Optimization of an Organic Rankine Cycle System for an LNG-Powered Ship

Abstract

:1. Introduction

- ORC systems should be applicable to both high-pressure and medium-pressure dual-fuel engines.

- A configuration of an ORC system should be simple because the available space is small.

- ORC systems should be more economical than a typical LNG fuel supply system. To this end, ORC systems should have high exergy efficiency and net power output.

2. Methods

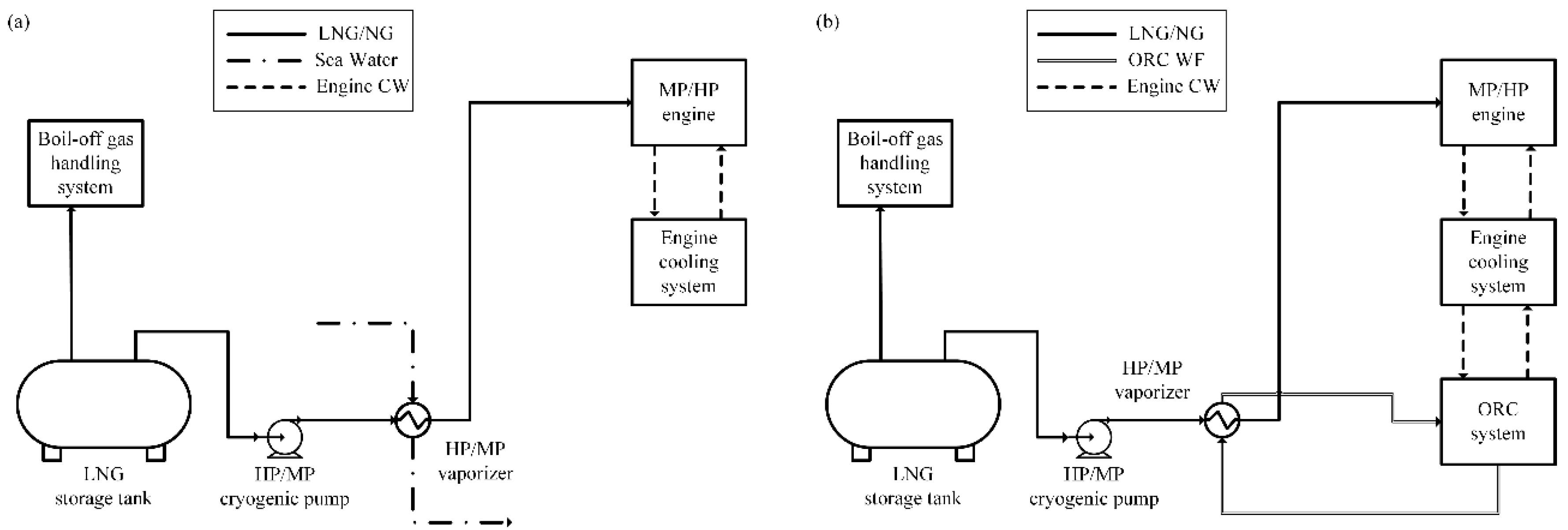

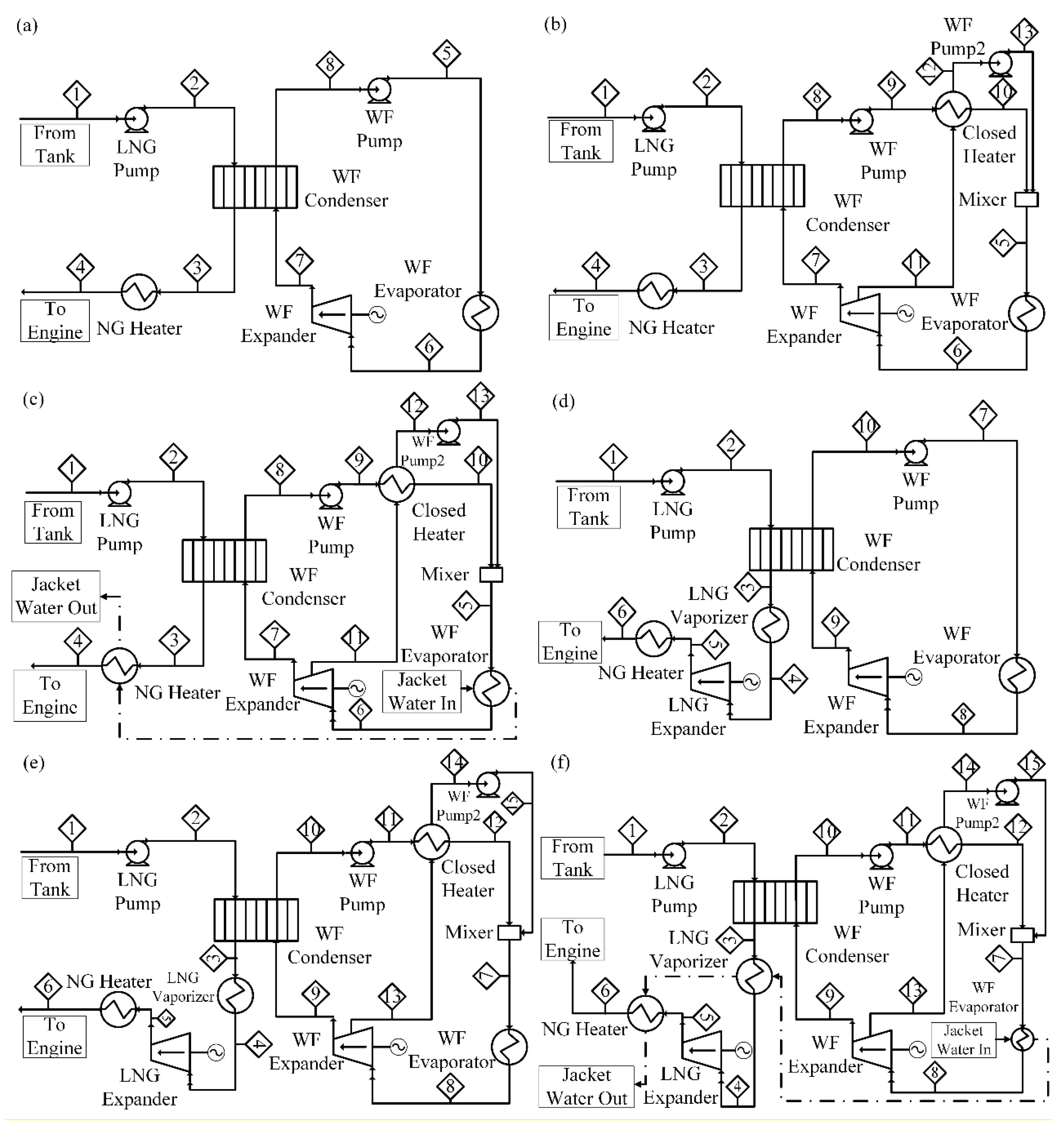

2.1. System Description

2.2. Simulation Model

2.3. Optimization Framework

2.4. Cost Estimation

3. Results and Discussion

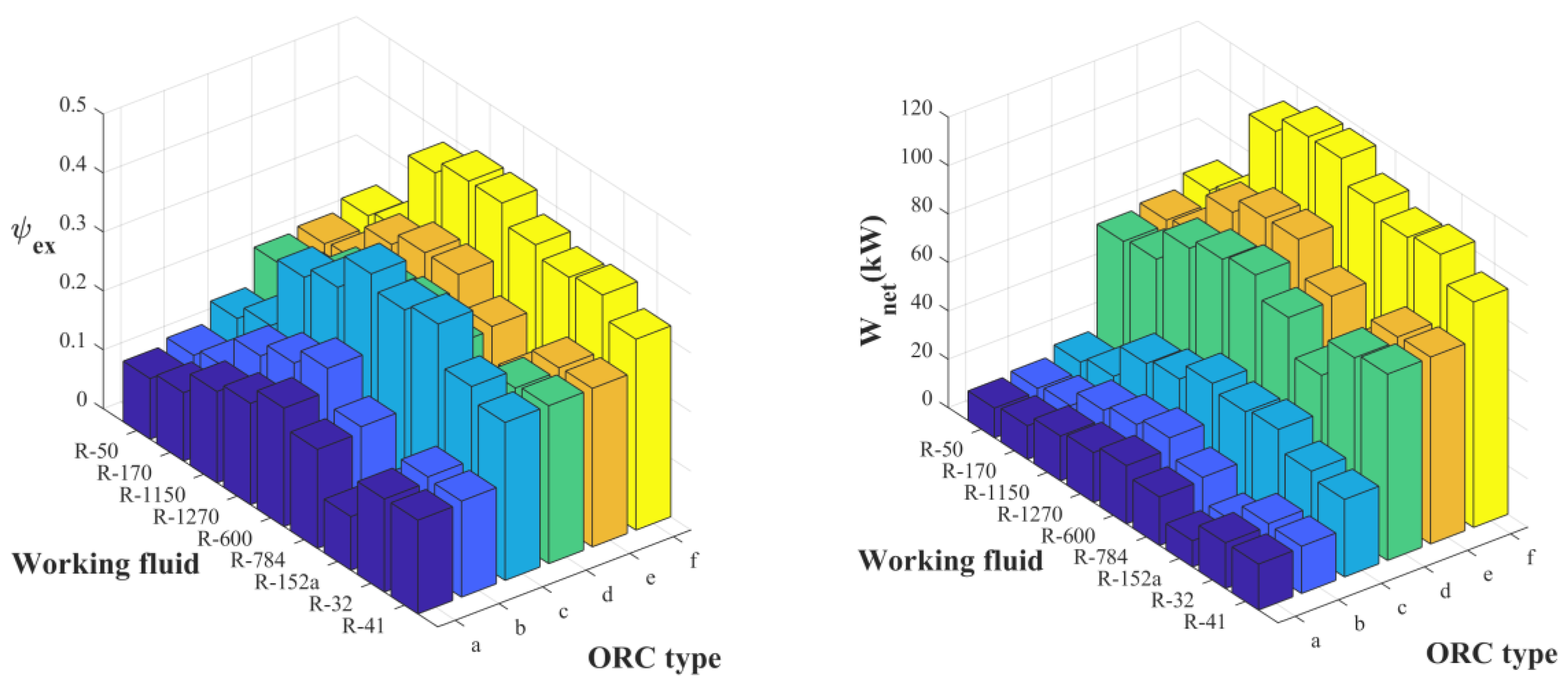

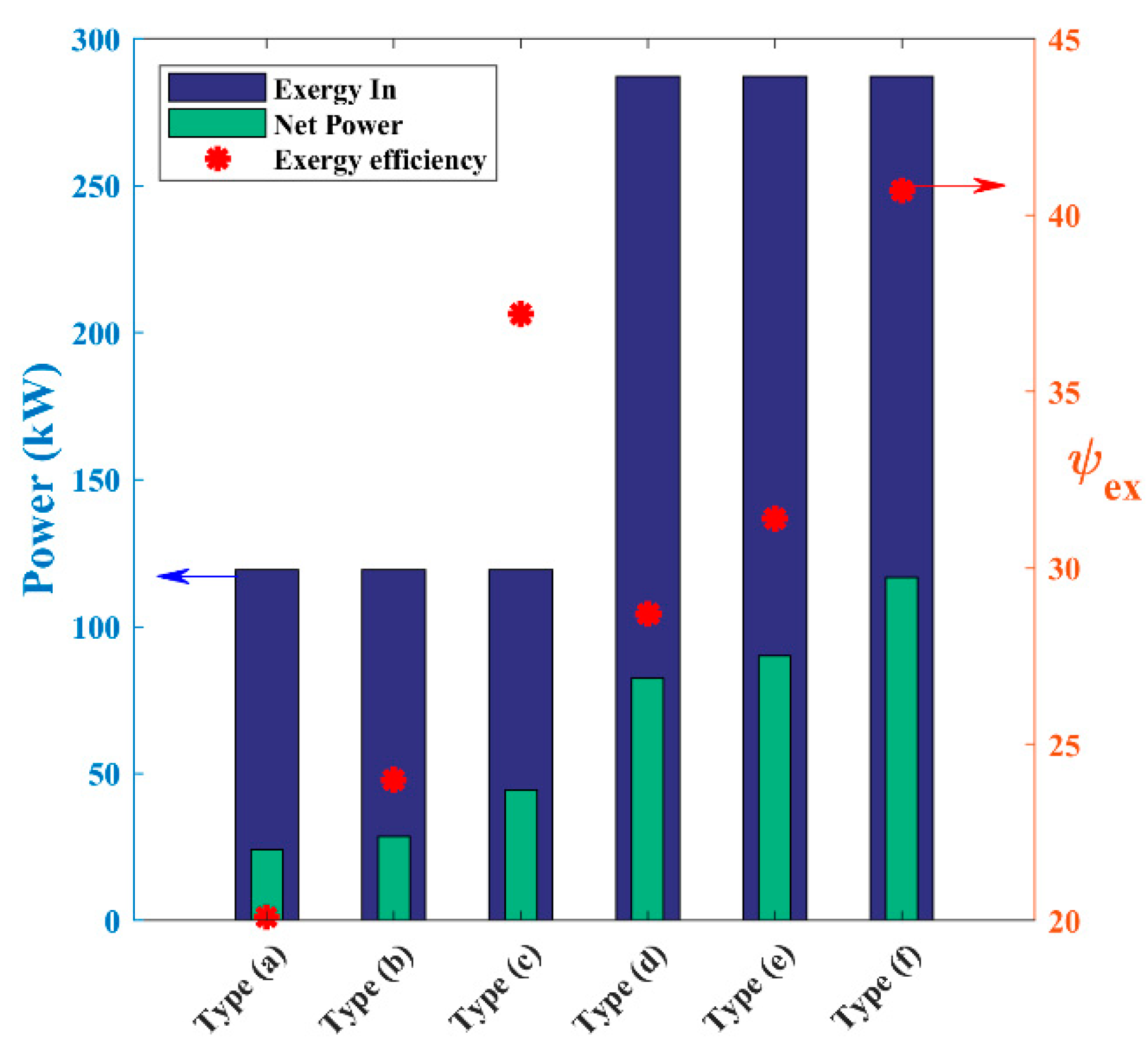

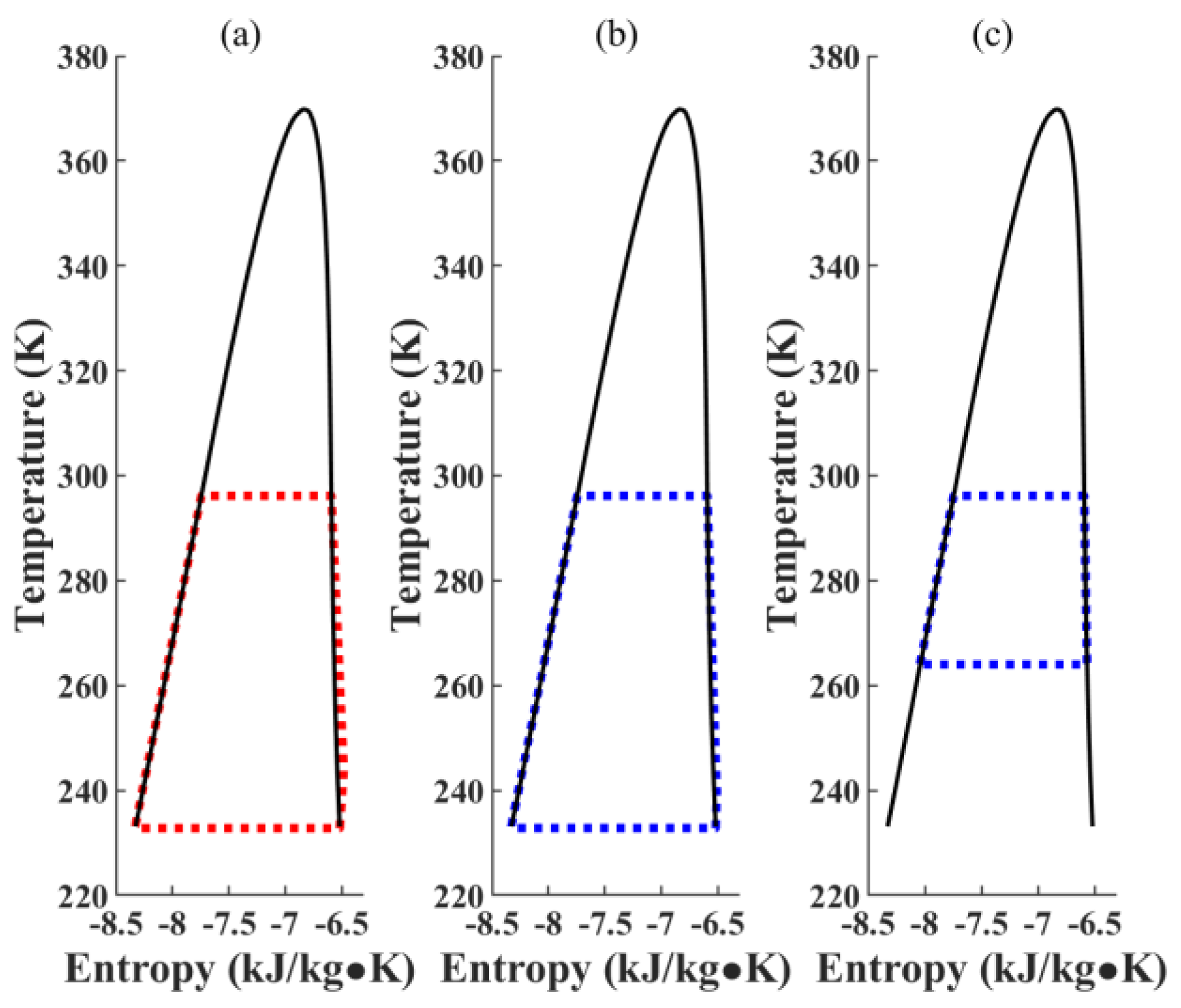

3.1. Optimization Results

3.2. Cost Estimation Results

3.3. Sensitivity Analysis

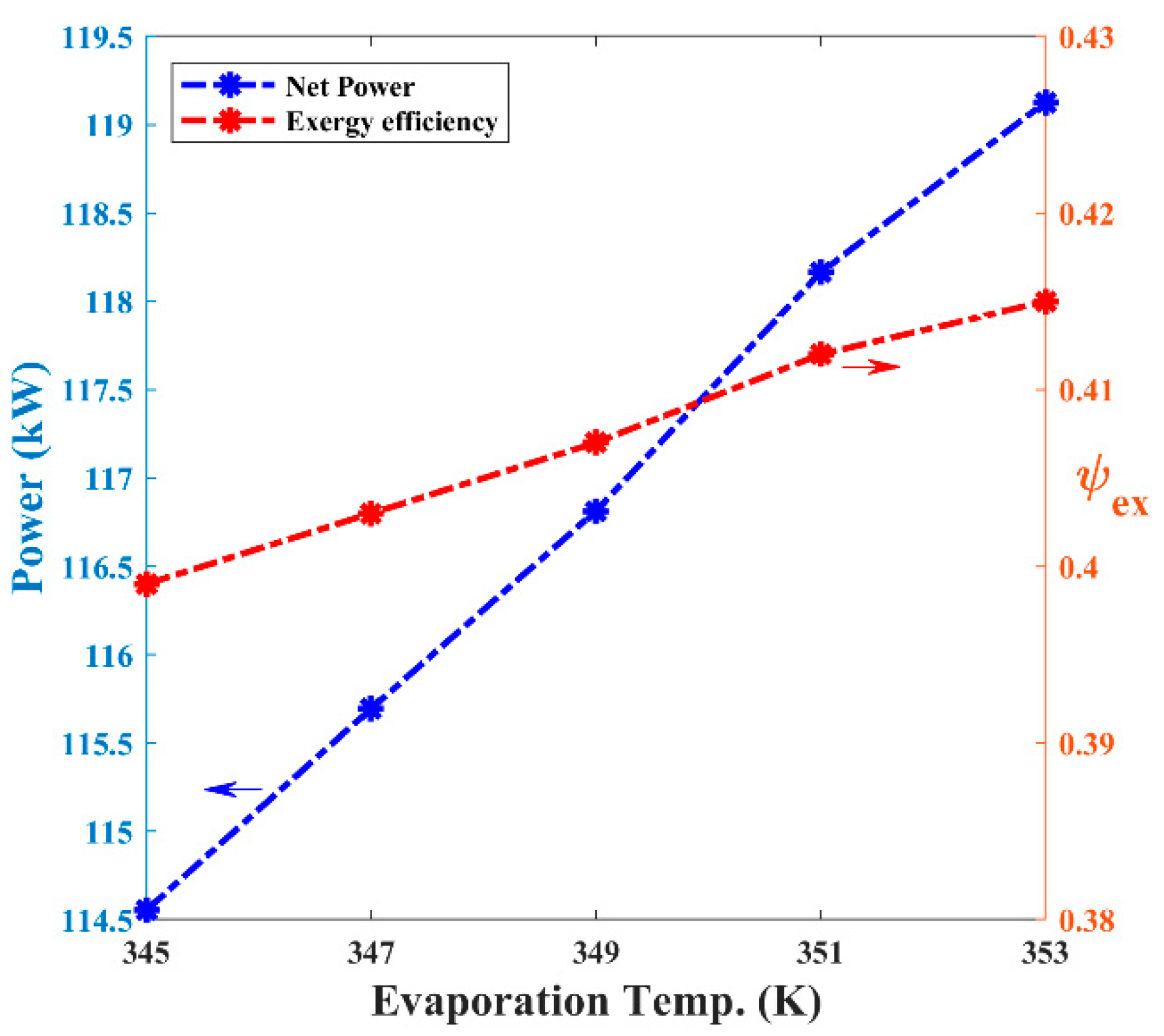

3.3.1. Changes in Evaporation Temperatures

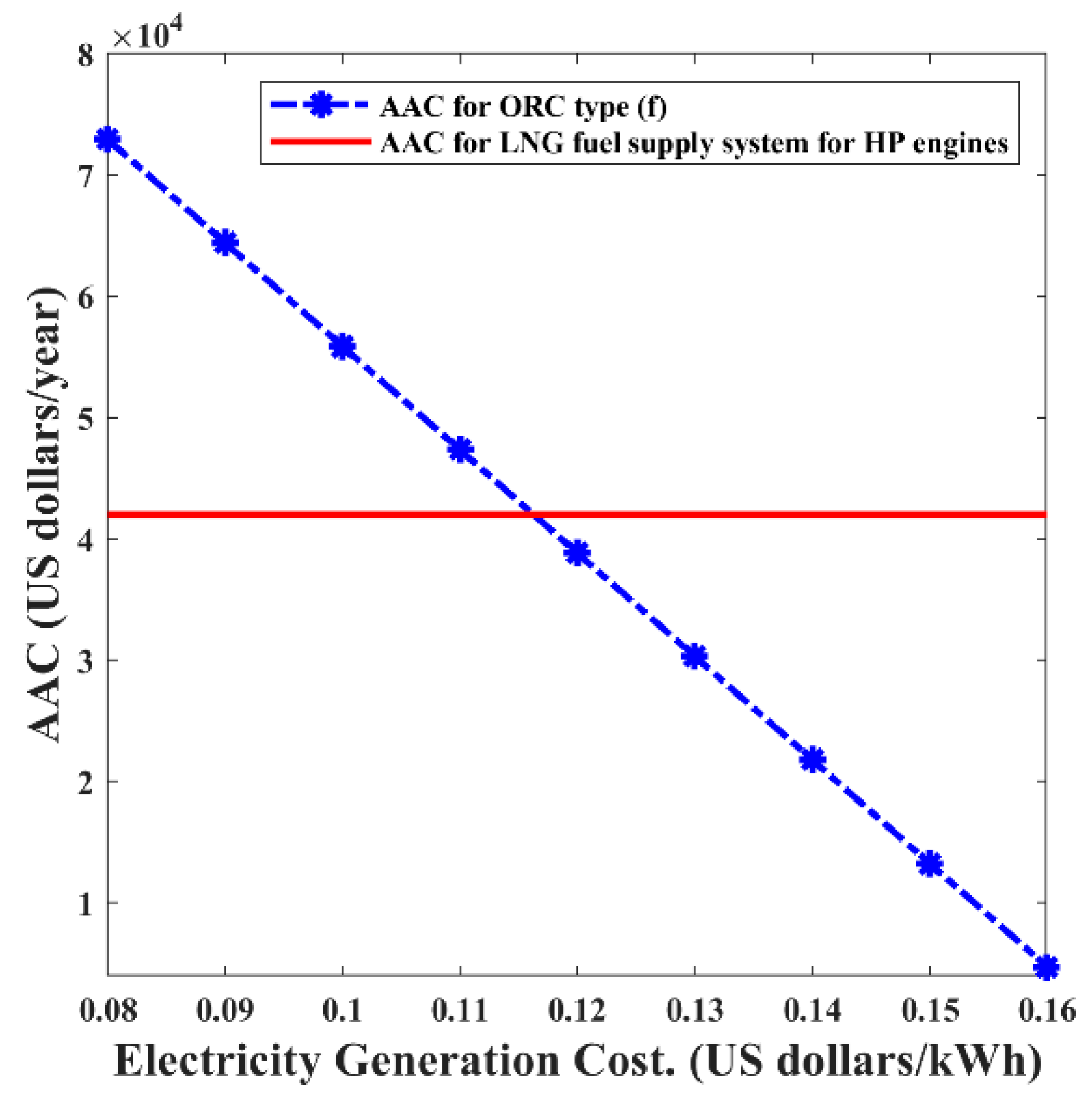

3.3.2. Changes in Electricity Generation Costs

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| AAC | actual annualized cost |

| CEPCI | chemical engineering plant cost index |

| CFOH | closed-feed organic fluid heater |

| ECA | emission control areas |

| GB | gigabyte |

| GWP | global warming potential |

| IMO | International Maritime Organization |

| LHV | lower heating value |

| LNG | liquefied natural gas |

| MITA | minimum internal temperature approach |

| NG | natural gas |

| ORC | organic Rankine cycle |

| PC | purchase cost |

| PSO | particle swarm optimization |

| RAM | random access memory |

| WF | working fluid |

| Symbols | |

| ψex | exergy efficiency |

| Ex | exergy potential |

| frwf | working fluid stream fraction ratio |

| h0 | enthalpy |

| hx | enthalpy at 293 K |

| mwr | mass flow rate of working fluid (kg/s) |

| Pexp1 | expander discharge pressure at WF condenser (bar) |

| Pexp2 | expander discharge pressure at CFOH (bar) |

| PLNG | LNG pump discharge pressure (bar) |

| Pwf | working fluid pump discharge pressure (bar) |

| s0 | entropy |

| sx | entropy at 293 K |

| SAC | simplified annualized cost (US dollars) |

| T0 | temperature at 293 K |

| Tboil | boiling temperature (K) |

| Tc | critical temperature (K) |

| Tsup | superheating temperature at WF evaporator (K) |

| vf | vapor fraction |

| Vcw | volumetric flow rate of cooling water (m3/h) |

| Wnet | net power output (kW) |

| Wpump | power consumed by pumps |

| Wturbine | power generated by turbines |

Appendix A

| Working Fluid | Chemical Formula | Tc (K) | Pc (bar) | Tboil (K) | GWP (100-yr) |

|---|---|---|---|---|---|

| Methane (R-50) | CH4 | 190.6 | 46.1 | 111 | 25 |

| Ethane (R-170) | C2H6 | 305.3 | 49.1 | 184.6 | 5.5 |

| Ethylene (R-1150) | C2H4 | 282.5 | 50.6 | 169 | 3.7 |

| Propane (R-1270) | C3H8 | 369.9 | 42.5 | 231.1 | 1.8 |

| n-Butane (R-600) | C4H10 | 425 | 38 | 273 | 4.0 |

| Krypton (R-784) | Kr | 209.5 | 55.2 | 119.8 | 0 |

| R-152a | C2H4F2 | 386.5 | 45.2 | 248.5 | 124 |

| R-32 | CH2F2 | 351.3 | 57.8 | 221.4 | 675 |

| R-41 | CH3F | 317.4 | 58.8 | 195 | 92 |

| Parameters | Value |

|---|---|

| Number of Particles | 14 per decision variable |

| Max. Iteration | 150 |

| Social-adjustment weight | 1.99 |

| Self-adjustment weight | 0.99 |

| Hybrid Function | Sequential Quadratic Programming |

| Parameters | Value | |

|---|---|---|

| Vessel engine duty (kW) | 12000 | |

| LNG pump duty (kW) | High-pressure engine: | 41.58 |

| Medium-pressure engine: | 2.17 | |

| Vaporizer area (m2) | High-pressure engine: | 7.05 |

| Medium-pressure engine: | 6.51 | |

| Cooling water flow (m3/h) | High-pressure engine: | 110.53 |

| Medium-pressure engine: | 164.18 | |

References

- Ancona, M.A.; Bianchi, M.; Branchini, L.; De Pascale, A.; Melino, F.; Mormile, M.; Palella, M.; Scarponi, L.B. Investigation on small-scale low pressure LNG production process. Appl. Energy 2017, 227, 672–685. [Google Scholar] [CrossRef]

- Kim, J.; Seo, Y.; Chang, D. Economic evaluation of a new small-scale LNG supply chain using liquid nitrogen for natural-gas liquefaction. Appl. Energy 2016, 182, 154–163. [Google Scholar] [CrossRef]

- Lim, W.; Choi, K.; Moon, I. Current Status and Perspectives of Liquefied Natural Gas (LNG) Plant Design. Ind. Eng. Chem. Res. 2013, 52, 3065–3088. [Google Scholar] [CrossRef]

- Seo, S.; Han, S.; Lee, S.; Chang, D. A pump-free boosting system and its application to liquefied natural gas supply for large ships. Energy 2016, 105, 70–79. [Google Scholar] [CrossRef]

- Eise Fokkema, J.; Buijs, P.; Vis, I.F.A. An investment appraisal method to compare LNG-fueled and conventional vessels. Transp. Res. Part Transp. Environ. 2017, 56, 229–240. [Google Scholar] [CrossRef]

- Geertsma, R.D.; Negenborn, R.R.; Visser, K.; Hopman, J.J. Design and control of hybrid power and propulsion systems for smart ships: A review of developments. Appl. Energy 2017, 194, 30–54. [Google Scholar] [CrossRef]

- Aspelund, A.; Gundersen, T.; Myklebust, J.; Nowak, M.P.; Tomasgard, A. An optimization-simulation model for a simple LNG process. Comput. Chem. Eng. 2010, 34, 1606–1617. [Google Scholar] [CrossRef]

- Wang, M.; Khalilpour, R.; Abbas, A. Thermodynamic and economic optimization of LNG mixed refrigerant processes. Energy Convers. Manag. 2014, 88, 947–961. [Google Scholar] [CrossRef]

- Yamamoto, T.; Furuhata, T.; Arai, N.; Mori, K. Design and testing of the Organic Rankine Cycle. Energy 2001, 26, 239–251. [Google Scholar] [CrossRef]

- Desai, N.B.; Bandyopadhyay, S. Process integration of organic Rankine cycle. Energy 2009, 34, 1674–1686. [Google Scholar] [CrossRef]

- Kajurek, J.; Rusowicz, A.; Grzebielec, A.; Bujalski, W.; Futyma, K.; Rudowicz, Z. Selection of refrigerants for a modified organic Rankine cycle. Energy 2019, 168, 1–8. [Google Scholar] [CrossRef]

- Astolfi, M.; Fantolini, A.M.; Valenti, G.; De Rinaldis, S.; Inglese, L.D.; Macchi, E. Cryogenic ORC To Enhance The Efficiency Of LNG Regasification Terminals. Energy Procedia 2017, 129, 42–49. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, K. A novel cryogenic power cycle for LNG cold energy recovery. Energy 2011, 36, 2828–2833. [Google Scholar] [CrossRef]

- Bao, J.; Lin, Y.; Zhang, R.; Zhang, N.; He, G. Effects of stage number of condensing process on the power generation systems for LNG cold energy recovery. Appl. Therm. Eng. 2017, 126, 566–582. [Google Scholar] [CrossRef]

- Bao, J.; Zhang, R.; Lin, Y.; Zhang, N.; Zhang, X.; He, G. Simultaneous optimization of system structure and working fluid for the three-stage condensation Rankine cycle utilizing LNG cold energy. Appl. Therm. Eng. 2018, 140, 120–130. [Google Scholar] [CrossRef]

- Tomków, L.; Cholewiński, M. Improvement of the LNG (liquid natural gas) regasification efficiency by utilizing the cold exergy with a coupled absorption—ORC (organic Rankine cycle). Energy 2015, 87, 645–653. [Google Scholar] [CrossRef]

- Lee, S. Multi-parameter optimization of cold energy recovery in cascade Rankine cycle for LNG regasification using genetic algorithm. Energy 2017, 118, 776–782. [Google Scholar] [CrossRef]

- Le, S.; Lee, J.-Y.; Chen, C.-L. Waste cold energy recovery from liquefied natural gas (LNG) regasification including pressure and thermal energy. Energy 2018, 152, 770–787. [Google Scholar] [CrossRef]

- LNG Fuel Gas Systems. Available online: https://marine.man-es.com/technology/marine-fuel-gas-systems/lng-fuel-gas-systems (accessed on 6 May 2019).

- Wärtsilä LNGPac—Fuel Gas Supply System. Available online: https://www.wartsila.com/products/marine-oil-gas/gas-solutions/lng-solutions/wartsila-lngpac (accessed on 6 May 2019).

- Rochyana, M.F.; Jinca, M.Y.; Siahaya, J. MDO and LNG as Fuels (Duel Fuel) to Support Sustainable Maritime Transport (A Case Study in KM. Ciremai). Int. Refereed J. Eng. Sci. 2014, 3, 32–38. [Google Scholar]

- Wang, E.; Zhang, H.; Fan, B.; Wu, Y. Optimized performances comparison of organic Rankine cycles for low grade waste heat recovery. J. Mech. Sci. Technol. 2012, 26, 2301–2312. [Google Scholar] [CrossRef]

- MAN Energy Solutions. Available online: https://marine.man-es.com/applications/projectguides/2stroke/content/epub/S50ME-C8_2-GI.pdf (accessed on 6 May 2019).

- The Motor Ship. Available online: https://www.motorship.com/__data/assets/pdf_file/0029/619229/X-DF-engines-brochure.pdf (accessed on 8 February 2019).

- Park, K.; Oh, S.-R.; Won, W. Techno-economic optimization of the integration of an organic Rankine cycle into a molten carbonate fuel cell power plant. Korean J. Chem. Eng. 2019, 36, 345–355. [Google Scholar] [CrossRef]

- Aghahosseini, S.; Dincer, I. Comparative performance analysis of low-temperature Organic Rankine Cycle (ORC) using pure and zeotropic working fluids. Appl. Therm. Eng. 2013, 54, 35–42. [Google Scholar] [CrossRef]

- Wang, E.H.; Zhang, H.G.; Fan, B.Y.; Ouyang, M.G.; Zhao, Y.; Mu, Q.H. Study of working fluid selection of organic Rankine cycle (ORC) for engine waste heat recovery. Energy 2011, 36, 3406–3418. [Google Scholar] [CrossRef]

- Sahraei, M.H.; Ricardez-Sandoval, L.A. An Integration Framework for CO2 Capture Processes. In Materials and Process Systems for CO2 Capture: Modeling, Design, Control and Integration, 1st ed.; Papadopoulos, A.I., Seferlis, P., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017; pp. 523–544. [Google Scholar]

- Park, K.; Won, W.; Shin, D. Effects of varying the ambient temperature on the performance of a single mixed refrigerant liquefaction process. J. Nat. Gas Sci. Eng. 2016, 34, 958–968. [Google Scholar] [CrossRef]

- Tian, D.; Shi, Z. MPSO: Modified particle swarm optimization and its applications. Swarm Evolut. Comput. 2018, 41, 49–68. [Google Scholar] [CrossRef]

- Xu, G.; Yu, G. On convergence analysis of particle swarm optimization algorithm. J. Comput. Appl. Math. 2018, 333, 65–73. [Google Scholar] [CrossRef]

- Godio, A.; Santilano, A. On the optimization of electromagnetic geophysical data: Application of the PSO algorithm. J. Appl. Geophys. 2018, 148, 163–174. [Google Scholar] [CrossRef]

- Chen, Y.; Li, L.; Xiao, J.; Yang, Y.; Liang, J.; Li, T. Particle swarm optimizer with crossover operation. Eng. Appl. Artif. Intell. 2018, 70, 159–169. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.; Li, G.; Zhao, D.; Chen, C. Two-stage multi-objective OPF for AC/DC grids with VSC-HVDC: Incorporating decisions analysis into optimization process. Energy 2018, 147, 286–296. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Zhao, D.; Li, G.; Chen, C. A two-stage approach for combined heat and power economic emission dispatch: Combining multi-objective optimization with integrated decision making. Energy 2018, 162, 237–254. [Google Scholar] [CrossRef]

- Douglas, J.M. Conceptual Design of Chemical Processes, 1st ed.; McGraw-Hill, Inc.: New York, NY, USA, 1988; pp. 37–42. [Google Scholar]

- Lee, U.; Jeon, J.; Han, C.; Lim, Y. Superstructure based techno-economic optimization of the organic rankine cycle using LNG cryogenic energy. Energy 2017, 137, 83–94. [Google Scholar] [CrossRef]

- Saito, N. The Economic Analysis of Commercial Ships with Hydrogen Fuel Cell through Case Studies. Master’s Thesis, World Maritime University, Malmö, Sweden, 2018. [Google Scholar]

- Boveri, A.; Silvestro, F.; Gualeni, P. Ship electrical load analysis and power generation optimization to reduce operational costs. In Proceedings of the 2016 International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference, Toulouse, France, 2–4 November 2016; IEEE: New York, NY, USA; pp. 1–6. [Google Scholar]

- Linstrom, P. NIST Chemistry WebBook, NIST Standard Reference Database 69; Stanford Library: Stanford, CA, USA, 1997. [Google Scholar]

| Decision Variables | Units | Types | Lower Bound | Upper Bound |

|---|---|---|---|---|

| WF mass flow rate (mwf) | kg/s | (A), (B), (C) (D), (E), (F) | 0.028 | 1.67 |

| Super heating temperature of the WF evaporator (Tsup) | K | (A), (B), (C) (D), (E), (F) | 273 | 443 |

| WF pump discharge pressure (Pwf) | bar | (A), (B), (C) (D), (E), (F) | 2 | Critical point |

| WF expander discharge pressure to the WF condenser (Pexp1) | bar | (A), (B), (C) (D), (E), (F) | 1.3 | Critical point |

| WF expander discharge pressure to the CFOH (Pexp2) | bar | (B), (C) (E), (F) | 1.3 | 30 |

| WF mass fraction to the CFOH (frwf) | - | (B), (C) (E), (F) | 0 | 0.3 |

| LNG pump discharge pressure (PLNG) | Bar | (D), (E), (F) | 17 | 80 |

| Parameters | Values | |

|---|---|---|

| Expander isentropic efficiency [14,15] | 0.8 | |

| Pump isentropic efficiency [14,15] | 0.8 | |

| Ambient temperature (K) | 293 | |

| Hot source temperature for the evaporator (K) | 298 | |

| Engine jacket water temperature (K) [23] | 353 | |

| Minimum approach temperature in heat exchangers (K) | 2 | |

| Pressure drop of heat exchangers (bar) | 0.2 | |

| Property package | Peng-Robinson | |

| Inlet LNG pressure (bar) | 1.01325 | |

| Inlet LNG temperature (K) | saturated | |

| Inlet LNG mass flow rate (kg/s) | High-pressure engine [23] | 0.487 |

| Medium-pressure engine [24] | 0.474 | |

| LNG composition (mol. %) [7,25] | N2: 0.37 C1: 95.89 C2: 2.96 C3: 0.72 nC4: 0.06 | |

| NG send-out pressure (bar) | High-pressure engine [23] | 299.6 |

| Medium-pressure engine [24] | 16.6 | |

| NG send-out temperature (K) | 293 | |

| WF | mwf (kg/s) | Tsup (K) | Pwf (bar) | Pexp1 (bar) | Pexp2 (bar) | frwf | PLNG (bar) | |

|---|---|---|---|---|---|---|---|---|

| Type a | Propane (R-1270) | 0.415 | 0.000 | 9.251 | 1.300 | - | - | - |

| Type b | Propane (R-1270) | 0.489 | 0.020 | 9.426 | 3.745 | 1.301 | 0.152 | - |

| Type c | Propane (R-1270) | 0.533 | 23.973 | 19.175 | 5.982 | 1.300 | 0.224 | - |

| Type d | Propane (R-1270) | 0.687 | 0.008 | 9.249 | 1.300 | - | - | 64.288 |

| Type e | Propane (R-1270) | 0.820 | 0.001 | 9.450 | 3.748 | 1.301 | 0.153 | 61.647 |

| Type f | Propane (R-1270) | 0.901 | 23.435 | 19.393 | 5.745 | 1.300 | 0.217 | 57.875 |

| Type | Simplified Annualized Costs 1 (US dollars/year) | Produced Electricity (kW) | Estimated Cost Saving 2 (US dollars/year) | Actual Annualized Costs (US dollars/year) |

|---|---|---|---|---|

| LNG fuel supply system (High-pressure) | 52,449 | 0 | 0 | 52,449 |

| ORC Type (a) (WF = propane) | 84,691 | 24.1 | 21,112 | 63,579 |

| ORC Type (b) (WF = propane) | 102,656 | 28.7 | 25,141 | 77,515 |

| ORC Type (c) (WF = propane) | 108,267 | 44.4 | 38,894 | 69,373 |

| LNG fuel supply system (Medium-pressure) | 42,008 | 0 | 0 | 42,008 |

| ORC Type (d) (WF = propane) | 111,597 | 82.4 | 72,182 | 39,415 |

| ORC Type (e) (WF = propane) | 132,244 | 90.2 | 79,015 | 53,229 |

| ORC Type (f) (WF = propane) | 141,154 | 116.8 | 102,316 | 38,838 |

| References | Working Fluid | Exergy Efficiency (%) | Evaporation Temperature (K) | Net Power Output (kW) |

|---|---|---|---|---|

| This study | Propane | 40.7 | 353 | 116.8 246.4 3 |

| [12] | R41 | N/A | 276–303 | 3250–3413 1 |

| [13] | CF4 + C3 (mixture) | 23.5 | 293 | 206.42 3 |

| [14] | Propane | N/A | 284 | 3134–8598 104.5–286.6 3 |

| [16] | Ethane + Krypton (mixture) | 3.3 | 277 | 9200 57.5 3 |

| [17] | Ethane + Propane (cascade) | 11.1 2 | 288 | 96.1 3 |

| [18] | Propane | 26 | 303 | 2153 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koo, J.; Oh, S.-R.; Choi, Y.-U.; Jung, J.-H.; Park, K. Optimization of an Organic Rankine Cycle System for an LNG-Powered Ship. Energies 2019, 12, 1933. https://doi.org/10.3390/en12101933

Koo J, Oh S-R, Choi Y-U, Jung J-H, Park K. Optimization of an Organic Rankine Cycle System for an LNG-Powered Ship. Energies. 2019; 12(10):1933. https://doi.org/10.3390/en12101933

Chicago/Turabian StyleKoo, Jamin, Soung-Ryong Oh, Yeo-Ul Choi, Jae-Hoon Jung, and Kyungtae Park. 2019. "Optimization of an Organic Rankine Cycle System for an LNG-Powered Ship" Energies 12, no. 10: 1933. https://doi.org/10.3390/en12101933

APA StyleKoo, J., Oh, S.-R., Choi, Y.-U., Jung, J.-H., & Park, K. (2019). Optimization of an Organic Rankine Cycle System for an LNG-Powered Ship. Energies, 12(10), 1933. https://doi.org/10.3390/en12101933