Adsorption Capacity of Organic Compounds Using Activated Carbons in Zinc Electrowinning

Abstract

1. Introduction

2. Materials and Methods

2.1. Adsorbate

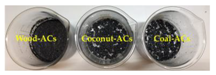

2.2. Activated Carbons (ACs) as Adsorbents

2.3. Adsorption Test

2.4. Adsorbate Analysis

2.4.1. n-Hexane Extraction

2.4.2. Total Organic Carbon (TOC)

2.5. Characterization of Electrodes

3. Results and Discussion

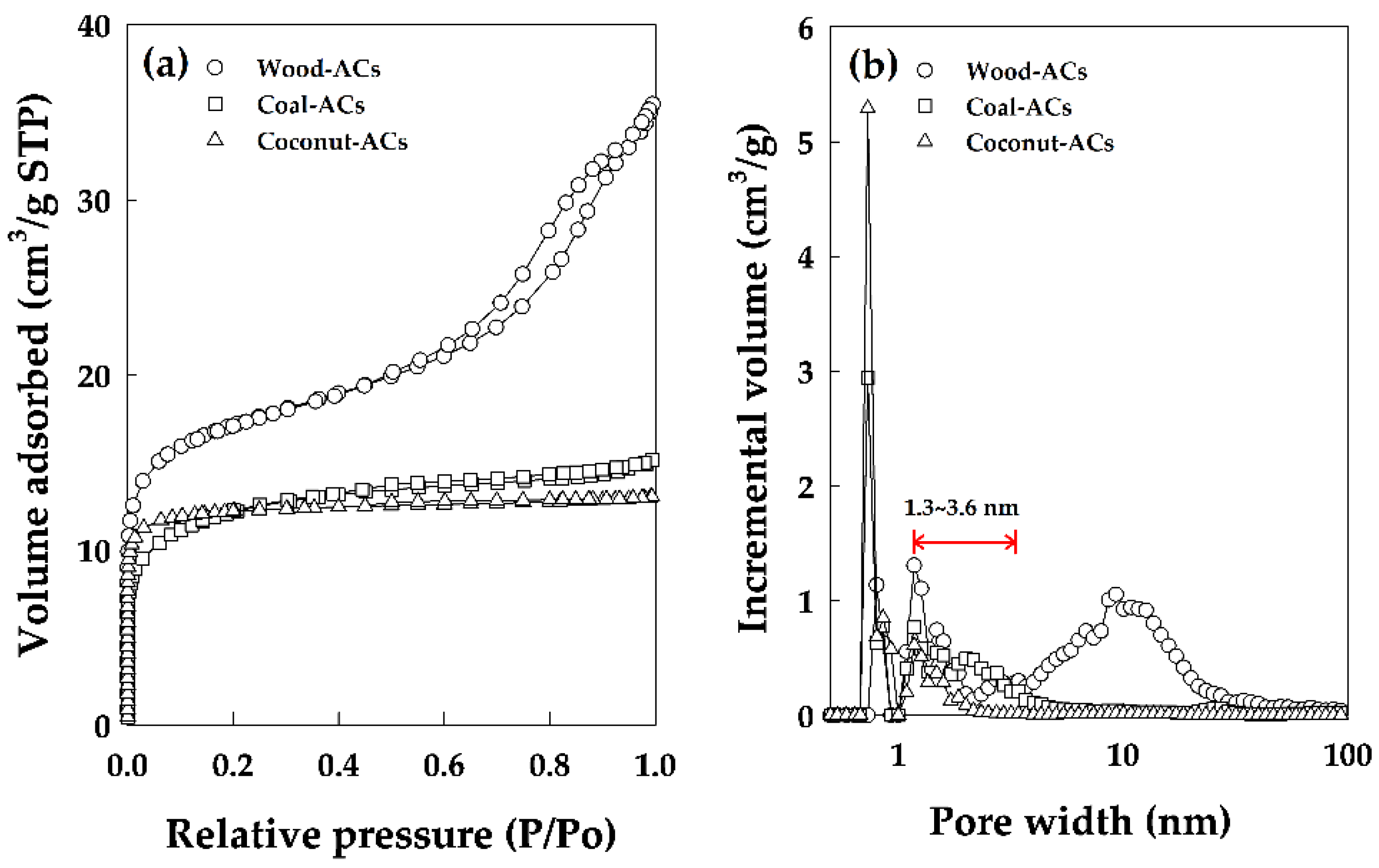

3.1. Characterization of ACs

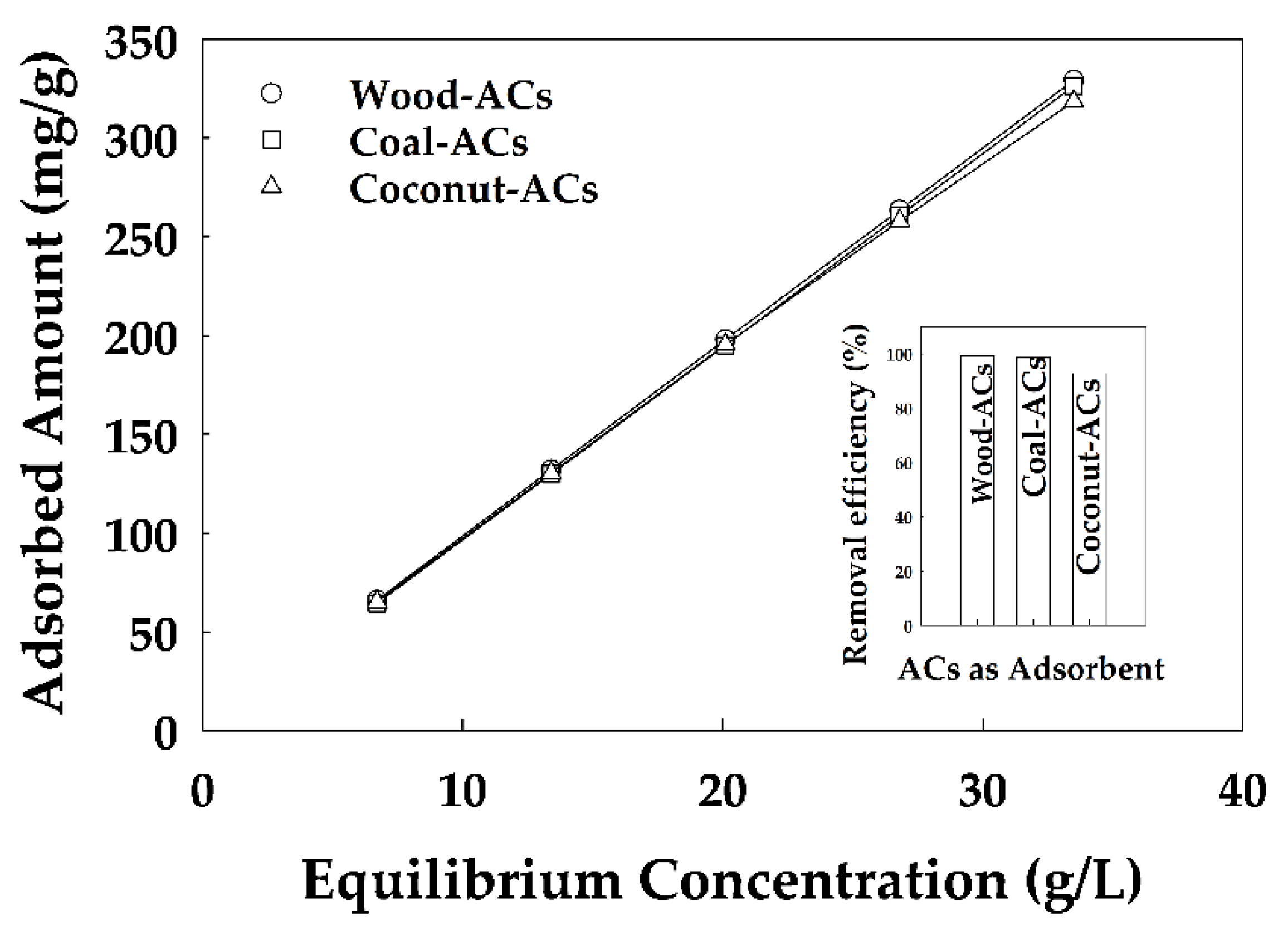

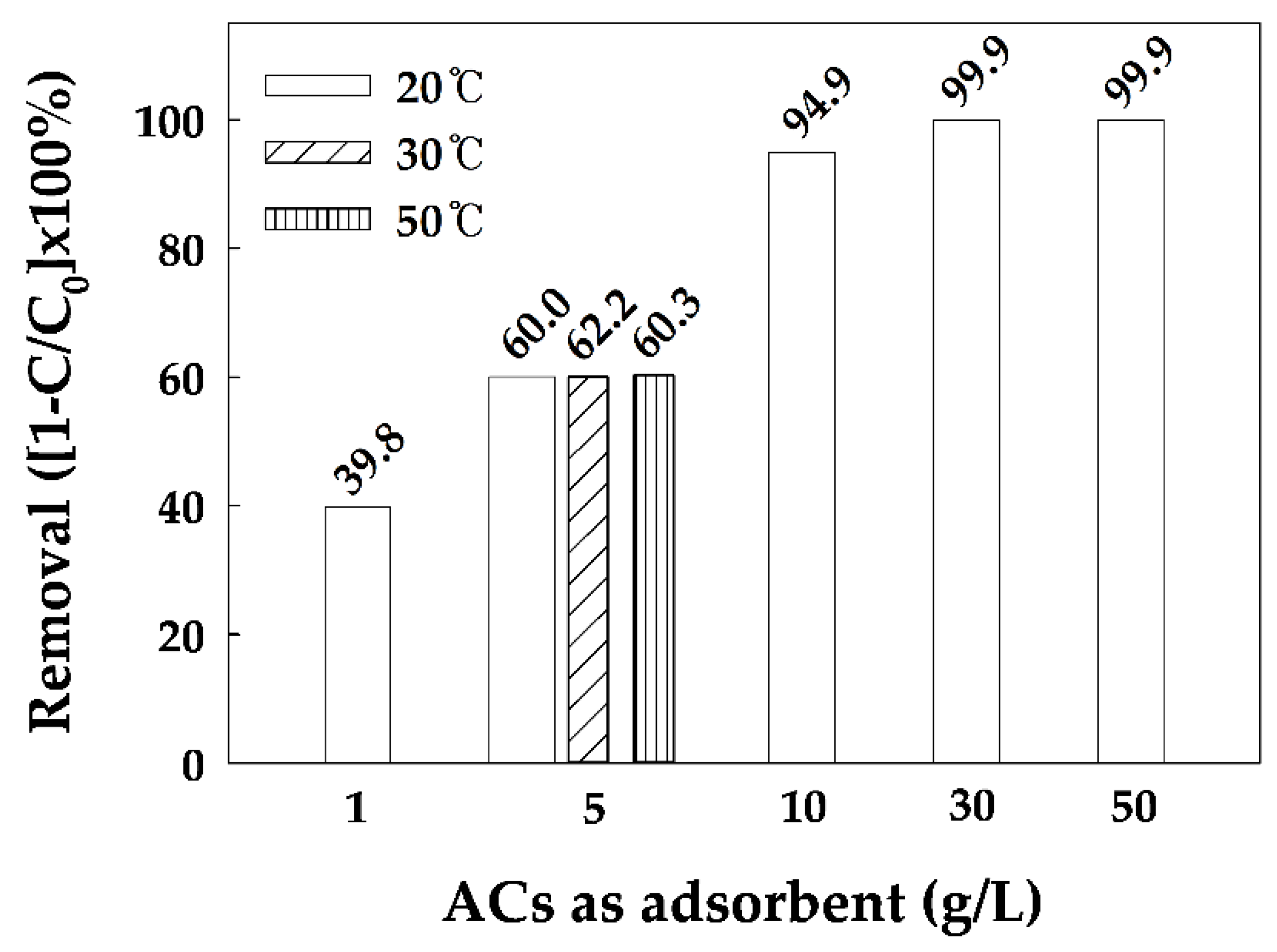

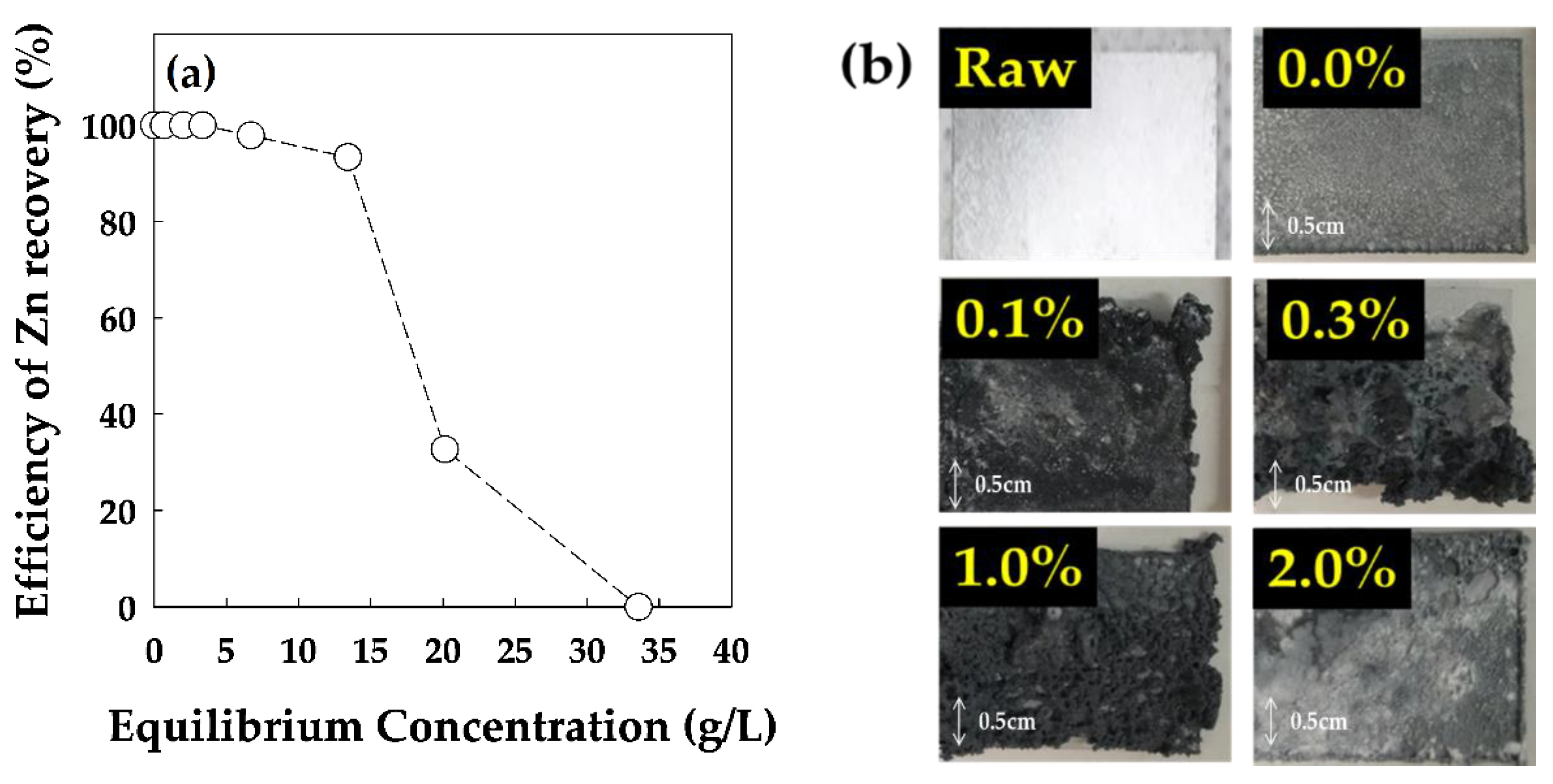

3.2. Adsorbate Removal Efficiency

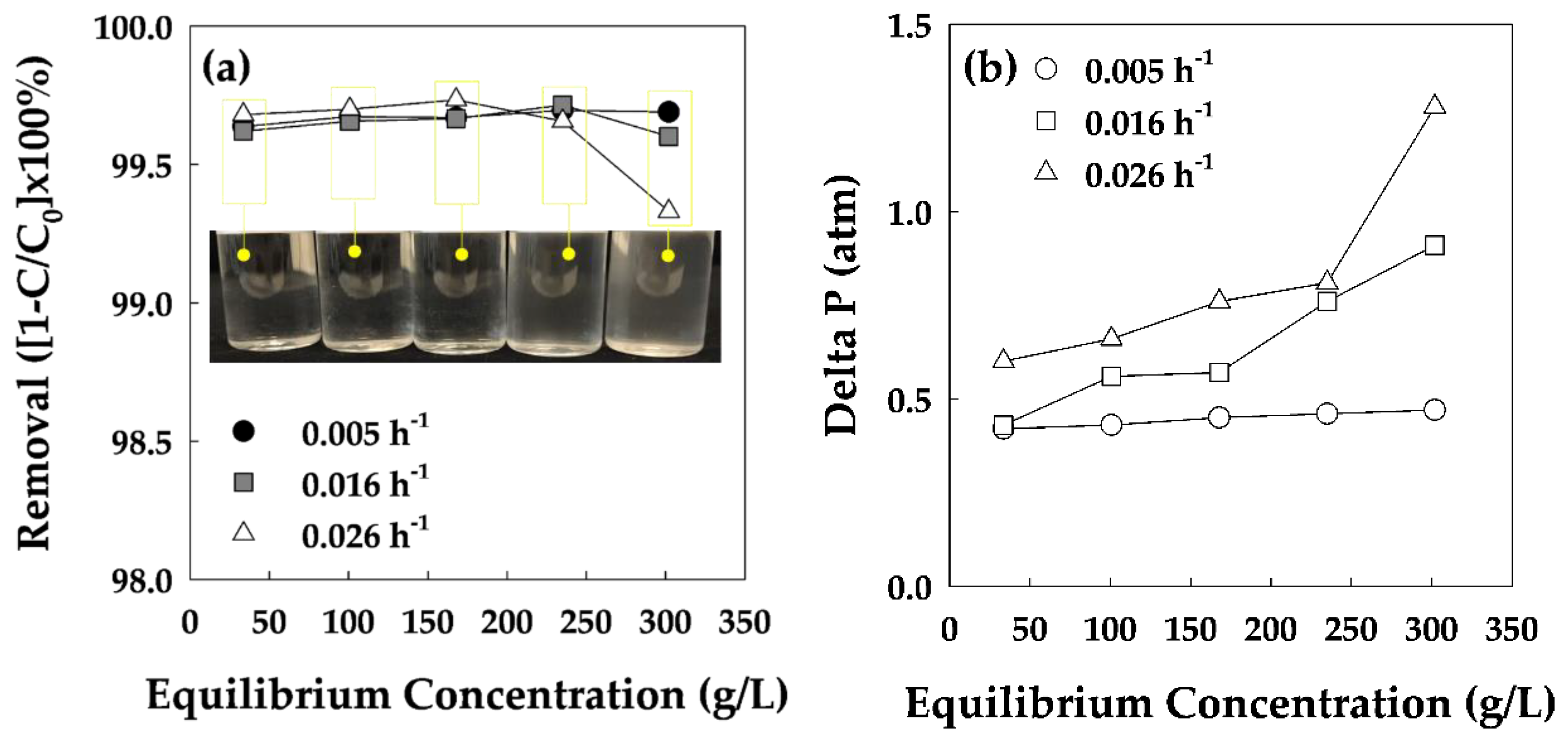

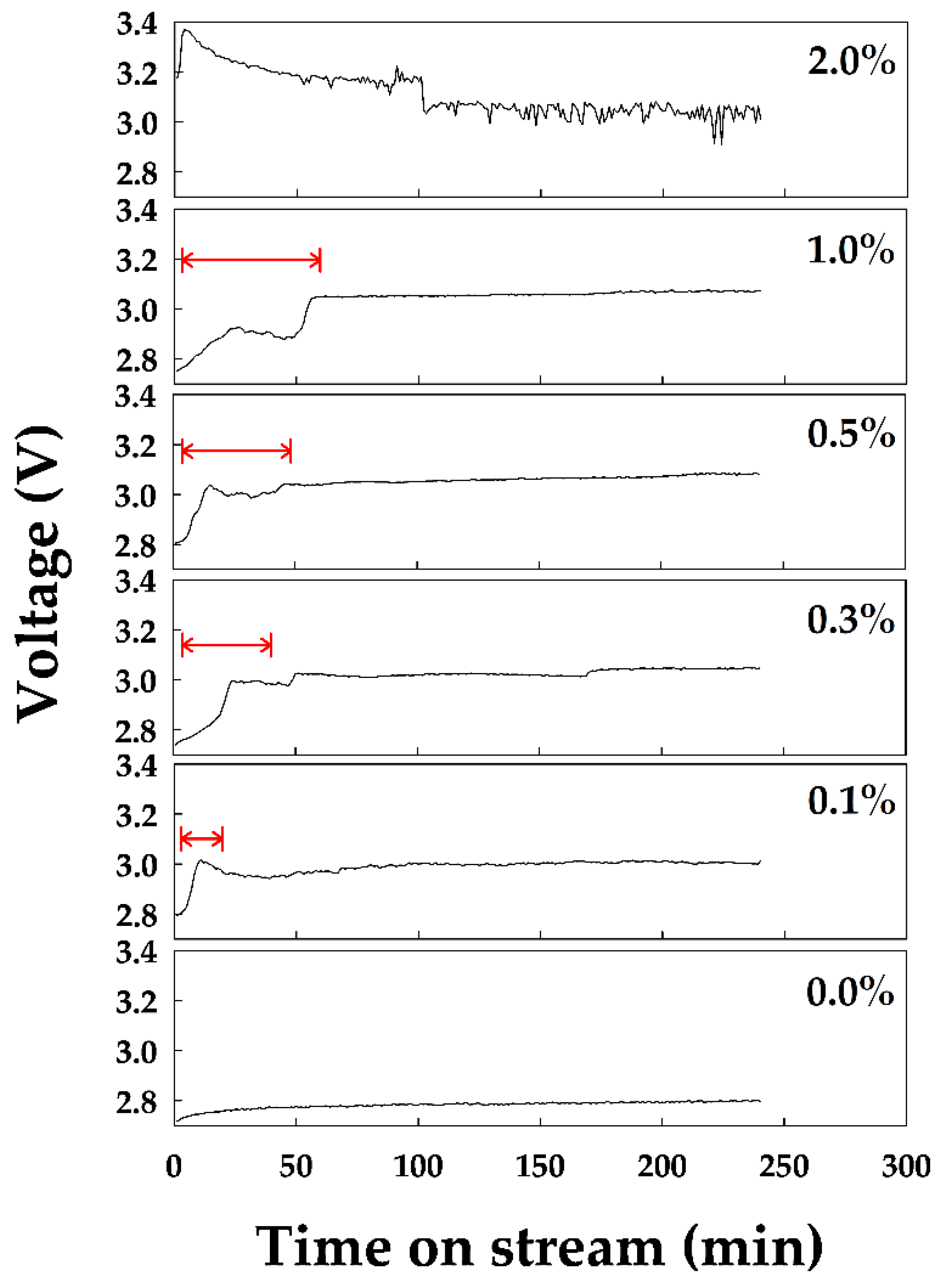

3.3. Zn Electrowinning Test

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gladysz, O.; Los, P.; Krzyzak, E. Influence of concentrations of copper, leveling agents and temperature on the diffusion coefficient of cupric ions in industrial electro-refining electrolytes. J. Appl. Electrochem. 2007, 37, 1093–1097. [Google Scholar] [CrossRef]

- Moats, M.; Free, M. A bright future for copper electrowinning. JOM 2007, 59, 34–36. [Google Scholar] [CrossRef]

- Alfantazi, A.; Valic, D. A study of copper electrowinning parameters using a statistically designed methodology. J. Appl. Electrochem. 2003, 33, 217–225. [Google Scholar] [CrossRef]

- Xue, J.; Wu, Q.; Wang, Z. Function of additives in electrolytic preparation of copper powder. Hydrometallurgy 2006, 82, 154–156. [Google Scholar] [CrossRef]

- Muresan, L.; Nicoara, A.; Varvara, S. Influence of Zn2+ ions on copper electrowinning from sulfate electrolytes. J. Appl. Electrochem. 1999, 29, 719–727. [Google Scholar] [CrossRef]

- Cole, P.M.; Sole, K.C. Zinc solvent extraction in the process industries. Miner. Process. Extr. Metall. Rev. 2003, 24, 91–137. [Google Scholar] [CrossRef]

- Zhu, Z.; Cheng, C.Y. A study on zinc recovery from leach solutions using Ionquest 801 and its mixture with D2EHPA. Miner. Eng. 2012, 39, 117–123. [Google Scholar] [CrossRef]

- Jha, M.K.; Gupta, D.; Choubey, P.K.; Kumar, V.; Jeong, J.; Lee, J. Solvent extraction of copper, zinc, cadmium and nickel from sulfate solution in mixer settler unit (MSU). Sep. Purif. Technol. 2014, 122, 119–127. [Google Scholar] [CrossRef]

- Daryabor, M.; Ahmadi, A.; Zilouei, H. Solvent extraction of cadmium and zinc from sulphate solutions: Comparison of mechanical agitation and ultrasonic irradiation. Ultrason. Sonochem. 2017, 34, 931–937. [Google Scholar] [CrossRef]

- Verbeken, K.; Verhaege, M.; Wettinck, E. Separation of iron from zinc sulfate electrolyte by combined liquid-liquid extraction and electroreductive stripping. In Lead-Zinc 2000; Dutrizac, J.E., Gonzalez, J.A., Henke, D.M., James, S.E., Siegmund, A.H.-J., Eds.; The Minerals, Metals & Materials Society: Warrendale, PA, USA, 2013; pp. 779–788. [Google Scholar] [CrossRef]

- Devi, N.B.; Nathsarma, K.C.; Chakravortty, V. Solvent extraction of zinc(II) using sodium salts of D2EHPA, PC88A and Cyanex 272 in kerosene. In Proceedings of the Mineral Processing: Recent Advances and Future Trends, Indian Institute of Technology, Kanpur, India, 11–15 December 1995; Mehrotra, S.P., Rajiv, S., Eds.; Volume 11–15, pp. 537–547. [Google Scholar]

- Jha, M.K.; Kumar, V.; Jeong, J.; Lee, J. Review on solvent extraction of cadmium from various solutions. Hydrometallurgy 2012, 111–112, 1–9. [Google Scholar] [CrossRef]

- Deep, A.; de Carvalho, J.M.R. Review on the Recent Developments in the Solvent Extraction of Zinc. Solvent Extr. Ion Exch. 2008, 26, 375–404. [Google Scholar] [CrossRef]

- Nathsarma, K.C.; Devi, N.B. Separation of Zn(II) and Mn(II) from sulphate solutions using sodium salts of D2EHPA, PC88A and Cyanex 272. Hydrometallurgy 2006, 84, 149–154. [Google Scholar] [CrossRef]

- Asadi, T.; Azizi, A.; Lee, J.; Jahani, M. Solvent extraction of zinc from sulphate leaching solution of a sulphide-oxide sample using D2EHPA and Cyanex 272. J. Dispers. Sci. Technol. 2017, 39, 1328–1334. [Google Scholar] [CrossRef]

- Mellah, A.; Benachour, D. The solvent extraction of zinc and cadmium from phosphoric acid solution by di-2-ethyl hexyl phosphoric acid in kerosene diluent. Chem. Eng. Process. 2006, 45, 684–690. [Google Scholar] [CrossRef]

- Dhak, D.; Asselin, E.; Carlo, S.D.; Alfantazi, A. An investigation on the effects of organic additives on zinc electrowinning from industrial electrolyte. ECS Trans. 2010, 28, 267–280. [Google Scholar] [CrossRef]

- Ivanov, I. Increased current efficiency of zinc electrowinning in the presence of metal impurities by addition of organic inhibitors. Hydrometallurgy 2004, 72, 73–78. [Google Scholar] [CrossRef]

- Moreno-Castilla, C. Adsorption of organic molecules from aqueous solutions on carbon materials. Carbon 2004, 42, 83–94. [Google Scholar] [CrossRef]

- Apul, O.G.; Karanfil, T. Adsorption of synthetic organic contaminants by carbon nanotubes: A critical review. Water Res. 2014, 68, 34–55. [Google Scholar] [CrossRef]

- Zhang, S.; Shao, T.; Bekaroglu, S.S.K.; Karanfil, T. Adsorption of synthetic organic chemicals by carbon nanotubes: Effects of background solution chemistry. Water Res. 2010, 44, 2067–2074. [Google Scholar] [CrossRef]

- Quinlivan, P.A.; Li, L.; Knappe, D.R.U. Effects of activated carbon characteristics on the simultaneous adsorption of aqueous organic micropollutants and natural organic matter. Water Res. 2005, 39, 1663–1673. [Google Scholar] [CrossRef]

- Park, J.E.; Yang, S.K.; Kim, J.H.; Park, M.-J.; Lee, E.S. Electrocatalytic activity of Pd/Ir/Sn/Ta/TiO2 composite electrodes. Energies 2018, 11, 3356. [Google Scholar] [CrossRef]

- Dora, S.K. Real time recrystallization study of 1, 2dodecanediol on highly oriented pyrolytic graphite (HOPG) by tapping mode atomic force microscopy. WJNSE 2017, 7, 1–15. [Google Scholar] [CrossRef][Green Version]

- Lu, J.R.; Thomas, R.K.; Binks, B.P.; Fletcher, P.D.I.; Penfold, J. Structure and composition of dodecane layers spread on aqueous solutions of dodecyland hexadecyltrimethylammonium bromides studied by neutron reflection. J. Phys. Chem. 1995, 99, 4113–4123. [Google Scholar] [CrossRef]

- Pendleton, P.; Wu, S.H.; Badalyan, A. Activated carbon oxygen content influence on water and surfactant adsorption. J. Colloid Interface Sci. 2002, 246, 235–240. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-H.; Wu, S.H.; Pendleton, P. Effect of surface properties of activated carbons on surfactant adsorption kinetics. Korean J. Chem. Eng. 2005, 22, 705–711. [Google Scholar] [CrossRef]

- Fendleton, P.; Wong, S.H.; Schumann, R.; Levay, G.; Denoyel, R.; Rouquerol, J. Properties of activated carbon controlling 2-methylisoborneol adsorption. Carbon 1997, 35, 1141–1149. [Google Scholar] [CrossRef]

- Nam, S.-W.; Choi, D.-J.; Kim, S.-K.; Herc, N.; Zoh, K.-D. Adsorption characteristics of selected hydrophilic and hydrophobic micropollutants in water using activated carbon. J. Hazard. Mater. 2014, 270, 144–152. [Google Scholar] [CrossRef] [PubMed]

- Tomul, F.; Arslan, Y.; Basoglu, F.T.; Babuccuoglu, Y.; Tran, H.N. Efficient removal of anti-inflammatory from solution by Fe-containing activated carbon: Adsorption kinetics, isotherms, and thermodynamics. J. Environ. Manag. 2019, 238, 296–306. [Google Scholar] [CrossRef]

- Majuste, D.; Bubani, F.C.; Bolmaro, R.E.; Martins, E.L.C.; Cetlin, P.R.; Ciminelli, V.S.T. Effect of organic impurities on the morphology and crystallographic texture of zinc electrodeposits. Hydrometallurgy 2017, 169, 330–338. [Google Scholar] [CrossRef]

| Adsorbents | Wood-AC | Coal-AC | Coconut-AC | |

|---|---|---|---|---|

| Raw Material | Wood | Coal | Coconut | |

| Surface Area (m2/g) | 1398 | 1030 | 1067 | |

| Total Pore volume (m3/g) | 1.19 | 0.52 | 0.45 | |

| Micropore size (A) | 6.56 | 6.16 | 5.38 | |

| Proximate analysis (wt.%) | Moisture | 0.18 | 0.18 | 0.72 |

| Volatile | 2.24 | 2.24 | 2.52 | |

| Fixed Carbon | 72.70 | 88.62 | 94.28 | |

| Ash | 20.90 | 8.96 | 2.48 | |

| Ultimate analysis (wt.%) | Carbon | 68.8 | 88.2 | 94.2 |

| Hydrogen | 1.0 | 0.4 | 0.4 | |

| Oxygen | 15.7 | 0.5 | 2.3 | |

| Nitrogen | 0.3 | 0.3 | 2.0 | |

| Sulphur | 0.1 | 0.0 | 0.0 | |

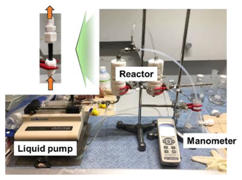

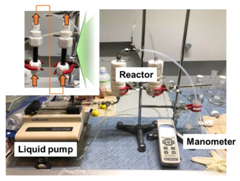

| Reactor | Ideal Scheme | Real Scheme |

|---|---|---|

| (a) Continuous Stirred Tank Reactor (CSTR) |  |  |

| Reaction condition | Adsorbent: Three types of activated carbons (ACs), Temperature: 20 °C~50 °C, Adsorbate: 2 M D2EPHA in Kerosene, Solvent: Adsorbate in 3 M H2SO4, Stirring: 1 h at 300 rpm | |

| (b) 1-Packed Bed Reactor (1PBR) |  |  |

| Reaction condition | Adsorbent: Three types of ACs, Temperature: 20 °C, Adsorbate: 2 M D2EPHA in Kerosene, Solvent: Adsorbate in H2SO4 (pH 2.2~2.3) | |

| (c) 2-Packed Bed Reactor (2PBR) |  |  |

| Reaction condition | Adsorbent: Wood-ACs, Temperature: 20 °C, Adsorbate: 2 M D2EPHA in Kerosene, Solvent: Adsorbate in H2SO4 (pH 2.2~2.3) | |

| Adsorbents | Wood-ACs | Coal-ACs | Coconut-ACs | |

|---|---|---|---|---|

| Removal efficiency (%) | N-Hexane 1 | 99.76 | 98.83 | 92.81 |

| Ave. TOC 2 | 98.29 | 97.45 | 95.10 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.E.; Kim, E.J.; Park, M.-J.; Lee, E.S. Adsorption Capacity of Organic Compounds Using Activated Carbons in Zinc Electrowinning. Energies 2019, 12, 2169. https://doi.org/10.3390/en12112169

Park JE, Kim EJ, Park M-J, Lee ES. Adsorption Capacity of Organic Compounds Using Activated Carbons in Zinc Electrowinning. Energies. 2019; 12(11):2169. https://doi.org/10.3390/en12112169

Chicago/Turabian StylePark, Jung Eun, Eun Ju Kim, Mi-Jung Park, and Eun Sil Lee. 2019. "Adsorption Capacity of Organic Compounds Using Activated Carbons in Zinc Electrowinning" Energies 12, no. 11: 2169. https://doi.org/10.3390/en12112169

APA StylePark, J. E., Kim, E. J., Park, M.-J., & Lee, E. S. (2019). Adsorption Capacity of Organic Compounds Using Activated Carbons in Zinc Electrowinning. Energies, 12(11), 2169. https://doi.org/10.3390/en12112169