Effectiveness of Selected Neural Network Structures Based on Axial Flux Analysis in Stator and Rotor Winding Incipient Fault Detection of Inverter-fed Induction Motors

Abstract

:1. Introduction

- -

- -

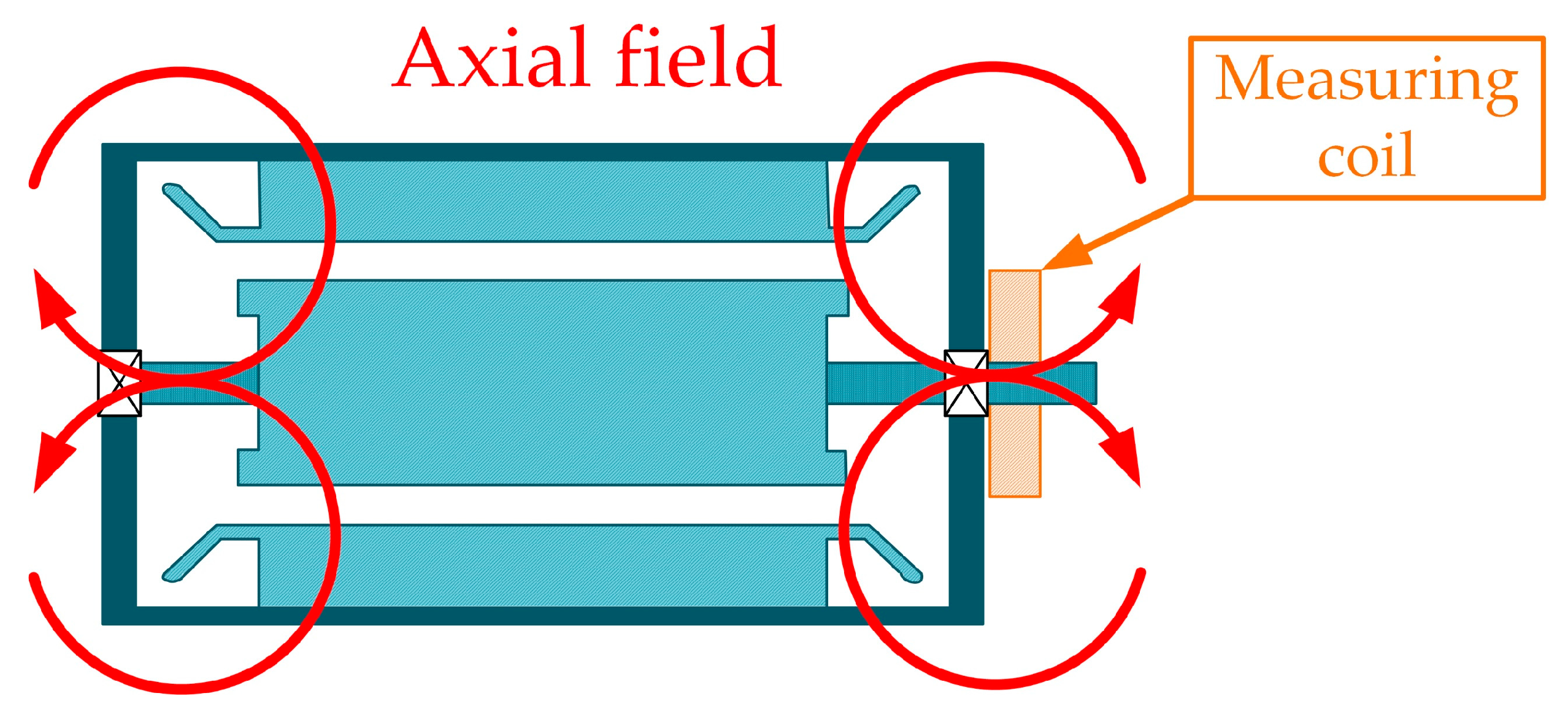

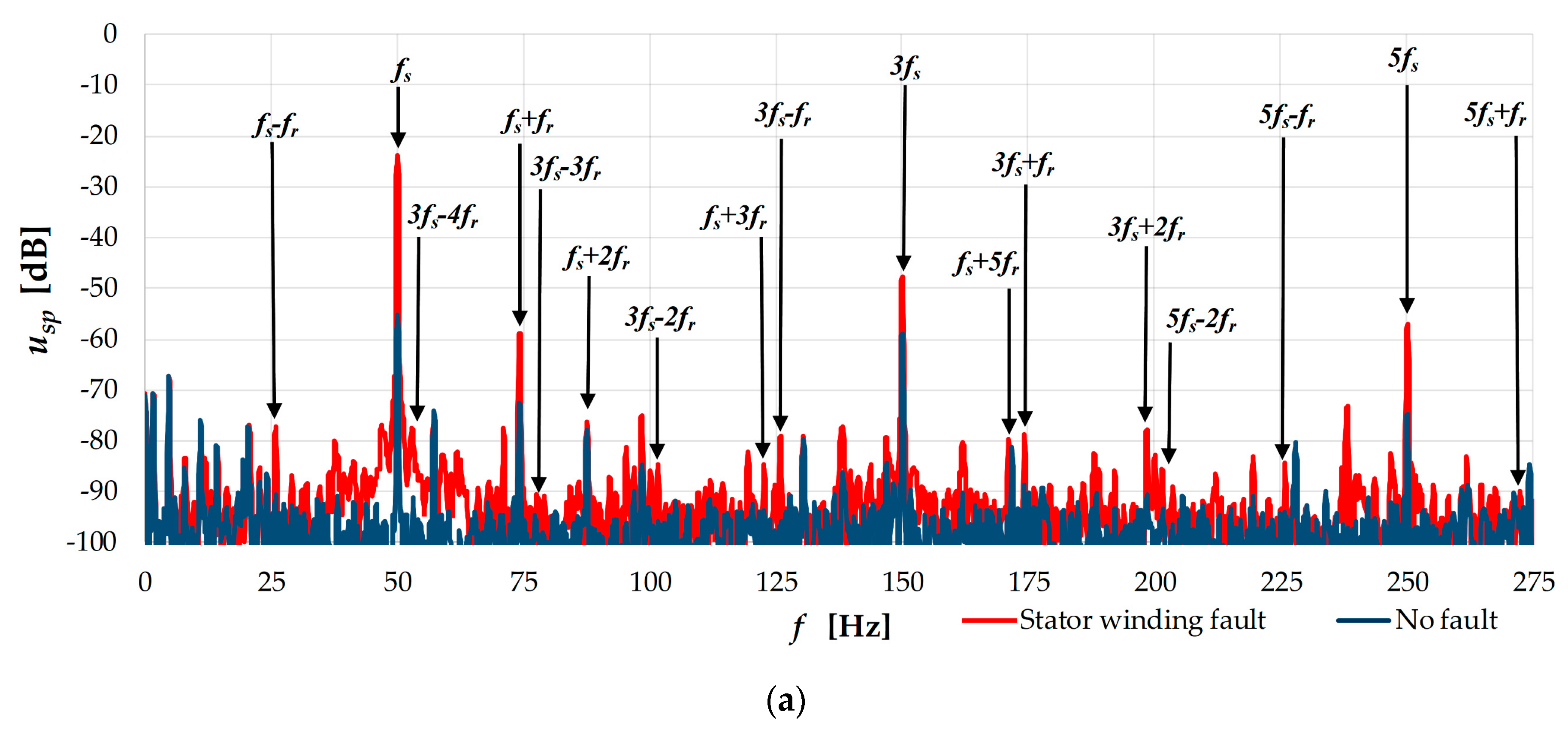

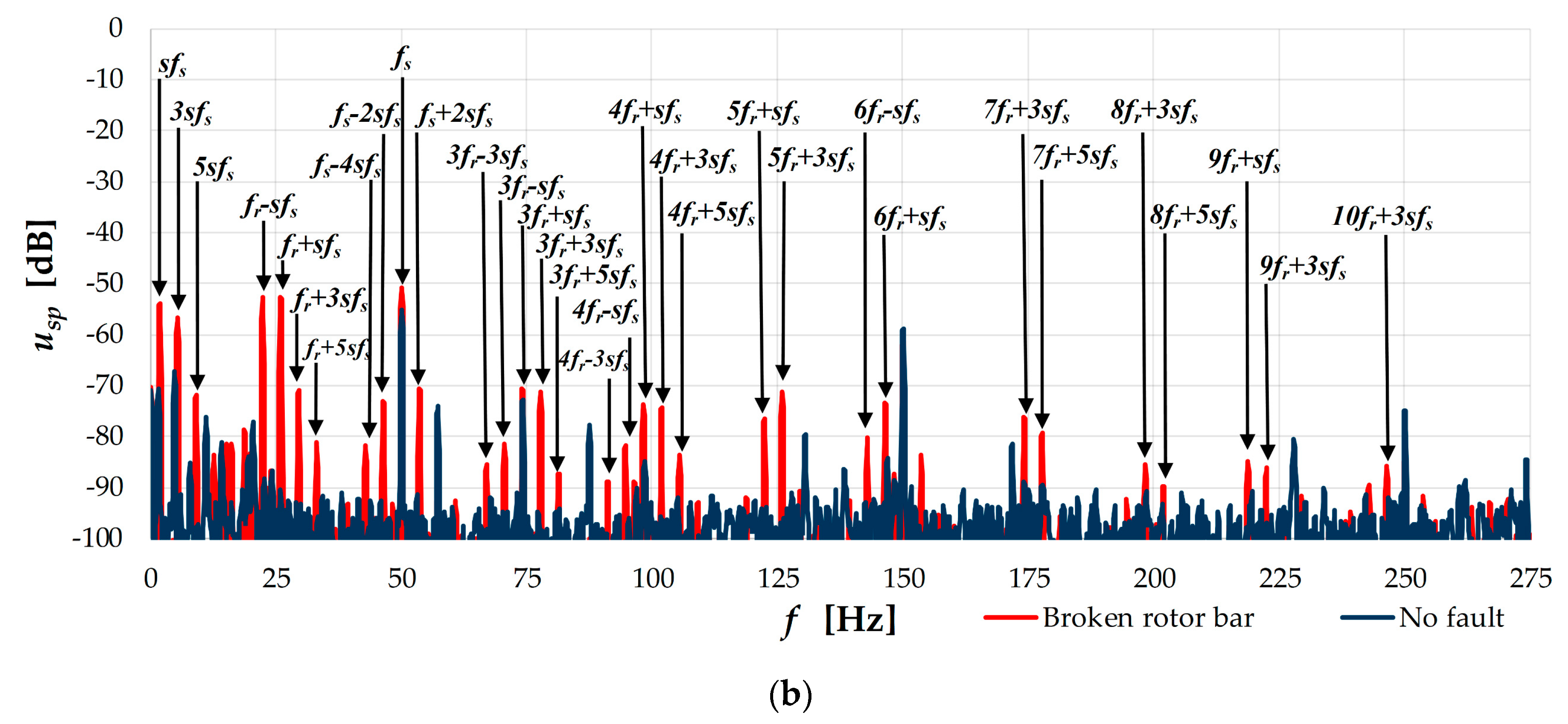

2. Symptoms of Induction Motor Circuit Faults Visible in Axial Leakage Flux

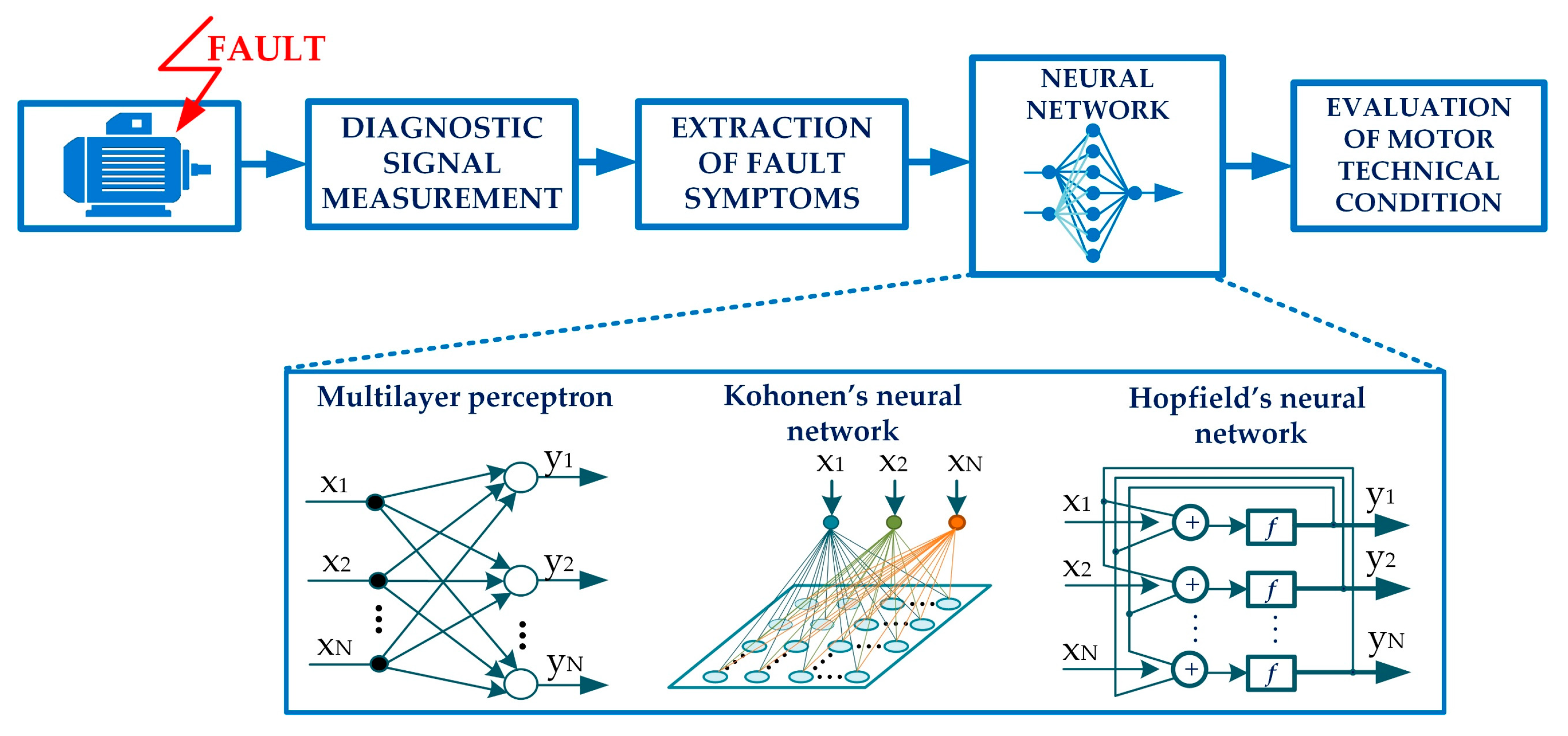

3. Application of Neural Networks in the Detection of Induction Motor Damages

3.1. General Remarks

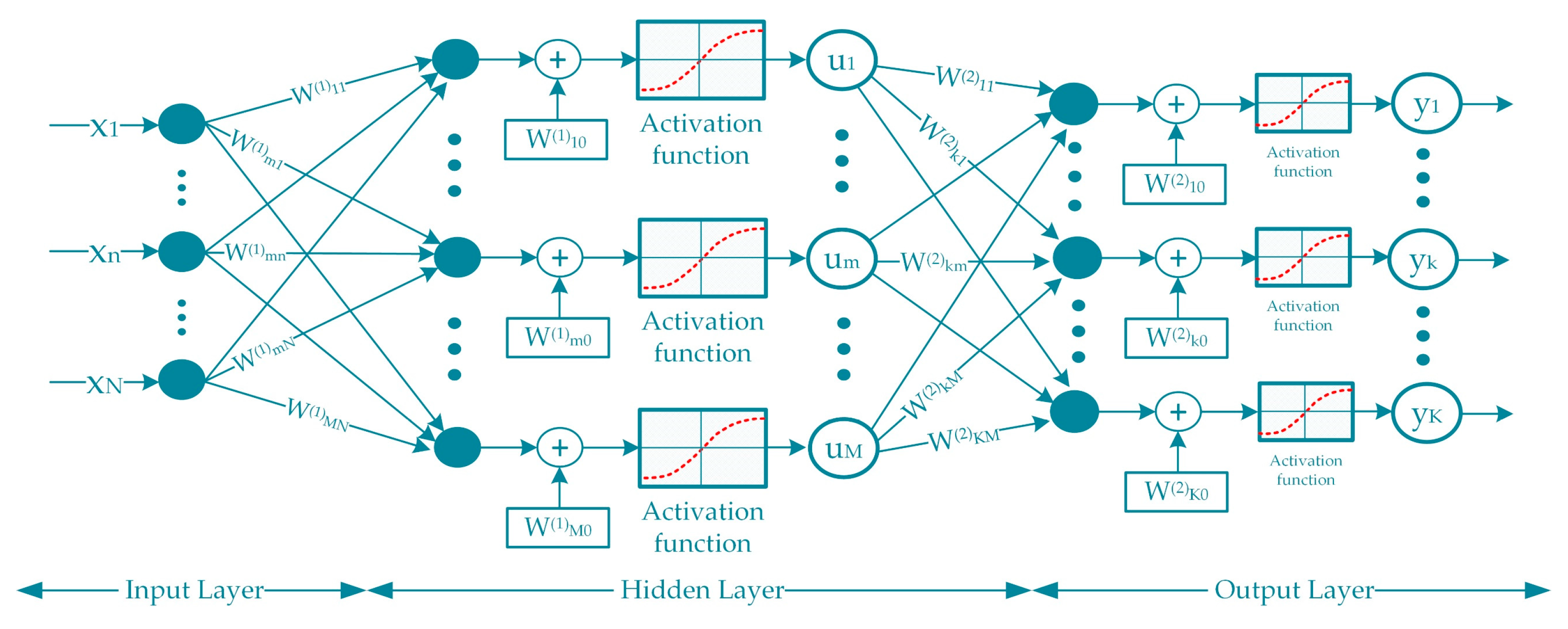

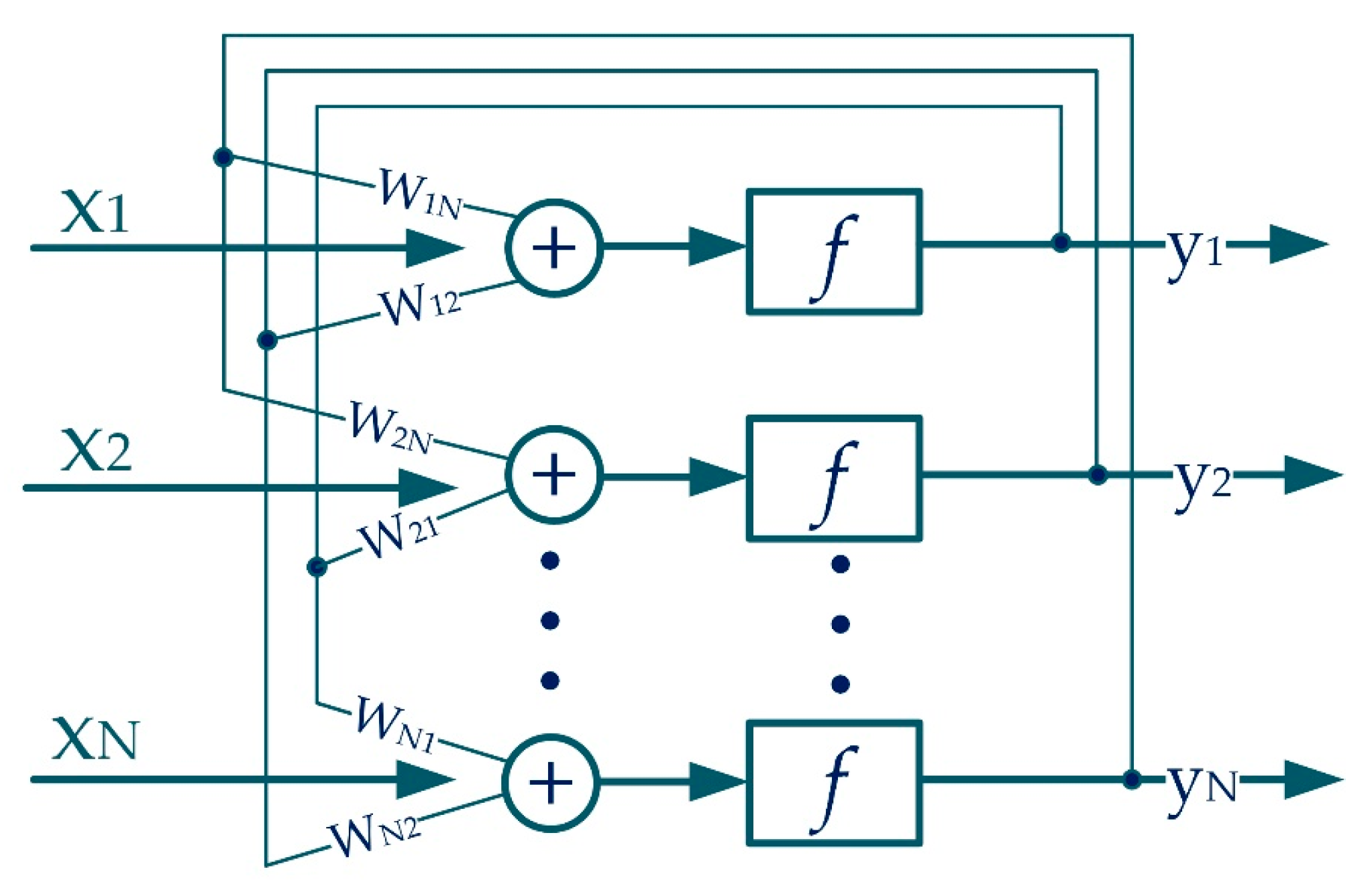

3.2. Multilayer Feedforward Network

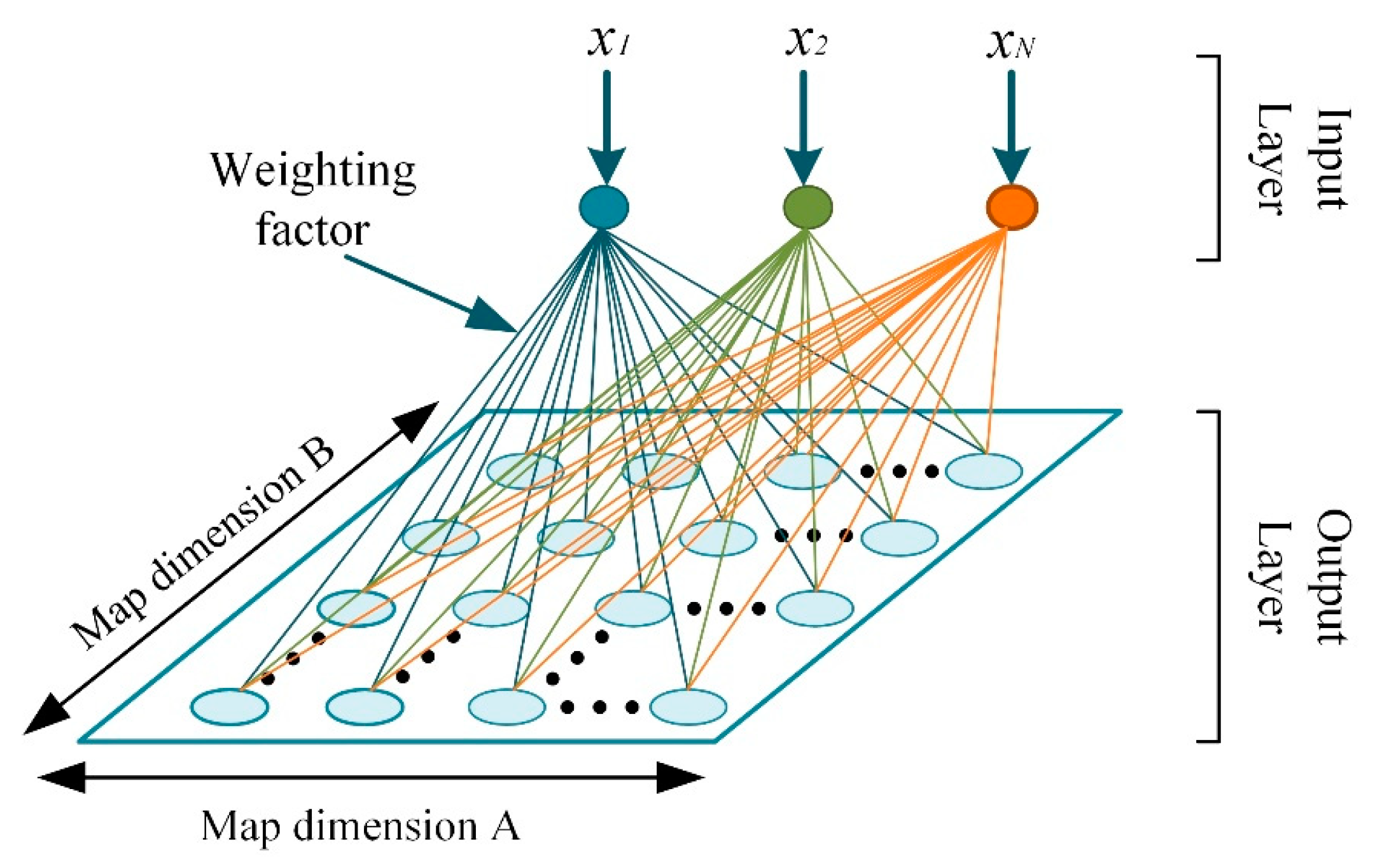

3.3. Self-Organizing Kohonen Map

3.4. Recurrent Hopfield Network

4. Experimental Verification of the Tested Fault Detectors

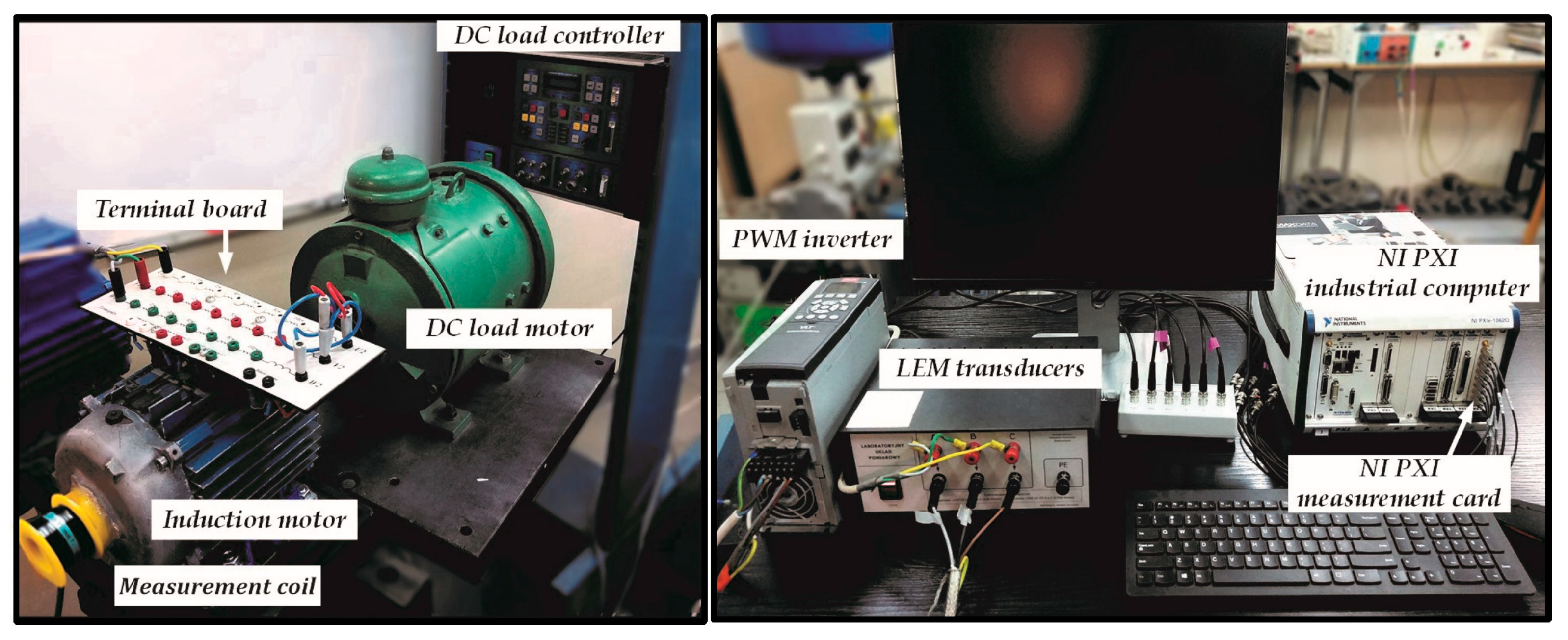

4.1. Description of the Experimental Set-Up and Conducted Tests

- 0–10 shorted turns of one stator phase,

- 0–3 damaged rotor cage bars.

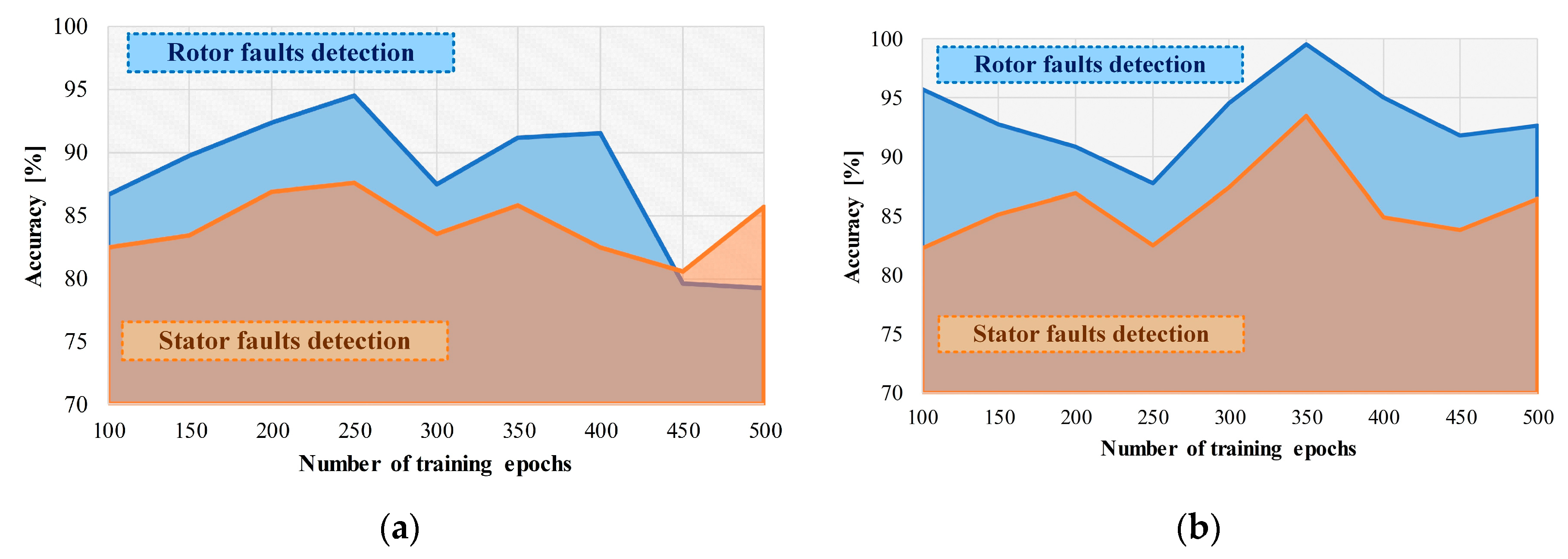

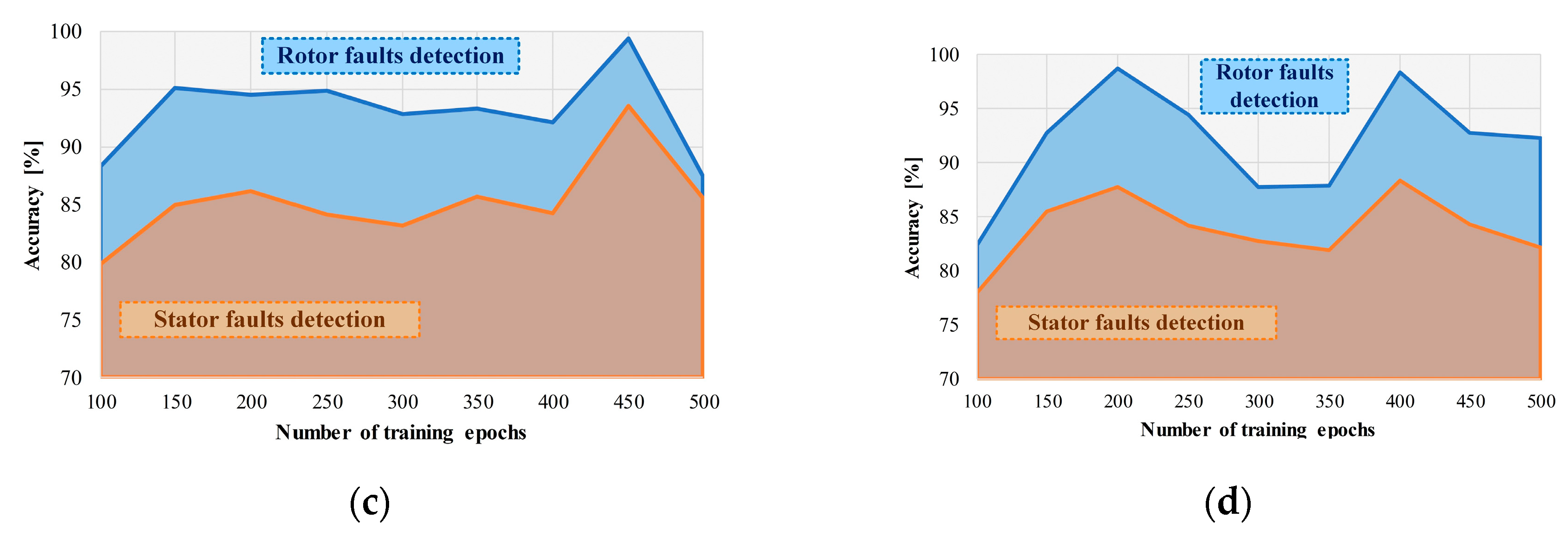

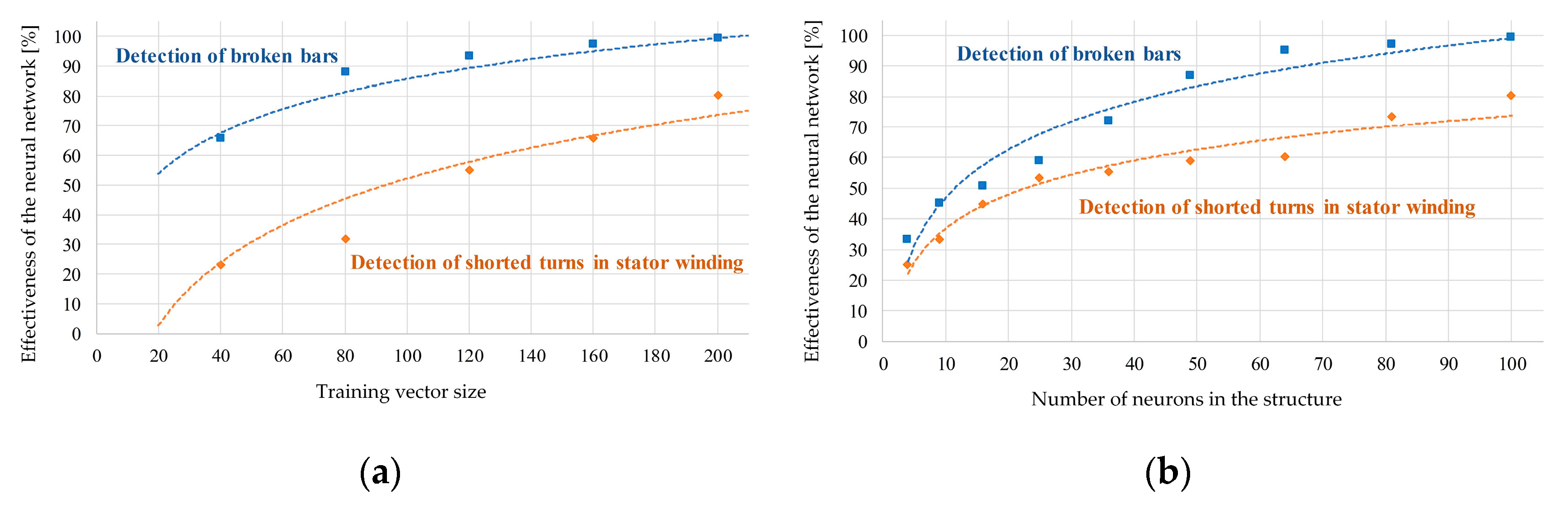

4.2. Result of the Fault Detection Using MLP Networks

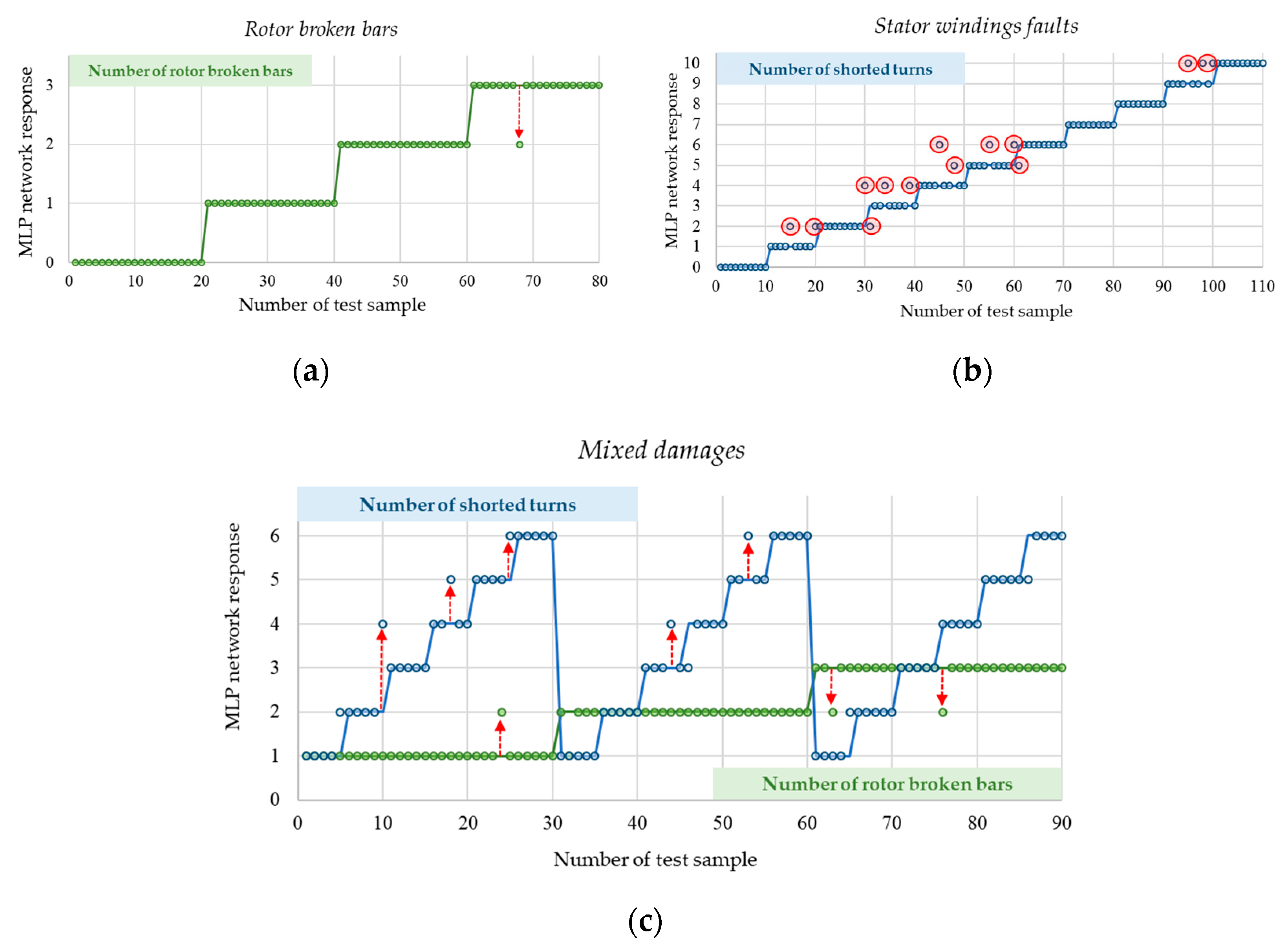

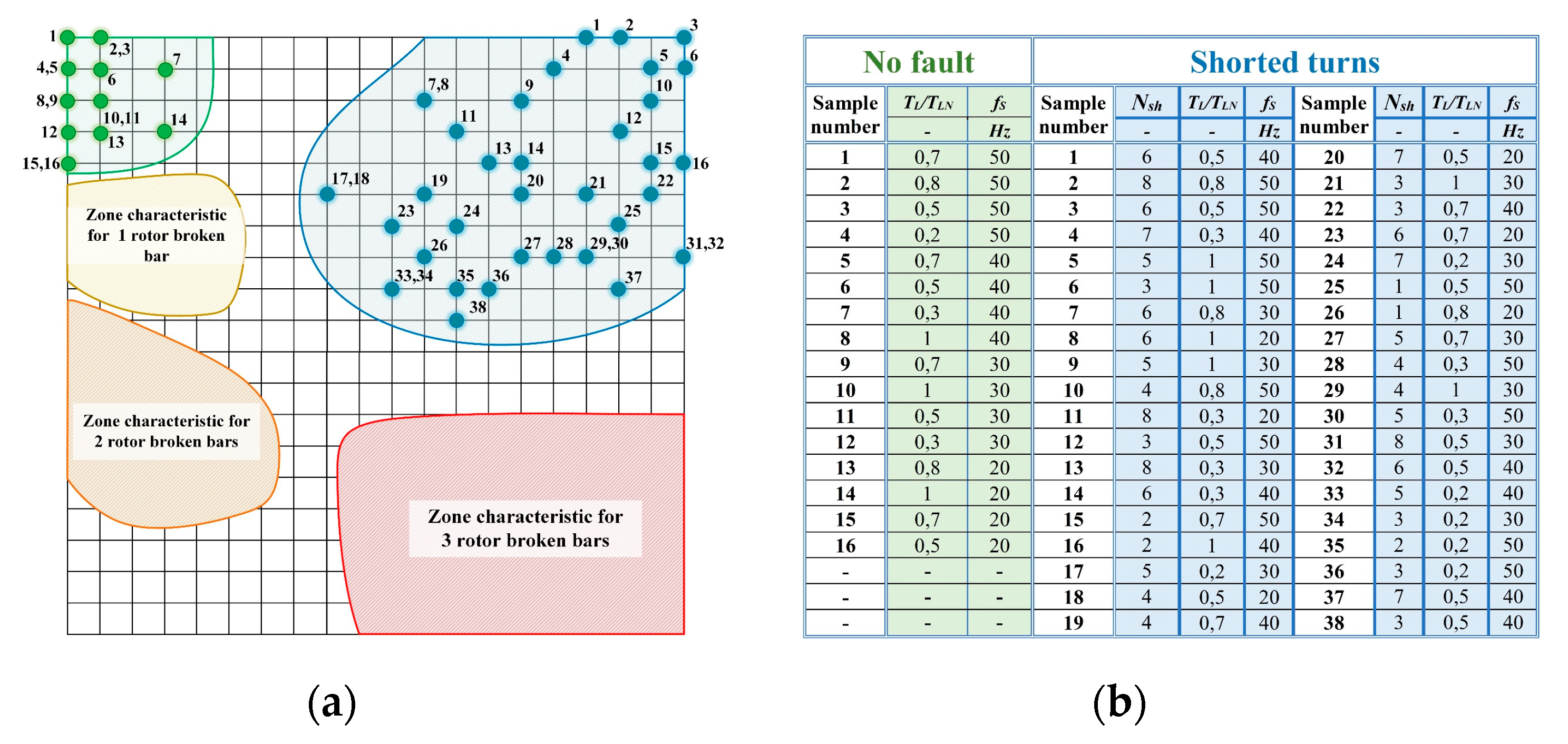

4.3. Result of the Fault Detection Using Kohonen Netoworks

- -

- the reduced stator fault detection efficiency is caused by the fact, that zones for Nsh = 1 and Nbb = 1 are close each other at high load,

- -

- the decrease in the effectiveness of stator damage grading results from too many overlapping neurons in smaller SOM; in the case of a (20 × 20) map active neurons are more “spread out” on the map,

- -

- reduced efficiency for the detection and classification of rotor damages by SOM (10 × 10) results from small distances between the zones for Nbb = 3 and Nbb = 2.

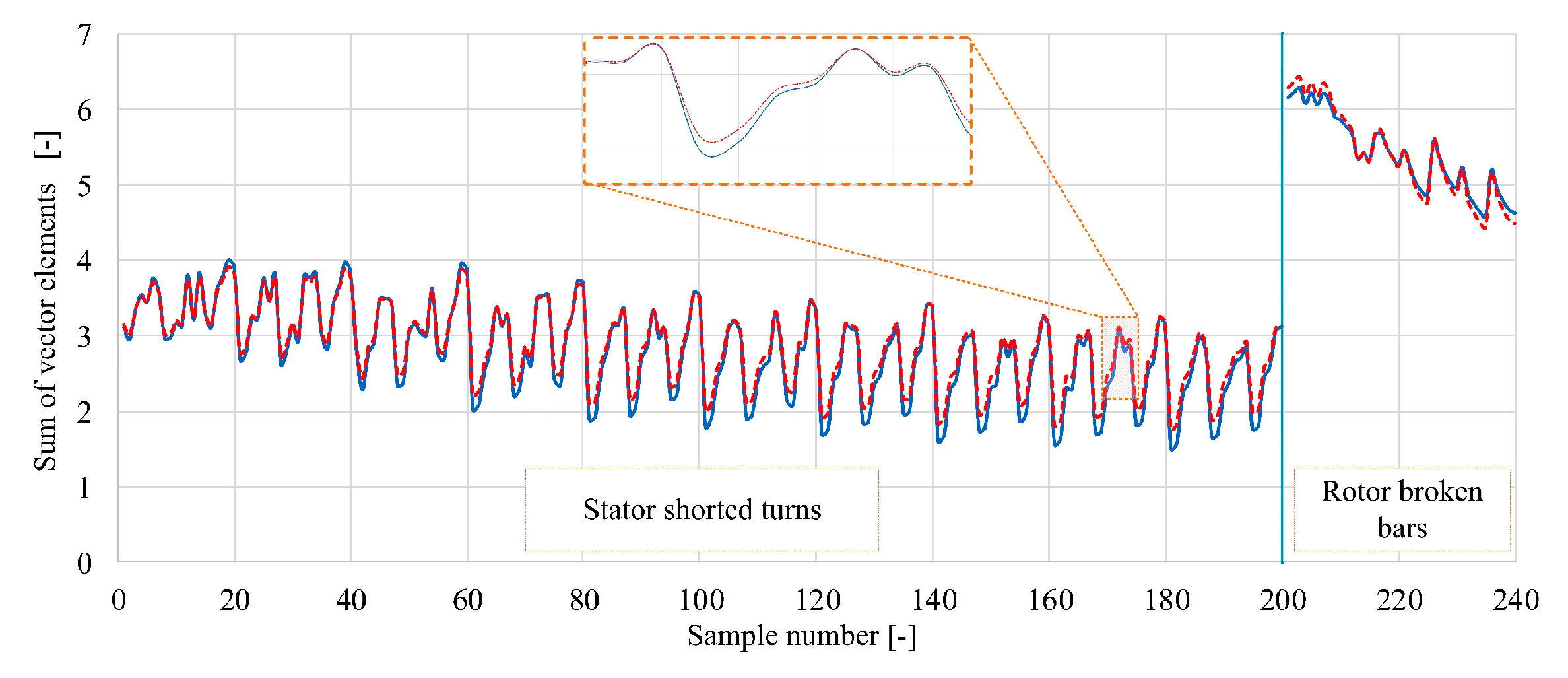

4.4. Result of the Fault Detection Using RHN

4.5. Comparison of the Used Neural Network Structures

- -

- the MLP network requires well-chosen signals in terms of changes due to damage (preferably linear changes);

- -

- the SOM was characterized by the ability to recognize patterns with a small amount of data. For the SOM, you do not have to choose the ‘ideal’ symptoms, because the individual categories will be classified anyway, while the input signals should not be associated with each other (correlations << −1);

- -

- in the case of RHN, a large size of the input vector with information resistant to interference is required.

- -

- in the case of MLP, the largest database of training patterns was required due to mixed damage tested;

- -

- in the case of SOM it was important that each category had a similar number of learning data;

- -

- RHN reached about 100% effectiveness for 200 training samples, therefore there was no need to enlarge the database.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Stone, G.C.; Boulter, E.A.; Culbert, I.; Dhirani, H. Electrical insulation for rotating machines. IEEE Press Ser. Power Eng. 2004, 21, 672. [Google Scholar]

- Filippetti, F.; Bellini, A.; Capolino, G. Condition monitoring and diagnosis of rotor faults in induction machines: State of art and future perspectives. In Proceedings of the 2013 IEEE Workshop on Electrical Machines Design, Control and Diagnosis, Paris, France, 11–12 March 2013. [Google Scholar]

- Jung, J.; Lee, J.; Kwon, B. Online Diagnosis of Induction Motors Using MCSA. IEEE Trans. Ind. Electron. 2006, 53, 1842–1852. [Google Scholar] [CrossRef]

- Cruz, S.M.A.; Cardoso, A.J.M. Stator winding fault diagnosis in three-phase synchronous and asynchronous motors, by the extended Park’s vector approach. IEEE Trans. Ind. Appl. 2001, 37, 1227–1233. [Google Scholar] [CrossRef]

- Riera-Guasp, M.; Antonino-Daviu, J.A.; Pineda-Sanchez, M.; Puche-Panadero, R.; Perez-Cruz, J. A General Approach for the Transient Detection of Slip-Dependent Fault Components Based on the Discrete Wavelet Transform. IEEE Trans. Ind. Electron. 2008, 55, 4167–4180. [Google Scholar] [CrossRef]

- Boukra, T.; Lebaroud, A.; Clerc, G. Statistical and Neural-Network Approaches for the Classification of Induction Machine Faults Using the Ambiguity Plane Representation. IEEE Trans. Ind. Electron. 2013, 60, 4034–4042. [Google Scholar] [CrossRef]

- Ghate, V.N.; Dudul, S.V. Optimal MLP neural network classifier for fault detection of three phase induction motor. Expert Syst. Appl. 2010, 37, 3468–3481. [Google Scholar] [CrossRef]

- Gardel, P.; Morinigo-Sotelo, D.; Duque-Perez, O.; Perez-Alonso, M.; Garcia-Escudero, L.A. Neural network broken bar detection using time domain and current spectrum data. In Proceedings of the 2012 20th International Conference on Electrical Machines, Marseille, France, 2–5 September 2012; pp. 2492–2497. [Google Scholar]

- Zolfaghari, S.; Noor, S.B.M.; Rezazadeh Mehrjou, M.; Marhaban, M.H.; Mariun, N. Broken Rotor Bar Fault Detection and Classification Using Wavelet Packet Signature Analysis Based on Fourier Transform and Multi-Layer Perceptron Neural Network. Appl. Sci. 2018, 8, 25. [Google Scholar] [CrossRef]

- Soualhi, A.; Clerc, G.; Razik, H. Detection and Diagnosis of Faults in Induction Motor Using an Improved Artificial Ant Clustering Technique. IEEE Trans. Ind. Electron. 2013, 60, 4053–4062. [Google Scholar] [CrossRef]

- Hamdani, S.; Mezerreg, H.; Boutikar, B.; Lahcene, N.; Touhami, O.; Ibtiouen, R. Rotor fault diagnosis in a Squirrel-Cage Induction Machine using support vector. In Proceedings of the 2012 20th International Conference on Electrical Machines, Marseille, France, 2–5 September 2012; pp. 1817–1822. [Google Scholar]

- Zhao, X.; Tang, X.; Zhao, J.; Zhang, Y. Fault Diagnosis of Asynchronous Induction Motor Based on BP Neural Network. In Proceedings of the 2010 International Conference on Measuring Technology and Mechatronics Automation, Changsha, China, 13–14 March 2010; pp. 236–239. [Google Scholar]

- Gui-li, Y.; Shi-wei, Q.; Mi, G. Motor fault diagnosis of RBF neural network based on immune genetic algorithm. In Proceedings of the 25th Chinese Control and Decision Conference (CCDC), Guiyang, China, 25–27 May 2013; pp. 1060–1065. [Google Scholar]

- Ewert, P. Use of axial flux in the detection of electrical faults in induction motors. In Proceedings of the International Symposium on Electrical Machines (SME), Naleczow, Poland, 18–21 June 2017; pp. 1–6. [Google Scholar]

- Wolkiewicz, M.; Skowron, M.; Kowalski, C.T. Electrical Fault Diagnostic System Based on the Kohonen Neural Network Classifier. In Proceedings of the 2018 International Symposium on Electrical Machines (SME), Andrychow, Poland, 10–13 June 2018; pp. 1–5. [Google Scholar]

- Kumar, P.S.; Xie, L.; Halick, M.S.M.; Vaiyapuri, V. Online stator end winding thermography using infrared sensor array. In Proceedings of the 2018 IEEE Applied Power Electronics Conference and Exposition (APEC), San Antonio, TX, USA, 4–8 March 2018; pp. 2454–2459. [Google Scholar]

- Maraaba, L.; Al-Hamouz, Z.; Abido, M. An Efficient Stator Inter-Turn Fault Diagnosis Tool for Induction Motors. Energies 2018, 11, 653. [Google Scholar] [CrossRef]

- Wolkiewicz, M.; Tarchała, G.; Orłowska-Kowalska, T.; Kowalski, C.T. Online Stator Interturn Short Circuits Monitoring in the DFOC Induction-Motor Drive. IEEE Trans. Ind. Electron. 2016, 63, 2517–2528. [Google Scholar] [CrossRef]

- Martins, J.F.; Pires, V.F.; Pires, A.J. PCA-Based On-Line Diagnosis of Induction Motor Stator Fault Feed by PWM Inverter. In Proceedings of the 2006 IEEE International Symposium on Industrial Electronics (ISIE), Montreal, QC, Canada, 9–13 July 2006; pp. 2401–2405. [Google Scholar]

- Skowron, M.; Wolkiewicz, M.; Orlowska-Kowalska, T.; Kowalski, C.T. Application of Self-Organizing Neural Networks to Electrical Fault Classification in Induction Motors. Appl. Sci. 2019, 9, 616. [Google Scholar] [CrossRef]

- Briz, F.; Degner, M.W.; Garcia, P.; Bragado, D. Broken Rotor Bar Detection in Line-Fed Induction Machines Using Complex Wavelet Analysis of Startup Transients. IEEE Trans. Ind. Appl. 2008, 44, 760–768. [Google Scholar] [CrossRef]

- Karvelis, P.; Tsoumas, I.P.; Georgoulas, G.; Stylios, C.D.; Antonino-Daviu, J.A.; Climente-Alarcón, V. An intelligent icons approach for rotor bar fault detection. In Proceedings of the IECON 2013–39th Annual Conference of the IEEE Industrial Electronics Society, Vienna, Austria, 10–13 November 2013; pp. 5526–5531. [Google Scholar]

- Puche-Panadero, R.; Pineda-Sanchez, M.; Riera-Guasp, M.; Roger-Folch, J.; Hurtado-Perez, E.; Perez-Cruz, J. Improved Resolution of the MCSA Method Via Hilbert Transform, Enabling the Diagnosis of Rotor Asymmetries at Very Low Slip. IEEE Trans. Energy Convers. 2009, 24, 52–59. [Google Scholar] [CrossRef]

- Antonino-Daviu, J.; Aviyente, S.; Strangas, E.G.; Riera-Guasp, M.; Roger-Folch, J.; Pérez, R.B. An EMD-based invariant feature extraction algorithm for rotor bar condition monitoring. In Proceedings of the 8th IEEE Symposium on Diagnostics for Electrical Machines, Power Electronics & Drives 2011, Bologna, Italy, 5–8 September 2011; pp. 669–675. [Google Scholar]

- Henao, H.; Demian, C.; Capolino, G.A. A frequency-domain detection of stator winding faults in induction machines using an external flux sensor. IEEE Trans. Ind. Electron. 2003, 39, 1272–1279. [Google Scholar] [CrossRef]

- Henao, H.; Capolino, A.G.; Fernandez-Cabanas, M.; Filippetti, F.; Bruzzese, C.; Strangas, E.; Hedayati-Kia, S. Trends in Fault Diagnosis for Electrical Machines: A Review of Diagnostic Techniques. IEEE Ind. Electron. Mag. 2014, 8, 31–42. [Google Scholar] [CrossRef]

- Ceban, A.; Pusca, R.; Romary, R. Study of Rotor Faults in Induction Motors Using External Magnetic Field Analysis. IEEE Trans. Ind. Electron. 2012, 59, 2082–2093. [Google Scholar] [CrossRef]

- Ramirez-Nunez, J.A.; Antonino-Daviu, J.; Climente-Alarcón, V.; Quijano-López, A.; Razik, H.; Osornio-Rios, R.A.; Romero-Troncoso, R.J. Evaluation of the Detectability of Electromechanical Faults in Induction Motors via Transient Analysis of the Stray Flux. IEEE Trans. Ind. Appl. 2018, 54, 4324–4332. [Google Scholar] [CrossRef]

- Hamdani, S.; Touhami, O.; Ibtiouen, R.; Fadel, M. Neural network technique for induction motor rotor faults classification-dynamic eccentricity and broken bar faults. In Proceedings of the 8th IEEE Symposium on Diagnostics for Electrical Machines, Power Electronics & Drives, Bologna, Italy, 5–8 September 2011; pp. 626–631. [Google Scholar]

- Kowalski, C.T.; Orlowska-Kowalska, T. Neural networks application for induction motor faults diagnosis. Math. Comput. Simul. 2003, 63, 435–448. [Google Scholar] [CrossRef]

- Chow, M.Y.; Yee, S.O. Methodology for on-line incipient fault detection in single-phase squirrel-cage induction motors using artificial neural networks. IEEE Trans. Energy Convers. 1991, 6, 536–545. [Google Scholar] [CrossRef]

- He, Q.; Du, D. Fault Diagnosis of Induction Motor using Neural Networks. In Proceedings of the 2007 International Conference on Machine Learning and Cybernetics, Hong Kong, China, 19–22 August 2007; pp. 1090–1095. [Google Scholar]

- Taïbi, Z.M.; Hasni, M.; Hamdani, S.; Rahmani, O.; Touhami, O.; Ibtiouen, R. Optimization of the feedforward neural network for rotor cage fault diagnosis in three-phase induction motors. In Proceedings of the 2011 IEEE International Electric Machines & Drives Conference (IEMDC), Niagara Falls, ON, Canada, 15–18 May 2011; pp. 194–199. [Google Scholar]

- Toma, S.; Capocchi, L.; Capolino, G. Wound-Rotor Induction Generator Inter-Turn Short-Circuits Diagnosis Using a New Digital Neural Network. IEEE Trans. Ind. Electron. 2013, 60, 4043–4052. [Google Scholar] [CrossRef]

- Khalfaoui, N.; Salhi, M.S.; Amiri, H. The SOM tool in mechanical fault detection over an electric asynchronous drive. In Proceedings of the 2016 4th International Conference on Control Engineering & Information Technology (CEIT), Hammamet, Tunisia, 16–18 December 2016; pp. 1–6. [Google Scholar]

- Sid, O.; Menaa, M.; Hamdani, S.; Touhami, O.; Ibtiouen, R. Self-organizing map approach for classification of electricals rotor faults in induction motors. In Proceedings of the 2011 2nd International Conference on Electric Power and Energy Conversion Systems (EPECS), Sharjah, United Arab Emirates, 15–17 November 2011; pp. 1–6. [Google Scholar]

- Kato, T.; Inoue, K.; Takahashi, T.; Kono, Y. Automatic Fault Diagnosis Method of Electrical Machinery and Apparatus by Using Kohonen’s Self-Organizing Map. In Proceedings of the 2007 Power Conversion Conference, Nagoya, Japan, 2–5 April 2007; pp. 1224–1229. [Google Scholar]

- Coelho, D.N.; Barreto, G.A.; Medeiros, C.M.S. Detection of short circuit faults in 3-phase converter-fed induction motors using kernel SOMs. In Proceedings of the 2017 12th International Workshop on Self-Organizing Maps and Learning Vector Quantization, Clustering and Data Visualization (WSOM), Nancy, France, 28–30 June 2017; pp. 1–7. [Google Scholar]

- Li, P.; Chai, Y.; Cen, M.; Qiu, Y.; Zhang, K. Multiple fault diagnosis of analog circuit using quantum Hopfield neural network. In Proceedings of the 2013 25th Chinese Control and Decision Conference (CCDC), Guiyang, China, 25–27 May 2013; pp. 4238–4243. [Google Scholar]

- Srinivasan, A.; Batur, C. Hopfield/ART-1 neural network-based fault detection and isolation. IEEE Trans. Neural Netw. 1994, 5, 890–899. [Google Scholar] [CrossRef]

- Hong, R.; Meizhu, L.; Mingfu, F. Equipment Diagnosis Method Based on Hopfield-BP Neural Networks. In Proceedings of the 2008 International Conference on Advanced Computer Theory and Engineering, Phuket, Thailand, 20–22 December 2008; pp. 170–173. [Google Scholar]

- Freeman, J.A.; Skapura, D.M. Neural Networks Algorithms. Applications and Programming Techniques. 1992. Available online: https://pdfs.semanticscholar.org/3847/897e4a15d1078499466087ea7885061c6465.pdf (accessed on 10 June 2019).

- Demuth, H.; Beale, M. Neural Network Toolbox User’s Guide ver.4. CiteSeerX 2000. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.220.1640&rep=rep1&type=pdf (accessed on 10 June 2019).

| Name of the Parameter | Symbol | Units | |

|---|---|---|---|

| Power | PN | 1500 | [W] |

| Torque | TN | 10.16 | [Nm] |

| Speed | nN | 1410 | [r/min] |

| Stator phase voltage | UsN | 230 | [V] |

| Stator current | IsN | 3.5 | [A] |

| Frequency | fsN | 50 | [Hz] |

| Pole pairs number | pp | 2 | [-] |

| Number of rotor bars | Nrb | 26 | [-] |

| Number of stator turns in each phase | Nst | 312 | [-] |

| Shorted Turns | Broken Bars | No Fault | ||

|---|---|---|---|---|

| Kohonen map (20 × 20) | Approximate effectiveness of faults detection | 93% | 95% | 95% |

| Approximate effectiveness of fault level classification | 70% | 93% | 95% | |

| Kohonen map (10 × 10) | Approximate effectiveness of faults detection | 90% | 92% | 95% |

| Approximate effectiveness of fault level classification | 65% | 88% | 95% |

| Evaluation Categories | Multilayer Perceptron Network | Self-organizing Kohonen Map | Recurrent Hopfield Network | |

|---|---|---|---|---|

| EXPERIMENTAL VERIFICATION | The effectiveness of early detection of electrical damages | HIGH | MEDIUM | LOW |

| The effectiveness of the stator damages level assessment | HIGH | MEDIUM | MEDIUM | |

| The effectiveness of the rotor damages level assessment | HIGH | HIGH | MEDIUM | |

| The effectiveness of the mixed damages level assessment | HIGH | LOW | LOW | |

| Resistance to interference of the diagnostic signal | MEDIUM | HIGH | LOW | |

| Hardware implementations | EASY | EASY | DIFFICULT | |

| Interpretation of the neural network response | EASY | DIFFICULT | EASY | |

| LEARNING PROCESS | Required size of the learning vector | LARGE | SMALL | LARGE |

| Selection of the components of input vector | DIFFICULT | EASY | DIFFICULT | |

| Selection of the neural network structure | HARD | EASY | EASY | |

| Selection of the neural network learning parameters | HARD | EASY | EASY | |

| Learning process time | LONG | MEDIUM | SHORT |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skowron, M.; Wolkiewicz, M.; Orlowska-Kowalska, T.; Kowalski, C.T. Effectiveness of Selected Neural Network Structures Based on Axial Flux Analysis in Stator and Rotor Winding Incipient Fault Detection of Inverter-fed Induction Motors. Energies 2019, 12, 2392. https://doi.org/10.3390/en12122392

Skowron M, Wolkiewicz M, Orlowska-Kowalska T, Kowalski CT. Effectiveness of Selected Neural Network Structures Based on Axial Flux Analysis in Stator and Rotor Winding Incipient Fault Detection of Inverter-fed Induction Motors. Energies. 2019; 12(12):2392. https://doi.org/10.3390/en12122392

Chicago/Turabian StyleSkowron, Maciej, Marcin Wolkiewicz, Teresa Orlowska-Kowalska, and Czeslaw T. Kowalski. 2019. "Effectiveness of Selected Neural Network Structures Based on Axial Flux Analysis in Stator and Rotor Winding Incipient Fault Detection of Inverter-fed Induction Motors" Energies 12, no. 12: 2392. https://doi.org/10.3390/en12122392

APA StyleSkowron, M., Wolkiewicz, M., Orlowska-Kowalska, T., & Kowalski, C. T. (2019). Effectiveness of Selected Neural Network Structures Based on Axial Flux Analysis in Stator and Rotor Winding Incipient Fault Detection of Inverter-fed Induction Motors. Energies, 12(12), 2392. https://doi.org/10.3390/en12122392