Optimization of Safety Stock under Controllable Production Rate and Energy Consumption in an Automated Smart Production Management

Abstract

1. Introduction

2. Problem Definition, Notation, and Assumptions

2.1. Problem Definition

2.2. Assumptions

- A smart production management is considered for single-type of products production under a controllable production rate and the optimum energy consumption.

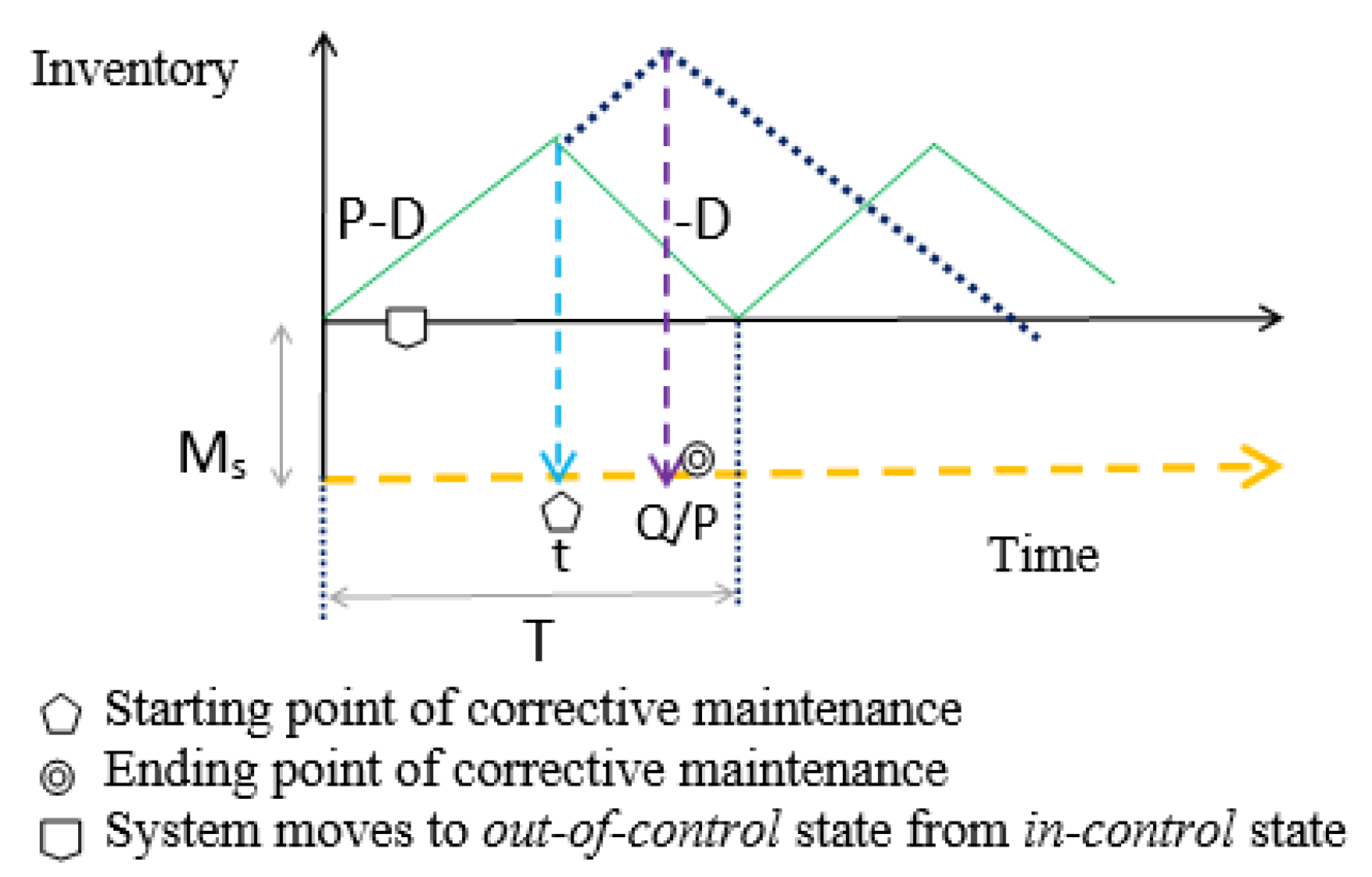

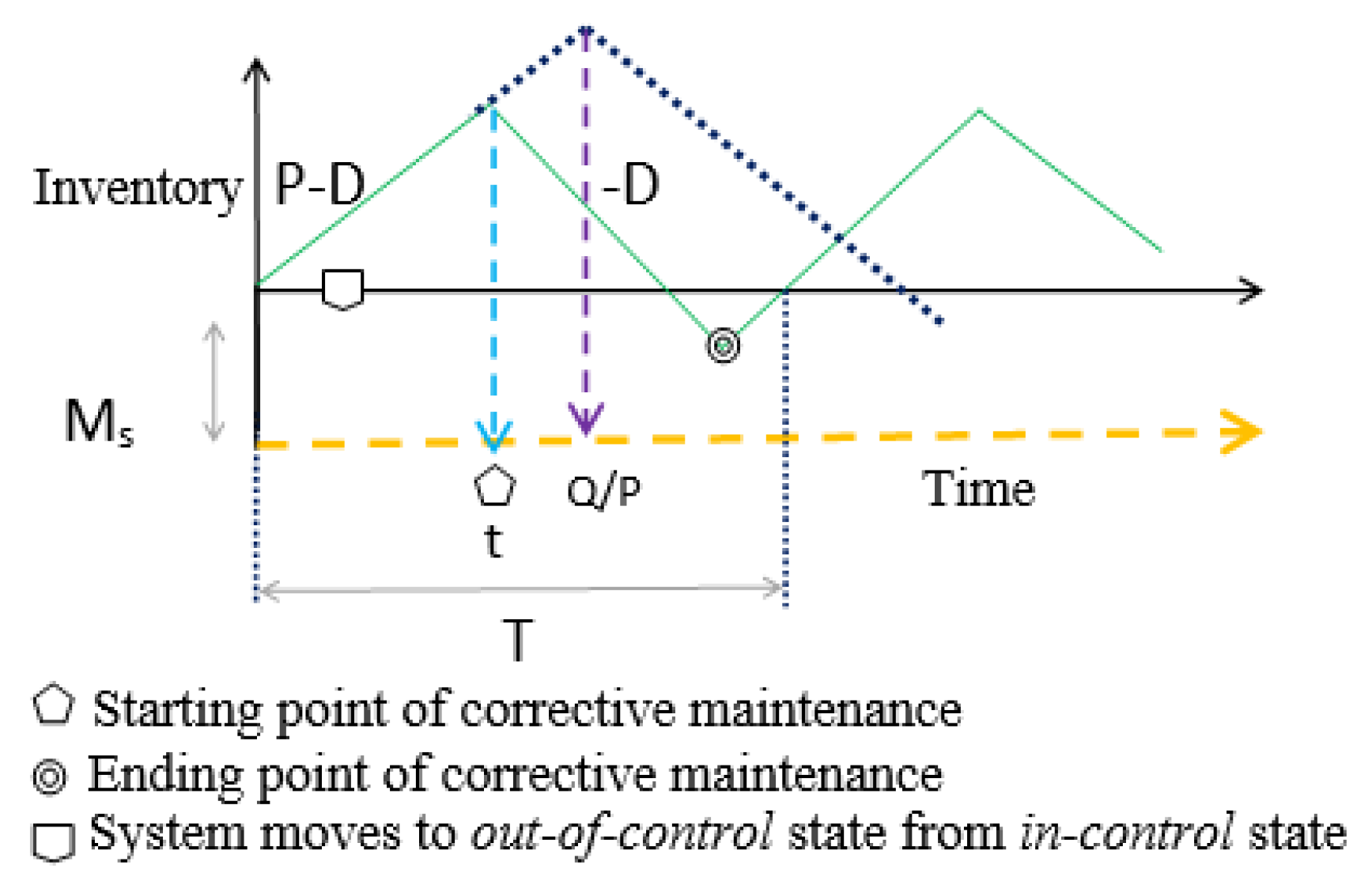

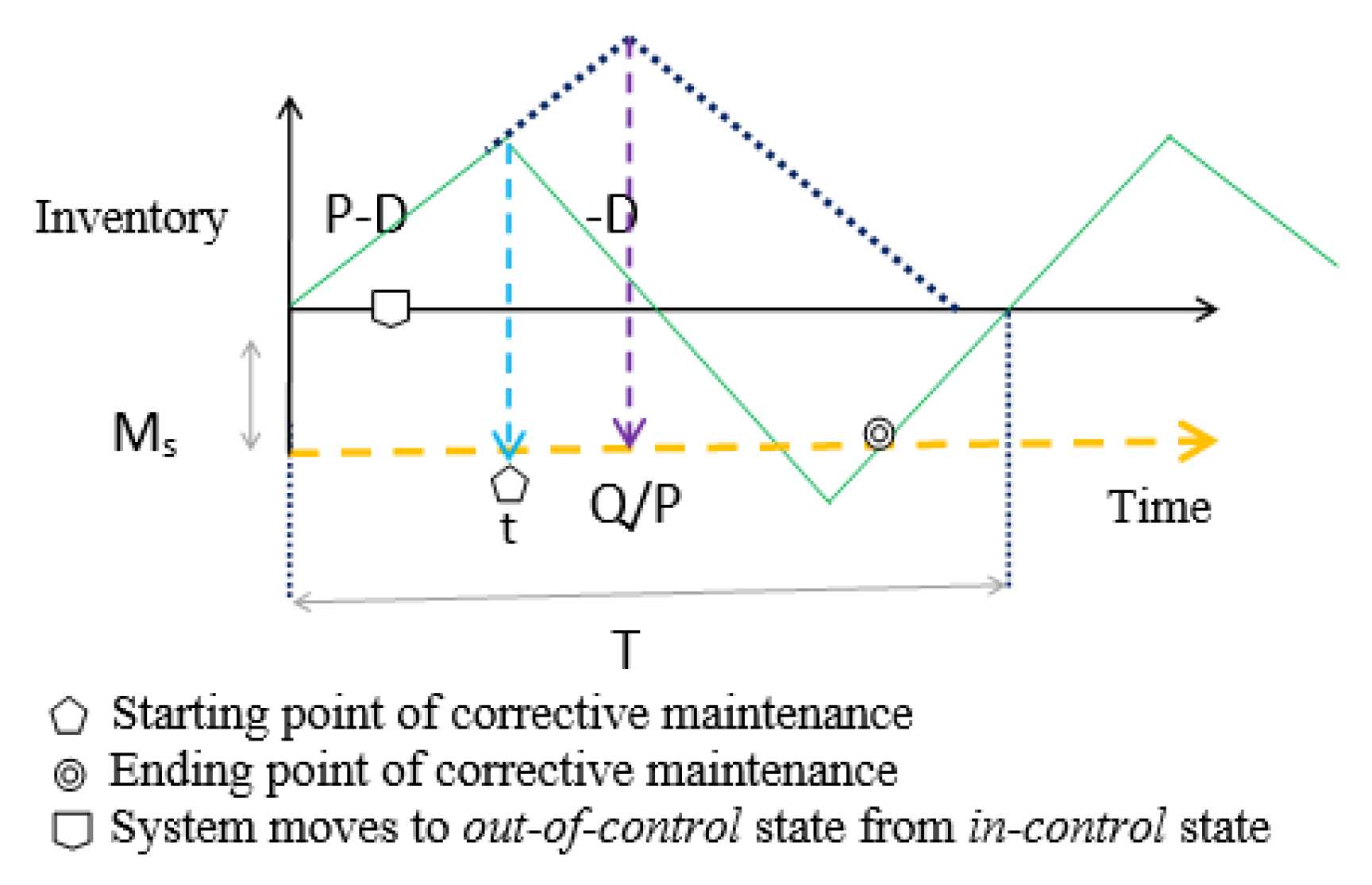

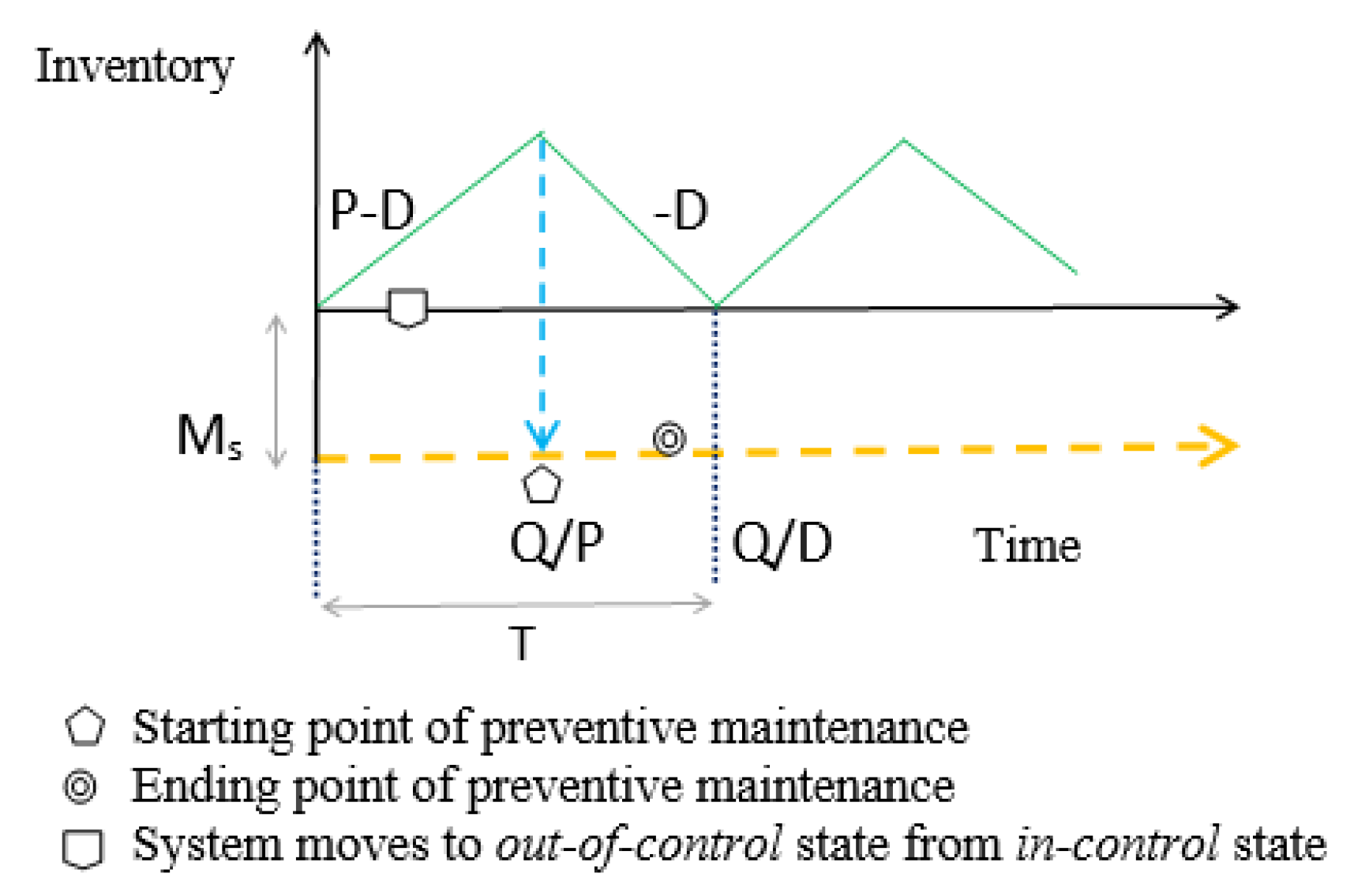

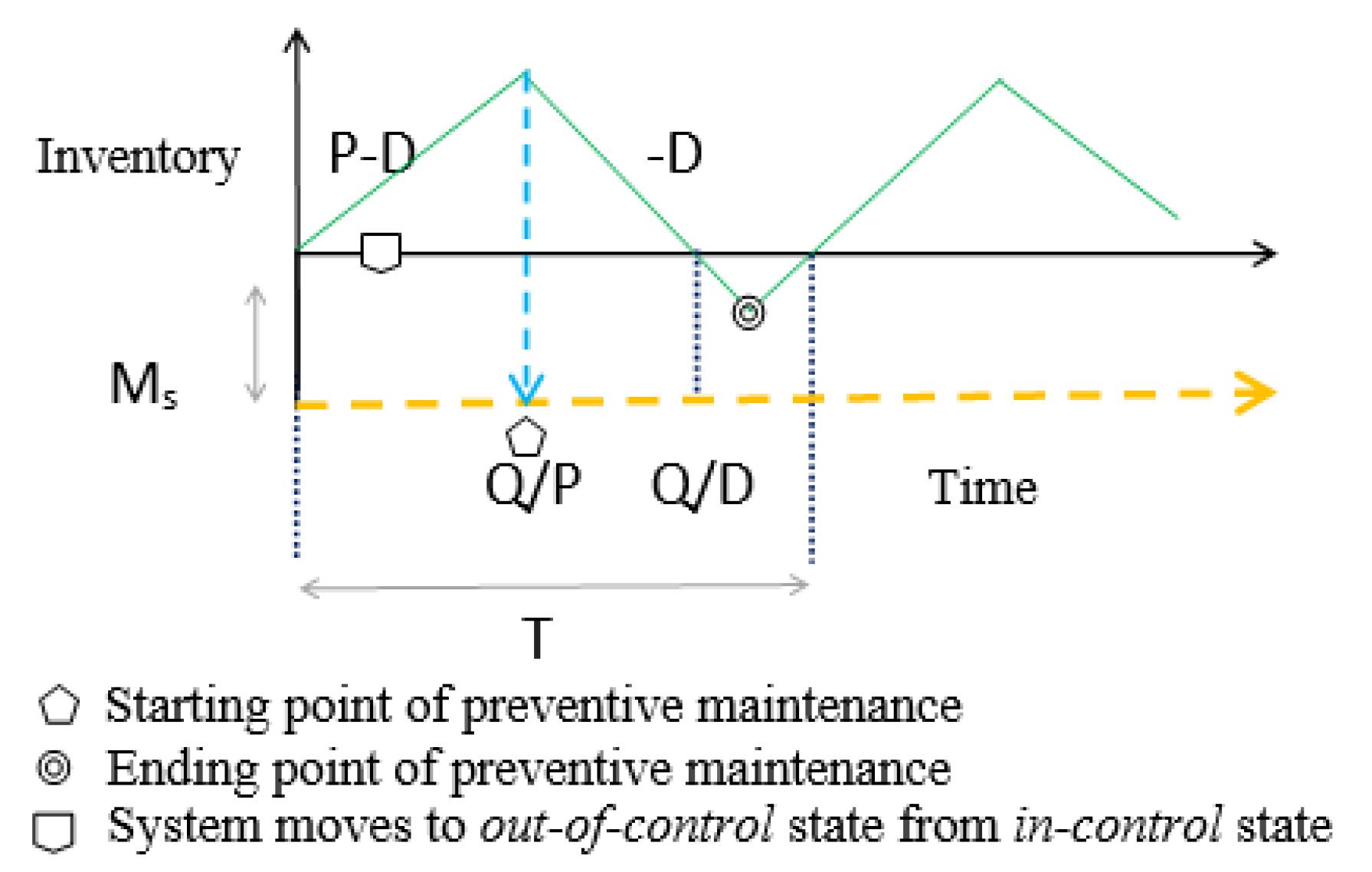

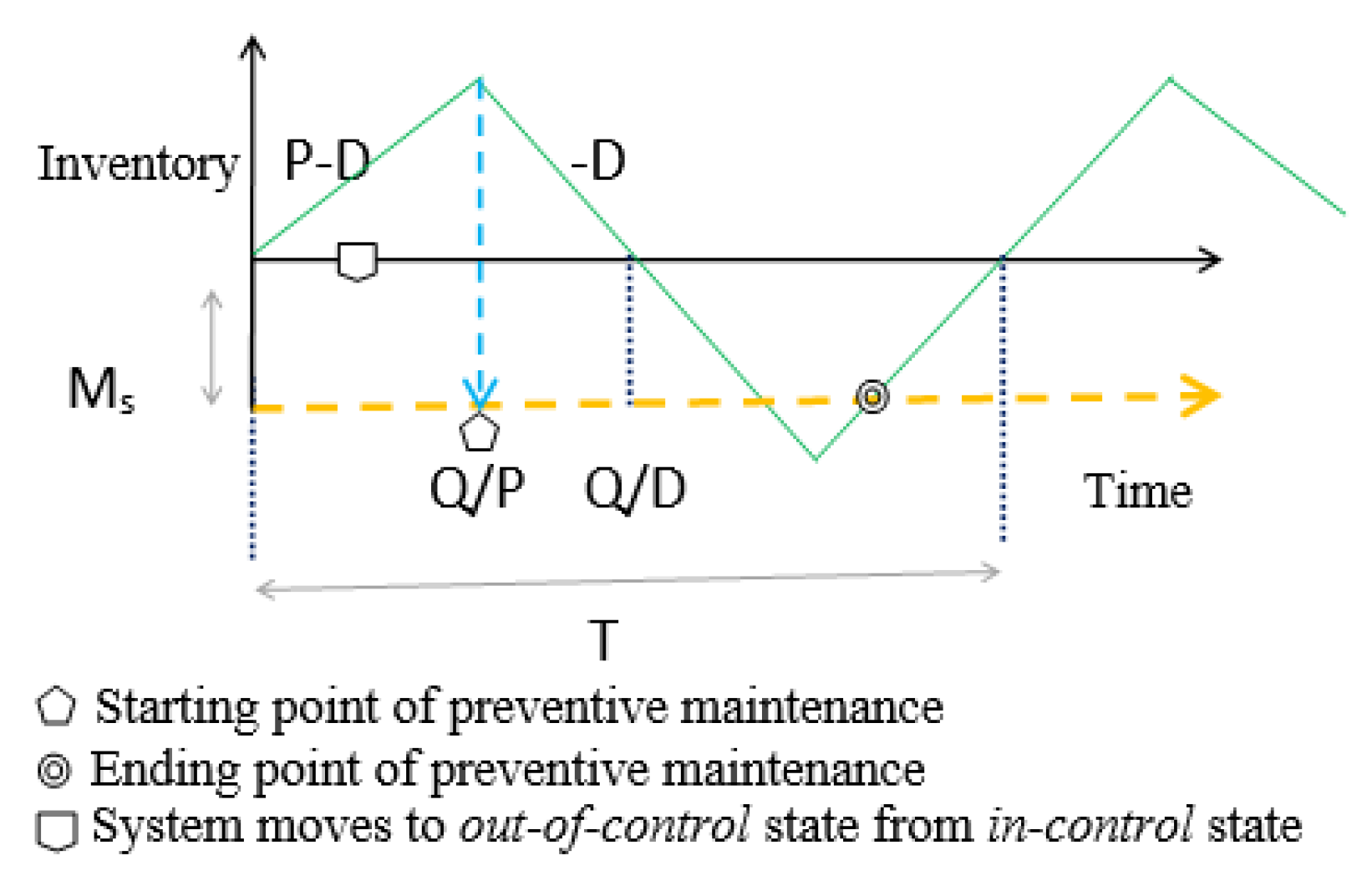

- During a long-run production system, the random breakdown may occur. Based on it, the model considers three cases as (i) the inventory just reaches to zero but no shortage appears (ii) the inventory may exceed the zero axis level but less than the safety stock level (iii) the inventory may cross the safety stock level and faces shortages.

- Regular and emergency maintenance are considered under the effect of energy with two specified probability distribution functions.

- Random breakdown may be at a random time, which follows an exponential distribution.

- The effect of energy is considered for all possible position with the optimum amount of energy consumption.

- Safety stock, production rate, and production quality are considered as decision variable where production rate may vary within the range of . The optimum value of production rate must lie within the interval.

- Shortages appear if the inventory crosses the safety stock level. If shortages appear, it is considered fully backordered.

2.3. Notation

3. Mathematical Model

4. Numerical Experiment

4.1. Numerical Example

4.2. Sensitivity Analysis

- (1)

- If the setup increased, the total cost of the smart production system increased. But wit the increases of setup cost, the total cost increased only . Thus, one can conclude that the setup cost was not effecting significantly the total cost of the production system. However as it was a smart production system, there were several smart technology and smart machinery systems and those were involved within this setup cost. Therefore, through the total cost only increased for a increase in the setup cost, still, it was a valuable and significant cost for any traditional or the smart production system.

- (2)

- The defective cost was most sensitive within all costs of the smart production system. For negative and positive charge of the defective cost, the total cost changed and in both directions, it was the same change. Thus, it can be concluded that the value of the rework cost follows an equilibrium position, which was the main theme for steady state of any production system. As this cost effects more, the automation policy can be used where the defective productions are inspected by a machine not by a human labor. Thus, the probability of defective products reduced and along with the defective cost and corresponding rework cost was reduced.

- (3)

- The cost of corrective and preventive maintenance were much less sensitive with the total cost compared to the other costs. As the breakdown was random, thus the preventive and corrective maintenance should be least sensitive among all cost parameters. The main reason behind it is that the production system is a smart production system. Thus, the probability of breakdown is very less. Therefore, these costs were less sensitive. If there was a breakdown then the importance of corrective maintenance increased, but still the effect of the breakdown was not more than the regular breakdown event as the production rate was controllable and before moving to out-of-control, the management reduced the production rate. Thus, the amount of loss was much less. But, still the corrective maintenance played an important role on that time. Thus, if a breakdown occurs, then the setup cost, defective cost, corrective maintenance cost, holding cost, and shortage cost will increase significantly, whereas the preventive maintenance cost will be reduced in the next cycle more as the huge corrective maintenance is already used during maintenance.

- (4)

- The holding cost of the smart production is very much sensitive with the total cost of the system. For negative change of the holding cost, the total cost is changed more than the positive change of it. Therefore, it can be concluded that the holding cost does not follow the equilibrium positions like the rework cost. However, the industry should try to reduce the holding cost for maintaining the minimum cost of the system. For the long term strategy to reduce holding cost, several policies should be adopted by the management such that it can reduce the total cost again.

- (5)

- As it is a smart manufacturing system and due to the random breakdown pattern, any time the inventory level can go below the safety stock level. Therefore, the shortage cost is almost equally sensitive like other costs. Just like the holding cost, the shortage cost is also the most sensitive in the negative change than the positive change of the total cost.

4.3. Managerial Insights

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sarkar, M.; Sarkar, B.; Iqbal, M.W. Effect of energy and failure rate in a multi-item smart production system. Energy 2018, 11, 2958. [Google Scholar] [CrossRef]

- Cárdenas-Barrón, L.E. Optimal production policy with shelf-life including shortages: A comment. J. Oper. Res. Soc. 2006, 57, 1499–1500. [Google Scholar] [CrossRef]

- Taleizadeh, A.A.; Sari-Khanbaglo, M.P.; Cárdenas-Barrón, L.E. Outsourcing rework of imperfect items in the economic production quantity (EPQ) inventory model with backordered demand. IEEE Trans. Syst. Man Cybern. Syst. 2017, 99, 1–12. [Google Scholar] [CrossRef]

- Wee, H.M.; Yang, W.H.; Chou, C.W.; Padilan, M.V. Renewable energy supply chains, performance, application barriers, and strategies for further development. Renew. Sustain. Energy Rev. 2012, 16, 5451–5465. [Google Scholar] [CrossRef]

- Kang, C.W.; Ramzan, M.B.; Sarkar, B.; Imran, M. Effect of inspection performance in smart manufacturing system based on human quality control system. Int. J. Adv. Manuf. Technol. 2018, 94, 4351–4364. [Google Scholar] [CrossRef]

- Porteus, E.L. Optimal lot sizing, process quality improvement and setup cost reduction. Oper. Res. 1986, 34, 137–144. [Google Scholar] [CrossRef]

- Khouja, M.; Mehrez, A. Economic Production Lot Size Model with Variable Production Rate and Imperfect Quality. J. Oper. Res. Soc. 1994, 45, 1405–1417. [Google Scholar] [CrossRef]

- Chung, K.J.; Hou, K.L. An optimal production run time with imperfect production processes and allowable shortages. Comput. Oper. Res. 2003, 30, 483–490. [Google Scholar] [CrossRef]

- Giri, B.C.; Dohi, T. Exact formulation of stochastic EMQ model for an unreliable production system. J. Oper. Res. Soc. 2005, 56, 563–575. [Google Scholar] [CrossRef]

- Avancini, D.B.; Rodrigues, J.J.P.C.; Martins, S.G.B.; Rabêlo, R.A.L.; Al-Muhtadi, J.; Solic, P. Energy meters evolution in smart grids: A review. J. Clean. Prod. 2019, 217, 702–715. [Google Scholar] [CrossRef]

- Chen, C.K.; Lo, C.C. Optimal production run length for products sold with warranty in an imperfect production system with allowable shortages. Math. Comput. Model. 2006, 44, 319–331. [Google Scholar] [CrossRef]

- Nižetić, S.; Djilali, N.; Papadopoulos, A.; Rodrigues, J.J.P.C. Smart technologies for promotion of energy efficiency, utilization of sustainable resources and waste management. J. Clean. Prod. 2019, 231, 565–591. [Google Scholar] [CrossRef]

- Sarkar, B.; Moon, I. An EPQ model with inflation in an imperfect production system. Appl. Math. Comput. 2011, 217, 6159–6167. [Google Scholar] [CrossRef]

- Sarkar, B. A production-inventory model with probabilistic deterioration in two-echelon supply chain management. Appl. Math. Model. 2013, 37, 3138–3151. [Google Scholar] [CrossRef]

- Lund, H.; Østergaard, P.A.; Connolly, D.; Mathiesen, B.V. Smart energy and smart energy systems. Energy 2017, 137, 556–565. [Google Scholar] [CrossRef]

- Edgar, T.F.; Pistikopoulos, E.N. Smart manufacturing and energy systems. Comput. Chem. Eng. 2018, 114, 130–144. [Google Scholar] [CrossRef]

- Sana, S.; Goyal, S.K.; Chaudhuri, K.S. An imperfect production process in a volume flexible inventory model. Int. J. Prod. Econ. 2007, 105, 548–559. [Google Scholar] [CrossRef]

- Louly, M.A.O.; Dolgui, A. Calculating safety stocks for assembly systems with random component procurement lead times: A branch and bound algorithm. Eur. J. Oper. Res. 2009, 199, 723–731. [Google Scholar] [CrossRef]

- Jaber, M.Y.; Bonney, M.; Moualek, I. An economic order quantity model for an imperfect production process with entropy cost. Int. J. Prod. Econ. 2009, 118, 26–33. [Google Scholar] [CrossRef]

- Sarkar, B.; Sana, S.S.; Chaudhuri, K. Optimal reliability, production lotsize and safety stock: An economic manufacturing quantity model. Int. J. Manag. Sci. Eng. Manag. 2010, 5, 192–202. [Google Scholar] [CrossRef]

- Sana, S.S. An economic production lot size model in an imperfect production system. Eur. J. Oper. Res. 2010, 201, 158–170. [Google Scholar] [CrossRef]

- Sarkar, B.; Ullah, M.; Kim, N. Environmental and economic assessment of closed-loop supply chain with remanufacturing and returnable transport items. Comput. Ind. Eng. 2017, 111, 148–163. [Google Scholar] [CrossRef]

- Sarkar, M.; Hur, S.; Sarkar, B. Effects of variable production rate and time-dependent holding cost for complementary products in supply chain model. Math. Probl. Eng. 2017, 2017, 2825103. [Google Scholar] [CrossRef]

- Sarkar, B.; Guchhait, R.; Sarkar, M.; Cárdenas-Barrón, L.E. How does an industry manage the optimum cash flow within a smart production system with the carbon footprint and carbon emission under logistics framework? Int. J. Prod. Econ. 2019, 213, 243–257. [Google Scholar] [CrossRef]

- Cárdenas-Barrón, L.E.; Sarkar, B.; Garza, G.T. An improved solution to the replenishment policy for the EMQ model with rework and multiple shipments. Appl. Math. Model. 2013, 37, 5549–5554. [Google Scholar] [CrossRef]

- Giotitsas, C.; Pazaitis, A.; Kostakis, V. A peer-to-peer approach to energy production. Technol. Soc. 2015, 42, 28–38. [Google Scholar] [CrossRef]

- Tayyab, M.; Sarkar, B. Optimal batch quantity in a cleaner multi-stage lean production system with random defective rate. J. Clean. Prod. 2016, 139, 922–934. [Google Scholar] [CrossRef]

- Omair, M.; Sarkar, B.; Cárdenas-Barrón, L.E. Minimum Quantity Lubrication and Carbon Footprint: A Step towards Sustainability. Sustainability 2017, 9, 714. [Google Scholar] [CrossRef]

- Kim, M.S.; Sarkar, B. Multi-stage cleaner production process with quality improvement and lead time dependent ordering cost. J. Clean. Prod. 2017, 144, 572–590. [Google Scholar] [CrossRef]

- Moon, I.; Shin, E.; Sarkar, B. Min–max distribution free continuous-review model with a service level constraint and variable lead time. App. Math. Comput. 2014, 229, 310–315. [Google Scholar] [CrossRef]

- Sarkar, B.; Majumder, A.; Sarkar, M.; Dey, B.K.; Roy, G. Two-echelon supply chain model with manufacturing quality improvement and setup cost reduction. J. Ind. Manag. Opt. 2017, 13, 1085–1104. [Google Scholar] [CrossRef]

- Kim, S.J.; Sarkar, B. Supply chain model with stochastic lead time, trade-credit financing, and transportation discounts. Math. Probl. Eng. 2017, 2017, 6465912. [Google Scholar] [CrossRef]

- Majumder, A.; Guchhait, R.; Sarkar, B. Manufacturing quality improvement and setup cost reduction in an integrated vendor-buyer supply chain model. Eur. J. Ind. Eng. 2017, 13, 588–612. [Google Scholar] [CrossRef]

- Soni, H.N.; Sarkar, B.; Mahapatra, A.S.; Majumder, S.K. Lost sales reduction and quality improvement with variable lead time and fuzzy costs in an imperfect production system. RAIRO Oper. Res. 2018, 52, 819–837. [Google Scholar] [CrossRef]

- Sarkar, B.; Guchhait, G.; Sarkar, M.; Pareek, S.; Kim, N. Impact of safety factors and setup time reduction in a two-echelon supply chain management. Robot. Comput. Int. Manuf. 2019, 55, 250–258. [Google Scholar] [CrossRef]

- Dey, B.K.; Sarkar, B.; Sarkar, M.; Pareek, S. An integrated inventory model involving discrete setup cost reduction, variable safety factor, selling-price dependent demand, and investment. RAIRO Oper. Res. 2019, 53, 39–57. [Google Scholar] [CrossRef]

- Sarkar, B.; Saren, S.; Sinha, D.; Hur, S. Effect of unequal lot sizes, variable setup cost, and carbon emission cost in a supply chain model. Math. Probl. Eng. 2015, 2015, 469486. [Google Scholar] [CrossRef]

- Biel, K.; Glock, C.H. On the use of waste heat in a two-stage production system with controllable production rates. Int. J. Prod. Econ. 2016, 181, 174–190. [Google Scholar] [CrossRef]

- Kim, M.S.; Kim, J.S.; Sarkar, B.; Sarkar, M.; Iqbal, M.W. An improved way to calculate imperfect items during long-run production in an integrated inventory model with backorders. J. Manuf. Syst. 2018, 47, 153–167. [Google Scholar] [CrossRef]

- Unver, U.; Kara, O. Energy efficiency by determining the production process with the lowest energy consumption in a steel forging facility. J. Clean. Prod. 2019, 215, 1362–1370. [Google Scholar] [CrossRef]

- Kumar, L.R.; Yellapu, S.K.; Zhang, X.; Tyagi, R.D. Energy balance for biodiesel production processes using microbial oil and scum. Bioresource Technol. 2019, 272, 379–388. [Google Scholar] [CrossRef]

- Morato, T.; Vaezi, M.; kumar, A. Assessment of energy production potential from agricultural residues in Bolivia. Renew. Sustain. Energy Rev. 2019, 102, 14–23. [Google Scholar] [CrossRef]

- Ahmed, W.; Sarkar, B. Impact of carbon emissions in a sustainable supply chain management for a second generation biofuel. J. Clean. Prod. 2018, 186, 807–820. [Google Scholar] [CrossRef]

- Darom, N.A.; Hishamuddin, H.; Ramli, R.; Nopiah, Z.M. An inventory model of supply chain disruption recovery with safety stock and carbon emission consideration. J. Clean. Prod. 2018, 197, 1011–1021. [Google Scholar] [CrossRef]

- Assid, M.; Gharbi, A.; Hajji, A. Production and setup control policy for unreliable hybrid manufacturing-remanufacturing systems. J. Manuf. Syst. 2019, 50, 103–118. [Google Scholar] [CrossRef]

- Sarkar, B. Mathematical and analytical approach for the management of defective items in a multi-stage production system. J. Clean. Prod. 2019, 218, 896–919. [Google Scholar] [CrossRef]

- Caro-Ruiz, C.; Lombardi, P.; Richter, M.; Pelzer, A.; Mojica-Nava, E. Coordination of optimal sizing of energy storage systems and production buffer stocks in a net zero energy factory. Appl. Energy 2019, 238, 851–862. [Google Scholar] [CrossRef]

- Dincer, I.; Ezzat, M.F. Solar Energy Production. Compr. Energy Syst. 2018, 3, 208–251. [Google Scholar]

- Dincer, I.; Al-Zareer, M. Geothermal Energy Production. Compr. Energy Syst. 2018, 3, 252–303. [Google Scholar]

- Dincer, I.; Rosen, M.A.; Al-Zareer, M. Electrochemical Energy Production. Compr. Energy Syst. 2018, 3, 416–469. [Google Scholar]

- Dincer, I.; Rosen, M.A.; Al-Zareer, M. Chemical Energy Production. Compr. Energy Syst. 2018, 3, 470–520. [Google Scholar]

- Dincer, I.; Bicer, Y. Photonic Energy Production. Compr. Energy Syst. 2018, 3, 707–754. [Google Scholar]

- Lu, Y.; Peng, T.; Xu, X. Energy-efficient cyber-physical production network: Architecture and technologies. Comput. Ind. Eng. 2019, 129, 56–66. [Google Scholar] [CrossRef]

- Kazemi, H.; Shokrgozar, M.; Kamkar, B.; Soltani, A. Analysis of cotton production by energy indicators in two different climatic regions. J. Clean. Prod. 2018, 190, 729–736. [Google Scholar] [CrossRef]

- Kluczek, A. An energy-led sustainability assessment of production systems—An approach for improving energy efficiency performance. Int. J. Prod. Econ. 2019, 216, 190–203. [Google Scholar] [CrossRef]

- Harris, T.M.; Devkota, J.P.; Khanna, V.; Eranki, P.L.; Landis, A.E. Logistic growth curve modeling of US energy production and consumption. Renew. Sustain. Energy Rev. 2018, 96, 46–57. [Google Scholar] [CrossRef]

- Bruni, G.; Rizzello, C.; Santucci, A.; Alique, D.; Tosti, S. On the energy efficiency of hydrogen production processes via steam reforming using membrane reactors. Int. J. Hydrog. Energy 2019, 44, 988–999. [Google Scholar] [CrossRef]

- Dehning, P.; Blume, S.; Dér, A.; Flick, D.; Herrmenn, C.; Thiede, S. Load profile analysis for reducing energy demands of production systems in non-production times. Appl. Energy 2019, 237, 117–130. [Google Scholar] [CrossRef]

- Nordborg, M.; Berndes, G.; Dimitriou, I.; Henriksson, A.; Mola-Yudego, B.; Rosenqvist, H. Energy analysis of willow production for bioenergy in Sweden. Renew. Sustain. Energy Rev. 2018, 93, 473–482. [Google Scholar] [CrossRef]

- Khalil, M.; Berawi, M.A.; Heryanto, R.; Rizalie, A. Waste to energy technology: The potential of sustainable biogas production from animal waste in Indonesia. Renew. Sustain. Energy Rev. 2019, 105, 323–331. [Google Scholar] [CrossRef]

- Keen, S.; Ayres, R.U.; Standish, R. A note on the role of energy in oroduction. Ecol. Econ. 2019, 157, 40–46. [Google Scholar] [CrossRef]

- Chen, X.; Li, C.; Tang, Y.; Li, L.; Li, L. Integrated optimization of cutting tool and cutting parameters in face milling for minimizing energy footprint and production time. Energy 2019, 175, 1021–1037. [Google Scholar] [CrossRef]

- Liang, J.; Wang, Y.; Zhang, Z.H.; Sun, Y. Energy efficient production planning and scheduling problem with processing technology selection. Comput. Ind. Eng. 2019, 132, 260–270. [Google Scholar] [CrossRef]

| Author(s) | Energy | Smart Production System | Breakdown | Safety Stock | Production Rate | Maintenance |

|---|---|---|---|---|---|---|

| Sarkar et al. [1] | Consumption | Smart | Random | NA | Variable | NA |

| Kang et al. [2] | NA | Smart | NA | NA | Constant | NA |

| Porteus [3] | NA | Traditional | NA | NA | Constant | NA |

| Khouja and Mehraj [4] | NA | Traditional | NA | NA | Variable | NA |

| Giri and Dohi [6] | NA | Traditinal | Random | NA | Constant | CM and PM |

| Chenand Lo [7] | NA | Traditional | NA | NA | Constant | NA |

| Sana et al. [8] | NA | Traditional | Random | NA | Constant | CM and PM |

| Louly and Dolgui [9] | NA | Traditional | NA | Variable | Constant | CM and PM |

| Sarkar et al. [11] | NA | Traditional | Random | Variable | Constant | CM and PM |

| This paper | Consumption | Smart | Random | Variable | Variable | CM and PM |

| Decision variables | |

| P | production rate (units/time) |

| Q | production lot size (units) |

| safety stock (units) | |

| Random variable | |

| random variable of shifting from in-control-state to an out-of-control state | |

| Parameters | |

| D | demand rate (units) |

| X | non-negative random variable denoting time |

| failure time-distribution of X with probability density function = | |

| corrective(emergency) repair time distribution with probability density function | |

| () with finite mean ( > 0) | |

| preventive(regular) repair time distribution with probability density function | |

| () with finite mean ( > 0) | |

| setup cost per setup for the smart manufacturing system | |

| energy cost for setup the production system | |

| corrective repair cost per unit time | |

| energy cost for corrective maintenance per unit time | |

| preventive repair cost per unit time | |

| preventive maintenance energy cost per unit time | |

| holding cost per unit per unit time | |

| energy cost to hold all products per unit per unit time | |

| shortage cost per unit product | |

| rework cost per unit of defective item | |

| energy cost per unit to rework defective items | |

| probability distribution function of the shift time distribution | |

| proportion of defective items produced in the out-of control state where | |

| T | cycle length of production-inventory system |

| units | /unit time | /unit time | |

| /item | /unit/unit time | /item | |

| /unit time | |||

| /unit/unit time | |||

| /item |

| Parameters | Changes (in %) | Changes of ETC (in %) | Parameters | Changes (in %) | Changes of ETC (in %) |

|---|---|---|---|---|---|

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarkar, M.; Sarkar, B. Optimization of Safety Stock under Controllable Production Rate and Energy Consumption in an Automated Smart Production Management. Energies 2019, 12, 2059. https://doi.org/10.3390/en12112059

Sarkar M, Sarkar B. Optimization of Safety Stock under Controllable Production Rate and Energy Consumption in an Automated Smart Production Management. Energies. 2019; 12(11):2059. https://doi.org/10.3390/en12112059

Chicago/Turabian StyleSarkar, Mitali, and Biswajit Sarkar. 2019. "Optimization of Safety Stock under Controllable Production Rate and Energy Consumption in an Automated Smart Production Management" Energies 12, no. 11: 2059. https://doi.org/10.3390/en12112059

APA StyleSarkar, M., & Sarkar, B. (2019). Optimization of Safety Stock under Controllable Production Rate and Energy Consumption in an Automated Smart Production Management. Energies, 12(11), 2059. https://doi.org/10.3390/en12112059