Experimental Study of a Bubble Mode Absorption with an Inner Vapor Distributor in a Plate Heat Exchanger-Type Absorber with NH3-LiNO3

Abstract

:1. Introduction

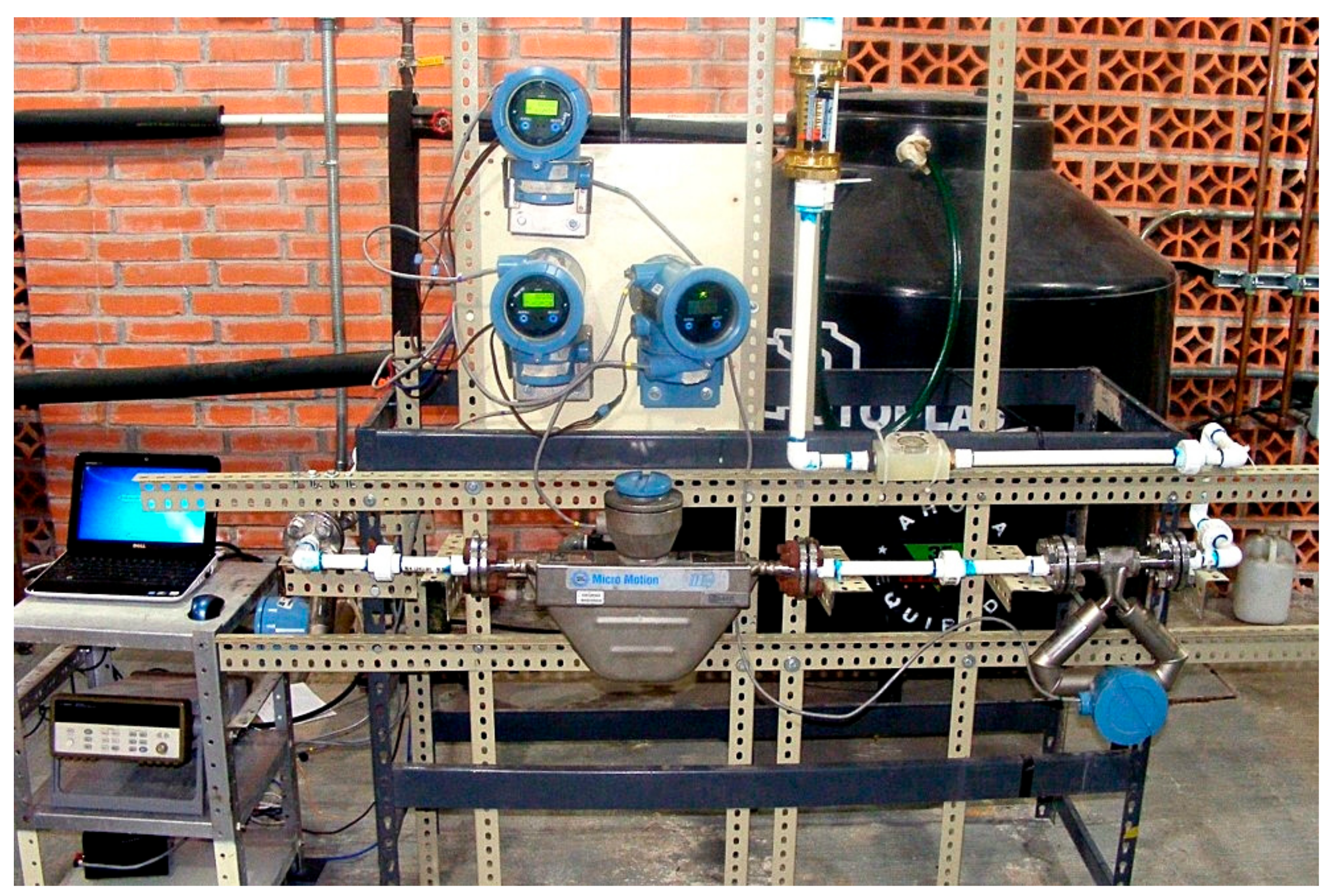

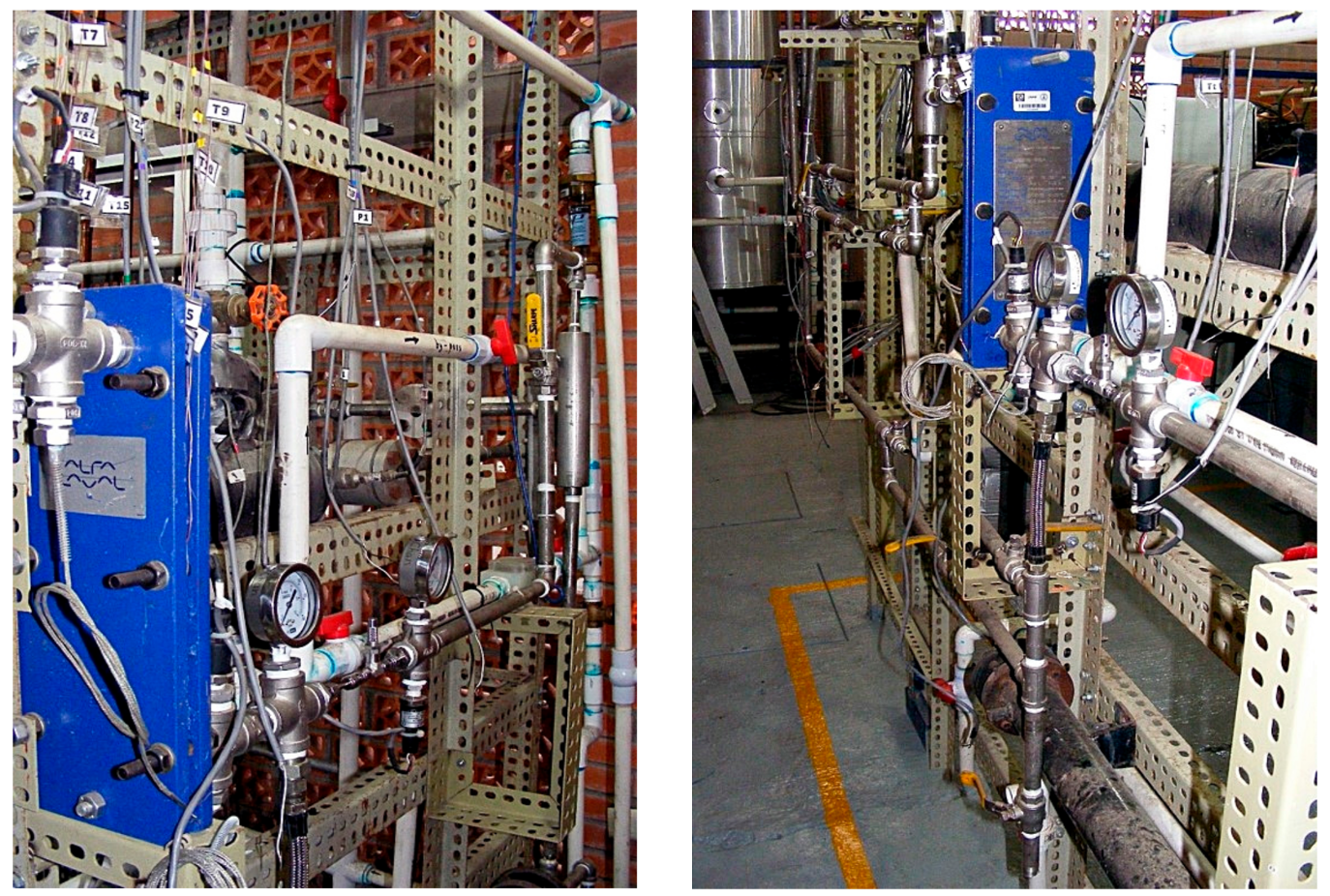

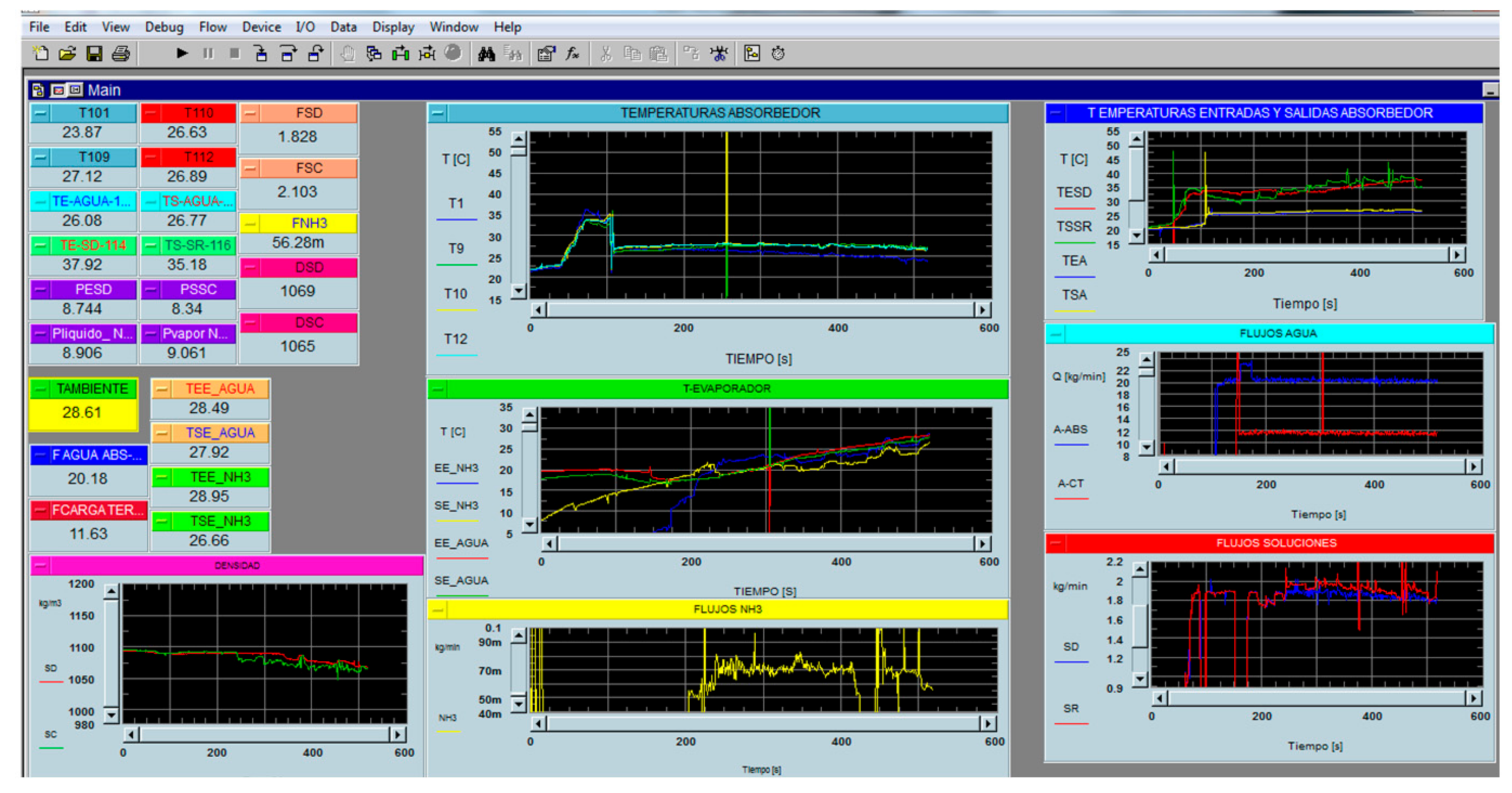

2. Description of the Experimental System

2.1. Test Rig Description

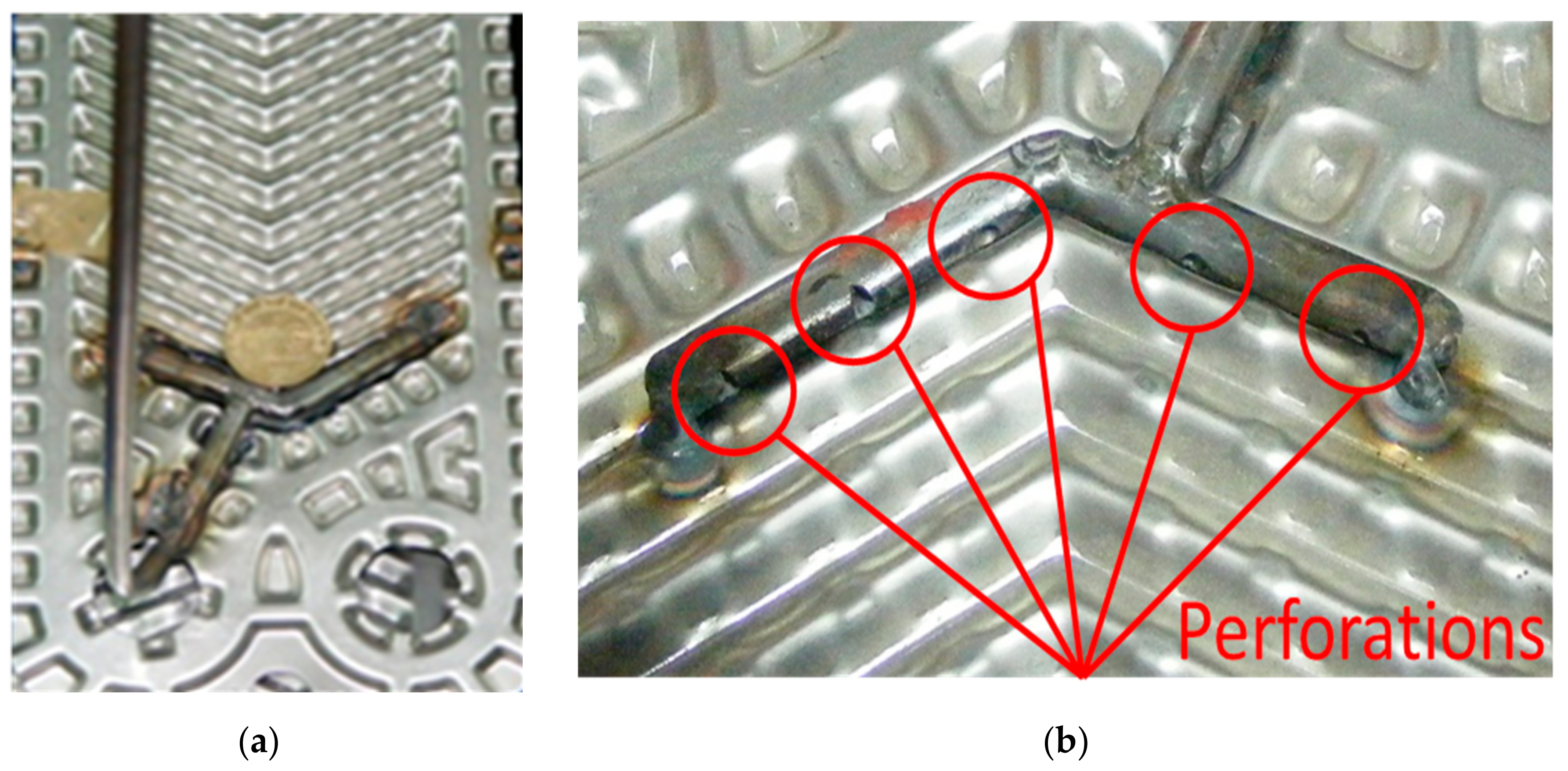

2.2. Plate Heat Exchanger as Absorber

3. Data Reduction

4. Discussion

5. Conclusions

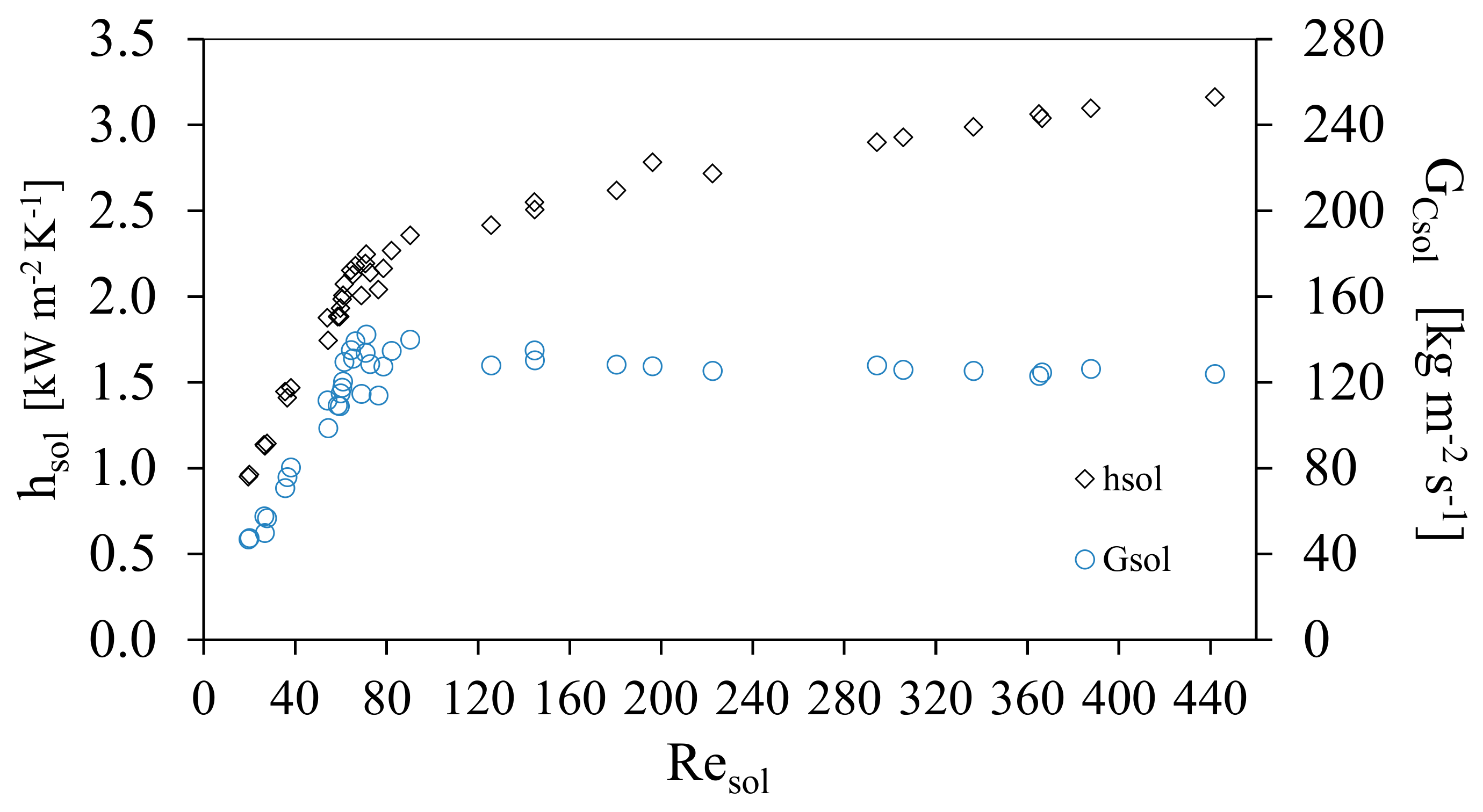

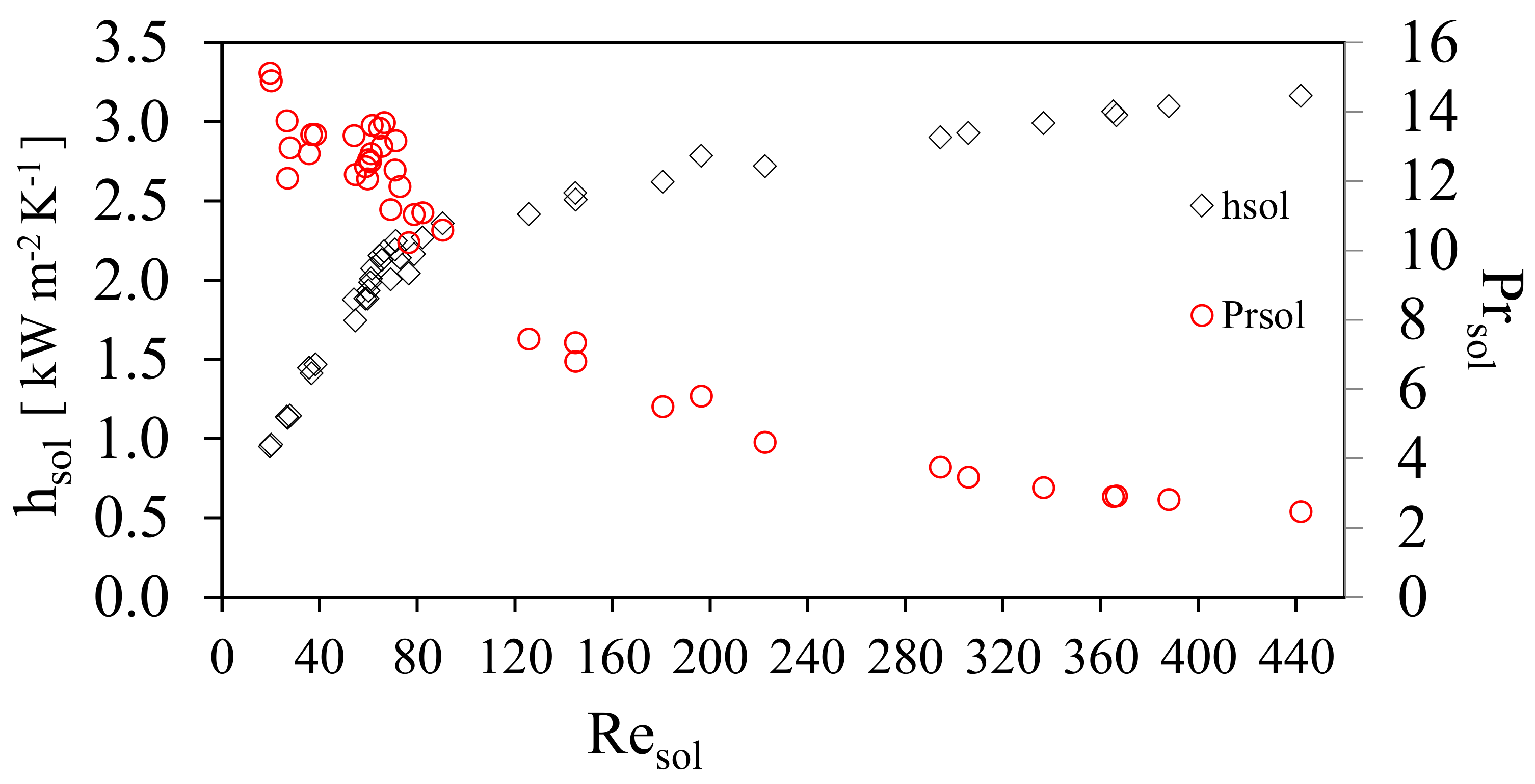

- The results obtained show that hsol increased from a value of 0.9 to 1.8 kW m−2K−1 for Resol values of 20 up to 80. For values of Resol greater than 120 and up to 440, due to limitations in the experimental rig, hsol increased slowly from 1.8 to 3.0 kW m−2K−1.

- The ammonia absorption flow FABS in the study had an almost constant value of 0.038 ± 0.004 kg m−2s−1, for all the mass flow velocities, GCsol throughout the experiments. The values are in the same range as the work by Oronel et al. [15] although for low values of Resol the values in this work are higher. This could be due to the vapor distributor and other operating conditions such as the higher pressure.

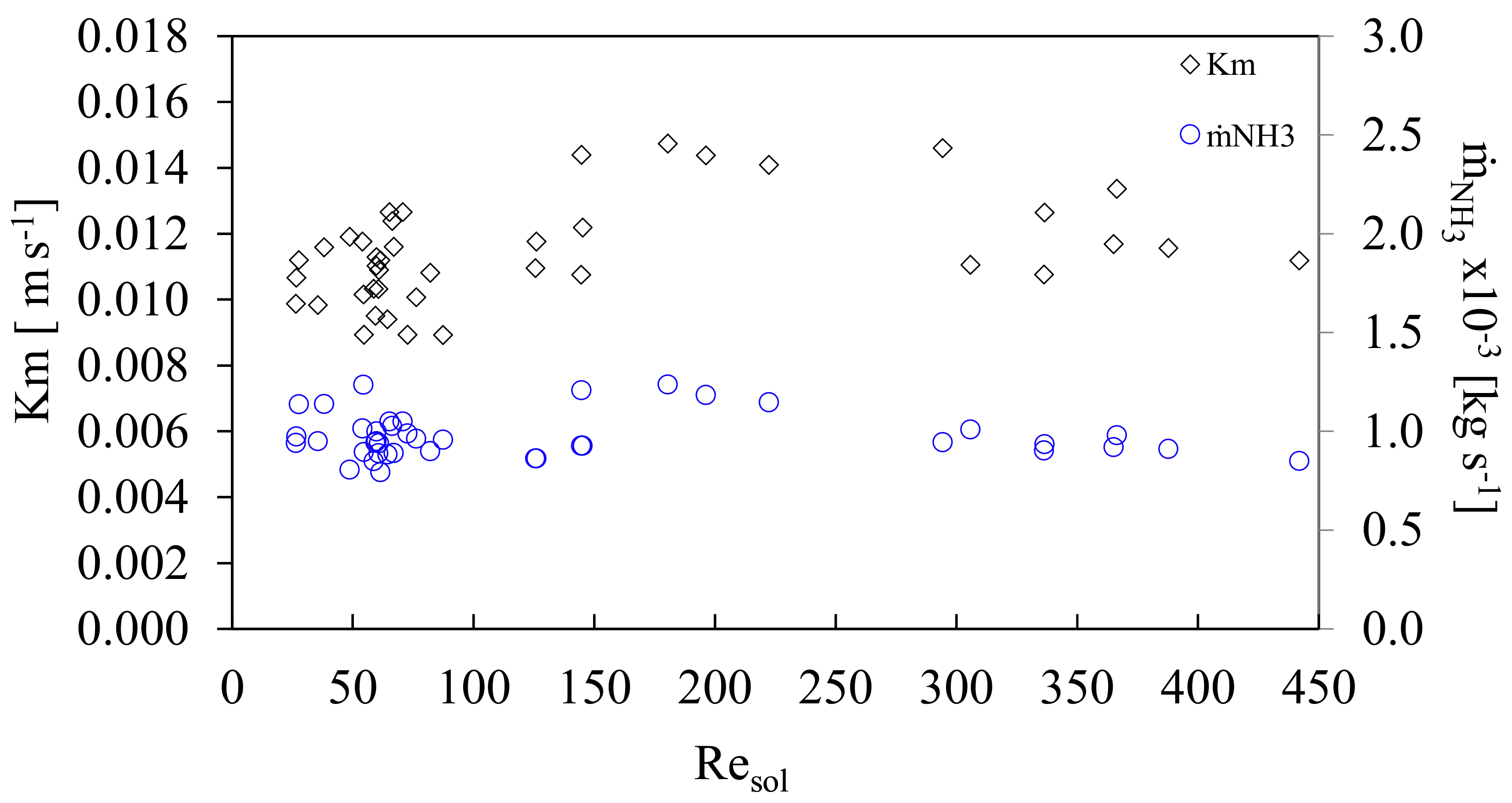

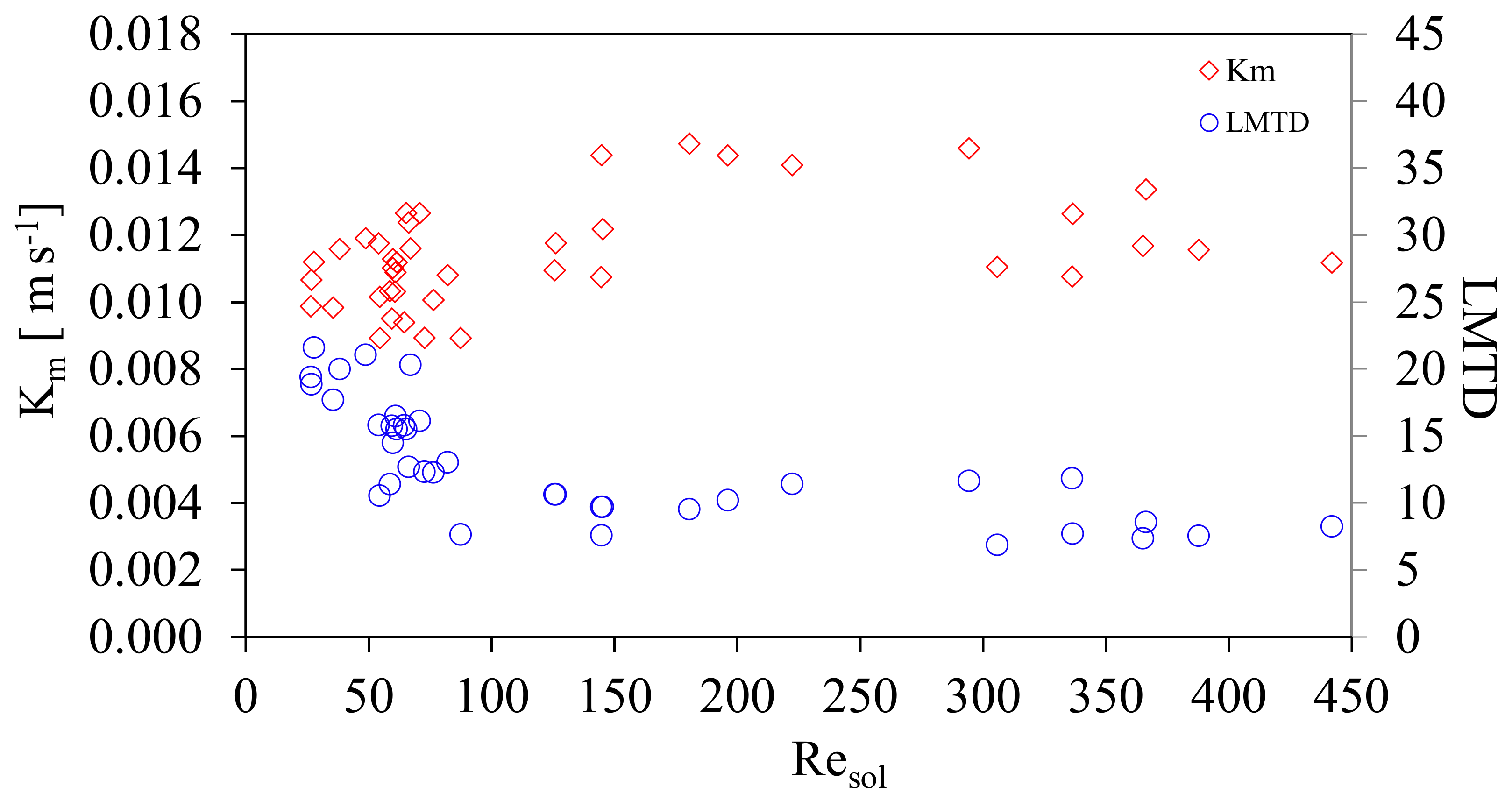

- It was found that the value of the mass transfer coefficient, Km, had a relatively large interval from 0.009 to 0.015 m s−1 with an average of 0.011 ± 0.002 m s−1. Although mass flows of ammonia and mass velocities remained almost constant, there were fluctuations in Km, which demonstrated that an additional factor affected its behavior. The additional factor was the logarithmic mean temperature difference (LMTD). It was observed that Km behaved inversely proportional to the LMTD.

- It was concluded that by increasing the effective height, Lp, of the modified heat exchanger, the absorption of ammonia vapor could be increased, as the residence time will be increased. In addition, the registered thermodynamic conditions of the dilute ammonia solution were suitable for a better absorption. In order to sustain the previous hypothesis, that, even by increasing the turbulence – that is increasing the mass flow of dilute ammonia solution—the vapor absorption of ammonia remained almost constant, showing a slight decrease at higher Resol values; and this was mainly due to the fact that there was no greater contact area between the ammonia solution and the ammonia vapor.

- A correlation for the Nusselt number governing the absorption of ammonia vapor by the NH3-LiNO3 solution in a PHE-type absorber was proposed at two ranges of Reynolds number.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Notation | Subscripts | ||

| A | Area [m2] | abs | Absorption |

| b | Channel height [m] | AW | Air-Water |

| Cp | Specific heat [J kg−1 K−1] | chann | Channel |

| De | Equivalent diameter [m2] | CW | Cooling Water |

| Dp | Port diameter. [m] | CS | Concentrated solution |

| GC | Mass speed [kg m−2s−1] | DS | Diluted solution |

| H | Enthalpy [kJ kg−1] | eff | Effective |

| h | Heat transfer coefficient [kW m−2K−1] | equi | Equilibrium |

| k | Thermal conductivity [kWm−1 K−1] | exch | Exchange |

| km | Overall mass transfer [kg m−2s−1] | f | Final |

| L | Plate length [m] | G | Gas |

| Lh | Effective width length [m] | Gen | Generation |

| Lv | Effective height length [m] | h | Effective height |

| ṁ | Mass flow rate [kg s−1] | i | Initial |

| Ncp | Passage channel number [dimensionless] | in | Input |

| Nu | Nusselt number [dimensionless] | l | Liquid |

| Pr | Prandtl number [dimensionless] | out | Out |

| Q | Heat transfer rate [kW] | sol | Solution |

| QC | Heat transfer rate transferred to cooling water [kW] | ss | Stainless Steel |

| Rel | Reynolds number [dimensionless] | v | Vapor |

| Sh | Sherwood number [dimensionless] | w | Water |

| T | Temperature [°C] | equi | Equilibrium |

| U | Overall heat transfer coefficient [W m−2K−1] | Greek letters | |

| W | Absorber width [m] | Λ | Spacing between channels [m] |

| x | Ammonia concentration [% by weight] | β | Chevron angle [degree] |

| Δt | Time increment [s] | υ | Kinematic viscosity [m2 s−1] |

| LMCD | Logarithmic mean concentration difference | μ | Dynamic viscosity [kg m−1s−1] |

| LMTD | Logarithmic mean temperature difference | ρ | Density [kg m−3] |

| Superficial enlargement factor [dimensionless] | |||

Appendix A

| Parameter | Nomenclature | Operating Range | Accuracy |

|---|---|---|---|

| Exchange area | Aexc | 0.0504 m2 | ±1.2% |

| Convective Coeficient of solution heat transfer | hSOL | 0.8 a 2.0 kW·m−2·K−1 | ±2.6% |

| Absorption flow | FABS | 0.073 a 0.033 kg·m−2·s−1 | ±1.5% |

| Convective coeficient of mass transfer | Km | 48.9 a 17.5 kg·m−2·s−1 | ±1.8% |

| Equivalent diameter | De | - | ±0.5% |

| Mass velocity in the channel | GC | 40 a 120 kg·m−2·s−1 | ±1.3% |

| Solution viscosity | µsol | (9 a 1)·10−3 kg·m−1·s−1 | ±5.6% |

| logarithmic mean temperature difference | LMTD | 5 to 15 | ±0.7% |

| logarithmic mean concentration difference | LMCD | 2 to 5 | ±0.6% |

| Solution Nussel number | NuSOL | 1.4 to 1.9 | ±2.7% |

| Solution Prandtl number | PrSOL | 15.1 to 2.5 | ±3.1% |

| Solution Reynolds number | ReSOL | 447 to 38 | ±7.5% |

References

- García-Valladares, O.; González, J.C.; Hernández, J.I.; y Brown, R.B. The Evaluation of a Small Capacity Shell and Tube Ammonia Evaporator. Appl. Therm. Eng. 2003, 23, 2151–2167. [Google Scholar] [CrossRef]

- McMullan, J.T. Refrigeration and environment-issues and strategies for the future. Int. J. Refrig. 2002, 25, 89–99. [Google Scholar] [CrossRef]

- Rivero, R. Programas integrales de ahorro de energía (exergía) en la industria petrolera. Revista del IMIQ año XXXVII 1996, 3–4, 26–30. [Google Scholar]

- Summerer, F. Evaluation of absorption cycles with respect to COP and economics. Int. J. Refrig. 1996, 19, 19–24. [Google Scholar] [CrossRef]

- Ayala, R. An Experimental Study of Heat Driven Absorption Cooling System. Ph.D. Thesis, University of Salford, Salford, UK, 1995. [Google Scholar]

- Antonopoulos, K.A.; Rogdakis, E.D. Performance of solar-driven ammonia-lithium nitrate and ammonia—Sodium thiocyanate absorption systems operating as coolers or heat pumps in Athens. Appl. Therm. Eng. 1996, 16, 127–147. [Google Scholar] [CrossRef]

- Sun, D.-W. Comparison of the performances of nh3-h2o, nh3-lino3 and nh3-nascn absorption refrigeration systems. Energy Convers. Manag. 1998, 39, 357–368. [Google Scholar] [CrossRef]

- Cerezo, J.R.; Best, R. Estudio del Proceso de Absorción con Diferentes Fluidos de Trabajo en Intercambiadores de Placas para Equipos de Refrigeración por Absorción; Internal Report, Post PhD; Centro de Investigación en Energía de la UNAM: Temixco, Mexico, 2010. [Google Scholar]

- Lee, K.B.; Chun, B.H.; Lee, J.C.; Lee, C.H.; Kim, S.H. Experimental analysis of bubble mode in a plate-type absorber. Chem. Eng. Sci. 2002, 57, 1923–1929. [Google Scholar] [CrossRef]

- Kang, Y.T.; Nagano, T.; Kashiwagi, T. Visualization of bubble behavior and bubble diameter correlation for nh3–h2o bubble absorption. Int. J. Refrig. 2002, 25, 127–135. [Google Scholar] [CrossRef]

- Kang, Y.T.; Nagano, T.; Kashiwagi, T. Mass transfer correlation of NH3-H2O bubble absortion. Int. J. Refrig. 2002, 25, 878–886. [Google Scholar] [CrossRef]

- Kang, Y.T.; Christensen, R.N. Ammonia-water (NH3-H2O) absorber with a plate heat exchanger. ASHRAE Trans. 1998, 11, 1565–1575. [Google Scholar]

- Cerezo, J.R. Estudio del Proceso de Absorción con Amoniaco Agua en Intercambiadores de Placa para Equipos de Refrigeración por Absorción. Ph.D. Thesis, Universitat Rivira i Virgili, Tarragona, Spain, 2006. [Google Scholar]

- Ayub, Z.H. Plate heat exchanger literature survey and new heat transfer and pressure drop correlations for refrigerant evaporators. Heat Transf. Eng. 2003, 24, 3–16. [Google Scholar] [CrossRef]

- Oronel, C.; Amaris, C.; Bourouis, M.; Vallès, M. Heat and mass transfer in a bubble plate absorber with NH3/LiNO3 and NH3/(LiNO3+H2O) mixtures. Int. J. Therm. Sci. 2013, 63, 105–114. [Google Scholar] [CrossRef]

- Best, R.; Rivera, W. A review of thermal cooling systems. Appl. Therm. Eng. 2014, 75, 1162–1175. [Google Scholar] [CrossRef]

- Libotean, S.; Martín, A.; Salavera, D.; Valles, M.; Esteve, X.; Coronas, A. Densities, viscosities, and heat capacities of ammonia + lithium nitrate and ammonia + lithium nitrate + water solutions between (293.15 and 353.15) k. J. Chem. Eng. Data 2008, 53, 2383–2388. [Google Scholar] [CrossRef]

- Infante Ferreira, C.A. Thermodynamic and physical property data equations for ammonia-lithium nitrate and ammonia-sodium thiocyanate solutions. Sol. Energy 1984, 32, 231–236. [Google Scholar] [CrossRef]

- Conde, M. Thermodynamic Properties of {NH3+ H2O} Mixtures for the Industrial Design of Absorption Refrigeration Equipment. Available online: http://www.mie.uth.gr/ekp_yliko/NH3_H2OProperties_1.pdf (accessed on 16 July 2018).

- Kakaç, S.; Liu, H. Heat Exchangers: Selection, Rating, and Thermal Design, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2002; pp. 373–404. ISBN 0-8493-0902-6. [Google Scholar]

- Wang, L.; Sunden, B.; Manglik, R.M. Plate Heat Exchangers: Design, Applications and Performance, 2nd ed.; WIT Press: Southampton, UK, 2007; ISBN 978-1-85312-737-3. [Google Scholar]

- Cerezo, J.; Bourouis, M.; Vallès, M.; Coronas, A.; Best, R. Experimental study of an ammonia–water bubble absorber using a plate heat exchanger for absorption refrigeration machines. Appl. Therm. Eng. 2009, 29, 1005–1011. [Google Scholar] [CrossRef] [Green Version]

- Kang, Y.T.; Akisawa, A.; Kashiwagi, T. Analytical investigation of two different absorption modes: Falling film and bubble types. Int. J. Refrig. 2000, 23, 430–443. [Google Scholar] [CrossRef]

- Kang, Y.; Kunugi, Y.; Kashiwagi, T. Review of advanced absorption cycles: Performance improvement and temperature lift enhancement. Int. J. Refrig. 2000, 23, 388–401. [Google Scholar] [CrossRef]

- Lee, J.C. A study on numerical simulations and experiments for mass transfer in bubble mode absorber of ammonia and water. Int. J. Refrig. 2003, 26, 551–558. [Google Scholar] [CrossRef]

- Treybal, R.E. Operaciones de Transferencia de Masa, 2nd ed.; McGraw-Hill: Mexico City, Mexico, 1987. [Google Scholar]

- Mejbri, K.; Bellagi, A. Modelling of the thermodynamic properties of water-ammonia mixture by three different approaches. Int. J. Refrig. 2006, 29, 211–218. [Google Scholar] [CrossRef]

- Çengel, Y.A. Heat Transfer a Practical Approach, 2nd ed.; McGraw-Hill: Mexico City, Mexico, 2003. [Google Scholar]

- Incropera, F.P.; DeWitt, D.P. Fundamentals of Heat and Mass Transfer, 5th ed.; John Wiley & Son: Hoboken, NJ, USA, 2002. [Google Scholar]

- Infante Ferreira, C.A. Operating Characteristics of NH3-LiNO3 and NH3-NaSCN Absorption Refrigeration Machines. In Proceedings of the Nineteenth International Congress of Refrigeration, Hague, The Netherlands, 20–25 August 1995; pp. 321–328. [Google Scholar]

- Venegas, M.; Arzoz, D.; Rodriguez, P.; Izquierdo, M. Heat and mass transfer in LiNO3-NH3 spray absorption system. Int. Commun. Heat Mass Transf. 2003, 30, 805–815. [Google Scholar] [CrossRef]

- Zacarías, A.; Venegas, M.; Ventas, R.; Lecuona, A. Experimental assessment of ammonia adiabatic absorption into ammonia–lithium nitrate solution using a flat fan nozzle. Appl. Therm. Eng. 2011, 31, 3569–3579. [Google Scholar] [CrossRef] [Green Version]

- Jiang, J.; He, G.; Liu, Y.; Liu, Y.; Cai, D. Flow boiling heat transfer characteristics and pressure drop of ammonia-lithium nitrate solution in a smooth horizontal tube. Int. J. Heat Mass Transf. 2017, 108, 220–231. [Google Scholar] [CrossRef]

- Jiang, J.; Liu, Y.; He, G.; Liu, Y.L.; Cai, D. Experimental investigations and an updated correlation of flow boiling heat transfer coefficients for ammonia/lithium nitrate mixture in horizontal tubes. Int. J. Heat Mass Transf. 2017, 112, 224–235. [Google Scholar] [CrossRef]

- Palacios, E.; Izquierdo, M.; Marcos, J.D.; Lizarte, R. Evaluation of mass absorption in LiBr flat-fan sheets. Appl. Energy 2009, 86, 2574–2582. [Google Scholar] [CrossRef]

| Parameter | Dimension |

|---|---|

| Spacing between channels, Λ [mm] | 6 |

| Inter-plate channel height, b [mm] | 2.18 |

| Effective width length, Lh [mm] | 77 |

| Pattern length, Lp [mm] | 275 |

| Effective height length, Lv [mm] | 280 |

| Inside width between gaskets edges Lw [mm] | 82 |

| Port diameter, Dp [mm] | 25 |

| Number of passes, Np | 1 |

| Chevron angle, β [degree] | 30 |

| Sensor | Device | Operating Range | Accuracy |

|---|---|---|---|

| Temperature | RTD | −180 a 520 °C | ±0.2 °C |

| Mass flow | Coriolis | 0 a 5 kg·min−1 | ±0.1% |

| Density | Coriolis | 700 a 1200 kg·m−3 | ±0.1% |

| Pressure | piezoelectric | 0 a 10 bar | ±0.15% |

| Mass flow | Turbine | 0 a 30 kg·min−1 | ±0.2% |

| Parameter | Resol | hsol [kW m−2K−1] | Km·10−5 [m s−1] | Method | Solution |

|---|---|---|---|---|---|

| Oronel et al. [15] | 10–70 | 2.5–8.0 | 16.7–38.9 | Experimental bubble mode absorption | NH3-LiNO3 |

| Cerezo et al. [22] | 170–370 | 2.7–5.4 | 100–200 | Experimental bubble mode absorption | NH3-H2O |

| Infante Ferreira [30] | 0.115 | Experimental falling film | NH3-LiNO3 | ||

| Venegas et al. [31] | 10–250 | 5.8 | 18.6 | Numerical spray absorption | NH3-LiNO3 |

| Zacarias et al. [32] | 6–17 | 34–101 | Experimental spray flat fan | NH3-LiNO3 | |

| Jiang J.A. et al. [33] | 300–950 | 0.97–1.95 | -- | Experimental flow boiling in smooth horizontal tubes | NH3-LiNO3 |

| Jiang J.A. et al. [34] | 300–950 | 0.95–1.95 | -- | Experimental flow boiling in horizontal tubes | NH3-LiNO3 |

| Palacios E. et al. [35] | 30 | Experimental spray flat fan | H2O-LiBr | ||

| This work | 20–450 | 0.96–3.00 | 820–1500 | Experimental bubble mode absorption | NH3-LiNO3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chan, J.J.; Best, R.; Cerezo, J.; Barrera, M.A.; Lezama, F.R. Experimental Study of a Bubble Mode Absorption with an Inner Vapor Distributor in a Plate Heat Exchanger-Type Absorber with NH3-LiNO3. Energies 2018, 11, 2137. https://doi.org/10.3390/en11082137

Chan JJ, Best R, Cerezo J, Barrera MA, Lezama FR. Experimental Study of a Bubble Mode Absorption with an Inner Vapor Distributor in a Plate Heat Exchanger-Type Absorber with NH3-LiNO3. Energies. 2018; 11(8):2137. https://doi.org/10.3390/en11082137

Chicago/Turabian StyleChan, Jorge J., Roberto Best, Jesús Cerezo, Mario A. Barrera, and Francisco R. Lezama. 2018. "Experimental Study of a Bubble Mode Absorption with an Inner Vapor Distributor in a Plate Heat Exchanger-Type Absorber with NH3-LiNO3" Energies 11, no. 8: 2137. https://doi.org/10.3390/en11082137