Abstract

The gasification and torrefaction of sewage sludge have the potential to make the thermal utilization of sewage sludge fully sustainable, thus limiting the use of expensive fossil fuels in the process. This includes sustainability in terms of electricity consumption. Although a great deal of work has been performed so far regarding the gasification of sewage sludge and some investigations have been performed in the area of its torrefaction, there is still a gap in terms of the influence of the torrefaction of the sewage sludge on its subsequent gasification. This study presents the results from the torrefaction tests, performed on a pilot scale reactor, as well as two consecutive steam gasification tests, performed in an allothermal fixed bed gasifier, in order to determine if torrefaction can be deemed as a primary method of the reduction of tar content for the producer gas, from the aforementioned gasification process. A comparative analysis is performed based on the results obtained during both tests, with special emphasis on the concentrations of condensable compounds (tars). The obtained results show that the torrefaction of sewage sludge, performed prior to gasification, can indeed have a positive influence on the gas quality. This is beneficial especially in terms of the content of heavy tars with melting points above 40 °C.

1. Introduction

1.1. Introduction

Sewage sludge is a residue of wastewater processing, is biologically active and consists of water, organic matter, including dead and alive pathogens, as well as organic and inorganic contaminants such as polycyclic aromatic hydrocarbons (PAHs) and heavy metals [1,2,3]. Utilization methods leading to stabilization and safe recycling are gradually replacing storage, landfilling and land-spreading. In the EU countries, novel methods are becoming increasingly popular [4], due to both environmental and economic reasons, as landfilling is deemed to be the most costly way to dispose of the sewage sludge [5].

Land-spreading is typically the most economical way to dispose of sewage sludge [5]. However, the cost of this can be subject to significant changes, depending on the distance between the sewage treatment plant and the location of the land where spreading takes place [5]. Moreover, any odor-related regulations, as well as the EU Nitrate Directive, might make this practice increasingly difficult. Incineration and co-incineration are also feasible options. However, relatively high moisture and ash content have negative influences on the combustion itself, as well as on the fuel logistics. This is the main obstacle in using the effect of scale in large power plants and combined heat and power (CHP) plants as well as in the cement industry, due to transportation costs. Novel thermal processes are currently a subject of active investigation, due to increasingly common restrictions on landfilling [6].

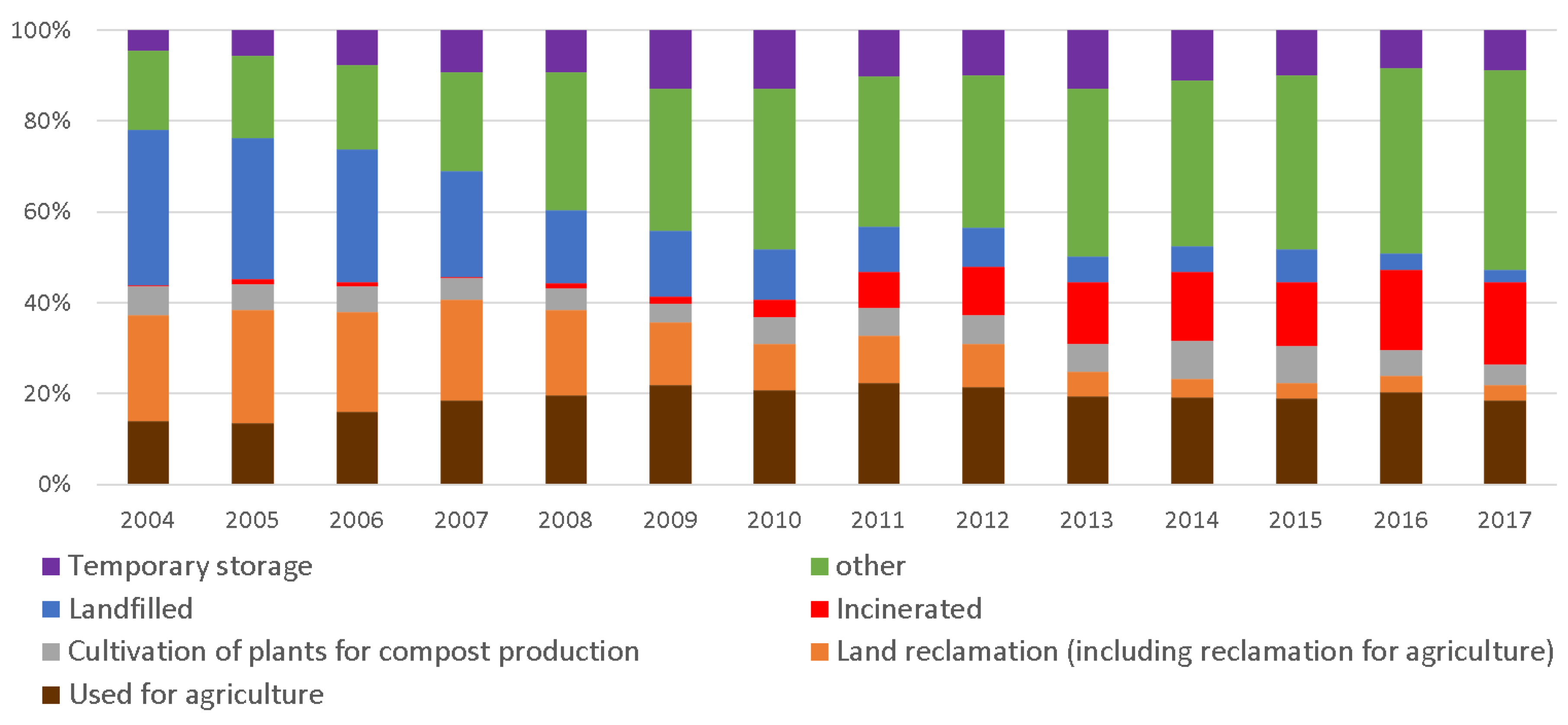

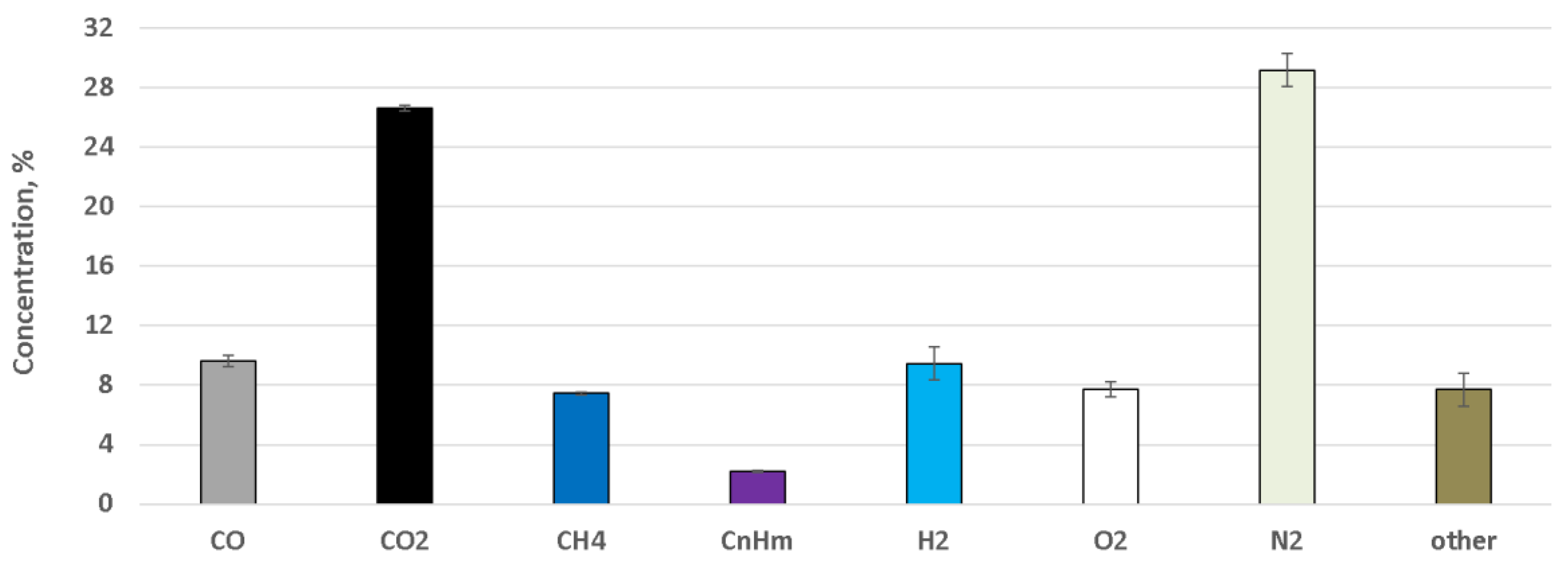

For example, in Poland (Figure 1), thermal treatment is an increasingly popular route for the utilization of the sewage sludge [7]. It is not difficult to notice from Figure 1 that the use of sewage sludge for land-spreading is fairly stable, and landfilling shows a constant decrease, whereas thermal utilization is increasingly important. In Poland, there are currently at least 45 installations for the drying of sewage sludge, mostly drum and tape dryers, as well as 12 installations using solar energy [8]. Incineration may be performed in existing incineration units (at least 11) that are based on fluidized bed (mostly) and grate furnaces [8,9,10]. Moreover, incineration is possible in 13 facilities of cement producers in Poland [11], as well as in municipal waste incineration facilities which are completed or in an advanced stage of construction (close to commissioning) in 17 different cities [12,13]. In all of these cases, logistics is critical for the economic feasibility of the solution; therefore, the problem of sewage sludge is the most severe in the case of small and medium size towns, without their own thermal utilization facilities, with limited possibilities of local land-spreading. It should not be overlooked that state-of-the-art thermal utilization leaves the problem of ashes unresolved. However, there are emerging technologies which allow ash to be used for the production of fertilizers [14].

Figure 1.

Changing trends for sewage sludge utilization in Poland according to the Main Statistical Office of Poland (GUS) [7] (“Used for agriculture” means the cultivation of all marketed crops, including crops designed to produce fodder; “Landfilled” is used exclusively for deposition in locations which have an official status as landfill areas).

1.2. Torrefaction of Sewage Sludge

Torrefaction is a thermal treatment, performed under a pressure close to ambient and elevated temperature (typically 250 °C to 300 °C) [15]. It can be performed in anaerobic conditions or with the presence of oxygen. Typically, oxygen is present when the flue gases are used as a heat source for direct torrefaction systems [15]. However, in the case of indirectly heated reactors, torgas can also contain some oxygen, due to leakages. Torgas is a by-product of the process that can consist mainly of condensable hydrocarbons, water, carbon dioxide. Some small amounts of carbon monoxide, as well as negligible amount of hydrogen, methane and other permanent gases (hydrocarbons), are also present [15,16,17].

Some fundamental work laying the foundations for the thermal treatment of sewage sludge has been performed, using TGA (thermo-gravimetric analysis) and DTG (differential thermo-gravimetric) techniques [18,19,20]. In general, very little has been published strictly on the torrefaction of sewage sludge, whereas some works have reported the results of experiments performed using materials other than sewage sludge, such as different types of industrial sludges.

Pulka et al. determined that torrefaction causes an increase in the higher heating value (HHV) of the pretreated material on a dry ash-free (daf) basis [21]. The significance of this increase was not substantial, due to the increased ash content of the torrefied samples [21]. An increase in ash content and HHV was also observed in another work of Poudel et al. for the torrefaction of sewage sludge [22], as well as for the torrefaction of sewage sludge blends with waste wood [23]. The successful torrefaction of sewage sludge, both using a fluidized bed reactor [24] and auger reactor [25], was performed by Atienza-Martinez et al. Residence times, used during preformed investions, were relevant for the practical operation of the torrefaction installations (13 to 35 min for the auger reactor and 3.6 up to 10.2 min for fluidized bed). A decrease in the energy density was observed in both cases (dry basis).

Huang et al. used a laboratory scale batch reactor to perform the torrefaction of waste from pulp industries [26]. The obtained energy densification ratios varied between 1.26 and 1.5, depending on the process parameters [26]. Huang et al. investigated the microwave co-torrefaction of sewage sludge with Leucaena and noticed a synergetic effect of the use of combined feedstocks for torrefaction [27,28]. An increase in the HHV on a dry ash-free basis was reported, and an HHV of 48 MJ/kg was obtained [27]. It was possible to achieve ratios of O/C and H/C similar to anthracite [27]. Huang et al. investigated the kinetics of the torrefaction of sewage sludge, using the simplified distributed activation energy model [29]. T.X. Do et al. used a series of heat and energy balance calculations to assess the performance of a hypothetical plant, using fry-drying and torrefaction as unit operations, along with a steam boiler using a part of the product [30]. The capability of achieving self-sufficiency, with an additional output of 33% of the dry solid mass, originally fed to the dryer, was reported [30]. The feasibility of using additives for the torrefaction of sewage sludge was also investigated by Pawlak-Kruczek et al. [31]. The study showed that the addition of lignite resulted in an improved heating value of the produced torgas, whereas the addition of CaO resulted in a relatively smaller amount of complex hydrocarbons present in torgas [31].

Peckyte and Baltrenaite studied the properties of carbonized products obtained from residues of various types of the sludges from paper and leather industries [32]. The performed research indicated that the form of biochar restrained the leaching of heavy metals [32], despite the concentrations being considerable when compared with the restrictions set by the regulations [33]. Wang et al. performed an assessment of the environmental effects of the carbonization of sewage sludge and concluded that it may have an overall positive environmental impact in comparison with landfilling and incineration [34].

Various studies reported results from the torrefaction of various types of feedstocks, performed under atmospheres containing oxygen, ranging from values close to 0% up to 15% [35,36,37,38,39,40,41]. However, for the case of the torrefaction of sewage sludge under the presence of oxygen, there is little information to be found in the literature. Pawlak-Kruczek, et al. presented results of such a study, performed in a laboratory-scale batch reactor and compared torrefaction in the presence of oxygen with torrefaction in vapothermal conditions [42]. The study concluded that similar results, in terms of mass and energy yields, can be achieved under comparably lower temperatures for vapothermal torrefaction [42].

1.3. Gasification of Raw and Torrefied Sewage Sludge

Gasification is a process of the conversion of a solid fuel into a mixture of gases such as hydrogen, carbon monoxide, carbon dioxide, methane and other hydrocarbons, often called producer gases [43]. The mixture produced for the purpose of chemical synthesis is called a syngas [43]. The optimization of this process typically aims to obtain a gas with a reasonably high calorific value and a minimum amount of impurities. Among these, tars are especially problematic from the practical point of view as they can condense or even become solid at ambient temperature, thus causing deposition problems [43]. According to this definition, tars are all organic contaminants with a molecular mass larger than that of benzene [44] (which amounts to 78.11 Da [45]). The limit of tar content for IC engines is typically from 50 up to 100 mg/m3 [46,47,48], although some of the published works state lower values [49,50]. The typical tar content for a producer gas is higher and can reach the orders of magnitude of 1 to 10 g/m3 [50]. However, the staged gasification of biomass can result in a tar content as low as 50 mg/m3 [50].

A significant amount of work has been performed to date on the gasification of sewage sludge. Werle reported a decreased temperature and increased concentration of combustible components of producer gases with an increase in the oxygen content of the sludge [51]. Schweizer et al. observed a hydrogen content exceeding 40% during the steam gasification of sewage sludge in a laboratory-scale fluidized bed gasifier [52]. In another work, Werle determined that the laminar flame speed increased with the increasing hydrogen content of the producer gas [53]. Werle and Dudziak assessed that it is possible to use producer gas from sewage sludge in spark-ignition engines [54]. However, Szwaja et al. determined that producer gas from sewage sludge requires a 40% addition of methane to obtain a satisfactory performance of a spark-ignition engine [55]. In another study, Werle confirmed that increased air temperature, at the inlet of a fixed bed gasifier, resulted in an increased yield of combustible compounds during the gasification of sewage sludge [56]. Calvo et al. reported a hydrogen content varying between 21.0% and 20.7% and tar content between 0.846 and 0.585 g/m3 of the gas from gasification of sewage sludge in a simple atmospheric fluidized bed gasifier [57]. Werle and Dudziak found that tars from the gasification of sewage sludge consisted mostly of phenols and their derivatives [1]. Akkache et al. observed a hydrogen content during the steam gasification of sewage sludge in a laboratory-scale fixed bed rig exceeding 30% [58]. Reed et al. investigated trace element distribution in the gasification of sewage sludge and determined that condensed phase may contain various species containing Ca, ammonium chloride (NH4Cl), as well as various species containing barium, mercury and zinc [59]. The presence of the latter in the gases could not be explained by existing thermodynamic models [59]. Judex et al. published results from existing sewage sludge gasification plants in Balingen and Manheim (Germany), with respective processing capacities of 1950 t/a and 5000 t/a of dry sewage sludge [60]. Producer gas from the fluidized bed gasifiers on average had lower heating values (LHVs) of 3.2 MJ/m3 and 4.7 MJ/m3, respectively [60]. The Balingen gasifier worked with an average gasification temperature of 820 °C, with an average excess air ratio (λ) of 0.33, whereas the gasifier in Manheim worked with an average gasification temperature of 870 °C, with an average excess air ratio (λ) of 0.28 [60]. Sewage sludge in Manheim had a comparably higher carbon content (30.0 %dry) and lower ash content (39.5 %dry) in comparison with sewage sludge from Balingen, having 16.9 %dry of carbon and 57.0 %dry of ash, respectively [60]. Hydrogen content was not significantly different: on average, 13.1% in Balingen and 13.3% in Manheim [60]. On average, a higher CO content (13.8% comparing to 8.1%) was measured in Manheim, whereas higher CO2 content was measured in Balingen (16.7% compared to 13.0%) [60]. The average methane content measured in Manheim (4.2%) was roughly double that measured in Balingen (2.1%) [60]. Kokalj et al. proposed using the plasma gasification of sewage sludge as an alternative mean of energy accumulation combined with sewage sludge utilization, as the work proposed the storage of the producer gas, which would be used during peak load and produced in off-peak time [61]. Huang et al. postulated the co-gasification of sewage sludge with torrefied biomass and performed calculations, using the thermodynamic equilibrium model, based upon the Gibbs free energy minimization [62]. The calculation showed that the optimum mixing ratio of wet sewage sludge was between 30% and 55%, depending on the gasification temperature [62]. In general, torrefaction offers enhancements for the subsequent gasification process from a general thermodynamic point of view [63], as well as in terms of a potentially decreased tar content [64]. Striūgas et al. performed research on the use of a plasma reactor for cleaning the gas from a downdraft gasification of the sewage sludge [48]. The study revealed that the use of plasma treatment for the gas produced in a downdraft gasifier can reduce the tar content down to 90 mg/mN3 [48]. However, there is hardly any information on the gasification of torrefied sewage sludge, let alone any experimental investigation trying to assess the effect of torrefaction on the quality of the gas produced, using this fuel.

2. Novelty, Relevance, Goals and Scope of Work

Although a lot of work has been performed to date on the gasification of sewage sludge, and some investigations have been performed in the area of its torrefaction, there is still a gap in terms of the influence of the torrefaction of the sewage sludge on its subsequent gasification. The attempt to address this gap is an important novelty aspect of this paper. Moreover, studies on the torrefaction of the sewage sludge published to date have focused on the torrefaction performed on bench-scale rigs. On the other hand, the torrefaction experiment performed within the scope of this study was conducted on a pilot-scale device. This study, in essence, is a continuation of the previously published paper [65] containing the concept of a novel, fully sustainable installation for the thermal utilization of sewage sludge.

In order to achieve a completely sustainable installation, it is necessary for it to not only match its own heat requirements, but also its requirements for electricity supply. The easiest way to perform this is to utilize existing infrastructure and use the gas from gasification in an existing CHP unit that utilizes biogas from the anaerobic digestion of the sludge. This, however, introduces the requirement of a reasonably clean producer gas.

Of course, cleaning might be necessary anyway. Nonetheless, its extent can potentially be limited by using torrefaction as a primary method of the reduction of the tar content of the producer gas. Moreover, while the ability to achieve high concentrations of hydrogen in the producer gas can be valuable, it might also be detrimental in terms of the subsequent use of the gas in an engine, due to potential issues with knocking.

This study presents the results from the torrefaction tests performed on a pilot-scale reactor, as well as two consecutive steam gasification tests, performed in an allothermal fixed bed gasifier. A relatively flat bed of the feedstock was used in order to simulate the steam gasification of the traveling grate, in order to validate the feasibility of this concept.

The most important goal of this study was the determination of whether torrefaction can be deemed as a primary method of the reduction of tar content for the gas, produced in the aforementioned gasification process. Moreover, this study introduces a novel way to present the results of tar analysis, named the tar deposition profile diagram. In this diagram, concentrations of individual tarry compounds are arranged according to their respective melting points, which is deemed to be critical in terms of their deposition. This diagram can be used as a simple tool to qualitatively assess the deposition potential of the producer gas, for example in gas coolers, by looking at the difference in the gas temperature between the inlet and the outlet of such a device and checking it against the diagram.

3. Materials and Methods

Samples of the sewage sludge for the suite of torrefaction experiments were obtained after the process of their drying in a commercial-scale paddle dryer, already described in a different paper [65]. Samples of wet sewage sludge used for the drying tests were originally obtained after the fermentation and mechanical dewatering stages of the sewage treatment, performed at the sewage treatment plant in Brzeg Dolny. Standard proximate analysis and the ultimate analysis of both raw sewage sludge and torrefied product were performed according to European standards. References of all the relevant standard procedures are presented in Table 1 (required accuracies are stated in the respective standards). The fusibility of the ashes was assessed using the standardized characteristic temperatures method, as specified in a Polish Standard PN-ISO 540:2001.

Table 1.

Proximate and ultimate analysis of the torrefied sewage sludge.

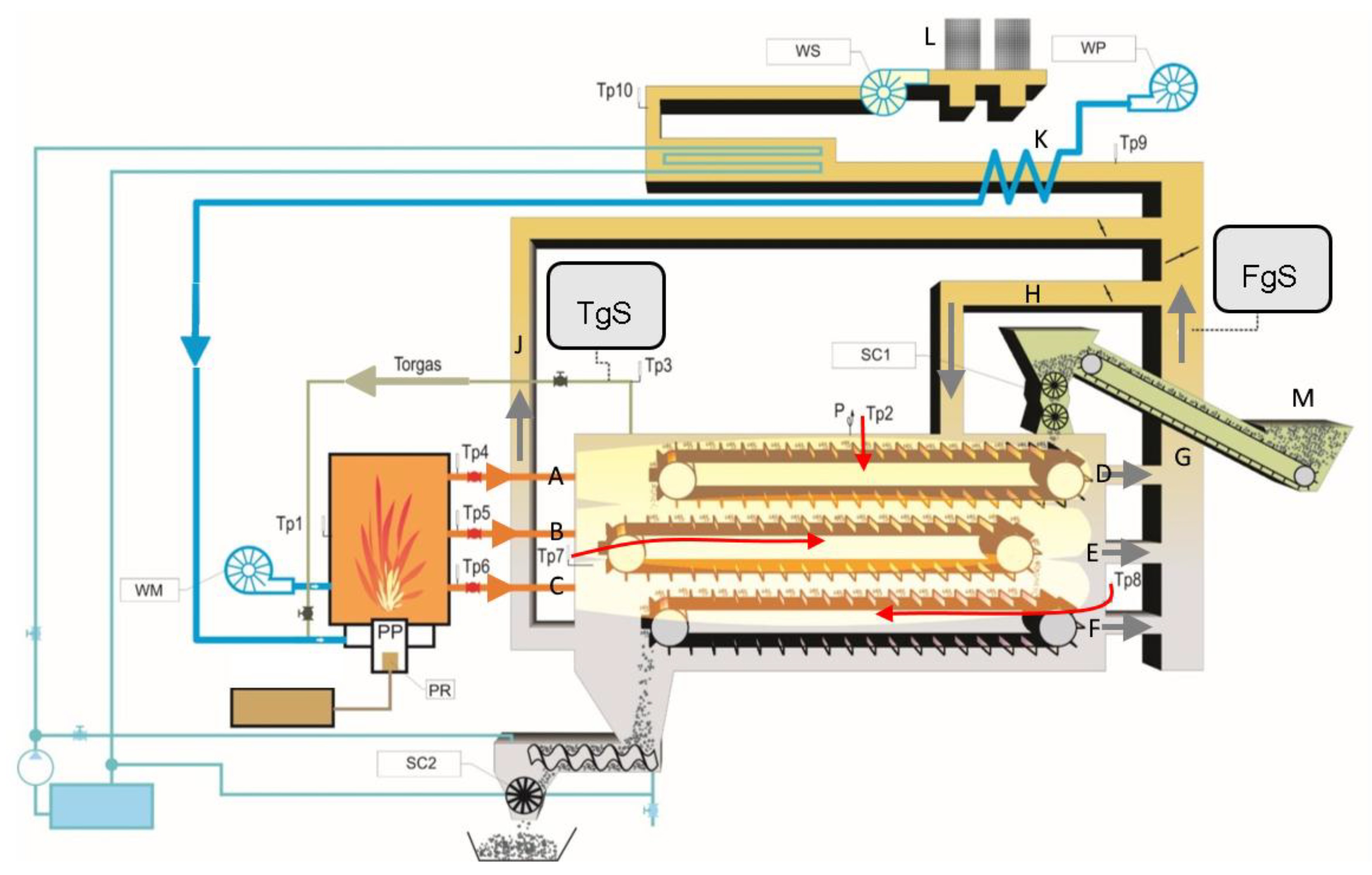

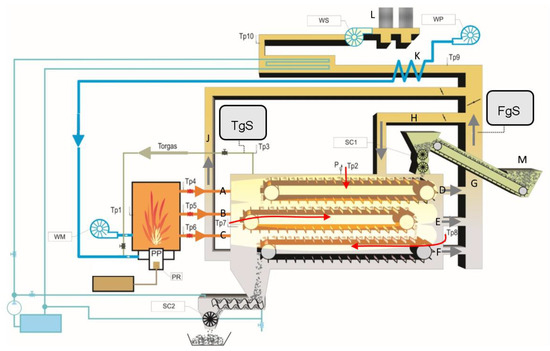

Approximately 150 kg of sewage sludge, dried in an industrial-scale paddle dryer, was torrefied using a multistage tape reactor (Figure 2), belonging to the research group of Boilers, Combustion and Thermal Processes at Wroclaw University of Science and Technology. Drying tests were described in detail in another paper [65].

Figure 2.

Multistage tape dryer/torrefier developed by Wroclaw University of Science and Technology (Tp—thermocouple; TgS—torgas sampling port; FgS—flue gas sampling port; WP—preheated secondary air blower; WM—primary air blower; WS—flue gas extraction fan; SC1—airlock at the inlet; SC2—airlock at the outlet; PR—pressure regulator; PP—oil burner; P—pressure gauge; A,B,C—ducts delivering hot flue gases to the inside of the shelves; D,E,F—ducts for evacuation of the flue gases out of the shelves; G—main flue gas extraction duct; H—flue gas recirculation to the freeboard of the reactor; J—duct for extraction of the gases out of the freeboard of the reactor; K—combustion air pre-heater; L—bag filters).

The patented technology presented in Figure 2 uses the external heating of the processed material, through the surface of three metal plates. The material is moved through the reactor by a chain conveying system and falls down from one plate into another, until it reaches the output auger, with a water jacket. The raw material is fed from the hopper to the reactor by another chain conveyor. To prevent the leakage of torgas to the surrounding area, airlocks are installed on both ends of the reactor.

The combustion chamber, with a ceramic refractory located beside the torrefier, is used for the burning of the torgas. An oil burner is used as a source of startup heat and as a pilot flame source during normal operation. The torrefier can also be used as a dryer, and in this type of operation, the oil burner is the main source of the heat. When working in torrefaction mode, the installation is operating reasonably close to the autothermal point, whereas the supply of auxiliary heat is determined by the moisture content of the feedstock.

The main advantage of this design is the possibility to significantly minimize the risk of the agglomeration of the particles, due to sticky tars condensing on the surfaces, as processed material only touches the hot surfaces of the reactor. In this way, the operational cost could be reduced by reducing the risk of emergency shutdowns due to clogging.

During the performed experiment, dried sewage sludge was gradually fed from the hopper to the reactor and subsequently torrefied. The average temperature, measured under the top plates of the shelves, was determined to be 391.9 °C. This was an arithmetic average and the calculation was based on the values measured by three thermocouples installed inside each of the shelves, close to the middle of the respective top plates (Tp2, Tp7 and Tp8—see Figure 2). The velocity of the chains along the length of the reactor, with the scrapers attached to them, was set in a way to allow the average total residence time of 20 min, under the assumption that there was no distribution of the particle residence time in the reactor.

In order to assess the severity of the torrefaction process, parameters of mass yield (Ym) and energy yield (Ye) were used as performance indicators typically used for that purpose [15,31,66,67]. Mass yield was assessed, using the volatile matter content of both feedstock and product, as proposed by Weber et al. [67]:

where

- Ym—mass yield, -;

- VM—respective volatile matter content of feedstock and product, %dry.

The well-established formula was used for the calculation of the energy yield [15,21,23]:

where

- Ye—energy yield, -;

- HHV—respective higher heating value of feedstock and product, MJ/kg.

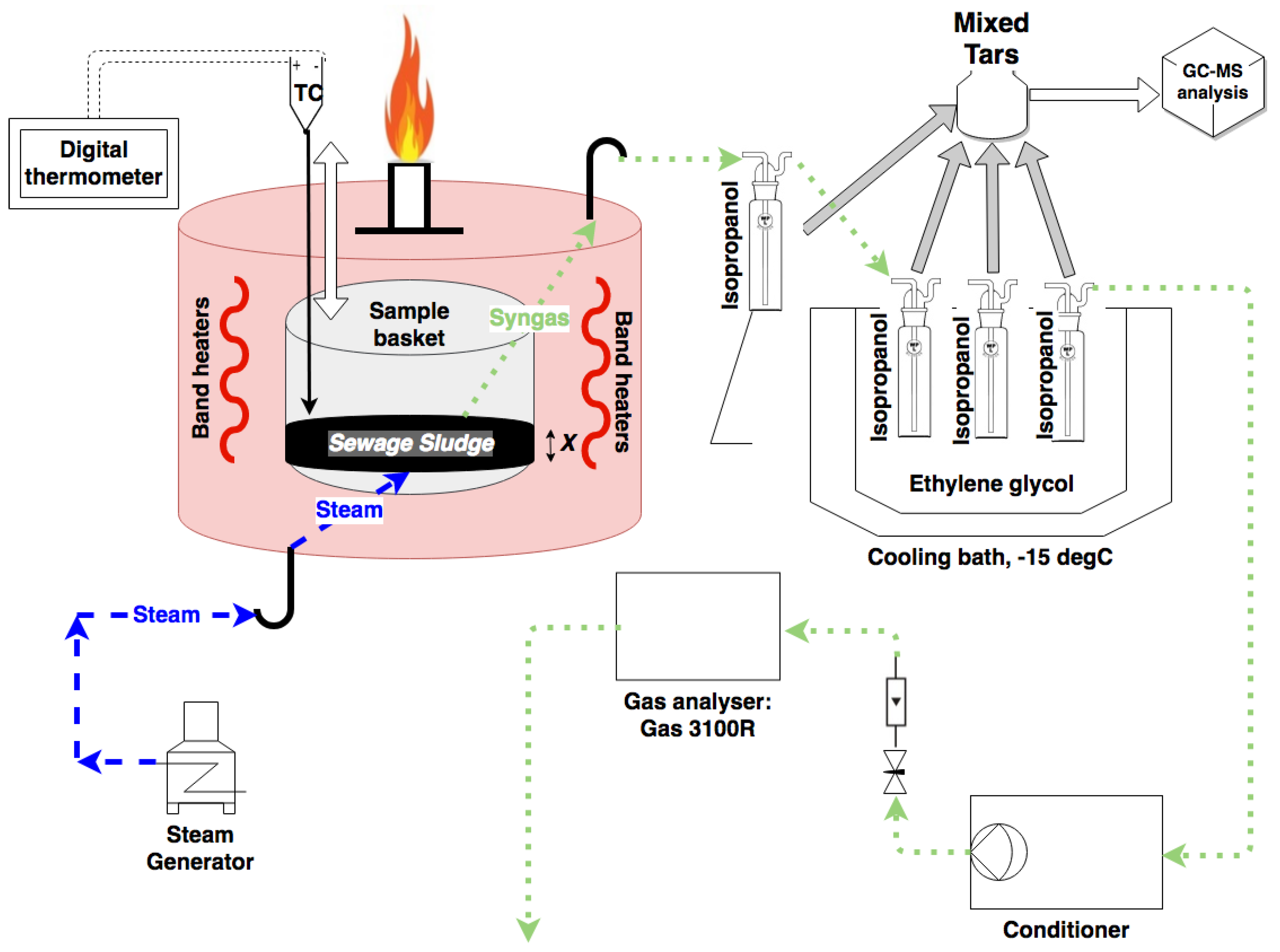

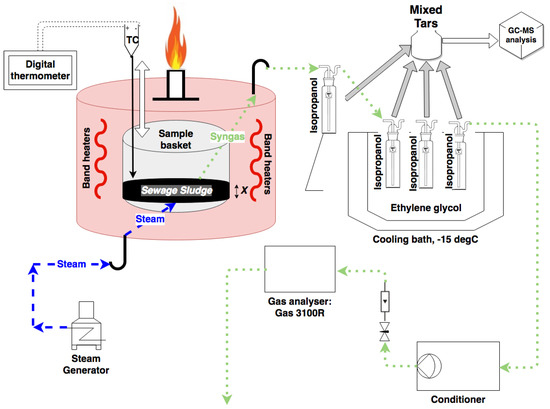

Gasification tests were performed using a laboratory scale allothermal batch gasifier (Figure 3), heated by a mantle made of 3 band heaters, installed on the side walls of the reactor. The temperature of the reactor was controlled by a PLC (Programmable Logic Controller), with a type K thermocouple installed inside of the ceramic refractory of one of the band heaters. The temperature of the mantle was set to 900 °C for both tests. This resulted in an average temperature at the edge of the feedstock layer of approximately 675 °C, with temperatures in the freeboard area varying between 760 °C and 350 °C, depending on the height.

Figure 3.

Allothermal gasifier: diagram of the test rig (TC—type K thermocouple; X—thickness of the sample layer).

Gasification was performed for both raw and torrefied sewage sludge samples, using steam as a gasifying agent. Steam was produced using an electrically heated steam generator, which had been calibrated prior to the performed tests. The calibration involved the measurement of the temperature of the steam at the outlet of the steam generator, as well as the mass flow rate of the steam, measured gravimetrically by condensing in the tank. The calibration allowed the setting of the control knob of the steam generator to achieve the desired temperature and mass flow rate of the live steam. For both tests, the steam generator was set in a way allowing a constant generation of 1000 g of live steam per hour, with an outlet temperature of 96 °C. Both samples were sieved through a set of calibrated sieves (ISO 3310-2 compliant), using a sieve shaker. A stack of the sieves with apertures of 1 mm, 2 mm, 3.15 mm, 4 mm, 5 mm and 6.3 mm was used.

A sample basket with a diameter of 30 cm and height of 45 cm, made of a stainless-steel mesh with an aperture of 0.5 mm, was used for the holding of a layer of 5-cm thick sample material in both of the cases. The basket was placed inside of the hot reactor, which was subsequently closed. It was anticipated that the layer of the material will resemble a layer on a grate in the case of a subsequent scaling up of the gasifier. This was expected to give some indication of the feasibility of the use of a traveling grate in the conceptual gasifier. Steam was fed directly under the bottom mesh (grate) of the sample basket.

A sample of the produced gas was taken from the top of the reactor and put through a series of impinger bottles filled with isopropanol. First, the impinger bottle was installed, using a laboratory grip, in the vicinity of the gas outlet, in order to minimize the length of the teflon hose, connecting the gas outlet of the gasifier with the aforementioned impinger bottle (Figure 3). In this way, the loss of the condensable by-products of gasification was minimized. A series of three impinger bottles, connected to the outlet of the first impinger, was immersed in a PLC-controlled cooling bath SD 07R-20. The bath was filled with ethylene glycol and the temperature was set to be −15 °C. After leaving the series of impinger bottles, dry, cold gas went through the conditioner, with an in-built pump, which helped to overcome the pressure drop introduced by the series of impingers. This allowed the sampling of the gas with a sufficiently high volumetric flow rate (at least 1.0 L/min as required by the analyzer).

The composition of permanent gases in both cold, dry producer gas and torgas were determined on-line using the Gas 3100R analyzer (manufactured by G.E.I.T Europe bvba, Bunsbeek, Belgium and supplied by Atut Sp. Z O.O. Lublin, Poland). This analyzer uses NDIR (non-dispersive infra-red) sensors for measurements of CO2, CO, CH4 and CxHy (light hydrocarbons, given as an equivalent of methane). A TCD (thermal conductivity detector) sensor is used to measure the H2 content, whereas an electrochemical sensor is used for the determination of the O2 content. The analyzer was calibrated using nitrogen with a purity of 5.0 before each measurement. The precision of Gas 3100R is 1% of the measuring range for CO2, CO, CH4, CxHy and 2% of the measuring range in the case of the TCD sensor for H2 and electrochemical sensor for O2. The measuring ranges were as follows: CO2, 20%; CO, 40%; CH4, 10%; CxHy, 5%; H2, 55%; and 25% in the case of O2. Gas 3100R has a linearity drift of 1% of measuring range per week, both for zero and for span. The excess of the gas was burned using a flare installed on the top cover.

Samples of the solutions from impinger bottles were mixed together in an Erlenmeyer flask of sufficient volume after the experiment. The mixed sample was subsequently analyzed using GC-MS, which consisted of an Agilent 7820-A chromatograph (manufactured by Agilent Technologies, Palo Alto, CA, USA) and an Agilent 5977B MSD spectrometer (Agilent Technologies, Palo Alto, CA, USA). In the chromatograph, a Stabilwax-DA column (Restek, Benner Circle, Bellefonte, PA, USA) was used. Helium was used as a carrier gas (1.5 mL/min). The heating-up program was set to achieve 50 °C in 5 min and subsequently heat the column with a ramp of 10 °C/min, until the temperature of 200 °C was reached, and held for another 20 min afterwards. The data obtained with GC/MS was analyzed using the base peak chromatograms (BPC). Mixed samples were analyzed three times, and average values are presented in this study. A few major compounds, detected in the tar mixtures, were the subject of quantitative analysis in addition to the qualitative analysis. The quantitative analysis was performed using the calibration curves done for each of the compounds. Calibration curves were made using four points which corresponded to four known concentrations of the particular compound in the solvent (isopropanol). Five repetitions were done for each of the determined points. Reference substances and isopropanol of chromatographic grade were used for the calibration.

Temperature distribution was measured along the height of the sample basket, using a first-class K type thermocouple and a digital thermometer. Measurement was performed in an empty gasifier. The thermocouple was inserted from the top of the gasifier through an opening located half way between the central axis of the basket and its circumference. The thermocouple was gradually moved down every 5 cm, starting from the top edge of the sampling basket, until the tip reached the depth of 40 cm. Then, the tip was moved down by 2.5 cm.

4. Results

The results of the proximate and ultimate analysis of both raw and torrefied sewage sludge are presented in Table 1 below. It is clear, when comparing it with the original material, that sewage sludge changed due to torrefaction. However, contrary to the expectations, a higher heating value of the torrefied sewage sludge decreased in comparison to the raw material.

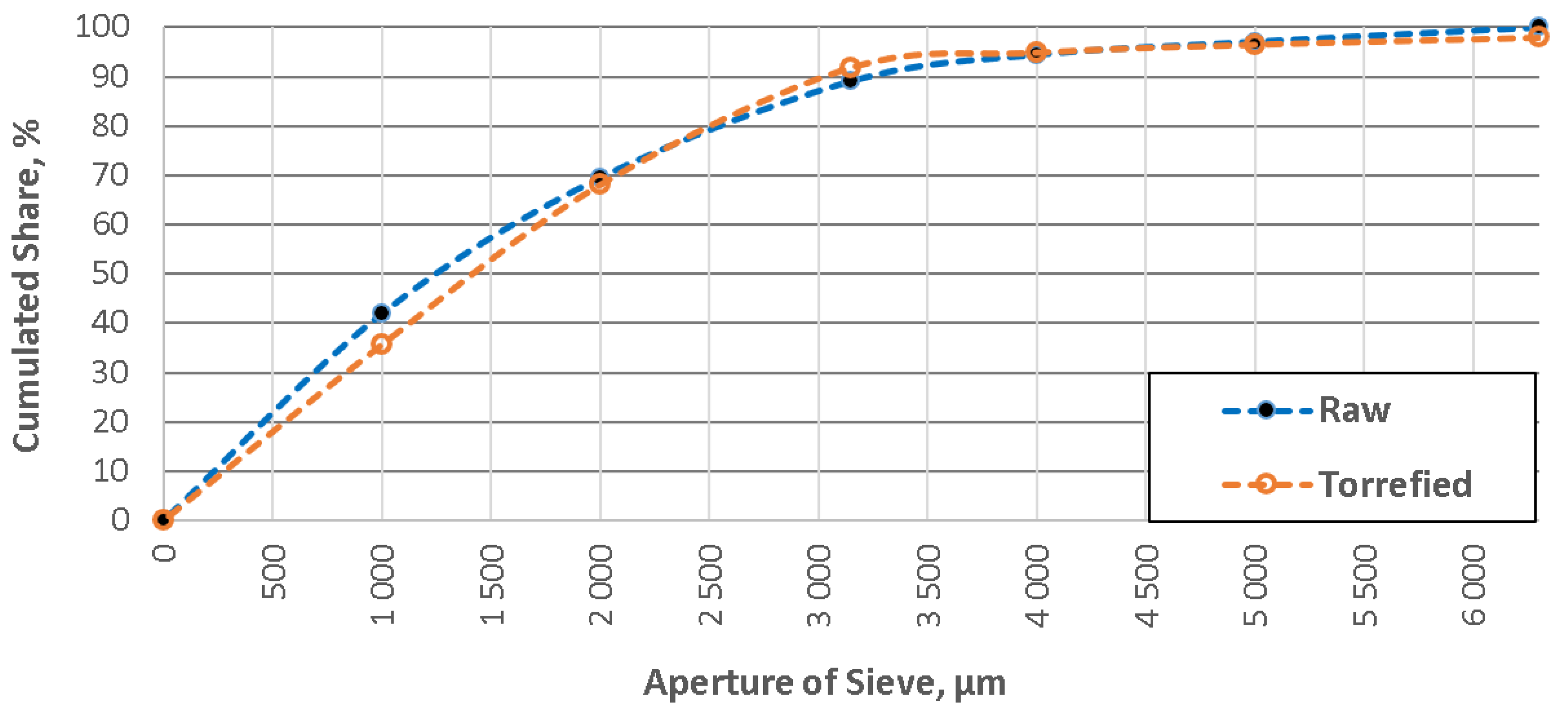

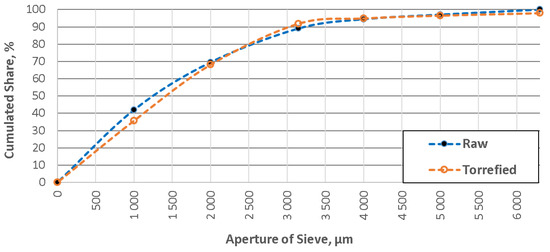

LHV also decreased, but only slightly (Table 1). The volatile matter content decreased significantly, as expected. Ash content was subject to a significant increase (Table 1). Particle size distribution (Figure 4) was similar both for raw and torrefied sewage sludge, even with a slightly higher number of fine particles (d > 1 mm) for the case of raw biomass. The calculated d50 diameter was 1292 µm for raw and 1442 µm for torrefied sewage sludge. The fusibility of the ashes was very similar in the case of both raw and torrefied sewage sludge (Table 2).

Figure 4.

Particle size distribution of raw (pre-dried) and torrefied sewage sludge.

Table 2.

Fusibility of the ashes for raw and torrefied sewage sludge under the reducing conditions (±20 °C for all presented results).

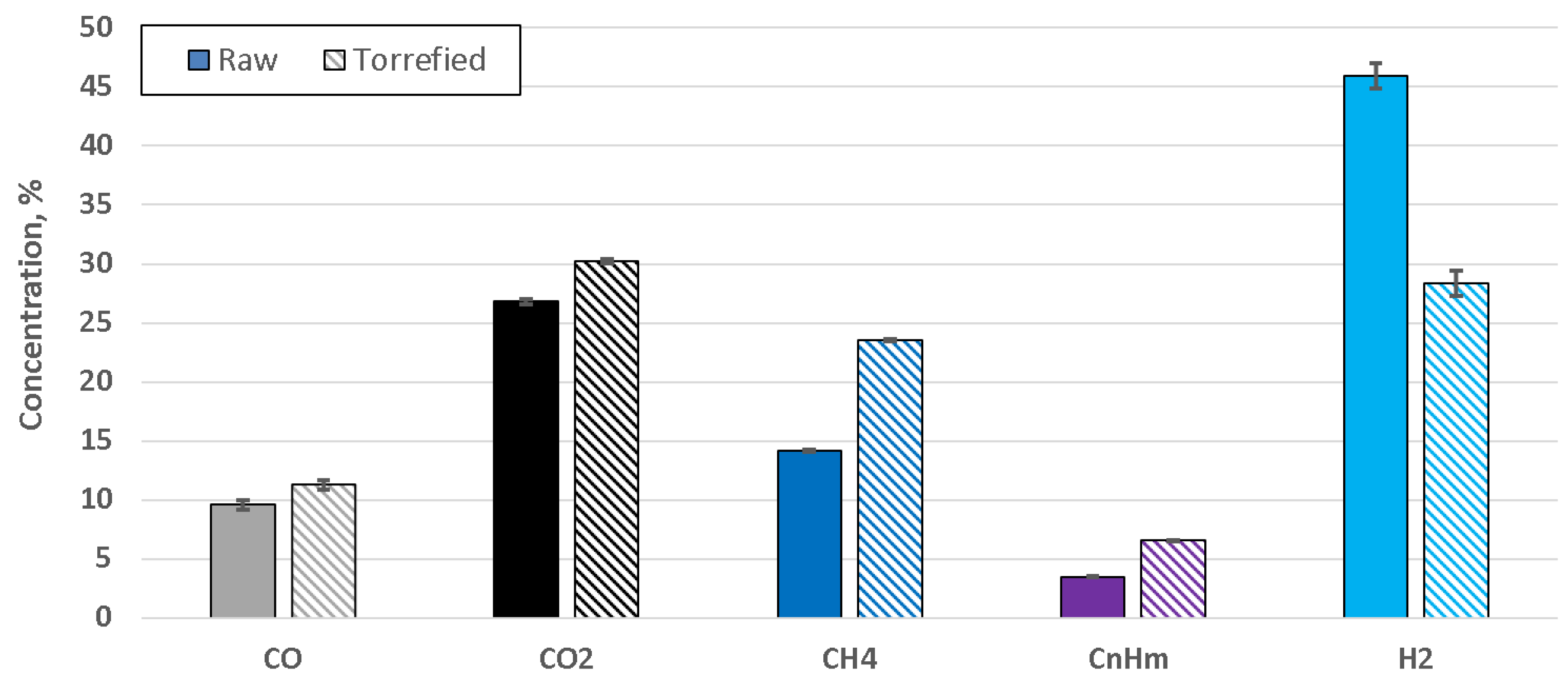

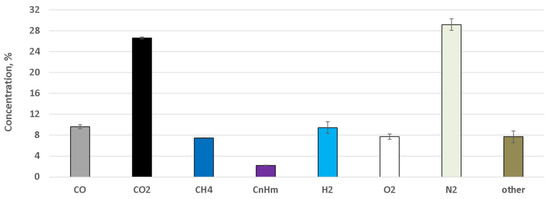

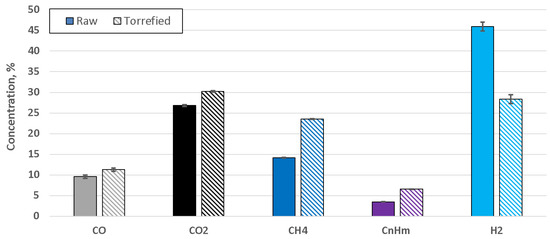

Torrefaction was performed in an oxidizing atmosphere, as can be clearly determined from the composition of torgas presented in Figure 5. Among the permanent gaseous products of torrefaction, CO2 was prevalent. Nonetheless, CO content was substantial. Moreover, the content of hydrogen, methane and other light hydrocarbons (CnHm) was significant when torrefaction processes were considered. The average LHV of the permanent gases produced from the torgas was relatively high (15.10 MJ/m3). The calculated mass yield was 0.754, whereas the calculated energy yield was 0.494.

Figure 5.

Composition of permanent gases present in torgas, measured during the torrefaction test of the pilot-scale installation.

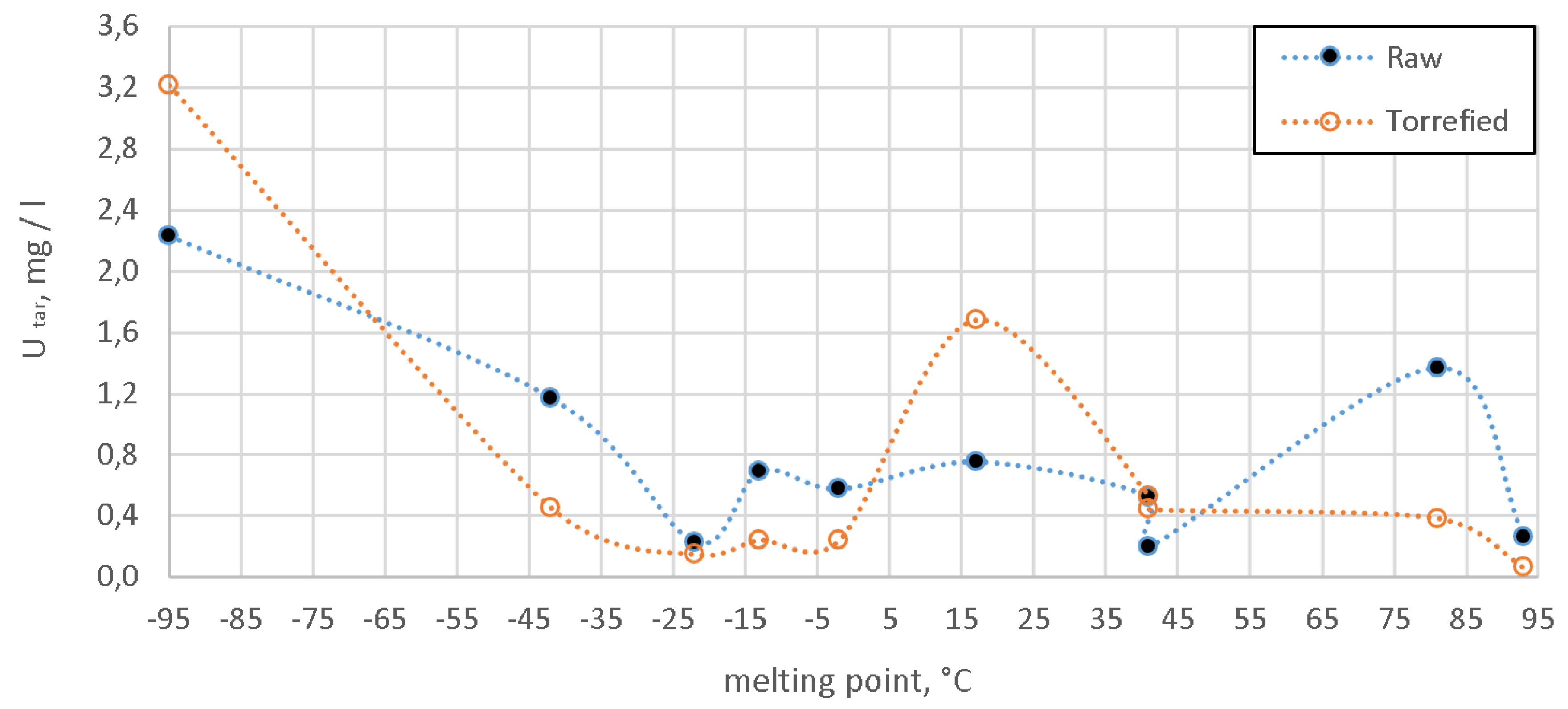

There were significant differences in the average composition of the gas obtained during both experiments (see Figure 6). The most notable was the difference in the hydrogen content, which was much higher in the case of the gasification of raw sewage sludge in comparison to the gasification of torrefied sewage sludge. On the other hand, the concentration of methane, as well as the concentration of other light hydrocarbons (CnHm), was substantially higher during the gasification of the torrefied sewage sludge. The contents of carbon dioxide and carbon monoxide were also higher for the experiment performed with torrefied feedstock. As a consequence of their respective compositions, dry producer gases from the gasification of raw sewage sludge had an average lower heating value of 13.51 MJ/m3, whereas the gas produced from torrefied sewage sludge reached 17.51 MJ/m3 on average.

Figure 6.

Composition of the dry producer gases obtained during both gasification experiments.

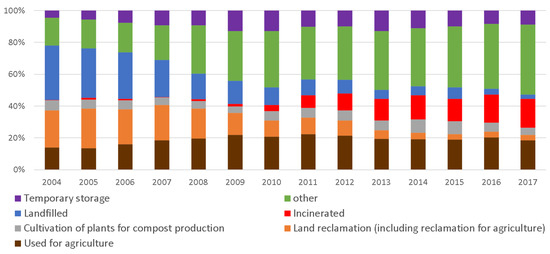

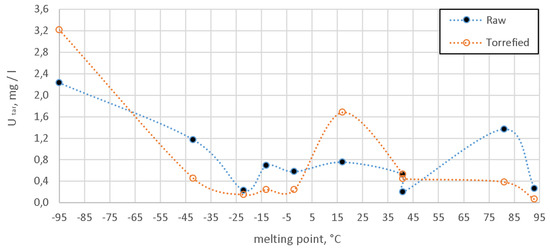

The condensable compounds detected in the samples of solvent (isopropanol) solution are reported in Table 3 and Table 4. The results presented in Table 3 are qualitative, whereas the results presented in Table 4 are quantitative. The concentrations of respective compounds are given as per kg of the feedstock. The names of all the compounds are the official IUPAC names. Melting points, boiling points and average masses were taken from the on-line database of the Royal Society of Chemistry [45]. Average values were used. The deposition profiles of tars collected during both experiments are presented in the diagram below (Figure 7). It was assumed that the likelihood of the tar deposition corresponds with the respective melting points of the compounds.

Table 3.

Condensable compounds, identified using GC-MS analysis—qualitative analysis.

Table 4.

Quantitative analysis of selected condensable compounds, identified using GC-MS analysis.

Figure 7.

Tar deposition profile diagram: content of major tarry compounds in the produced gas arranged according to their respective melting points.

5. Discussion

The average temperature of the torrefaction process was high (391.9 °C) in comparison to a typical range of the torrefaction temperatures for biomass [15]. However, some additional factors should be taken into account. Firstly, sewage sludge is not a typical lignocellulosic biomass. It contains proteins which are cracked into more simple compounds, such as amines, as well as nitrile and nitrogen-containing heterocyclic compounds, at temperatures between 300 °C and 500 °C [25]. Moreover, temperatures below 400 °C are considered to be low in terms of the thermal decomposition of the unsaturated fatty acids [25]. Additionally, practical difficulties of the measurements performed at a pilot-scale installation should be taken into account. The design of the reactor, with scrapers moving the material on top of the shelves, makes it impossible to measure the actual process temperature inside the layer of the torrefied material. Therefore, an average from three thermocouples installed close to the top plate of the shelves seems to be the best way to indicate the process temperature. It should be taken into account that the heat transfer between the flue gases inside of the shelves (convection), heat conduction of the shelves themselves, as well as heat transfer between the top side of the shelves and the torrefied material, and heat transfer within the bed itself, can influence the actual temperature. This temperature would undoubtfully be lower than the temperature used in the manuscript for the characterization of the process.

In terms of the torrefaction, some counterintuitive results have been obtained. Typically, torrefaction leads to the increase in the heating value of the processed biomass [15,16,17,68,69,70]. In the case of this study, both HHV and LHV decreased as a consequence of the performed treatment (Table 1). Moreover, the carbon content decreased after the torrefaction. In general, it seems plausible to justify this by a couple of factors, such as the severity of the process (temperature), torrefaction in the oxidizing atmosphere (see Figure 5), as well as the autocatalytic effect of the inorganic fraction of the material. It is clear from Table 1 that ash content increased significantly during torrefaction. Moreover, the initial ash content of the sewage sludge, prior to torrefaction, was high.

The severity of the torrefaction resulted in a relatively low mass yield of 0.754, which is similar to the value determined by Poudel et al. (approx. 0.63 for 400 °C) [22]. However, the aforementioned sharp decrease in HHV, caused by the significant increase in the ash content, resulted in a very low energy yield of 0.494, significantly lower than in the case of the work of Poudel et al. (approx. 0.61 for 400 °C) [22]. This difference between the literature results and results reported by this study could probably be attributed to the differences between the samples of the sewage sludge, as that used in the work of Poudel et al. had an initial ash content of approximately 15%, which increased up to approximately 26% after torrefaction at 400 °C. In the case of torrefaction in a pilot-scale reactor, as presented in this study, slightly less than half of the energy contained in the original material remained in the product. Such a disproportion between mass and energy yields indicates a significant part of the chemical energy going into torgas, which finds confirmation in the heating value of dry torgas (15.10 MJ/m3).

This would indicate a good combustibility of the obtained torgas. In the context of the previous paper with a novel installation concept [65], such a high share of the energy going to torgas would not be disadvantageous, as the introduction of torgas into the gasifier was proposed in that particular solution. Moreover, relatively high concentrations of combustible compounds in torgas, such as methane, light hydrocarbons and carbon monoxide, seem beneficial from that point of view as well. The oxygen content detected in the torgas can be explained by the fact that it was not completely air-tight. Overall, for the pilot-scale installation, indirect methods seem better for the determination of the mass balance, such as that developed by Weber et al. [67]. The evidence could be found in respective d50 diameters and particle size distributions of both feedstock and product; i.e., the d50 was higher for the torrefied material, whereas the content of fine particles was higher for the raw sewage sludge. Common sense would dictate that in such a reactor, a part of the material will be always broken down into smaller particles, due to the mechanical attrition caused by the scrapers. The most plausible explanation of the obtained results seems to be the loss of fine particles within the cavities of the reactor. This would introduce an additional bias if a direct method was to be used for the purpose of ensuring the mass balance of an experiment in such a reactor.

Gasification testing, performed using raw sewage sludge, confirmed the results presented in other literature sources, in terms of a very high hydrogen content which can be achieved during the steam gasification of sewage sludge. In general, the performed tests confirmed the hypothesis that the torrefaction of the sewage sludge was beneficial with respect to its subsequent gasification. Producer gas from the gasification of torrefied sewage sludge was more calorific, with an average LVH of 17.15 MJ/m3 in comparison to the average LHV of 13.51 MJ/m3 for the gas produced using raw sewage sludge. This was, most likely, caused by significantly higher concentration of methane and other light hydrocarbons (CnHm) as well as a slightly higher concentration of carbon monoxide (Figure 6), for the case of the gasification of torrefied material. The hydrogen concentration was lower during the test with torrefied sewage sludge. It seems plausible to attribute this difference to the higher extent of the gas–char reactions. The torrefied sewage sludge had already been partially devolatilized, prior to the gasification. It is typical for the torrefaction process to increase the reactivity of the material by influencing its surface, and such results have already been reported for other types of biomass [71]. The influence of the torrefaction on the surface of the torrefied sewage sludge and its reactivity should be a subject of further investigation. The differences in the obtained average gas compositions between both experiments might also be attributed to some extent to the autocatalytic effects due to the fact that the ash content of the torrefied sewage sludge was significantly higher, in comparison to the raw sewage sludge (see Table 1).

The composition of the producer gas obtained during the gasification of torrefied sewage sludge can be considered slightly advantageous if the producer gas is supposed to be used in an engine, as hydrogen typically causes knocking issues.

The results presented in this paper indicate a positive influence of torrefaction with respect to the subsequent gasification of sewage sludge, especially in the context of the composition of tars. Tar deposition profiles (Figure 7) based on the quantitative analysis of tars for both samples demonstrate clearly that the torrefaction of the sewage sludge resulted in a decreased content of heavy tars, with their respective melting points between 40 °C and 95 °C, in the gas. The use of the producer gas in the engine requires its cooling to approximately 30 °C prior to the intake. This typically introduces a requirement to install a gas cooler. The aforementioned tars exist either as solids or as highly viscous liquids within the range of the temperatures mentioned above. In the longer term, this could lead to the deposition of heavy tars, leading to maintenance problems and frequent shutdowns, caused by the blockages due to the buildup of the clogs of tars and particulates sticking to the cool surfaces. Indeed, torrefaction clearly caused concentrations of naphthalene and acenaphthylene to be lower in comparison to the gas produced using raw sewage sludge. It is possible that the slightly lower moisture content of the torrefied sludge likely caused different temperature gradients across the bed of material, probably resulting in higher temperatures on average.

Overall, the decrease in the concentration of the condensable compounds was not tremendous and decreased by 7.4% as the total tar content decreased from 7.99 g/m3 to 7.40 g/m3. However, this could be attributed mostly to a substantial increase in the content of toluene, which increased from 2.23 g/m3 to 3.21 g/m3. The melting point of toluene is −95 °C and its viscosity in ambient conditions is not much different to water. The decrease in the concentration of the compounds with melting points higher than 40 °C was substantial (39.5%). The content of selected tar species deemed to be the most problematic decreased from 2.35 g/m3 to 1.42 g/m3, which is still substantial. Nonetheless, it should not be overlooked that the temperature of the gasification process was relatively low (675 °C). Moreover, it seems reasonable to expect that such a decrease would help in terms of a subsequent cleaning of the gas. The authors believe that the optimization of both steps (torrefaction and gasification) could lead to a further decrease of the tar content. The idea of gasification on the traveling grate needs further refinement, as the study showed practical difficultie, that could occur in terms of the ability of the gasifier to achieve higher temperatures, as the gasifier was allothermal and used electric heating. Some other types of heat source would be needed for the gasifier with steam as the only gasification agent, as there is no chance for this solution to maintain the autothermal character of the process. Plasma gasification, with steam as the gasification agent, should be taken into consideration. On a larger scale, this would, however, require a source of plasma which would be easy to maintain.

6. Conclusions

A suite of performed experiments demonstrated clearly the potential of torrefaction as a viable primary method for decreasing the tar content of the producer gas. Torrefaction led to the improvement of the calorific value of the producer gas and its quality. The severity of the torrefaction was high, which resulted in a good quality of the torgas and a relatively high amount of the chemical energy going to torgas. Even though it could potentially lead to the thermal runaway of the installation, this solution seems to be beneficial, as torgas could potentially be mixed with the producer gas in the gasifier. More research is needed in two main research areas:

- Since the test was performed in an allothermal gasifier, investigation is needed to confirm if the gasification process can be authothermal;

- Tests performed on a pilot-scale gasifier should be performed in order to confirm if such an improvement in tar composition is indeed sufficient to significantly improve the maintenance of such a gasifier and decrease the frequency of the shutdowns.

Further optimization of both the torrefaction and gasification of sewage sludge is needed to reap all the benefits of the combination of these two technologies. More studies are needed on both the gasification and torrefaction of the sewage sludge, using many samples of different origins, as the differences between the treatment facilities could lead to significant differences in terms of the obtained results. Moreover, it would be interesting to perform some more detailed studies on the influence of the composition of the inorganic fraction of the sewage sludge on the torrefaction and gasification processes. In light of the performed experiments, the feasibility of the concept of the gasification on traveling grates still cannot be fully confirmed. Further refinement of the concept is needed.

Author Contributions

H.P.-K., W.J.T., J.G.-T., conceived the concept of the installation as well as the concept of the paper. They analyzed the results obtained from the measurements and took part in writing the paper. Moreover, H.P.-K. played an advisory role, checked and approved the study in its present form. M.W. designed the sampling system for the measurement of the concentration of tars in the producer gas and performed GC-MS analysis. L.N. has written a significant part of the paper, made the tar deposition profile diagram and took part in the making of the sampling diagram for gasification tests. K.K. designed the sampling system for the measuring of gaseous compounds of torgas and producer gas, and performed the ultimate analysis of both materials. M.K. performed gasification experiments, took part in torrefaction experiments and performed proximate analysis. J.Z., M.C., M.O. and M.B. took part in the torrefaction tests, the making of the diagram of the pilot scale installation and the analysis of the results. Moreover, M.C. prepared the overview of the utilization of sewage sludge in Poland.

Funding

This work was supported by Regional Operational Program for the Opole Voivodship 2014–2020, Priority Axis 01 Innovation in the Economy, Measure 1.1 Innovation in the Economy. Key Project No. RPOP.01.01.00-16-44/2016.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Werle, S.; Dudziak, M. Analysis of organic and inorganic contaminants in dried sewage sludge and by-products of dried sewage sludge gasification. Energies 2014, 7, 462–476. [Google Scholar] [CrossRef]

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage sludge disposal strategies for sustainable development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef]

- Lee, L.H.; Wu, T.Y.; Shak, K.P.Y.; Lim, S.L.; Ng, K.Y.; Nguyen, M.N.; Teoh, W.H. Sustainable approach to biotransform industrial sludge into organic fertilizer via vermicomposting: A mini-review. J. Chem. Technol. Biotechnol. 2018, 93, 925–935. [Google Scholar] [CrossRef]

- Cieślik, B.M.; Namieśnik, J.; Konieczka, P. Review of sewage sludge management: Standards, regulations and analytical methods. J. Clean. Prod. 2015, 90, 1–15. [Google Scholar] [CrossRef]

- Andersen, A. Disposal and Recycling Routes for Sewage Sludge Part 4: Economic Report; Office for Official Publications of the European Communities: Luxembourg, 2002. [Google Scholar]

- Werle, S.; Wilk, R.K. A review of methods for the thermal utilization of sewage sludge: The Polish perspective. Renew. Energy 2010, 35, 1914–1919. [Google Scholar] [CrossRef]

- GUS, Departament Badań Regionalnych i Środowiska. Ochrona Środowiska 2017; GUS: Warszawa, Poland, 2017; p. 551. [Google Scholar]

- Werle, S. Sewage Sludge-to-Energy Management in Eastern Europe: A Polish Perspective. Ecol. Chem. Eng. S 2015, 22, 459–469. [Google Scholar] [CrossRef]

- Pajak, T. Thermal Treatment as sustainable sewage sludge management. Environ. Prot. Eng. 2013, 39, 41–53. [Google Scholar] [CrossRef]

- Bień, J. Zagospodarowanie komunalnych osadów ściekowych metodami termicznymi. Inż. Ochr. Śr. 2012, 15, 439–450. [Google Scholar]

- Bień, J.; Bień, B. Utilisation of Municipal Sewage Sludge by Thermal Methods in the Face of Storage Disallowing. Inż. Ekol. 2015, 45, 36–43. [Google Scholar] [CrossRef]

- Jurczyk, M.P.; Pająk, T. Initial Operating Experience with the New Polish Waste-to-Energy Plants. In Waste Management; Thomé-Kozmiensky, K.J., Thiel, S., Eds.; TK Verlag: Neuruppin, Germany, 2016. [Google Scholar]

- Cyranka, M.; Jurczyk, M.; Pająk, T. Municipal Waste-to-Energy plants in Poland—Current projects. E3S Web Conf. 2016, 10, 00070. [Google Scholar] [CrossRef]

- Gorazda, K.; Tarko, B.; Wzorek, Z.; Kominko, H.; Nowak, A.K.; Kulczycka, J.; Henclik, A.; Smol, M. Fertilisers production from ashes after sewage sludge combustion—A strategy towards sustainable development. Environ. Res. 2017, 154, 171–180. [Google Scholar] [CrossRef] [PubMed]

- Moscicki, K.J.; Niedzwiecki, L.; Owczarek, P.; Wnukowski, M. Commoditization of biomass: Dry torrefaction and pelletization-a review. J. Power Technol. 2014, 94, 233–249. [Google Scholar]

- Van der Stelt, M.J.C.; Gerhauser, H.; Kiel, J.H.A.; Ptasinski, K.J. Biomass upgrading by torrefaction for the production of biofuels: A review. Biomass Bioenergy 2011, 35, 3748–3762. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Sokhansanj, S.; Hess, J.R.; Wright, C.T.; Boardman, R.D. A review on biomass torrefcation process and product properties for energy applications. Ind. Biotechnol. 2011, 7, 384–401. [Google Scholar] [CrossRef]

- Nyakuma, B.B.; Magdziarz, A.; Werle, S. Physicochemical, Thermal and Kinetic Analysis of Sewage Sludge. Proc. ECOpole 2016, 10, 473–480. [Google Scholar] [CrossRef]

- Magdziarz, A.; Wilk, M.; Kosturkiewicz, B. Investigation of sewage sludge preparation for combustion process. Chem. Process Eng. Inz. Chem. Proces. 2011, 32, 299–309. [Google Scholar] [CrossRef]

- Magdziarz, A.; Werle, S. Analysis of the combustion and pyrolysis of dried sewage sludge by TGA and MS. Waste Manag. 2014, 34, 174–179. [Google Scholar] [CrossRef]

- Pulka, J.; Wiśniewski, D.; Gołaszewski, J.; Białowiec, A. Is the biochar produced from sewage sludge a good quality solid fuel? Arch. Environ. Prot. 2016, 42, 125–134. [Google Scholar] [CrossRef]

- Poudel, J.; Ohm, T.I.; Lee, S.H.; Oh, S.C. A study on torrefaction of sewage sludge to enhance solid fuel qualities. Waste Manag. 2015, 40, 112–118. [Google Scholar] [CrossRef]

- Poudel, J.; Karki, S.; Gu, J.H.; Lim, Y.; Oh, S.C. Effect of Co-Torrefaction on the Properties of Sewage Sludge and Waste Wood to Enhance Solid Fuel Qualities. J. Residuals Sci. Technol. 2017, 14, 23–36. [Google Scholar] [CrossRef]

- Atienza-Martínez, M.; Fonts, I.; ábrego, J.; Ceamanos, J.; Gea, G. Sewage sludge torrefaction in a fluidized bed reactor. Chem. Eng. J. 2013, 222, 534–545. [Google Scholar] [CrossRef]

- Atienza-Martínez, M.; Mastral, J.F.; Ábrego, J.; Ceamanos, J.; Gea, G. Sewage sludge torrefaction in an auger reactor. Energy Fuels 2015, 29, 160–170. [Google Scholar] [CrossRef]

- Huang, M.; Chang, C.C.; Yuan, M.H.; Chang, C.Y.; Wu, C.H.; Shie, J.L.; Chen, Y.H.; Chen, Y.H.; Ho, C.; Chang, W.R.; et al. Production of torrefied solid bio-fuel from pulp industry waste. Energies 2017, 10, 910. [Google Scholar] [CrossRef]

- Huang, Y.-F.; Sung, H.-T.; Chiueh, P.-T.; Lo, S.-L. Microwave torrefaction of sewage sludge and leucaena. J. Taiwan Inst. Chem. Eng. 2017, 70, 236–243. [Google Scholar] [CrossRef]

- Huang, Y.-F.; Sung, H.-T.; Chiueh, P.-T.; Lo, S.-L. Co-torrefaction of sewage sludge and leucaena by using microwave heating. Energy 2016, 116, 1–7. [Google Scholar] [CrossRef]

- Huang, Y.W.; Chen, M.Q.; Luo, H.F. Nonisothermal torrefaction kinetics of sewage sludge using the simplified distributed activation energy model. Chem. Eng. J. 2016, 298, 154–161. [Google Scholar] [CrossRef]

- Do, T.X.; Lim, Y.; Cho, H.; Shim, J.; Yoo, J.; Rho, K.; Choi, S.-G.; Park, B.-Y. Process modeling and energy consumption of fry-drying and torrefaction of organic solid waste. Dry Technol. 2017, 35, 754–765. [Google Scholar] [CrossRef]

- Pawlak-Kruczek, H.; Krochmalny, K.K.; Wnukowski, M.; Niedzwiecki, L. Slow pyrolysis of the sewage sludge with additives: Calcium oxide and lignite. J. Energy Resour. Technol. 2018, 140. [Google Scholar] [CrossRef]

- Pečkytė, J.; Baltrėnaitė, E. Assessment of heavy metals leaching from (bio) char obtained from industrial sewage sludge. Environ. Prot. Eng. 2015, 7, 399–406. [Google Scholar] [CrossRef]

- Council Decision. Council of the European Union 2003/33/EC—Council Decision establishing criteria and procedures for the acceptance of waste at landfills pursuant to Article 16 of and Annex II to Directive 1999/31/EC. Off. J. Eur. Communities 2003, L 11/27, 27–49. [Google Scholar]

- Wang, N.Y.; Shih, C.H.; Chiueh, P.T.; Huang, Y.F. Environmental effects of sewage sludge carbonization and other treatment alternatives. Energies 2013, 6, 871–883. [Google Scholar] [CrossRef]

- Lasek, J.A.; Kopczyński, M.; Janusz, M.; Iluk, A.; Zuwała, J. Combustion properties of torrefied biomass obtained from flue gas-enhanced reactor. Energy 2017, 119, 362–368. [Google Scholar] [CrossRef]

- Joshi, Y.; Di Marcello, M.; Krishnamurthy, E.; De Jong, W. Packed-Bed Torrefaction of Bagasse under Inert and Oxygenated Atmospheres. Energy Fuels 2015, 29, 5078–5087. [Google Scholar] [CrossRef]

- Uemura, Y.; Saadon, S.; Osman, N.; Mansor, N.; Tanoue, K.I. Torrefaction of oil palm kernel shell in the presence of oxygen and carbon dioxide. Fuel 2015, 144, 171–179. [Google Scholar] [CrossRef]

- Uemura, Y.; Omar, W.; Othman, N.A.; Yusup, S.; Tsutsui, T. Torrefaction of oil palm EFB in the presence of oxygen. Fuel 2013, 103, 156–160. [Google Scholar] [CrossRef]

- Chen, W.H.; Zhuang, Y.Q.; Liu, S.H.; Juang, T.T.; Tsai, C.M. Product characteristics from the torrefaction of oil palm fiber pellets in inert and oxidative atmospheres. Bioresour. Technol. 2016, 199, 367–374. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.H.; Lu, K.M.; Liu, S.H.; Tsai, C.M.; Lee, W.J.; Lin, T.C. Biomass torrefaction characteristics in inert and oxidative atmospheres at various superficial velocities. Bioresour. Technol. 2013, 146, 152–160. [Google Scholar] [CrossRef]

- Lu, K.M.; Lee, W.J.; Chen, W.H.; Liu, S.H.; Lin, T.C. Torrefaction and low temperature carbonization of oil palm fiber and eucalyptus in nitrogen and air atmospheres. Bioresour. Technol. 2012, 123, 98–105. [Google Scholar] [CrossRef]

- Pawlak-Kruczek, H.; Wnukowski, M.; Krochmalny, K.; Kowal, M.; Baranowski, M.; Zgóra, J.; Czerep, M.; Ostrycharczyk, M.; Niedzwiecki, L. The staged thermal conversion of sewage sludge in presence of oxygen. In The Clearwater Clean Coal Conference: Proceedings of the 43rd International Technical Conference on Clean Energy; Sakkestad, B.A., Ed.; Published by Coal Technologies Associates Post Office Box 1130 Louisa, VA 23093 USA: Clearwater, FL, USA, 2018. [Google Scholar]

- Reed, T.B.; Das, A. Handbook of Biomass Downdraft Gasifier Engine Systems; Biomass Energy Foundation: Golden, CO, USA, 1988. [Google Scholar]

- Devi, L.; Ptasinski, K.J.; Janssen, F.J.J.G. A review of the primary measures for tar elimination in biomass gasification processes. Biomass Bioenergy 2002, 24, 125–140. [Google Scholar] [CrossRef]

- Royal Society of Chemistry ChemSpider | Search and Share Chemistry. Available online: http://www.chemspider.com/ (accessed on 23 November 2018).

- Asadullah, M. Biomass gasification gas cleaning for downstream applications: A comparative critical review. Renew. Sustain. Energy Rev. 2014, 40, 118–132. [Google Scholar] [CrossRef]

- Hasler, P.; Nussbaumer, T. Gas cleaning for IC engine applications from fixed bed biomass gasification. Biomass Bioenergy 1999, 16, 385–395. [Google Scholar] [CrossRef]

- Striūgas, N.; Valinčius, V.; Pedišius, N.; Poškas, R.; Zakarauskas, K. Investigation of sewage sludge treatment using air plasma assisted gasification. Waste Manag. 2017. [Google Scholar] [CrossRef] [PubMed]

- Brown, M.D.; Baker, E.G.; Mudge, L.K. Environmental design considerations for thermochemical biomass energy. Biomass 1986, 11, 255–270. [Google Scholar] [CrossRef]

- Bui, T.; Loof, R.; Bhattacharya, S.C. Multi-stage reactor for thermal gasification of wood. Energy 1994, 19, 397–404. [Google Scholar] [CrossRef]

- Werle, S. Sewage sludge gasification: Theoretical and experimental investigation. Environ. Prot. Eng. 2013, 39, 25–32. [Google Scholar] [CrossRef]

- Schweitzer, D.; Gredinger, A.; Schmid, M.; Waizmann, G.; Beirow, M.; Spörl, R.; Scheffknecht, G. Steam gasification of wood pellets, sewage sludge and manure: Gasification performance and concentration of impurities. Biomass Bioenergy 2018, 111, 308–319. [Google Scholar] [CrossRef]

- Werle, S. Numerical analysis of the combustible properties of sewage sludge gasification gas. Chem. Eng. Trans. 2015, 1021–1026. [Google Scholar] [CrossRef]

- Werle, S.; Dudziak, M. Evaluation of the possibility of the sewage sludge gasification gas use as a fuel. Ecol. Chem. Eng. S 2016, 23, 229–236. [Google Scholar] [CrossRef]

- Szwaja, S.; Kovacs, V.B.; Bereczky, A.; Penninger, A. Sewage sludge producer gas enriched with methane as a fuel to a spark ignited engine. Fuel Process. Technol. 2013, 110, 160–166. [Google Scholar] [CrossRef]

- Werle, S. Impact of feedstock properties and operating conditions on sewage sludge gasification in a fixed bed gasifier. Waste Manag. Res. 2014, 32, 954–960. [Google Scholar] [CrossRef]

- Calvo, L.F.; García, A.I.; Otero, M. An experimental investigation of sewage sludge gasification in a fluidised bed reactor. Sci. World J. 2013. [Google Scholar] [CrossRef] [PubMed]

- Akkache, S.; Hernández, A.B.; Teixeira, G.; Gelix, F.; Roche, N.; Ferrasse, J.H. Co-gasification of wastewater sludge and different feedstock: Feasibility study. Biomass Bioenergy 2016, 89, 201–209. [Google Scholar] [CrossRef]

- Reed, G.P.; Paterson, N.P.; Zhuo, Y.; Dugwell, D.R.; Kandiyoti, R. Trace element distribution in sewage sludge gasification: Source and temperature effects. Energy Fuels 2005, 19, 298–304. [Google Scholar] [CrossRef]

- Judex, J.W.; Gaiffi, M.; Burgbacher, H.C. Gasification of dried sewage sludge: Status of the demonstration and the pilot plant. Waste Manag. 2012, 32, 719–723. [Google Scholar] [CrossRef] [PubMed]

- Kokalj, F.; Arbiter, B.; Samec, N. Sewage sludge gasification as an alternative energy storage model. Energy Convers. Manag. 2017, 149, 738–747. [Google Scholar] [CrossRef]

- Huang, Y.W.; Chen, M.Q.; Li, Q.H.; Xing, W. Hydrogen-rich syngas produced from co-gasification of wet sewage sludge and torrefied biomass in self-generated steam agent. Energy 2018, 161, 202–213. [Google Scholar] [CrossRef]

- Prins, M.J.; Ptasinski, K.J.; Janssen, F.J.J.G. More efficient biomass gasification via torrefaction. Energy 2006, 31, 3458–3470. [Google Scholar] [CrossRef]

- Dudyński, M.; Van Dyk, J.C.; Kwiatkowski, K.; Sosnowska, M. Biomass gasification: Influence of torrefaction on syngas production and tar formation. Fuel Process. Technol. 2015, 131, 203–212. [Google Scholar] [CrossRef]

- Tic, W.; Guziałowska-Tic, J.; Pawlak-Kruczek, H.; Woźnikowski, E.; Zadorożny, A.; Niedźwiecki, Ł.; Wnukowski, M.; Krochmalny, K.; Czerep, M.; Ostrycharczyk, M.; et al. Novel Concept of an Installation for Sustainable Thermal Utilization of Sewage Sludge. Energies 2018, 11, 748. [Google Scholar] [CrossRef]

- Pawlak-Kruczek, H.; Krochmalny, K.; Mościcki, K.; Zgóra, J.; Czerep, M.; Ostrycharczyk, M.; Niedźwiecki, Ł. Torrefaction of Various Types of Biomass in Laboratory Scale, Batch-Wise Isothermal Rotary Reactor and Pilot Scale, Continuous Multi-Stage Tape Reactor. Eng. Prot. Environ. 2017, 20, 457–472. [Google Scholar] [CrossRef]

- Weber, K.; Heuer, S.; Quicker, P.; Li, T.; Løvås, T.; Scherer, V. An Alternative Approach for the Estimation of Biochar Yields. Energy Fuels 2018. [Google Scholar] [CrossRef]

- Nhuchhen, D.; Basu, P.; Acharya, B. A Comprehensive Review on Biomass Torrefaction. Int. J. Renew. Energy Biofuels 2014, 2014, 506376. [Google Scholar] [CrossRef]

- Esseyin, A.E.; Steele, P.H.; Pittman, C.U., Jr. Current trends in the production and applications Torrefied Wood/Biomass—A review. Bioresources 2015, 10, 8812–8858. [Google Scholar] [CrossRef]

- Chew, J.J.; Doshi, V. Recent advances in biomass pretreatment—Torrefaction fundamentals and technology. Renew. Sustain. Energy Rev. 2011, 15, 4212–4222. [Google Scholar] [CrossRef]

- Saeed, M.A.; Andrews, G.E.; Phylaktou, H.N.; Gibbs, B.M.; Niedzwiecki, L.; Walton, R. Explosion and Flame Propagation Properties of Coarse Wood: Raw and Torrefied. In Proceedings of the Eighth International Seminar on Fire & Explosion Hazards (ISFEH8); Choa, J., Molkov, V., Sunderland, P., Tamanini, F., Torero, J., Eds.; USTC Press: Hefei, China, 2016; pp. 579–588. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).