Multifractal Characteristics and Classification of Tight Sandstone Reservoirs: A Case Study from the Triassic Yanchang Formation, Ordos Basin, China

Abstract

1. Introduction

2. Methodology

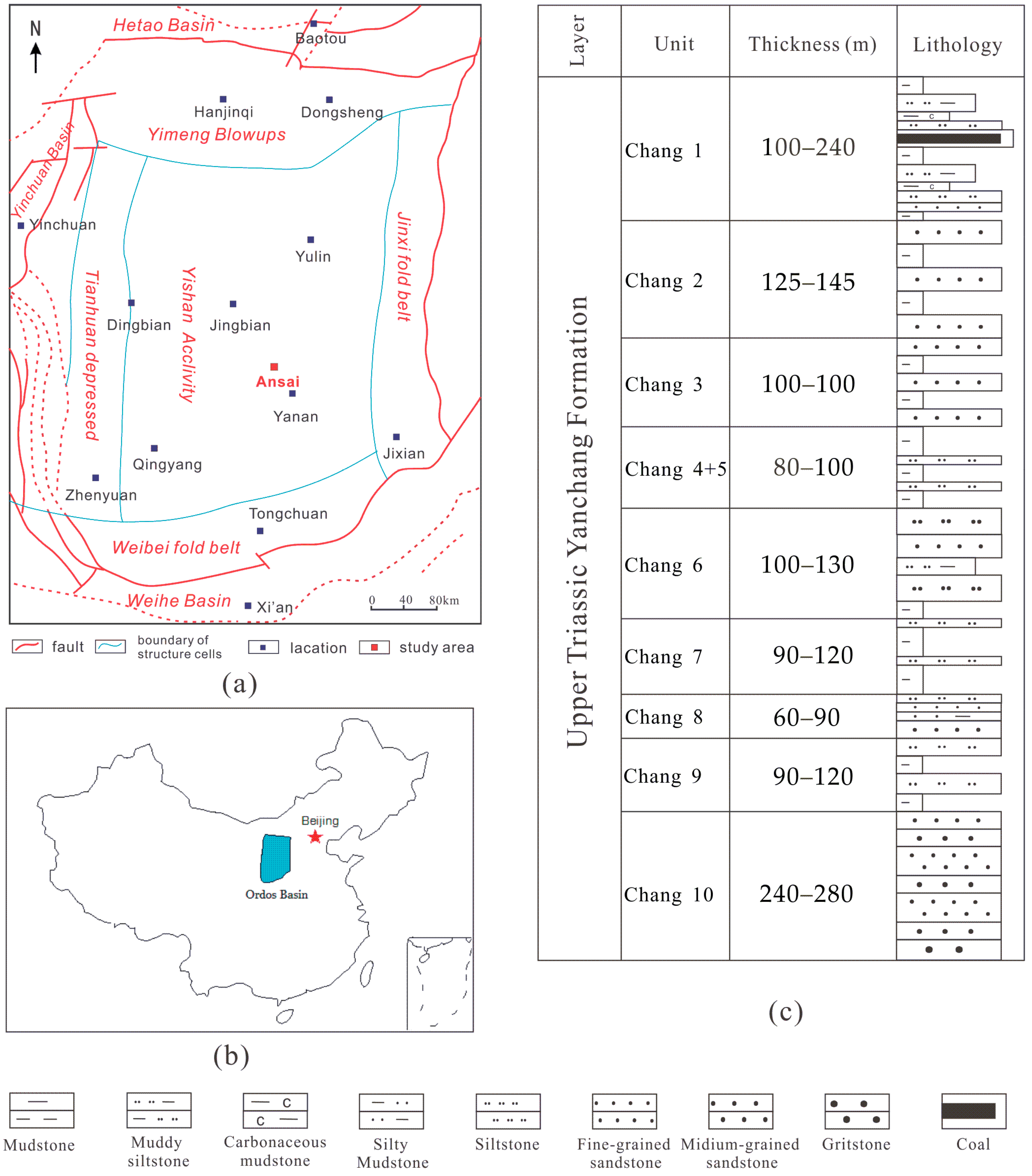

2.1. Geological Setting

2.2. Experiments

2.3. Multifractal Analysis Theory

2.4. Mercury Injection Capillary Pressure (MICP) Theory

3. Results and Discussion

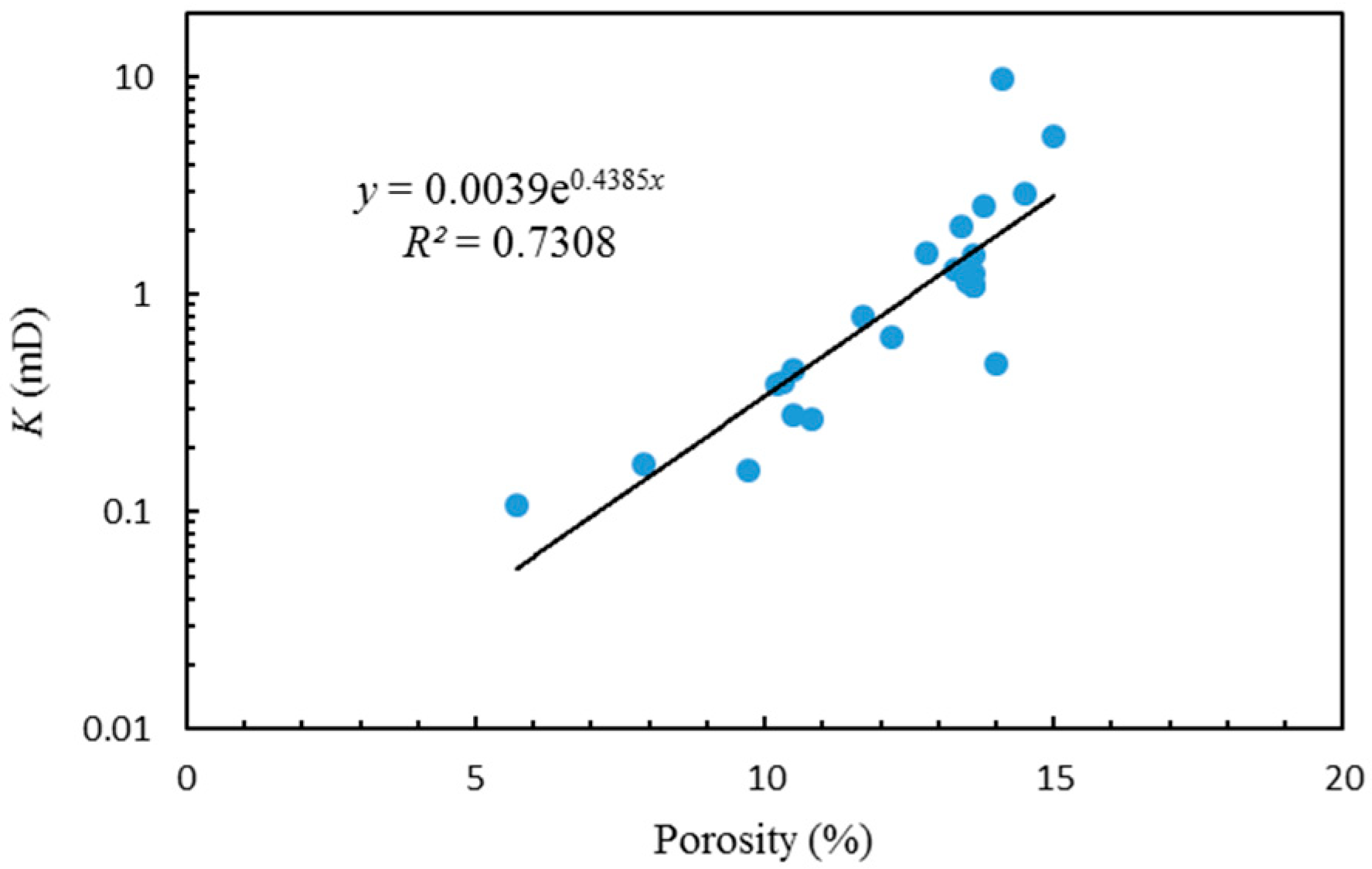

3.1. Porosity, Permeability and MICP Data

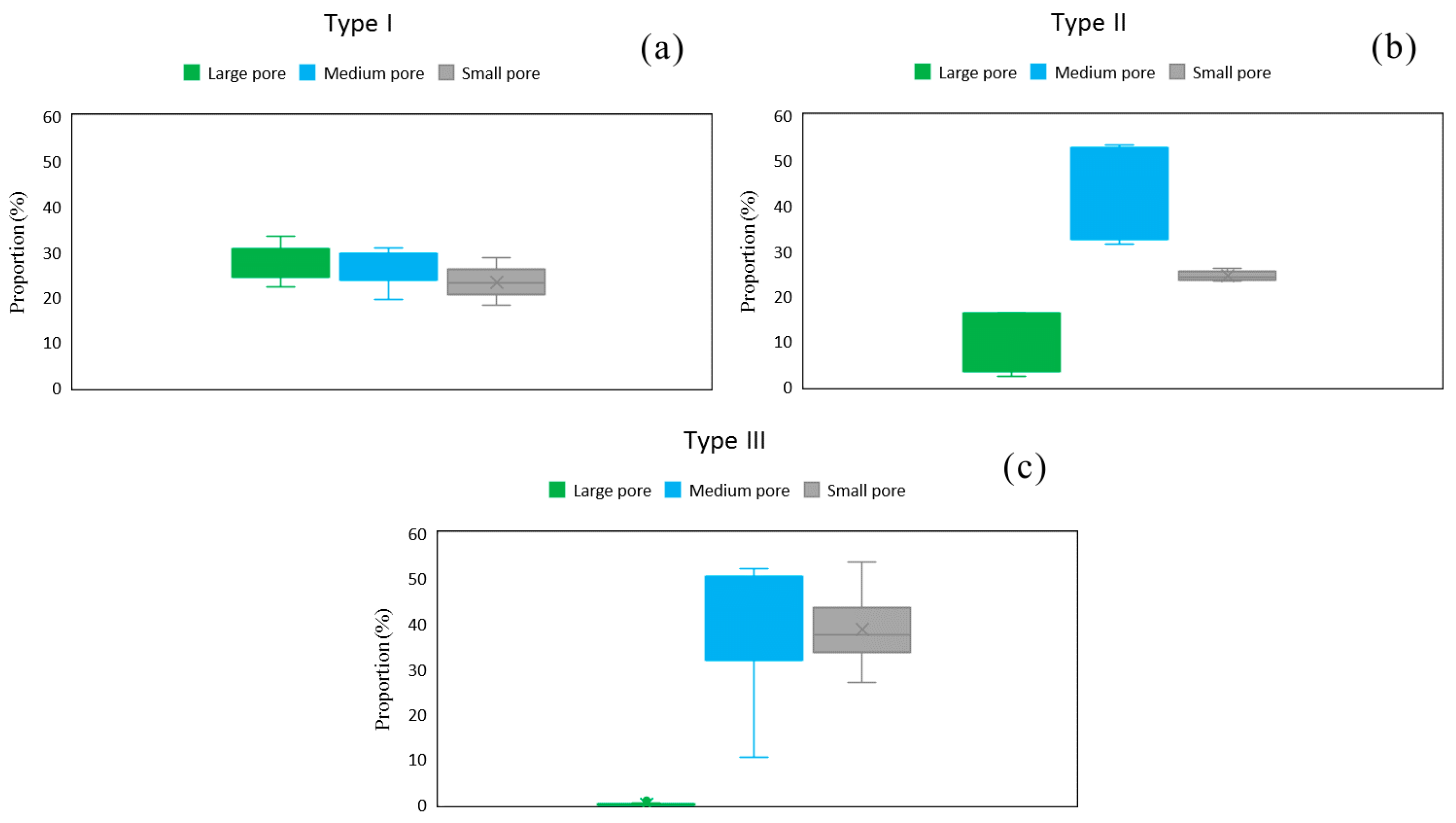

3.2. Classification of the Pore Structure

3.3. Pore Characteristics of Reservoirs with Different Pore Structure Types

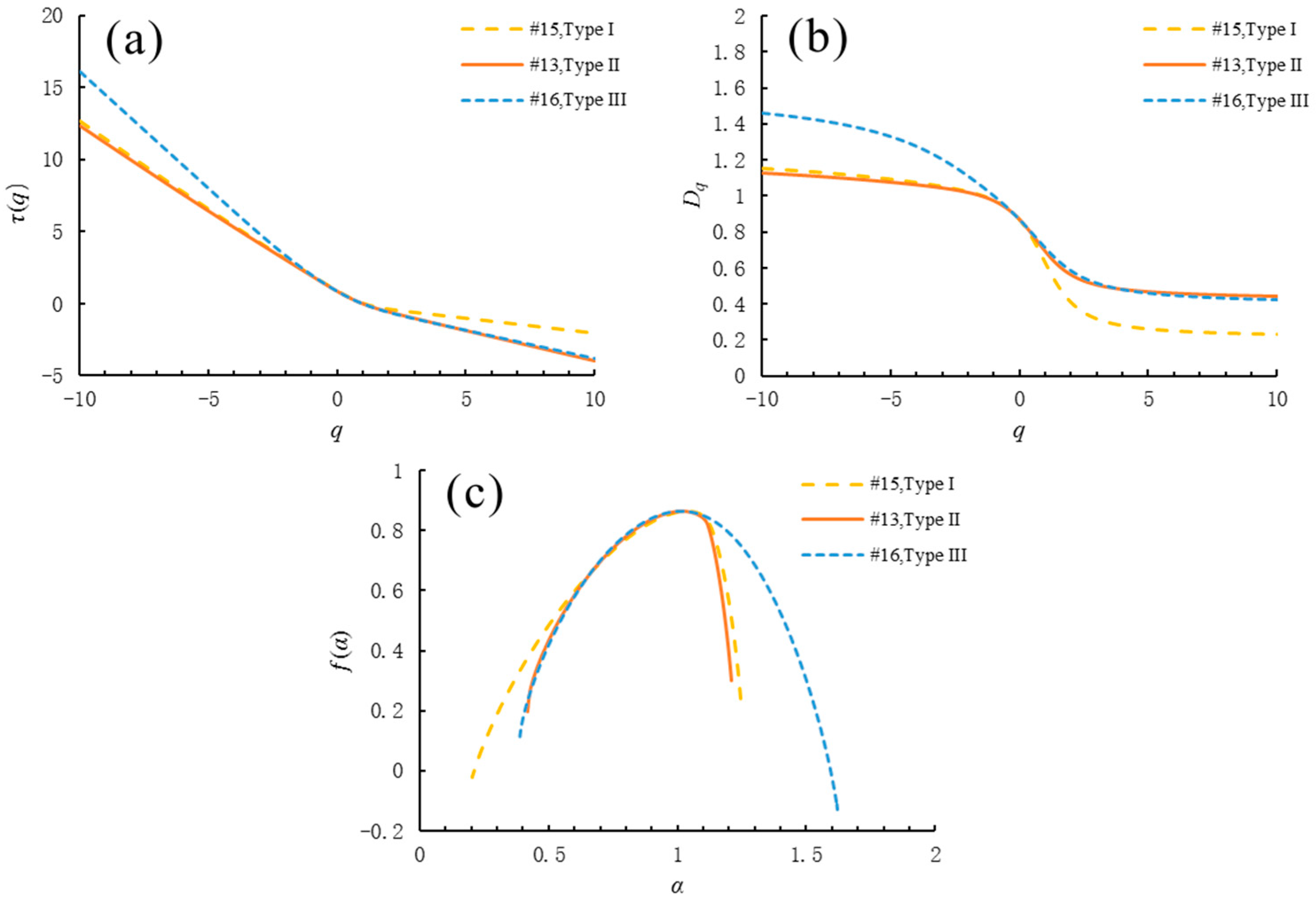

3.4. Multifractal Spectrum Parameters

3.5. Multifractal Characteristics of Pore Structure in Tight Sandstones

3.6. The Relationship between Multifractal Parameters and the Porosity and Permeability

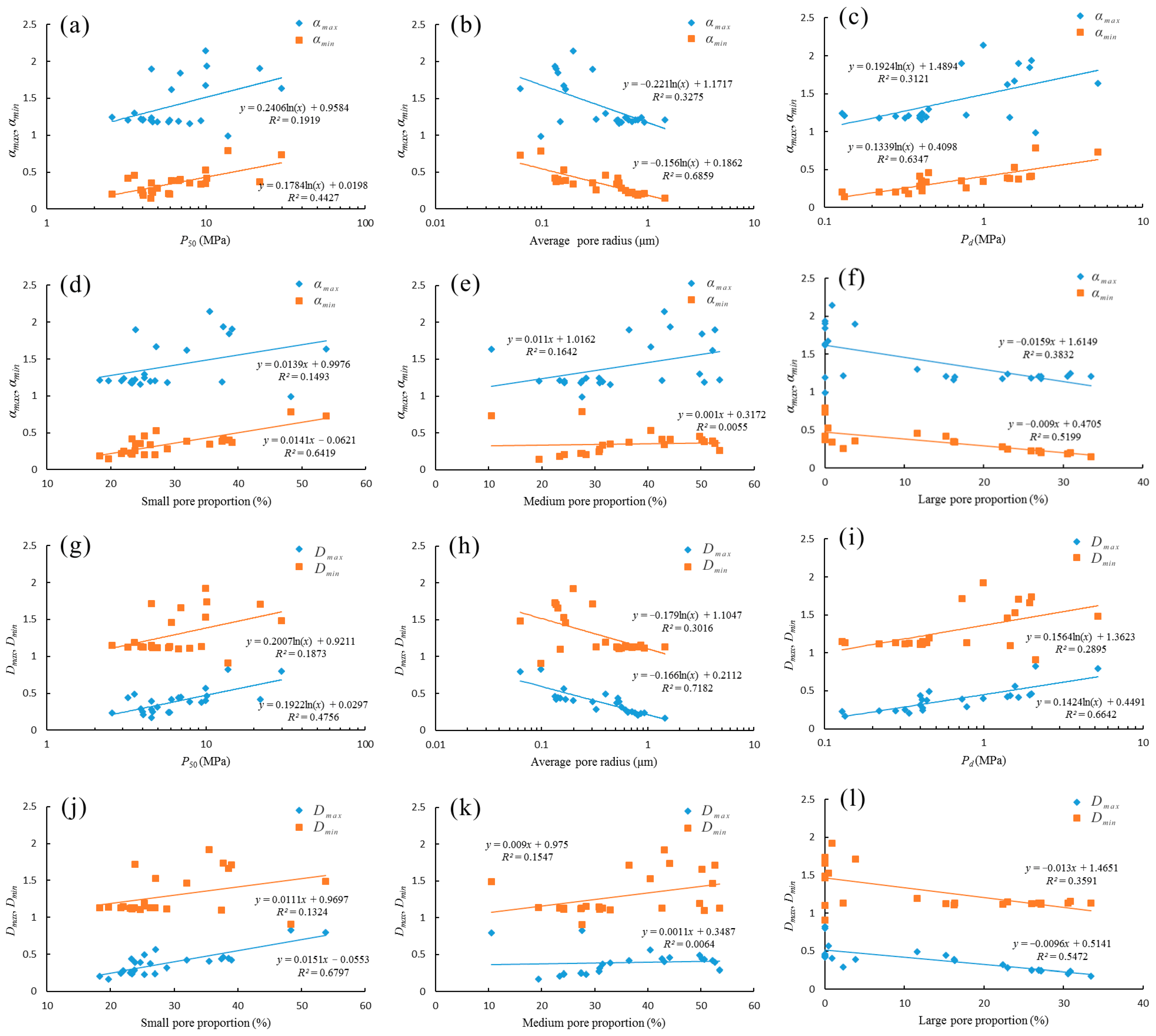

3.7. The Relationship between Multifractal Parameters and Pore Structure Parameters

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Guo, C.; Xu, J.; Wei, M.; Jiang, R. Experimental study and numerical simulation of hydraulic fracturing tight sandstone reservoirs. Fuel 2015, 159, 334–344. [Google Scholar] [CrossRef]

- Zeng, F.; Guo, J.; Liu, H.; Yin, J. Optimization design and application of horizonal well-staged fracturing in tight gas reservoirs. Acta Pet. Sin. 2013, 34, 959–968. [Google Scholar]

- Sakhaee-Pour, A.; Bryant, S.L. Effect of pore structure on the producibility of tight-gas sandstones. AAPG Bull. 2014, 98, 663–694. [Google Scholar] [CrossRef]

- Zhao, P.; Wang, Z.; Sun, Z.; Cai, J.; Wang, L. Investigation on the pore structure and multifractal characteristics of tight oil reservoirs using NMR measurements: Permian Lucaogou Formation in Jimusaer Sag, Junggar Basin. Mar. Pet. Geol. 2017, 86, 1067–1081. [Google Scholar] [CrossRef]

- Cai, J.; Wei, W.; Hu, X.; Wood, D.A. Electrical conductivity models in saturated porous media: A review. Earth-Sci. Rev. 2017, 171, 419–433. [Google Scholar] [CrossRef]

- Anovitz, L.M.; Cole, D.R. Characterization and analysis of porosity and pore structures. Rev. Mineral. Geochem. 2015, 80, 61–164. [Google Scholar] [CrossRef]

- Higgs, K.E.; Zwingmann, H.; Reyes, A.G.; Funnell, R.H. Diagenesis, porosity evolution, and petroleum emplacement in tight gas reservoirs, Taranaki basin, New Zealand. J. Sediment. Res. 2007, 77, 1003–1025. [Google Scholar] [CrossRef]

- Hu, Q.; Ewing, R.P.; Dultz, S. Low pore connectivity in natural rock. J. Contam. Hydrol. 2012, 133, 76–83. [Google Scholar] [CrossRef] [PubMed]

- Hansen, J.P.; Skjeltorp, A.T. Fractal pore space and rock permeability implications. Phys. Rev. B 1988, 38, 2635–2638. [Google Scholar] [CrossRef]

- Fu, J.; Yu, J.; Xu, L.; Niu, X.; Feng, S.; Wang, X.; You, L.; Li, T. New progress in exploration and development of tight oil in Ordos basin and main controlling factors of large-scale enrichment and exploitable capacity. China Pet. Explor. 2015, 20, 9–19. [Google Scholar]

- Gao, H.; Li, H. Pore structure characterization, permeability evaluation and enhanced gas recovery techniques of tight gas sandstones. J. Nat. Gas Sci. Eng. 2016, 28, 536–547. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Cao, J.; Xiao, C.; Wang, S.; Pang, X.; Dai, Q.; He, Z.; Fan, X.; Yang, L.; et al. Investigation of pore structure and petrophysical property in tight sandstones. Mar. Pet. Geol. 2018, 91, 179–189. [Google Scholar] [CrossRef]

- Zou, C.; Zhu, R.; Bai, B.; Yang, Z.; Wu, S.; Li, X. First discovery of nanopore throat in oil and gas reservoir in China and its scientific value. Acta Pet. Sin. 2011, 27, 1857–1864. [Google Scholar]

- Shi, X.; Pan, J.; Hou, Q.; Jin, Y.; Wang, Z.; Niu, Q.; Li, M. Micrometer-scale fractures in coal related to coal rank based on micro-CT scanning and fractal theory. Fuel 2018, 212, 162–172. [Google Scholar] [CrossRef]

- Pan, S.; Zou, C.; Yang, Z.; Dong, D.; Wang, Y.; Wang, S.; Wu, S.; Huang, J.; Liu, Q.; Wang, D.; et al. Methods for shale gas play assessment: A comparison between Silurian Longmaxi shale and Mississippian Barnett shale. J. Earth Sci. 2015, 26, 285–294. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Fan, Z.; Chen, J.; Wang, S.; Zhou, Z.; Fan, X. Insight into the pore structure of tight sandstones using NMR and HPMI measurements. Energy Fuels 2016, 30, 10200–10214. [Google Scholar] [CrossRef]

- Ge, X.; Fan, Y.; Zhu, X.; Chen, Y.; Li, R. Determination of nuclear magnetic resonance T2 cutoff value based on multifractal theory—An application in sandstone with complex pore structure. Geophysics 2014, 80, D11–D21. [Google Scholar] [CrossRef]

- Cao, Z.; Liu, G.; Zhan, H.; Li, C.; You, Y.; Yang, C.; Jiang, H. Pore structure characterization of Chang-7 tight sandstone using MICP combined with N2GA techniques and its geological control factors. Sci. Rep. 2016, 6, 36919. [Google Scholar] [CrossRef] [PubMed]

- Shao, X.; Pang, X.; Li, H.; Zhang, X. Fractal analysis of pore network in tight gas sandstones using NMR method: A case study from the Ordos basin, China. Energy Fuels 2017, 31, 10358–10368. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Fan, Z.; Zhou, Z.; Chen, J.; Wang, S. Fractal analysis of tight shaly sandstones using nuclear magnetic resonance measurements. AAPG Bull. 2018, 102, 175–193. [Google Scholar] [CrossRef]

- Mao, Z.; Zhang, C.; Xiao, L. A NMR-based porosity calculation method for low porosity and low permeability gas reservoir. Oil Geophys. Prospect. 2010, 45, 105–109. [Google Scholar]

- Xiao, L.; Mao, Z.; Wang, Z.; Jin, Y. Application of NMR logs in tight gas reservoirs for formation evaluation: A case study of Sichuan basin in China. J. Petrol. Sci. Eng. 2012, 81, 182–195. [Google Scholar] [CrossRef]

- Feng, C.; Shi, Y.; Hao, J.; Wang, Z.; Mao, Z.; Li, G.; Jiang, Z. Nuclear magnetic resonance features of low-permeability reservoirs with complex wettability. Pet. Explor. Dev. 2017, 44, 274–279. [Google Scholar] [CrossRef]

- Xiao, L.; Liu, D.; Wang, H.; Li, J.; Lu, J.; Zou, C. The applicability analysis of models for permeability prediction using mercury injection capillary pressure (MICP) data. J. Petrol. Sci. Eng. 2017, 156, 589–593. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Y.; Tang, H.; Wang, F.; Chen, L. Application of capillary pressure curves and fractal theory to reservoir classification. Lithol. Reserv. 2014, 26, 89–92. [Google Scholar]

- Feng, C.; Shi, Y.; Li, J.; Chang, L.; Li, G.; Mao, Z. A new empirical method for constructing capillary pressure curves from conventional logs in low-permeability sandstones. J. Earth Sci. 2017, 28, 516–522. [Google Scholar] [CrossRef]

- Xiao, L.; Zou, C.; Mao, Z.; Jin, Y.; Zhu, J. A new technique for synthetizing capillary pressure (Pc) curves using NMR logs in tight gas sandstone reservoirs. J. Petrol. Sci. Eng. 2016, 145, 493–501. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. The Fractal Geometry of Nature; W. H. Freeman: New York, NY, USA, 1982. [Google Scholar]

- García-Gutiérrez, C.; Martínez, F.S.J.; Caniego, J. A protocol for fractal studies on porosity of porous media: High quality soil porosity images. J. Earth Sci. 2017, 28, 888–896. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Pourghasemi, H.R.; Lee, Y.H. Fractal analysis of rainfall-induced landslide and debris flow spread distribution in the Chenyulan Creek Basin, Taiwan. J. Earth Sci. 2016, 27, 151–159. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. Multifractal measures, especially for the geophysicist. Pure Appl. Geophys. 1989, 131, 5–42. [Google Scholar] [CrossRef]

- Muller, J. Characterization of the North Sea chalk by multifractal analysis. J. Geophys. Res. Solid Earth. 1994, 99, 7275–7280. [Google Scholar] [CrossRef]

- Cai, J.; Yu, B.; Zou, M.; Mei, M. Fractal analysis of surface roughness of particles in porous media. Chin. Phys. Lett. 2010, 27, 157–160. [Google Scholar]

- Zhang, X.; Wu, C.; Li, T. Comparison analysis of fractal characteristics for tight sandstones using different calculation methods. J. Geophys. Eng. 2017, 14, 120–131. [Google Scholar] [CrossRef]

- Peng, J.; Han, H.; Xia, Q.; Li, B. Evaluation of the pore structure of tight sandstone reservoirs based on multifractal analysis: A case study from the Kepingtage Formation in the Shuntuoguole uplift, Tarim Basin, NW China. J. Geophys. Eng. 2018, 15, 1122–1136. [Google Scholar] [CrossRef]

- Dai, J.; Li, J.; Luo, X.; Zhang, W.; Hu, G.; Ma, C.; Guo, J.; Ge, S. Stable carbon isotope compositions and source rock geochemistry of the giant gas accumulations in the Ordos Basin, China. Org. Geochem. 2005, 36, 1617–1635. [Google Scholar] [CrossRef]

- Shi, Y.; Liang, X.; Mao, Z.; Guo, H. An identification method for diagenetic facies with well logs and its geological significance in low-permeability sandstones: A case study on Chang 8 reservoirs in the Jiyuan Region, Ordos Basin. Acta Pet. Sin. 2011, 32, 820–828. [Google Scholar]

- Zou, C.; Zhu, R.; Wu, S.; Yang, Z.; Tao, S.; Yuan, X.; Hou, L.; Yang, H.; Xu, C.; Li, D.; et al. Types, characteristics, genesis and prospects of conventional and unconventional hydrocarbon accumulations: taking tight oil and tight gas in China as an instance. Acta Pet. Sin. 2012, 33, 173–187. [Google Scholar]

- Jia, C.; Zou, C.; Li, J.; Li, D.; Zheng, M. Assessment criteria, main types, basic features and resource prospects of the tight oil in China. Acta Pet. Sin. 2012, 33, 343–350. [Google Scholar]

- Cai, J.; Wei, W.; Hu, X.; Liu, R.; Wang, J. Fractal characterization of dynamic fracture network extension in porous media. Fractals 2017, 25, 1750023. [Google Scholar] [CrossRef]

- Dathe, A.; Tarquis, A.M.; Perrier, E. Multifractal analysis of the pore- and solid-phases in binary two-dimensional images of natural porous structures. Geoderma 2006, 134, 318–326. [Google Scholar] [CrossRef]

- Xia, Y.; Cai, J.; Wei, W.; Hu, X.; Wang, X.I.N.; Ge, X. A new method for calculating fractal dimensions of porous media based on pore size distribution. Fractals 2018, 26, 1850006. [Google Scholar] [CrossRef]

- Halsey, T.C.; Jensen, M.H.; Kadanoff, L.P.; Procaccia, I.I.; Shraiman, B.I. Fractal measures and their singularities: the characterization of strange sets. Nucl. Phys. B 1987, 2, 501–511. [Google Scholar] [CrossRef]

- Li, K.; Zeng, F.; Cai, J.; Sheng, G.; Xia, P.; Zhang, K. Fractal characteristics of pores in Taiyuan formation shale from Hedong coal field, China. Fractals 2018, 26, 1840006. [Google Scholar] [CrossRef]

- Chakraborty, B.; Haris, K.; Latha, G.; Maslov, N.; Menezes, A. Multifractal approach for seafloor characterization. IEEE Geosci. Remote Sens. Lett. 2014, 11, 54–58. [Google Scholar] [CrossRef]

- Paz Ferreiro, J.; Vidal Vázquez, E. Multifractal analysis of Hg pore size distributions in soils with contrasting structural stability. Geoderma 2010, 160, 64–73. [Google Scholar] [CrossRef]

- Nelson, P.H. Pore-throat sizes in sandstones, tight sandstones, and shales. AAPG Bull. 2009, 93, 329–340. [Google Scholar] [CrossRef]

- Li, C.; Zhou, C.; Li, X.; Hu, F.; Zhang, L.; Wang, W. A novel model for assessing the pore structure of tight sands and its application. Appl. Geophys. 2010, 7, 283–291. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, N.; Sima, L.; Meng, F.; Guo, Y. Pore structure characterization of the tight reservoir: Systematic integration of mercury injection and nuclear magnetic resonance. Energy Fuels 2018, 32, 7471–7484. [Google Scholar] [CrossRef]

- Zhao, P.; Cai, J.; Huang, Z.; Ostadhassan, M.; Ran, F. Estimating permeability of shale gas reservoirs from porosity and rock compositions. Geophysics 2018, 83, MR283–MR294. [Google Scholar] [CrossRef]

- Zeng, D.; Li, S. Types and characteristics of low permeability sandstone reservoirs in China. Acta Pet. Sin. 1994, 15, 38–46. [Google Scholar]

- Tang, W.; Tang, R. Fractal dimensions of mercury-ejection capillary pressure curves in Donghe-1 Oilfield. Acta Pet. Sin. 2005, 26, 90–93. [Google Scholar]

- Xiao, D.; Jiang, S.; Thul, D.; Lu, S.; Zhang, L.; Li, B. Impacts of clay on pore structure, storage and percolation of tight sandstones from the Songliao Basin, China: Implications for genetic classification of tight sandstone reservoirs. Fuel 2018, 211, 390–404. [Google Scholar] [CrossRef]

- Zhao, P.; Sun, Z.; Luo, X.; Wang, Z.; Mao, Z.; Wu, Y.; Xia, P. Study on the response mechanisms of nuclear magnetic resonance (NMR) log in tight oil reservoirs. Chin. J. Geophys. 2016, 59, 1927–1937. [Google Scholar]

- Tang, R.; Ceng, Y. Study on several factors affecting the efficiency of mercury removal from rock. Exp. Pet. Geol. 1994, 1, 84–93. [Google Scholar]

| No. | Porosity (%) | K (mD) | P50 (MPa) | R50 (µm) | Pd (MPa) | Smax (%) | We (%) | Large Pore (%) | Medium Pore (%) | Small Pore (%) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 12.2 | 0.635 | 21.8635 | 0.0336 | 0.1362 | 1.6577 | 75.49 | 32.3168 | 0 | 36.47 | 39.02 |

| 2 | 14.1 | 9.987 | 4.5277 | 0.1624 | 1.4537 | 0.1341 | 72.59 | 37.2628 | 33.47 | 19.46 | 19.66 |

| 3 | 12.8 | 1.553 | 4.6343 | 0.1586 | 0.7140 | 0.3210 | 76.47 | 29.1339 | 25.96 | 27.38 | 23.13 |

| 4 | 13.3 | 1.318 | 7.9185 | 0.0928 | 0.5350 | 0.4078 | 73.78 | 30.1309 | 16.23 | 32.9 | 24.65 |

| 5 | 14.5 | 2.951 | 5.9248 | 0.1241 | 0.7622 | 0.2800 | 78.42 | 31.2342 | 27.2 | 24.23 | 26.99 |

| 6 | 13.4 | 1.285 | 9.3323 | 0.0788 | 0.5089 | 0.4364 | 74.11 | 30.1099 | 16.36 | 31.5 | 26.25 |

| 7 | 13.5 | 1.151 | 4.9514 | 0.1485 | 0.5617 | 0.3976 | 82.15 | 32.5816 | 22.36 | 30.91 | 28.88 |

| 8 | 15.0 | 5.365 | 5.8377 | 0.1259 | 0.9252 | 0.2202 | 74.77 | 32.7690 | 27.18 | 24.22 | 23.37 |

| 9 | 13.6 | 1.244 | 4.5437 | 0.1618 | 0.6162 | 0.4111 | 75.79 | 29.7635 | 23 | 30.77 | 22.02 |

| 10 | 13.6 | 1.515 | 4.0092 | 0.1834 | 0.6537 | 0.4114 | 76.13 | 30.5637 | 26.91 | 27.55 | 21.67 |

| 11 | 13.4 | 2.088 | 4.0521 | 0.1814 | 0.8023 | 0.3387 | 72.23 | 28.0463 | 30.56 | 23.35 | 18.32 |

| 12 | 5.7 | 0.108 | 29.7888 | 0.0247 | 0.0629 | 5.2180 | 64.38 | 31.5089 | 0 | 10.58 | 53.8 |

| 13 | 13.6 | 1.107 | 3.2311 | 0.2275 | 0.5251 | 0.3982 | 81.24 | 29.9167 | 15.25 | 42.66 | 23.33 |

| 14 | 13.6 | 1.107 | 3.9024 | 0.1884 | 0.3257 | 0.7812 | 79.67 | 33.3898 | 2.33 | 53.54 | 23.8 |

| 15 | 13.8 | 2.585 | 2.5664 | 0.2864 | 0.8658 | 0.1289 | 84.58 | 28.2272 | 30.89 | 28.38 | 25.31 |

| 16 | 14.0 | 0.486 | 6.0551 | 0.1214 | 0.1679 | 1.4097 | 84.15 | 31.8996 | 0 | 52.21 | 31.94 |

| 17 | 10.2 | 0.392 | 6.9278 | 0.1061 | 0.1420 | 1.9421 | 88.75 | 36.6435 | 0 | 50.19 | 38.56 |

| 18 | 9.7 | 0.156 | 13.7947 | 0.0533 | 0.0979 | 2.1185 | 75.9 | 20.6429 | 0 | 27.61 | 48.29 |

| 19 | 7.9 | 0.168 | 9.9355 | 0.0740 | 0.1976 | 0.9940 | 79.53 | 28.3013 | 0.91 | 43.11 | 35.51 |

| 20 | 10.8 | 0.271 | 10.0876 | 0.0729 | 0.1335 | 1.9989 | 81.85 | 31.1925 | 0 | 44.17 | 37.68 |

| 21 | 10.3 | 0.395 | 9.9605 | 0.0738 | 0.1609 | 1.5684 | 68.03 | 20.1933 | 0.43 | 40.5 | 27.1 |

| 22 | 11.7 | 0.800 | 4.5632 | 0.1611 | 0.3004 | 0.7287 | 80.32 | 29.9648 | 3.82 | 52.64 | 23.86 |

| 23 | 10.5 | 0.451 | 3.5488 | 0.2071 | 0.4010 | 0.4524 | 86.62 | 27.8590 | 11.59 | 49.73 | 25.3 |

| 24 | 10.5 | 0.279 | 6.7273 | 0.1093 | 0.1505 | 1.4602 | 88.1000 | 30.7172 | 0 | 50.65 | 37.45 |

| No. | Quartz (%) | Feldspar (%) | Mica (%) | Chlorite (%) | Iron Calcite (%) | Main Particle Size (μm) | Sorting | Grinding Roundness | Cementation Type |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 18 | 42 | 23 | 5 | 2 | 0.10–0.30 | M | A | chlorite thin film |

| 3 | 22 | 53 | 5 | 4 | 6 | 0.2–0.5 | M | A | chlorite thin film |

| 4 | 20 | 54 | 7 | 4 | 2 | 0.15–0.5 | M | SA-A | chlorite thin film |

| 7 | 21 | 55 | 3 | 4 | 7 | 0.15–0.4 | M | A | pore-chlorite thin film |

| 9 | 23 | 57 | 0 | 6 | 1 | 0.1–0.3 | M-G | SA-A | chlorite thin film |

| 11 | 22 | 55 | 5 | 6.5 | 1 | 0.1–0.32 | M-G | SA-A | chlorite thin film |

| 12 | 15 | 50 | 7 | 0 | 18 | 0.10–0.35 | M | A | pore |

| 13 | 20 | 60 | 3 | 6 | 2 | 0.10–0.30 | M-G | A | chlorite thin film |

| 15 | 21 | 56 | 5 | 5 | 3 | 0.10–0.35 | M | A | pore-chlorite thin film |

| 16 | 22 | 55 | 6 | 7 | 3 | 0.05–0.15 | G | A | pore-chlorite thin film |

| 20 | 30 | 39 | 8 | 2 | 1 | 0.05–0.20 | M | SA | chlorite thin film-pore |

| 21 | 23 | 53.5 | 3 | 3 | 1.5 | 0.2–0.5 | M | SA | chlorite thin film-pore |

| 22 | 22 | 48 | 8.5 | 3 | 2 | 0.12–0.38 | M | A | pore-chlorite thin film |

| 23 | 22 | 55 | 6 | 3 | 2 | 0.16–0.28 | G | A | pore |

| 24 | 22 | 52 | 6 | 3 | 0 | 0.12–0.24 | G | A | pore-chlorite thin film |

| Type | Porosity (%) | K (Md) | P50 (MPa) | Pd (MPa) | Large Pore (%) | Medium Pore (%) | Small Pore (%) | |

|---|---|---|---|---|---|---|---|---|

| Type I | 12.8–15 | 1.151–9.987 | 2.57–5.92 | 0.56–1.45 | 0.13–0.41 | 22.36–33.47 | 19.46–30.91 | 18.32–28.88 |

| 13.81 | 3.160 | 4.56 | 0.82 | 0.29 | 27.50 | 26.25 | 23.26 | |

| Type II | 10.5–13.6 | 0.451–1.318 | 3.23–9.33 | 0.30–0.54 | 0.40–0.78 | 2.33–16.36 | 31.5–53.54 | 23.33–26.25 |

| 12.68 | 1.011 | 5.42 | 0.43 | 0.53 | 10.93 | 43.83 | 24.53 | |

| Type III | 5.7–14 | 0.108–0.635 | 6.06–29.79 | 0.06–0.20 | 0.99–5.22 | 0–0.91 | 10.58–52.21 | 27.1–53.8 |

| 10.3 | 0.369 | 11.97 | 0.15 | 1.91 | 0.52 | 40.81 | 37.32 |

| Type | αmax | αmin | Dmax | Dmin | D1 | D2 | △α | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Type I | 1.18–1.24 | 0.14–0.28 | 0.17–0.32 | 1.11–1.15 | 0.56–0.70 | 0.31–0.53 | 0.22–0.50 | −0.01–0.00 | 0.90–1.06 | 0.22–0.50 |

| 1.21 | 0.21 | 0.24 | 1.13 | 0.63 | 0.42 | 0.37 | 0.00 | 0.99 | 0.37 | |

| Type II | 1.16–1.90 | 0.26–0.46 | 0.29–0.49 | 1.11–1.71 | 0.67–0.80 | 0.48–0.67 | 0.00–0.59 | 0.00–0.20 | 0.79–1.54 | −0.01–0.55 |

| 1.33 | 0.36 | 0.39 | 1.23 | 0.71 | 0.56 | 0.29 | 0.07 | 0.97 | 0.23 | |

| Type III | 0.99–2.14 | 0.34–0.79 | 0.40–0.82 | 0.91–1.92 | 0.71–0.92 | 0.58–0.93 | −0.28–0.19 | −0.19–0.55 | 0.2–1.80 | −0.30–0.45 |

| 1.66 | 0.48 | 0.53 | 1.50 | 0.77 | 0.69 | −0.07 | 0.08 | 1.17 | 0.05 |

| αmax | αmin | Dmax | Dmin | D1 | D2 | Δα | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Porosity | −0.278 | −0.580 | 0.618 | −0.264 | −0.737 | −0.730 | 0.393 | −0.054 | −0.024 | 0.224 |

| K | −0.261 | −0.682 | −0.714 | −0.238 | −0.780 | −0.831 | 0.510 | −0.101 | −0.011 | 0.316 |

| P50 | 0.192 | 0.443 | 0.476 | 0.188 | 0.439 | 0.514 | −0.189 | 0.047 | 0.012 | −0.062 |

| −0.328 | −0.686 | −0.718 | −0.302 | −0.712 | −0.804 | 0.582 | −0.114 | −0.028 | 0.360 | |

| Pd | 0.312 | 0.635 | 0.664 | 0.290 | 0.649 | 0.742 | −0.523 | 0.099 | 0.028 | −0.316 |

| L-pore | −0.383 | −0.512 | −0.547 | −0.359 | −0.598 | −0.660 | 0.572 | −0.060 | −0.069 | 0.373 |

| M-pore | 0.164 | 0.006 | 0.006 | 0.155 | 0.032 | 0.030 | −0.225 | −0.012 | 0.133 | −0.205 |

| S-pore | 0.149 | 0.642 | 0.680 | 0.132 | 0.653 | 0.735 | −0.363 | 0.118 | 0.000 | −0.171 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Z.; Mao, Z.; Shi, Y.; Wang, D. Multifractal Characteristics and Classification of Tight Sandstone Reservoirs: A Case Study from the Triassic Yanchang Formation, Ordos Basin, China. Energies 2018, 11, 2242. https://doi.org/10.3390/en11092242

Jiang Z, Mao Z, Shi Y, Wang D. Multifractal Characteristics and Classification of Tight Sandstone Reservoirs: A Case Study from the Triassic Yanchang Formation, Ordos Basin, China. Energies. 2018; 11(9):2242. https://doi.org/10.3390/en11092242

Chicago/Turabian StyleJiang, Zhihao, Zhiqiang Mao, Yujiang Shi, and Daxing Wang. 2018. "Multifractal Characteristics and Classification of Tight Sandstone Reservoirs: A Case Study from the Triassic Yanchang Formation, Ordos Basin, China" Energies 11, no. 9: 2242. https://doi.org/10.3390/en11092242

APA StyleJiang, Z., Mao, Z., Shi, Y., & Wang, D. (2018). Multifractal Characteristics and Classification of Tight Sandstone Reservoirs: A Case Study from the Triassic Yanchang Formation, Ordos Basin, China. Energies, 11(9), 2242. https://doi.org/10.3390/en11092242