1. Introduction

With the growing of the energy crisis and the awareness of human environmental protection, wind power is increasingly used as a green energy source [

1]. Wind turbines are usually installed in harsh environments such as coastal areas, deserts, and mountainous areas. This means that the reliability of large wind turbine system operations need to be improved. However, in recent years, the accidents of wind turbines and power grid disturbances (such as voltage sag mitigation [

2,

3] to which wind energy conversion systems (WECSs) are highly sensitive) caused by loss of control in the design, manufacture, installation, operation and maintenance of intermediate links have threatened the safe operation of wind farms. The probability of failure of actuators and sensors is very high, and maintenance costs are enormous [

4,

5]. Therefore, fault detection and diagnosis of wind turbines have become a vital and stiff topic.

To realize the fault detection and isolation (FDI) of WECSs, the issue of how to construct the closed-loop control system is a prerequisite. The WECS is a complex stochastic switching nonlinear dynamic system, which is integrating mechanisms, electricity and liquid. Therefore, the traditional control methods have difficulty in achieving satisfactory performance [

5]. In these features of WECSs, the stochastic switching, which is caused by the randomness of the wind, is the most important feature of the WECS. Notably, the stochastic switching feature can be represented as having the Markov jump characteristics, so the WECS can be described as a Markov jump linear system (MJLS). The Markov jump linear system is a nonlinear system that describes the system with uncertainty and disturbance as a Markov chain process. In 2012, Bernardini and Bemporad [

6] proposed a scenario-based stochastic model predictive control for the stochastic Markov jump linear system. This kind of scenario-based stochastic model predictive control can be well applied to stochastic MJLSs. The main benefit of stochastic model predictive control is that it can make predictions with the full use of the statistical information of disturbance. Stochastic model predictive control (SMPC) has been used in many fields, such as drinking water networks [

7], microgrids [

8,

9], electric vehicles [

10], and so forth [

11,

12]. Furthermore, the scenario-based stochastic model predictive control has rarely been applied to solve the optimal control problem of wind turbines under random wind speed [

13].

With the closed-loop system, estimating the system states is needed by the FDI of WECSs. Scholars also have extensive and in-depth research on state estimation [

14,

15,

16,

17,

18,

19,

20]. In the literature, the Kalman filter is the most commonly used method to estimate states [

14]. For discrete-time state-space Markov models, Crisan [

15] uses a sequential Monte Carlo method to design nested structure particle filters to approximate the posterior probability measure of the static parameters and the dynamic state variables of the system. Hu [

16], based on the Markov chain Monte Carlo to Sequential Monte Carlo algorithm, propose a state space model with Bayesian online estimation method to derive the optimal Bayesian estimation. Notably, it is a significant issue in the literature to accurately locate faults for hybrid systems. Liu [

21] designed the robust estimation algorithm for a typical hybrid system (the aircraft). In this paper, the control object is the wind turbines, and the control method is the more advanced and complicated SMPC.

A lot of research has been started in recent years for the fault diagnosis and isolation of wind turbines [

22,

23,

24,

25,

26,

27,

28,

29]. Karim [

22] designed an observer scheme for FDI, which is integrated with a maximum-shift strategy and a time-varying Kalman filter for the additive and multiplicative measurement failures of voltage and current. Silvio [

23] used fuzzy models to estimate fault residuals for diagnosis and isolation. Iury [

24] uses data-driven methods for fault detection, and a fuzzy/Bayesian network to distinguish faults. However, current research works do not systematically consider the stochastic hybrid characteristics of wind turbines and do not estimate the continuous and discrete states of the wind turbine during fault diagnosis and isolation.

This work presents a new FDI method based on stochastic hybrid estimation for WECSs. First, the scenario-based SMPC controller is used to deal with the control problem of wind energy conversion systems. By extracting the probability information of wind speed, the Markov jump linearization model of the wind turbine can be constructed, so that the random switching characteristics of the wind turbine can be accurately described. With this model, the SMPC can be benefited from the probability information of the wind to achieve a better control performance. Second, this paper proposed a stochastic hybrid estimator that estimates the continuous state and the discrete states of WECSs with unknown fault inputs. The proposed estimator decouples the unknown fault inputs from the estimation error dynamics of the hybrid system. With this decoupling, it can guarantee that the estimation is not influenced by the fault input. At last, the comprehensive FDI method is used to detect and isolate the actuators’ faults of WECSs. The innovation of the FDI algorithm proposed in this paper is that it can accurately estimate both the continuous and discrete states of the WECS with unknown fault inputs. The principle is to construct the system fault residual based on the accurate estimation of the proposed estimator and use the statistical decision tool to realize fault detection and isolation. The continuous state estimation of the system can be obtained by stochastic hybrid estimation, and the discrete state estimation of the system can be derived by Bayesian theory. The simulation results show that the SMPC controller has good control performance for the WECS, and the FDI algorithm has good fault detection and isolation effect. Both the fault amplitude and the fault occurrence can be effectively estimated by the proposed method.

This paper has been divided into five parts. The first part deals with the SMPC controller design in

Section 2; the second part focuses on the stochastic hybrid estimation for WECSs in

Section 3; the third part presents the comprehensive FDI algorithm for WECSs in

Section 4; the fourth part is the simulation verification of the SMPC controller and the FDI method shown in

Section 5; the last part is the conclusion, which gives a brief summary in

Section 6.

3. Design of Stochastic Hybrid Estimator

In this section, we propose a stochastic hybrid estimator [

21] for unknown faults (disturbances) of WECSs. The faults are arranged in combination, and the continuous and discrete states of the system are estimated separately. This approach will only require three designed filters. When the FDI algorithm in

Section 4 determines that the system has failed, the user finds the discrete state of the system and the fault of the corresponding continuous state as needed.

3.1. The Problem of Stochastic Hybrid Estimation Algorithm

Combing the wind turbine discrete Markov jump linearization model (11) with the wind speed Markov state transition matrix

established in

Section 2.1, the stochastic hybrid estimation problem can be described as the estimated system status. In order to estimate the state of the system, it is necessary to estimate the probability distribution of the discrete state of the system and then estimate the continuous state of the system that is not affected by the fault input.

This paper proposes a stochastic hybrid estimation algorithm for hybrid systems which is insensitive to actuators’ unknown fault inputs. Note that when the WECS operates in a discrete state, its characteristics are the same as those of linear time-invariant (LTI) systems . Therefore, a state estimator is designed for an LTI system.

Consider

where

is the continuous state estimation,

is the discrete state, and

is the parameter matrix to be designed. For the sake of easy understanding,

and

are regarded as the fixed matrix of the state

; from the next section,

and

are the time-varying matrix, which needs to be updated online with the simulation. Define the estimation error as

Combining model (12) and Equation (20) with Equation (22), the error dynamics of the discrete state

can be detailed as:

To ensure that the state is not affected by the unknown fault inputs, namely the robustness of the estimation algorithm,

is decoupled from estimation error (23) and residual dynamics (24). The decoupling problem is equivalent to

3.2. Individual Robust Estimator Design

The design of a single robust estimator can be expressed as a constrained optimization problem [

21].

Problem 1: For the robust state estimator of the LTI system , the design of and should meet the following objectives:

Minimize: minimize the mean square estimation error .

Subject to: Constraint (25) and (26) being satisfied, that is, the actuator fault input is decoupled from the system estimation error (23) and residual (24).

Theorem 1. The solution matrix of Problem 1 can be parameterized aswhere and is the full row rank matrix of the corresponding appropriate dimension. Proof. Assumptions 1 and 2 guarantees that (25) is solvable. The solution of (25) can be expressed as

where

represents the Moore–Penrose pseudo-inverse of the matrix

.

is a full row rank matrix whose row space is orthogonal to the column space of

. We can assume

, where

is a full row rank matrix of suitable dimension. In Equation (29),

is the parameter matrix to be solved. From (26),

can be given as

.

From the system state estimate (20) and the estimation error (23), the covariance matrix of the estimation error

can be written as

Then, Equation (30) can be rewritten as

Substituting (29) into Formula (33):

Minimizing

is equivalent to minimizing the mean square of the estimation error. Note that in Equation (34), only

is a free variable to be determined, and

can be regarded as a quadratic function of

. Referring to the method of finding the extremum from the quadratic function,

is partially derived to

, and then

let

, solving (35),

It should be noted that in (36), is a time-varying matrix. Substituting (36) into (29) yields the solution as given in Equation (27). ☐

3.3. Stochastic Hybrid Estimation Algorithm

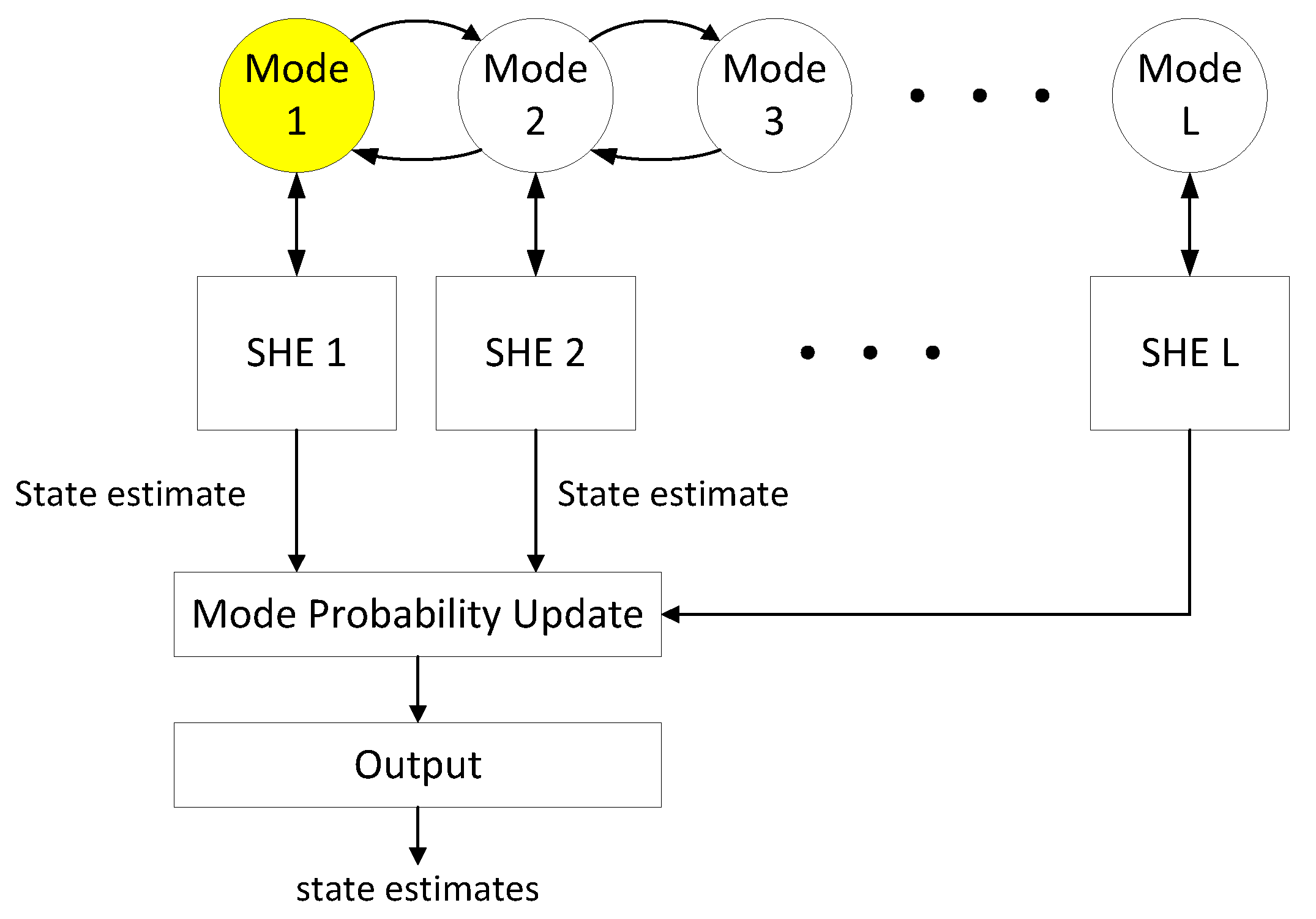

Based on the design of the single-state estimator in the previous section, this section will introduce the stochastic hybrid estimation algorithm [

21] in this paper. The stochastic estimator algorithm is illustrated in

Figure 4. To estimate the continuous and discrete states of WECSs, a robust estimator is used in this paper. The algorithm of a single robust estimator is given in

Section 3.2. The discrete state estimated by the stochastic hybrid estimator is the state of the most likely previous state of the system, and the continuous state is the weighted sum of the outputs of the estimators. Since each estimator has been decoupled from the fault and the estimation error has been minimized, the entire stochastic hybrid estimator is not influenced by the fault input and the estimation is fairly accurate. State estimation of hybrid systems is quite complex. If the historical operating record of the hybrid system is not available, the possible evolutions of the hybrid system state may increase exponentially. In order to prevent this, a hybrid strategy similar to the interacting multiple model (IMM) algorithm is introduced to reduce the complexity of the algorithm from exponential to constant. The stochastic hybrid estimation algorithm is derived as follows:

Assume that the initial probability distribution of the mixed state

is

where

.

is the discrete probability distribution,

indicates the probability of an event. For state

, the probability density distribution

of the state

is calculated in real time.

The online running process in

Figure 4 are shown as follows:

Calculate the mixing probability: the mixing probability is defined as

. According to the Bayesian theory

where

is a constant. In order to calculate the Equation (39), the following method can be used to evaluate the state transition probability

:

For Markov jump systems, such as the Markov jump linear system of wind turbines established in

Section 2, the Markov transition matrix has recorded the transition probability between states. Then

in (39) can be written as:

Calculate the initial conditions of each robust estimator: at each moment, the initial state of each robust estimator can be approximated by a simple Gaussian distribution. The initial state (estimated mean

) of the

-th robust estimator can be given by:

Mode-matched filter: For each robust estimator, the estimated mean

is calculated under the current system condition

. According to the calculation process of a single robust estimator in

Section 3.2, the gain

can be given by (27); the robust estimator (REs) can be given by (20), and the robust estimator residuals

, weighting matrix

, and covariance matrix

will be updated in a similar way.

Update the discrete state probability density function: For each SHE, the likelihood function

is

where

and

are the residual vectors and its covariance generated by the

-th robust estimator. By the Bayes’ theorem, the discrete state probability

is given by

where

is an appropriate normalizing constant.

Output: the estimation of the continuous state is obtained by a weighted sum of the output of each robust estimator.

The discrete state estimation is given by the discrete state with the highest probability.

and

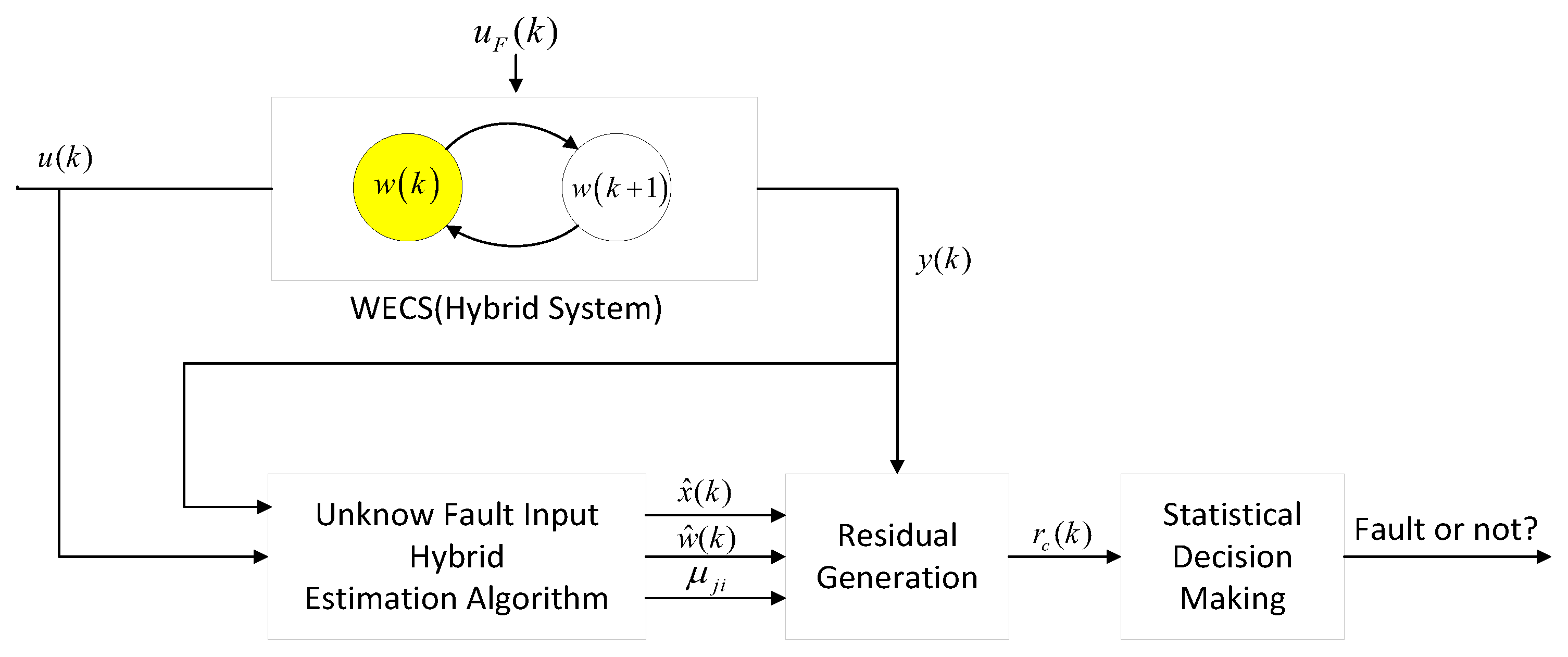

4. Comprehensive Fault Detection and Isolation Method

This section designs the FDI algorithm [

21] for WECSs. Based on the results of

Section 3, the state-space equation of the system is reconstructed by the idea of replication. Then, use the residual

to fit the fault input

of the system. Finally, statistical decision tools are used to determine whether the fitted fault input

is a fault. The block diagram of the FDI scheme is shown in

Figure 5.

4.1. Residual Generation Algorithm and Reconstruction of the Fault

Before studying the characteristics of the residual, review the Assumption 2 of

Section 2.3: the column rank of

does not exceed the row rank of

. This assumption can be explained as to isolate different fault inputs, at least one of the elements corresponds to a single fault input in

.

can be defined as:

where

where

. To ensure that the algorithm proposed in this paper is solvable, make the following assumptions:

Assumption 3. The Moore–Penrose pseudo-inverse solution of.

Remark 1. It is assumed by Assumption 2 that is of full column rank. Therefore, only is distinct; let be irreversible. Since is a random variable in the range , it is almost inevitable that takes the value of 0 at some specific time. , and make the Moore–Penrose pseudo-inverse be able to be resolved.

Equation (48) gives to the residual and output estimate a one-to-one corresponding value. The following will demonstrate that the unknown fault inputs of the system can be estimated by .

Theorem 2. Calculated from (48)–(50), satisfies

where .

Proof. Based on the stochastic hybrid estimator in

Section 3, coupled with the idea of replication, we can reconstruct the WECS system, and then use the reconstructed system to derive the unknown fault inputs.

Considering that the estimator designed in

Section 3 is not affected by the actuator failure, we always have the relation

. Recalling (12), we obtain

Substituting (55) into (48), then

Combined with (49), then (56) can be reorganized as

∵

, ∴

Then (51) is proved. ☐

It is noted in (57) that the and are both satisfied with a Gaussian distribution, and letting , the variance of , be a positive real number, then (52) is proved.

4.2. Statistical Decision-Making Algorithm

After calculating the residuals in

Section 4.1, this section will design the FDI algorithm to detect any significant changes in the residuals which indicate faults.

Section 4.1 showed that the residual follows a Gaussian distribution, and once the mean

is offset by 0, the system fails. There are many algorithms that can detect changes in time series. The algorithm for determining whether the system has failed is the same one to determine whether the mean value of the system fault input is 0. In this way, the purpose of fault isolation is achieved.

For the sake of determining each fault component separately, (52) is re-expressed as:

In order to detect significant changes in the system (deviation from mean value 0), a detection algorithm proposed by Segen [

38] can be used. This algorithm can detect whether the random sequence is offset by the Gaussian process.

When the system state maintains a Gaussian random process, is basically constant. When the system state deviates from the Gaussian process, is a monotonic increasing function. Therefore, the difference for , is close to 0 when the system is in the Gaussian process. In contrary, when the system deviates from the Gaussian process (, is the set threshold), it can be determined that the input component has failed. The process to detect the fault input and quantify its amount was shown in Algorithm 1.

| Algorithm 1 The process to detect the fault input and quantify its amount |

For k = 1:T % T is the simulation time

If then

The system is normal;

; % is the -th component of fault input

Else

The system is abnormal;

;

End If

End For |

5. Simulation Results

The simulations are designed and given in this chapter to validate the control effectiveness of the scenario-based SPMC controller, the performance of the stochastic hybrid estimator, and the fault detection and isolation ability of the proposed FDI algorithm.

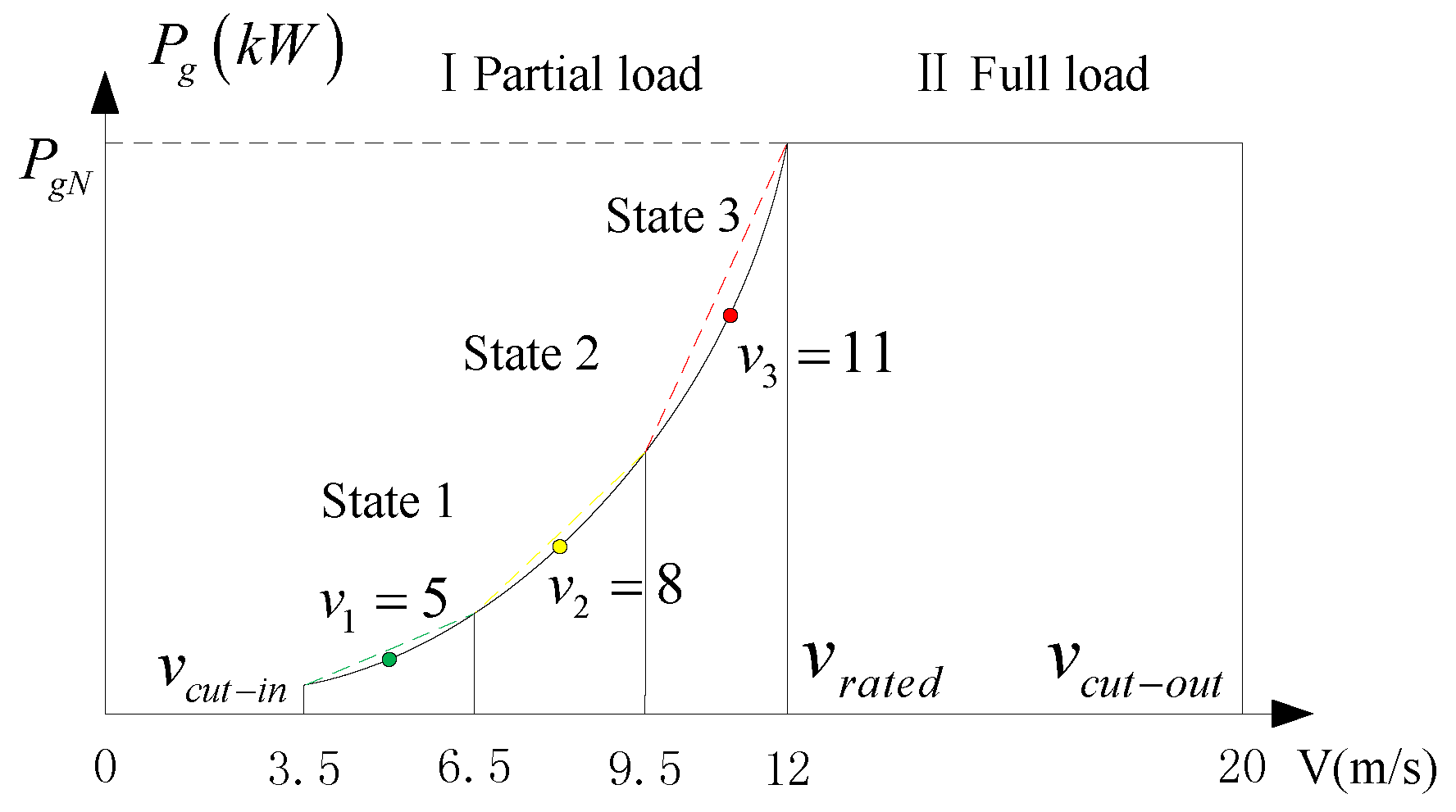

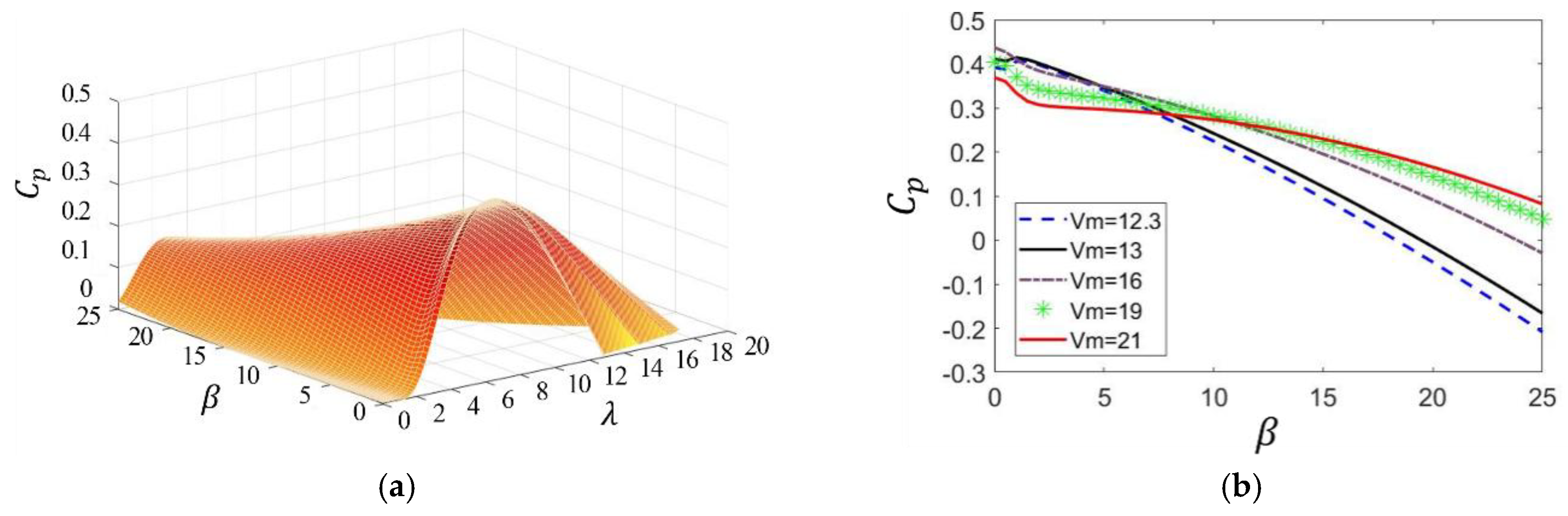

Table 1 gives the physical parameters of the simulated WECS, which is a 225 kW power system [

32]. As a prerequisite, the WECS model (4) is discretized and linearized to model (11) at three operating points (the wind speeds are 5, 8 and 11 m/s, respectively), and the parameters of the model are shown in

Table 2.

With the WECS assembly model, the next step is to obtain the Markov transition matrix. Respectively, the input and state constraint are and , prediction horizon , scenario tree layer , the Markov transition matrix , weight matrix and .

Furthermore, the simulations are performed in the environment (MATLAB R2015a) on an Intel

® Core™ i5-2400 CPU 3.10 GHz RAM 4 GB (FOUNDER, Beijing, China). The simulation Simulink structure of the proposed FDI algorithm is shown in

Figure 5, which contains three part: SMPC, SHE and FDI running synchronously. The major calculation load is solving a SMPC problem (14) quadratic constrained quadratic programming (QCQP), which costs 2.1 ms on average.

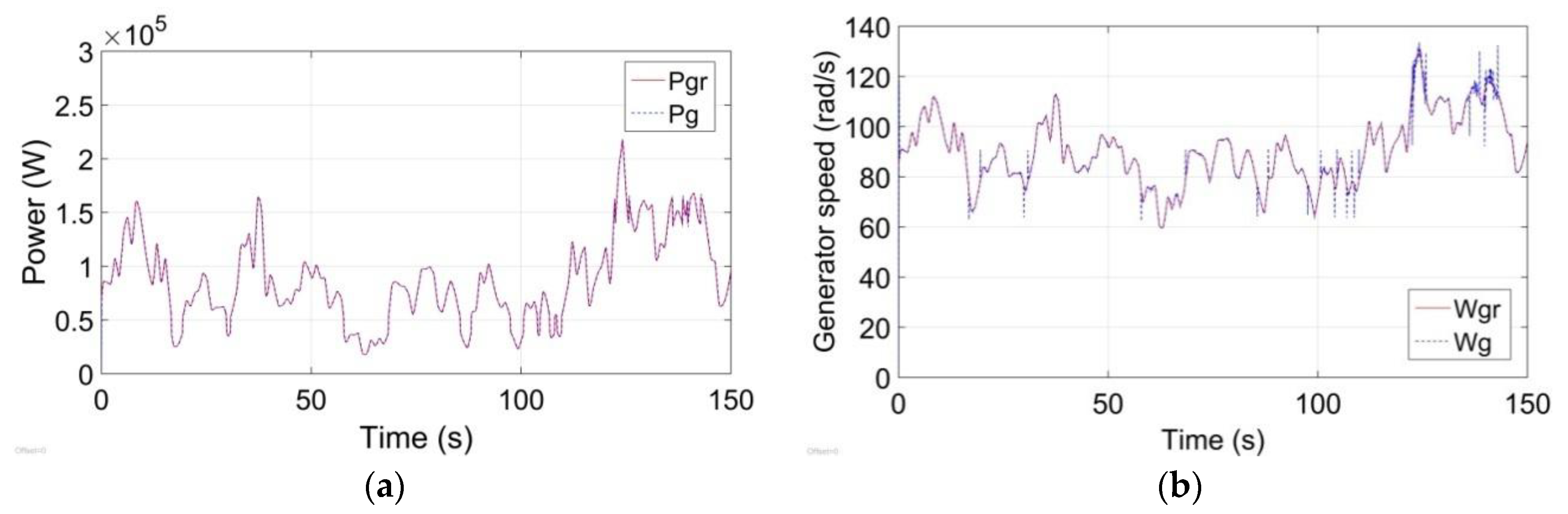

5.1. The Control Performance of the SMPC Controller without Fault

The control performance of the SMPC controller is investigated for a WECS without fault. In this simulation, the maximum power reference

can be given through reference to the table in [

39]. Meanwhile, the generator speed reference

can be calculated with the best tip speed ratio

. The

Figure 6 shows the tracking performance of a wind energy conversion system’s maximum wind energy under the random wind speed. All the red solid and blue dotted lines are the WECS references and outputs, respectively. First, the tracking of maximum power and generator speed are shown in

Figure 6a,b. It can be seen that the proposed SMPC controller has good control performance to minimize the tracking errors. Meanwhile,

Figure 6d reveals that there has been a steady fluctuation for the pitch angle

(about 7–12°) in accordance with the actual situation. Finally, as shown in

Figure 6e, the tip speed ratio

is close to its optimal value

with limited tracking errors. These simulation results indicate that in normal status, the presented stochastic model predictive controller can capture the maximum wind energy precisely and effectively.

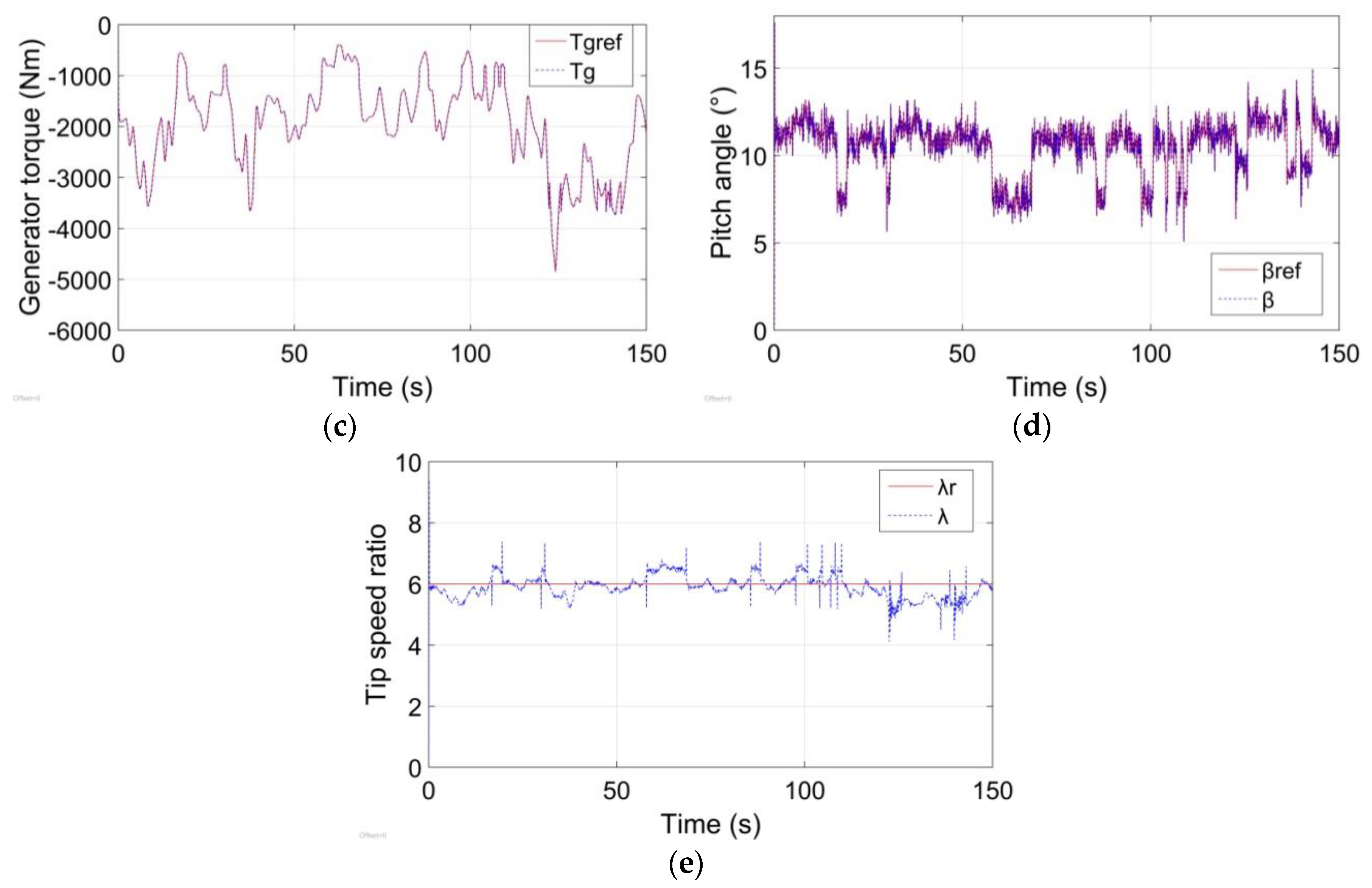

5.2. Stochastic Hybrid Estimation with Unknown Fault Inputs

In this section, the simulations are designed and implemented to verify the effectiveness of the proposed stochastic hybrid estimator with unknown fault inputs.

First, the pre-defined faults are shown in

Figure 7a. The faults of the generator torque reference

occur at

, and the fault values are from 0 to 500 Nm; the time range of the input fault pitch angle reference

is

and the pitch angle values are in the range (0–6°). This setting of the faults is based on two purposes: (1) the set of the time range can investigate different combinations of the two kinds of actuators’ faults (only

failure in

,

failure and

failure at the same time in

, and only

failure in

); (2) the set of the value range can cover all three operating domains of the WECS. Therefore, the fault sets are reasonable to verify the estimation performance of the proposed stochastic hybrid estimator.

Second,

Figure 7b,c show the bad tracking performance of the actuators caused by the fault set above. In the period of

in

Figure 7b, the generator torque

cannot achieve the set value

when the actuator is faulty. Meanwhile, the pitch angle reference

in

Figure 7c has obvious errors when the fault occurs from 110 s to 140 s. These results suggest that the actuators’ fault cannot be ignored since it leads to bad operating performance of the WECS.

Third, the proposed stochastic hybrid estimator is used to estimate the system states (including the discrete states and the continuous states).

Figure 7d shows the estimation results of the generator speed and the power of the WECS. The estimation errors are very small, this means the proposed estimator can estimate the states of the WECS effectively. Meanwhile, the estimation error has only small fluctuations during the simulation, which suggests the estimator has stable estimation performance.

Figure 7e is the estimation of the discrete state of the WECS. Each discrete state represents one working point of the WECS. The proposed method can quickly and precisely estimate the current working point of the WECS. Notably, the proposed estimator does not have the information of the fault sets, this means the estimator is robust to the faults of the actuators. This is valuable for designing a fault detection algorithm to detect whether the WECS is in fault mode, which is one optional future work for the authors.

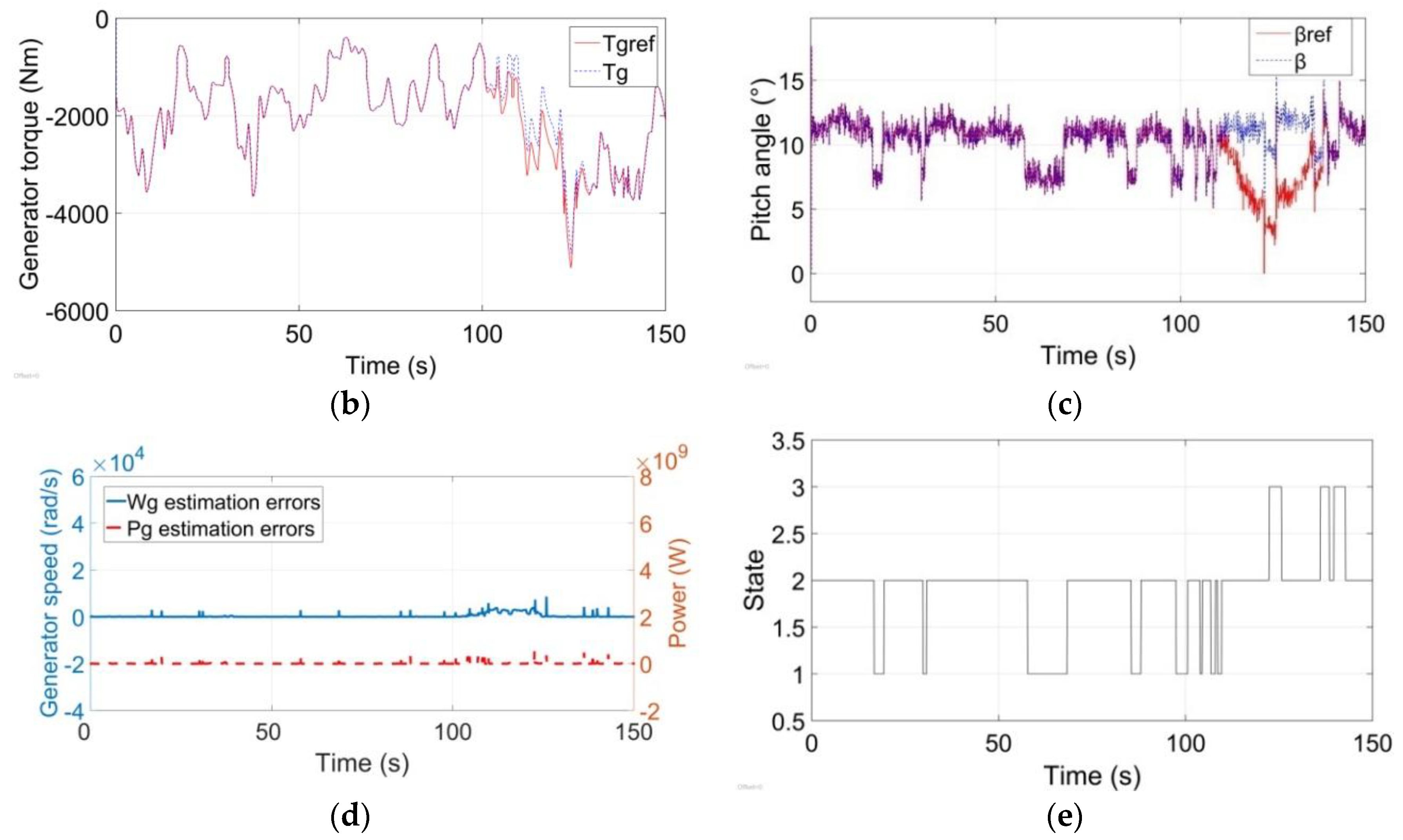

5.3. Fault Detection and Isolation of WECS

In this section, the simulation is given to verify the comprehensive FDI algorithm to accomplish the fault diagnosis and isolation of a WECS with an unknown actuator fault input. This section follows the same fault sets in

Section 5.2.

Figure 8a shows the unknown fault inputs residuals, which are generated by the proposed FDI algorithm. The time of the fitted fault by the FDI algorithm is the same as the time of the pre-defined fault, and the value of the fitted fault is in the small range around the fault. Besides, it can be seen that the

fluctuation is smaller and the pitch angle reference

fluctuation is relatively larger. This is because the amplitude of the

is about 1000 times larger than the value of

. Therefore, the impact of the Gaussian white noise on

is very small. The simulation results show that the proposed FDI algorithm can fit the fault input accurately.

Figure 8b is the result of the statistical decision part of the FDI method. This decision is based on the quantitatively fitting results in the

Figure 8a. To make the decision, we set a small threshold

(such as 0.05) to the statistical decision result in

Figure 8b. When the curve indicating the probability of failure of

and

exceeds the threshold, it is determined that the WECS has faults.

Figure 8b precisely indicates that the

has failed in the time range

, and

has failed in that of

. The determination result is in accordance with the fault sets of

Figure 7a, and the determination results of the two failures do not affect each other. These results suggest that the fault diagnosis and isolation are all achieved with great success.

6. Conclusions

This paper proposes a comprehensive stochastic hybrid state estimation and FDI method for WECSs. To describe the stochastic dynamics of the WECS, the Markov-jump linear model is developed. Based on this model, the SMPC controller with a scenario-tree gives good control performance of the WECS. With the closed-loop control system, the stochastic hybrid estimation is studied and used to estimate the system states. Finally, based on the information from the proposed estimator, the FDI algorithm is given to implement the fault detection and isolation of the WECS’ actuators unknown fault inputs. The simulation results suggest that the proposed method has good FDI performance, and that is a powerful method for the fault detection and isolation of WECS.

However, this work only considers the unknown fault inputs

. Future research should be undertaken to investigate other uncertainties (such as parametric variations, faults on the outputs measurements, etc.). Furthermore, the proposed stochastic hybrid estimation and FDI algorithm may be integrated to mitigate voltage dips [

2,

3] to improve the industrial value of the proposed method.