Abstract

Annually, coal-fired power plants in Vietnam discharge hundreds of thousand tons of coal ash. Most of this ash goes into the environment without treatment or any plan for the efficient reuse of this precious resource. There are many reasons for this, such as poor quality of the ash, no suitable and feasible ash treatment technology, a lack of awareness about environmental pollution and resource saving, and inappropriate sanctions and policies. This study analyzed and summarized information and data pertaining to the current status of the production, discharge, and utilization of coal ash from the Cao Ngan Power Plant (CNPP) in Thai Nguyen Province, Vietnam. In addition, the potential for applying advanced emission reduction technologies in order to recycle coal ash for cement production, as well as geographical, socio-economic, and market factors were assessed. This paper reveals the results of a preliminary assessment of carbon-mineralization technologies which seek to achieve the following three goals: (1) effectively disposing of coal ash to protect the environment and local community, (2) contributing to the nationally determined effort to mitigate greenhouse gas emissions which cause climate change, and (3) making value-added products and bringing economic benefits to a sustainable society.

1. Introduction

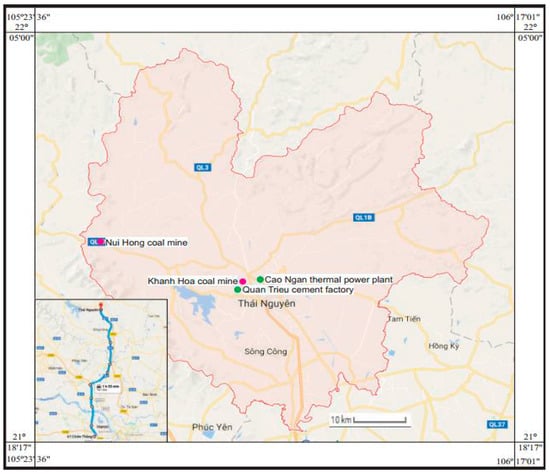

Thai Nguyen province in Vietnam is a political and economic center in the northeastern midland and mountainous region of the country. It occupies an area of 3562.82 km2. It is also a gateway for socio-economic exchanges between the northeastern midland and the mountainous regions with the Red River delta. Thai Nguyen Province is bordered by Bac Kan province to the north, Vinh Phuc and Tuyen Quang provinces to the west, Lang Son and Bac Giang provinces to the southeast, and Hanoi to the south. Thai Nguyen province is approximately 80 km away from the center of Hanoi. The location of the study area is shown in Figure 1. Thai Nguyen province is characterized by mountainous terrain formed by Limestone Mountains and hills, and interspersed with low fields. The terrain of Thai Nguyen province slopes downwards in the north-south direction, in line with the direction of the Cau River. Mountainous areas at altitudes exceeding 100 m account for two thirds of the province, while the altitude of the remaining area is less than 100 m. The highest point in the Tam Dao Mountain Range stands at about 1590 m.

Figure 1.

Location of the study area.

The Cao Ngan Power Plant has a total area of 13 hectares, located on the relatively flat terrain in Quan Trieu ward, Thai Nguyen City, occupying the old location of the Thai Nguyen power plant. The activities of the Cao Ngan Power Plant and the two main coal mines (i.e., the Khanh Hoa mine in Phuc Ha and An Khanh communes and the Nui Hong coal mine in the Yen Lang commune, which supply raw materials to the power plant) have changed the city’s natural geomorphology, especially with the appearance of ash mountains and artificial ash-heaps with heights from tens of meters to more than 250 m. The slag of the Cao Ngan Power Plant is gathered at a waste dump site with a total area of about 3.4 ha, tens of meters in height and approximately 6 km from the plant. The Khanh Hoa mine’s ash not only accounts for 50% of the Phuc Ha commune’s surface, but also occupies a remarkable area of the An Khanh commune. It has reached a height of over 250 m (Figure 2), buried some pathways, and presents a high risk of sliding which threatens surrounding residential areas within a radius of 50–100 m [1].

Figure 2.

Disposal site of Khanh Hoa coal mine has reached 250 m in height and significantly altered provincial geomorphology.

Coal Deposits

Geologically, Thai Nguyen province is located in three tectonic zones, Lo Gam, Hien River, and An Chau, which are filled by Cambrian to Quaternary formations of sedimentary and magmatic rock. Carbonate rock is distributed widely in the province, constituting the major components of the Mo Dong, Than Sa, Na Mo, Phu Ngu, Cau River, Pia Phuong, Mia Le, Na Quan, Bac Son, Dong Dang, Na Khuat, and the Ha Coi formations, with ages from the Cambrian to the Jurassic. The thickness of these formations varies from at least 300 m to more than 1000 m. The petrological composition includes conglomerate materials, sandstone, siltstone, and limestone interbedded with clay and clayey limestone. Particularly in the Na Quan, Bac Son, and Dong Dang formations, the major component is limestone which meets quality requirements for cement production, with one example being the La Hien limestone quarry. In some places, limestone was dolomitized at a good quality level, for example in the La Giang, La Hien, and Vo Nhai areas [2]. Coal deposits are distributed in the Van Tri Late-Triassic formation, which is mainly composed of conglomerate, sandy siltstone interbedded with clay shale, and coal shale. In addition, some anthracite and lignite seams are interbedded in the shale and siltstone of the Van Lang formation (Table 1 and Table 2) [2].

Table 1.

Properties of Nui Hong coal.

Table 2.

Quality of Khanh Hoa commercial coal.

Thai Nguyen province is considered to have the second largest coal reserves in Vietnam, including anthracite and lignite, which are distributed in Dai Tu and Phu Luong districts. The potential of lignite exceeds 15 million tons, of which the explored reserves are about 8.5 million tons. The lignite is of good quality and is located in the Phan Me, Cam village, and Am Hon mines. The total explored reserves of anthracite are nearly 90 million tons, and are located in the Ba Son, Khanh Hoa, and Nui Hong mines. The Khanh Hoa and Nui Hong coal mines are currently the main sources of feedstock for the Cao Ngan Power Plant.

2. Socio-Economic Characteristics

According to the statistical yearbook of Thai Nguyen in 2015, the province has a population of 1,233,019, with a density of 320 people/km2. Some areas have greater concentrations of administrative units and greater population densities, such as the downtown area of Thai Nguyen City and the Dai Tu, Phu Binh, and Pho Yen districts. Meanwhile, other areas with low population densities are the Vo Nhai, Dinh Hoa, and Dong Hy districts. Similar to the entire country, Thai Nguyen has a young population, with 855,468 people in the working age range (15–60 years), accounting for 69.38% of the total population. Those under 15 number 273,360, accounting for 22.17% of the total population, and 104,190 people are over 60 years old, accounting for 8.45% [3].

Thai Nguyen province’s economic structure has shifted towards increasing the contributed proportion of the industry-construction and service sectors, and reducing the contribution of the agriculture and forestry sectors to Gross domestic product (GDP). In 2016, industry and construction comprised 41.77%, services accounted for 36.95%, and agriculture, forestry, and fisheries accounted for 21.28%. Thai Nguyen’s average annual economic growth is estimated to be 13.1%, which is 7.28% higher than the national average. According to a recent report on socio-economic development in 2016, and the direction and tasks with regard to socio-economic development in 2017 for Thai Nguyen, the local GDP growth rate is 15.2%, and the GDP per capita is 2235 USD as of 2016 [4].

Apart from fast-growing production in the electronics, telecom, and mineral processing industries, traditional industrial products such as iron and steel, electricity, and commercial electricity for manufacturing purposes also contributed considerably to the annual industrial production value of the province, which exceeded the plan in all regions and economic sectors. In 2016, the Cao Ngan Power Plant exceeded their plan as well. In particular, electricity for production reached 1.610 million kWh (Kilo Watt Hour), increasing by 79.1%, and commercial electricity reached 3.980 million kWh, increasing by 55.5% when compared to those rates from the same period in 2015, equivalent to 123.9% of the plan. According to a report by the Vietnam Chamber of Commerce and Industry (VCCI), Thai Nguyen is considered to be one of the provinces with the highest level of infrastructure quality in Vietnam as of 2016 [5].

Recently, Thai Nguyen has focused on the development of technical infrastructure and industrial zones. This is a task, a purpose, and a platform to attract investors for the urban and socio-economic development of the province. Regarding the transport infrastructure, several important projects which have had a great impact on the economic development of the province include: (1) the New National Highway No. 3 (Hanoi-Thai Nguyen), (2) upgrading and renovation of the old National Highway No. 3 (Thai Nguyen-Cho Moi, Bac Kan), and (3) the completion of roads and urban areas under the urban development project of Thai Nguyen city. These works have been creating a highly connected transport system between Thai Nguyen province and Hanoi city and other northern areas and provinces.

With regard to the infrastructure for industrial parks, there are currently six industrial parks in the province, with a total area of 1420 hectares. Among them, four have been put into operation, attracting 170 projects including 85 foreign investment projects, as well as 85 domestic investment projects, with total registered capital exceeding 7 billion USD and 12,800 billion VND. Projects by the Samsung group and other businesses are prominent examples. In the industrial zones, transportation, electricity, clean water systems, waste water treatment systems, security, and fire protection represent investments which have operated steadily. Most of the planned industrial zones are located along the new Highway No. 3 between Hanoi and Thai Nguyen (e.g., the Yen Binh and Diem Thuy industrial zones), on the old National Highway No. 3 (e.g., the Nam Pho Yen, Cong River I and Cong River II industrial zones), and on provincial roads, to ensure connections between socio-economic systems inside and outside of the industrial zone [6].

2.1. Cao Ngan Factory’s Operation and Status of Wastes’ Treatment

2.1.1. Overview of Cao Ngan Power Plant

The Cao Ngan Power Plant was built in Thai Nguyen, and has a capacity of 100 MWs (Mega Watts), an annual output of 600 million kWhs (Kilo Watt Hours), and a total investment amount of USD 123.9 million [7]. Construction started on the plant in November of 2002, and from February of 2006 it started operation and became connected to the national power network [8]. The Cao Ngan Power Plant Company, Vinacomin, formerly known as the Cao Ngan Power Plant Company, or National Coal and Mineral Industries Group (TKV), is a subsidiary company of the Vinacomin Electricity Corporation (belonging to the Vietnam National Coal Group). This company was established by Decision No. 171/QD-BCN by the Ministry of Industry on 24 October 2003 [9]. It is responsible for helping Vinacomin to manage and supply electricity.

Raw materials supplied to the Cao Ngan Power Plant are mainly from the Khanh Hoa and Nui Hong coal mines [10]. The Khanh Hoa mine is located in the Phuc Ha commune in Thai Nguyen city and the An Khanh commune in Dai Tu district, whereas the Nui Hong coal mine belongs to the Yen Lang commune in Dai Tu district. In order to supply coal to the Cao Ngan Power Plant, the Nui Hong Coal Company has built a 2.7 km-long conveyor belt from the Khanh Hoa coal mine through Quan Trieu and Tan Long Ward, which terminates at the Cao Ngan Power Plant. The Cao Ngan factory is responsible for consuming coal from the Khanh Hoa and Nui Hong mines, while ensuring electricity security for six northern border provinces [11].

2.1.2. The Technology of the Cao Ngan Power Plant

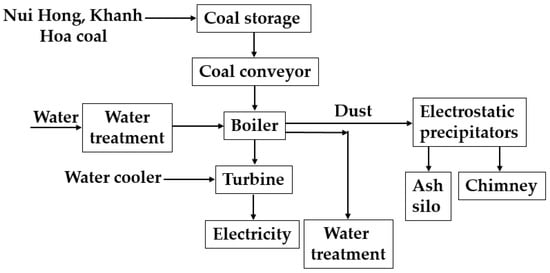

The Cao Ngan Power Plant consumes about 500,000 tons of coal each year from the Khanh Hoa and Nui Hong coal mines. These are two coal seams of low quality (grade 6b), containing a considerable amount of sulfur. This is also why the Cao Ngan Power Plant uses circulating fluidized bed combustion (CFB) technology [12], which uses limestone to desulfurize while operating. It is similar to other coal-powered power plants of the Vietnam National Coal Group, such as the Na Duong, Cam Pha, Son Dong and Mao Khe plants. The Cao Ngan Power Plant has a capacity of 115 MW (Mega Watt) (equivalent to 700 million kWh (Kilo Watt Hour) per year). A technology flow chart and the waste generation plan are shown in Figure 3.

Figure 3.

Technology flow chart and waste generation.

Coal exploited from the Nui Hong and Khanh Hoa coal mines is transported by the conveyor system through a pre-grinding mill, and then placed in a hopper, before being incinerated through the coal feeders. The coal flows into a heat-generating furnace, which transmits heat to a steam generator. Here, the heat generated by the coal-burning turbine generates electricity, and the electric current then is led to a step-up transformer, from which it is supplied to the national power grid. Burning coal disperses fly ash and bottom ash, which are blown down through funnels to silos, and then transported to the Quan Trieu Cement Factory, an unbaked brick factory, and landfills.

2.2. Current Status of Ash Management and Disposal in Thai Nguyen Province

2.2.1. Coal Mine Ashes (Residues)

Presently, several open coal mines in Thai Nguyen have discharged hundreds of millions of cubic meters of waste rocks into the designated dumping grounds. These coal mine ash dumps are hundreds of meters in height and use hundreds of hectares of land. In the rainy season, subsidence and landslide are common in most ash dumps with heights exceeding 50 m. For example, a sliding volume of about 1.5 million cubic meters occurred from an elevation of 140 m down to 55–60 m at waste yard No. 3 at the Phan Me coal mine in Thai Nguyen at the end of March of 2012. On 15 April 2012, another sliding mass, which moved a distance of 150–200 m horizontally in just 12 h, caused the death of five workers and buried ten houses (Figure 4). These accidents occurred because the height of the ashes heap in each case exceeded the allowed height for stability, with the supporting ground composed of weakly mixed clay as well [13].

Figure 4.

Heavy rains in April 2012 caused landslide at slag heap of Phan Me coal mine, killing 5 people and burying 10 houses.

Ash dumps not only present a high level of risk of erosion, but also occupy very large land areas, which gradually encroach on to other land uses. Since 2008, the People’s Committee of Thai Nguyen province has assigned more than 18 ha of farmland in the An Khanh commune to the Khanh Hoa Coal Company to build slag dumps. In 2013, this company also took 29 hectares of farmland for the dumping of slag, including a road next to the mine [14]. As a result, slag disposal here has been a subject of protest by local people.

The ash dumps of the Khanh Hoa Coal Company not only cause environmental pollution, but also create ash mountains higher than 250 m, putting the local community at a high risk of a landslide at any time. The dumping site of the Khanh Hoa Coal Company in the Phuc Ha Commune occupies nearly 3 km2, accounting for nearly 50% of the total area of 6.48 km2 of the commune. According to Vietnamese regulations, the height of the disposal site must be less than 190 m; however, in the southern part of the dumping ground, some heaps exceed 250 m, and resemble artificial mountains (Figure 5). Moreover, the distance from a house to the dumping site must be more than 200 m, but many houses are less than 50 m away [15].

Figure 5.

The slag heap of Khanh Hoa coal company, with a protest signboard by local people regarding a dispute with agricultural land and roads (photo taken in August 2017) [14].

2.2.2. Discharged Coal Ash and Slag from Cao Ngan Power Plant

The Cao Ngan Power Plant (TPP) uses circulating fluidized-bed (CFB) technology to match the coal quality of two abovementioned mines. However, this also represents a major challenge for the company, as the coal ash is not of sufficient quality to produce construction materials. The slag discharged by the Cao Ngan Power Plant amounts to nearly 200,000 tons per year. Coal ash and slag associated with circulating fluidized-bed technology have different features and mineralogical compositions from those from coal-fired spraying technology. When using circulating fluidized-bed technology to eliminate sulfur in the form of sulfur dioxide (SO2) released via coal combustion, it can be made to react with an adsorbent (limestone) to form gypsum. Free lime (CaO) also exists in ash and slag. The main components of ash in the circulating fluidized-bed technology include the following [16,17]:

- Fly ash: Fly ash is one of the types of waste discharged by coal combustion. This is a fine powder which remains after the burning of coal in a power plant. Fly ash is a non-combustible, inorganic material in coal which forms a crystalline substance after combustion. Fly ash solidifies when suspended in the emission, and is then recovered from an electrostatic dust filter system. Because fly ash hardens while floating in the emission, it generally has a globular shape, with diameters ranging from 0.5 μm to 100 μm. The composition of fly ash is predominantly silica (SiO2), aluminum oxide (Al2O3) and iron oxide (Fe2O3). Fly ash is an important material for producing compacted concrete, high-value lightweight brick, and special additives. The leaching results of fly ash are presented in Table 3 [18].

Table 3. Leaching results of fly ash samples taken in fly ash silo.

Table 3. Leaching results of fly ash samples taken in fly ash silo. - Bottom ash: Bottom ash is coarser than fly ash. It is an unburned component which remains and becomes concentrated at the bottom of the furnace. Its particle size ranges from 0.125 to 2 mm. It is often used instead of sand in the production of non-baked construction materials (bricks and tile), as well as in roadbed construction and to fill in swamp land. The leaching results of bottom ash are presented in Table 4 [18].

Table 4. Leaching results of bottom ash samples taken in bottom ash silo.

Table 4. Leaching results of bottom ash samples taken in bottom ash silo. - Gypsum: This material is derived from desulfurization in the exhaust gas, which is done to prevent air pollution. Gypsum can be collected separately if the desulphurization system is installed outside the kiln. Vinacomin’s CFB kilns do not have off-kiln systems, meaning that gypsum is normally mixed in with the ash [16,17].

During the period from 2013 to the present, the annual amount of coal ash released from Vinacomin’s five coal-fired power plants which run at full capacity has been estimated to be 2.8 million tonnes per year (of which 1.7 million tonnes is bottom ash) [17]. For the Cao Ngan power plant in particular, ash amounts to nearly 200,000 tonnes per year. Yearly, out of the abovementioned ash volume of the Cao Ngan Power Plant, about 120,000 tons of fly ash are supplied to the Quan Trieu Cement Plant and the ATK Thai Nguyen Adobe Material Company) as input materials. The remaining 80,000 tonnes of bottom ash is abundant for recycling, because the ignition loss of Cao Ngan ash is very high (about 18%) [12]. In addition, there are significant amounts of lime in bottom ash. Therefore, this ash cannot be used for cement production or for the production of aggregated bricks. This has also led to many problems for the Cao Ngan plant, such as environmental pollution, the requirement of waste disposal sites, and additional waste treatment costs. At present, the Cao Ngan Power Plant is still seeking solutions for the recycling of ash, especially bottom ash for construction materials.

2.3. Treatment of Ash Slag at Quan Trieu Cement Factory

The construction of the Quan Trieu Cement Factory, part of the Vinacomin Coal and Minerals Group, has been completed; the plant officially came into operation in September of 2011. By successfully signing a contract to supply cement products for the construction of a Samsung Electronics Plant in Thai Nguyen province and maintaining the stable consumption of cement in traditional markets, the production for the first six months of 2018 year of the Quan Trieu Cement Joint Stock Company (based in An Khanh commune, Dai Tu district) increased sharply compared to that of the same period in 2016 [19]. Specifically, the production and consumption of cement and clinkers exceeded 334 thousand tonnes (an increase of 16.5% compared with the same period in 2016), and revenue reached nearly 276 billion VND (increasing by 19.4%). The contribution to the state budget is more than 10 billion VND (increasing by 69%). The company maintains jobs for more than 400 employees, with an average income of 5.8 million VND per person per month [19,20]. At present, the company is specialized in producing and distributing cement and clinker products in Thai Nguyen province and in other neighboring provinces, as well as receiving ash slag from the Cao Ngan Power Plant as raw input materials.

The company possesses an abundant source of limestone and coal from seam No. 16 of the Khanh Hoa coal mine near the factory. In addition, the Quan Trieu cement factory also receives ash slag, which is discharged directly from the Cao Ngan Power Plant. Therefore, the costs of mining, transportation, and production are minimal. This is a convenient point for the Quan Trieu Cement factory in their effort to retain competitive prices. The average selling price of Quan Trieu factory’s cement in 2014 was lower than that of Nghi Son, Vicem Hoang Thach, or Vicem Bim Son cement by 150,000–200,000 VND/ton. The two main products of the Quan Trieu cement factory are PCB30 and PCB40 cement, both meeting the TCVN (National Standards of Vietnam) 6260: 2009 Vietnam standards [20,21,22]. These products help increase the ductility of concrete and mortar and the waterproofing capacity, anti-corrosion, and durability over time, which are suitable for the climate in Vietnam.

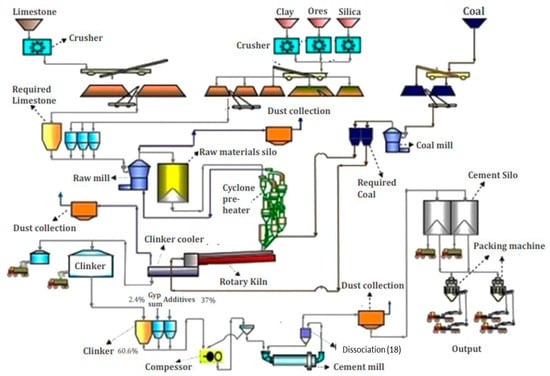

Cement products are characterized by high fineness, a blue gray color, a setting time of 120–170 min, consolidation in 3–4 h, and high stability. For these reasons, they are suitable for works using dismantled planks and quickly poured molds, with improved efficiency, and are especially superior for industrial and civil construction, transportation, and irrigation [20,21,22]. The company’s products are present in most Northern provinces, such as Lao Cai, Cao Bang, Lang Son, Bac Ninh, Bac Giang, and especially Hanoi. Among them, Thai Nguyen, Hanoi, and Bac Giang provinces are three largest cement markets, accounting for 76% of total consumption. Another advantage is favorable transportation for the Quan Trieu cement factory. The export of Quan Trieu’s cement accounts for only 0.17% (667.22 tons of cement), indicating that the company’s cement mainly serves the domestic market, though they are currently moving towards overseas markets. Regarding clinkers, exports amounted to 91.32% (218,993.83 tons), indicating that the main markets are overseas, with the domestic market only accounting for less than 10% [20,22]. For better visualization of the cement production technology used at the factory, the process with the input material of ash slag from the Cao Ngan factory is depicted in Figure 6.

Figure 6.

Cement production process at Quan Trieu cement factory [20,22].

According to the factory’s financial report, raw material and fuel are the two most costly factors affecting the production cost and product price. In detail, the material costs account for 32% of the product value, while fuel cost accounts for 28%. Secondly, the operation cost accounts for 17%, and salaries account for 12% [22]. In order to reduce the product price, the company can focus on technological innovations and the reuse of recycled materials. This also helps the company to reduce both the quantities of raw materials used, and fuel costs. Specifically, when applying green and clean low-carbon technologies, the company will have more opportunities to access the government’s favorable policies. This will optimize the profitability of the production and consumption processes.

3. Status of Recycling Coal Slag in Vietnam

3.1. The Situation of Coal Ash in Vietnam

Currently, there exist 20 coal-fired power plants in operation, with a total capacity of nearly 14,500 MW, generating approximately 15.7 million tons of coal slag per year, of which coal ash amounts to 75%. It is predicted that by 2020, there will be 43 factories generating more than 30 million tons of coal slag per year. However, most of these factories only have a license of five years to access dump sites, and slag is mostly buried. Therefore, at present, there are no suitable solutions with which to deal with this large amount of slag. In order to contain this amount of waste, 600,000 hectares of land will be needed; in other words, every four years, the land area of an average commune in Vietnam will be consumed. Meanwhile, the ability to recycle slag from coal-fired power plants is very limited. This causes many environmental problems, and increases land use requirements for waste disposal sites and treatment costs. Therefore, at present, the recycling of slag from coal-fired power plants is an urgent matter in Vietnam [6].

According to certain calculations, in order to have a capacity of 36,000 MWs by 2020, power plants (PPs) will need 67 million tons of coal/year; to generate a capacity of 75,000 MWs by 2030, power plants will need 171 million tons coal/year. The amount of slag accounts for 25% to 60% of coal fuel, depending on coal quality and combustion efficiency [6].

Principally, ash may be used as an additive for cement production, concrete, unbaked bricks, and other construction materials. Generally, this type of ash contains a considerable amount of char, possibly as high as 20% to 30%. Therefore, to reuse ash, it is necessary to separate out residual coal through a separation process. Thus, the company must invest in a system which separates coal from ash. At present, technology for separating residual coal from ash slag is not widely available, making its reuse very limited. Vietnam is facing environmental problems caused by the development of coal-fired power plants. By 2030, it is necessary to manage many slag dumps with a total area of more than 28 thousand hectares (a two-meter depth assumed), distributed throughout the country in the form of large electric centers in the northern and central areas and the Mekong Delta of Vietnam [6].

3.2. Environmental Issues in the Surrounding Area of the Cao Ngan Power Plant

Environmental protection activities must comply with Vietnamese environmental regulations, which require the control of the water- and air-borne pollutants, and the maximization of natural resources. Therefore, the company has used low-quality coal from the Khanh Hoa and Nui Hong mines as input materials for production. The factory, including two engine units with a total capacity of 100 MWs, is using circulating fluidized bed combustion technology, which can accept low-calorific coal. The heating chamber has a low temperature of 800–950 °C, with internal desulphurization accomplished through the use of limestone. This limits the emission of NOx. Although the coal used in the factory has a high sulfur content (1–3 wt%), the designed engine system uses limestone for internal desulphurization; therefore, the emission of SOx is limited (i.e., the SOx concentration is below the allowable limit). The process of dust filtration uses an electrostatic precipitator—one of the most advanced dust-processing technologies—with a dust removal efficiency of 99.9%, so that the amount of dust released into the atmosphere is minimal. These systems are maintained frequently throughout the production process [18].

During the operation of the Cao Ngan Power Plant, some pollutants, such as noise, dust, wastewater, and solid waste, all generated by the production and transportation of materials, can affect the surrounding environment and health of the staff in the plant, as well as local people around the plant. Below are some assessments of the environmental conditions of the Cao Ngan Power Plant. The impacts of dust and noise generated during the production, transport, and grinding of materials such as coal and limestone, on the surrounding environment were assessed based on an analysis of air samples inside the plant and in surrounding areas, as presented in Table 5 and Table 6 [18].

Table 5.

Analytical results of the air environment around the Cao Ngan Power Plant in 2016.

Table 6.

Analytical results of the air environment inside the Cao Ngan Power Plant in 2016.

It is important to assess the amount of wastewater generated during the production process, which requires water to cool the system, as well as water in the form of steam, which is condensed after being supplied to the circulatory boiling system. The recharge source of water is the Cau River. Before using it for production activities, it passes through a standard water-treatment process. Post-production water is discharged at two mouths of the factory’s operation system. Analytical results of wastewater samples which were collected at the two discharge mouths are presented in Table 7 [18].

Table 7.

Analytical results of wastewater at production sites No. 1 and 2.

However, ash disposal sites still present a high risk of environmental pollution. Survey results show that soil and water around ash dumps in many parts of the country are severely affected, with very high levels of toxic substances such as heavy metals.

3.3. Overview of Solutions for Treating and Recycling Coal Ash of Power Plants

In addition, advanced technologies such as the integrated gasification combined cycle (IGCC) and pressurized fluidized bed combustion (PFBC) will allow increases of 50% in efficiency rates in the future, meaning less emissions per kWh from newer plants compared to older plants [22]. Ultra-clean coal (UCC) technology with new processing solutions will reduce fly ash to below 0.25%, and sulfur to a very low level [23], meaning that ground coal can be used as fuel instead of heavy oil for large-sized navigation engines. However, this leads to several problems related to the waste generated by UCC. Therefore, a gasification process using steam and oxygen to transform coal into carbon monoxide and hydrogen have also been studied and applied.

One of the other potential solutions is toward recycling technologies and the efficient use of ash slag. The use of ash has a history dating back before the previous millennium. From ancient times, the Romans knew how to use volcanic ash and limestone to construct buildings with additives such as milk, blood and animal fat. Many of those buildings have existed for thousands of years. For example, a Roman gate was built in year 236 BC from volcanic ash and limestone, and it still stands today. The use of ash from power plants in construction replicates the technology used in the abovementioned works [24]. In developed countries, which typically have stringent environmental regulations, many electricity companies are often linked to cement companies, to use all of the coal ash slag discharged from a power plant. As a result, there is usually a cement factory near a power plant. The Quan Trieu Cement Plant is situated near the Cao Ngan Power Plant. This factory is also an investment of Vinacomin.

In Vietnam, the government has recognized that the development of coal-fired power plants is an optimal solution to the current situation. Because the cost of operating coal-fired power plants is lower than the generation of other sources of electricity (e.g., hydroelectricity, gas, oil, and renewable energy), and considering that the raw materials for coal-fired power plants are also more abundant, these factors help Vietnamese companies reduce their production costs. In contrast, the development of coal-fired power plants causes numerous environmental problems due to a large amount of waste generated (i.e., solid, water and gas types). However, this problem can be solved, and the cost of treating waste made more affordable considering the current technological potential in Vietnam in cooperation with other countries around the world.

The goal of the Vietnamese government is to recycle at least 60% of ash released from power plants for building materials by 2020. Recently, Decision No. 452/QD-TTg of the Prime Minister, dated 12 April 2017, approved a project which accelerates the treatment and reuse of ash slag and gypsum from power plants and fertilizer chemical factories as raw materials for construction [17]. This decision also states that the recycling of ash slag as a material for the production of building materials and in construction works must be aimed at protecting the environment, and reducing both the use of dump areas and mineral resources for building materials, to ensure sustainable development.

Recently in Vietnam, ash slag from power plants using circulating fluidized bed combustion technology with desulphurization has become a subject of research. Until the end of 2015, the Cao Ngan factory delivered nearly 32,000 tons of fly ash for the testing of cement production at the Quan Trieu Cement Plant. The average monthly amount was around 6500 to 7000 tons (particularly, the amounts of fly ash used in May, June, July, August, September, and October were 1886 tons, 7155 tons, 5857 tons, 3047 tons, 6882 tons, and 6262 tons, respectively. However, the remaining 80 tons of bottom ash from the Cao Ngan Power Plant were not reused for any purpose. It is a difficult mission to determine a field in which the bottom ash could be used, as the loss on ignition (LOI) of Cao Ngan power plant’s ash slag is very high (about 18%). In addition, there is a considerable amount of lime in bottom ash. Hence, it cannot be used for the production of cement or aggregated brick. At present ATK’s bricks consist of 80% grit and 20% fly ash from the Cao Ngan power plant.

Annually, the plant consumes about 500,000 tons of coal. Accordingly, if it saves 1%, the equivalent amount is 5000 tons of coal. In addition, coal prices are more than 1 million VND per ton, meaning that they will save 5 billion VND each year. However, it is difficult to find a way to save money, because the nature of this depends on the following three factors: the quality of the input coal, the operation mode, and the electricity supply. Therefore, it is very important for coal power plants to conduct research and to implement modern technologies which utilize circulating fluidized bed combustion technology to create useful products from fly ash and bottom ash.

4. Carbon Mineralization Technology as a Solution

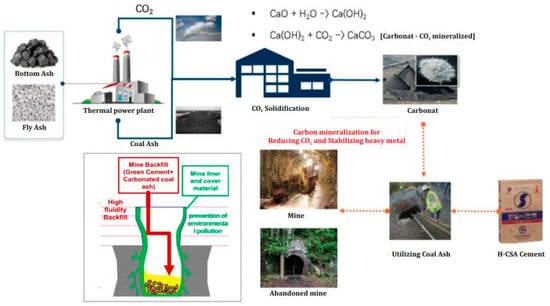

4.1. Carbon Mineralization Technology Utilizing Coal Ash of Power Plant to Produce Green Cement

Concrete is a widely used building material with significant impacts of greenhouse gas, mainly due to cement production. Fortunately, the cement industries around the world and in Vietnam are already familiar with the use of additional cementitious materials, such as ash slag, to reduce the cement content in concrete.

In general, the concrete industry is actively developing and testing new additional cement materials to meet the demand for clean and durable concrete products. The strategies outlined in the specific module of the climate-friendly purchasing toolkit will allow government buyers to reduce the specific greenhouse gas impact associated with procurement. With the aim of mitigating climate change, researchers from the Korea Institute of Geosciences and Mineral Science (KIGAM) and the Korea Hanil Company have collaborated in the research and production of H-CSA (calcium sulfoaluminate). The production of H-CSA releases low amounts of CO2, and H-CSA cement has properties superior to those of Portland cement. Therefore, H-CSA is a special type of cement that is used in many applications, especially in places where high durability and rapid setting are required, such as bridge floors, airport runways, patchwork, and tunnels.

Concrete made from H-CSA instead of ordinary Portland cement (OPC) can achieve compression strengths in excess of 5000 psi after only 24 h. Compared to Portland cement, CSA cement will achieve the same hardness after 24 h, while Portland cement will take up 28 days to fully solidify [25]. This is the main reason why H-CSA is used instead of OPC for specific applications. Rapid fixation is essential in the case of the construction of an airport runway or the repair of a damaged bridge or highway that must be fixed rapidly. Portland cement is burned in a kiln at about 1500 °C (2700 °F), while H-CSA cement only requires combustion at approximately 1250 °C (2250 °F). The obtained H-CSA clinkers will be softer than the OPC clinkers; therefore, the process requires less power during grinding.

4.2. Reduction of CO2 Emissions

Chemical conversion from limestone to calcium oxide releases approximately 48% of all CO2 emissions generated during the production of OPC. The burning of fossil fuels to achieve high temperatures inside the kiln accounts for another 42% of total CO2 emissions [26]. Thus, nearly 90% of total CO2 emissions are directly related to the conversion of limestone into cement. In contrast, the production of one ton of H-CSA cement only emits 216 kg CO2, approximately 62% less than that associated with OPC. This reduction is much more effective than the use of pozzolan-based industrial waste types [27,28,29,30], such as fly ash and steel-furnace slag, to replace OPC with a typical ratio of about 10–30% of the total used amount of Portland cement. Concrete made entirely of 100% H-CSA cement will contribute to environmental protection, also known as “green cement”. CO2 emissions using H-CSA cement is two to six times less than that of OPC, which already has a significant amount of green “pozzolan” replacement by fly ash and slag. In fact, H-CSA cement has the lowest CO2 emission rates among nine different types of cement, including magnesia (Sorel cement), sodium metasilicate (liquid glass), and calcium aluminate cement.

This material has been used in many different contexts, such as the construction of bridge floors and airport runways, as noted above, and the repair of roads and sidewalks, where it is necessary to use high-grade and rapid-fixation cement. In addition, H-CSA cement is sometimes used in shrinkage-compensated concrete by mixing it with Portland cement and adding certain controlled-low-strength materials (CLSM), which are used for underground pits. Other industrial by-products have higher alumina contents than coal bottom ash. However, coal bottom ash is used because other industrial by-products are not suitable for CSA production. The chemical composition of CSA is presented in Table 8. Korea does not have bauxite as the source of alumina for CSA production, and therefore, must use industrial by-products instead for CSA production. The chemical composition of OPC and CSA cements are presented in Table 8.

Table 8.

Chemical composition of OPC and CSA cement.

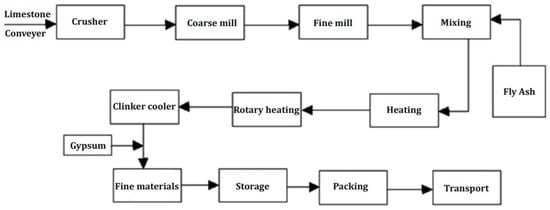

The process of producing CSA cement from coal bottom ash is shown in Figure 7.

Figure 7.

The process of CSA (calcium sulfoaluminate) cement production.

4.3. Applications of Green Concrete in Korea

Conceptually, green cement is a mixture of 10% H-CSA and 90% Portland cement. Green cement was developed to increase the range of applications in the construction industry at a price equal to that of Portland cement. Green concrete is a mixture of green cement mixed with carbonate and bottom ash, which is formed by carbon mineralization. Mixing carbonate additives into the concrete mixture will increase the grade of the concrete by treating it with supercritical carbon dioxide (SCF). Carbon dioxide (CO2) penetrates deeply into the concrete mixture and reacts with calcium hydroxide [Ca(OH)2] formed by hydrated cement adhesives, to form calcium carbonate. This process not only increases the loading capacity of the concrete, but also increases the waterproofing capacity, making the concrete more durable; this is a useful application of carbon dioxide. This is also the case when lime is used as a binder. Green concrete is usually used as a bed liner in underground pits. Some applications of green concrete are shown in Figure 8.

Figure 8.

Applications of green concrete. H-CSA—Hydrated Calcium Sulfo Aluminate.

Green concrete is an excellent option to recycle CO2 and bottom ash emitted by power plants, and it can be used in the construction, especially underground tunnels. This solution, if proven feasible and practical, will also be an integrated, multi-purpose arrow, complementing the supply of clean building materials and other specific purposes. It is well-suited to the natural and economic characteristics of the region, contributing to the treatment of coal ash from power plants which cause environmental pollution in Vietnam, as well as to the storage and recycling of greenhouse gases such as CO2, in order to mitigate the impacts of climate change. In addition, it will create sustainable livelihoods for local people. This is in line with the Vietnamese government’s orientation through Decision No. 1696/QD-TTg, dated 23 September 2014 [31], regarding solutions for the treatment of ash, slag, and gypsum from coal power and chemical fertilizer plants to produce building materials. It also matches the commitment of the Vietnamese government at COP 21 (Conference of Parties (countries) 21), with Intended Nationally Determined Contributions (INDC) to reduce greenhouse gas emissions by 8% as part of the normal development schedule, and by 25% if effective international support is received. Therefore, this technology has been proposed as a pilot model for the development of green materials in the study area associated with the current research.

4.4. Quantification on the Amount of Reducible CO2 when Applying the Technology (Reduction of CO2 Emission in CSA (Calcium Sulfo Aluminate) Cement Production)

The best method for lucrative finance and sustainable development in the cement industry is the use of industrial by-products and waste for production. This strategy not only reduces costs, but also contributes significantly to the reduction in CO2 emissions per ton of cement produced.

Industrial additives used for the production of H-CSA cement are gypsum and fly ash. Gypsum can be used as one component of calcium sulfate cement (CSA) to ensure lower temperatures. Fly ash is a by-product of coal combustion which arises during the process of generating energy. It is a very fine ash formed by inorganic particles after the carbon constituent of coal is burned. Fly ash undergoes a pozzolanic reaction with alkali activators such as calcium hydroxide, which is released during cement hydration, to form cementitious compounds. Today, it is a standard component in most types of cement and concrete in varying quantities. The addition of fly ash to cement allows a reduction of the total carbon dioxide emission per ton of cement produced. It is estimated that the production of Portland cement accounts for about 8% of global CO2 emissions.

The major benefit of green cement technology is that it is environmentally friendly, and can thus reduce the impact of climate change. At present, Vietnamese scientists and managers are looking for solutions for large-scale slag treatment in power plants. During the H-CSA cement production process, fly ash has an advantage in that it can be used as a substitute for clay in cement, thus reducing the quantity of natural resources which must be used. Hence, the investment cost will be significantly reduced for raw material purchases, as well as for finding new mines. Green concrete allows waste, as well as bottom ash from power plants, to be recycled, and it can reduce the cost of waste treatment systems in factories. Economically, recycling one ton of fly ash would cost about 40 US dollars. If sold at a price close to the price of cement (because fly ash is also a type of adhesive), the economic effect can be seen clearly. In addition, if we take into account other factors such as environmental improvement and the saving of land area for slag dumps, the economic efficiency would be enormous.

5. Conclusions

In the field of recycling slag ash for a cement plant, when producing one ton of cement, one ton of carbon dioxide is also released, meaning that the amount of fly ash replacing cement in concrete is identical to the amount of emissions that we can reduce. Therefore, it is necessary to study the possibility of applying co-operative capacities, as committed to by Vietnam at COP 21 in Paris, to seek opportunities for investments in coal ash treatments from developed countries when they wish to exchange greenhouse gas emission rights with Vietnam.

The use of ash, slag, Flue-gas desulfurization (FGD) gypsum, and phospho-gypsum (PG) gypsum as input material for the production of building materials and in construction works for the purpose of environmental protection, the conservation of land areas, and the recycling of mineral resources for the production of building materials must be done to ensure sustainable development. It must be made a priority to use ash, slag, FGD, and PG gypsum, which meet the standards, technical regulations, and technical guidelines for raw materials for construction materials and buildings (civil housing, industrial constructions, transportation, agriculture, rural development, and mine redevelopment).

- The benefits of green cement technology are that it is environment friendly and reduces the impact of climate change.

- In H-CSA cement production, fly ash has the advantage that it can be used as a substitute for clay in cement; therefore, this reduces the amount of natural resources to be used. Hence, investment costs will be significantly reduced for raw material purchase, as well as for finding new mines.

- Green concrete can recycle waste, as well as the bottom ash from power plants, and save on the costs of waste treatment systems in factories.

- Economically, recycling one ton of fly ash would cost about 40 US dollars. If sold at a price close to the price of cement (because fly ash is also a type of adhesive), the economic effect can be seen clearly.

With regard to CSA cement production technology from ash, as described above, it is clear that this is a technology that can be used in Vietnam, and that it requires additional feasibility studies and trial production tests.

Author Contributions

T.H.S., H.H.H., D.T.N.T., N.T.T.T., L.Q.T., D.T.T.T., D.T.N.H. collected all the information from various places in several months and submit the prefeasibility report to Korea Institute of Geoscience and Mineral Resources (KIGAM). T.T., R.C. analyzed the data and wrote the manuscript. T.T.V. and N.T.M.N. (Head/Team Leader of the prefeasibility research in Vietnam, in charge of synthesizing data & information collected in Cao Ngan), and J.W.A. corrected the final manuscript and agreed to submit this data to Energies journal.

Acknowledgments

This research was supported by the National Strategic Project-Carbon Upcycling of the National Research Foundation of Korea (NRF) funded by the Ministry of Science and ICT (MSIT), the Ministry of Environment (ME) and the Ministry of Trade, Industry and Energy (MOTIE), grant number 2017M3D8A2084752.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Thinh, D.; Nguyen, T. Nearly Half of Phuc Ha Commune Is Dumping Ground. People’s Army Newspaper. Available online: http://www.qdnd.vn/phong-su-dieu-tra/dieu-tra/thai-nguyen-gan-mot-nua-dien-tich-xa-phuc-ha-la-bai-do-thai-than-492349 (accessed on 11 November 2016).

- Ha-Duong, M.; Truong, A.H.; Nguyen, N.; Anh, H.; Nguyen, T. Synthesis Report on Socio-Environmental Impacts of Coal and Coal-Fired Power Plants in Vietnam; Clean Energy and Sustainable Development Lab Report; Clean Energy and Sustainable Development Lab: Hanoi, Vietnam, 30 June 2016. [Google Scholar]

- La, N.H. Achievement of Social-Economic Development, Thai Nguyen Statistical Year Book 2015; Vietnam Statistical Publishing House: Thai Nguyen, Vietnam, 2016. [Google Scholar]

- Thai Nguyen People’s Committee. Report No. 272/BC-UBND on Current Performance of Socio-Economic Development Tasks in 2016, Directions and Tasks of Socio-Economic Development in 2017 in Thai Nguyen Province. Available online: http://festivaltra.thainguyen.gov.vn/wps/wcm/connect/a7e8ad004f8f4fc38286da184ade83b3/bc+272.pdf?MOD=AJPERES&CACHEID=a7e8ad004f8f4fc38286da184ade83b3 (accessed on 18 November 2016).

- Malesky, E.; Dau, T.A.; Pham, T.N.; Nguyen, L.N.; Le, H.T.; Nguyen, H.T.T.; Nguyen, H.L.; Nguyen, V.H. Provincial competitiveness indicator (PCI) of Vietnam in 2016. Annu. Rep. Vietnam Chamb. Commer. Ind. (VCCI) 2016, 1–160. [Google Scholar]

- Thai Nguyen People’s Committee. PCI 2016 Infrastructure: Confirm the Effort of Thai Nguyen. 2017. Available online: http://moc.gov.vn/en/web/guest/trang-chi-tiet/-/tin-chi-tiet/Z2jG/299847/306486/xu-ly-triet-de-tro-xi-cua-cac-nha-may-nhiet-dien-chay-than.html (accessed on 7 January 2016).

- Machines and Industrial Equipment Corporation. Thai Nguyen Power Plant. Ministry of Industry and Trade. 2014. Available online: http://mie.com.vn/du-an/nha-may-nhiet-dien–cao -ngan-thai-nguyen/135.html (accessed on 2 June 2017).

- Institute of Building Materials, Ministry of Construction. National Standards TCVN 6260: 2009 on Portland Blended Cement—Specifications, 2009. Academy of Managers for Construction and Cities, Ministry of Construction. Available online: http://amc.edu.vn/vi/co-so-du-lieu-/tieu-chuan-quy-chuan/766-vat-lieu-xay-dung/3093-tcvn-6260-2009-xi-mang-pooc-lang-hon-hop-yeu-cau-ky-thuat (accessed on 17 April 2009).

- Huyen, N.T. Cao Ngan Power Plant: 10 Years-a Development Stage. In Thainguyen Adm. Commer. Ind. News.; 2013. Available online: http://congthuong thain guyen.gov.vn/en/news--events/cao-ngan-power-plant-10-years-%E2%80%93-a-development-stage-3801.phtml (accessed on 4 November 2013).

- Nga, T. Cao Ngan Power: 8 Years to Find a Way to Consume Coal Ash. Ministry of Construction’s Electronic Newspaper. 2015. Available online: http://www.baoxaydung.comvn/news/vn/vat-lieu/nhiet-dien-cao-ngan-8-nam-tim-duong-tieu-thu-tro-xi.html (accessed on 17 April 2009).

- Phuong, H. Cao Ngan Power Plant Builds an Unburned Brick Production Line to Handle Ash in Production. Vietnam Environmental Administration Online Newspaper. 2011. Available online: http://tapchimoitruong.vn/pages/article.aspx?item=Nhi%E1%BB%87t-%C4%91i%E1%BB%87n-Cao-Ng%E1%BA%A1n-x%C3%A2y-d%E1%BB%B1ng-d%C3%A2y-chuy%E1%BB%81n-s%E1%BA%A3n-xu%E1%BA%A5t-g%E1%BA%A1ch-kh%C3%B4ng-nung-%C4%91%E1%%BB%83-x%E1%BB%AD-l%C3%BD-tro-x%E1%BB%89-trong-s%E1%BA%A3n-xu%E1%BA%A5t-40239 (accessed on 12 December 2011).

- Thao, N.D. Development strategy and the application of circulating fluidized bed combustion in power generation projects of Vietnam National Coal Corporation (VINACOAL). Electr. Supply Ind. Transit. Issues Prospect Asia 2004, 14-16, 16-24–16-34. [Google Scholar]

- Luu, T.V.; Do, T.N.; Le, T.X. Causes Distortion of Open Pit Mine Discharge and Recommend Some Solutions to Ensure Stability. Institute of Mining Science and Technology, VINACOMIN. 2012. Available online: http://imsat.vn/admin/uploads/5499-Bai%2010.doc (accessed on 20 October 2012).

- Luc, D. Nearly 1000 Police Keep Order the People Oppose Coal Mining in Thai Nguyen Province. Family and Social Newspaper. 2017. Available online: http://giadinh.net.vn/xa-hoi/thai-nguyen-gan-1000-canh-sat-giu-trat-tu-khu-vuc-dan-phan-doi-khai-thac-than-20170824215314193.htm (accessed on 24 August 2017).

- Thao, D. The Impacts of Mineral Exploitation on the Environment and People in Thai Nguyen, Case Study: Khanh Hoa Coal Mine, Thai Nguyen, Viet Nam. Vietnam Resilience System Web Site. 2013. Available online: https://vietnam.resiliencesystem.org/impacts-mineral-exploitation-environment-and-people-thai-nguyen (accessed on 29 November 2013).

- Dinh, V.Q. Output for Ash Slag for Power Plant. Cam Pha Power Joint Stock Company. 2012. Available online: http://www.nhietdiencampha.com.vn/tin-tuc/Dau-ra-cho-tro-xi-thai-nha-may-nhiet-dien.html (accessed on 17 July 2012).

- Dinh, V.Q. Output for Ash Slag for Power Plant. Vietnam National Coal-Mineral Industries Holding Corporation Limited Web Site. 2012. Available online: http://www.vinacomin.vn/tap-chi-than-khoang-san/dau-ra-cho-tro-xi-thai-nha-may-nhiet-dien-2201.htm (accessed on 17 July 2012).

- Nguyen, G.T. Report on Environmental Monitoring in 2016 of Thai Nguyen Province; Centre of Environmental Resources Monitoring, Department of Thai Nguyen Natural Resources and Environment: Thai Nguyen, Vietnam, 30 December 2016; pp. 1–50. [Google Scholar]

- Quynh, T. Quan Trieu Cement: Business Targets Increased Sharply in the First Half of 2015. Vietnam Cement Association Online Newspaper. 2015. Available online: http://ximang.vn/doanh-nghiep/thanh-tuu/xi-mang-quan-trieu-cac-chi-tieu-sxkd-tang-manh-nua-dau-nam-2015-7460.htm (accessed on 10 July 2015).

- Trung, T.D. Practical Report of Cement Joint Stock Company. 2015. Available online: https://www.slideshare.net/tranductrungpl1/thc-tp-trn-c-trung-2 (accessed on 10 July 2015).

- Bao, Q.B.; Vu, A.T.P.; Tung, M.T.; Hien, D.L. Tentative to use wastes from the power plants for construction building materials. IOP Conf. Ser. Earth Environ. Sci. 2014, 143, 1–6. [Google Scholar]

- Global CCS Institute. Clean Coal Technologies, Carbon Capture and Sequestration, Updated Information, September 2017. Available online: http://www.world-nuclear.org/information-library/energy-and-the-environment/clean-coal-technologies.aspx (accessed on 12 September 2017).

- Rubiera, F.; Arenillas, A.; Arias, B.; Pis, J.J.; Suárez-Ruiz, I.; Steel, K.M.; Patrick, J.W. Combustion behaviour of ultra clean coal obtained by chemical demineralization. Fuel 2003, 82, 2145–2151. [Google Scholar] [CrossRef]

- Quoc, P.H.D. Analysis on the Utilization of Coal Ash from Power Plant in Vietnam; Institute of Industrial Sciences, University of Tokyo: Tokyo, Japan, 2017; Available online: http://www.nsl.hcmus.edu.vn/greenstone/collect/hnkhbk/archives/HASH015b/16fa54b7.dir/doc.pdf (accessed on 14 February 2017).

- Paria, S.; Yuet, P.K. Solidification—Stabilization of organic and inorganic contaminants using Portland cement: A literature review. Environ. Rev. 2006, 14, 217–255. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production. Earth Syst. Sci. Data 2018, 10, 195–217. [Google Scholar] [CrossRef]

- Williams, M.; Ortega, J.M.; Sanchez, I.; Cabeza, M.; Climent, M.A. Nondestructive study of the microstructural effects of sodium and magnesium sulphate attack on mortars containing silica fume using impedance spectroscopy. Appl. Sci. 2017, 7, 648. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sanchez, I.; Climent, M.A. Impedance spectroscopy study of the effect of environmental conditions in the microstructure development of OPC and slag cement mortars. Arch. Civ. Mech. Eng. 2015, 15, 569–583. [Google Scholar] [CrossRef]

- Joshaghani, A.; Balapour, M.; Ramezanianpour, A.A. Effect of controlled environmental conditions on mechanical microstructural and durability properties of cement mortar. Constr. Build. Mater. 2018, 164, 134–149. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Malhotra, V.M. Effect of curing on the compressive strength, resistance to chloride ion penetration and porosity of concretes incorporating slag, fly ash or silica fume. Cem. Concr. Comps. 1995, 17, 125–133. [Google Scholar] [CrossRef]

- Decision No. 1696/QD-TTg Dated 23/09/2014 of the Prime Minister on Some Solutions to Treat ash, Slag, Gypsum of Power Plants, Chemical Fertilizer Plants Raw Materials for Construction Materials. Law Library Online. Available online: https://thuvienphapluat.vn/van-ban/Van-hoa-Xa-hoi/Quyet-dinh-1696-QD-TTg-phe-duyet-Chuong-trinh-hanh-dong-quoc-gia-ve-binh-dang-gioi-2016-2020-292378.aspx (accessed on 23 September 2014).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).