A Text-Mining Approach to Assess the Failure Condition of Wind Turbines Using Maintenance Service History

Abstract

1. Introduction

2. Materials and Methods

2.1. Performance Metrics

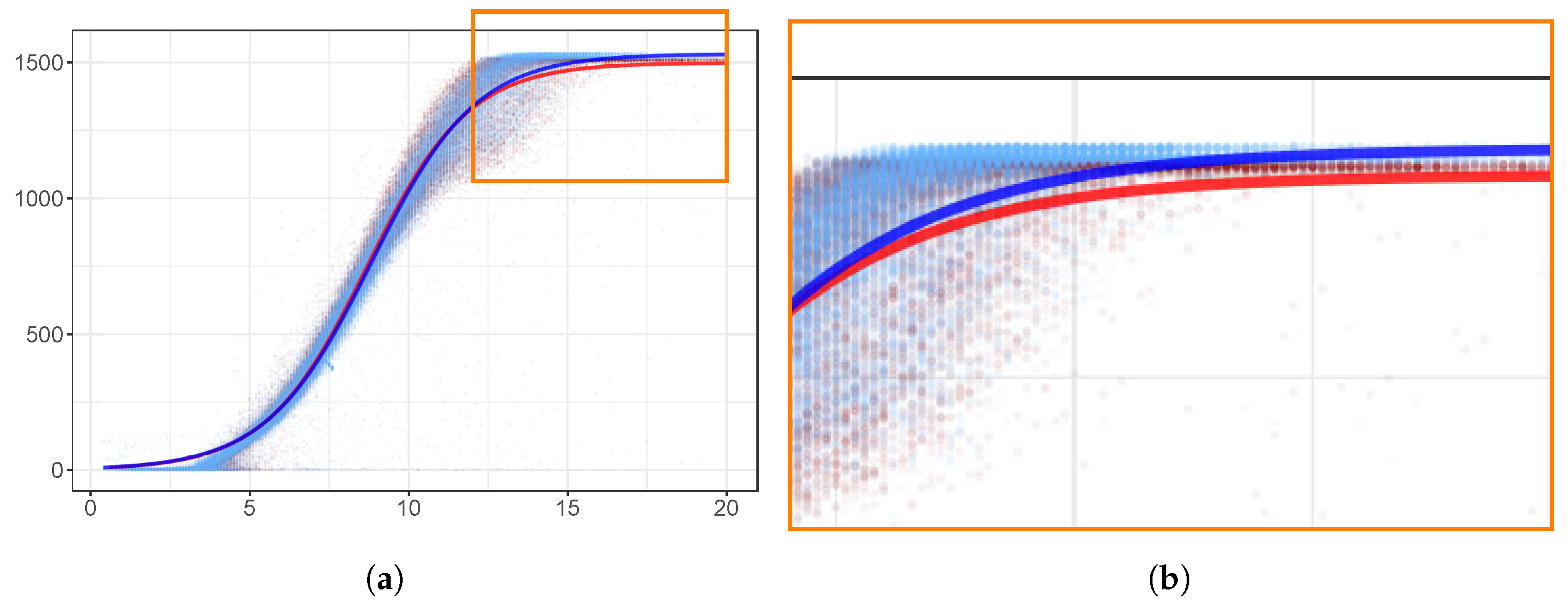

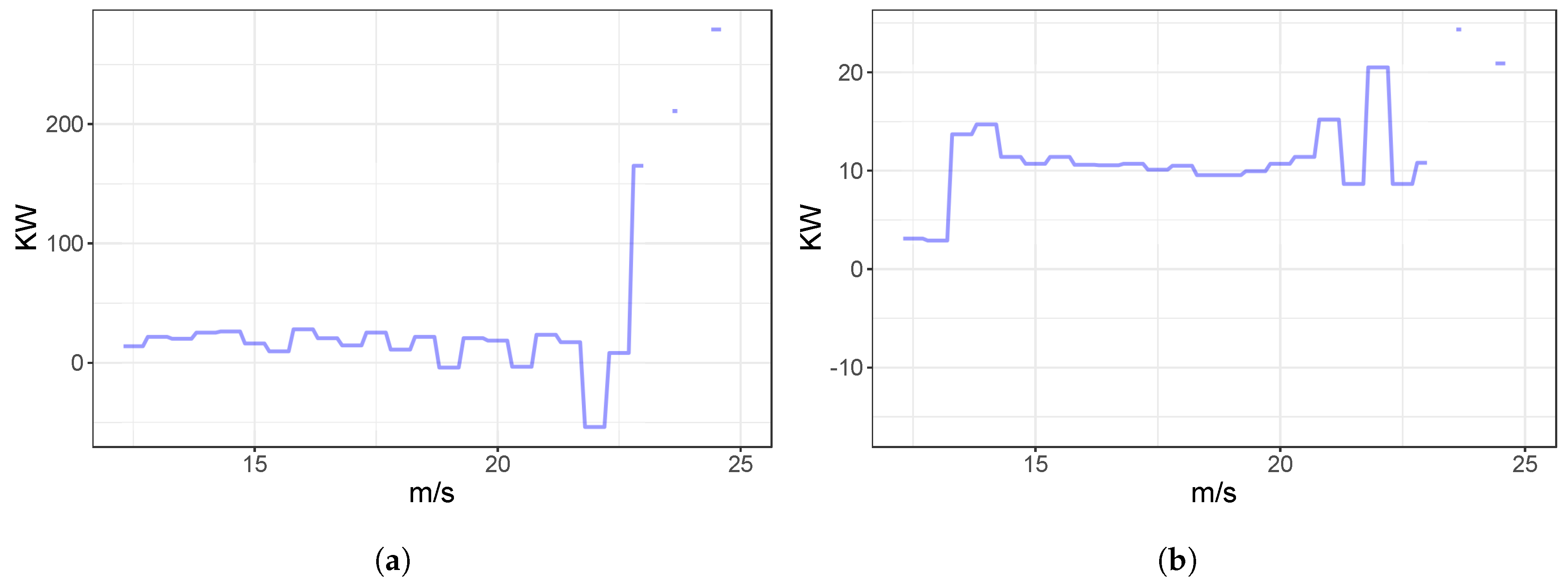

- Download the wind and power features, separately for each turbine. Then, a discretization was applied to the wind values with a precision of 0.1 m/s.

- Find the logistic function that better fits the cloud of points (wind speed, power). Two R functions were used (SSlogis and NLS) to derive the three parameters of the curve in a MSE framework. These three parameters were the horizontal asymptote (Asym), the inflection point (Xmid) and the step of the curve.

2.2. Data

2.2.1. Work Order Download

- The hour and date were instantaneous.

- The WO id identified each intervention. There can be several lines for each WO id because each one was duplicated for each material used and for each comment entered in the system.

- The “wo_class” tag identified a class of intervention categorized in one of the major failures.

- The important files were: work_description (indicates in a extended way the work done), material_code (indicates the material used), problem_found (indicates what happened), problem_source (indicates the origin of the problem), problem_solution (indicates the adopted solution ).

2.2.2. Common Errors

2.2.3. Removing Words

2.3. Building the Training and Testing Dataset

- The register in which the repair intervention started is labelled as “F” register.

- The register in which the repair intervention ended is labelled as “FF” register.

- The registers 1 to F-1 are labelled as “1”, indicating ‘before failure repair’ events.

- The The registers FF+1 to N are labelled as “0”, indicating ‘after failure repair’ events.

2.4. Text Mining

- The dots and commas were eliminated: removePunctuation

- The numbers were deleted: removeNumbers

- The empty spaces at the begining and at the end were eliminated: stripWhitespace

- All text was converted to lowercase: tolower

- All the brackets such as ’()’, ’’ or ’[]’ were deleted: bracketX

- All the words loaded in the step Section 2.2.3, together with the STOP words were eliminated: removeWords stopwords (for the Spanish language, ’ES’)

- Common errors loaded in the step Section 2.2.2 were repaired.

- All the accents were cleared, changing the vowel with accent for the equivalent without accent.

- All the text was stemmed using the function STEMDOCUMENT of the package TM, using the parameters for the Spanish language (’ES’)

2.4.1. Document Term Matrix

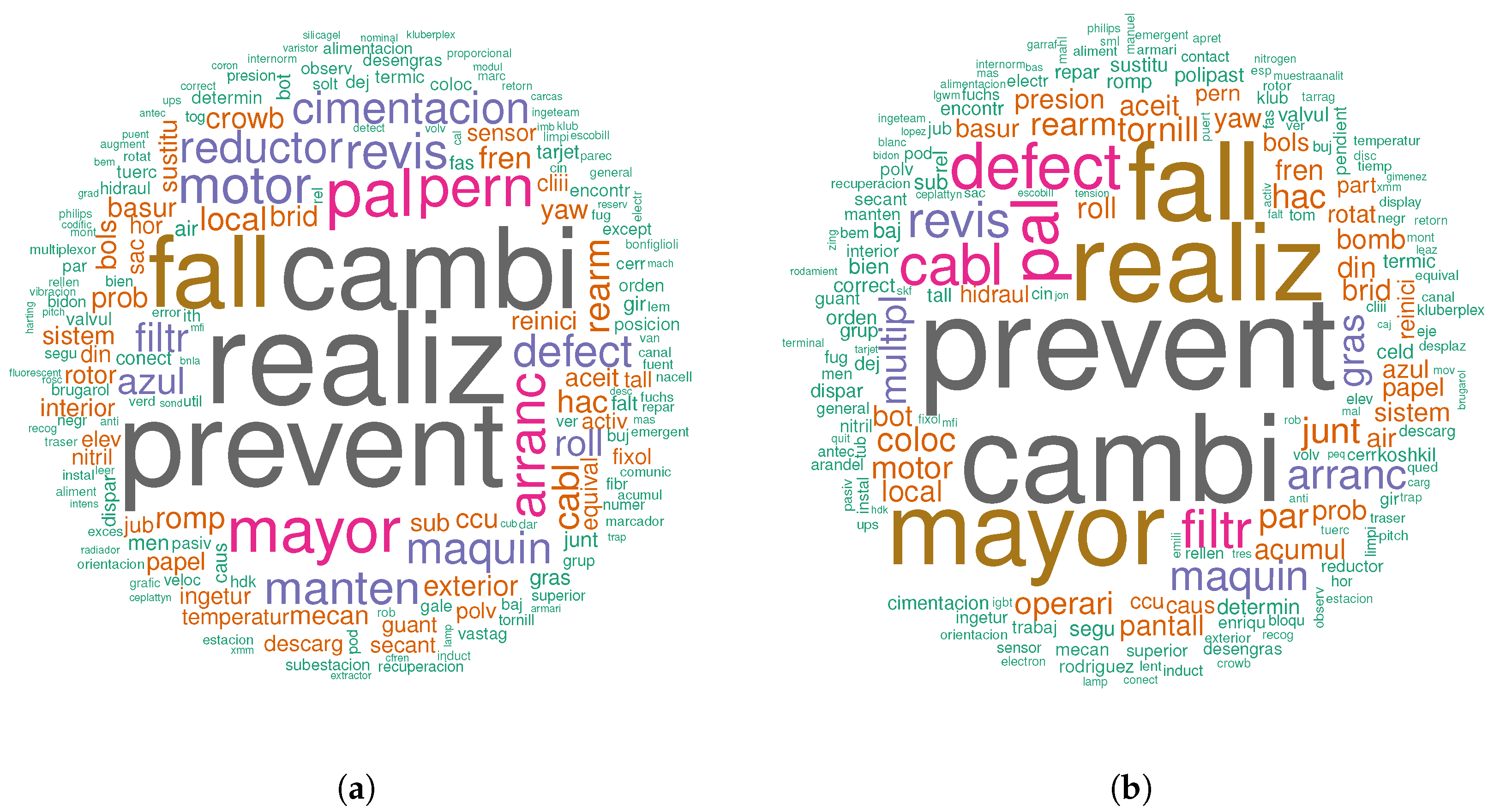

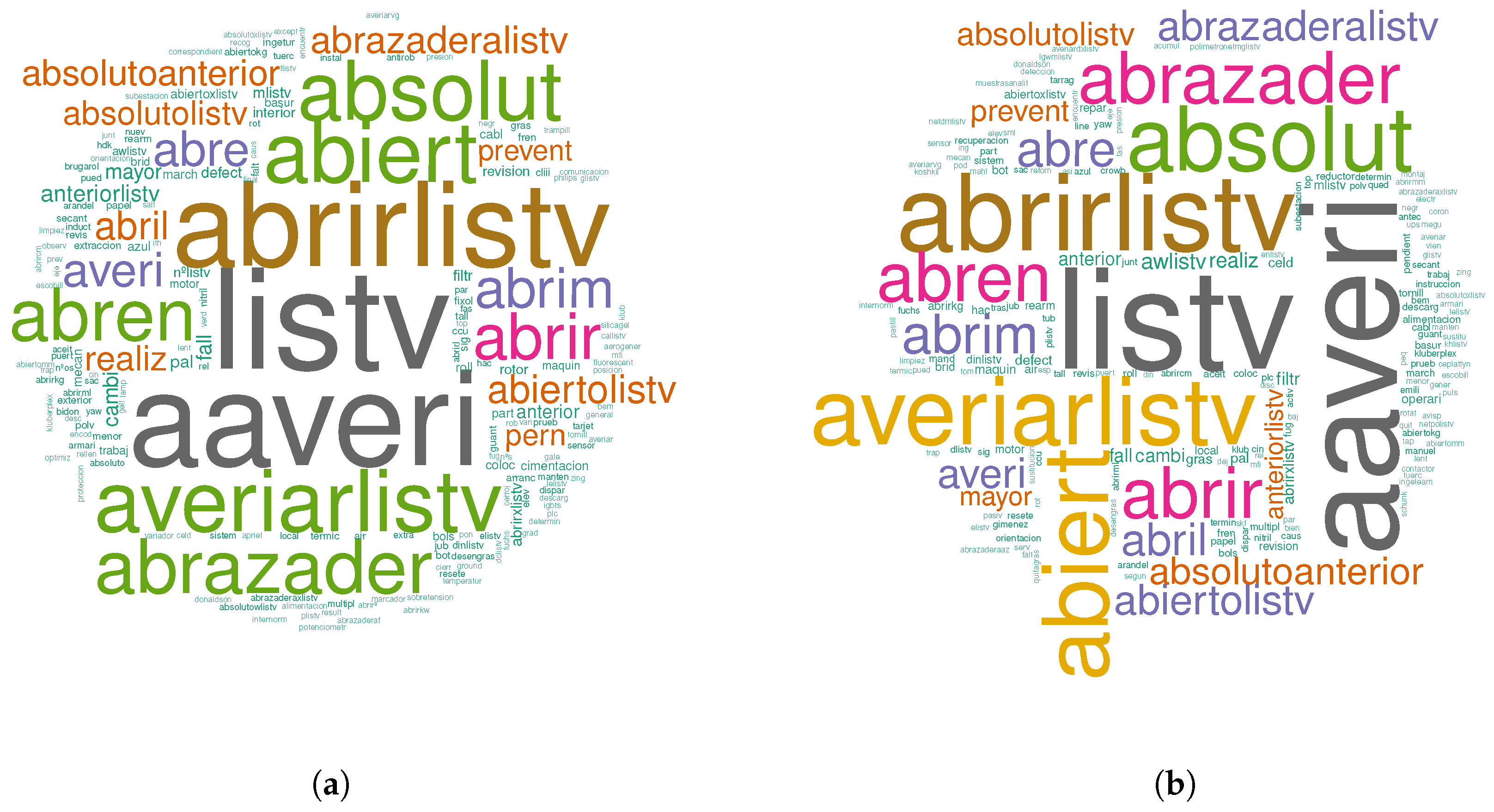

2.4.2. Word Clouds

2.5. Modelling

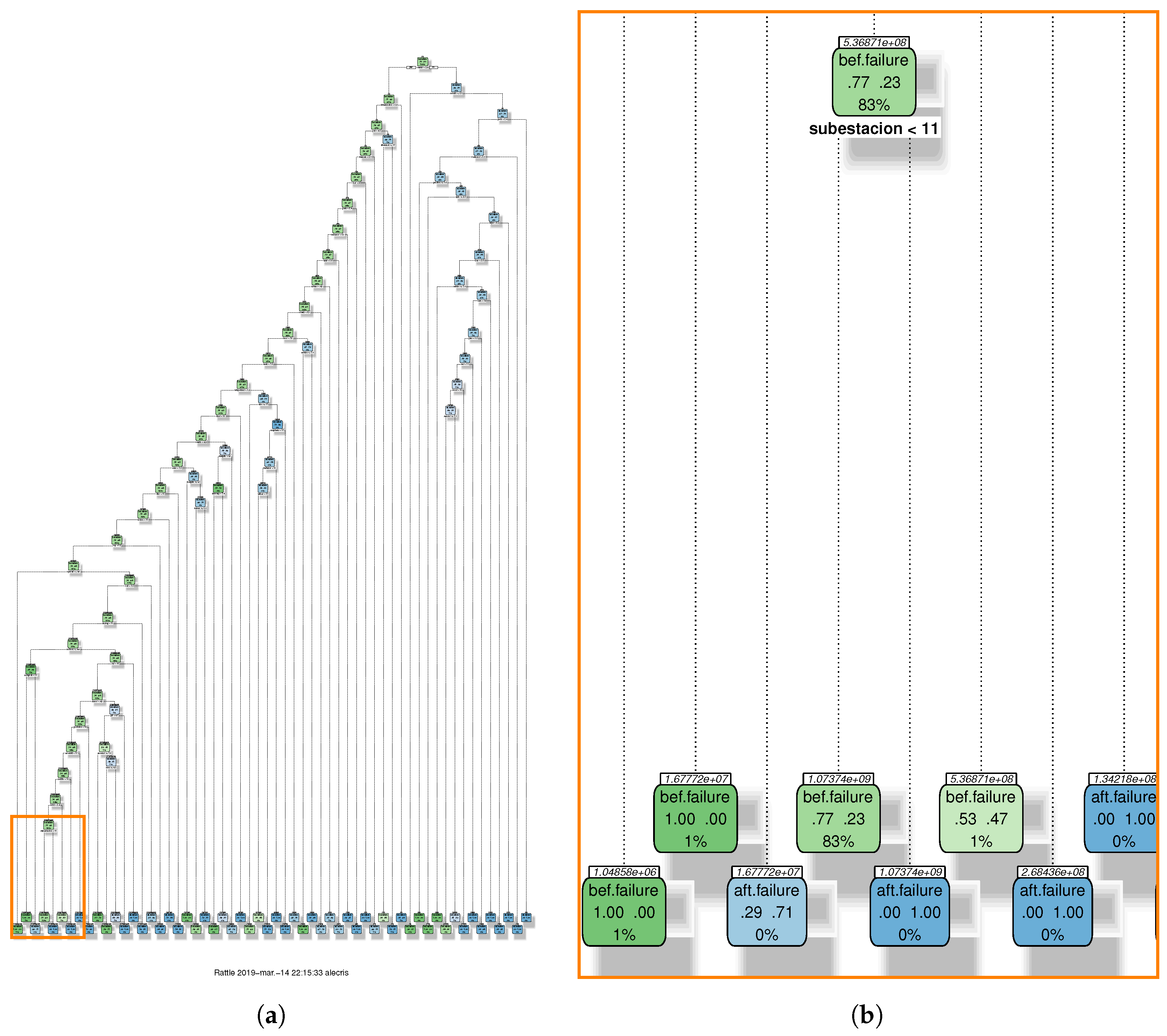

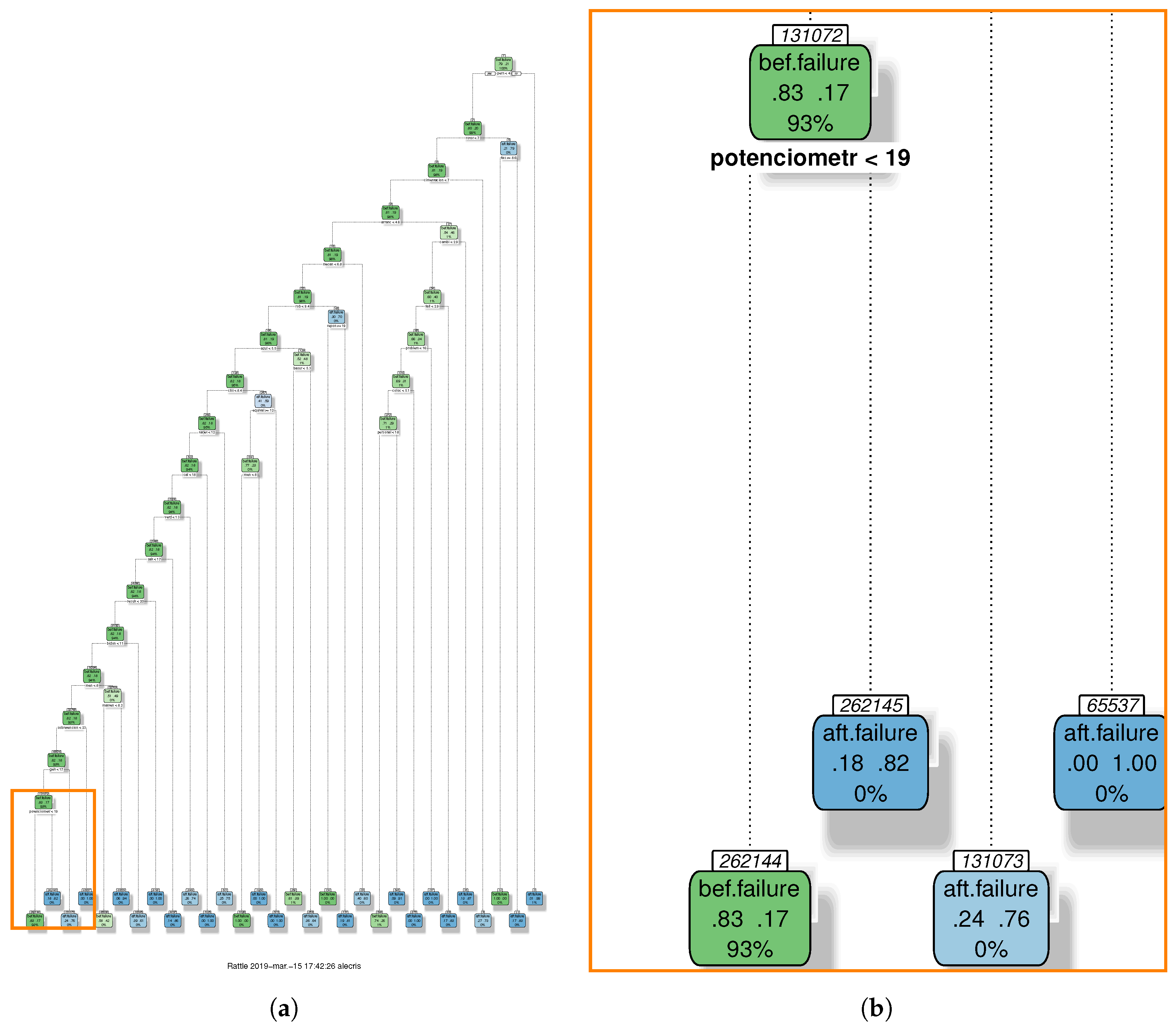

2.5.1. Decision Trees

2.5.2. Random Forest

3. Results and Discussion

3.1. Performance Metrics

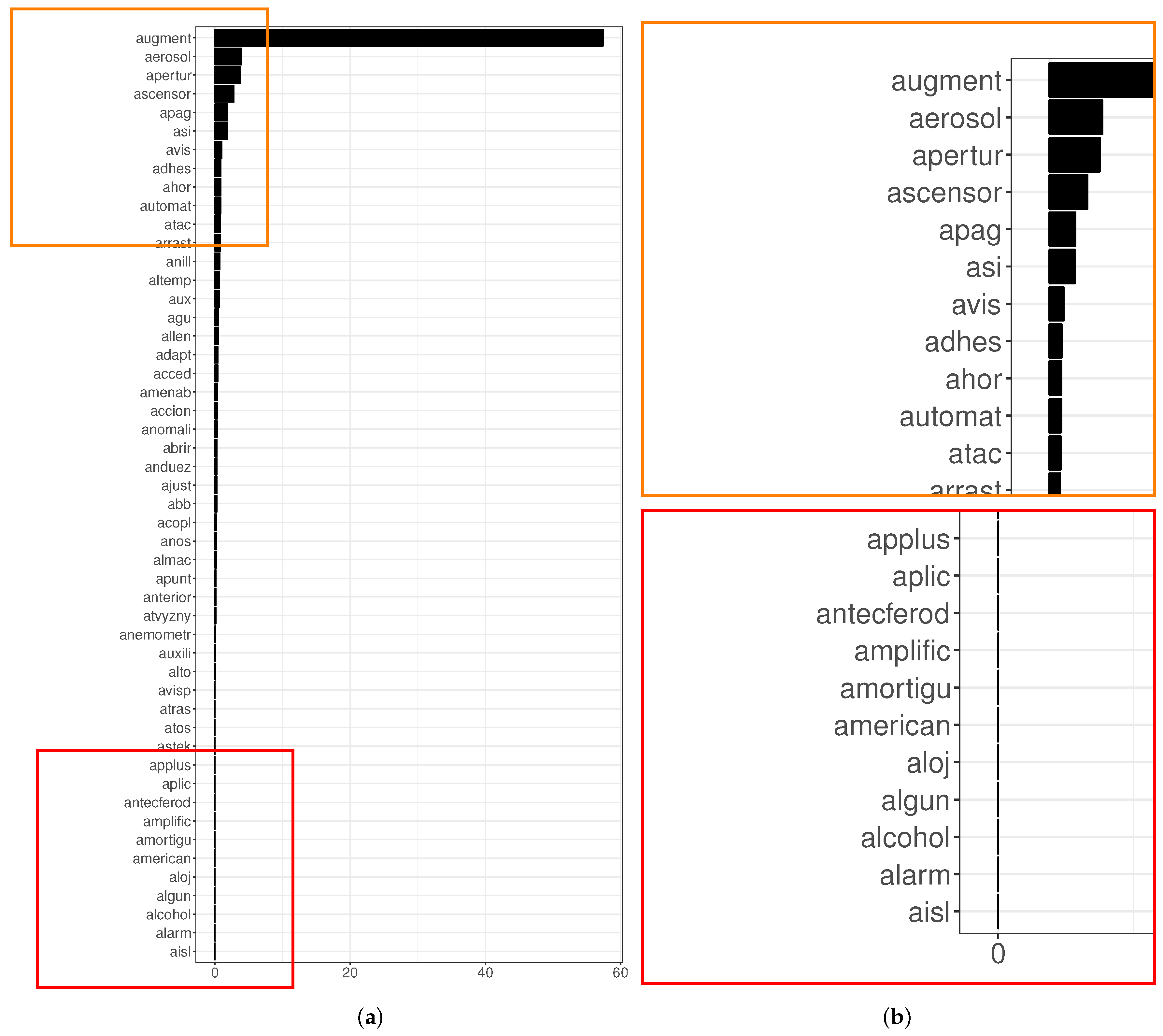

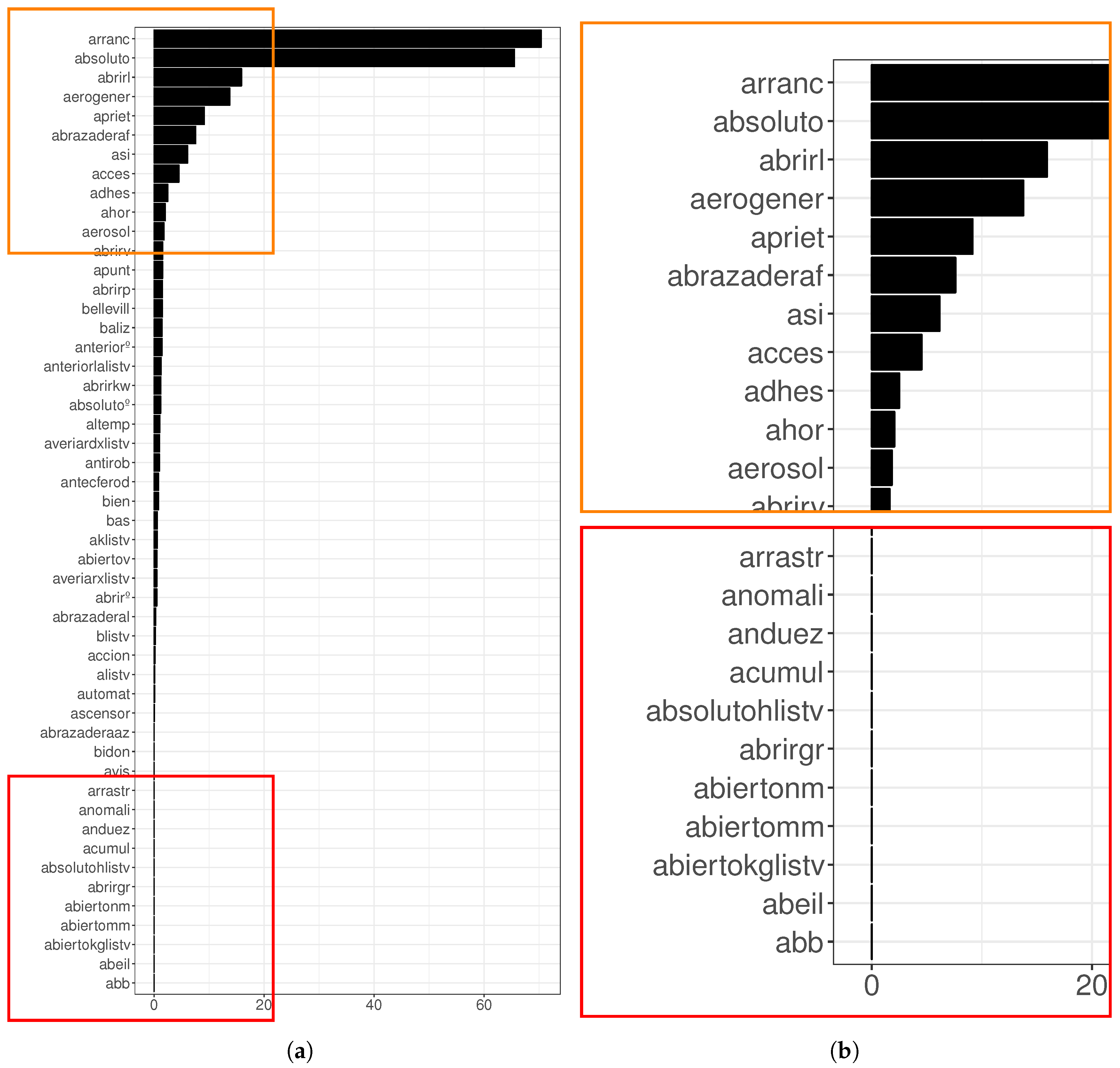

3.2. Word Clouds

3.3. Model Results

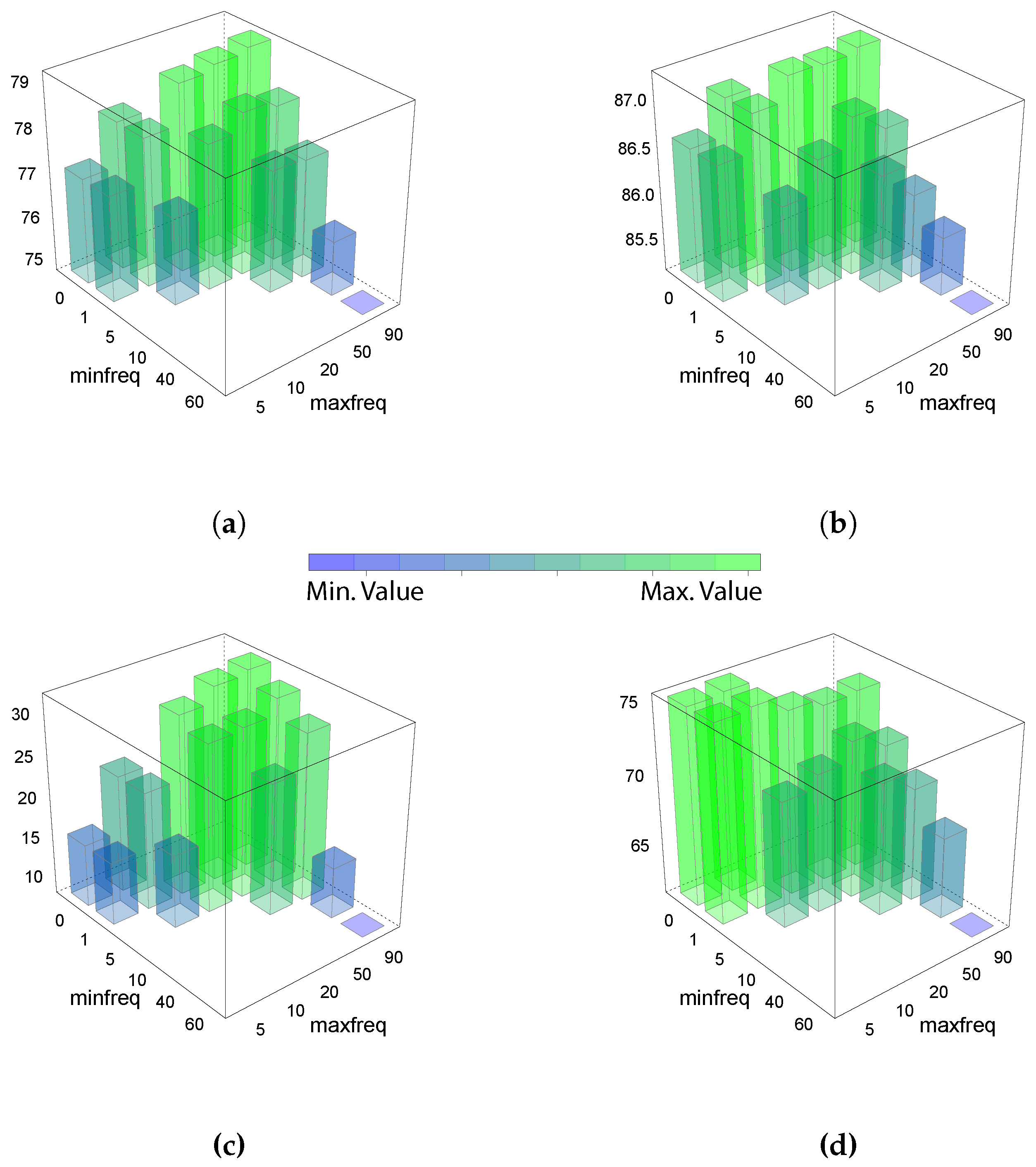

3.3.1. Decision Trees

Generator Failures

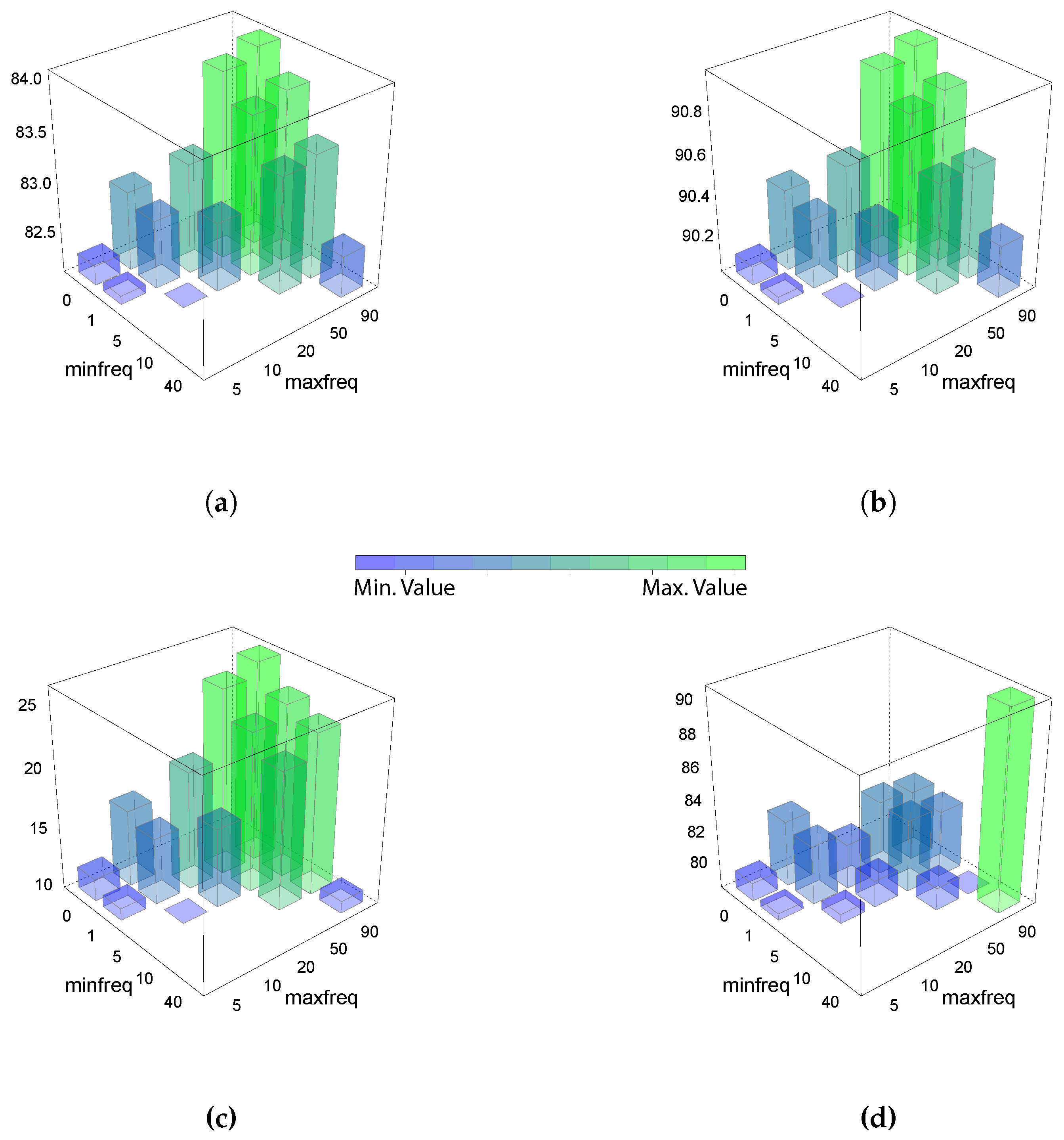

Gearbox Failures

3.3.2. Random Forest

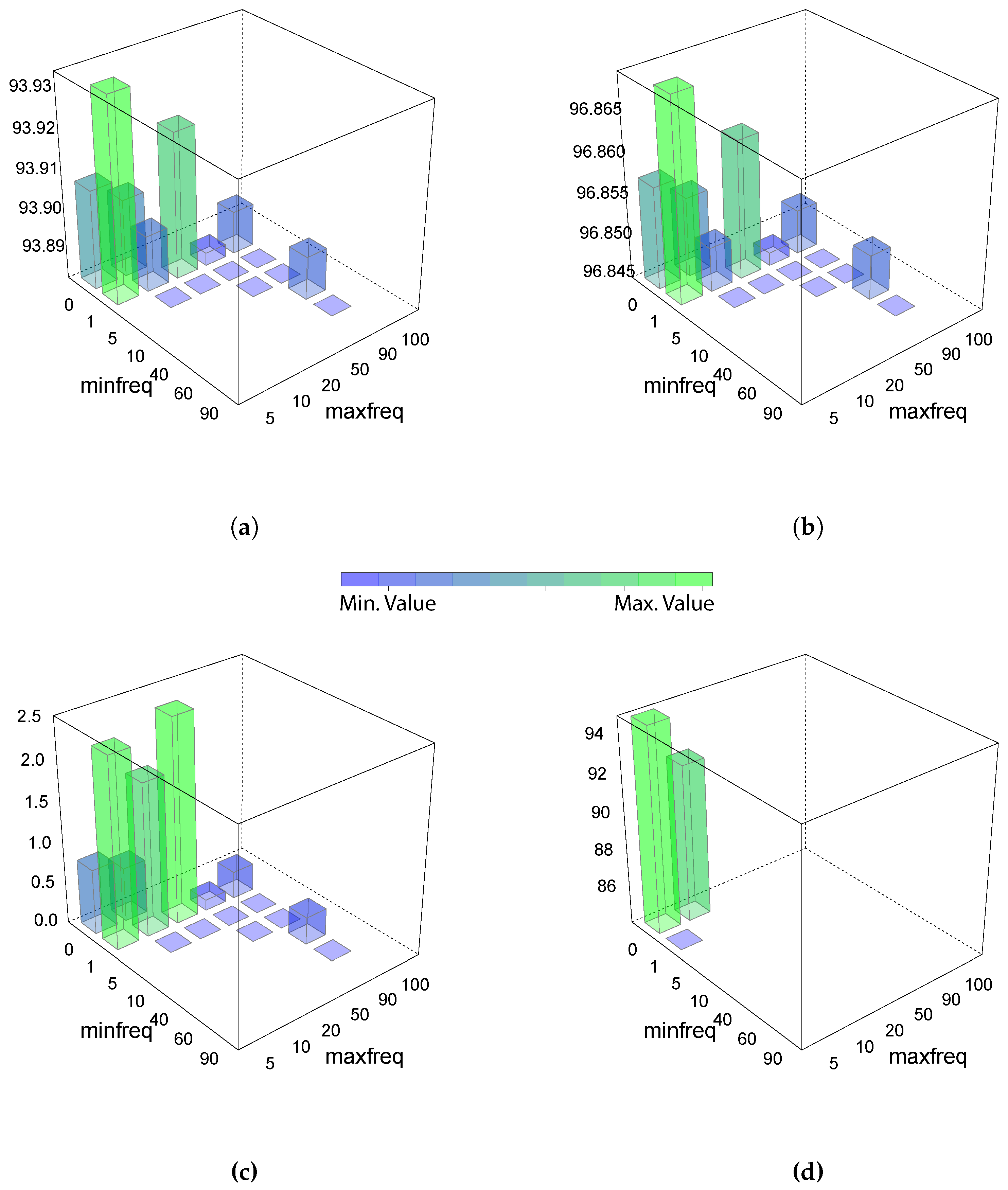

Generator Failures

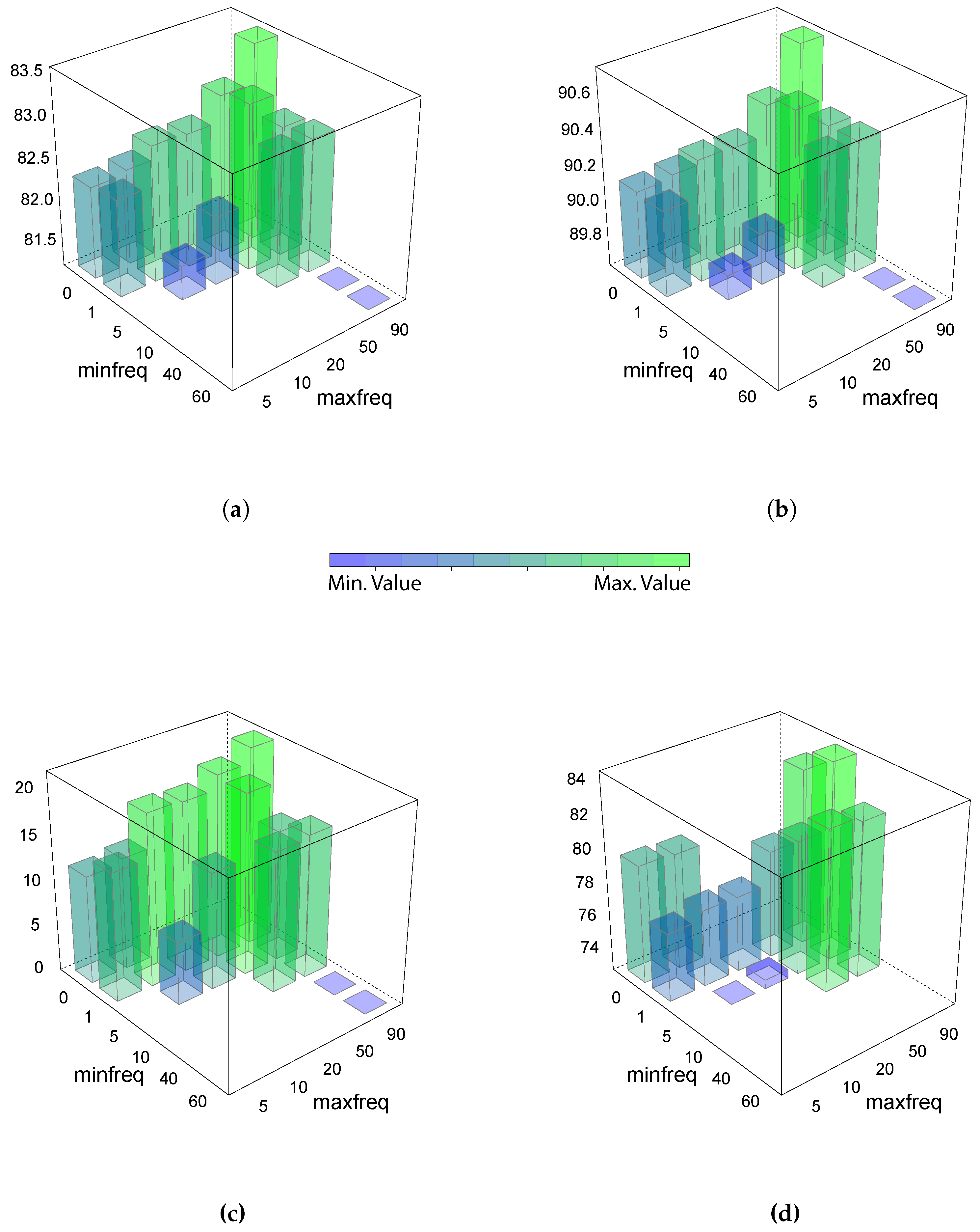

Gearbox Failures

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| AUC | area under the curve |

| CBM | condition based maintenance |

| CMS | condition monitoring systems |

| CM | confusion matrix |

| CP | decision trees complexity parameter |

| DT | decision trees |

| MAE | mean absolute error |

| MSE | mean squared error |

| O&M | operation and maintenance |

| RF | random forest |

| SCADA | supervisory control and data acquisition data |

| WO | work order |

References

- Renewable Energy Policy Network for the 21st Century. Renewables 2016—Global Status Report; Technical Report; REN21: Paris, France, 2016; ISBN 978-3-9818107-0-7. [Google Scholar]

- European Comission. Renewable Energy: Progressing towards the 2020 Target. Technical Report 31 November 2011. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52011DC0031 (accessed on 21 March 2019).

- Eurostat. Energy Balance Sheets 2011–2012; Technical Report 9; Eurostats (European Union): Luxembourg, 2014. [Google Scholar] [CrossRef]

- Milborrow, D. Operation and Maintenance Costs Compared and Revealed; Haymarket Business Media: London, UK, 2006; Volume 19, pp. 1–87. [Google Scholar]

- Besnard, F.; Bertling, L. An approach for condition-based maintenance optimization applied to wind turbine blades. IEEE Trans. Sustain. Energy 2010, 1, 77–83. [Google Scholar] [CrossRef]

- European Commission. European Commission Guidance for the Design of Renewables Support Schemes. 2013. Available online: https://ec.europa.eu/energy/sites/ener/files/com_2013_public_intervention_swd04_en.pdf (accessed on 21 March 2019).

- European Commission. Energy and Environment State Aid Guidelines 2014–2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52014XC0628(01)&from=EN (accessed on 21 March 2019).

- García Márquez, F.P.; Tobias, A.M.; Pérez, J.M.P.; Papaelias, M. Condition monitoring of wind turbines: Techniques and methods. Renew. Energy 2012, 46, 169–178. [Google Scholar] [CrossRef]

- Kelley, N.D.; Jonkman, B.J.; Scott, G.; Bialasiewicz, J.; Redmond, L.S. Impact of Coherent Turbulence on Wind Turbine Aeroelastic Response and Its Simulation; Technical Report; National Renewable Energy Lab. (NREL): Golden, CO, USA, 2005.

- Churchfield, M.J.; Lee, S.; Michalakes, J.; Moriarty, P.J. A numerical study of the effects of atmospheric and wake turbulence on wind turbine dynamics. J. Turbul. 2012, 13, N14. [Google Scholar] [CrossRef]

- Nandi, T.N.; Herrig, A.; Brasseur, J.G. Non-steady wind turbine response to daytime atmospheric turbulence. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2017, 375, 20160103. [Google Scholar] [CrossRef] [PubMed]

- Choudhary, A.K.; Oluikpe, P.; Harding, J.A.; Carrillo, P.M. The needs and benefits of Text Mining applications on Post-Project Reviews. Comput. Ind. 2009, 60, 728–740. [Google Scholar] [CrossRef]

- Rajpathak, D.G. An ontology based text mining system for knowledge discovery from the diagnosis data in the automotive domain. Comput. Ind. 2013, 64, 565–580. [Google Scholar] [CrossRef]

- Te Liew, W.; Adhitya, A.; Srinivasan, R. Sustainability trends in the process industries: A text mining-based analysis. Comput. Ind. 2014, 65, 393–400. [Google Scholar] [CrossRef]

- Hossain, M.L.; Abu-Siada, A.; Muyeen, S. Methods for Advanced Wind Turbine Condition Monitoring and Early Diagnosis: A Literature Review. Energies 2018, 11, 1309. [Google Scholar] [CrossRef]

- Küçük, D.; Arslan, Y. Semi-automatic construction of a domain ontology for wind energy using Wikipedia articles. Renew. Energy 2014, 62, 484–489. [Google Scholar] [CrossRef]

- Asian, S.; Ertek, G.; Haksoz, C.; Pakter, S.; Ulun, S. Wind turbine accidents: A data mining study. IEEE Syst. J. 2017, 11, 1567–1578. [Google Scholar] [CrossRef]

- Martin-del Campo, S.; Sandin, F.; Strömbergsson, D. Dictionary learning approach to monitoring of wind turbine drivetrain bearings. arXiv 2019, arXiv:1902.01426. [Google Scholar]

- Çinicioğlu, E.N.; Ertek, G.; Demirer, D.; Yörük, H.E. A framework for automated association mining over multiple databases. In Proceedings of the IEEE 2011 International Symposium on Innovations in Intelligent Systems and Applications, Istanbul, Turkey, 15–18 June 2011; pp. 79–85. [Google Scholar]

- Ertek, G.; Tokdemir, G.; Sevinç, M.; Tunç, M.M. New knowledge in strategic management through visually mining semantic networks. Inf. Syst. Front. 2017, 19, 165–185. [Google Scholar] [CrossRef][Green Version]

- Uluyol, O.; Parthasarathy, G.; Foslien, W.; Kim, K. Power curve analytic for wind turbine performance monitoring and prognostics. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, Montreal, QC, Canada, 25–29 September 2011; Volume 2, pp. 1–8. [Google Scholar]

- Lydia, M.; Selvakumar, A.I.; Kumar, S.S.; Kumar, G.E.P. Advanced Algorithms for Wind Turbine Power Curve Modeling. IEEE Trans. Sustain. Energy 2013, 4, 827–835. [Google Scholar] [CrossRef]

- Feinerer, I.; Hornik, K.; Meyer, D. Text Mining Infrastructure in R. J. Stat. Softw. 2008, 25, 1–54. [Google Scholar] [CrossRef]

- Hotho, A.; Nürnberger, A.; Paaß, G. A Brief Survey of Text Mining. Ldv Forum 2005, 20, 19–62. [Google Scholar] [CrossRef]

- Karl, A.; Wisnowski, J.; Rushing, W.H. A practical guide to text mining with topic extraction. Wiley Interdiscip. Rev. Comput. Stat. 2015, 7, 326–340. [Google Scholar] [CrossRef]

- Gan, Q.; Zhu, M.; Li, M.; Liang, T.; Cao, Y.; Zhou, B. Document visualization: An overview of current research. Wiley Interdiscip. Rev. Comput. Stat. 2014, 6, 19–36. [Google Scholar] [CrossRef]

- Fellows, I. Wordcloud: Word Clouds; R Package Version 2.6. Available online: https://cran.r-project.org/web/packages/wordcloud/wordcloud.pdf (accessed on 21 March 2019).

| Model Type | Min. Freq. % | Mx. Freq. % | Accuracy | F-Score | AUC | Kappa |

|---|---|---|---|---|---|---|

| DT | 0 | 5 | 0.772 | 0.866 | 0.755 | 0.159 |

| 0 | 10 | 0.782 | 0.87 | 0.757 | 0.226 | |

| 1 | 5 | 0.772 | 0.866 | 0.755 | 0.159 | |

| 1 | 10 | 0.782 | 0.870 | 0.757 | 0.226 | |

| 1 | 20 | 0.790 | 0.873 | 0.746 | 0.302 | |

| 1 | 50 | 0.792 | 0.873 | 0.741 | 0.321 | |

| 1 | 90 | 0.793 | 0.873 | 0.743 | 0.326 | |

| 5 | 10 | 0.768 | 0.862 | 0.705 | 0.172 | |

| 5 | 20 | 0.781 | 0.866 | 0.714 | 0.288 | |

| 5 | 50 | 0.785 | 0.869 | 0.727 | 0.291 | |

| 5 | 90 | 0.783 | 0.866 | 0.716 | 0.310 | |

| 10 | 50 | 0.776 | 0.864 | 0.710 | 0.244 | |

| 10 | 90 | 0.775 | 0.861 | 0.696 | 0.287 | |

| 40 | 90 | 0.760 | 0.858 | 0.674 | 0.145 | |

| 60 | 90 | 0.748 | 0.852 | 0.617 | 0.082 | |

| RF | 0 | 5 | 0.9391 | 0.9686 | 0.950 | 0.008 |

| 0 | 10 | 0.9390 | 0.9685 | 0.924 | 0.007 | |

| 1 | 5 | 0.9393 | 0.9687 | 0.841 | 0.023 | |

| 1 | 10 | 0.9390 | 0.9685 | 0.750 | 0.019 | |

| 1 | 20 | 0.9392 | 0.9686 | 0.788 | 0.025 | |

| 1 | 50 | 0.9388 | 0.9685 | 0.869 | 0.001 | |

| 1 | 90 | 0.9389 | 0.9685 | 0.969 | 0.003 | |

| 5 | 10 | 0.9388 | 0.9684 | NA | NA | |

| 5 | 20 | 0.9388 | 0.9684 | NA | NA | |

| 5 | 50 | 0.9388 | 0.9684 | NA | NA | |

| 5 | 90 | 0.9388 | 0.9684 | NA | NA | |

| 10 | 50 | 0.9388 | 0.9684 | NA | NA | |

| 10 | 90 | 0.9388 | 0.9684 | NA | NA | |

| 40 | 90 | 0.9389 | 0.9685 | 0.969 | 0.003 | |

| 60 | 90 | 0.9388 | 0.9684 | NA | NA |

| Model Type | Min. Freq. % | Max. Freq. % | Accuracy | F-Score | AUC | Kappa |

|---|---|---|---|---|---|---|

| DT | 0 | 5 | 0.823 | 0.901 | 0.796 | 0.117 |

| 0 | 10 | 0.829 | 0.904 | 0.825 | 0.163 | |

| 1 | 5 | 0.822 | 0.901 | 0.788 | 0.109 | |

| 1 | 10 | 0.828 | 0.904 | 0.821 | 0.155 | |

| 1 | 20 | 0.832 | 0.905 | 0.812 | 0.198 | |

| 1 | 50 | 0.840 | 0.909 | 0.831 | 0.254 | |

| 1 | 90 | 0.841 | 0.910 | 0.828 | 0.266 | |

| 5 | 10 | 0.821 | 0.900 | 0.790 | 0.099 | |

| 5 | 20 | 0.828 | 0.903 | 0.801 | 0.165 | |

| 5 | 50 | 0.837 | 0.908 | 0.830 | 0.232 | |

| 5 | 90 | 0.838 | 0.909 | 0.826 | 0.244 | |

| 10 | 50 | 0.833 | 0.906 | 0.798 | 0.214 | |

| 10 | 90 | 0.834 | 0.906 | 0.784 | 0.234 | |

| 40 | 90 | 0.825 | 0.903 | 0.908 | 0.109 | |

| RF | 0 | 5 | 0.823 | 0.901 | 0.798 | 0.119 |

| 0 | 10 | 0.824 | 0.901 | 0.797 | 0.124 | |

| 1 | 5 | 0.824 | 0.901 | 0.768 | 0.142 | |

| 1 | 10 | 0.828 | 0.903 | 0.773 | 0.19 | |

| 1 | 20 | 0.828 | 0.903 | 0.773 | 0.188 | |

| 1 | 50 | 0.831 | 0.905 | 0.792 | 0.203 | |

| 1 | 90 | 0.836 | 0.907 | 0.833 | 0.219 | |

| 5 | 10 | 0.816 | 0.898 | 0.727 | 0.070 | |

| 5 | 20 | 0.820 | 0.899 | 0.732 | 0.129 | |

| 5 | 50 | 0.832 | 0.905 | 0.807 | 0.199 | |

| 5 | 90 | 0.828 | 0.904 | 0.846 | 0.145 | |

| 10 | 50 | 0.828 | 0.904 | 0.824 | 0.155 | |

| 10 | 90 | 0.828 | 0.904 | 0.820 | 0.158 | |

| 40 | 90 | 0.812 | 0.896 | NA | NA | |

| 60 | 90 | 0.812 | 0.896 | NA | NA |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blanco-M., A.; Marti-Puig, P.; Gibert, K.; Cusidó, J.; Solé-Casals, J. A Text-Mining Approach to Assess the Failure Condition of Wind Turbines Using Maintenance Service History. Energies 2019, 12, 1982. https://doi.org/10.3390/en12101982

Blanco-M. A, Marti-Puig P, Gibert K, Cusidó J, Solé-Casals J. A Text-Mining Approach to Assess the Failure Condition of Wind Turbines Using Maintenance Service History. Energies. 2019; 12(10):1982. https://doi.org/10.3390/en12101982

Chicago/Turabian StyleBlanco-M., Alejandro, Pere Marti-Puig, Karina Gibert, Jordi Cusidó, and Jordi Solé-Casals. 2019. "A Text-Mining Approach to Assess the Failure Condition of Wind Turbines Using Maintenance Service History" Energies 12, no. 10: 1982. https://doi.org/10.3390/en12101982

APA StyleBlanco-M., A., Marti-Puig, P., Gibert, K., Cusidó, J., & Solé-Casals, J. (2019). A Text-Mining Approach to Assess the Failure Condition of Wind Turbines Using Maintenance Service History. Energies, 12(10), 1982. https://doi.org/10.3390/en12101982