A Deep-Sea Pipeline Skin Effect Electric Heat Tracing System

Abstract

:1. Introduction

2. System Model

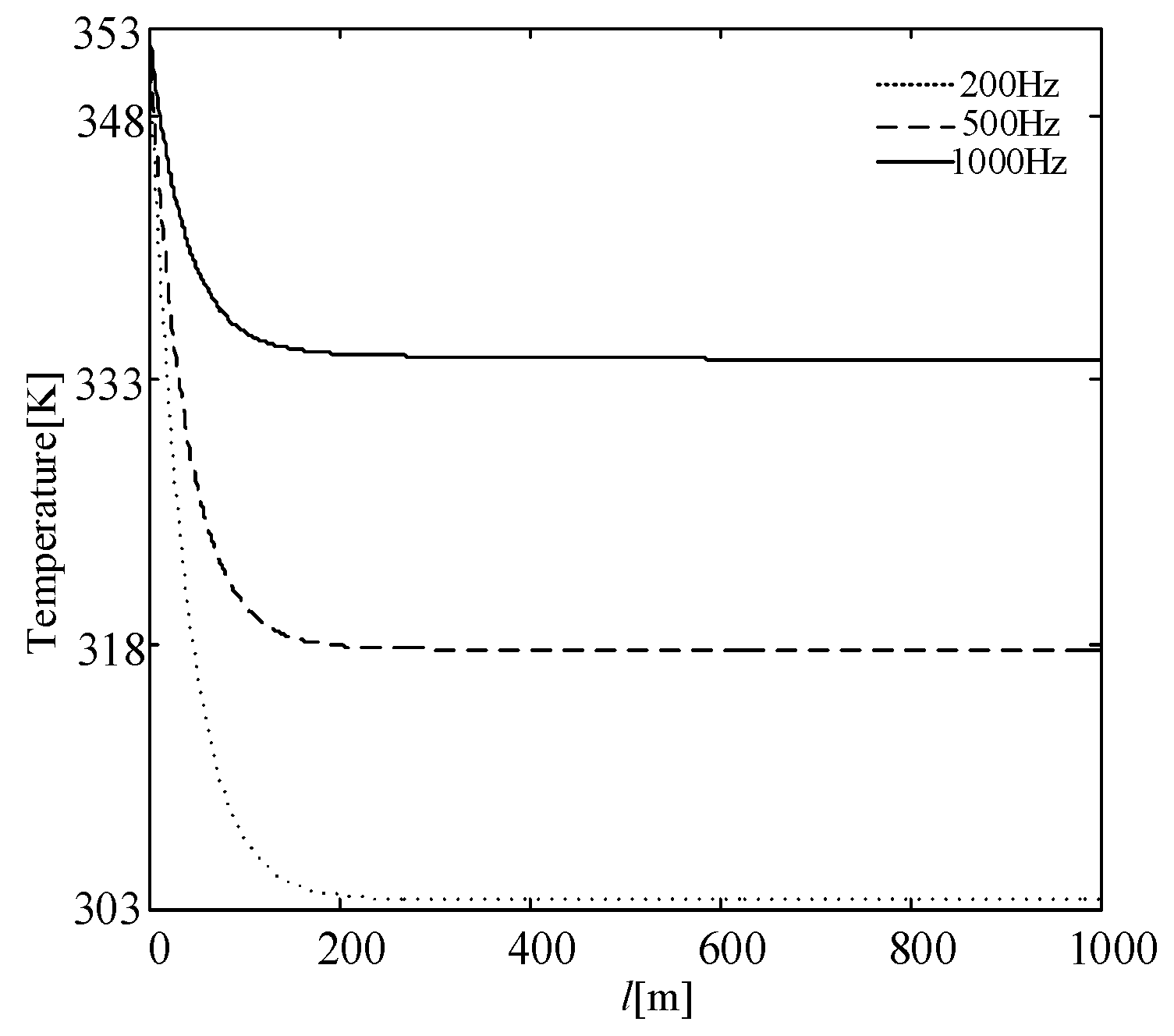

2.1. Axial Temperature Distribution Model

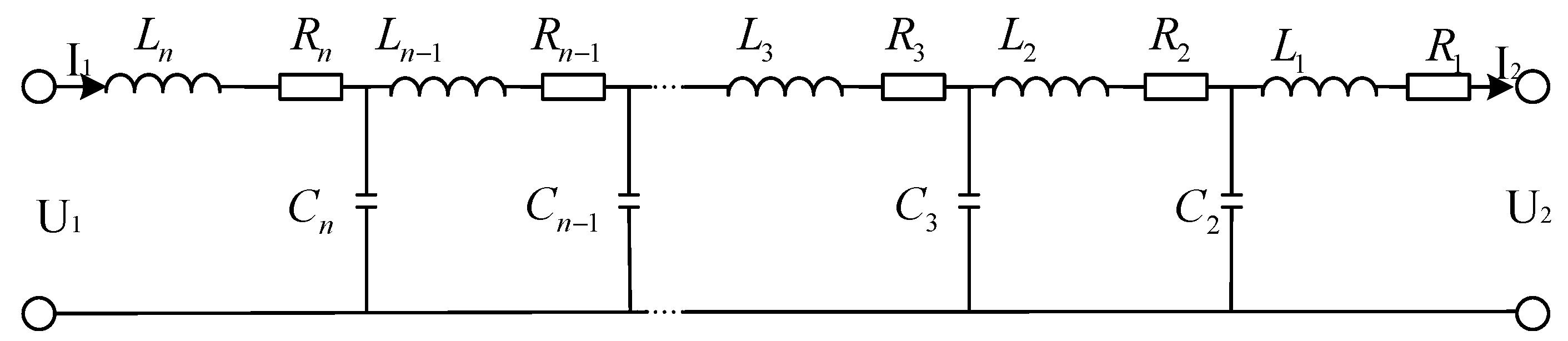

2.2. Circuit Model of Skin Effect Electric Heat Tracing System

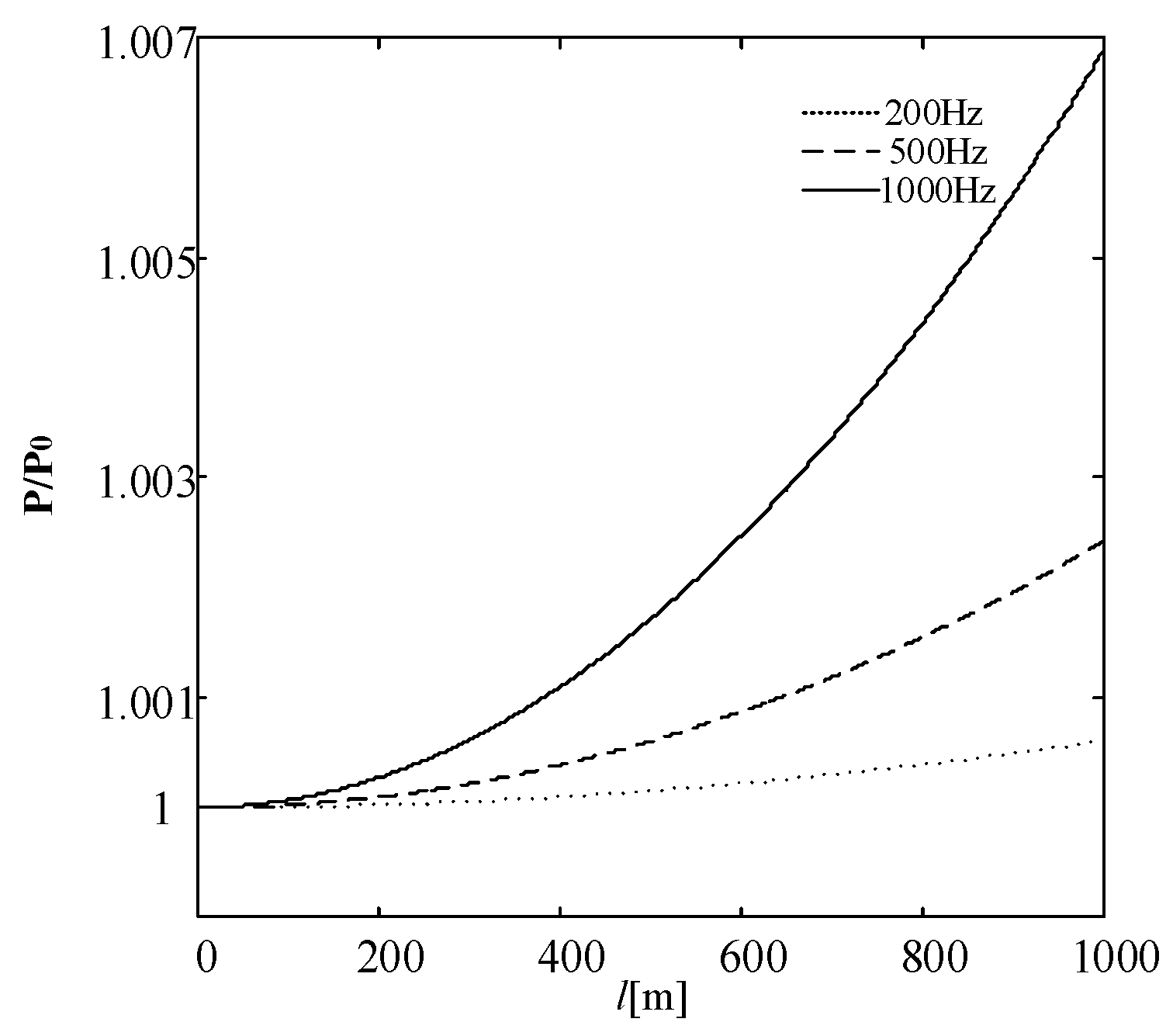

2.3. Effect of Frequency on Electric Heating Efficiency

3. Controller Design

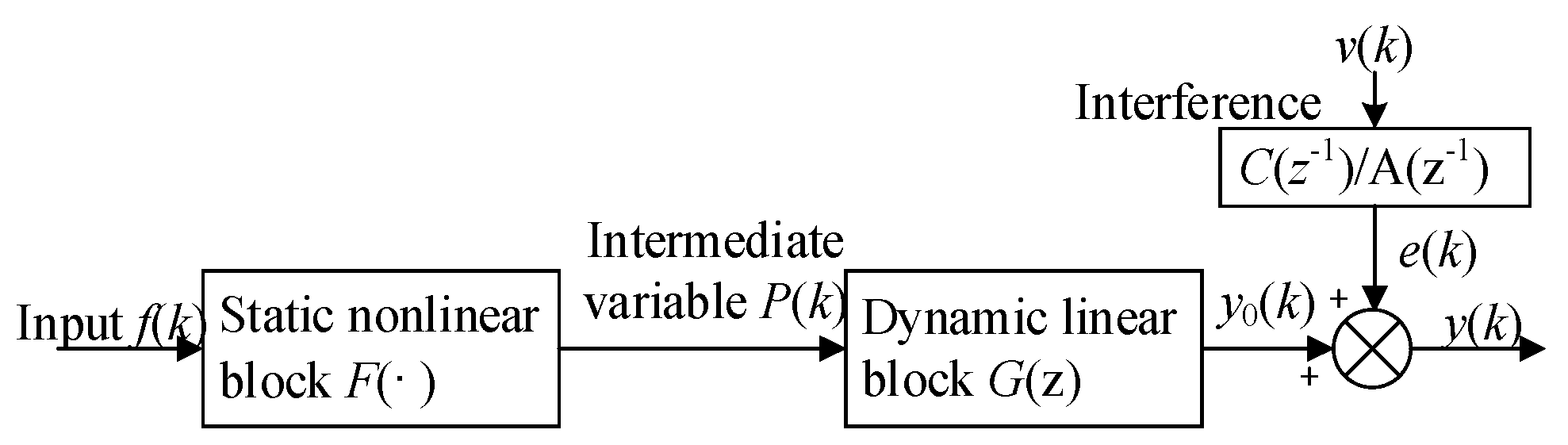

3.1. Predictive Control Based on Hammerstein Model

3.2. Constrained Generalized Predictive Control

- Step 1. The unknown parameter in Equation (23) is required for parameter identification. If the model parameters are known, this step is omitted.

- Step 2. Under the unconstrained condition, the optimal control increment ΔP(k) at the current moment is obtained by Equation (36).

- Step 3. Determine whether the set value satisfies the constraint condition (38), if ΔP(k) ∊ [Δmin, Δmax], go to Step 5.

- Step 4. If ΔP(k) ∉ [Δmin, Δmax], the corresponding processing is performed according to Equation (40).

- Step 5. Calculate and implement the current control variable P(k) by Equation (41).

- Step 6. At the next sampling moment, return to Step 1.

3.3. System Stability Analysis

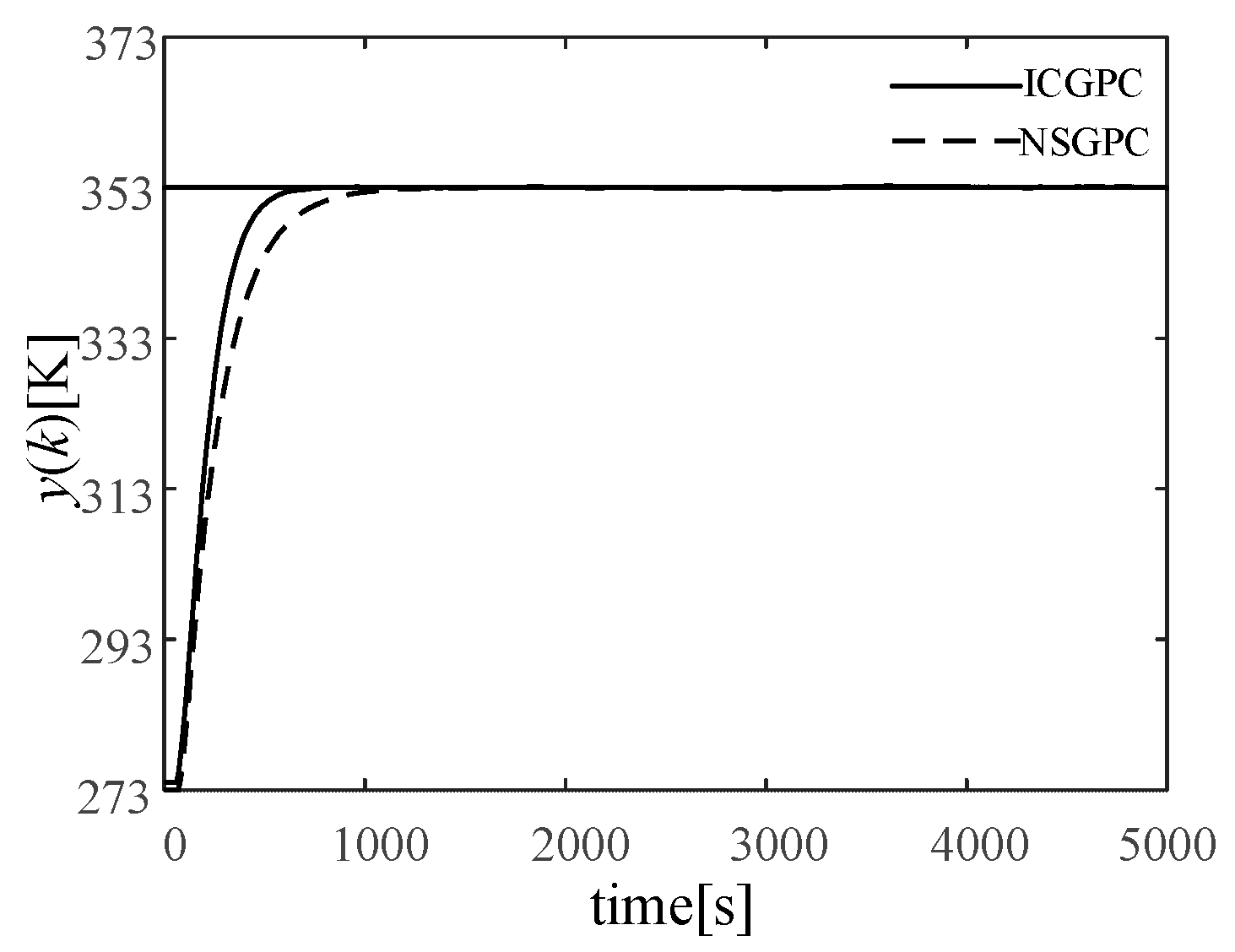

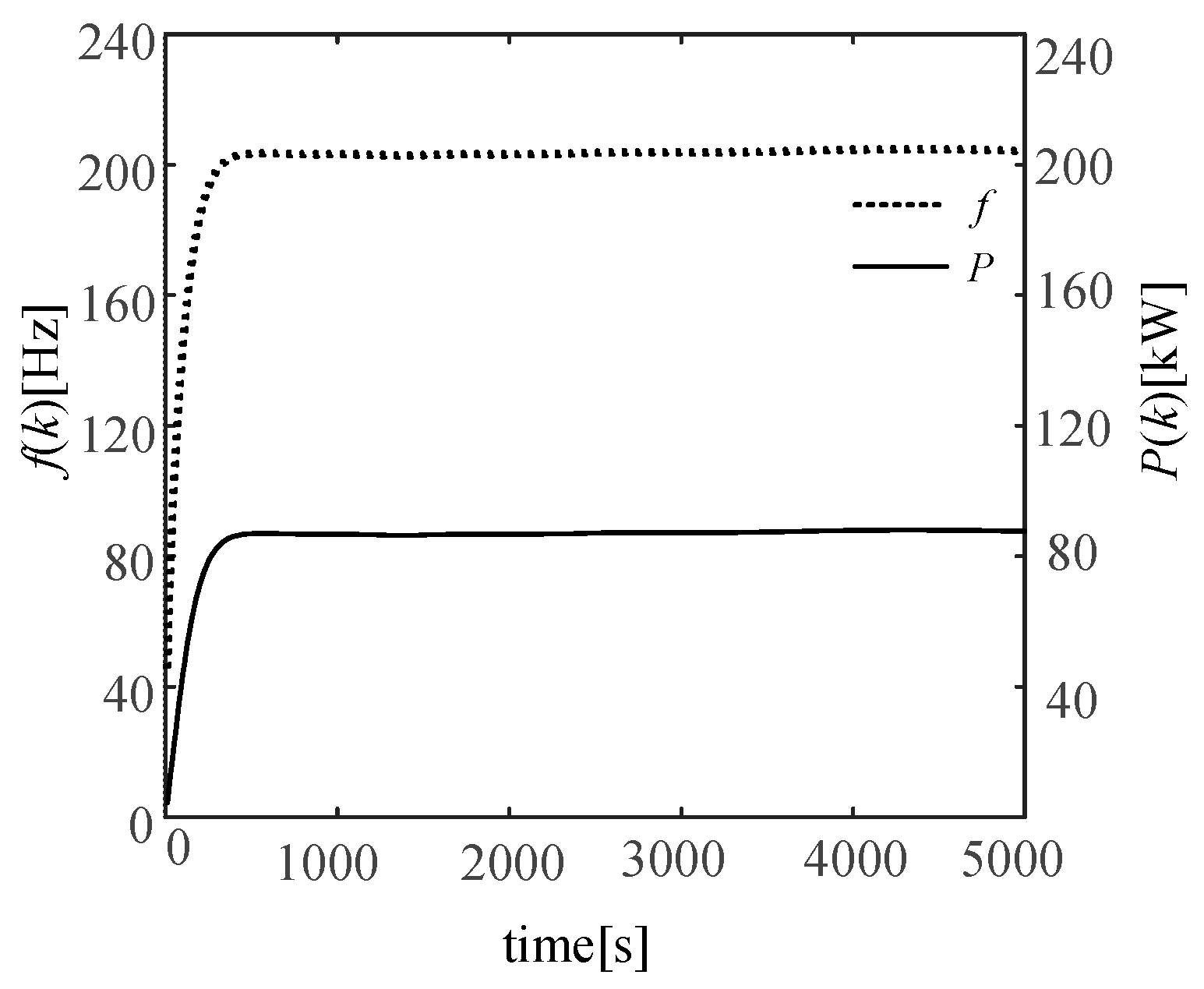

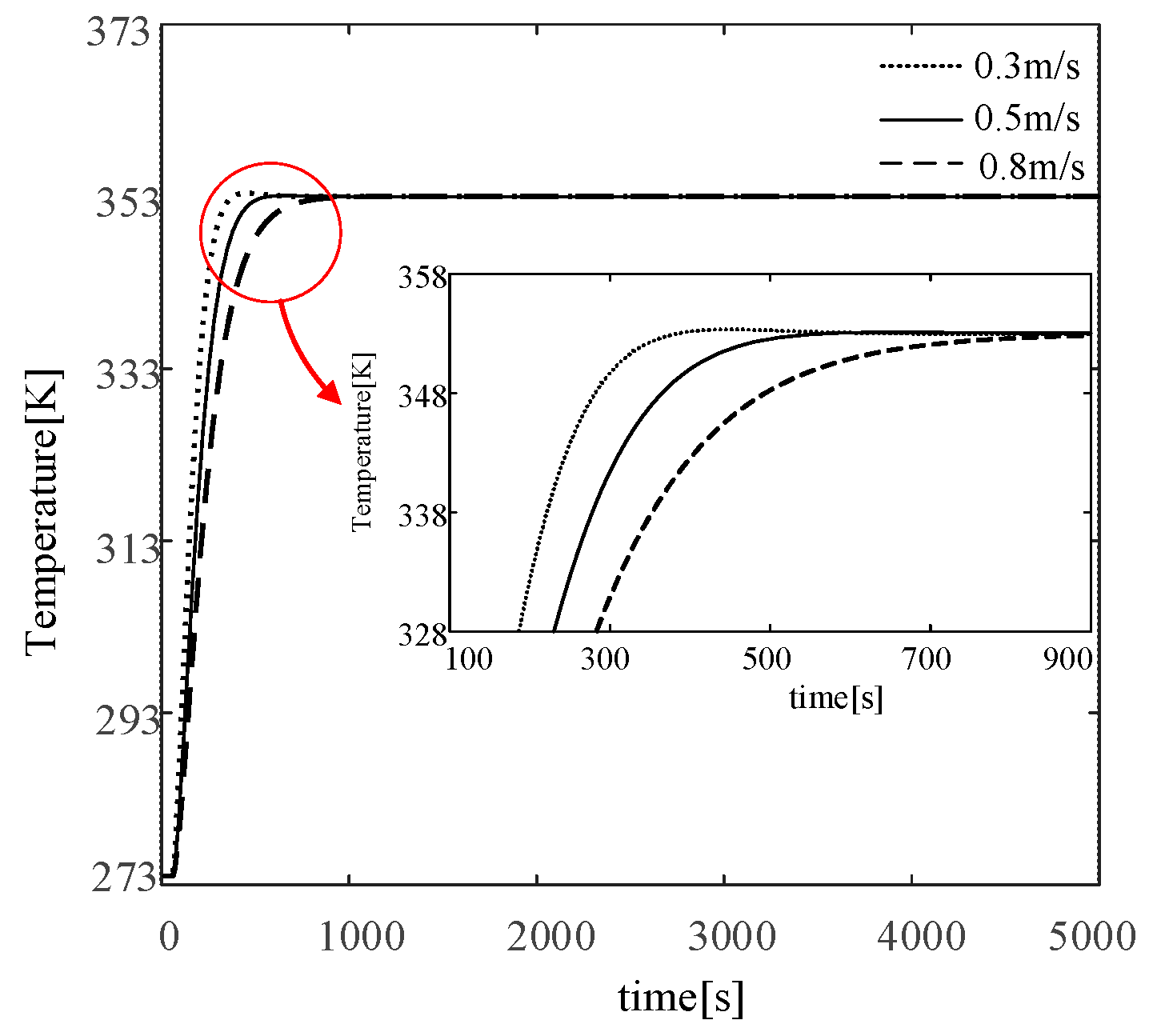

4. Simulation Verification

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| T | heavy oil temperature |

| TA | ambient temperature |

| Kw | heat transfer coefficient |

| D | pipeline diameter |

| G | heavy oil mass |

| c | heavy oil specific heat |

| l | pipeline length |

| P | electric heating power |

| R | equivalent resistance |

| L | equivalent inductance |

| C | equivalent capacitance |

| w | angular velocity |

| f | power frequency |

| HQ | magnetic field strength |

| EZ | electric field strength |

| σ | electrical conductivity |

| μ | magnetic permeability |

| magnetic induction average value | |

| r1 | cable radius |

| r2, r3 | heat tracing tube internal and external radius |

| k0 | determinable constant |

| k1 | pipeline amplification factor |

| τ | time inertia constant |

| t0 | delay time |

References

- Wang, D. Comparison and analysis of active heating technology in deep-water subsea flow line. Petro- Chem. Equip. 2016, 45, 64–68. Available online: http://www.cnki.com.cn/Article/CJFDTotal-SYSB201603015.htm (accessed on 26 June 2019).

- Havre, K.; Stornes, K.O.; Stray, H. Taming slug flow in pipelines. ABB Rev. 2000, 4, 55–63. [Google Scholar]

- Malekzadeh, R.; Henkes, R.; Mudde, R.F. Severe slugging in a long pipeline–riser system: Experiments and predictions. Int. J. Multiph. Flow 2012, 46, 9–21. [Google Scholar] [CrossRef]

- Zhou, X.; Shi, Y. Study of Subsea Pipeline Heat Tracing Technology. Pipeline Tech. Equip. 2017, 5, 53–56. [Google Scholar]

- Guo, X.; Wu, Z.; Shi, Z. Research and application of skin-effect current tracing in submarine pipeline. In Proceedings of the Fifteenth China Ocean (Ashore) Engineering Symposium (Part II), Taiyuan, China, 3–6 August 2011; pp. 1488–1490. [Google Scholar]

- Li, P.; Zhou, X.; Zhou, X.; Wang, D.; Li, H. Design discussion on the flow assurance for transportation pipelines of high pour point crude oil. Oil-Gas Field Surface Eng. 2018, 37, 52–55. Available online: http://www.cnki.com.cn/Article/CJFDTotal-YQTD201802018.htm (accessed on 26 June 2019).

- Trichtchenko, L. Modeling electromagnetic induction in pipelines. In Proceedings of the CORROSION 2004, New Orleans, LA, USA, 28 March–1 April 2004; pp. 1–13. [Google Scholar]

- Lervik, J.K.; Børnes, A.H.; Nysveen, A.; Høyer-Hansen, M. Electromagnetic modelling of steel pipelines for DEH applications. In Proceedings of the Seventeenth International Offshore and Polar Engineering Conference, Lisbon, Portugal, 1–6 July 2007; pp. 1014–1018. [Google Scholar]

- Ahlen, C.H.; Torkildsen, B.; Klevjer, G.; Lauvdal, T.; Lervik, J.K.; Ronningen, K. Electrical Induction Heating System of Subsea Pipelines. In Proceedings of the Second International Offshore and Polar Engineering Conference, San Francisco, CA, USA, 14–19 June 1992; pp. 78–85. [Google Scholar]

- Sun, M.; Fang, X.; Zheng, N.; Kang, Q. Research on electric heating special frequency converter for heavy oil exploitation. J. Univ. Pet. 2003, 27, 116–118. [Google Scholar]

- Fang, X.; Sun, M.; Xu, W.; Yang, G.; Chang, F.; Cheng, J. Theoretical analysis and practice of an energy-saving method in heavy oil thermal recovery. J. Tsinghua Univ. 2003, 43, 891–894. Available online: http://www.cnki.com.cn/Article/CJFDTotal-QHXB200307008.htm (accessed on 26 June 2019).

- Lervik, J.K.; Iversen, Ø.; Solheim, K.T. Optimizing electrical heating system of subsea oil production pipelines. In Proceedings of the 28th International Ocean and Polar Engineering Conference, Sapporo, Japan, 10–15 June 2018; pp. 108–113. [Google Scholar]

- Yin, Z.; Wang, X.; Wu, J. Study of large skin effect power tracing system. J. Zhejiang Univ. 2004, 38, 636–639. [Google Scholar]

- Ding, L.; Zhang, J.; Lin, A. Modeling and control strategy of skin effect electric tracing system. Acta Petrolei Sinica 2018, 39, 837–844. [Google Scholar] [CrossRef]

- Xu, X. Adaption Control and Model Predictive Control; Tsinghua University Press: Beijing, China, 2017; pp. 216–218. ISBN 978-7-302-44922-5. [Google Scholar]

- Demircloglu, H. Constrained continuous-time generalised predictive control. IEE Proc.: Control Theory Appl. 1999, 146, 470–476. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, S. Constrained generalized predictive control using genetic algorithm. J. Shanghai Jiaotong Univ. 2004, 38, 1562–1566. [Google Scholar]

- Tong, C.; Xiao, L.; Peng, K.; Li, J. Constrained generalized predictive control of mould level based on genetic algorithm. Control Decis. 2009, 24, 1735–1739. Available online: http://www.cnki.com.cn/Article/CJFDTotal-KZYC200911026.htm (accessed on 26 June 2019).

- Smoczek, J.; Szpytko, J. Constrained generalized predictive control with particle swarm optimizer for an overhead crane. In Proceedings of the International Conference on Methods & Models in Automation & Robotics (MMAR), Miedzyzdroje, Poland, 28–31 August 2017; pp. 756–761. [Google Scholar]

- Smoczek, J.; Szpytko, J. Particle Swarm Optimization-Based Multivariable Generalized Predictive Control for an Overhead Crane. IEEE/ASME Trans. Mechatron. 2017, 22, 258–268. [Google Scholar] [CrossRef]

- Jin, Y. New generalized predictive control with input constraints. Control Decis. 2002, 17, 506–508. Available online: http://www.cnki.com.cn/Article/CJFDTotal-KZYC200204032.htm (accessed on 26 June 2019).

- Su, B. Constrained Fuzzy Predictive Control for the Nonlinear System. Ph.D. Thesis, Nankai University, Tianjin, China, 2006. [Google Scholar]

- Archer, R.A.; Osullivan, M. Models for heat transfer from a buried pipe. SPE 1997, 2, 186–193. [Google Scholar] [CrossRef]

- Yang, X.; Chen, L.; Wang, F.; Liu, J. Characteristics of Salinity Distribution in Surface Seawater of the Oceans. J. Oceanogr. Taiwan Strait 1990, 9, 88–91. [Google Scholar]

- Sun, M.; Zheng, N.; Fang, X.; Kang, Q.; Li, Z.; Wang, L.; Sun, Y.; Yao, C. Research on high-efficiency methods of electrical heating in gathering heavy oil. Acta Phys. Sin. 2002, 51, 2906–2910. [Google Scholar]

- Qiu, G. Circuit Principle, 5th ed.; Higher Education Press: Beijing, China, 2006; pp. 480–484. ISBN 978-7-04-019671-9. [Google Scholar]

- Paul, C.R. Analysis of Multi Conductor Transmission Lines, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2008; pp. 110–158. ISBN 978-0-470-13154-1(cloth). [Google Scholar]

- Guo, L. Study on Characteristic Mode Theory for Composite Electromagnetic Structures and its Applications. Ph.D. Thesis, University of Electronic Science & Technology of China, Chengdu, China, 2018. [Google Scholar]

- Tang, X. Research of Skin Effect Current Tracing Controlling System on Oil Pipelines. Master’s Thesis, China Jiliang University, Hangzhou, China, 2014. [Google Scholar]

- Ding, L.; Zhang, J.; Sun, H. Modeling and control strategy of built-in skin effect electric tracing system. CMES 2018, 117, 213–229. [Google Scholar] [CrossRef]

- Ding, B. Theory and Method of Predictive Control, 2nd ed.; China Machine Press: Beijing, China, 2017; pp. 61–63. ISBN 978-7-111-56002-9. [Google Scholar]

- Liao, S. Ferromagnetics, 2nd ed.; Science Press: Beijing, China, 1988; pp. 6–21. ISBN 703-0-002-318. [Google Scholar]

- Muthukumar, N.; Srinivasan, S.; Ramkumar, K.; Kavitha, P.; Balas, V.E. Supervisory GPC and evolutionary PI controller for web transport systems. Acta Polytech. Hung. 2015, 12, 135–153. [Google Scholar]

- Chen, Z.; Huang, J.; He, Y.; Wang, Z.; Liu, H. Non-uniform temperature fields of a deep-sea pipeline in steady flow. J. Harbin Eng. Univ. 2017, 38, 189–194. [Google Scholar] [CrossRef]

| f (kHz) | R(mΩ·m−1) | L(μH·m−1) | α × 10−5 | β × 10−5 |

|---|---|---|---|---|

| 0.2 | 5.8 | 4.365 | 1.17 | 2.74 |

| 0.5 | 8.9 | 2.765 | 2.30 | 5.43 |

| 1 | 12.5 | 1.956 | 3.83 | 9.12 |

| Parameters | Actual Value | Estimates for Different Disturbances | |||

|---|---|---|---|---|---|

| 0.1 | 0.2 | 0.3 | 0.4 | ||

| k0 | 2.1 | 2.1003 | 2.0984 | 2.1007 | 2.1004 |

| a1 | −0.670 | −0.669 | −0.672 | −0.669 | −0.668 |

| b1 | 0.0003 | 0.0002 | 0.0003 | 0.0004 | 0.0002 |

| d | 6 | 6.0021 | 6.0021 | 5.9947 | 6.0000 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, L.; Zhang, J.; Lin, A. A Deep-Sea Pipeline Skin Effect Electric Heat Tracing System. Energies 2019, 12, 2466. https://doi.org/10.3390/en12132466

Ding L, Zhang J, Lin A. A Deep-Sea Pipeline Skin Effect Electric Heat Tracing System. Energies. 2019; 12(13):2466. https://doi.org/10.3390/en12132466

Chicago/Turabian StyleDing, Li, Jiasheng Zhang, and Aiguo Lin. 2019. "A Deep-Sea Pipeline Skin Effect Electric Heat Tracing System" Energies 12, no. 13: 2466. https://doi.org/10.3390/en12132466

APA StyleDing, L., Zhang, J., & Lin, A. (2019). A Deep-Sea Pipeline Skin Effect Electric Heat Tracing System. Energies, 12(13), 2466. https://doi.org/10.3390/en12132466