DC Flashover Dynamic Model of Post Insulator under Non-Uniform Pollution between Windward and Leeward Sides

Abstract

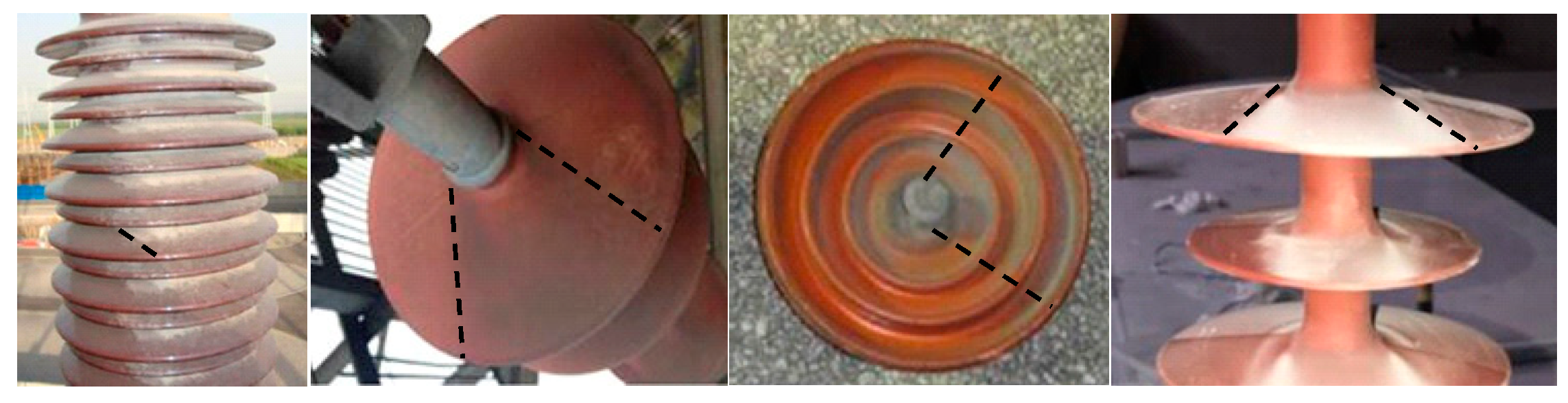

:1. Introduction

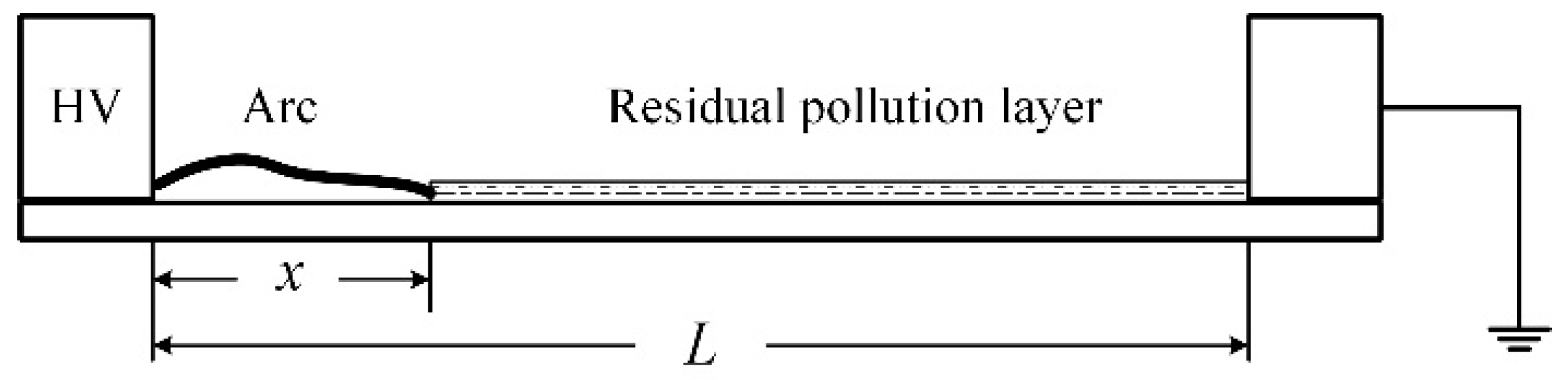

2. Analysis of Residual Pollution Layer Resistance for Pollution Flashover Dynamic Model

2.1. Residual Pollution Layer Resistance under Uniform Pollution

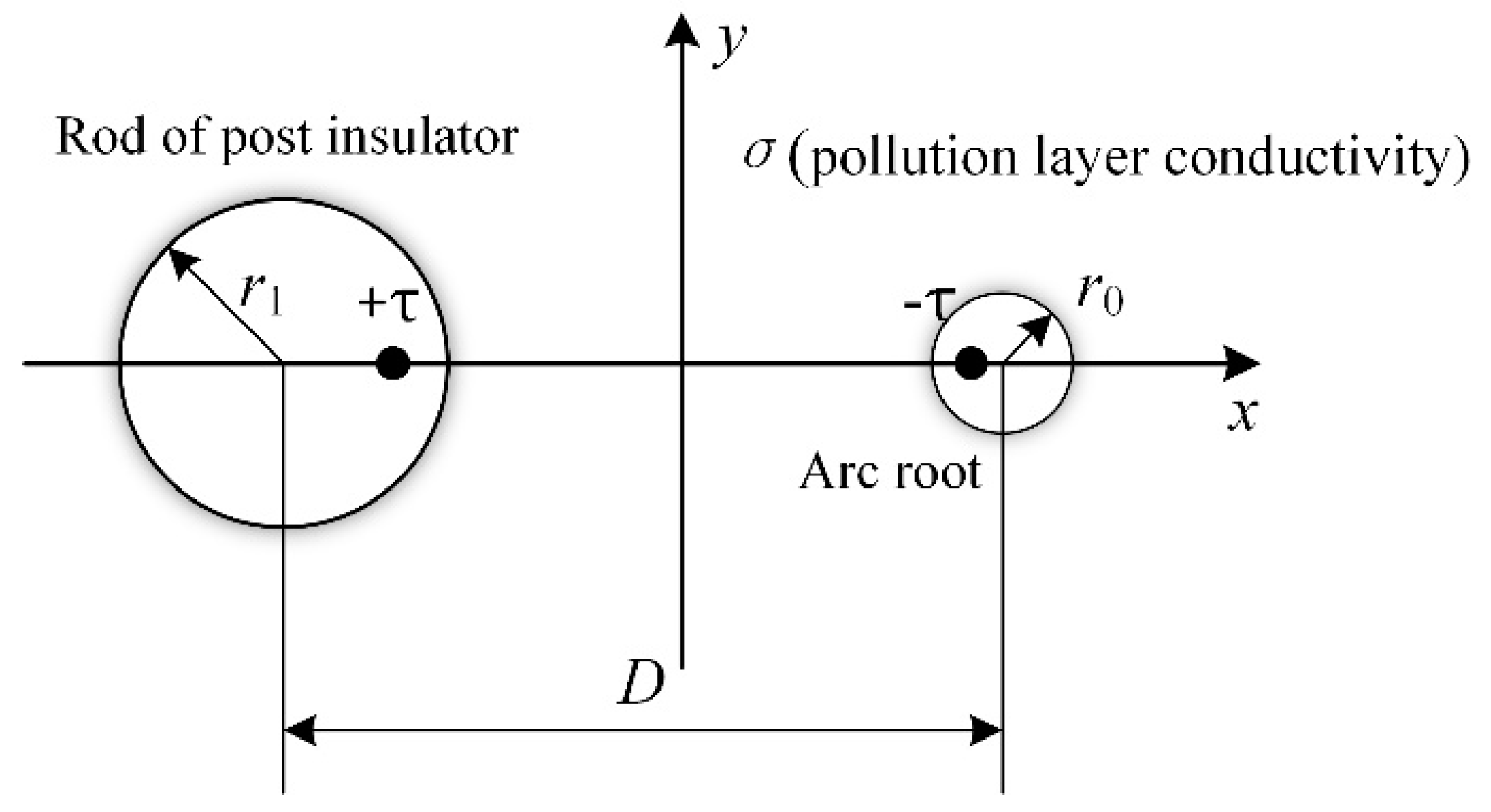

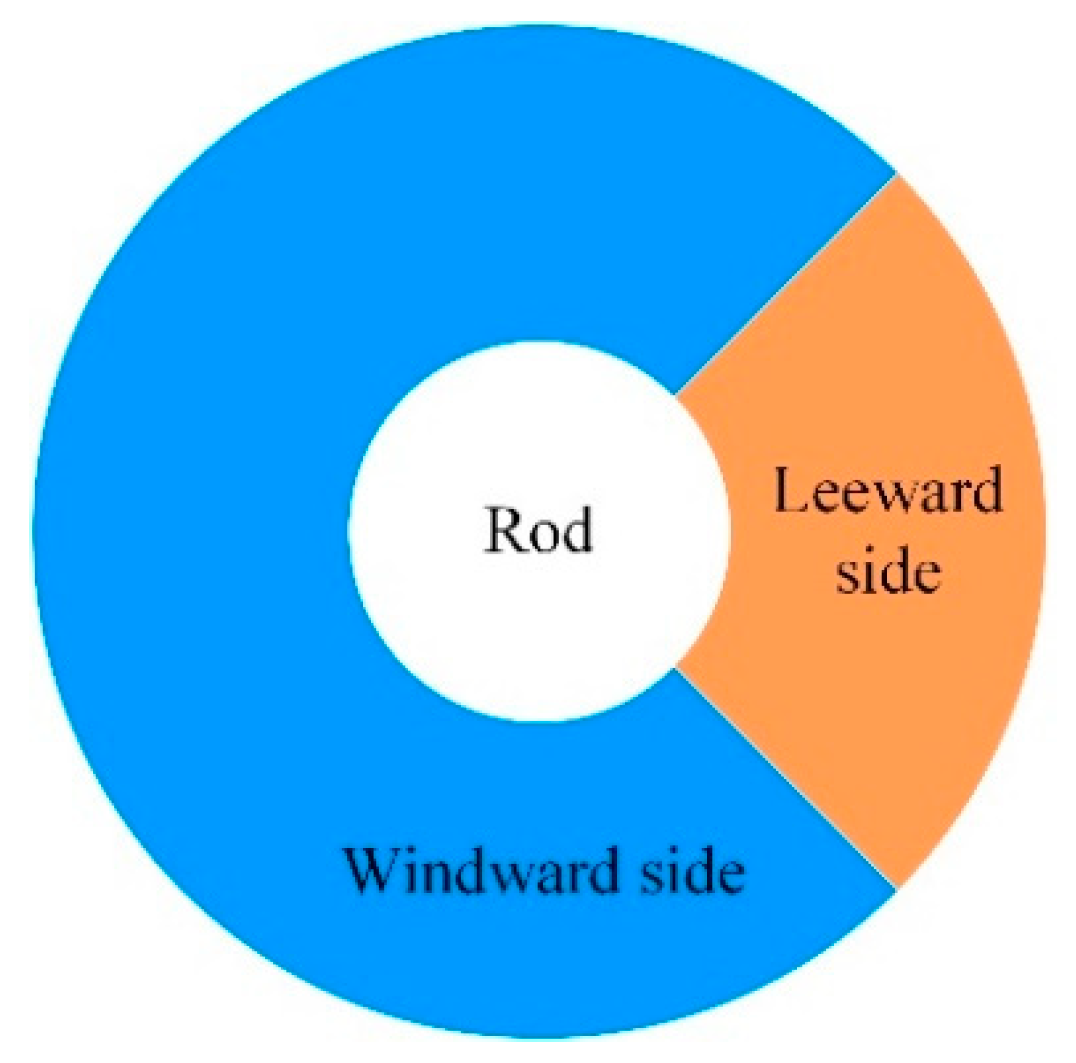

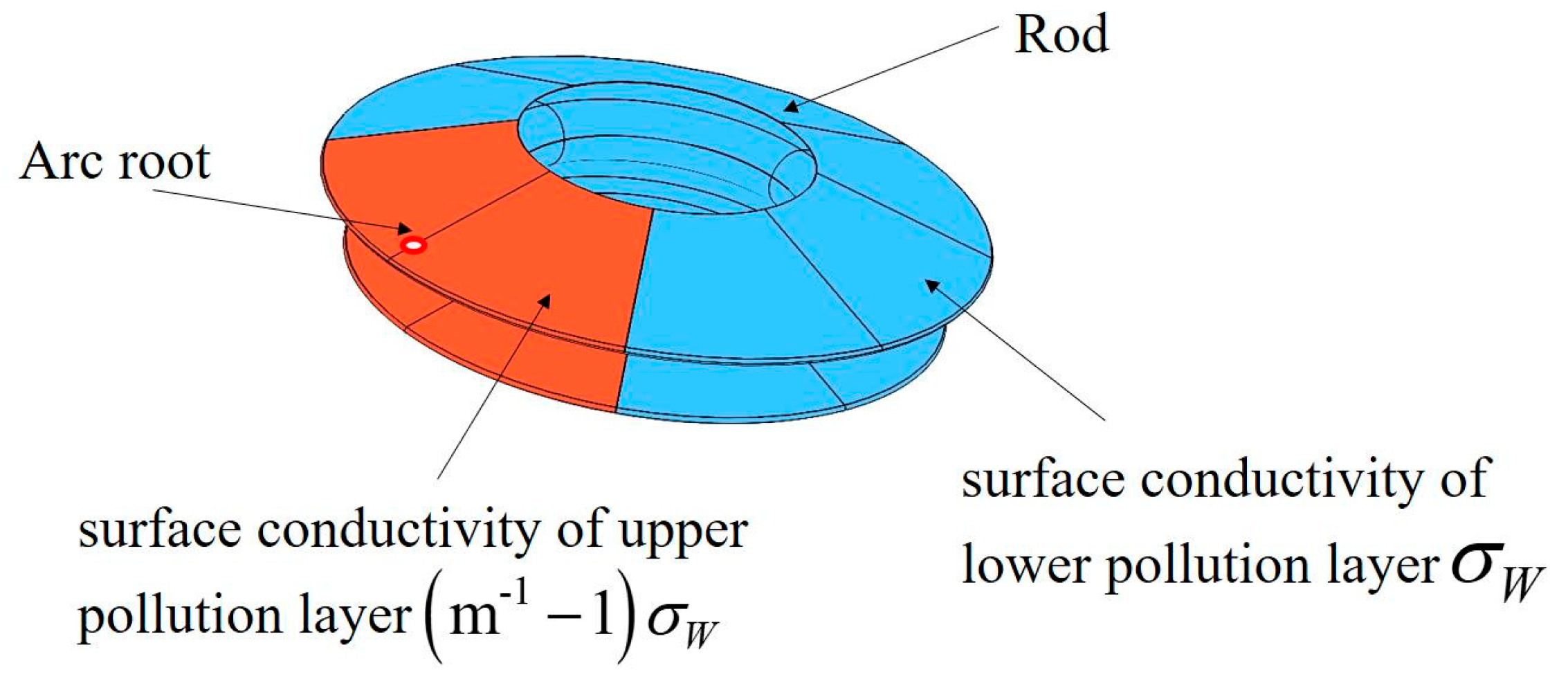

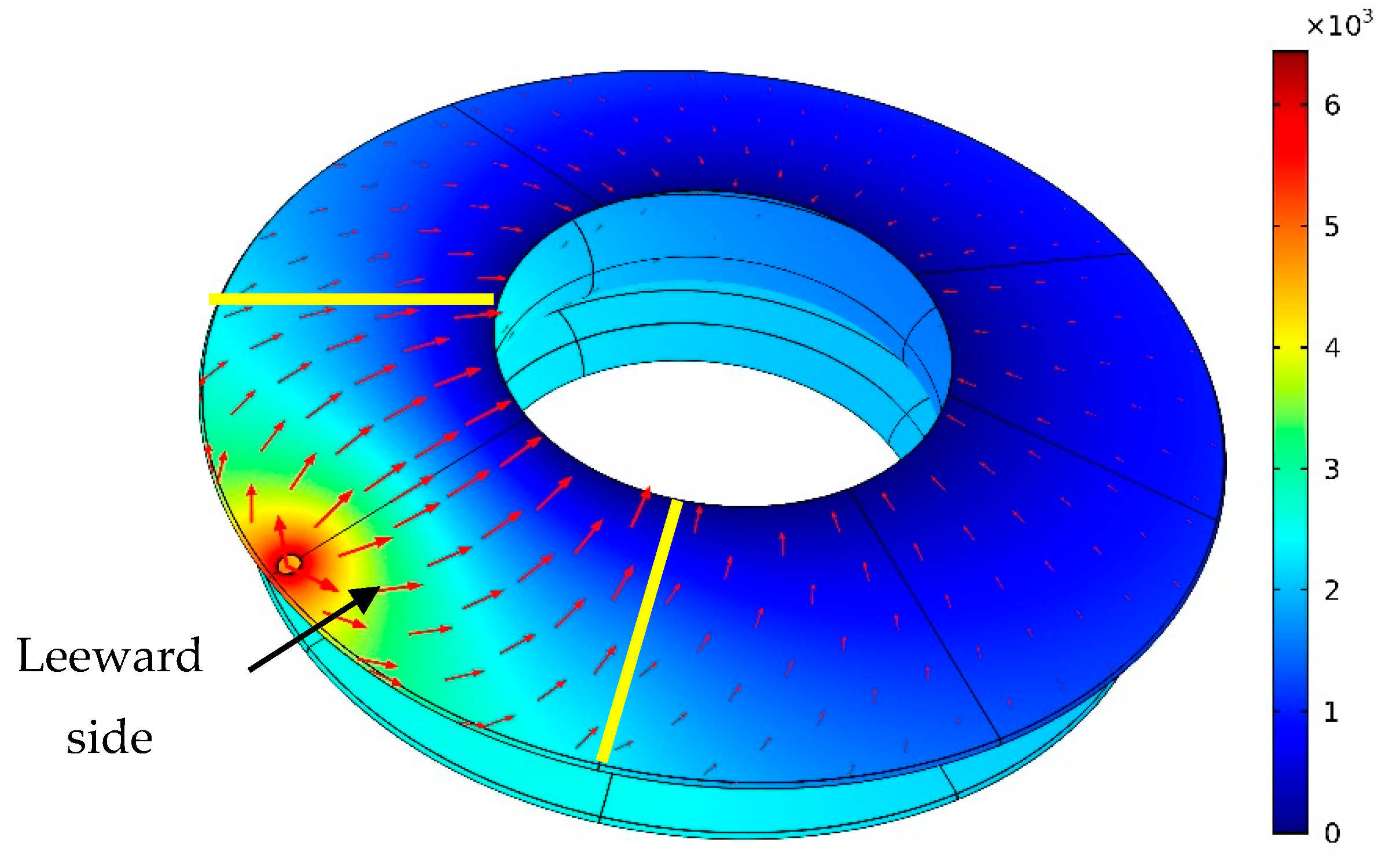

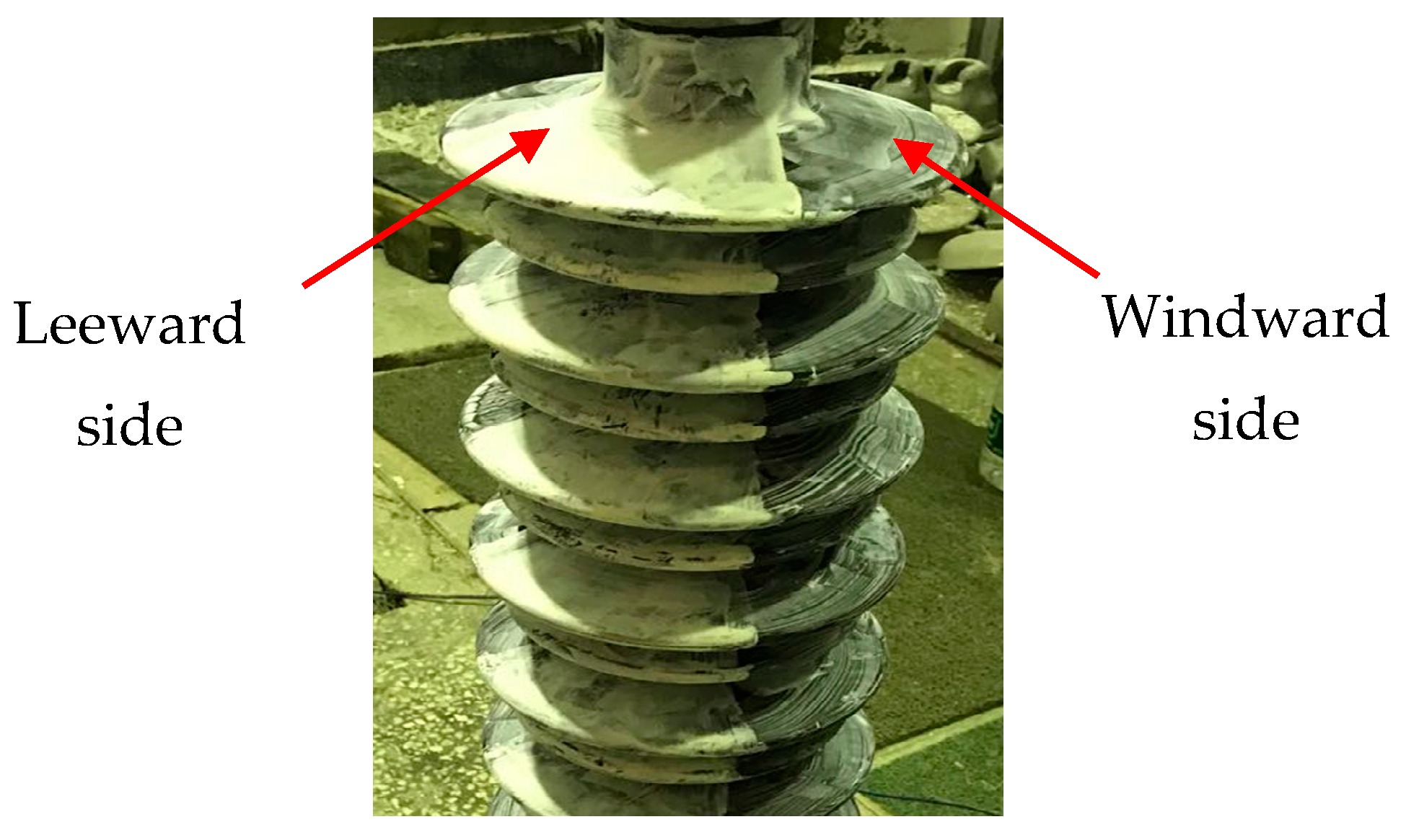

2.2. Residual Pollution Layer Resistance under Non-Uniform Pollution between Windward and Leeward Sides

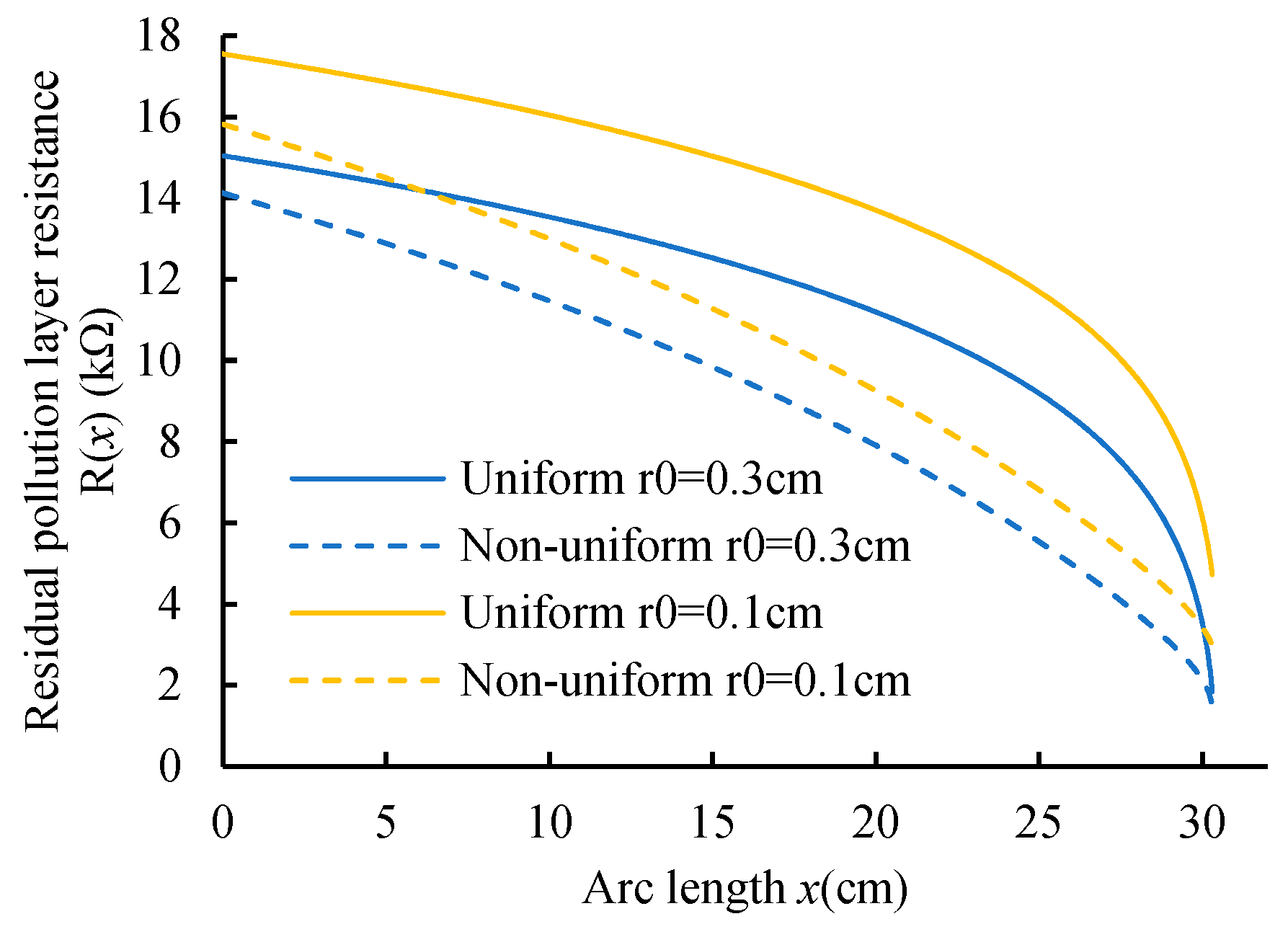

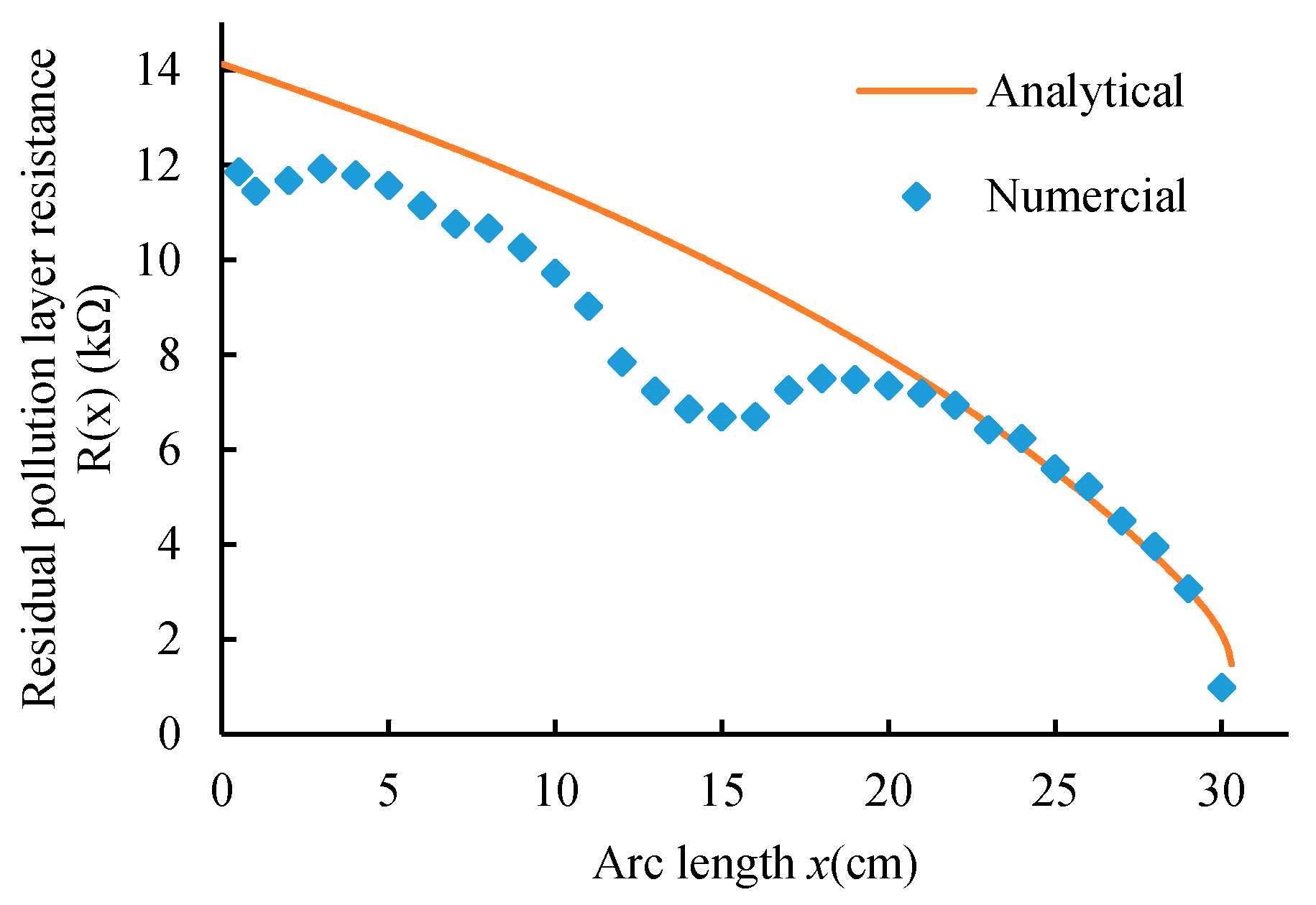

2.3. Comparative Results of Residual Pollution Layer Resistance

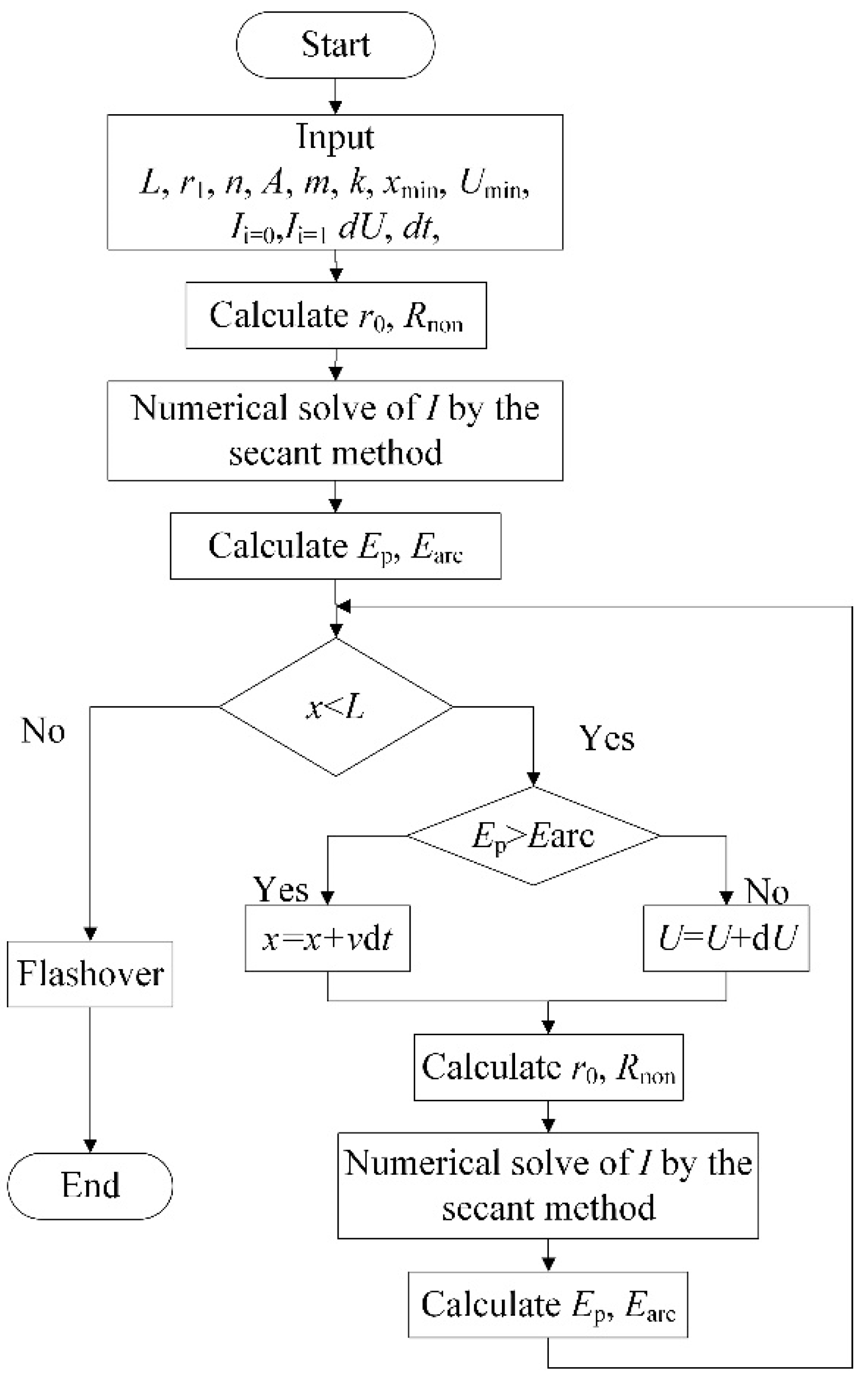

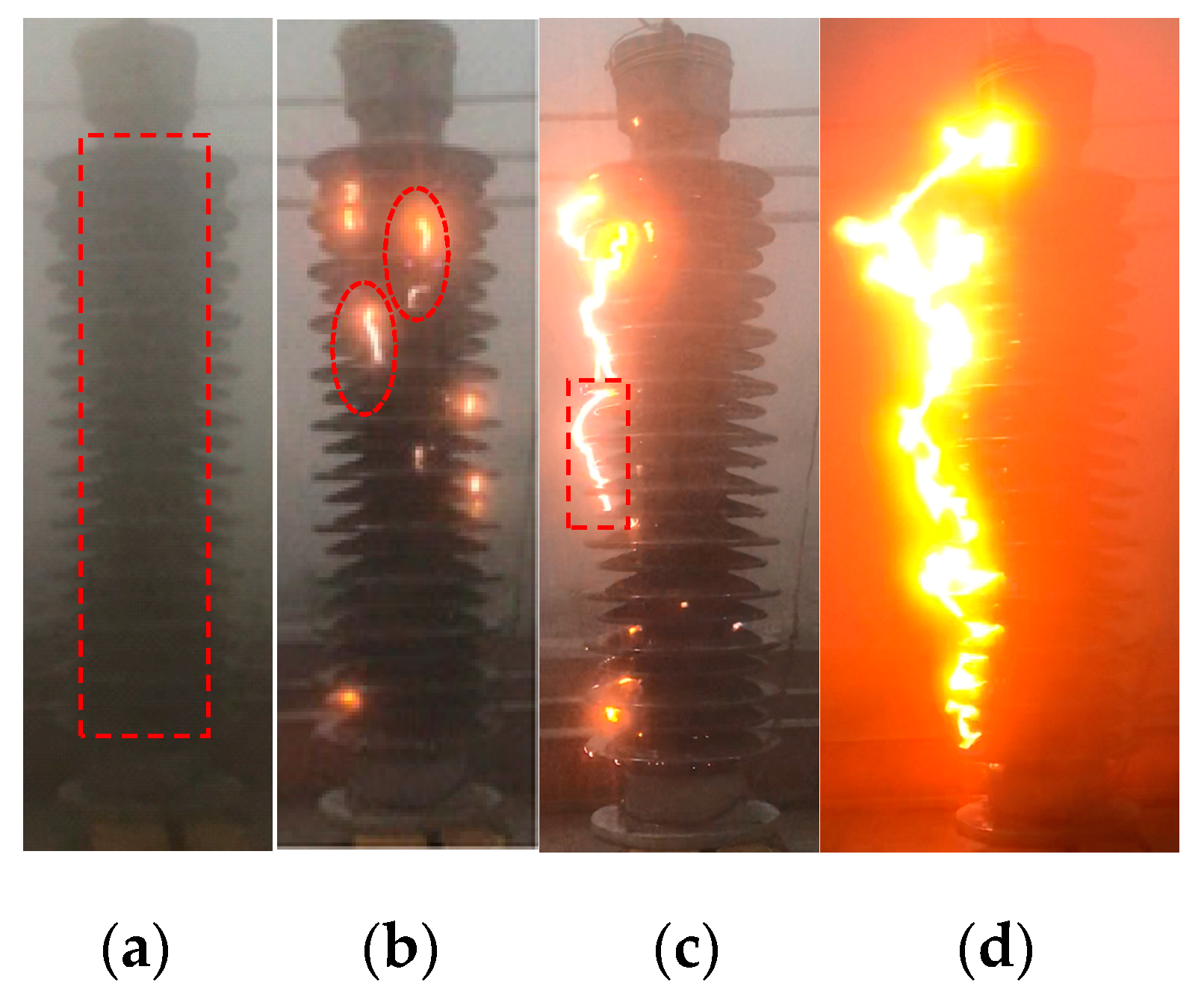

3. DC Flashover Dynamic Model and Experimental Validation

3.1. DC Pollution Flashover Dynamic Model

3.2. Experimental Validation

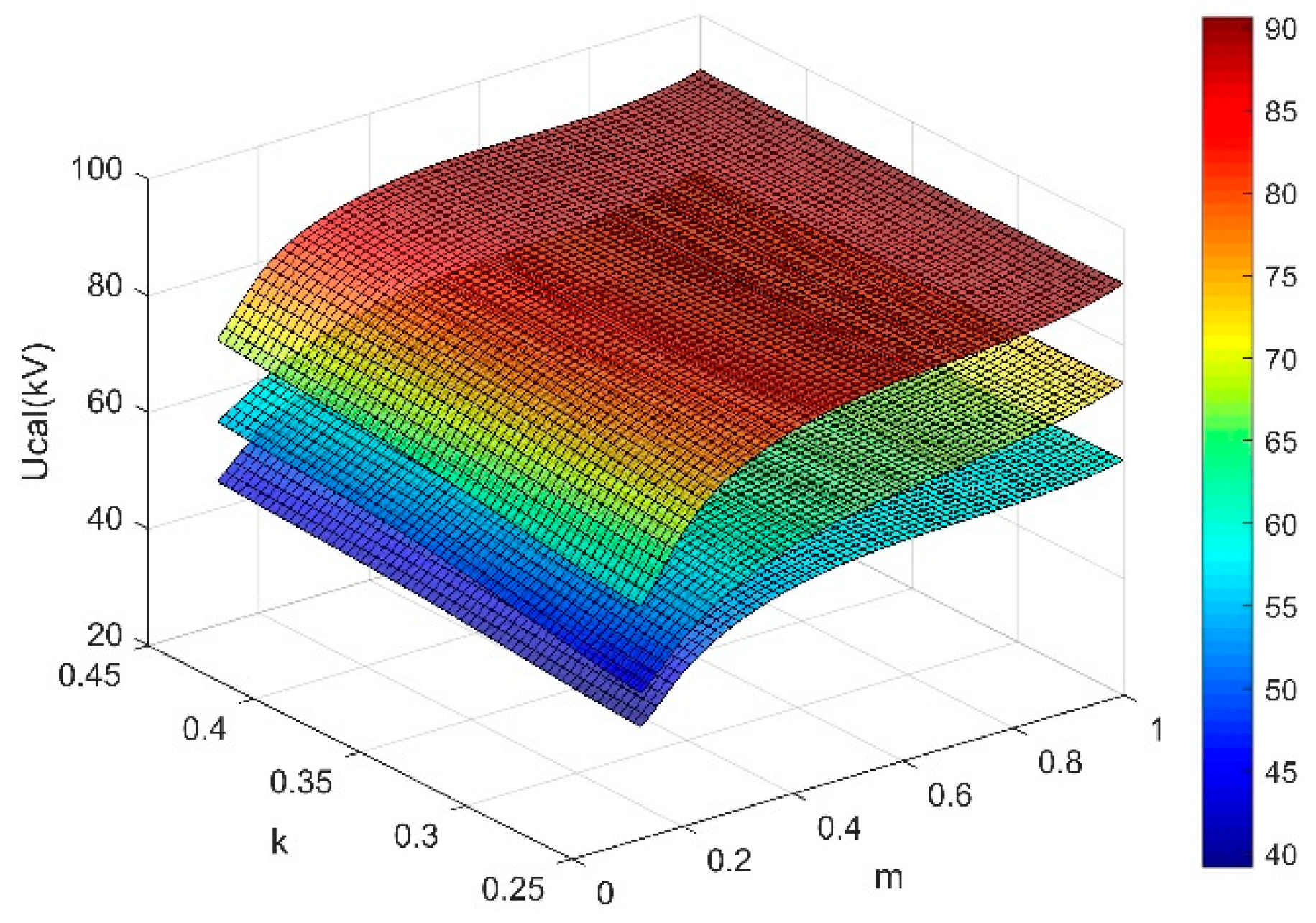

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, Z.; You, J.; Wei, D.; Jiang, X.; Zhang, D.; Bi, M. Investigations on AC pollution flashover performance of insulator string under different non-uniform pollution conditions. IET Gener. Transm. Distrib. 2016, 10, 437–443. [Google Scholar] [CrossRef]

- Zhang, R.; Wu, G.; Yuan, T. Analysis on natural contamination characteristics of UHV AC post porcelain insulator. In Proceedings of the 2016 China International Conference on Electricity Distribution (CICED), Xi’an, China, 10–13 August 2016; pp. 1–8. [Google Scholar]

- Zhang, Z.; Qiao, X.; Zhang, Y.; Tian, L.; Zhang, D.; Jiang, X. AC flashover performance of different shed configurations of composite insulators under fan-shaped non-uniform pollution. High Volt. 2018, 3, 199–206. [Google Scholar] [CrossRef]

- Sun, J.; Gao, G.; Wu, G.; Cao, X.; Zhu, G. Influence of pollution distribution on insulator surface on flashover characteristics. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1637–1646. [Google Scholar] [CrossRef]

- Karamousantas, D.C.; Chatzarakis, G.E.; Oikonomou, D.S.; Ekonomou, L.; Karampelas, P. Effective insulator maintenance scheduling using artificial neural networks. IET Gener. Transm. Distrib. 2010, 479–484. [Google Scholar] [CrossRef]

- Zhang, Z.; Qiao, X.; Yang, S.; Jiang, X. Non-Uniform Distribution of Contamination on Composite Insulators in HVDC Transmission Lines. Appl. Sci. 2018, 8, 1962. [Google Scholar] [CrossRef]

- Vita, V.; Ekonomou, L.; Chatzarakis, G.E. Design of artificial neural network models for the estimation of distribution system voltage insulators’ contamination. In Proceedings of the 12th WSEAS International Conference on Mathematical Methods, Computational Techniques and Intelligent Systems (MAMECTIS’10), Sousse, Tunisia, 3–6 May 2010; pp. 227–231. [Google Scholar]

- Pappas, S.S.; Ekonomou, L.; Heraklion, Ν. Comparison of adaptive techniques for the prediction of the equivalent salt deposit density of medium voltage insulators. WSEAS Trans. Power Syst. 2017, 12, 220–224. [Google Scholar]

- Gençoğlu, M.T.; Cebeci, M. The pollution flashover on high voltage insulators. Electr. Power Syst. Res. 2008, 78, 1914–1921. [Google Scholar] [CrossRef]

- Bessedik, S.A.; Hadi, H.; Volat, C.; Jabbari, M. Refinement of residual resistance calculation dedicated to polluted insulator flashover models. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1207–1215. [Google Scholar] [CrossRef]

- Jabbari, M.; Volat, C.; Fofana, I. Application of a new dynamic numerical model to predict polluted insulator flashover voltage. In Proceedings of the 2014 IEEE Electrical Insulation Conference (EIC), Philadelphia, PA, USA, 8–11 June 2014. [Google Scholar]

- Abimouloud, A.; Arif, S.; Korichi, D.; Ale-Emran, S.M. Prediction of DC flashover voltage of cap-andpin polluted insulator. IET Sci. Meas. Technol. 2019, 13, 279–286. [Google Scholar] [CrossRef]

- Volat, C.; Farzaneh, M.; Mhaguen, N. Improved fem models of one- and two-arcs to predict ac critical flashover voltage of ice-covered insulators. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 393–400. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, D.; You, J.; Zhao, J.; Jiang, X.; Hu, J. Study on the DC flashover performance of various types of insulators with fan-shaped nonuniform pollution. IEEE Trans. Power Deliv. 2015, 30, 1871–1879. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, Z.; Jiang, X.; Zhang, W.; Zhao, J.; Bi, M. Influence of fan-shaped non-uniform pollution on the electrical property of typical type HVDC insulator and insulation selection. IET Gener. Transm. Distrib. 2016, 10, 3555–3562. [Google Scholar] [CrossRef]

- Zhang, Z.; You, J.; Zhang, D.; Jiang, X.; Hu, J.; Zhang, W. AC flashover performance of various types of insulators under fan-shaped non-uniform pollution. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1760–1768. [Google Scholar] [CrossRef]

- Boudissa, R.; Bayadi, A.; Baersch, R. Effect of pollution distribution class on insulators flashover under AC voltage. Electr. Power Syst. Res. 2013, 104, 176–182. [Google Scholar] [CrossRef]

- Sundararajan, R.; Gorur, R.S. Dynamic arc modeling of pollution flashover of insulators under DC voltage. IEEE Trans. Dielectr. Electr. Insul. 1993, 28, 209–218. [Google Scholar] [CrossRef]

- Wilkins, R. Flashover voltage of high-voltage insulators with uniform surface-pollution films. Proc. Inst. Electr. Eng. 1969, 116, 457–465. [Google Scholar] [CrossRef]

- Jabbari, M.; Volat, C.; Farzaneh, M. A new single-arc AC dynamic FEM model of arc propagation on ice surfaces. In Proceedings of the 2013 IEEE Electrical Insulation Conference (EIC), Ontario, ON, Canada, 2–5 June 2013; pp. 360–364. [Google Scholar]

- Edmonds, D.S., Jr.; Corson, M.R. The resistance between two contacts in a plane and the capacitance between paraxial cylinders. Am. J. Phys. 1986, 54, 811–816. [Google Scholar] [CrossRef]

- Li, Y.; Yang, H.; Zhang, Q.; Yang, X.; Yu, X.; Zhou, J. Pollution flashover calculation model based on characteristics of AC partial arc on top and bottom wet-polluted dielectric surfaces. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1735–1746. [Google Scholar] [CrossRef]

- Topalis, F.V.; Gonos, I.F.; Stathopulos, I.A. Dielectric behaviour of polluted porcelain insulators. IEE Proc.-Gener. Transm. Distrib. 2001, 148, 269–274. [Google Scholar] [CrossRef] [Green Version]

- Slama, M.; Beroual, A.; Hadi, H. Analytical computation of discharge characteristic constants and critical parameters of flashover of polluted insulators. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1764–1771. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, J.; Zhang, D.; Jiang, X.; Li, Y.; Wu, B.; Wu, J. Study on the dc flashover performance of standard suspension insulator with ring-shaped non-uniform pollution. High Volt. 2018, 3, 133–139. [Google Scholar] [CrossRef]

- Sundararajan, R.; Gorur, R.S. Role of non-soluble contaminants on the flashover voltage of porcelain insulators. IEEE Trans. Dielectr. Electr. Insul. 1996, 3, 113–118. [Google Scholar] [CrossRef]

- Hampton, B.F. Flashover mechanism of polluted insulation. Proc. Inst. Electr. Eng. 2010, 111, 985–990. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, X.; Chao, Y.; Chen, L.; Sun, C.; Hu, J. Study on DC pollution flashover performance of various types of long string insulators under low atmospheric pressure conditions. IEEE Trans. Power Deliv. 2010, 25, 2132–2142. [Google Scholar] [CrossRef]

- Artificial Pollution Tests on High-Voltage Insulators to Be Used on dc. Systems; IEC Tech. Rep. 1245.; IEC: Geneva, Switzerland, 1993.

- Zhang, Z.; Jiang, X.; Sun, C.; Hu, J.; Huang, H. Study of the influence of test methods on DC pollution flashover voltage of insulator strings and its flashover process. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1787–1795. [Google Scholar] [CrossRef]

| Shed Parameters (mm) | Leakage Distance (mm) | Structure Diagram |

|---|---|---|

| L1 = 75 | 3528 |  |

| L2 = 58 | ||

| H1 = 69 | ||

| H2 = 39 | ||

| D = 270 | ||

| H = 1050 |

| Test Condition | Experimental Values Uave(kV) | σ,% | Theoretical Values Ucal (kV) | Relative Error ΔU,% | ||

|---|---|---|---|---|---|---|

| SDD = 0.05 mg/cm2 | m = 1:1 | k = 25% | 83.2 | 3.9 | 90.6 | 8.9 |

| m = 1:5 | k = 25% | 72.0 | 2.1 | 70.1 | −2.6 | |

| m = 1:5 | k = 35% | 73.8 | 5.8 | 74.8 | 1.3 | |

| SDD = 0.10 mg/cm2 | m = 1:3 | k = 35% | 60.3 | 2.5 | 63.3 | 5.0 |

| m = 1:1 | k = 35% | 64.7 | 5.2 | 73.5 | 13.6 | |

| m = 1:8 | k = 45% | 57.5 | 6.2 | 54.9 | −4.5 | |

| SDD = 0.15 mg/cm2 | m = 1:8 | k = 25% | 45.0 | 3.4 | 39.2 | −12.8 |

| m = 1:5 | k = 25% | 49.5 | 3.9 | 46.2 | −6.7 | |

| m = 1:8 | k = 45% | 50.1 | 4.9 | 44.7 | −10.8 | |

| , Uave is experimental flashover voltage, Ucal is theoretical flashover voltage. | ||||||

| m | k | |||||

|---|---|---|---|---|---|---|

| 25% | 35% | 45% | ||||

| a | b | a | b | a | b | |

| 1:1 | 30.9 | 0.36 | 30.9 | 0.36 | 30.9 | 0.36 |

| 1:3 | 26.1 | 0.37 | 27.1 | 0.37 | 28.1 | 0.37 |

| 1:5 | 21.9 | 0.39 | 22.8 | 0.39 | 24.7 | 0.38 |

| 1:8 | 18.7 | 0.39 | 20.6 | 0.38 | 21.9 | 0.39 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Yang, S.; Jiang, X.; Qiao, X.; Xiang, Y.; Zhang, D. DC Flashover Dynamic Model of Post Insulator under Non-Uniform Pollution between Windward and Leeward Sides. Energies 2019, 12, 2345. https://doi.org/10.3390/en12122345

Zhang Z, Yang S, Jiang X, Qiao X, Xiang Y, Zhang D. DC Flashover Dynamic Model of Post Insulator under Non-Uniform Pollution between Windward and Leeward Sides. Energies. 2019; 12(12):2345. https://doi.org/10.3390/en12122345

Chicago/Turabian StyleZhang, Zhijin, Shenghuan Yang, Xingliang Jiang, Xinhan Qiao, Yingzhu Xiang, and Dongdong Zhang. 2019. "DC Flashover Dynamic Model of Post Insulator under Non-Uniform Pollution between Windward and Leeward Sides" Energies 12, no. 12: 2345. https://doi.org/10.3390/en12122345

APA StyleZhang, Z., Yang, S., Jiang, X., Qiao, X., Xiang, Y., & Zhang, D. (2019). DC Flashover Dynamic Model of Post Insulator under Non-Uniform Pollution between Windward and Leeward Sides. Energies, 12(12), 2345. https://doi.org/10.3390/en12122345