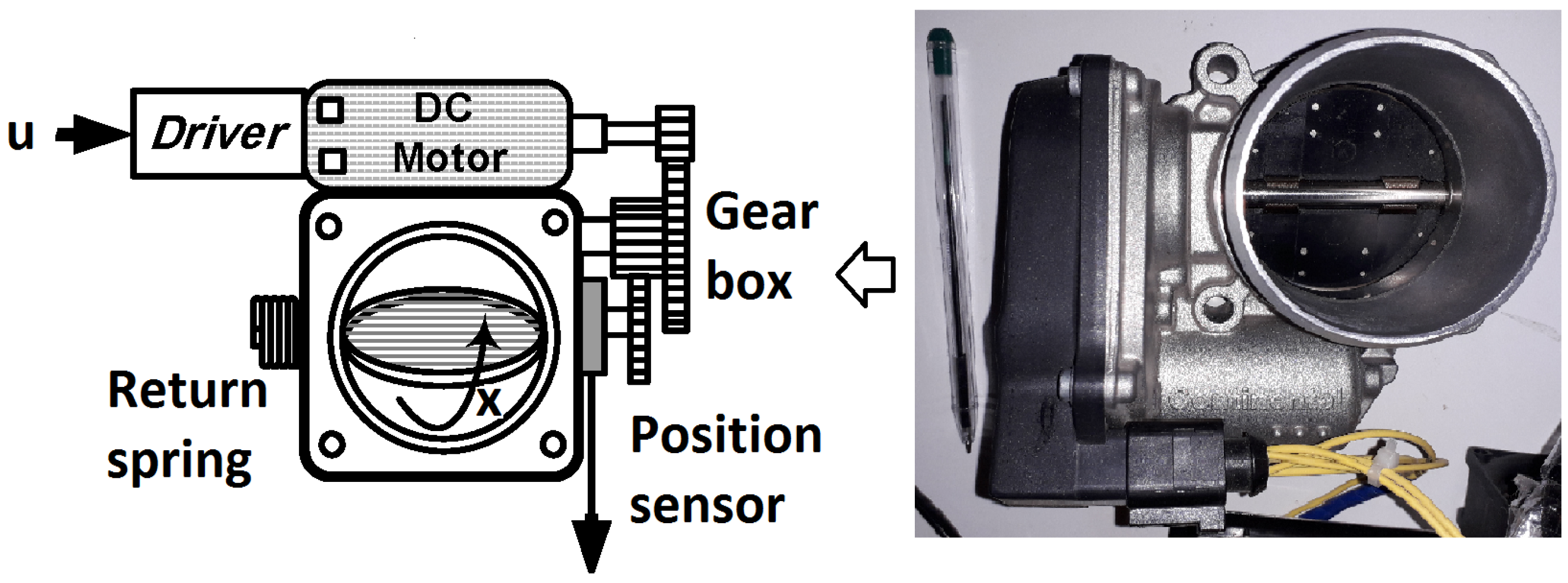

A Proportional Plus a Hysteretic Term Control Design: A Throttle Experimental Emulation to Wind Turbines Pitch Control

Abstract

1. Introduction

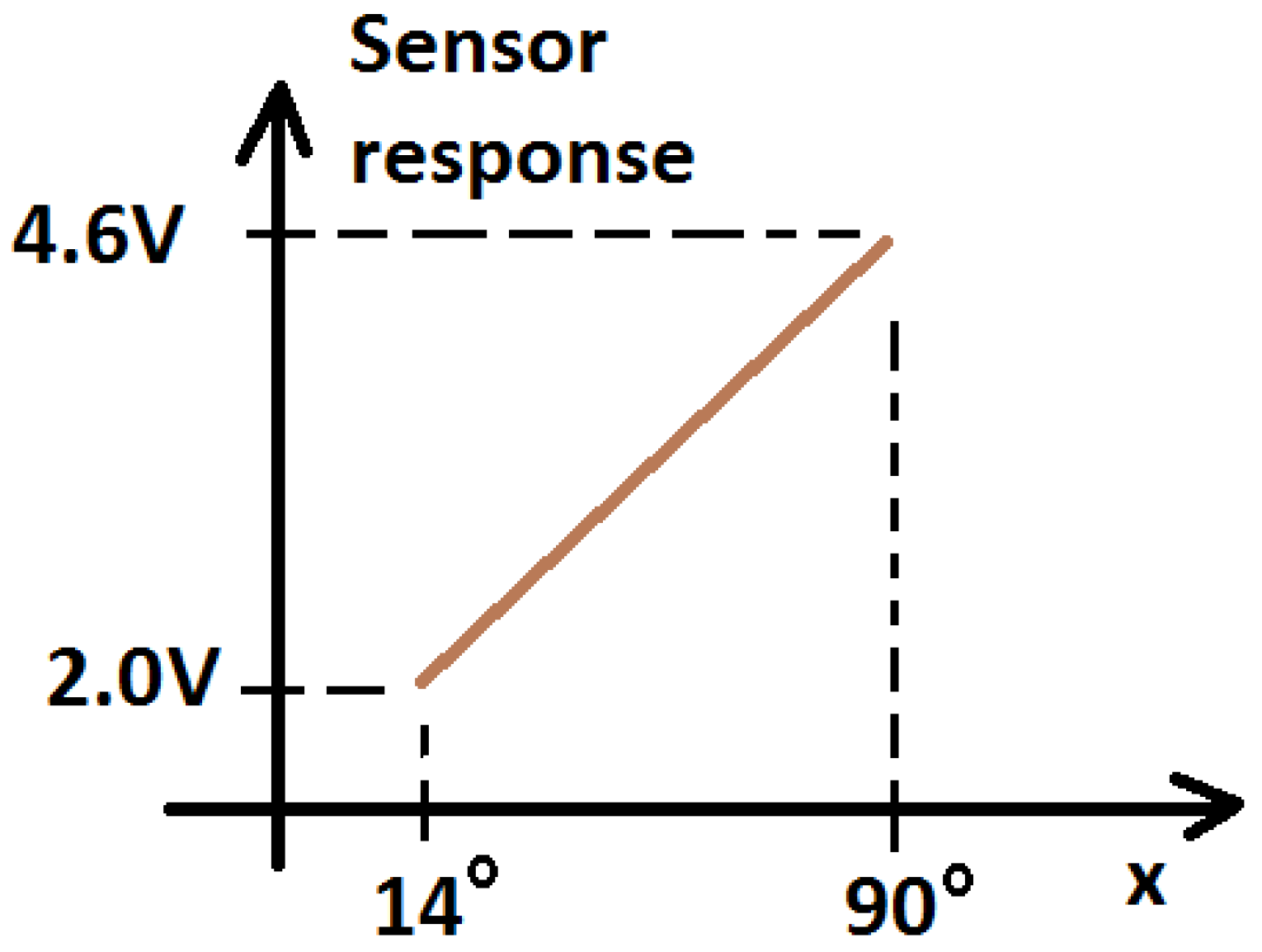

- Stick-slip friction

- Limp-home

- Backlash

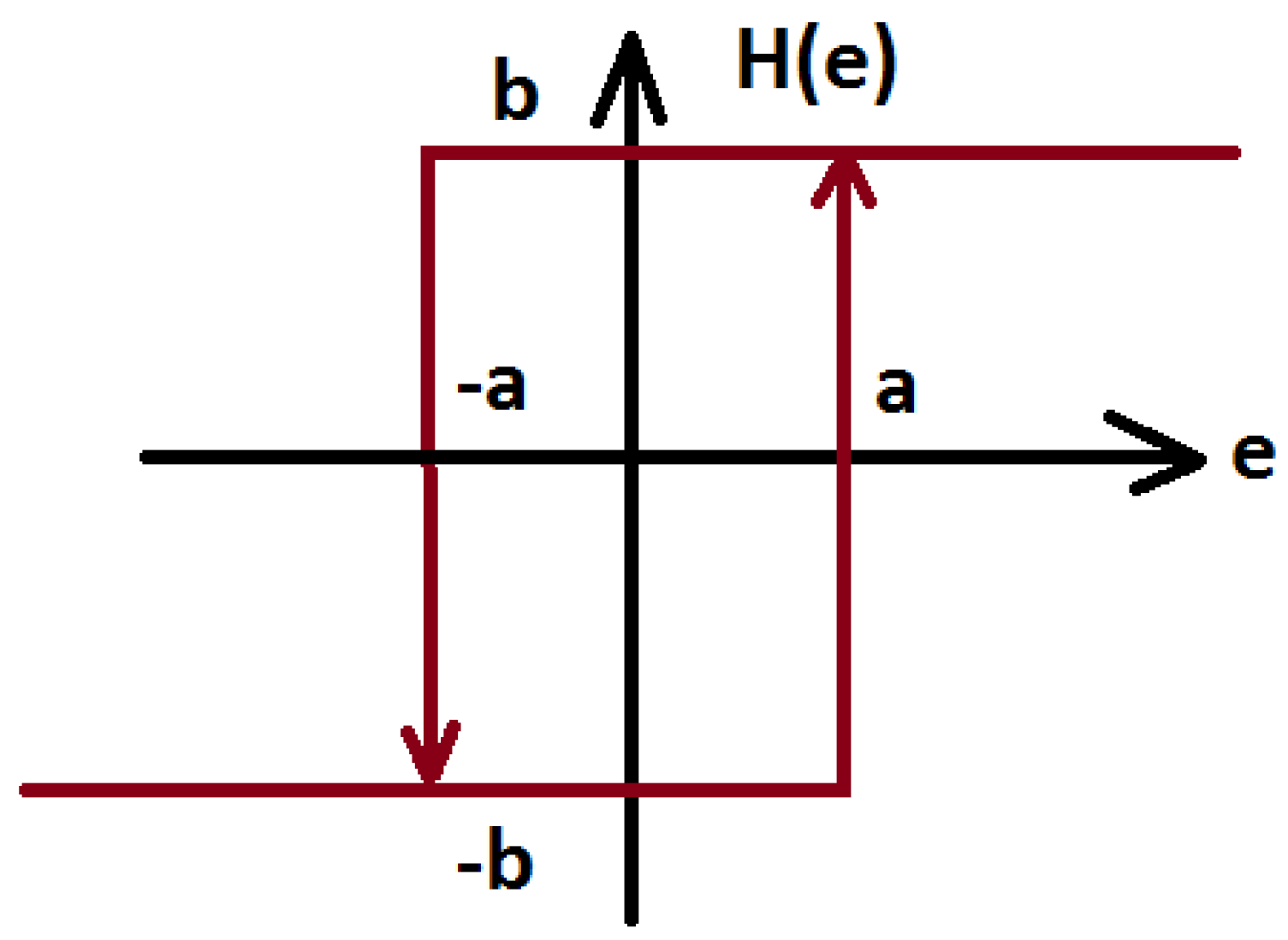

- Based on a simple model of the throttle device, a proportional and a hysteretic term controller is conceived

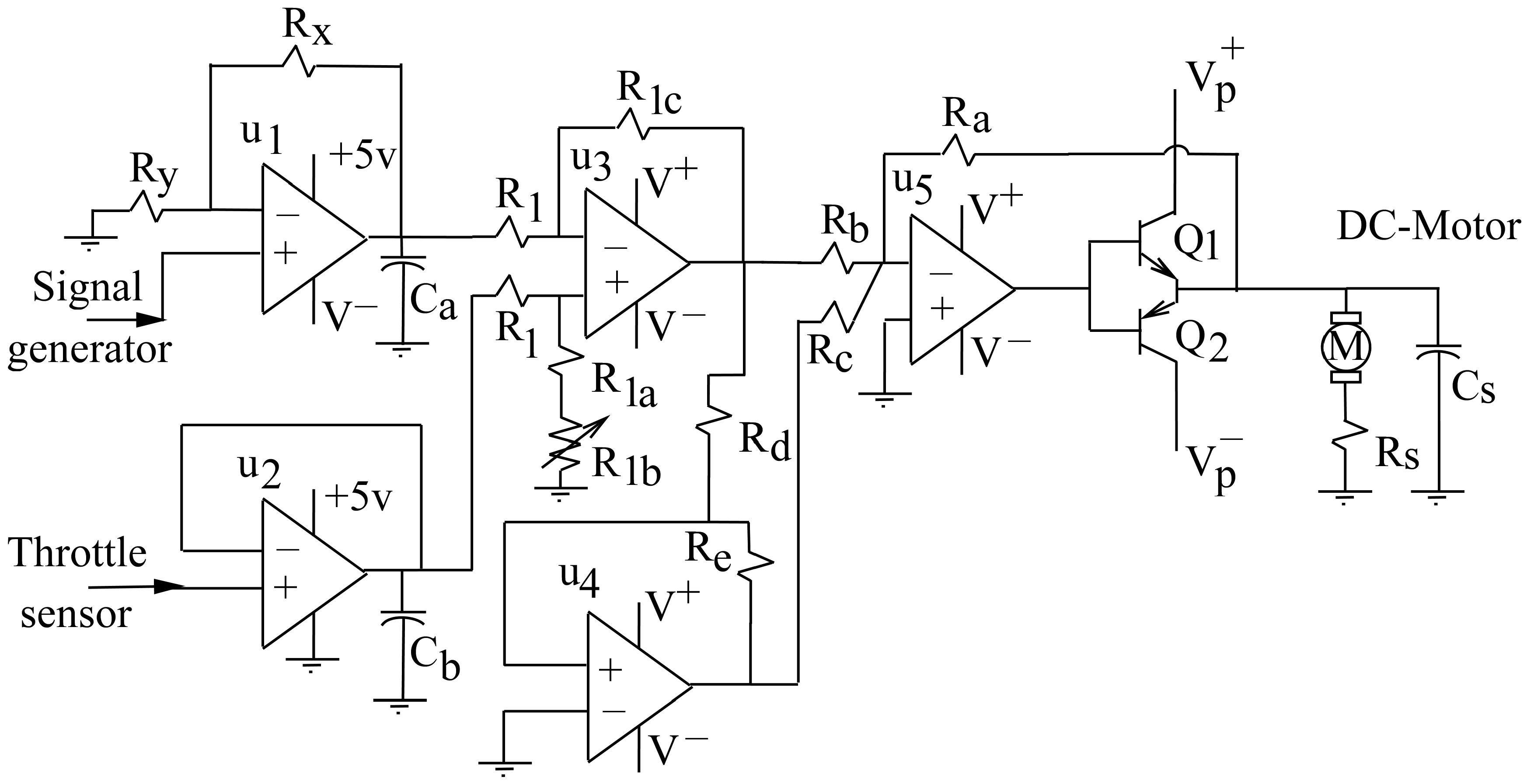

- A low cost control realization is granted by mainly using operational amplifiers

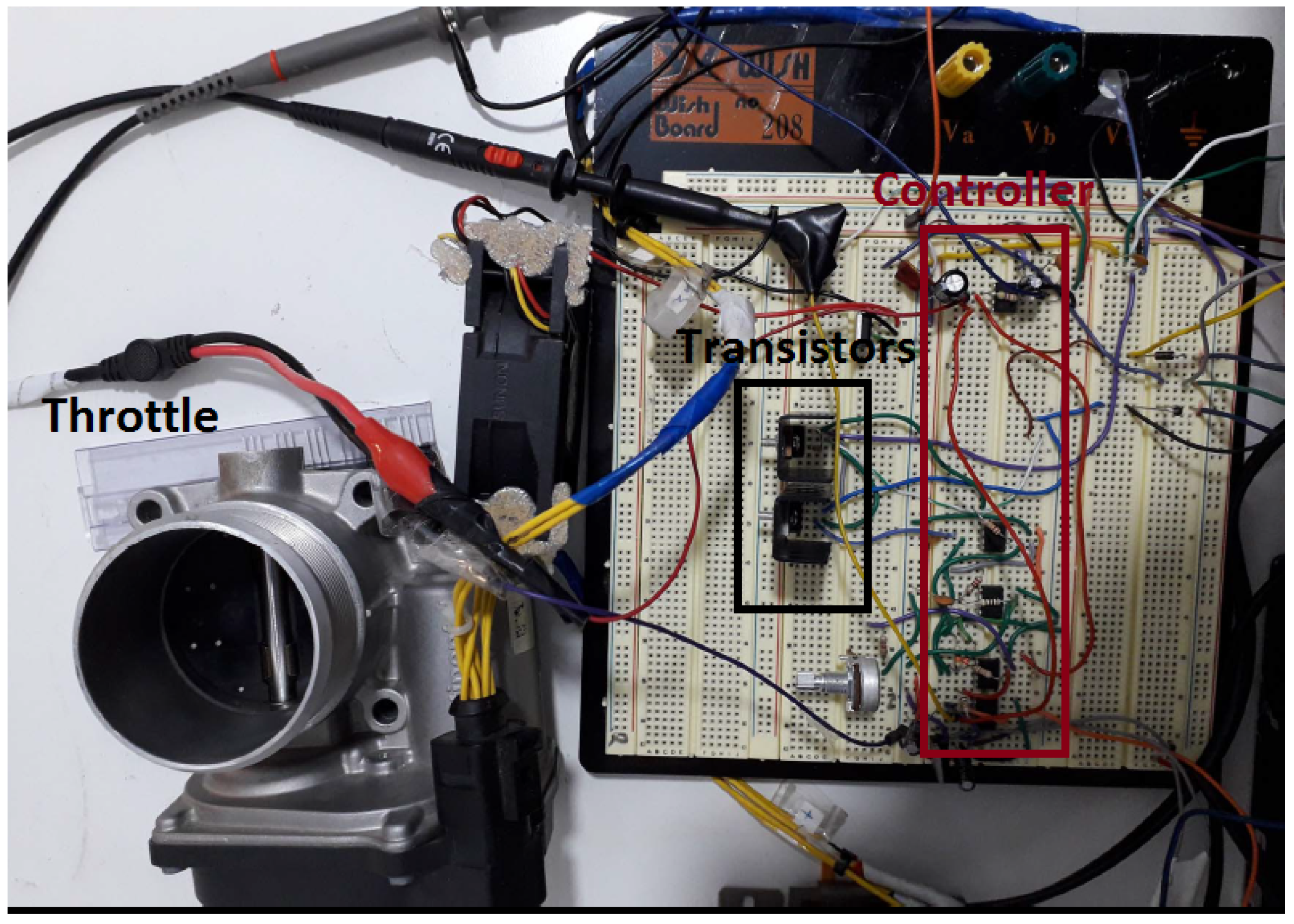

- The development of a low cost experimental platform is obtained.

Nomenclature

- R: Resistance

- C: Capacitance

- Q: Transistor

- V: Voltage source

- u: Operational amplifier

2. Control Design

3. Control Realization, Experimental Results and Discussion

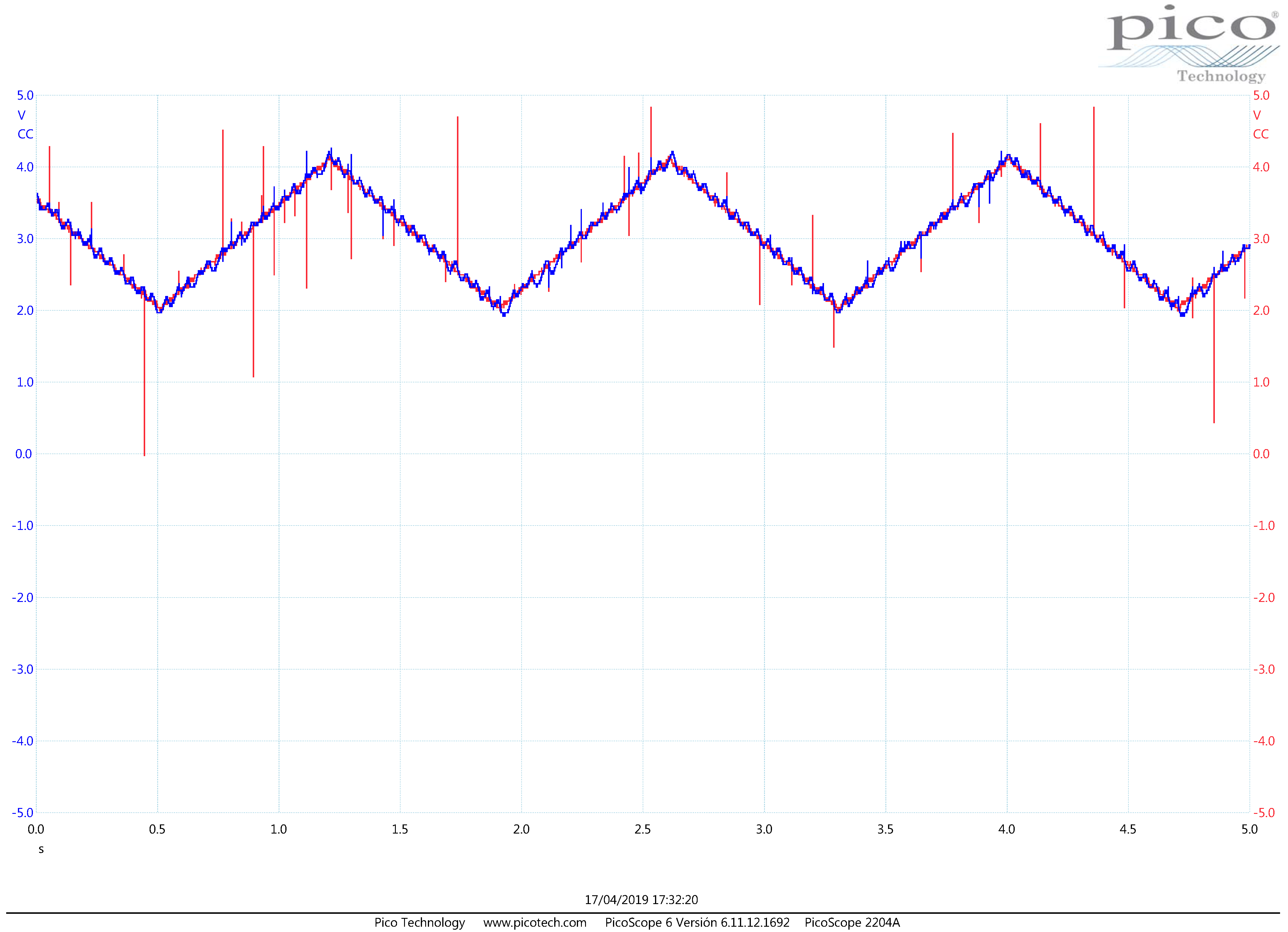

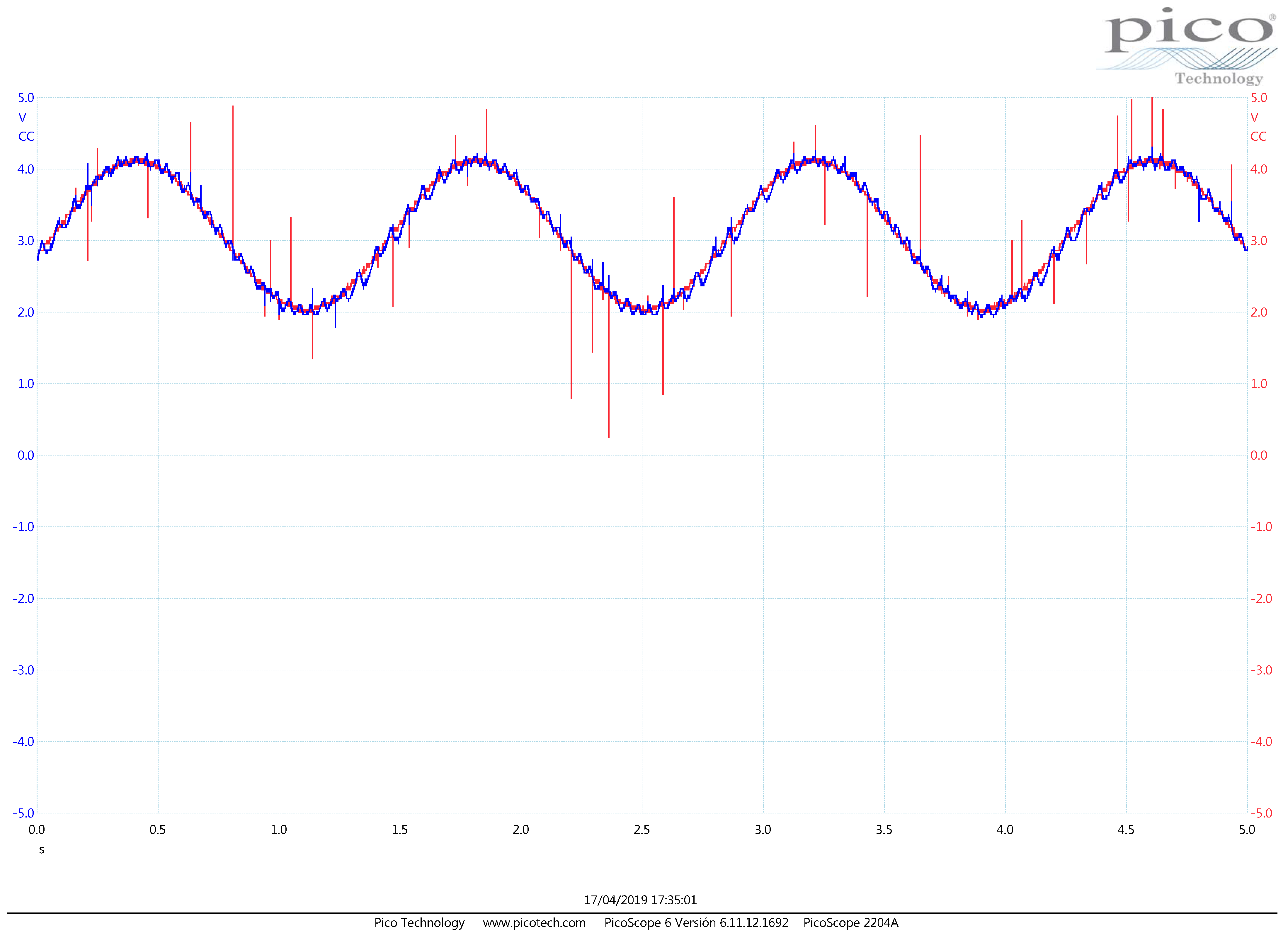

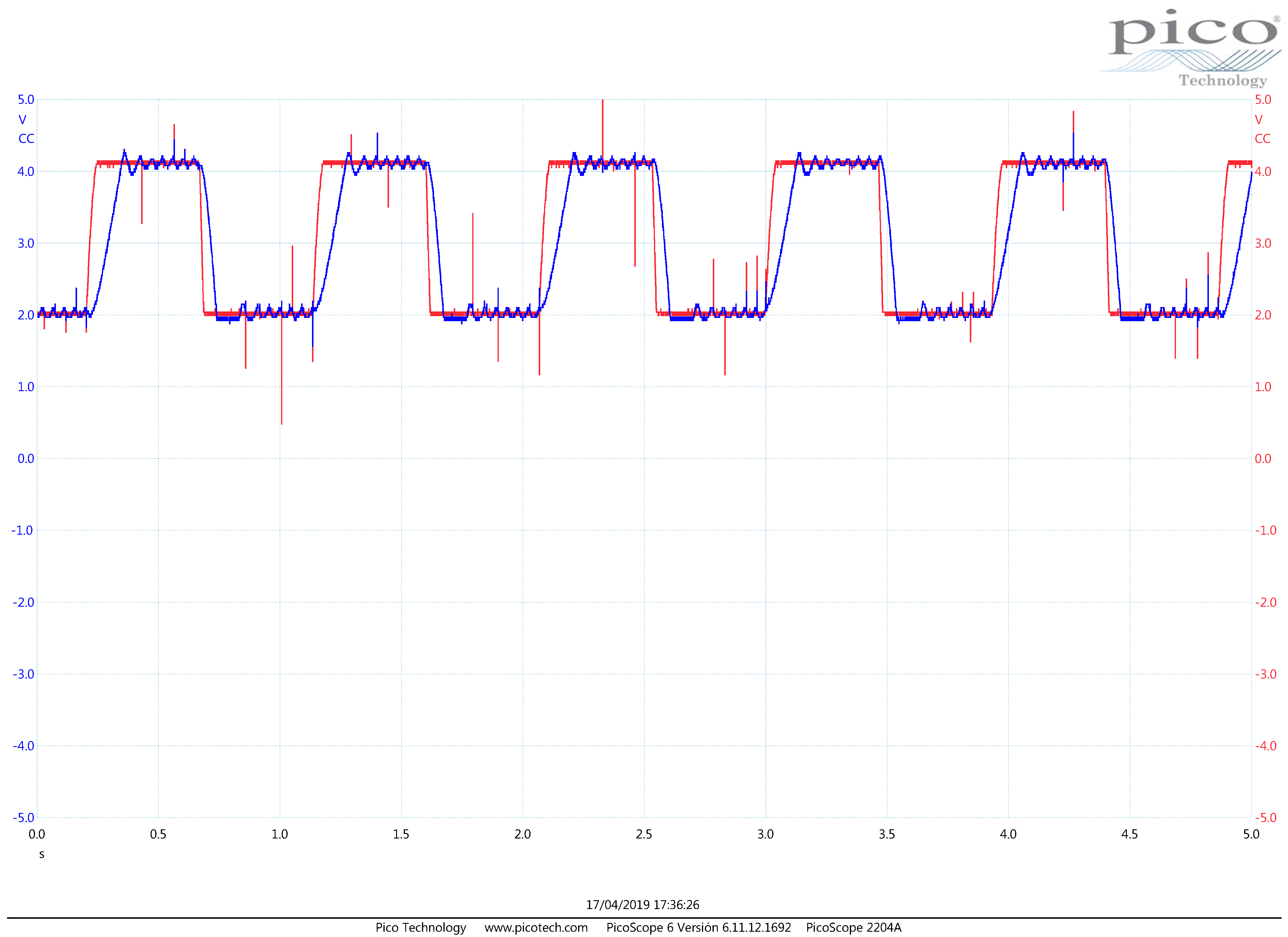

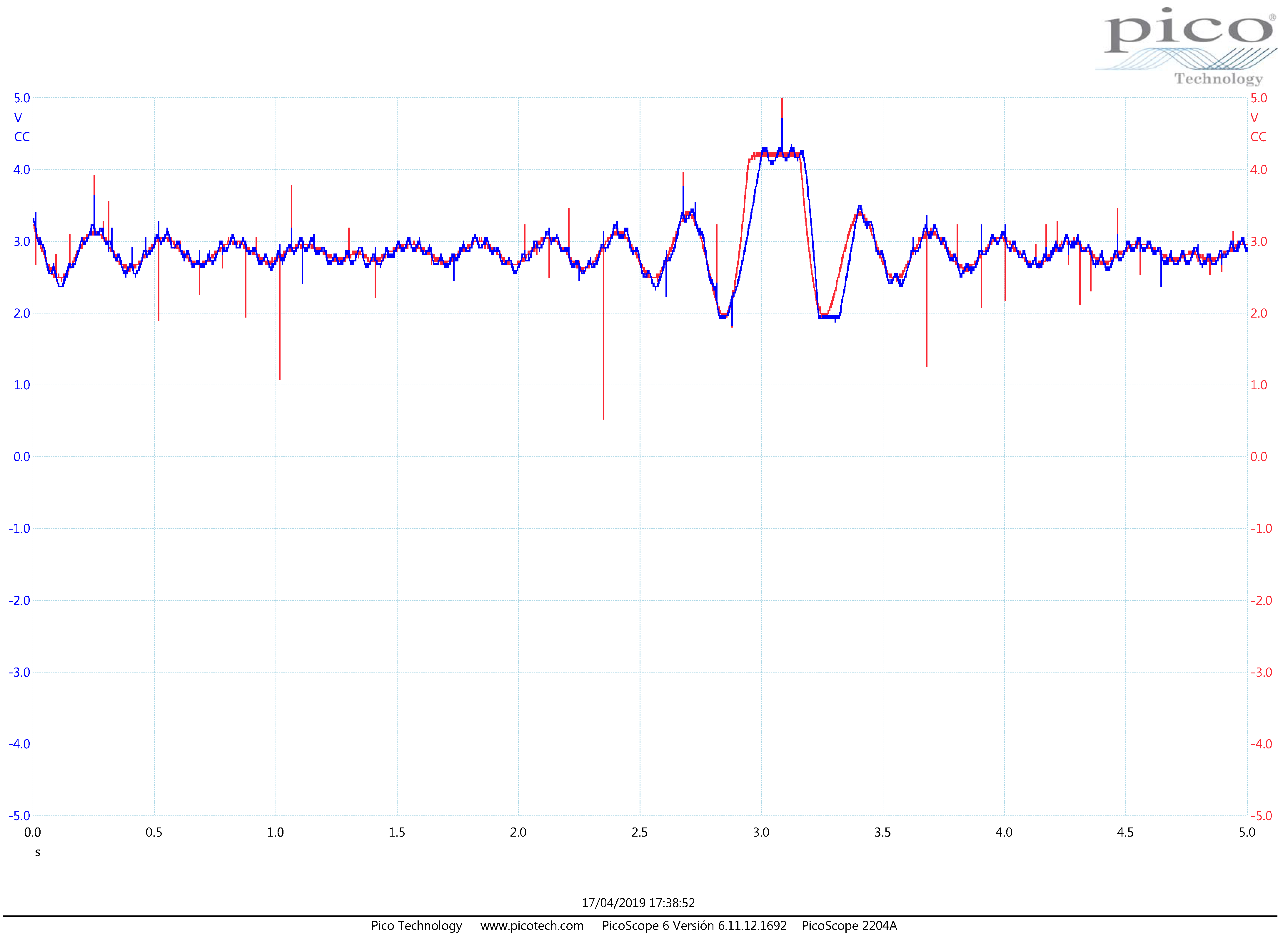

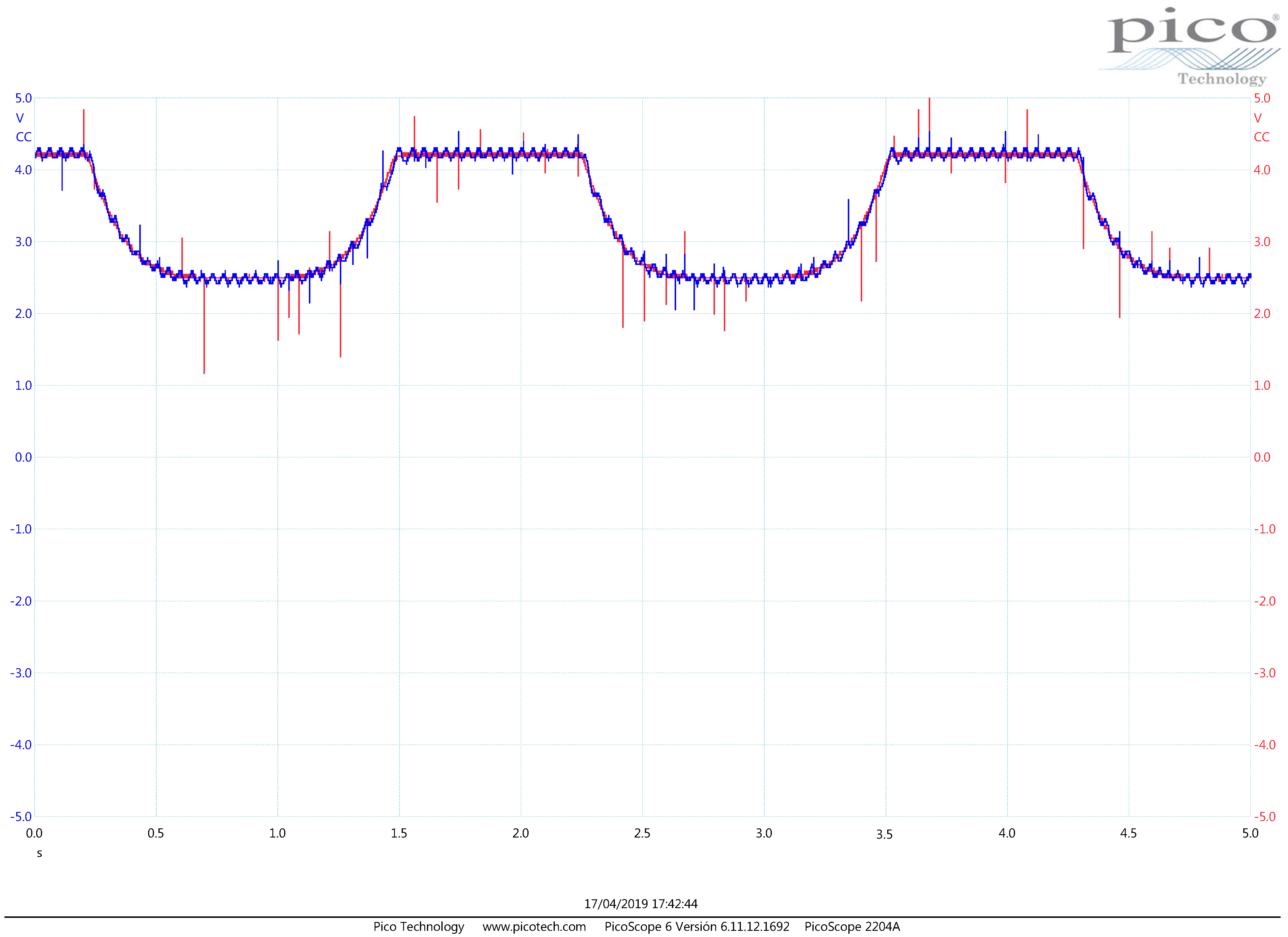

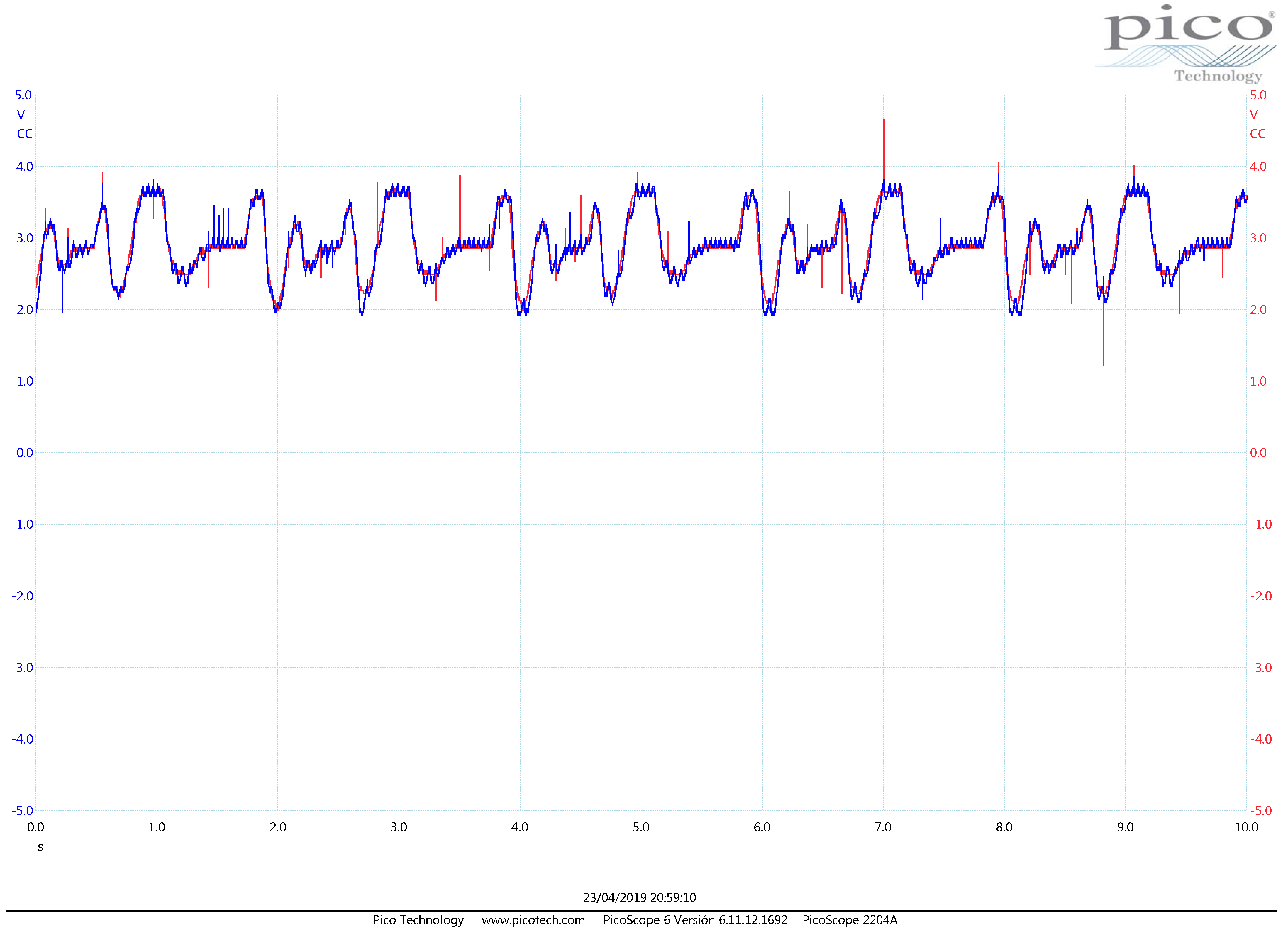

- The difference block that produces the error signal by reading the throttle sensor and the reference trajectory signal is implemented by the operational amplifier . The potentiometer in this block is employed to compensate mismatch among the resistance values. Therefore, is conceived to buffer the throttle sensor information, and is a buffer and amplifier of the user reference trajectory supplied by a signal generator device. We use the signal generator block from the PicoScope 2000 Series digital Oscilloscope (PicoScope, Cambridgeshire, UK) device, and we employ it to read other voltage signals too. Hence, the output at this operational amplifier is actually the reference trajectory utilized by the controller.

- The hysteretic block is implemented by the operational amplifier . Its functionality and description can be found, for example, in [27].

- The operational amplifier is armed to collect the proportional and the hysteretical terms to produce the control signal at the output of this operational amplifier.

- The power amplifier stage to send the control signal to the throttle DC-Motor is coined by the power amplifiers and .

- The capacitor is connected in parallel to the throttle DC-Motor, which is important not just to mitigate radiation of electromagnetic perturbation waves, but also to reduce other noises in the closed-loop system because of the commutation actions produced by the hysteretical block.

- The capacitors and are not critical. These can be any values, for instance, between 0.01 μF to 10 μF. These capacitors are used to filter noisy signals.

- The power resistance is added as an option to measure the current demanded by the throttle DC-Motor. This was implemented for future works where this information may be important depending on the future application.

- From the experimental result pictures, we can observe some “spikes” that may be eliminated by using appropriate filters and well tuned choke inductors. We decide to keep them, however, in order to validate the robustness controller performance under sensor noise perturbation too.

- The controller approach is more simple than a PID controller, for instance.

- To develop a Hardware-In-the-Loop system where a wind turbine is simulated in a computer and the pitch actuator dynamic is captured by a throttle device.

- To realize a fault detection algorithm applied to wind turbine pitch systems. Then, to use the proposed platform for its performance validation.

- To compare other controller strategies with respect to the given controller approach.

4. Conclusions

Funding

Conflicts of Interest

Abbreviations

| DC-Motor | Direct-Current motor |

| PID controller | Proportional-Integral-Derivative controller |

| VDO | Vereinigte DEUTA - OTA (English: United DEUTA - OTA) |

| signum | |

| P.N. | Part Number |

| M | Motor |

References

- Vidal Seguí, Y.; Acho Zuppa, L.; Pozo Montero, F. Robust control of an electronic throttle system via switched chattering control: Benchmark experiments. In Proceedings of the IFAC Workshop on Engine and Powertrain Control, Simulation and Modeling, Rueil, France, 30 November–2 December 2009. [Google Scholar]

- Vidal, Y.; Acho, L.; Luo, N.; Tutiven, C. Hardware in the loop wind turbine simulator for control system testing. In Wind Turbine Control and Monitoring; Springer: Berlin, Germany, 2014; pp. 449–466. [Google Scholar]

- Vidal, Y.; Acho, L.; Luo, N.; Zapateiro, M.; Pozo, F. Power control design for variable-speed wind turbines. Energies 2012, 5, 3033–3050. [Google Scholar] [CrossRef]

- Deur, J.; Pavkovic, D.; Peric, N.; Jansz, M.; Hrovat, D. An electronic throttle control strategy including compensation of friction and limp-home effects. IEEE Trans. Ind. Appl. 2004, 40, 821–834. [Google Scholar] [CrossRef]

- Pavković, D.; Deur, J.; Jansz, M.; Perić, N. Adaptive control of automotive electronic throttle. Control Eng. Pract. 2006, 14, 121–136. [Google Scholar] [CrossRef]

- Vargas, A.N.; Menegaz, H.M.; Ishihara, J.Y.; Acho, L. Unscented Kalman filters for estimating the position of an automotive electronic throttle valve. IEEE Trans. Veh. Technol. 2016, 65, 4627–4632. [Google Scholar] [CrossRef]

- Pujol, G.; Vidal, Y.; Acho, L.; Vargas, A.N. Asymmetric modelling and control of an electronic throttle. Int. J. Numer. Model. Electron. Netw. Devices Fields 2016, 29, 192–204. [Google Scholar] [CrossRef]

- Vargas, A.; Acho Zuppa, L.; Pujol Vázquez, G.; Oliveira, R.C.; do Val, J.B.; Peres, P.L. Robust H2 static output feedback to control an autmomotive throttle valve. In Proceedings of the 2014 American Control Conference—ACC, Portland, OR, USA, 4–6 June 2014; pp. 3141–3146. [Google Scholar]

- Vargas, A.N.; Acho, L.; Pujol, G.; Costa, E.F.; Ishihara, J.Y.; do Val, J.B. Output feedback of Markov jump linear systems with no mode observation: An automotive throttle application. Int. J. Robust Nonlinear Control 2016, 26, 1980–1993. [Google Scholar] [CrossRef]

- Zaki, A.M.; El-Bardini, M.; Soliman, F.; Sharaf, M.M. Embedded two level direct adaptive fuzzy controller for DC motor speed control. Ain Shams Eng. J. 2018, 9, 65–75. [Google Scholar] [CrossRef]

- Zapateiro De la Hoz, M.; Acho, L.; Vidal, Y. An experimental realization of a chaos-based secure communication using arduino microcontrollers. Sci. World J. 2015, 2015, 123080. [Google Scholar] [CrossRef] [PubMed]

- Acho, L. A discrete-time chaotic oscillator based on the logistic map: A secure communication scheme and a simple experiment using Arduino. J. Frankl. Inst. 2015, 352, 3113–3121. [Google Scholar] [CrossRef]

- Barber, R.; Horra, M.; Crespo, J. Control practices using simulink with arduino as low cost hardware. IFAC Proc. Vol. 2013, 46, 250–255. [Google Scholar] [CrossRef]

- Gambier, A.; Behera, A. Integrated Pitch Control System Design of a Wind Turbine by Using Multiobjective Optimization. IFAC-PapersOnLine 2018, 51, 239–244. [Google Scholar] [CrossRef]

- Yuan, Y.; Tang, J. Adaptive pitch control of wind turbine for load mitigation under structural uncertainties. Renew. Energy 2017, 105, 483–494. [Google Scholar] [CrossRef]

- Gao, R.; Gao, Z. Pitch control for wind turbine systems using optimization, estimation and compensation. Renew. Energy 2016, 91, 501–515. [Google Scholar] [CrossRef]

- Hatami, A.; Moetakef-Imani, B. Innovative adaptive pitch control for small wind turbine fatigue load reduction. Mechatronics 2016, 40, 137–145. [Google Scholar] [CrossRef]

- Oueslati, M.; Dahmouni, A.; Nasrallah, S.B. Effects of sudden change in pitch angle on oscillating wind turbine airfoil performances. Eng. Anal. Bound. Elem. 2017, 81, 21–34. [Google Scholar] [CrossRef]

- Rezaeiha, A.; Kalkman, I.; Blocken, B. Effect of pitch angle on power performance and aerodynamics of a vertical axis wind turbine. Appl. Energy 2017, 197, 132–150. [Google Scholar] [CrossRef]

- Jiao, X.; Li, G.; Wang, H. Adaptive finite time servo control for automotive electronic throttle with experimental analysis. Mechatronics 2018, 53, 192–201. [Google Scholar] [CrossRef]

- Chaaban, R.; Ginsberg, D.; Fritzen, C.P. Structural load analysis of floating wind turbines under blade pitch system faults. In Wind Turbine Control and Monitoring; Springer: Berlin, Germany, 2014; pp. 301–334. [Google Scholar]

- Dimeas, I.; Petras, I.; Psychalinos, C. New analog implementation technique for fractional-order controller: A DC motor control. AEU-Int. J. Electron. Commun. 2017, 78, 192–200. [Google Scholar] [CrossRef]

- Grochowski, E.T.; Sharma, V.; Matthews, G.S.; Joshi, V.; Kling, R.M. Microprocessor with Digital Power Throttle. U.S. Patent 6,564,328, 13 May 2003. [Google Scholar]

- Krieder, R.D. Automatic Speed Control for Heavy Vehicles. U.S. Patent 4,419,729, 6 December 1983. [Google Scholar]

- Guerra, R.; Acho, L.; Aguilar, L. Adaptive friction compensation for mechanisms: A new perspective. Int. J. Robot. Autom. 2007, 22, 155–159. [Google Scholar] [CrossRef]

- Guerra, R.; Acho, L. Adaptive friction compensation for tracking control of mechanisms. Asian J. Control 2007, 9, 422–425. [Google Scholar] [CrossRef]

- Franco, S. Design with Operational Amplifiers and Analog Integrated Circuits; McGraw-Hill: New York, NY, USA, 2002; Volume 1988. [Google Scholar]

- Chybowski, L. Azimuth Thruster Hydraulic Instalations Reliability Model. In Proceedings of the Бaлттехмаш 2006, Kaliningrad, Russia, 20–23 June 2006; pp. 103–109. [Google Scholar]

- Chybowski, L.; Matuszak, Z. A Particular Model of Redundancy Useful in the Assessment of Operational Reliability and Safety of a Dynamic Positioning System of an Offshore Vessel. Pol. J. Environ. Stud. 2006, 15, 27–34. [Google Scholar]

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acho, L. A Proportional Plus a Hysteretic Term Control Design: A Throttle Experimental Emulation to Wind Turbines Pitch Control. Energies 2019, 12, 1961. https://doi.org/10.3390/en12101961

Acho L. A Proportional Plus a Hysteretic Term Control Design: A Throttle Experimental Emulation to Wind Turbines Pitch Control. Energies. 2019; 12(10):1961. https://doi.org/10.3390/en12101961

Chicago/Turabian StyleAcho, Leonardo. 2019. "A Proportional Plus a Hysteretic Term Control Design: A Throttle Experimental Emulation to Wind Turbines Pitch Control" Energies 12, no. 10: 1961. https://doi.org/10.3390/en12101961

APA StyleAcho, L. (2019). A Proportional Plus a Hysteretic Term Control Design: A Throttle Experimental Emulation to Wind Turbines Pitch Control. Energies, 12(10), 1961. https://doi.org/10.3390/en12101961