail water fluctuation amplitude is, the greater the fluctuation of the speed will be. Moreover, as the tail water fluctuation frequency increases, the fluctuation amplitude of the rotational speed first decreases and then increases. When the frequency is selected as 0.40 Hz, the fluctuation amplitude of speed will get the minimum value. These results indicate that the frequency and amplitude of tail water fluctuation really have great effects on the start-up of small hydroelectric power plants. The parameters of the governor should be optimized in advance to achieve a rapid and stable start-up under tail water fluctuation.

(2) The start-up characteristics of a small hydropower station under the ITAE index and the MOC index were compared. The comparative results of the start-up characteristics under the ITAE index and the MOC index are given in Table 1 and Figure 11 and Figure 12. As shown in Table 1 and Figure 11, the product of the time and the frequency deviation was 35.80 under the MOC index, which is much larger than that of 19.19 under the ITAE index. Both of these two indices can ensure the rapidity of the start-up process, whereas the start-up time for the MOC index was only 4.43 s more than the ITAE index. Additionally, compared with the ITAE index, as shown in Figure 12, the discharge fluctuation in the water diversion pipeline under the MOC index was more stable. The fluctuation of the torque during the start-up process was smaller than that under the ITAE index. In general, although the product of the time and the frequency deviation was relatively small under the ITAE index, the start-up characteristics of the unit were not necessarily excellent. The result is consistent with the achievements of previous studies, which proves the validity and practicability of the MOC index proposed in this paper.

6. Conclusions

The tail water level of a small hydropower station usually has large fluctuations during flood discharge and therefore greatly affects the work head. In order to investigate the effect of tail water fluctuation on the start-up process, the fluctuation law of the tail water from a flood discharge model test was introduced as the boundary condition. Then, the impact of the tail water fluctuation, including the frequency and amplitude, on the start-up was compared and verified employing a numerical simulation of a practical project. Finally, the start-up characteristics under the ITAE index and the MOC index were compared by applying PSO.

In conclusion, the frequency and amplitude of tail water fluctuation have great influence on the start-up, and the parameters of the governor should be optimized in advance. Moreover, both the MOC index and the ITAE index can ensure the rapidity of the start-up process, and the discharge fluctuation in the water diversion pipeline and the torque fluctuation under the MOC index are much smaller compared with the ITAE index. The comprehensive performance index can realize the rapidity and stability of the start-up, thereby reducing the negative effect on turbine runner blades during start-up processes.

This study provides theoretical support for the start-up of a small hydropower station under tail water fluctuation. However, only tail water fluctuation caused by flood discharge was investigated in this paper, and the upstream water level fluctuation was not considered. Therefore, future research should focus on the impact of other factors on the start-up process.

Author Contributions

Conceptualization, S.C., X.W. and X.Y.; methodology, S.C., G.L., X.W. and J.Z.; software, D.W.; writing—original draft, S.C.; writing—review & editing, G.L., D.W., J.Z. and X.Y.

Funding

This research was supported by the CRSRI Open Research Program (Program SN: CKWV2018462/KY), National Natural Science Foundation of China (Grant No. 51709087), and the Fundamental Research Funds for the Central Universities (Grant No. 2018B55514).

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Deviation of mechanical torque | |

| Deviation of discharge | |

| Deviation of rotating speed | |

| Deviation of water head | |

| Rated unit torque | |

| Rated unit speed | |

| Rated unit flow | |

| Characteristic function of unit torque | |

| Characteristic function of unit discharge | |

| Main relay stroke | |

| Hydro-turbine unit inertia time constant | |

| Load disturbance torque | |

| Wave velocity | |

| A | Pipe area |

| Head loss of conduit | |

| D | Pipe diameter |

| Head | |

| Discharge | |

| Relative head loss of pipeline | |

| Proportional coefficient | |

| Integral coefficient | |

| Differential coefficient | |

| Reaction time constant of main servomotor | |

| Reaction time constant of auxiliary servomotor | |

| Time of duration rising from 0 to rated speed | |

| switching time of turning point for two-phase opening scheme | |

| switching frequency of turning point for two-phase opening scheme | |

| Deviation between expected and actual speed | |

| Deviation between initial head and head at any instant | |

| Speed overshoot | |

| Value of amplitude of the tail water fluctuation | |

| The initial phase | |

| Frequency of the tail water fluctuation |

References

- Feng, Z.K.; Niu, W.J.; Cheng, C.T.; Liao, S.L. Hydropower system operation optimization by discrete differential dynamic programming based on orthogonal experiment design. Energy 2017, 126, 720–732. [Google Scholar] [CrossRef]

- Manzano-Agugliaro, F.; Taher, M.; Zapata-Sierra, A.; Juaidi, A.; Montoya, F.G. An overview of research and energy evolution for small hydropower in Europe. Renew. Sustain. Energy Rev. 2017, 75, 476–489. [Google Scholar] [CrossRef]

- François, B.; Zoccatelli, D.; Borga, M. Assessing small hydro/solar power complementarity in ungauged mountainous areas: A crash test study for hydrological prediction methods. Energy 2017, 127, 716–729. [Google Scholar] [CrossRef]

- Jumani, S.; Rao, S.; Machado, S.; Prakash, A. Big concerns with small projects: Evaluating the socio-ecological impacts of small hydropower projects in India. AMBIO 2017, 46, 500–511. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.N.; Zhao, W.D.; Li, Z.H.; Xu, X.F.; Xiao, B.W.; Niu, D.X. Can hydropower develop as expected in China? A scenario analysis based on system dynamics model. Energy 2018, 161, 118–129. [Google Scholar] [CrossRef]

- Cheng, C.T.; Miao, S.M.; Luo, B.; Sun, Y.J. Forecasting monthly energy production of small hydropower plants in ungauged basins using grey model and improved seasonal index. J. Hydroinform. 2017, 19, 993–1008. [Google Scholar] [CrossRef]

- Zhang, X.; Zha, T.; Zhao, Y.; Qin, J.; Lyv, Z.; Ma, Z.; Yu, H.; Zhu, Y.; Wang, G.; Tettenborn, F.; et al. Sustainable Effects of Small Hydropower Substituting Firewood Program in Majiang County, Guizhou Province, China. Sustainability 2017, 9, 988. [Google Scholar] [CrossRef]

- Qiao, H.J.; Zhang, C.L.; Zhang, J.; Yan, J. Analysis on Promoting the Development of Small Hydropower in China. Haihe Water Resour. 2015, 2, 35–37. [Google Scholar]

- Chang, X.L.; Liu, X.H.; Zhou, W. Hydropower in China at present and its further development. Energy 2010, 35, 4400–4406. [Google Scholar] [CrossRef]

- Cheng, C.T.; Wu, H.J.; Wu, X.Y.; Shen, J.J.; Wang, J. Power Generation Scheduling for Integrated Large and Small Hydropower Plant Systems in Southwest China. J. Water Resour. Plann. Manag. 2017, 143, 04017027. [Google Scholar] [CrossRef]

- Panić, M.; Urošev, M.; Pešić, A.M.; Brankov, J.; Bjeljac, Z. Small hydropower plants in Serbia: Hydropower potential, current state and perspectives. Renew. Sustain. Energy Rev. 2013, 23, 341–349. [Google Scholar] [CrossRef]

- Dadu, V.; Dadu, A.; Frunza, D.; Catarig, G.; Popa, F.; Popa, B. Innovative Concepts Applied to Recent Small Hydropower Plants. Energy Procedia 2017, 112, 426–433. [Google Scholar] [CrossRef]

- Kang, L.; Jiang, T.B.; Ye, L.Q. Study on the Rules and the Simulations in Opening Process for Hydroturbines. J. Huazhong Univ. Sci. Tech. 1999, 27, 49–51. [Google Scholar] [CrossRef]

- Yang, W.J.; Yang, J.D. Study on optimum start-up method for hydroelectric generating unit based on analysis of the energy relation. In Proceedings of the 2012 Asia-Pacific Power and Energy Engineering Conference, Shanghai, China, 27–29 March 2012. [Google Scholar]

- Kang, L.; Ye, L.Q.; Jiang, T.B. A closed-loop start-up control strategy and its simulation studies for hydroelectric generating units. In Proceedings of the International Conferences on Info-Tech and Info-Net 2001, Beijing, China, 29 October–1 November 2001. [Google Scholar]

- Chen, S.Y.; Zhang, G.S.; Zhao, R.; Cao, N.; Cao, B.D. Porgram Control Based Starting-up Control Strategy of Hydroelectric Generating Sets. Power Syst. Technol. 2005, 29, 76–79. [Google Scholar] [CrossRef]

- Bao, H.Y.; Yang, J.D.; Fu, L. Study on nonlinear dynamical model and control strategy of transient process in hydropower station with Francis turbine. In Proceedings of the 2009 Asia-Pacific Power and Energy Engineering Conference, Wuhan, China, 27–31 March 2009. [Google Scholar]

- Li, C.S.; Mao, Y.F.; Zhou, J.Z.; Zhang, N.; An, X.L. Design of a fuzzy-PID controller for a nonlinear hydraulic turbine governing system by using a novel gravitational search algorithm based on Cauchy mutation and mass weighting. Appl. Soft Comput. 2017, 52, 290–305. [Google Scholar] [CrossRef]

- Fang, H.Q.; Chen, L.; Shen, Z.Y. Application of an improved PSO algorithm to optimal tuning of PID gains for water turbine governor. Energy Convers. Manag. 2011, 52, 1763–1770. [Google Scholar] [CrossRef]

- Wang, Z.B.; Li, C.S.; Lai, X.J.; Zhang, N.; Xu, Y.H.; Hou, J.J. An Integrated Start-Up Method for Pumped Storage Units Based on a Novel Artificial Sheep Algorithm. Energies 2018, 11, 151. [Google Scholar] [CrossRef]

- Maiti, D.; Acharya, A.; Chakraborty, M.; Konar, A.; Janarthanan, R. Tuning PID and PIλDδ Controllers using the Integral Time Absolute Error Criterion. In Proceedings of the 2008 4th International Conference on Information and Automation for Sustainability, Colombo, Sri Lanka, 12–14 December 2008. [Google Scholar]

- Zhou, B.; Su, Y.L.; Luo, R.J.; Wu, J. Comparison and Optimization of Two Control Technologies on Hydraulic Turbine Start-up Process. Hydropower Autom. Dam Monit. 2013, 37, 17–19. [Google Scholar] [CrossRef]

- Hou, J.J.; Li, C.S.; Tian, Z.Q.; Xu, Y.H.; Lai, X.J.; Zhang, N.; Zheng, T.P.; Wu, W. Multi-Objective Optimization of Start-up Strategy for Pumped Storage Units. Energies 2018, 11, 1141. [Google Scholar] [CrossRef]

- Li, J.P.; Yang, J.D. Effect of tail water level fluctuation on stable operation of units in hydropower station. Eng. J. Wuhan Univ. 2004, 37, 28–32. [Google Scholar] [CrossRef]

- Li, H.H.; Chen, D.Y.; Zhang, X.G.; Wu, Y.H. Dynamic analysis and modelling of a Francis hydro-energy generation system in the load rejection transient. IET Renew. Power Gen. 2016, 10, 1140–1148. [Google Scholar] [CrossRef]

- Zhang, C.; Li, C.S.; Peng, T.; Xia, X.; Xue, X.M.; Fu, W.L.; Zhou, J.Z. Modeling and Synchronous Optimization of Pump Turbine Governing System Using Sparse Robust Least Squares Support Vector Machine and Hybrid Backtracking Search Algorithm. Energies 2018, 11, 3108. [Google Scholar] [CrossRef]

- Wu, Q.Q.; Zhang, L.K.; Ma, Z.Y. A model establishment and numerical simulation of dynamic coupled hydraulic-mechanical-electric-structural system for hydropower station. Nonlinear Dynam. 2017, 87, 459–474. [Google Scholar] [CrossRef]

- Guo, W.C.; Yang, J.D. Stability performance for primary frequency regulation of hydro-turbine governing system with surge tank. Appl. Math. Model. 2018, 54, 446–466. [Google Scholar] [CrossRef]

- Chen, Z.H.; Yuan, X.H.; Ji, B.; Wang, P.T.; Tian, H. Design of a fractional order PID controller for hydraulic turbine regulating system using chaotic non-dominated sorting genetic algorithm II. Energy Convers. Manag. 2014, 84, 390–404. [Google Scholar] [CrossRef]

- Shen, Z.Y. Hydraulic Turbine Regulation, 3rd ed.; China Water & Power Press: Beijing, China, 1998. [Google Scholar]

- Liang, J.; Yuan, X.H.; Yuan, Y.B.; Chen, Z.H.; Li, Y.Z. Nonlinear dynamic analysis and robust controller design for Francis hydraulic turbine regulating system with a straight-tube surge tank. Mech. Syst. Signal. Process. 2017, 85, 927–946. [Google Scholar] [CrossRef]

- Xu, B.B.; Chen, D.Y.; Zhang, H.; Wang, F.F. Modeling and stability analysis of a fractional-order Francis hydro-turbine governing system. Chaos Solitons Fract. 2015, 75, 50–61. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).