Design and Control of a Permanent Magnet RotLin Motor for New Foldable Photovoltaic Units

Abstract

:1. Introduction

2. Mathematic Model of the RotLin Motor

2.1. Mechanical Structure

2.2. Basic Operation

2.3. Dynamic Equations

3. Magnetic Circuit Design

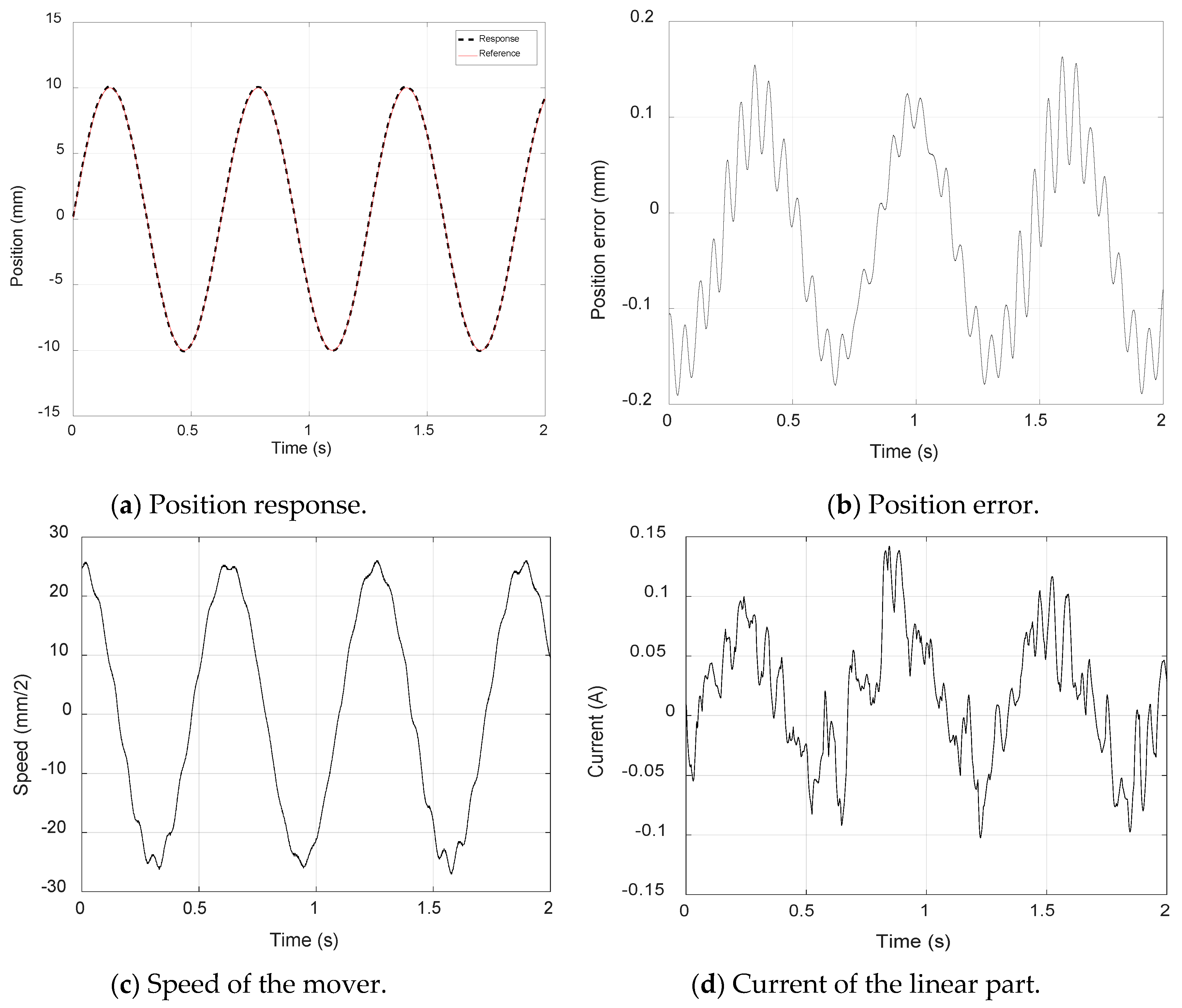

4. Control Scheme and Experimental Verification

4.1. Control Scheme

4.2. Experimental Results

5. Discussion

5.1. Deformation of the Mover

5.2. Decoupling Effect between the Linear Movement and the Rotational Part

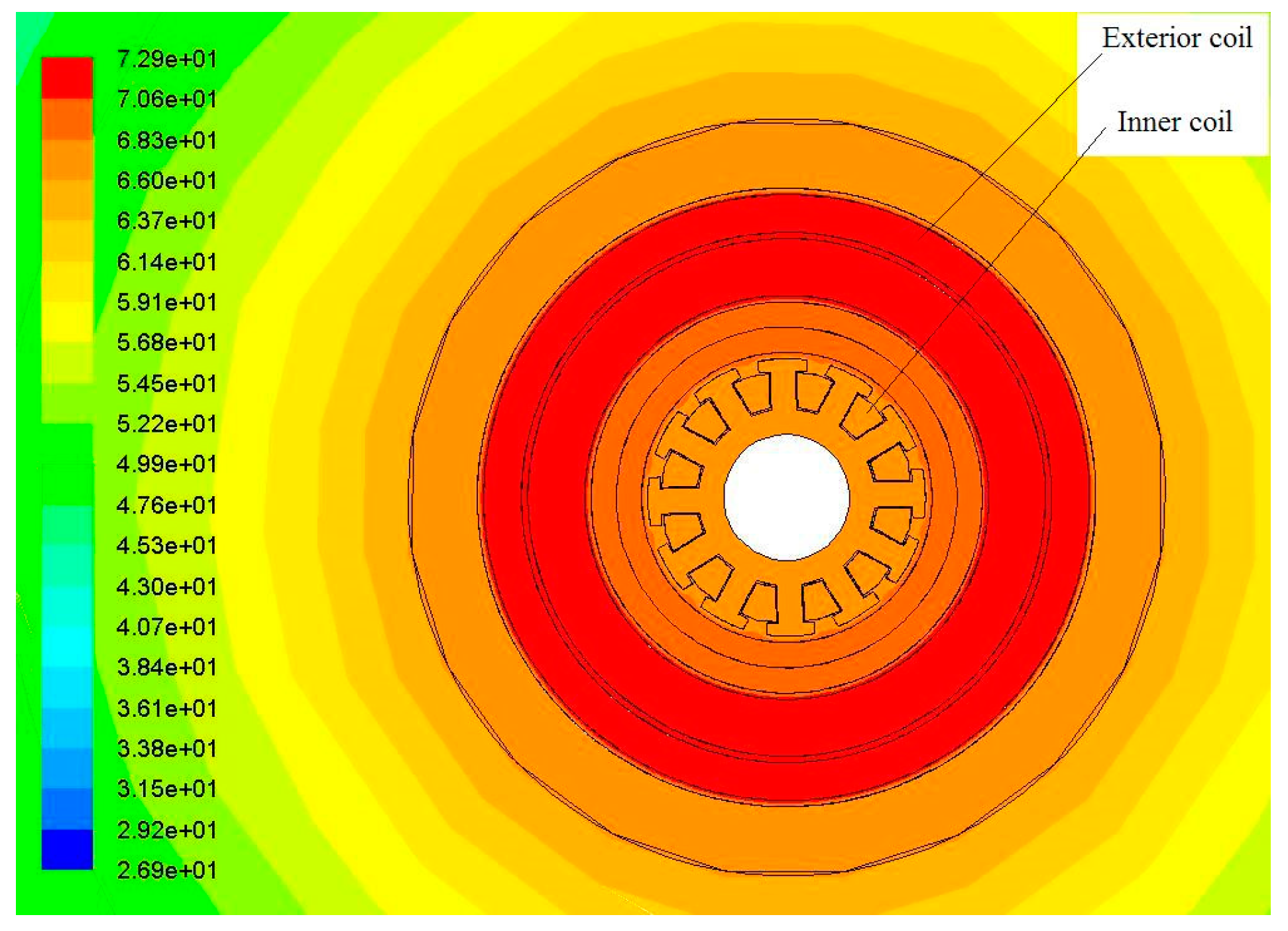

5.3. Thermal Field Discussion of the Motor

5.4. New Foldable Photovoltaic Unit with the RotLin Motor

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Teo, T.J.; Yang, G. Linear Rotary Electromagnetic Actuator. U.S. Patent 2012/0262259 A1, 18 October 2012. [Google Scholar]

- Teo, T.J.; Zhu, H.Y.; Chen, S.L. Principle and Modeling of a Novel Moving Coil Linear-Rotary Electromagnetic Actuator. IEEE Trans. Ind. Elctro. 2016, 63, 6930–6940. [Google Scholar] [CrossRef]

- Lu, B.L.; Xu, Y.L. Development and Analysis of a Novel Spherical 2-Degree-of-Freedom (2-DOF) Hybrid Stepping Motor. Energies 2018, 11, 41. [Google Scholar]

- Chung, M.J.; Yee, Y.H.; Kim, Y.J. Development of High Precision X-Y Stage Using for Production and Inspection Equipment of Organic Electro Luminescence Display. In Proceedings of the SICE Annual Conference, Takamatsu, Japan, 17‒20 September 2007; pp. 1649–1652. [Google Scholar]

- Overboom, T.T.; Jansen, J.W.; Lomonova, E.A. Design and optimization of a rotary actuator for a two-degree of freedom zϕ-module. IEEE Trans. Ind. Appl. 2010, 46, 2401–2409. [Google Scholar] [CrossRef]

- Si, J.K.; Feng, H.C.; Ai, L.W. Design and Analysis of a 2-DOF Split-Stator Induction Motor. IEEE Trans. Ener. Conver. 2015, 30, 1200–1208. [Google Scholar] [CrossRef] [Green Version]

- Wu, W.; Feng, H.C.; Cheng, Z.P. Rotor Eddy Current Loss Calculation of a 2DoF Direct-Drive Induction Motor. Energies 2019, 12, 1134. [Google Scholar] [CrossRef]

- Xie, L.J.; Si, J.K.; Hu, Y.H. Characteristics Analysis of the Motions of the 2-Degree-of-Freedom Direct Drive Induction Motor. IEEE Trans. Ind. Electro. 2019. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Zhou, H.B.; Duan, J.A. Design and Analysis of a High Acceleration Rotary-Linear Voice Coil Motor. IEEE Trans. Magn. 2017, 53. [Google Scholar] [CrossRef]

- Pan, J.F.; Zou, Y.; Cheung, N.C. Performance analysis and decoupling control of an integrated rotary–linear machine with coupled magnetic paths. IEEE Trans. Magn. 2014, 50. [Google Scholar] [CrossRef]

- Xu, L.; Lin, M.Y.; Fu, X.H. Orthogonal magnetic field analysis of a double-stator linear-rotary permanent magnet motor with orthogonally arrayed permanent magnets. IEEE Trans. Magn. 2017, 53. [Google Scholar] [CrossRef]

- Sato, Y.; Murakami, K.; Tsuboi, Y. Sensorless torque and thrust estimation of a rotational/linear two degrees-of-freedom switched reluctance motor. IEEE Trans. Magn. 2016, 52. [Google Scholar] [CrossRef]

- Liu, C.T.; Chiang, T.S. Design and performance evaluation of a micro linear switched-reluctance motor. IEEE Trans. Magn. 2004, 40, 806–809. [Google Scholar] [CrossRef]

- Li, S.Y.; Cheng, K.W.E.; Cheung, N.; Zou, Y. Design and Control of a Decoupled Rotary-Linear Switched Reluctance Motor. IEEE Trans. Energy Convers. 2018, 33, 1363–1370. [Google Scholar] [CrossRef]

- Zou, Y.; Cheng, K.W.E.; Hu, J.F. A new decoupled RotLin motor with fuzzy sliding mode control. IEEE Trans. Magn. 2018, 54. [Google Scholar] [CrossRef]

- Xu, L.; Lin, M.Y.; Fu, X.H. Design and Analysis of a Double-Stator Linear–Rotary Permanent-Magnet Motor. IEEE Trans. Appl. Supercon. 2016, 26. [Google Scholar] [CrossRef]

- Pham, T.T.; Vu, N.H.; Shin, S.Y. Novel Design of Primary Optical Elements Based on a Linear Fresnel Lens for Concentrator Photovoltaic Technology. Energies 2019, 12, 7. [Google Scholar] [CrossRef]

- Wang, H.; Huang, J.; Song, M.J.; Hu, Y.X.; Wang, Y.F.; Lu, Z.J. Simulation and Experimental Study on the Optical Performance of a Fixed-Focus Fresnel Lens Solar Concentrator Using Polar-Axis Tracking. Energies 2018, 11, 4. [Google Scholar] [CrossRef]

- Morón, C.; Ferrández, D.; Saiz, P.; Vega, G.; Díaz, J.P. New Prototype of Photovoltaic Solar Tracker Based on Arduino. Energies 2017, 10, 9. [Google Scholar] [CrossRef]

- Pan, J.F.; Cheung, N.C.; Zou, Y. An Improved Force Distribution Function for Linear Switched Reluctance Motor on Force Ripple Minimization with Nonlinear Inductance Modeling. IEEE Trans. Magn. 2012, 48, 3064–3067. [Google Scholar] [CrossRef]

- Xue, X.D.; Cheng, K.W.E.; Ho, S.L. Optimization and Evaluation of Torque-Sharing Functions for Torque Ripple Minimization in Switched Reluctance Motor Drives. IEEE Trans. Power Electron. 2009, 24, 2076–2090. [Google Scholar] [CrossRef]

- Xue, X.D.; Cheng, K.W.E.; Bao, Y.J.; Leung, P.L.; Cheung, N. Switched Reluctance Generators with Hybrid Magnetic Paths for Wind Power Generation. IEEE Trans. Magn. 2012, 48, 3863–3866. [Google Scholar] [CrossRef]

| Specifications | Quantity (SI) |

|---|---|

| Rated power of linear part | 30 W |

| Rated current of the motor ) | 2 A |

| Diameter of interior stator (D) | 22 mm |

| Radium of mover (R1) | 17 mm |

| Pole pitch of mover () | 4.8 mm |

| Stack length of interior stator (l) | 60 mm |

| Length of exterior stator (w) | 60 mm |

| Back iron thickness of exterior stator (q) | 3 mm |

| Size of PM | 2 × 17 × 30 mm |

| Pole width of exterior stator (p) | 4 mm |

| Rated power of rotary part () | 20 W |

| Mass of mover (M) | 169.8 g |

| Thickness of exterior stator(q) | 3.5 mm |

| Length of air gap 1 (g1) | 0.5 mm |

| Length of air gap 2 (g2) | 0.5 mm |

| Linear winding turns () | 250 |

| Rotational winding turns (N) | 12 × 12 |

| Linear encoder accuracy | 1 μm |

| Rotational encoder lines | 81,920 |

| Specifications | Value |

|---|---|

| Propotional gain of postion controller | 2 |

| Intergral gain of position controller | 0.01 |

| Propotional gain of speed controller | 0.1 |

| Intergral gain of speed controller | 0.003 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, Y.; Cheng, K.W.E. Design and Control of a Permanent Magnet RotLin Motor for New Foldable Photovoltaic Units. Energies 2019, 12, 1983. https://doi.org/10.3390/en12101983

Zou Y, Cheng KWE. Design and Control of a Permanent Magnet RotLin Motor for New Foldable Photovoltaic Units. Energies. 2019; 12(10):1983. https://doi.org/10.3390/en12101983

Chicago/Turabian StyleZou, Yu, and Ka Wai Eric Cheng. 2019. "Design and Control of a Permanent Magnet RotLin Motor for New Foldable Photovoltaic Units" Energies 12, no. 10: 1983. https://doi.org/10.3390/en12101983

APA StyleZou, Y., & Cheng, K. W. E. (2019). Design and Control of a Permanent Magnet RotLin Motor for New Foldable Photovoltaic Units. Energies, 12(10), 1983. https://doi.org/10.3390/en12101983