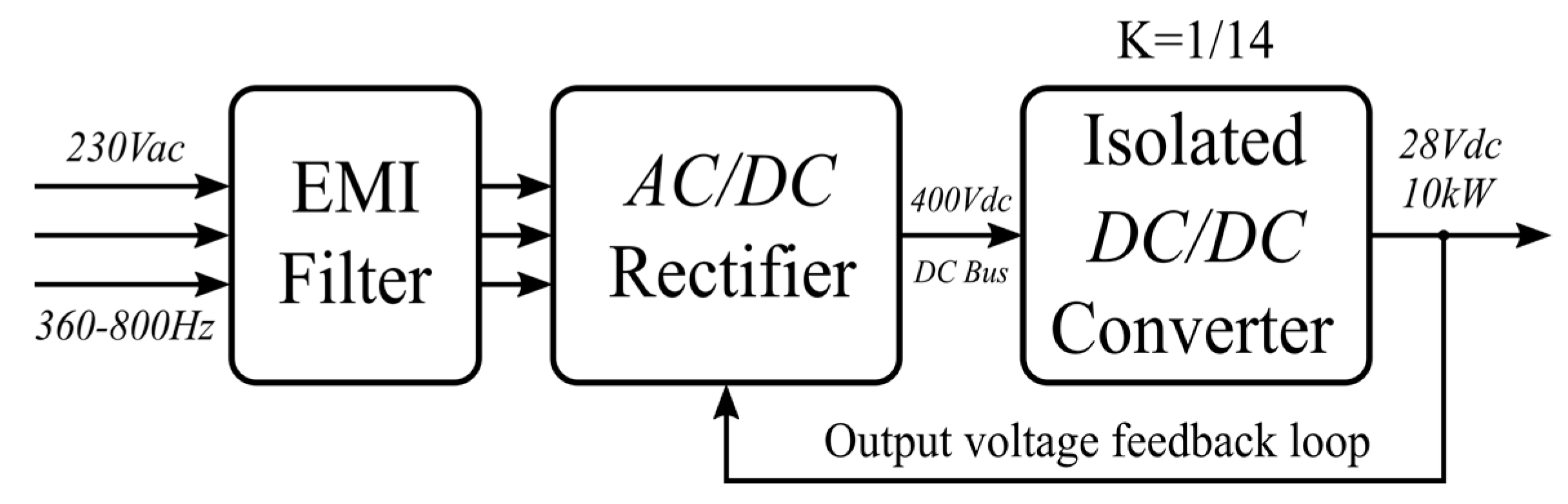

ZVS Auxiliary Circuit for a 10 kW Unregulated LLC Full-Bridge Operating at Resonant Frequency for Aircraft Application

Abstract

1. Introduction

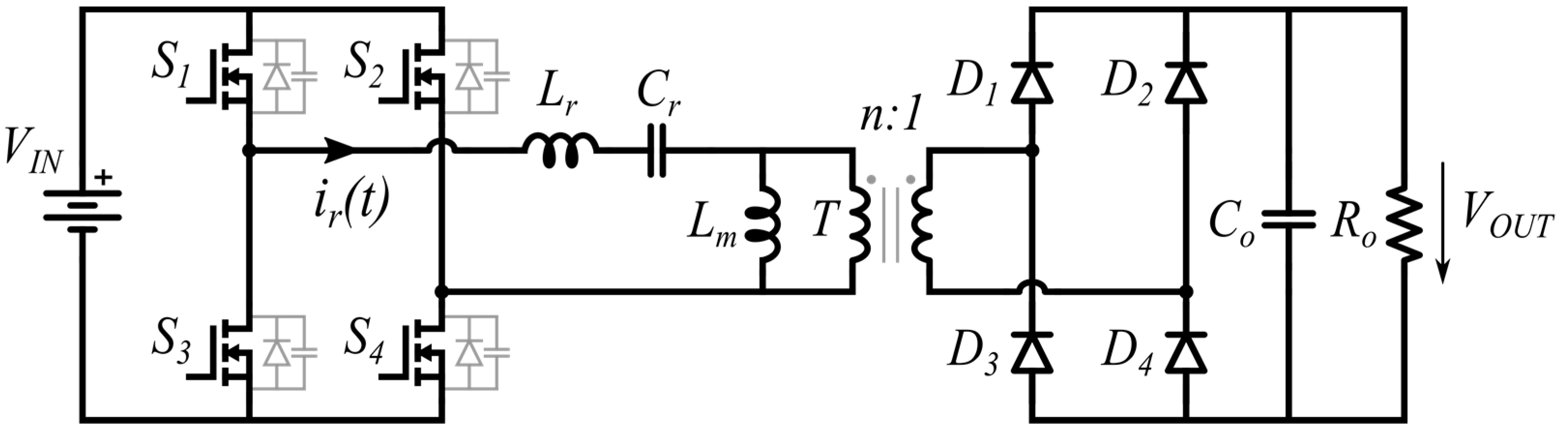

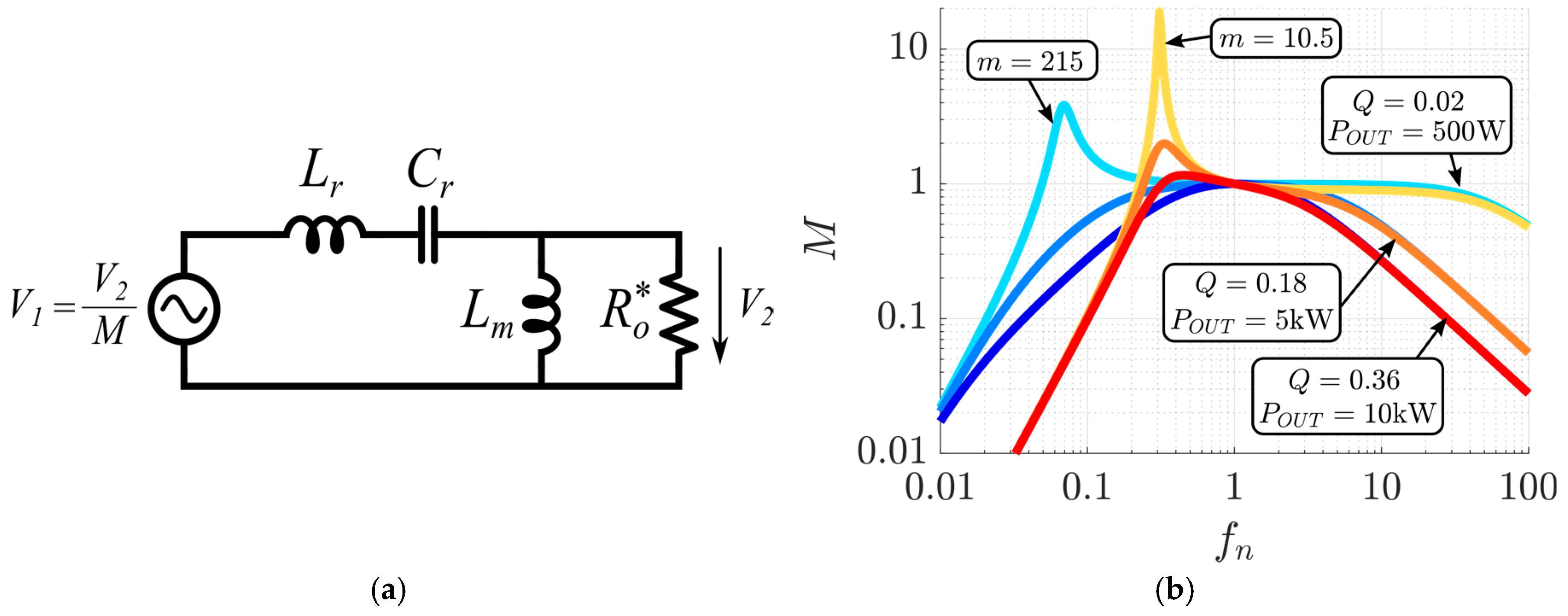

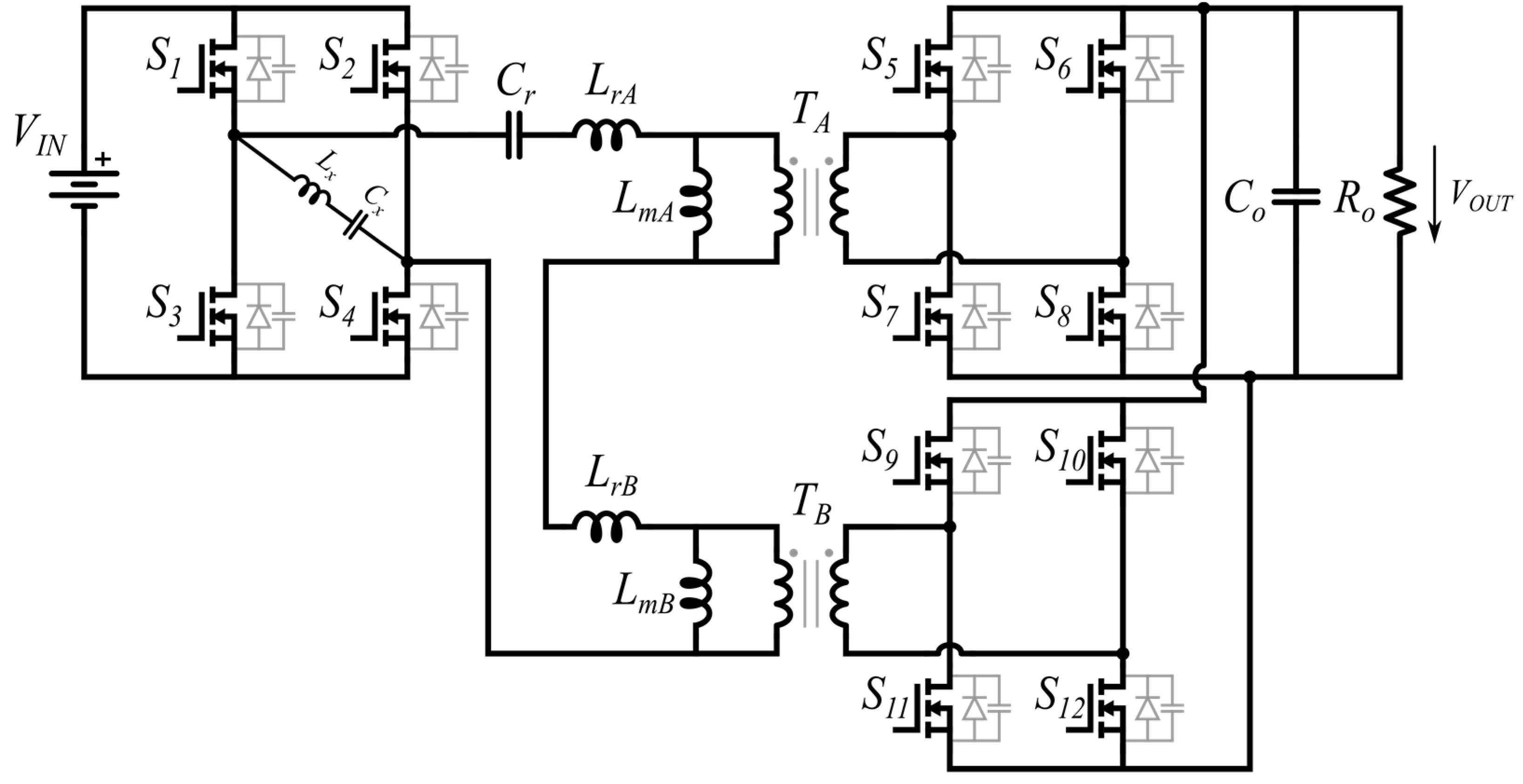

2. LLC Full-Bridge Topology: Operation Principle and Accurate Modeling

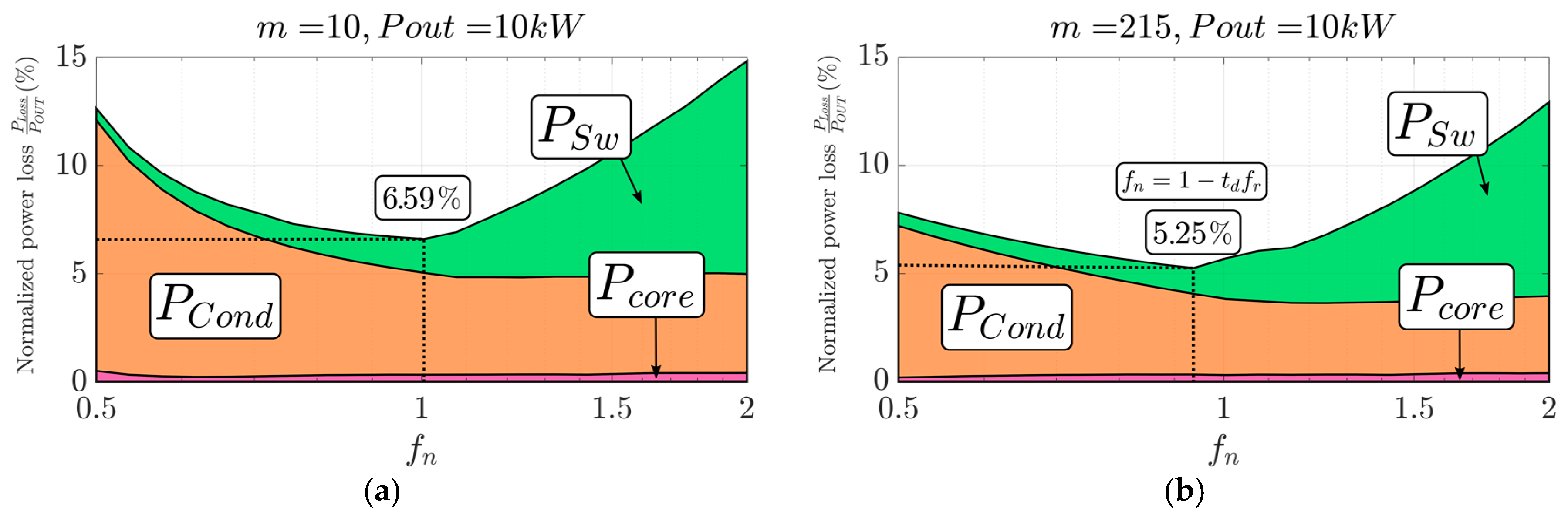

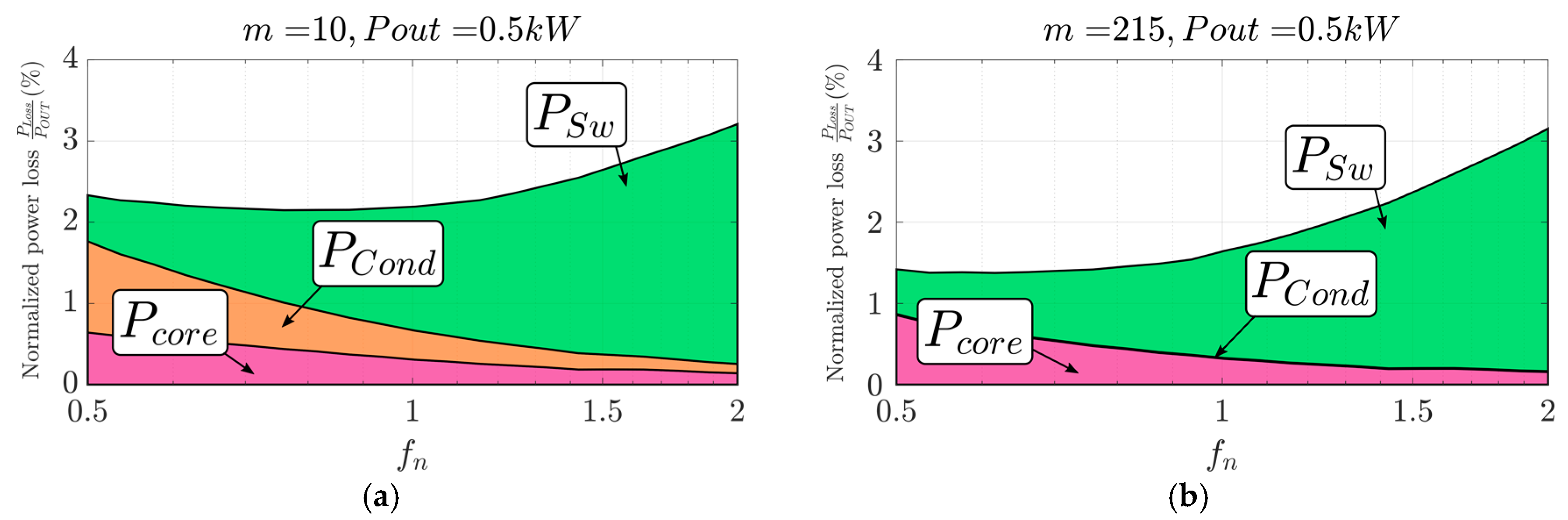

2.1. Unregulated LLC Optimum Design and Power Loss Model

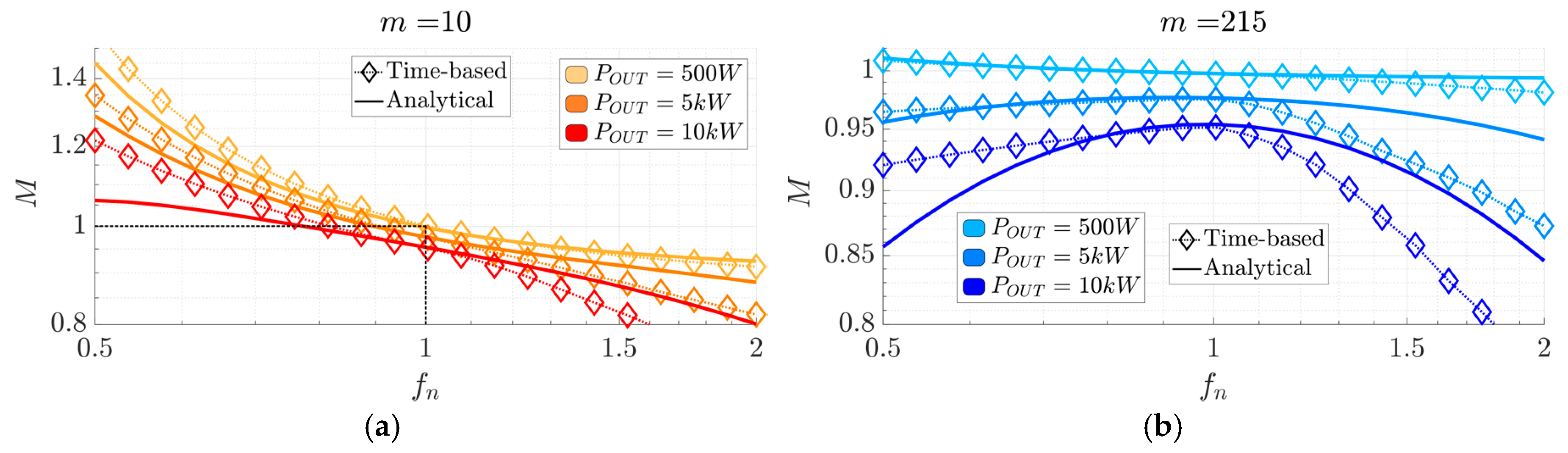

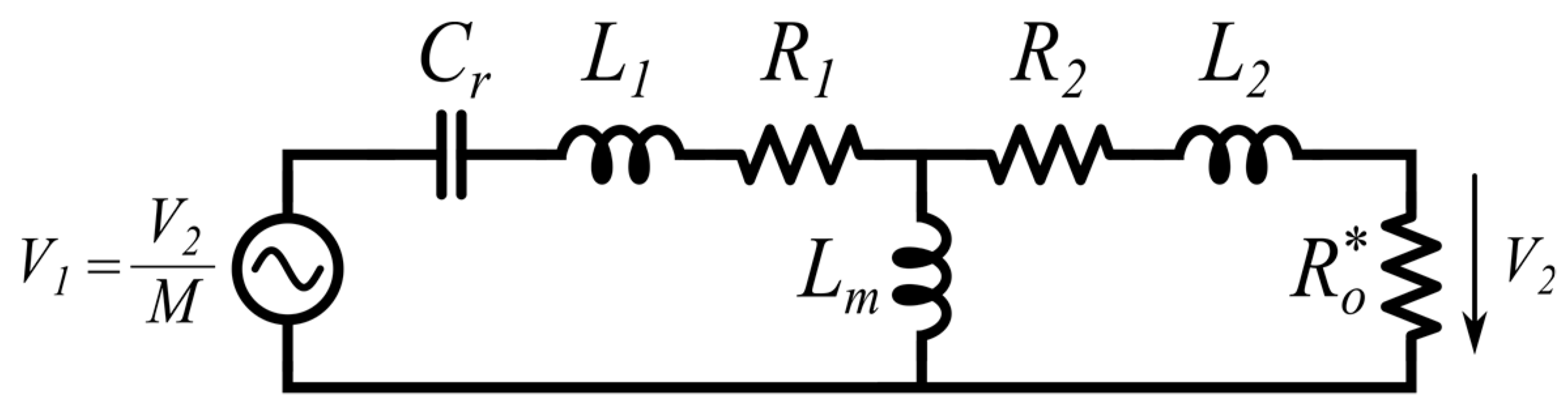

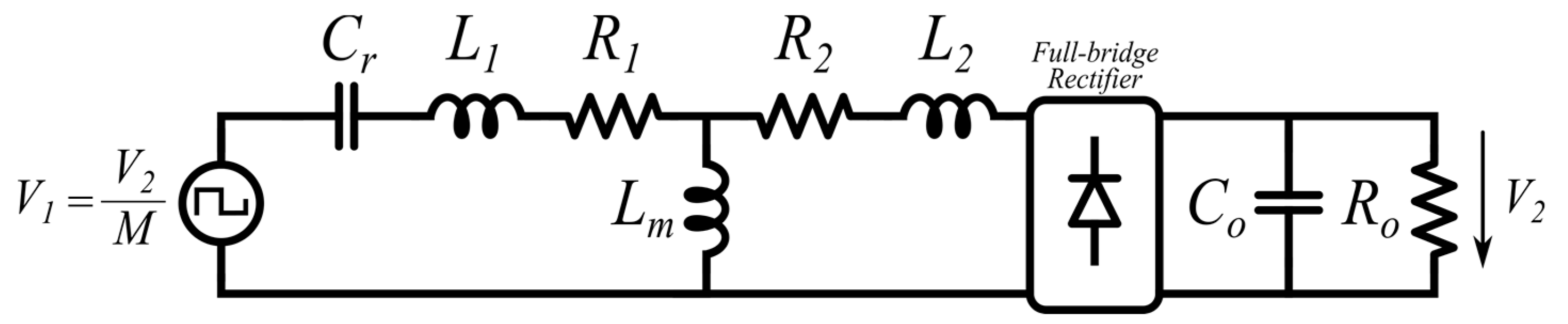

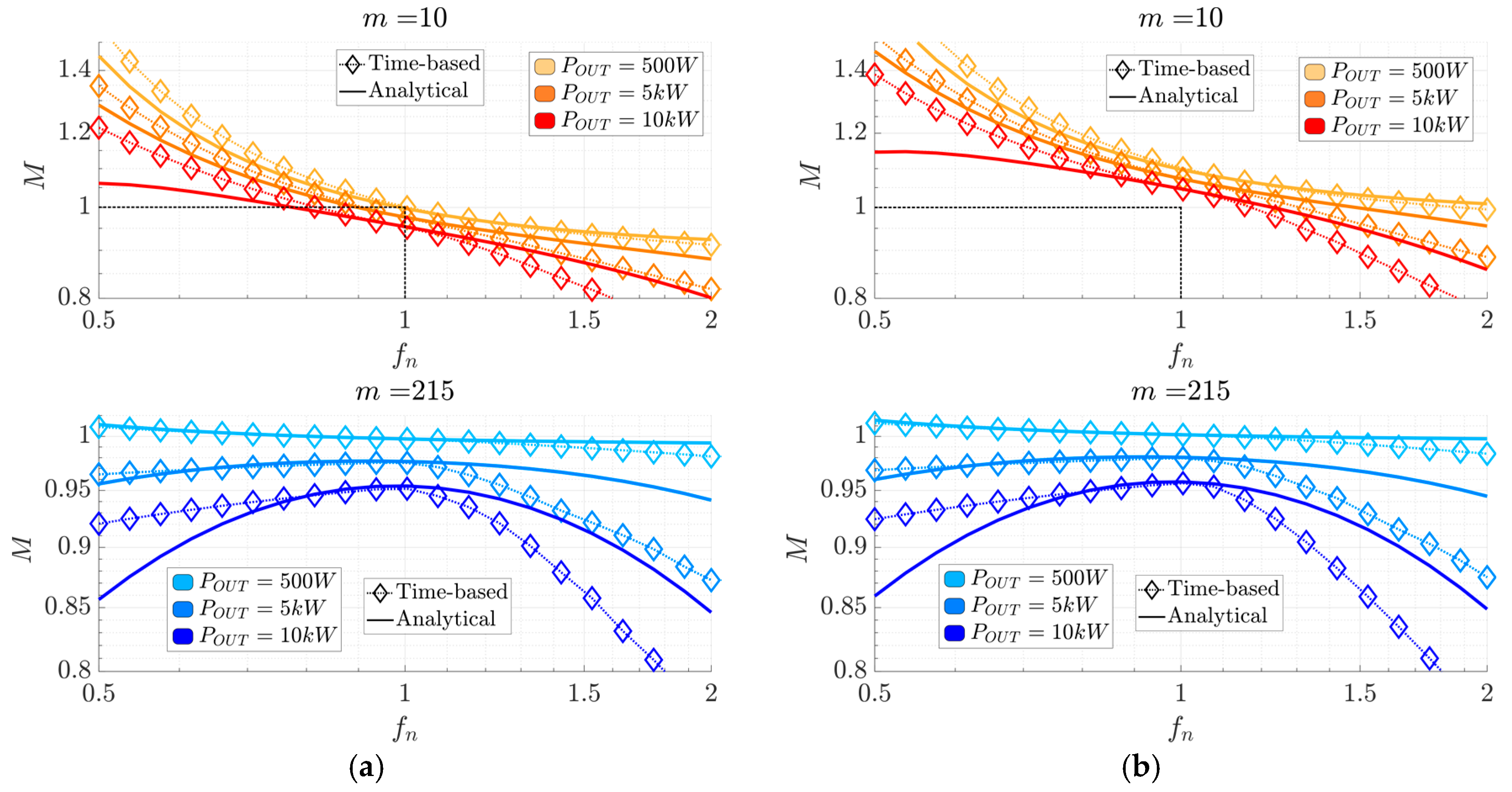

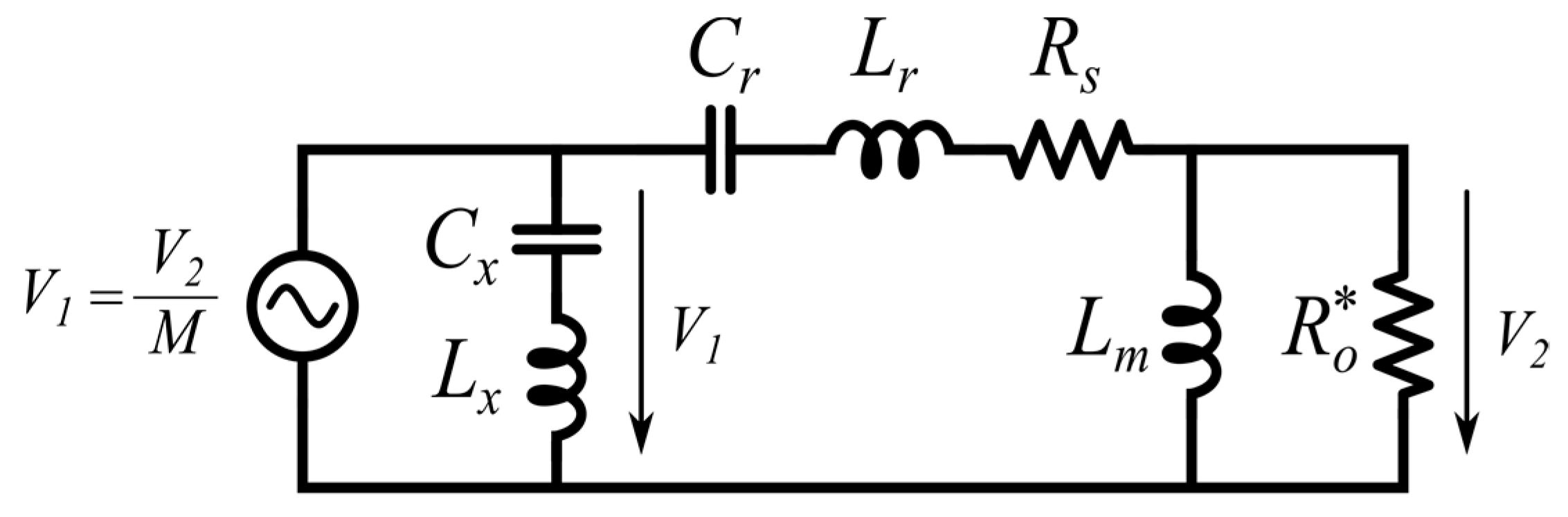

2.2. FHA and TB Models Considering the Series Resistance

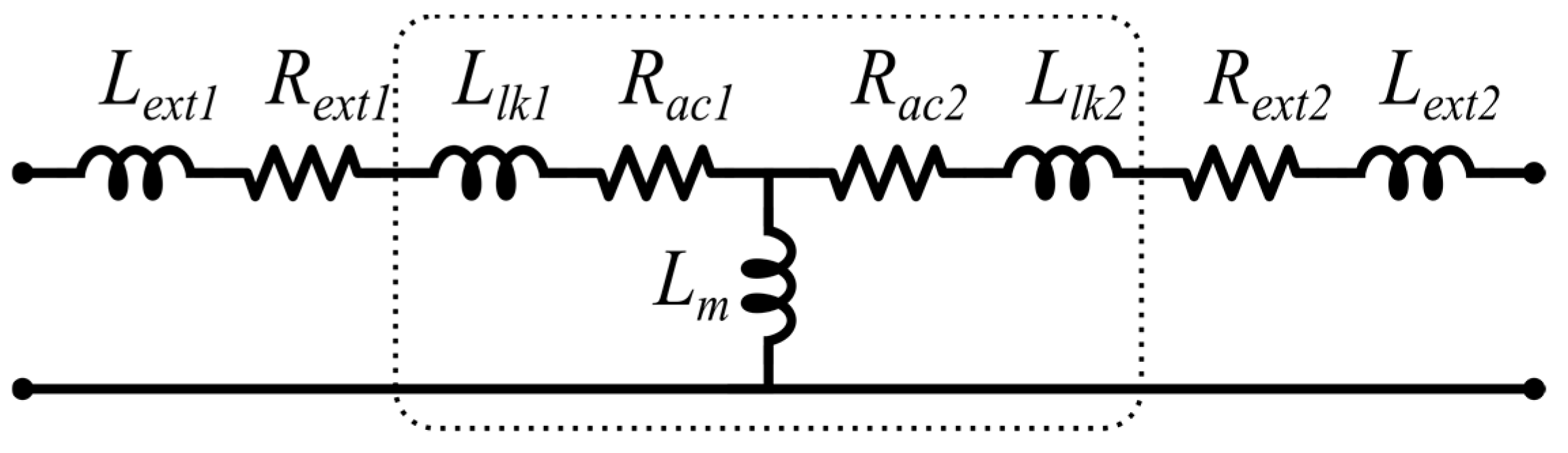

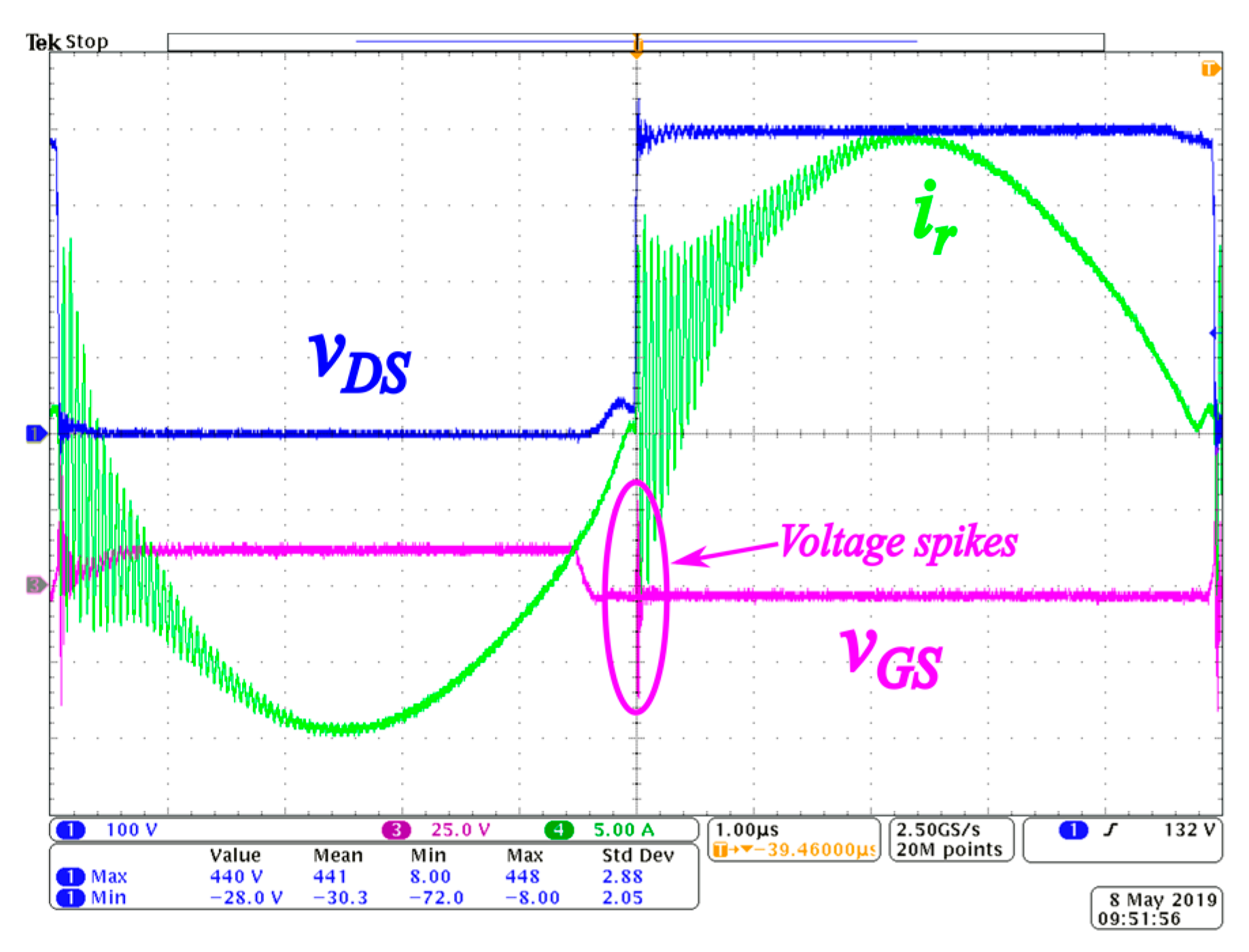

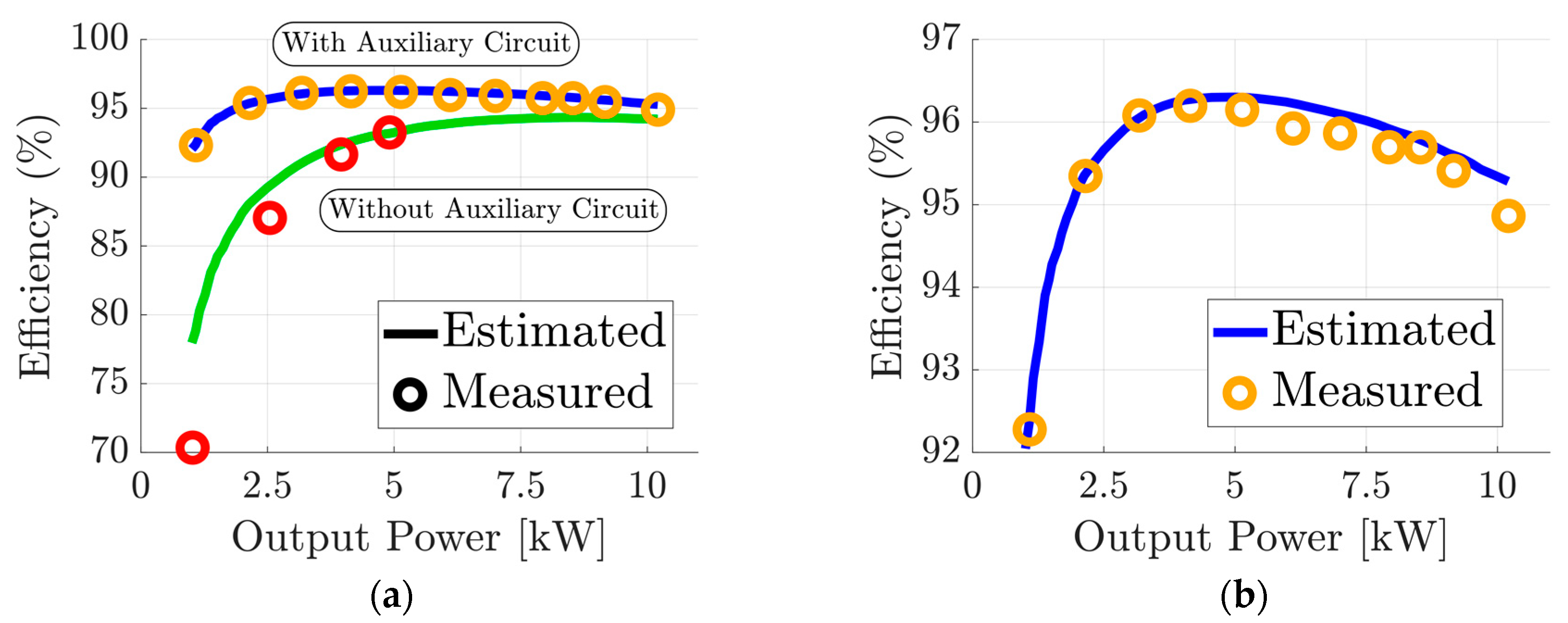

2.3. FHA and TB Models Considering Distributed Impedance Model

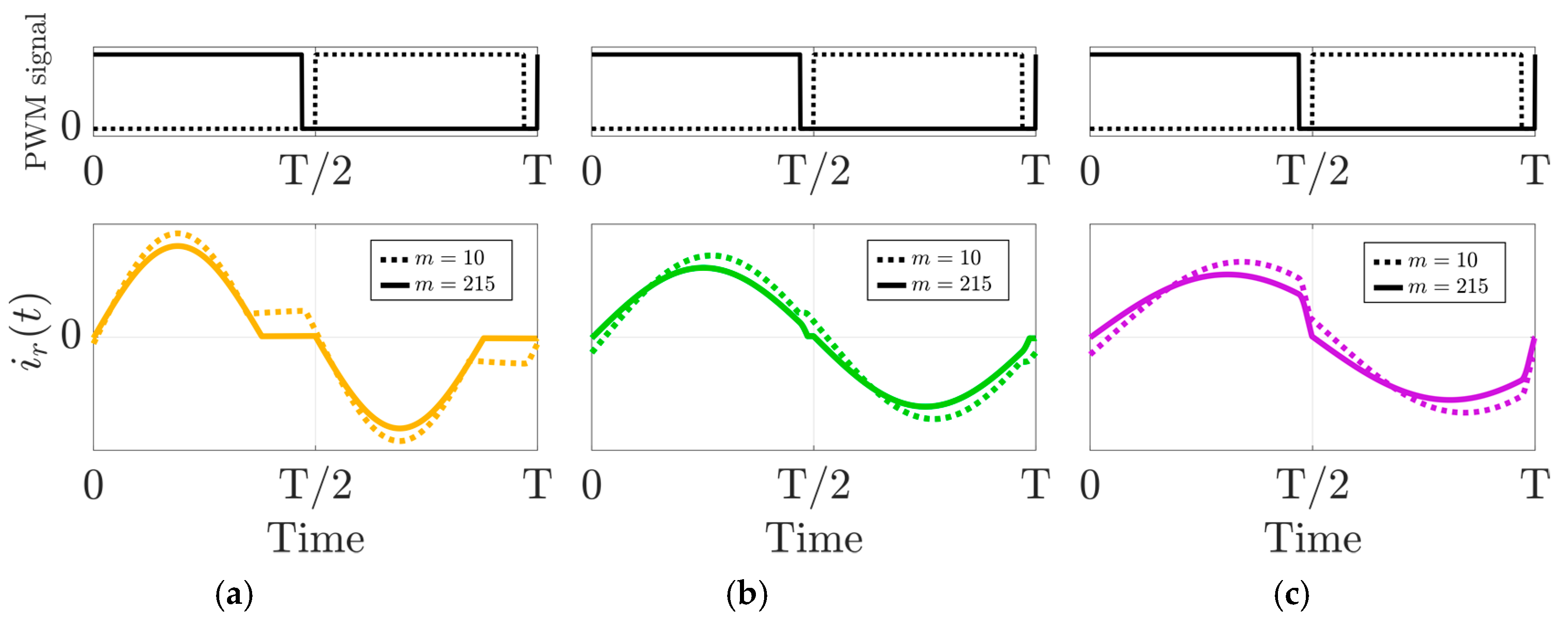

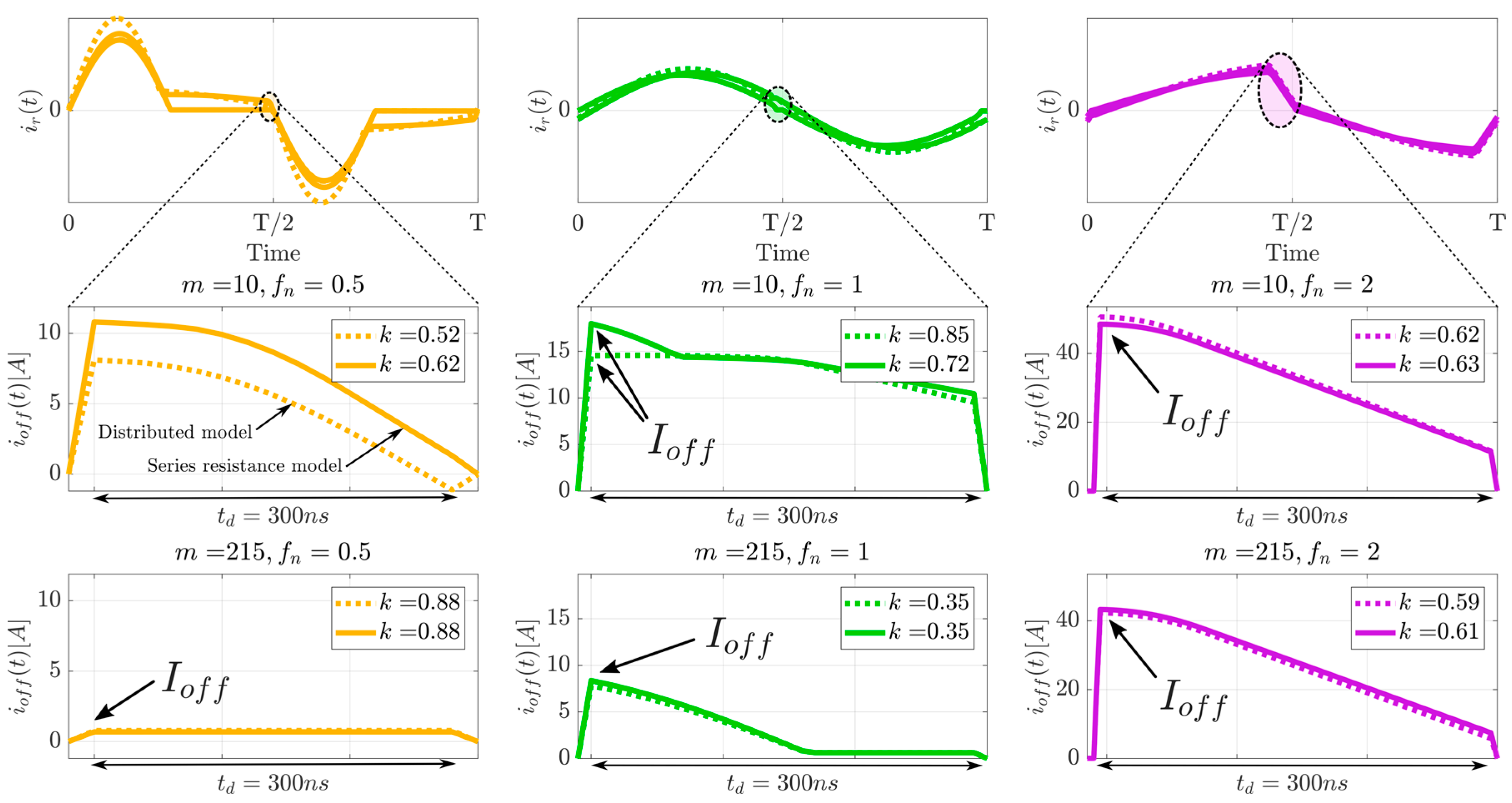

2.4. Time-Based Models for Current Analysis

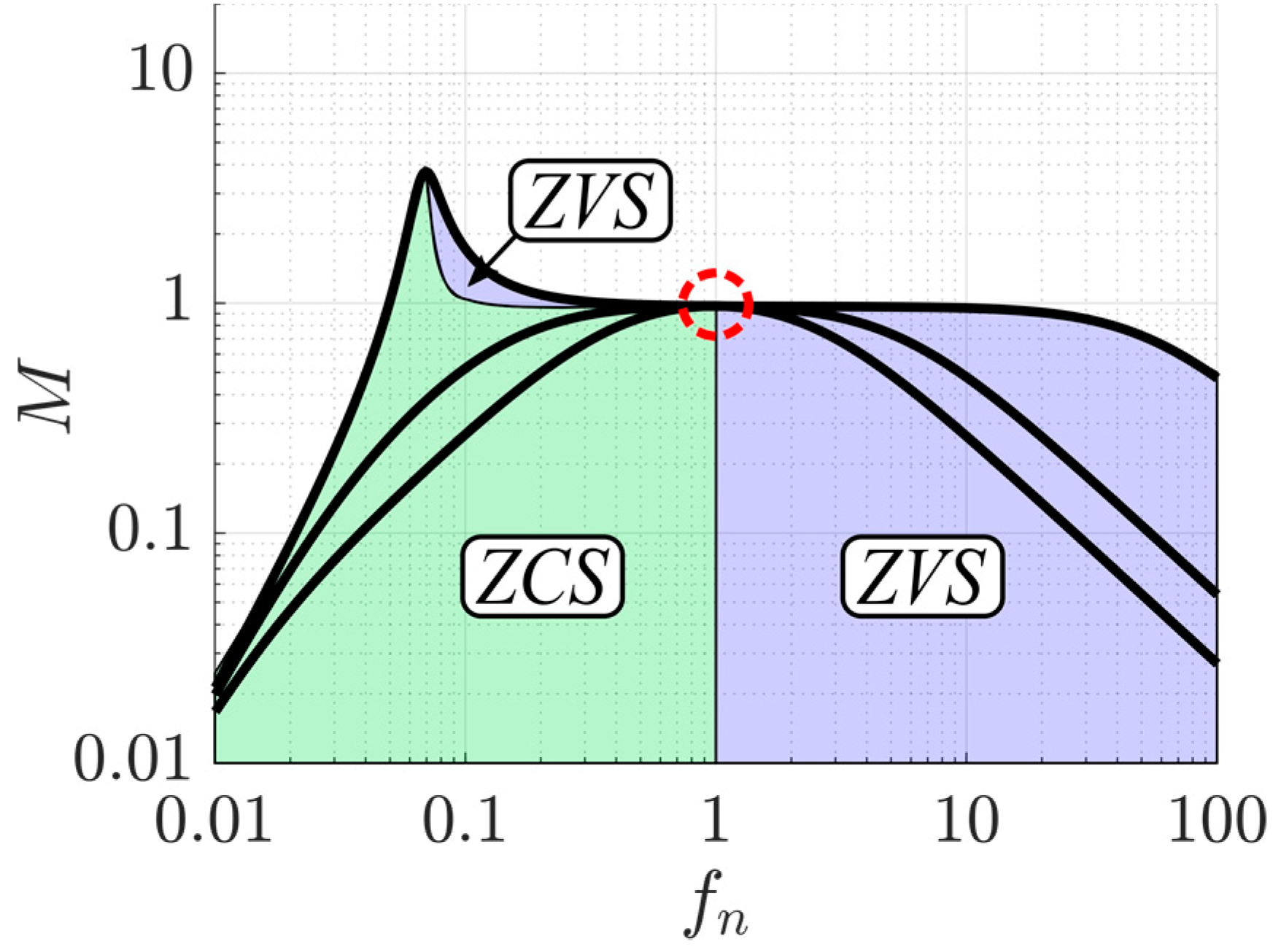

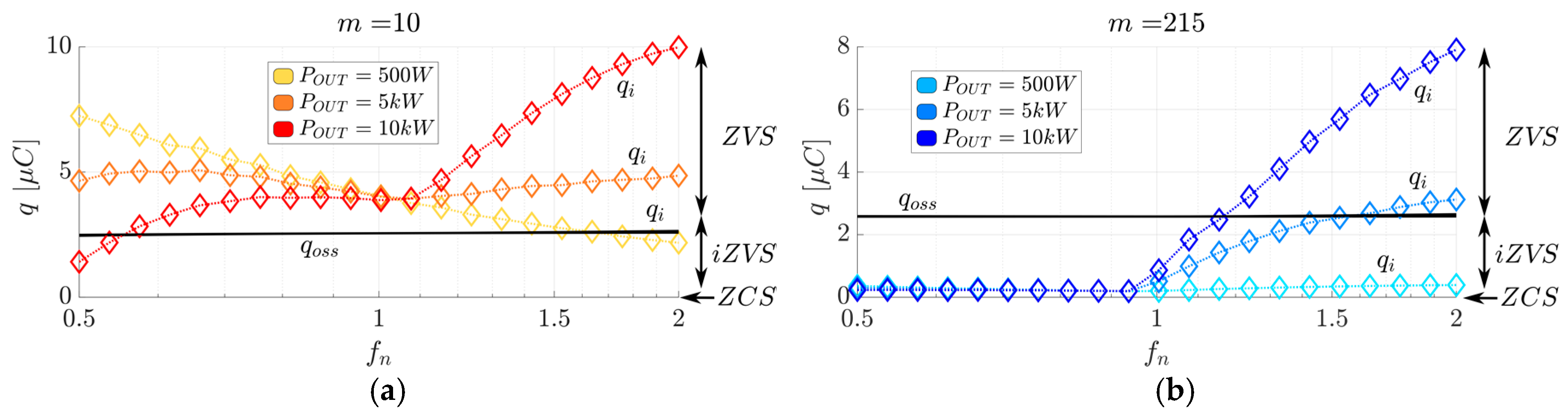

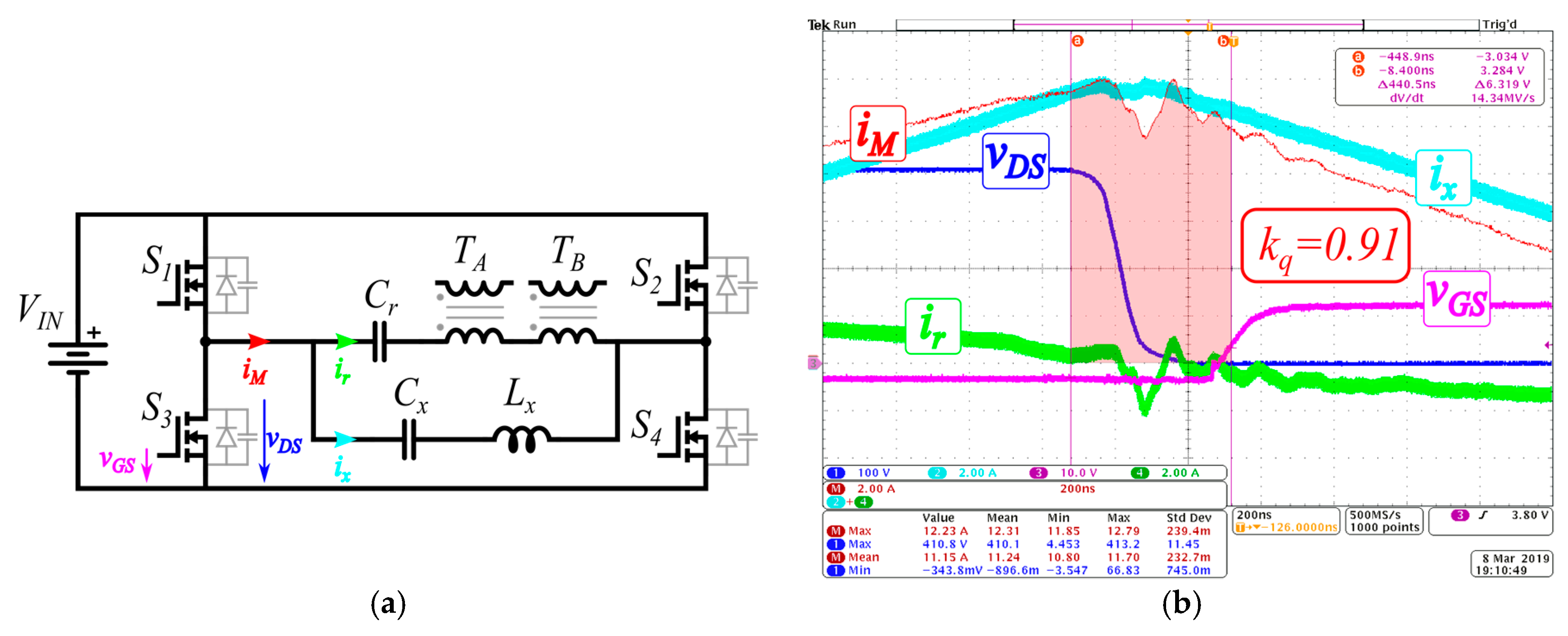

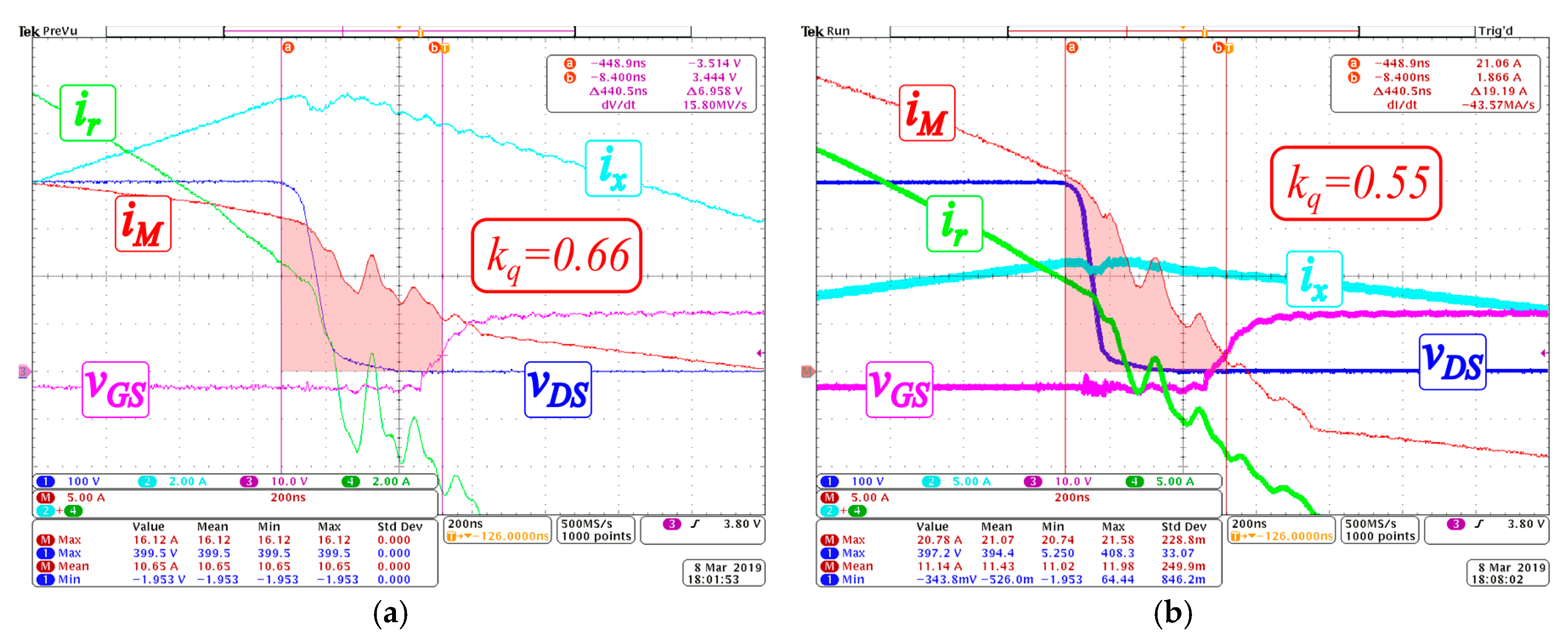

3. ZVS Analysis for the Unregulated LLC Converter

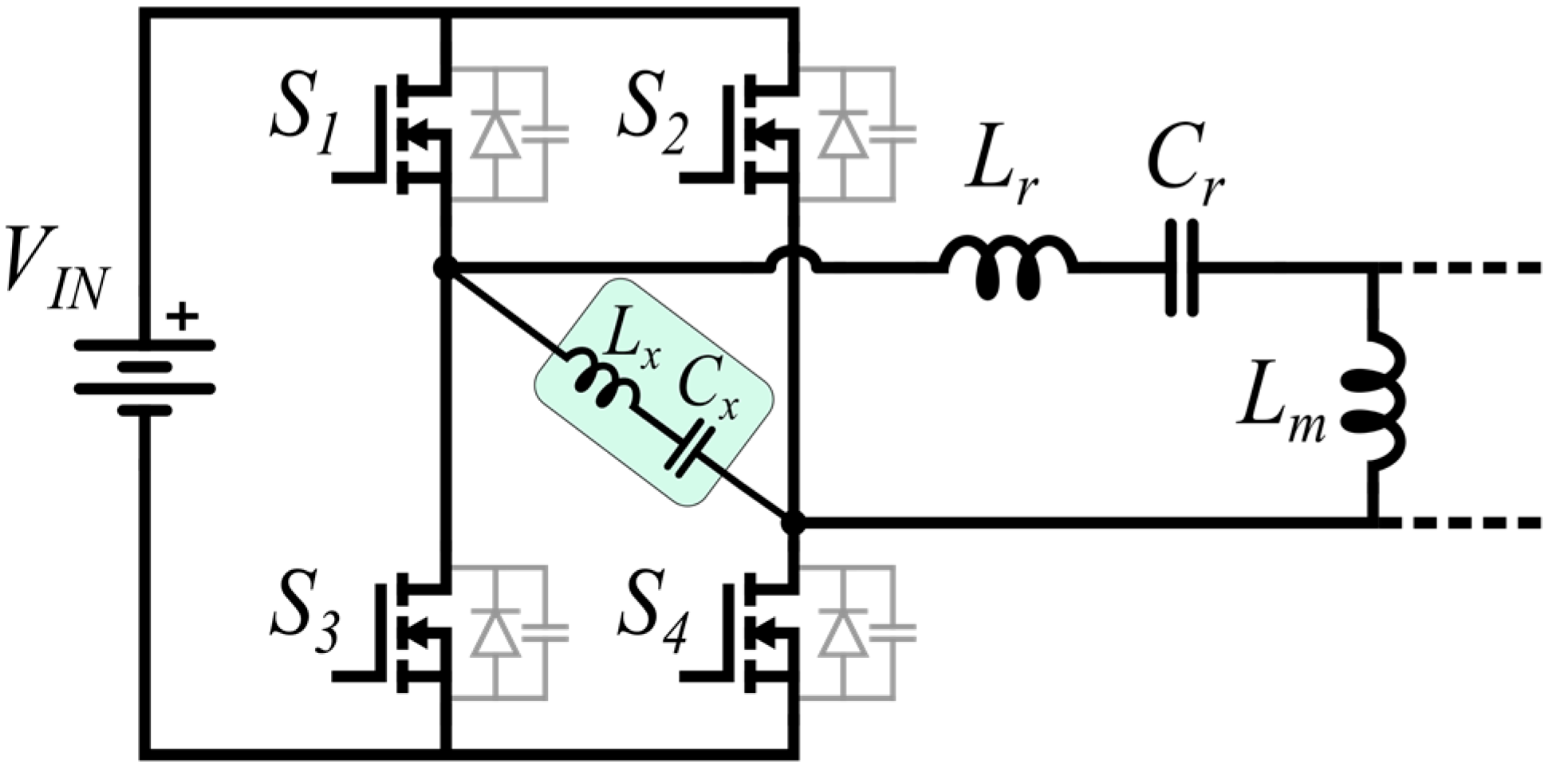

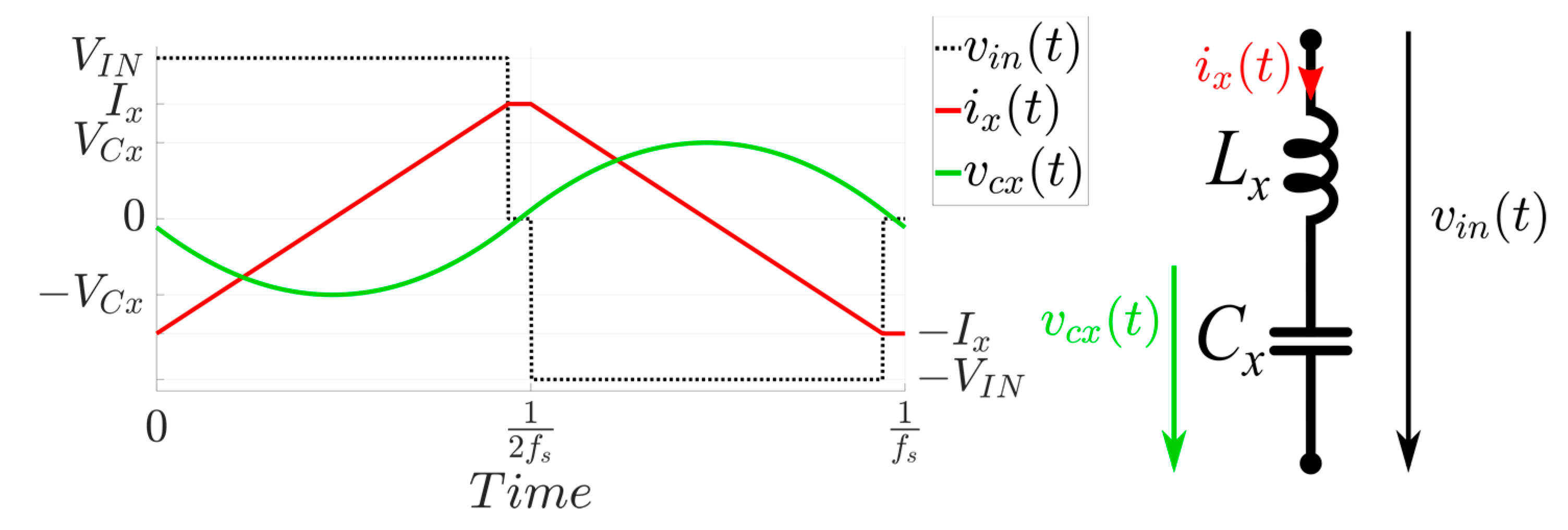

4. Proposed Auxiliary Circuit

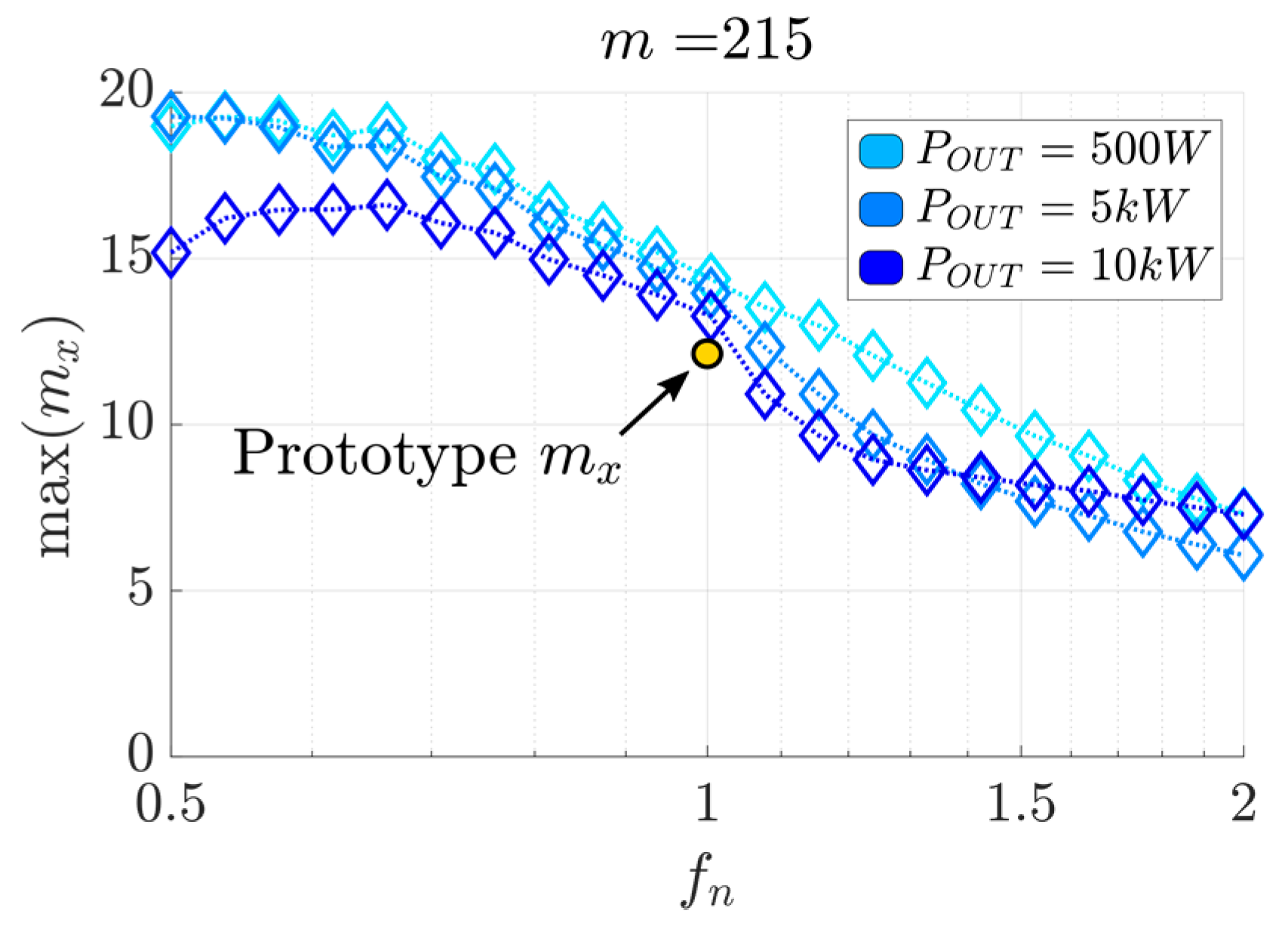

- The normalized auxiliary frequency:

- The auxiliary inductance ratio :

4.1. Auxiliary Circuit Analysis and Design

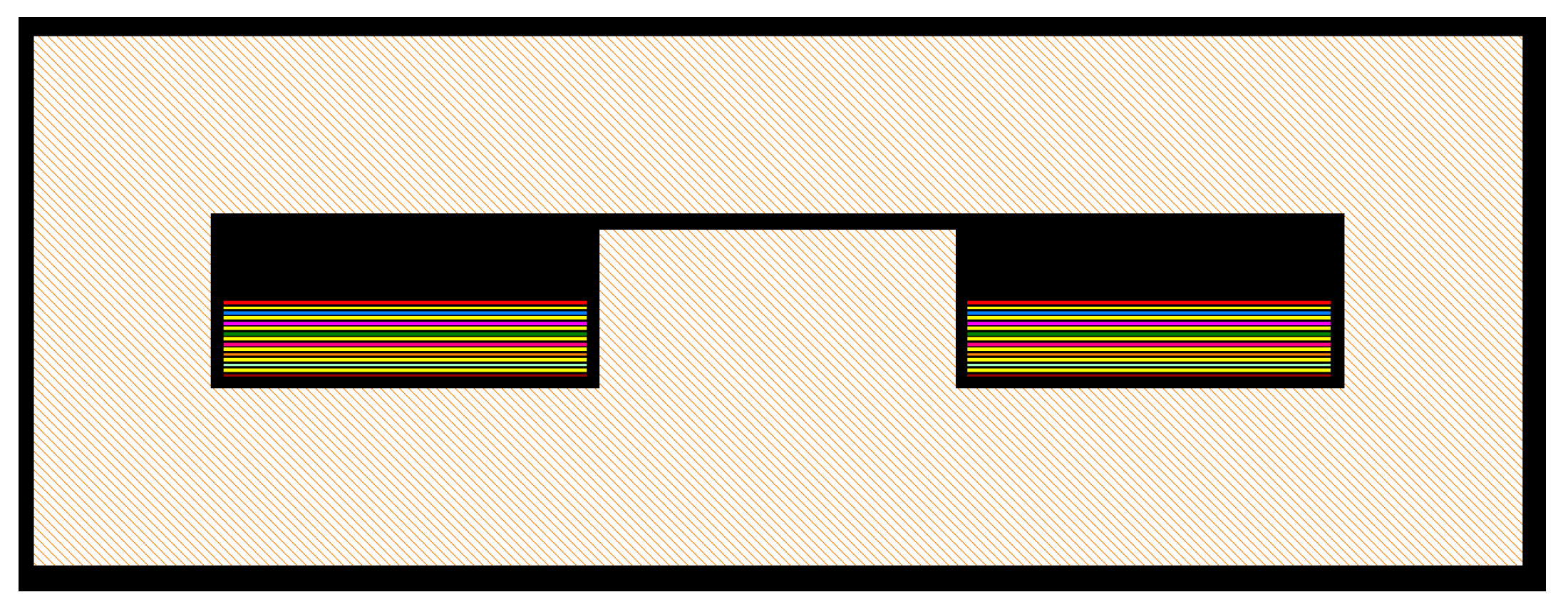

4.2. Transformer Design and Comparison

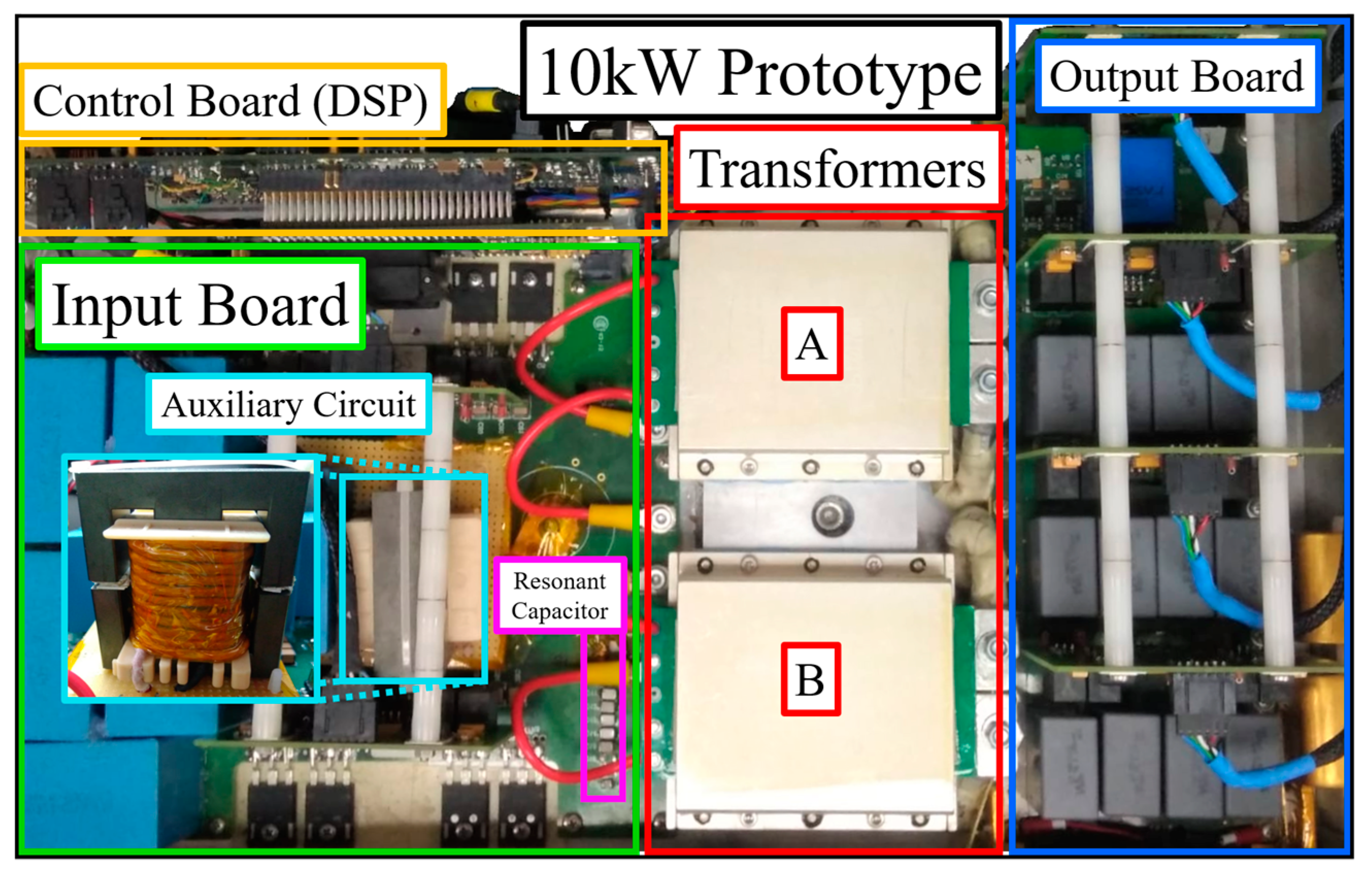

5. Prototype

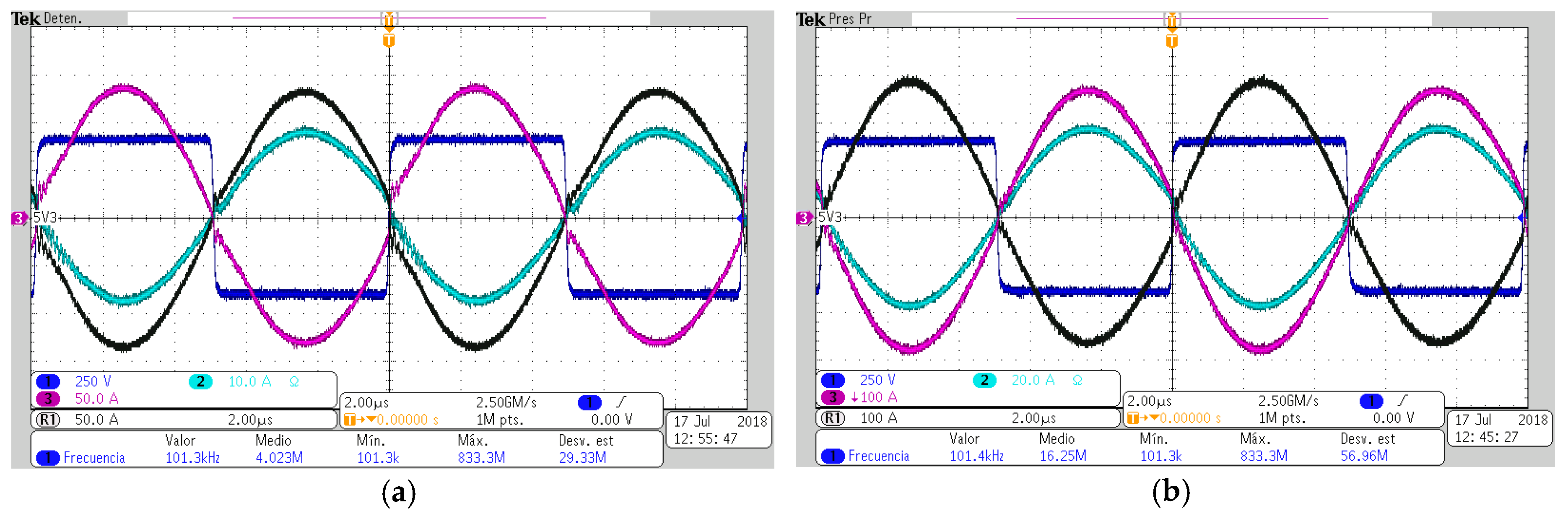

6. Experimental Results

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Emadi, K.; Ehsani, M. Aircraft power systems: Technology, state of the art, and future trends. IEEE Aerosp. Electron. Syst. Mag. 2000, 15, 28–32. [Google Scholar] [CrossRef]

- Rosero, J.A.; Ortega, J.A.; Aldabas, E.; Romeral, L. Moving towards a more electric aircraft. IEEE Aerosp. Electron. Syst. Mag. 2007, 22, 3–9. [Google Scholar] [CrossRef]

- Jones, R.I. The more electric aircraft: The past and the future? In Proceedings of the IEE Colloquium Electrical Machines and Systems for the More Electric Aircraft, London, UK, 9 November 1999; p. 1. [Google Scholar]

- Zhao, X.; Guerrero, J.M.; Wu, X. Review of aircraft electric power systems and architectures. In Proceedings of the 2014 IEEE International Energy Conference (ENERGYCON), Cavtat, Croatia, 13–16 May 2014; pp. 949–953. [Google Scholar]

- Bouvier, Y.E.; Borović, U.; Vasić, M.; Oliver, J.A.; Alou, P.; Cobos, J.A.; Árevalo, F.; García-Tembleque, J.C.; Carmena, J. DC/DC fixed frequency resonant LLC full-bridge converter with series-parallel transformers for 10 kW high efficiency aircraft application. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017; pp. 3788–3795. [Google Scholar]

- Borovic, U.; Zhao, S.; Silva, M.; Bouvier, Y.E.; Vasić, M.; Oliver, J.A.; Alou, P.; Cobos, J.A.; Árevalo, F.; García-Tembleque, J.C.; et al. Comparison of three-phase active rectifier solutions for avionic applications: Impact of the avionic standard DO-160 F and failure modes. In Proceedings of the 2016 IEEE Energy Conversion Congress and Exposition (ECCE), Milwaukee, WI, USA, 18–22 September 2016; pp. 1–8. [Google Scholar]

- Bell, B.; Hari, A. Topology key to Power Density in Isolated DC-DC Converters. Available online: https://pdfs.semanticscholar.org/fbac/b2391b4df41435779e2c69690ef052db2481.pdf (accessed on 14 May 2019).

- Yeon, C.-O.; Park, M.-H.; Ko, S.-H.; Lim, C.-Y.; Jang, Y.-J.; Moon, G.-W.; Kang, F.-S. A new LLC resonant converter with resonant frequency change for high conversion efficiency and high power density. In Proceedings of the 2017 IEEE 3rd International Future Energy Electronics Conference and ECCE Asia (IFEEC 2017-ECCE Asia), Kaohsiung, Taiwan, 3–7 June 2017; pp. 265–269. [Google Scholar]

- Fei, C.; Lee, F.C.; Li, Q. High-efficiency high-power-density LLC converter with an integrated planar matrix transformer for high-output current applications. IEEE Trans. Ind. Electron. 2017, 64, 9072–9082. [Google Scholar] [CrossRef]

- Pavlovic, Z.; Oliver, J.A.; Alou, P.; Garcia, Ó.; Cobos, J.A. Bidirectional multiple port dc/dc transformer based on a series resonant converter. In Proceedings of the 2013 Twenty-Eighth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 17–21 March 2013. [Google Scholar]

- Tomas-Manez, K.; Zhang, Z.; Ouyang, Z. Unregulated series resonant converter for interlinking DC nanogrids. In Proceedings of the 2017 IEEE 12th International Conference on Power Electronics and Drive Systems (PEDS), Honolulu, HI, USA, 12–25 December 2017; pp. 647–654. [Google Scholar]

- Gopiyani, A.; Patel, V.; Shah, M.T. A novel half-bridge LLC resonant converter for high power DC power supply. In Proceedings of the 2010 Conference Proceedings IPEC, Singapore, 27–29 October 2010; pp. 34–39. [Google Scholar]

- Hu, S.; Deng, J.; Mi, C.; Zhang, M. LLC resonant converters for PHEV battery chargers. In Proceedings of the 2013 Twenty-Eighth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Long Beach, CA, USA, 17–21 March 2013; pp. 3051–3054. [Google Scholar]

- Fu, D.; Lu, B.; Lee, F.C. 1MHz high efficiency LLC resonant converters with synchronous rectifier. In Proceedings of the 2007 IEEE Power Electronics Specialists Conference, Orlando, FL, USA, 17–21 June 2007; pp. 2404–2410. [Google Scholar]

- Zhang, X.; Chen, W.; Ruan, X.; Yao, K. A novel ZVS PWM phase-shifted full-bridge converter with controlled auxiliary circuit. In Proceedings of the 2009 Twenty-Fourth Annual IEEE Applied Power Electronics Conference and Exposition, Washington, DC, USA, 15–19 February 2009; pp. 1067–1072. [Google Scholar]

- Safaee, A.; Jain, P.; Bakhshai, A. A robust low-RMS-current passive auxiliary circuit for ZVS operation of both legs in full bridge converters. In Proceedings of the 2015 IEEE Applied Power Electronics Conference and Exposition (APEC), Charlotte, NC, USA, 15–29 March 2015; pp. 21–27. [Google Scholar]

- Chen, W.; Ruan, X.; Ge, J. A novel full-bridge converter achieving ZVS over wide load range with a passive auxiliary circuit. In Proceedings of the 2010 IEEE Energy Conversion Congress and Exposition, Atlanta, GA, USA, 12–16 September 2010; pp. 1110–1115. [Google Scholar]

- Safaee, A.; Jain, P.K.; Bakhshai, A. An adaptive ZVS full-bridge DC–DC converter with reduced conduction losses and frequency variation range. IEEE Trans. Power Electron. 2015, 30, 4107–4118. [Google Scholar] [CrossRef]

- Steigerwald, R.L. A comparison of half-bridge resonant converter topologies. IEEE Trans. Power Electron. 1988, 3, 174–182. [Google Scholar] [CrossRef]

- Huang, H. FHA-based voltage gain function with harmonic compensation for LLC resonant converter. In Proceedings of the 2010 Twenty-Fifth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Palm Springs, CA, USA, 21–25 February 2010; pp. 1770–1777. [Google Scholar]

- Liu, J.; Zhang, J.; Zheng, T.Q.; Yang, J. A modified gain model and the corresponding design method for an LLC resonant converter. IEEE Trans. Power Electron. 2017, 32, 6716–6727. [Google Scholar] [CrossRef]

- Graovac, D.; Purschel, M.; Andreas, K. MOSFET Power Losses Calculation Using the Data-Sheet Parameters; Infineon Technologies AG: Neubiberg, Germany, 2006. [Google Scholar]

- Li, J.; Abdallah, T.; Sullivan, C.R. Improved calculation of core loss with nonsinusoidal waveforms. In Proceedings of the Conference Record of the 2001 IEEE Industry Applications Conference. 36th IAS Annual Meeting (Cat. No.01CH37248), Chicago, IL, USA, 30 September–4 October 2001; Volume 4, pp. 2203–2210. [Google Scholar]

- de Simone, S.; Adragna, C.; Spini, C. Design guideline for magnetic integration in LLC resonant converters. In Proceedings of the 2008 International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Ischia, Italy, 11–13 June 2008; pp. 950–957. [Google Scholar]

- Zhang, J.; Hurley, W.G.; Wolfle, W.H. Gapped transformer design methodology and implementation for LLC resonant converters. IEEE Trans. Ind. Appl. 2016, 52, 342–350. [Google Scholar] [CrossRef]

- Yang, B.; Chen, R.; Lee, F.C. Integrated magnetic for LLC resonant converter. In Proceedings of the APEC. Seventeenth Annual IEEE Applied Power Electronics Conference and Exposition (Cat. No.02CH37335), Dallas, TX, USA, 10–14 March 2002; pp. 346–351. [Google Scholar]

- Kasper, M.; Burkat, M.R.; Deboy, G.; Kolar, J.W. ZVS of power MOSFETs revisited. IEEE Trans. Power Electron. 2016, 31, 8063–8067. [Google Scholar] [CrossRef]

- Borage, M.; Tiwari, S.; Kotaiah, S. A passive auxiliary circuit achieves zero-voltage-switching in full-bridge converter over entire conversion range. IEEE Power Electron. Lett. 2005, 3, 141–143. [Google Scholar] [CrossRef]

- Kim, D.-K.; Moon, S.; Yeon, C.-O.; Moon, G.-W. High efficiency LLC resonant converter with high voltage gain using auxiliary LC resonant circuit. IEEE Trans. Power Electron. 2016, 31, 6901–6909. [Google Scholar] [CrossRef]

- Prieto, R.; Cobos, J.A.; Garcia, O.; Alou, P.; Uceda, J. High frequency resistance in flyback type transformers. In Proceedings of the APEC 2000. Fifteenth Annual IEEE Applied Power Electronics Conference and Exposition (Cat. No.00CH37058), New Orleans, LA, USA, 6–10 February 2000; Volume 2, pp. 714–719. [Google Scholar]

- Lin, B.R.; Chen, P.L.; Huang, C.L. Analysis of LLC converter with series-parallel connection. In Proceedings of the 2010 5th IEEE Conference on Industrial Electronics and Applications, Taichung, Taiwan, 15–17 June 2010; pp. 346–351. [Google Scholar]

| Input Voltage | Output Voltage | Output Power | Output Current |

|---|---|---|---|

| 400 V | 28 V | 10 kW | 360 A |

| Normalized frequency | Inductance ratio |

| Load quality factor | Normalized voltage gain |

| Transformers 1 | Auxiliary Inductor | Total Losses 1 | Total Volume 1 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Power Loss | Δθ | Volume | Power Loss | Δθ | Volume | |||||

| PCu | PFe | PCu | PFe | |||||||

| Design I | 9.8 W | 13 W | 61 °C | 0.18 dm3 | 2.0 W | 2.2 W | 55 °C | 0.13 dm3 | 49.8 W | 0.49 dm3 |

| Design II | 25.5 W | 18 W | 101 °C | 0.37 dm3 | - | - | - | - | 87 W | 0.74 dm3 |

| Q (500 W) | Q (5 kW) | Q (10 kW) | QS | m | mx | fn | fxn |

|---|---|---|---|---|---|---|---|

| 0.02 | 0.18 | 0.36 | 7.5 | 215 | 12.5 | 0.99 | 0.023 |

| Lr | Cr | Lm | Lx | Cx | Rs | fr | fs |

|---|---|---|---|---|---|---|---|

| 7.11 μH | 349 nF | 2 × 750 μH | 74 μH | 60 μF | 602 mΩ | 102 kHz | 101 kHz |

| Component | Reference | Type | Quantity |

|---|---|---|---|

| Input capacitor | B32778G8606K | Film | 5 |

| Primary transistors | IPW65R037C6 | Coolmos | 8 |

| Resonant capacitor | C4532C0G2E473J320KA | Multilayer Ceramic | 6 |

| C3225C0G2E103J160KA | 3 | ||

| Transformer core | Planar E-core | Ferrite | 2 |

| Transformer winding | Copper foil | 200 μm | - |

| Secondary transistors | IPP10004S2L-03 | Optimos | 32 |

| Output capacitors | B32774D4226J000 | Film | 12 |

| Auxiliary inductor core | E65/32/27 | Ferrite | 1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bouvier, Y.E.; Serrano, D.; Borović, U.; Moreno, G.; Vasić, M.; Oliver, J.A.; Alou, P.; Cobos, J.A.; Carmena, J. ZVS Auxiliary Circuit for a 10 kW Unregulated LLC Full-Bridge Operating at Resonant Frequency for Aircraft Application. Energies 2019, 12, 1850. https://doi.org/10.3390/en12101850

Bouvier YE, Serrano D, Borović U, Moreno G, Vasić M, Oliver JA, Alou P, Cobos JA, Carmena J. ZVS Auxiliary Circuit for a 10 kW Unregulated LLC Full-Bridge Operating at Resonant Frequency for Aircraft Application. Energies. 2019; 12(10):1850. https://doi.org/10.3390/en12101850

Chicago/Turabian StyleBouvier, Yann E., Diego Serrano, Uroš Borović, Gonzalo Moreno, Miroslav Vasić, Jesús A. Oliver, Pedro Alou, José A. Cobos, and Jorge Carmena. 2019. "ZVS Auxiliary Circuit for a 10 kW Unregulated LLC Full-Bridge Operating at Resonant Frequency for Aircraft Application" Energies 12, no. 10: 1850. https://doi.org/10.3390/en12101850

APA StyleBouvier, Y. E., Serrano, D., Borović, U., Moreno, G., Vasić, M., Oliver, J. A., Alou, P., Cobos, J. A., & Carmena, J. (2019). ZVS Auxiliary Circuit for a 10 kW Unregulated LLC Full-Bridge Operating at Resonant Frequency for Aircraft Application. Energies, 12(10), 1850. https://doi.org/10.3390/en12101850