Performance Analysis of a Small-Scale ORC Trigeneration System Powered by the Combustion of Olive Pomace

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Combustion Process Model

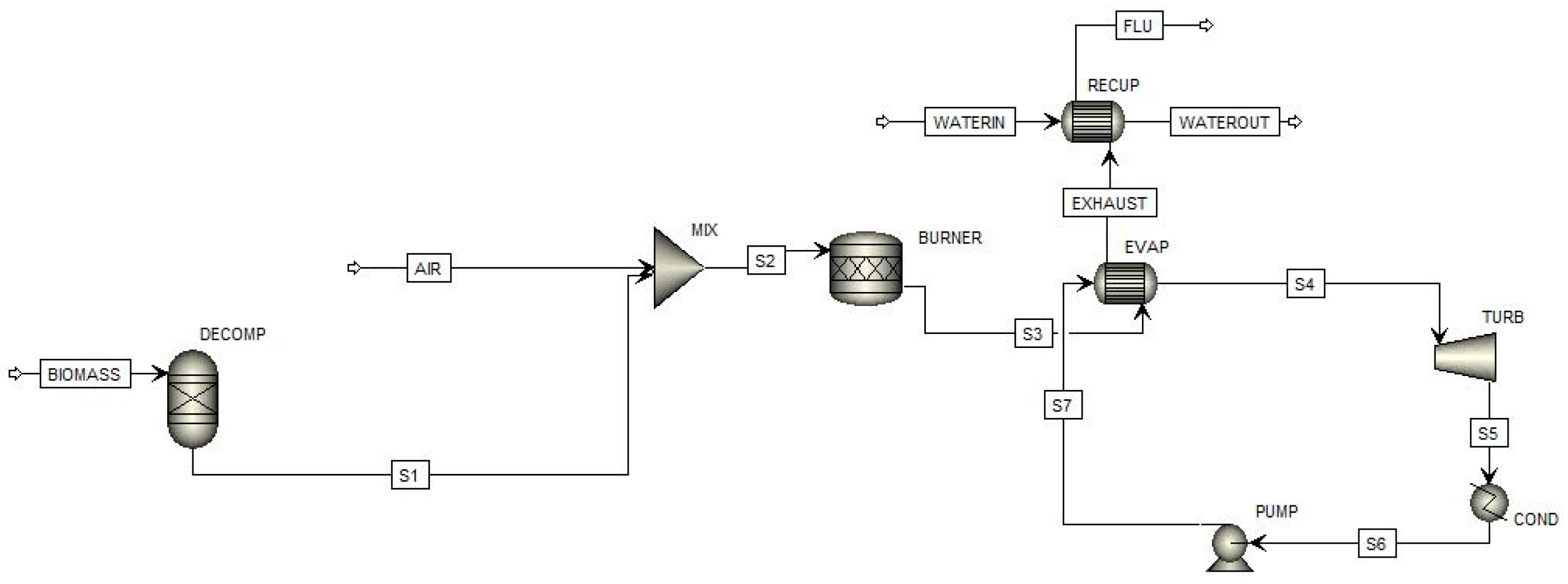

2.3. ORC-Based CCHP System Model

3. Results and Discussion

3.1. Combustion Products

3.2. Mechanical, Thermal and Electrical Efficiencies

3.3. Sensitivity Analysis

3.4. Proposed Scenario

4. Conclusions

- At a national level, considering an olive pomace production ratio of 2250 kg/ha and about 1052000 ha of Italy being occupied with olive trees aimed at oil production in 2017 [42], the energy potential of this energy system would be of 5.9 GWh, 31.1 GWh and 10.7 GWh, corresponding to a 0.286 Mtoe (Million Tonnes of Oil Equivalent) in terms of primary energy, which would give an important contribution to the overall primary energy national production.

- The triple energy could be used within the agricultural chain, representing a virtuous case of distributed generation.

- At a local level, the developed model shows that Cyclopentene is the most highly performing fluid in terms of electricity production, while R245fa is the least.

- The increasing pressure entails an energy benefit in terms of power production and electric efficiency, but the increasing trend is slower at the highest pressures of the considered range.

Author Contributions

Funding

Conflicts of Interest

References

- Marcantonio, V.; De Falco, M.; Capocelli, M.; Bocci, E.; Colantoni, A.; Villarini, M. Process analysis of hydrogen production from biomass gasification in fluidized bed reactor with different separation systems. Int. J. Hydrogen Energy 2019, 44, 10350–10360. [Google Scholar] [CrossRef]

- Villarini, M.; Marcantonio, V.; Colantoni, A.; Bocci, E. Sensitivity Analysis of Different Parameters on the Performance of a CHP Internal Combustion Engine System Fed by a Biomass Waste Gasifier. Energies 2019, 12, 688. [Google Scholar] [CrossRef]

- Rajabi Hamedani, S.; Villarini, M.; Colantoni, A.; Moretti, M.; Bocci, E. Life Cycle Performance of Hydrogen Production via Agro-Industrial Residue Gasification—A Small Scale Power Plant Study. Energies 2018, 11, 675. [Google Scholar] [CrossRef]

- Hamedani Rajabi, S.; Bocci, E.; Villarini, M.; Di Carlo, A.; Naso, V. Techno-economic Analysis of Hydrogen Production Using Biomass Gasification -A Small Scale Power Plant Study. Energy Procedia 2016, 101, 806–813. [Google Scholar] [CrossRef]

- Begum, S.; Rasul, M.G.; Akbar, D.; Ramzan, N. Performance analysis of an integrated fixed bed gasifier model for different biomass feedstocks. Energies 2013, 6, 6508–6524. [Google Scholar] [CrossRef]

- Anifantis, A.S.; Colantoni, A.; Pascuzzi, S. Thermal energy assessment of a small scale photovoltaic, hydrogen and geothermal stand-alone system for greenhouse heating. Renew. Energy 2017, 103, 115–127. [Google Scholar] [CrossRef]

- Büyüktahtakın, E.; Cobuloglu, H.I. Food vs. biofuel: An optimization approach to the spatio-temporal analysis of land-use competition and environmental impacts. Appl. Energy 2015, 140, 418–434. [Google Scholar] [CrossRef]

- Barbanera, M.; Lascaro, E.; Stanzione, V.; Esposito, A.; Altieri, R.; Bufacchi, M. Characterization of pellets from mixing olive pomace and olive tree pruning. Renew. Energy 2016, 88, 185–191. [Google Scholar] [CrossRef]

- Tekin, A.R.; Dalgıç, A.C. Biogas production from olive pomace. Resour. Conserv. Recycl. 2000, 30, 301–313. [Google Scholar] [CrossRef]

- Marco IDe Riemma, S.; Iannone, R. Global Warming Potential Analysis of Olive Pomace Processing. Chem. Eng. Trans. 2017, 57, 601–606. [Google Scholar] [CrossRef]

- Shen, L.; Zhang, D.-K. An experimental study of oil recovery from sewage sludge by low-temperature pyrolysis in a fluidised-bed. Fuel 2003, 82, 465–472. [Google Scholar] [CrossRef]

- Borello, D.; De Caprariis, B.; De Filippis, P.; Di Carlo, A.; Marchegiani, A.; Pantaleo, A.M.; Shah, N.; Venturini, P. Thermo-Economic Assessment of a Olive Pomace Gasifier for Cogeneration Applications. Energy Procedia 2015, 75, 252–258. [Google Scholar] [CrossRef]

- Christoforou, E.; Fokaides, P.A. A review of olive mill solid wastes to energy utilization techniques. Waste Manag. 2016, 49, 346–363. [Google Scholar] [CrossRef] [PubMed]

- Miranda, M.T. Combined combustion of various phases of olive wastes in a conventional combustor. Fuel 2007, 86, 367–372. [Google Scholar] [CrossRef]

- Atimtay, A.T.; Topal, H. Co-combustion of olive cake with lignite coal in a circulating fluidized bed. Fuel 2004, 83, 859–867. [Google Scholar] [CrossRef]

- Varol, M.; Atimtay, A.T. Combustion of olive cake and coal in a bubbling fluidized bed with secondary air injection. Fuel 2007, 86, 1430–1438. [Google Scholar] [CrossRef]

- Caputo, A.C.; Palumbo, M.; Pelagagge, P.M.; Scacchia, F. Economics of biomass energy utilization in combustion and gasification plants: Effects of logistic variables. Biomass Bioenergy 2005, 28, 35–51. [Google Scholar] [CrossRef]

- Celma, A.R.; Rojas, S.; López-Rodríguez, F. Waste-to-energy possibilities for industrial olive and grape by-products in Extremadura. Biomass Bioenergy 2007, 31, 522–534. [Google Scholar] [CrossRef]

- Celma, A.R.; Rojas, S.; López, F.; Montero, I.; Miranda, T. Thin-layer drying behaviour of sludge of olive oil extraction. J. Food Eng. 2007, 80, 1261–1271. [Google Scholar] [CrossRef]

- Monarca, D.; Cecchini, M.; Colantoni, A.; Marucci, A. Feasibility of the Electric Energy Production through Gasification Processes of Biomass: Technical and Economic Aspects. In Proceedings of the International Conference on Computational Science and Its Applications, Santander, Spain, 20–23 June 2011. [Google Scholar]

- Guo, C.; Du, X.; Yang, L.; Yang, Y. Performance analysis of organic Rankine cycle based on location of heat transfer pinch point in evaporator. Appl. Therm. Eng. 2014, 62, 176–186. [Google Scholar] [CrossRef]

- Saadatfar, B.; Fakhrai, R.; Fransson, T. Conceptual modeling of nano fluid ORC for solar thermal polygeneration. Energy Procedia 2014, 57, 2696–2705. [Google Scholar] [CrossRef]

- Liu, H.; Shao, Y.; Li, J. A biomass-fired micro-scale CHP system with organic Rankine cycle (ORC)-Thermodynamic modelling studies. Biomass Bioenergy 2011, 35, 3985–3994. [Google Scholar] [CrossRef]

- Wang, J.; Diao, M.; Yue, K. Optimization on pinch point temperature difference of ORC system based on AHP-Entropy method. Energy 2017, 141, 97–107. [Google Scholar] [CrossRef]

- Cataldo, F.; Mastrullo, R.; Mauro, A.W.; Vanoli, G.P. Fluid selection of Organic Rankine Cycle for low-temperature waste heat recovery based on thermal optimization. Energy 2014, 72, 159–167. [Google Scholar] [CrossRef]

- Collings, P.; Yu, Z.; Wang, E. A dynamic organic Rankine cycle using a zeotropic mixture as the working fluid with composition tuning to match changing ambient conditions. Appl. Energy 2016, 171, 581–591. [Google Scholar] [CrossRef]

- Chen, T.; Zhuge, W.; Zhang, Y.; Zhang, L. A novel cascade organic Rankine cycle (ORC) system for waste heat recovery of truck diesel engines. Energy Convers. Manag. 2017, 138, 210–223. [Google Scholar] [CrossRef]

- TERNA. Consumi Energia Elettrica Per Settore Merceologico Italia. Available online: https://www.terna.it/it-it/sistemaelettrico/statisticheeprevisioni/consumienergiaelettricapersettoremerceologico.aspx (accessed on 22 April 2019).

- Colonna N (ENEA). Valorizzazione energetica dei residui agroindustriali per produrre energia a servizio delle filiere agroalimentari, tra tecnologie ed efficienza energetica. Agriregionieuropa. 2014. Available online: https://www.eimaenergy.it/pdf/Colonna-15novembre.pdf (accessed on 22 April 2019).

- International Organization for Standardization. ISO 18134-1:2015-Solid Biofuels-Determination of Moisture Content -Oven Dry Method-Part 1: Total Moisture–Reference Method. Available online: https://www.iso.org/standard/61538.html (accessed on 22 May 2019).

- International Organization for Standardization. ISO 18122:2015-Solid Biofuels-Determination of Ash Content. Available online: https://www.iso.org/standard/61515.html (accessed on 22 May 2019).

- ISO 16948:2015-Olid Biofuels-Determination of Total Content of Carbon, Hydrogen and Nitrogen. Available online: https://www.iso.org/standard/58004.html (accessed on 22 May 2019).

- Channiwala, S.A.; Parikh, P.P. A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel 2002, 81, 1051–1063. [Google Scholar] [CrossRef]

- Ye, G.; Xie, D.; Qiao, W.; Grace, J.R.; Lim, C.J. Modeling of fluidized bed membrane reactors for hydrogen production from steam methane reforming with Aspen Plus. Int. J. Hydrogen Energy 2009, 34, 4755–4762. [Google Scholar] [CrossRef]

- Lv, P.; Xiong, Z.; Chang, J.; Wu, C.; Chen, Y.; Zhu, J. An experimental study on biomass air–steam gasification in a fluidized bed. Bioresour. Technol. 2004, 95, 95–101. [Google Scholar] [CrossRef]

- Sadaka, S.S.; Ghaly, A.E.; Sabbah, M.A. Two phase biomass air-steam gasification model for fluidized bed reactors: Part I—Model Development. Biomass Bioenergy 2002, 22, 439–462. [Google Scholar] [CrossRef]

- Demirbaş, A. Carbonization ranking of selected biomass for charcoal, liquid and gaseous products. Energy Convers. Manag. 2001, 42, 1229–1238. [Google Scholar] [CrossRef]

- Yang, X.; Liu, B.; Song, W.; Lin, W. Process simulation of emission and control for NO and N2O during coal combustion in a circulating fluidized bed combustor based on Aspen Plus. Energy Fuels 2011, 25, 3718–3730. [Google Scholar] [CrossRef]

- Rajabloo, T.; Iora, P.; Invernizzi, C. Mixture of working fluids in ORC plants with pool boiler evaporator. Appl. Therm. Eng. 2016, 98, 1–9. [Google Scholar] [CrossRef]

- Wieland, C.; Meinel, D.; Eyerer, S.; Spliethoff, H. Innovative CHP concept for ORC and its benefit compared to conventional concepts. Appl. Energy 2016, 183, 478–490. [Google Scholar] [CrossRef]

- Decree 412/93. 1993. Available online: http://www.gazzettaufficiale.it/eli/id/1993/10/14/093G0451/sg (accessed on 29 September 2017).

- ISTAT. Tavola C27: Superficie (ettari) e produzione (quintali): Olivo, olive da tavola, olive da olio, olio di pressione. Dettaglio per Ripartizione Geografica –Anno. 2017. Available online: http://agri.istat.it/jsp/dawinci.jsp?q=plC270000010000011000&an=2017&ig=1&ct=311&id=15A%7C21A%7C30A%7C32A (accessed on 26 May 2019).

| Biomass | Proximate Analysis (%wt, Dry Basis) | Ultimate Analysis (%wt, Dry Basis) | LHV (MJ/kg) | HHV (MJ/kg) | Moisture (%wet) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ash | Volatile Matter | Fixed Carbon | C | H | N | O | |||||

| S1 | OP surface 1st stage | 2.9 | 78.1 | 19 | 50.86 | 8.22 | 1.20 | 36.82 | 21.86 | 23.55 | 18.00 |

| S2 | 25 cm OP depth 1st stage | 3.3 | 77.9 | 18.8 | 51.96 | 8.49 | 1.46 | 34.79 | 22.71 | 24.45 | 19.00 |

| S3 | OP surface, 3rd stage | 3.8 | 77.6 | 18.6 | 52.90 | 8.94 | 2.54 | 31.82 | 23.75 | 25.59 | 14.6 |

| S4 | OP surface, 3rd stage | 3.6 | 77.7 | 18.7 | 58.28 | 8.92 | 2.35 | 26.85 | 26.13 | 27.97 | 17.4 |

| S5 | 25 cm OP depth, 3rd stage | 3.5 | 77.6 | 18.9 | 56.73 | 8.13 | 2.92 | 28.72 | 24.62 | 26.30 | 16.8 |

| Aspen Plus Name | Block ID | Description |

|---|---|---|

| RYIELD | DECOMP | Yield reactor—converts the non-conventional stream “BIOMASS” into its conventional components |

| MIXER | MIX | Mixer—mixes oxidising fluid with S1 stream, which represents combustible fluid |

| RSTOIC | BURNER | Rstoic reactor—simulates the combustion process |

| HEATX | EVAP | HeatX—represents the evaporator of the ORC |

| - | RECUP | HeatX—heats up the temperature of the water until the utilisation level is reached |

| TURBINE | TURB | Turbine—represents the turbine of the ORC |

| HEATER | COND | Heater—represents the condenser of the ORC |

| PUMP | PUMP | Pump—represents the pump of the ORC |

| Heat source temperature (°C) | 500 |

| Heat source mass flow rate (kg/h) | 200 |

| Isentropic efficiency of turbine | 0.85 |

| Mechanical efficiency of turbine | 0.75 |

| Isentropic efficiency of pump | 0.80 |

| Working Fluid | Fluid Type | Condensing Pressure at 30 °C (bar) | Critical Temperature (°C) | Critical Pressure (bar) | ODP |

|---|---|---|---|---|---|

| R245fa | Isentropic | 1.77 | 154.29 | 36.50 | 0 |

| R245ca | Isentropic/dry | 1.21 | 174.58 | 39.30 | 0 |

| Cyclobutane | Isentropic | 1.83 | 187.05 | 49.88 | 0 |

| Cyclopentene | Isentropic/dry | 0.61 | 234.11 | 48.05 | 0 |

| ppump (bar) | R245fa | R245ca | Cyclobutene | Cyclopentene | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 30 | 20 | 30 | 20 | 30 | 40 | 20 | 30 | 40 | |

| Qexhaust (kWth) | 65.41 | 65.22 | 61.91 | 61.20 | 64.00 | 63.20 | 63.00 | 61.00 | 59.30 | 59.00 |

| ΔPpump (kW) | 0.21 | 0.31 | 0.19 | 0.28 | 0.37 | 0.57 | 0.78 | 0.36 | 0.56 | 0.75 |

| Pexpansion (kW) | 3.62 | 4.01 | 4.52 | 5.01 | 4.33 | 5.00 | 5.30 | 5.92 | 6.51 | 6.93 |

| Pel (kWe) | 3.41 | 3.80 | 4.30 | 4.85 | 4.17 | 4.85 | 5.12 | 5.72 | 6.30 | 6.68 |

| ηmecc | 13.10% | 14.51% | 14.34% | 15.60% | 14.91% | 16.72% | 17.80% | 17.80% | 19.00% | 20.00% |

| ηtherm | 70.30% | 70.00% | 66.60% | 65.81% | 68.81% | 68.00% | 68.00% | 65.00% | 63.70% | 63.52% |

| ηel | 12.77% | 14.10% | 13.93% | 15.12% | 14.41% | 16.20% | 17.20% | 17.20% | 18.40% | 19.40% |

| Working Fluid | R245fa | R245ca | Cyclobutene | Cyclopentene | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ppump (bar) | 20 | 30 | 20 | 30 | 20 | 30 | 40 | 20 | 30 | 40 |

| Qexhaust (kWth) | 65.41 | 65.22 | 61.91 | 61.2 | 64 | 63.2 | 63 | 61 | 59.3 | 59 |

| Qchiller_feeding (kWth) | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| Pcooling (kWe) | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 |

| Qheat_use (kWth) | 15.41 | 15.22 | 11.91 | 11.2 | 14 | 13.20 | 13 | 11 | 9.30 | 9 |

| Wwater (kg/h) | 205 | 202 | 159 | 149 | 186 | 176 | 173 | 146 | 124 | 120 |

| Working Fluid | R245fa | R245ca | Cyclobutene | Cyclopentene | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ppump (bar) | 20 | 30 | 20 | 30 | 20 | 30 | 40 | 20 | 30 | 40 |

| Qexhaust (kWth) | 65.41 | 65.22 | 61.91 | 61.20 | 64 | 63.20 | 63 | 61 | 59.30 | 59 |

| Wwater (kg/h) | 870 | 868 | 824 | 815 | 852 | 841 | 838 | 812 | 789 | 785 |

| ppump (bar) | R245fa | R245ca | Cyclobutene | Cyclopentene | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 30 | 20 | 30 | 20 | 30 | 40 | 20 | 30 | 40 | |

| Electric energy (MWhe) | 17 | 19 | 22 | 24 | 21 | 24 | 26 | 29 | 32 | 33 |

| Thermal Energy (MWhth) | 195 | 194 | 180 | 177 | 189 | 185 | 184 | 176 | 169 | 167 |

| Cooling Energy (MWhe) | 58 | 58 | 58 | 58 | 58 | 58 | 58 | 58 | 58 | 58 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colantoni, A.; Villarini, M.; Marcantonio, V.; Gallucci, F.; Cecchini, M. Performance Analysis of a Small-Scale ORC Trigeneration System Powered by the Combustion of Olive Pomace. Energies 2019, 12, 2279. https://doi.org/10.3390/en12122279

Colantoni A, Villarini M, Marcantonio V, Gallucci F, Cecchini M. Performance Analysis of a Small-Scale ORC Trigeneration System Powered by the Combustion of Olive Pomace. Energies. 2019; 12(12):2279. https://doi.org/10.3390/en12122279

Chicago/Turabian StyleColantoni, Andrea, Mauro Villarini, Vera Marcantonio, Francesco Gallucci, and Massimo Cecchini. 2019. "Performance Analysis of a Small-Scale ORC Trigeneration System Powered by the Combustion of Olive Pomace" Energies 12, no. 12: 2279. https://doi.org/10.3390/en12122279

APA StyleColantoni, A., Villarini, M., Marcantonio, V., Gallucci, F., & Cecchini, M. (2019). Performance Analysis of a Small-Scale ORC Trigeneration System Powered by the Combustion of Olive Pomace. Energies, 12(12), 2279. https://doi.org/10.3390/en12122279