The Influence of Operating Parameters on Adsorption/Desorption Characteristics and Performance of the Fluidised Desiccant Cooler

Abstract

:1. Introduction

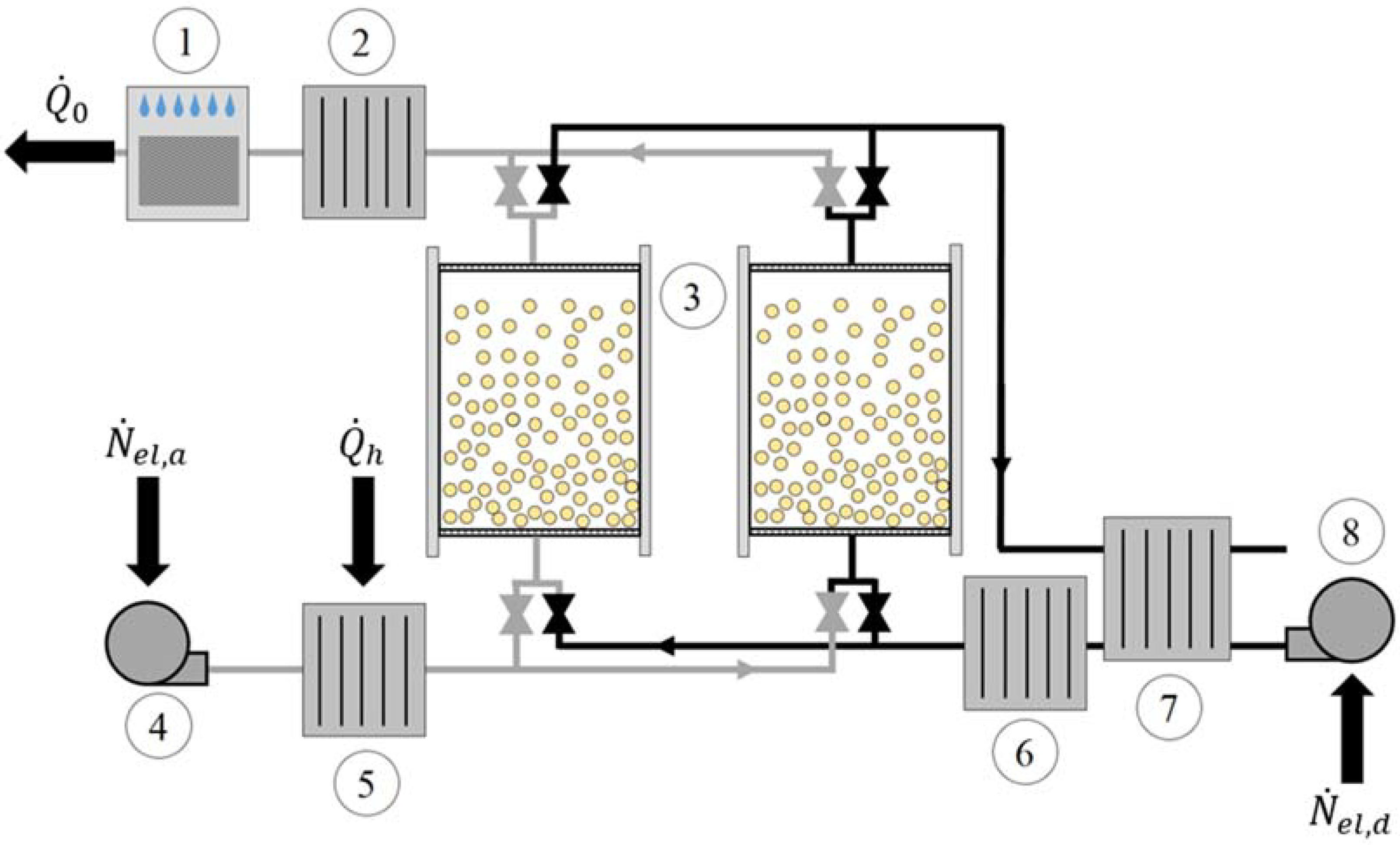

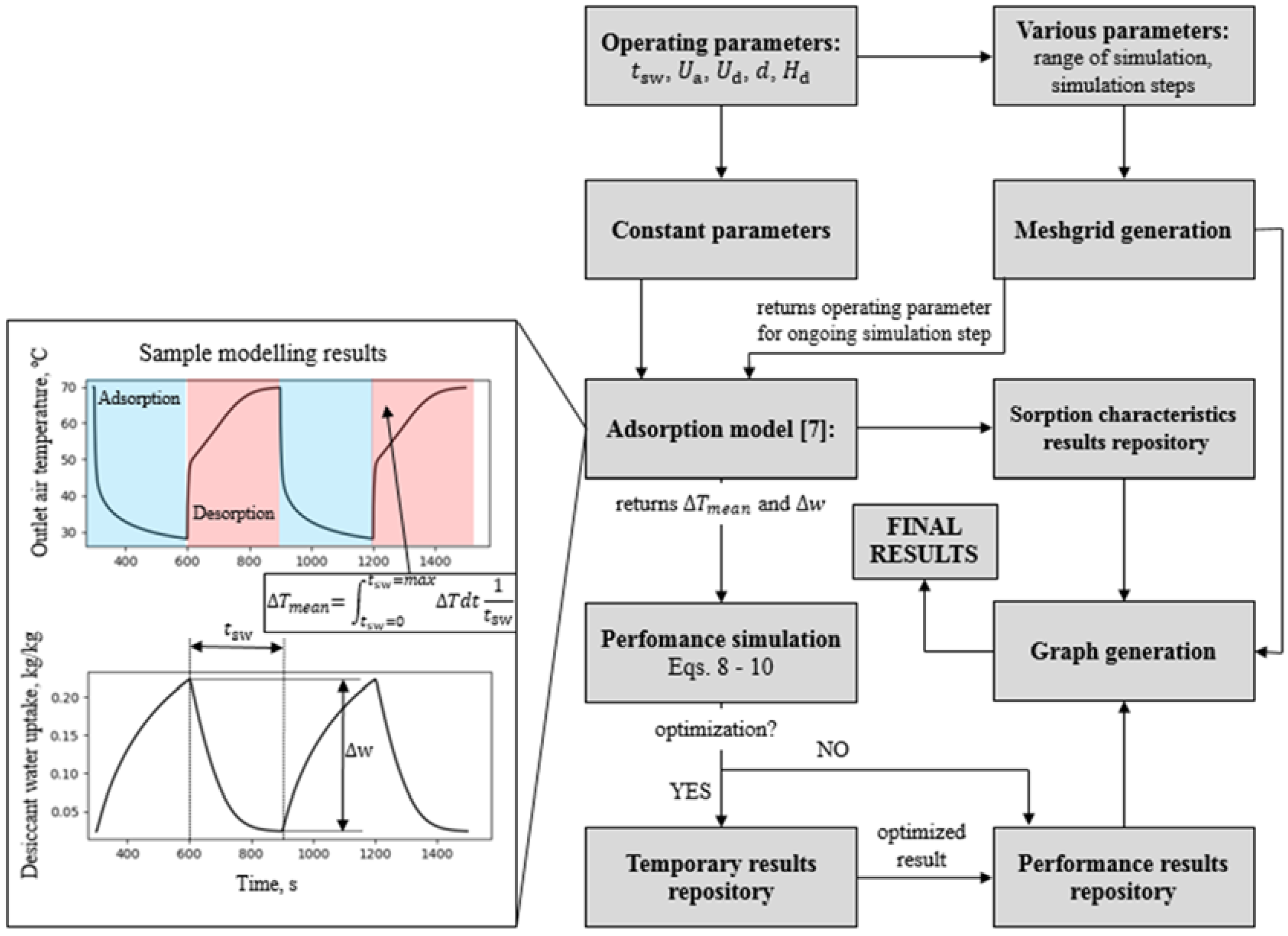

2. Modelling

3. Results and Discussion

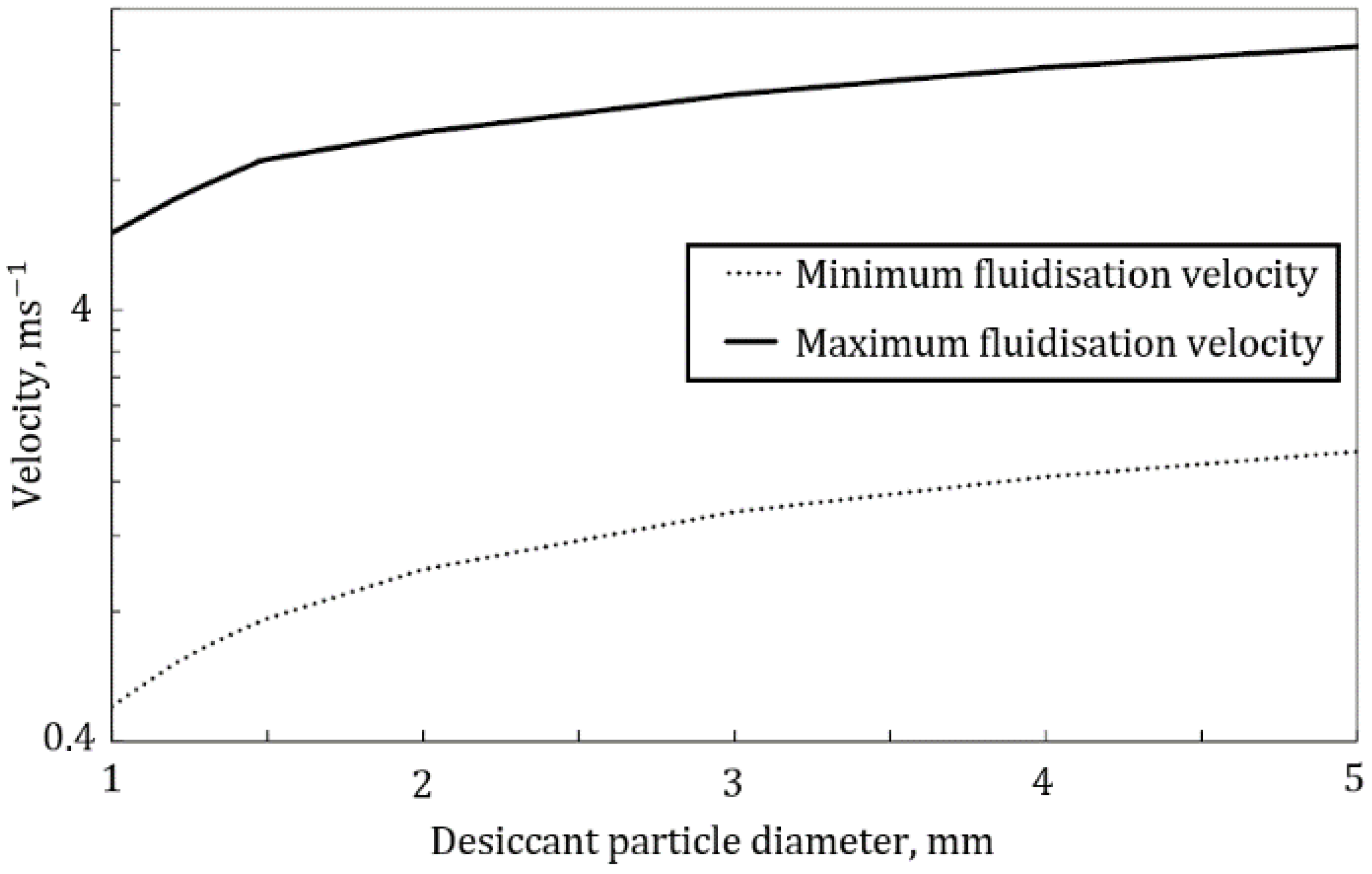

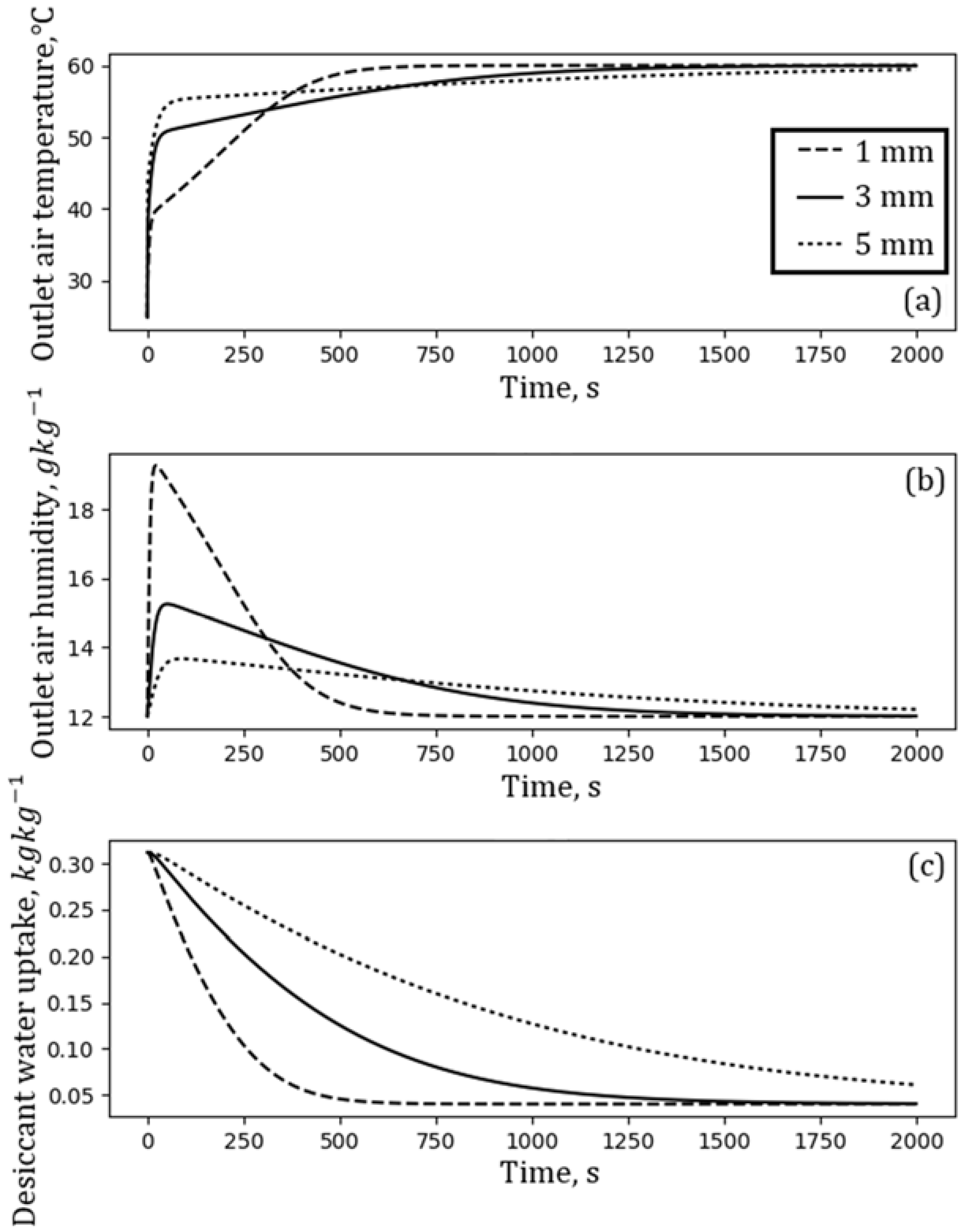

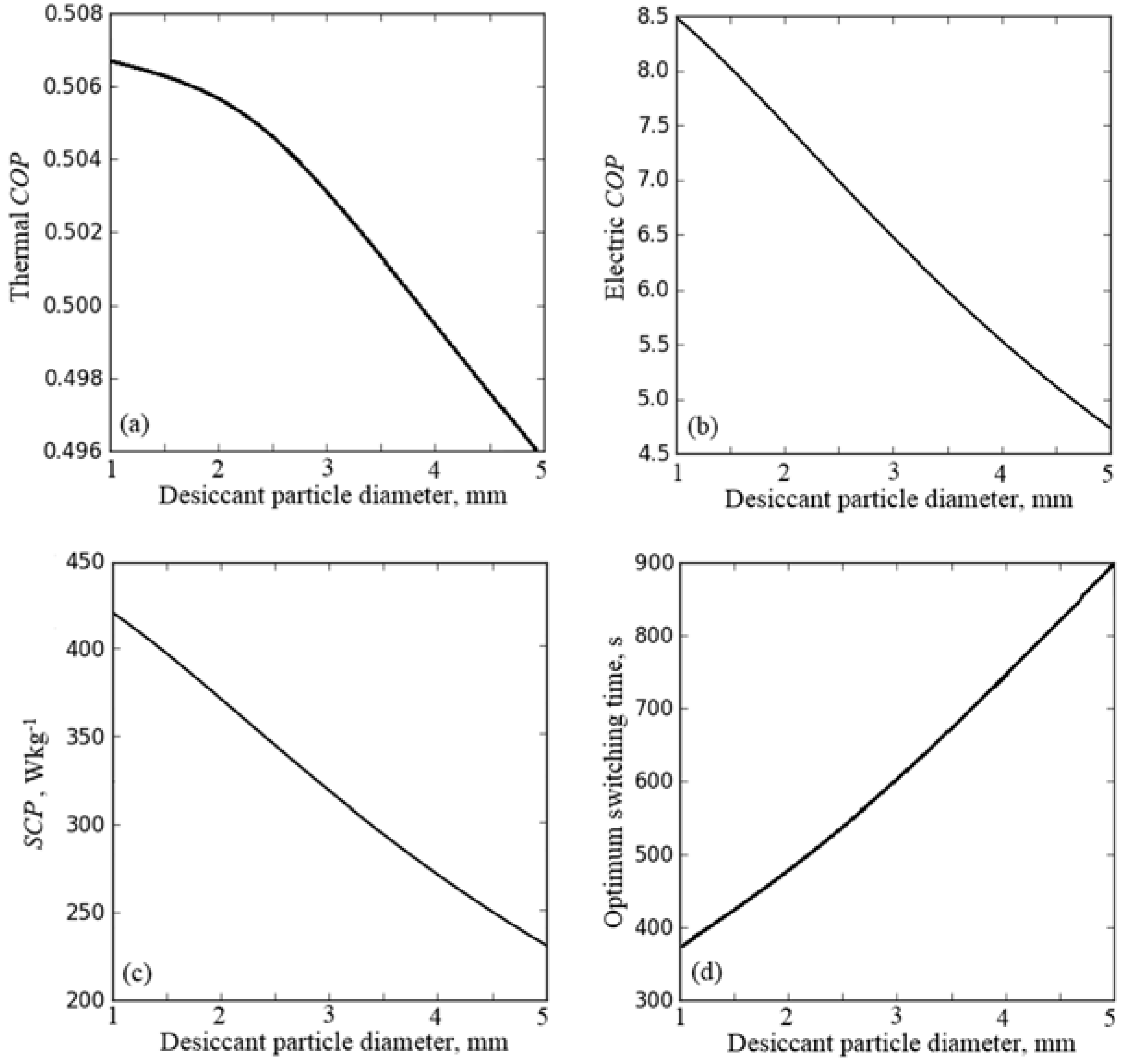

3.1. The Effect of Desiccant Particle Diameter

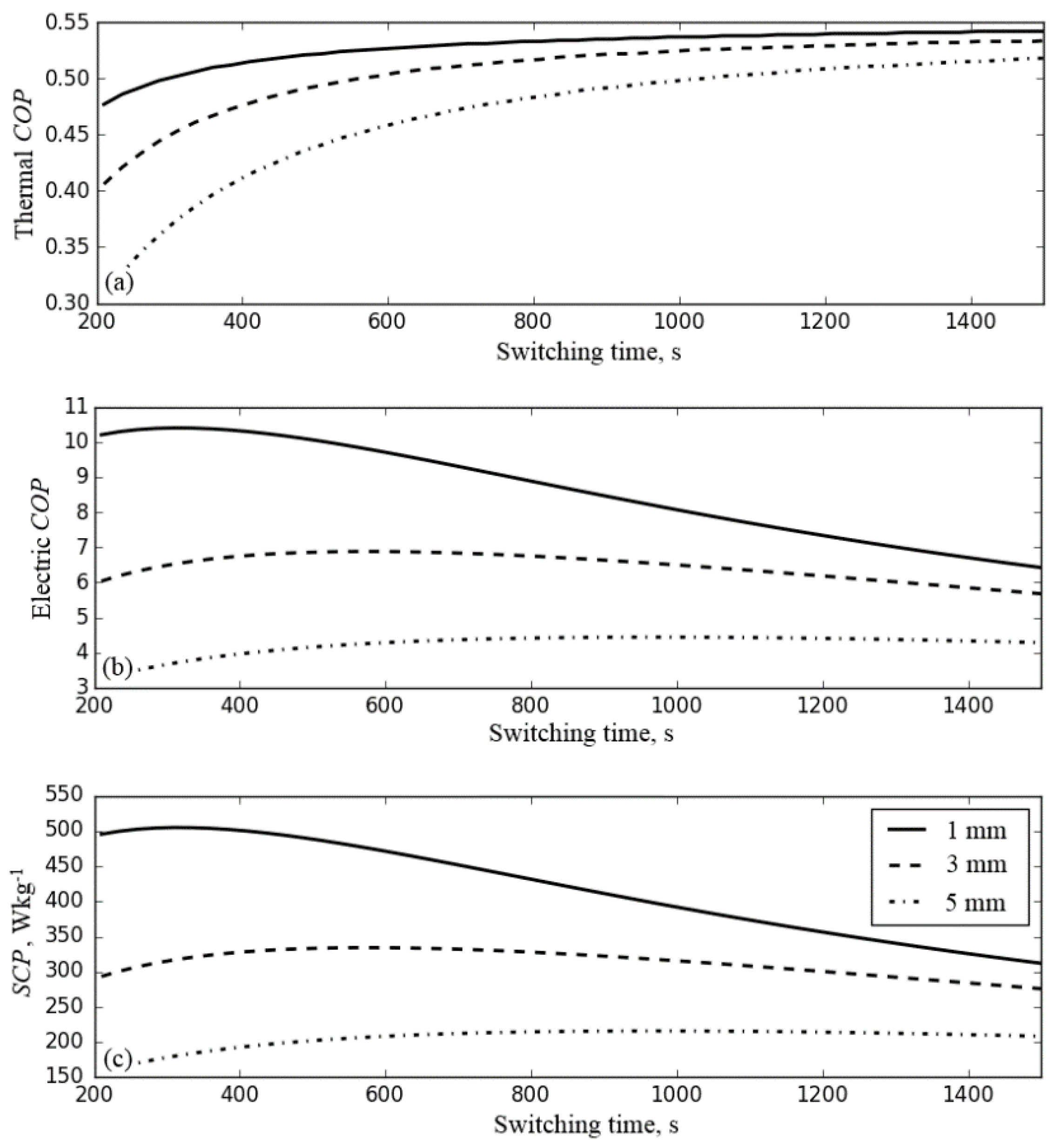

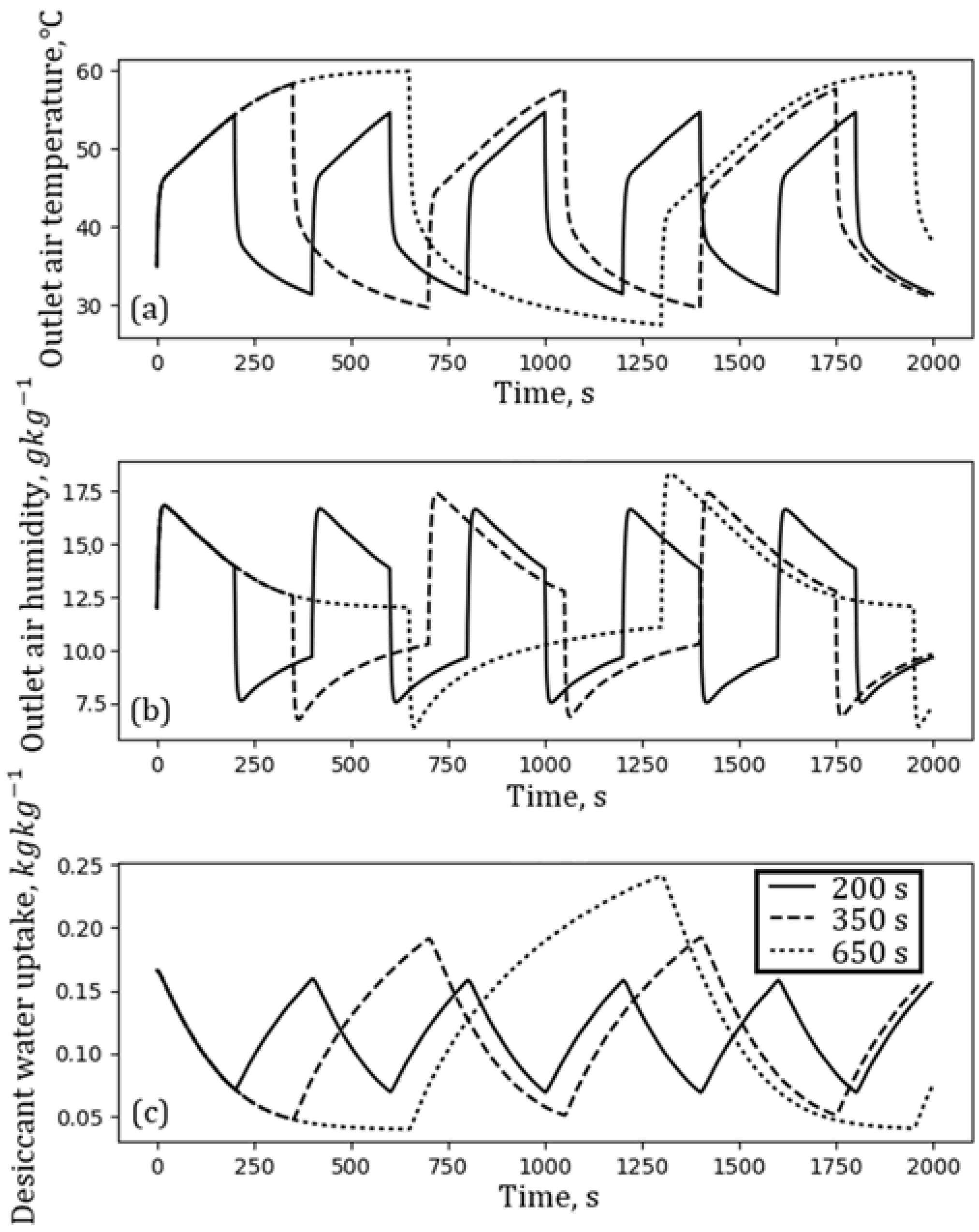

3.2. The Effect of Switching Time

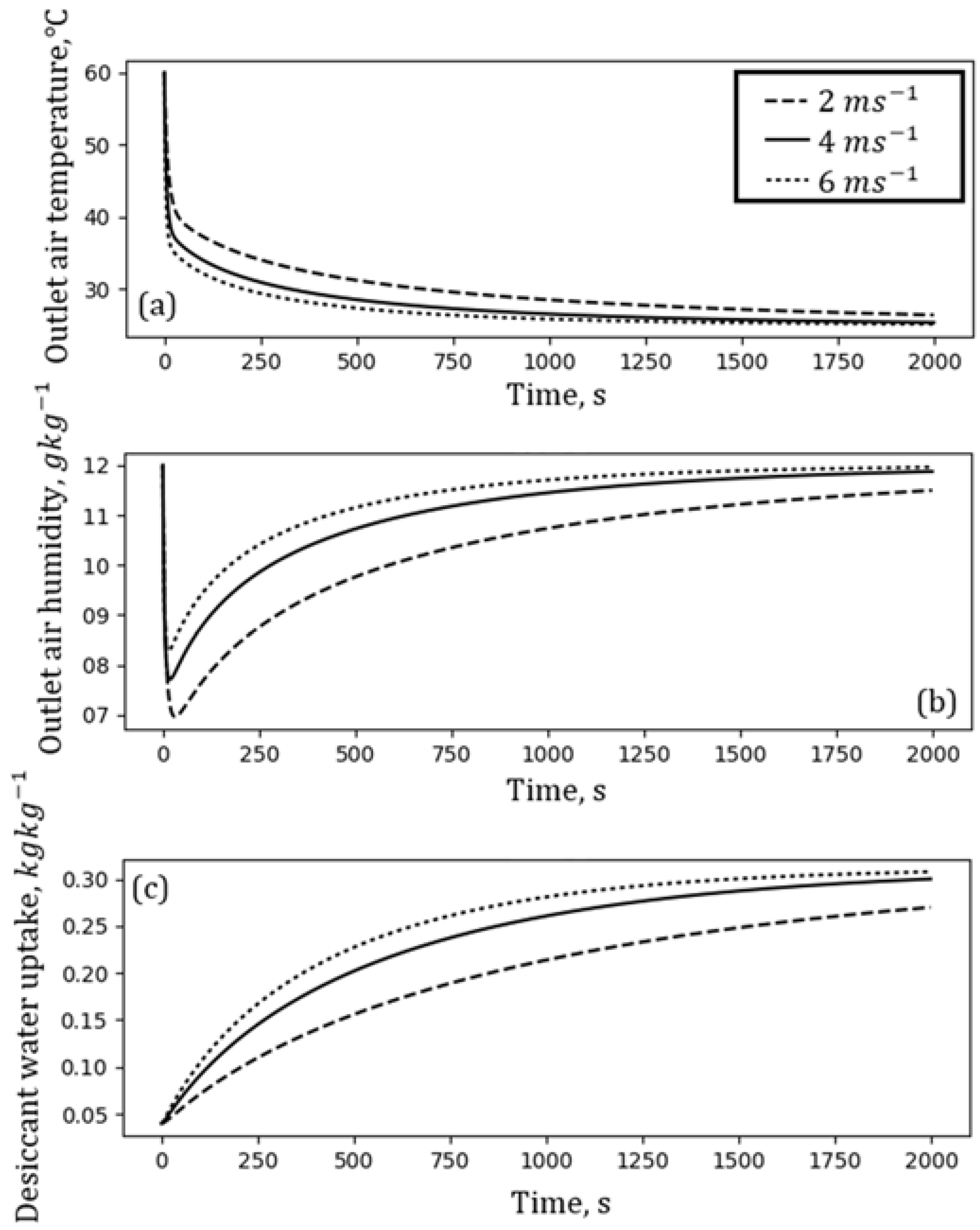

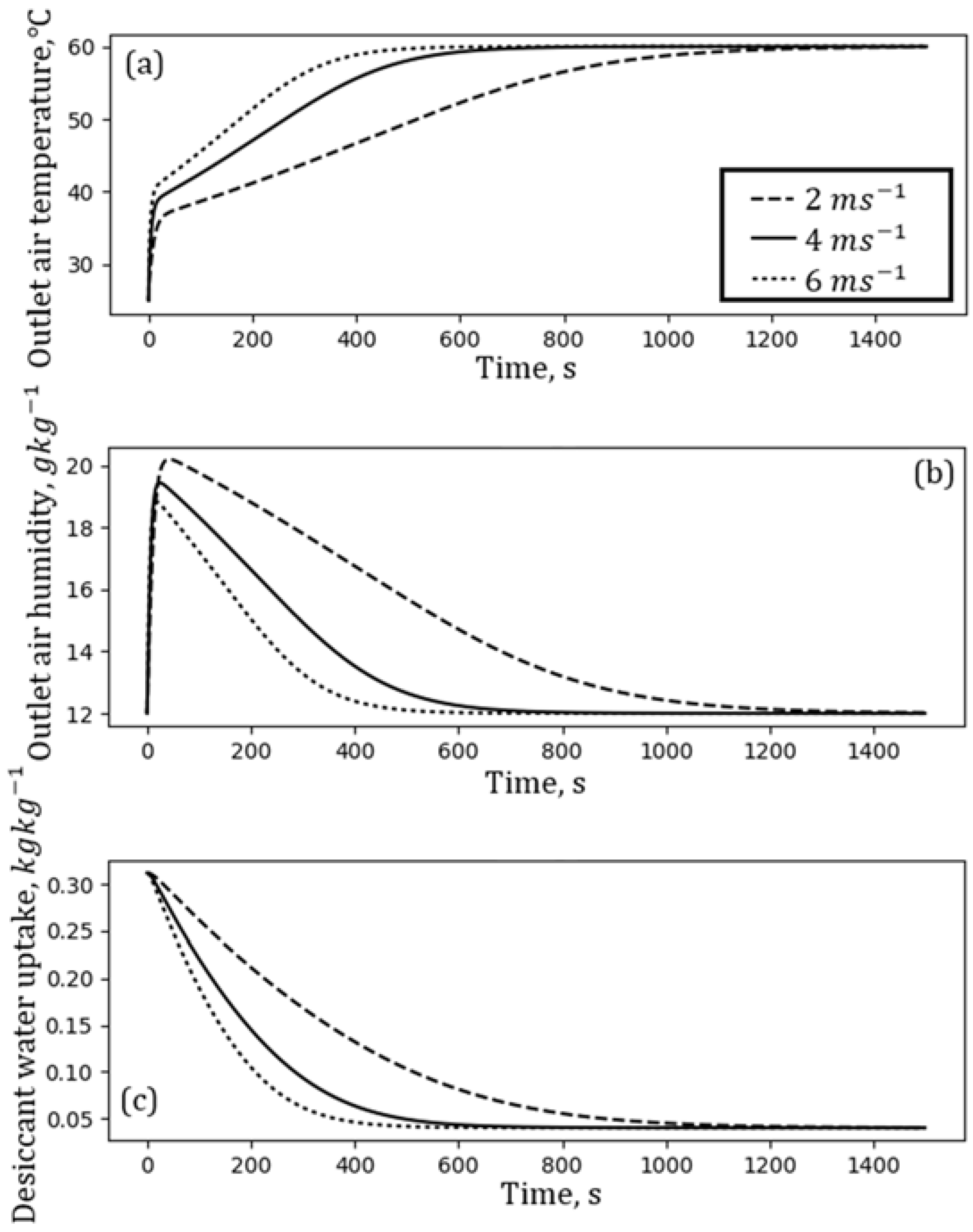

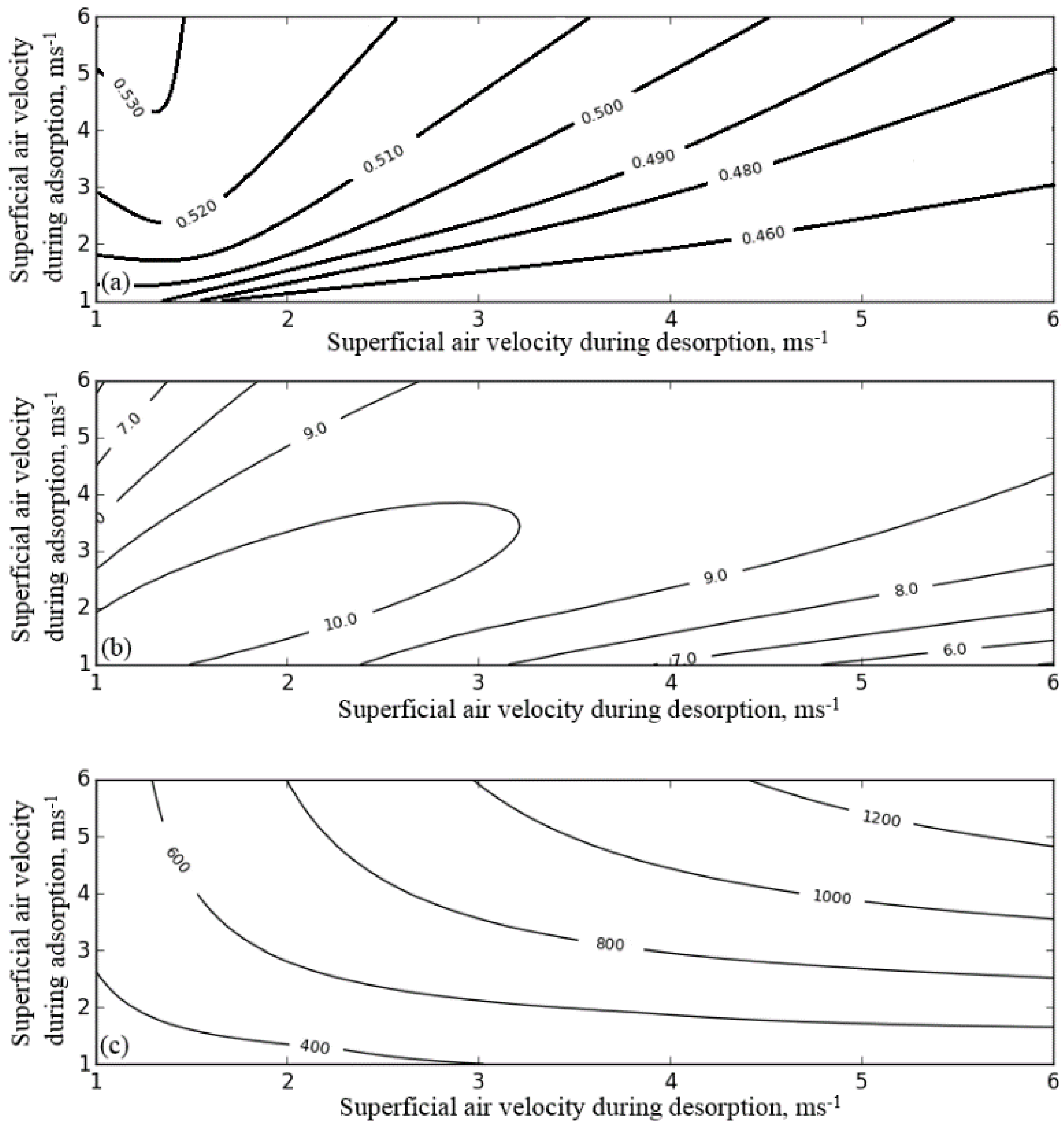

3.3. The Effect of Superficial Air Velocity

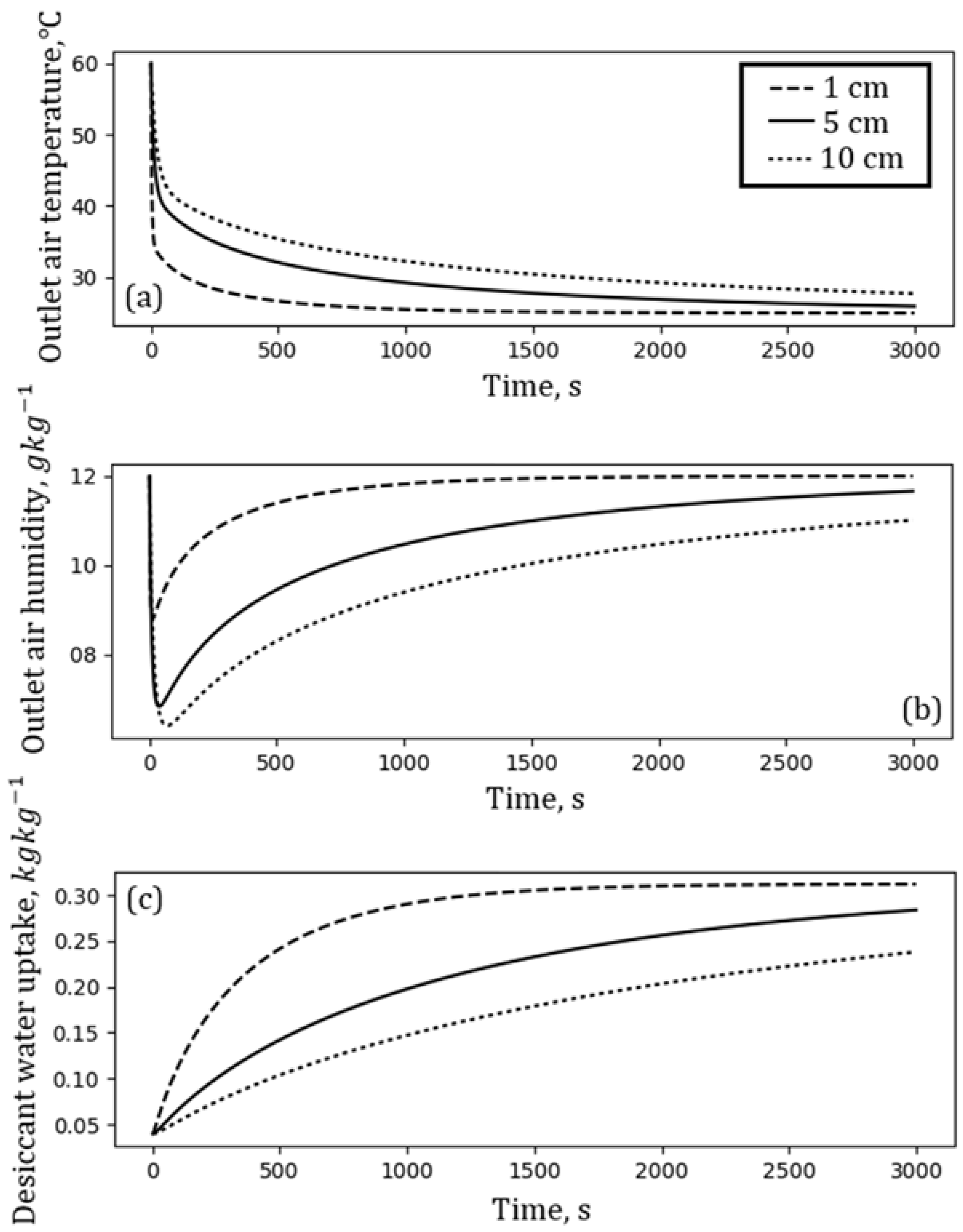

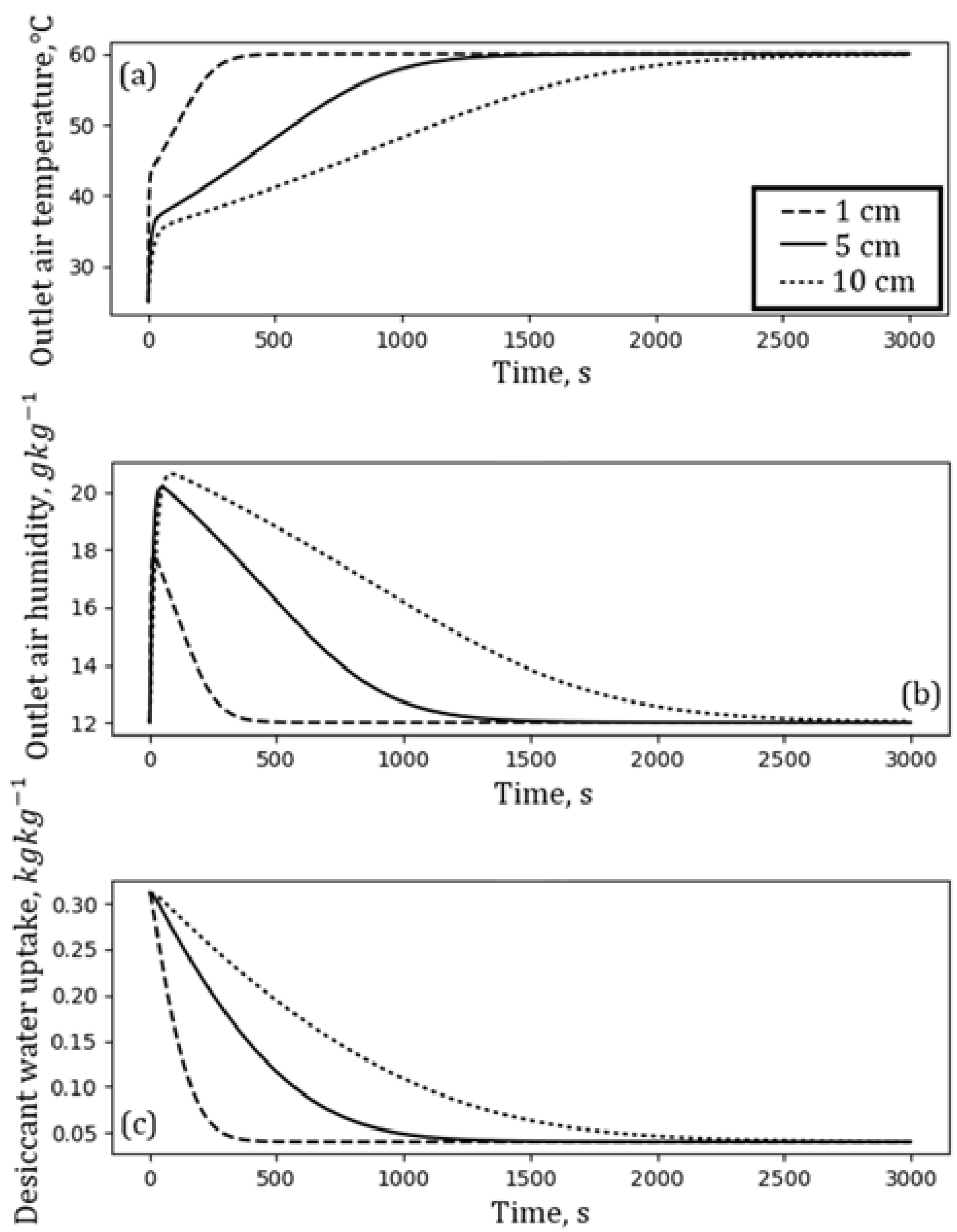

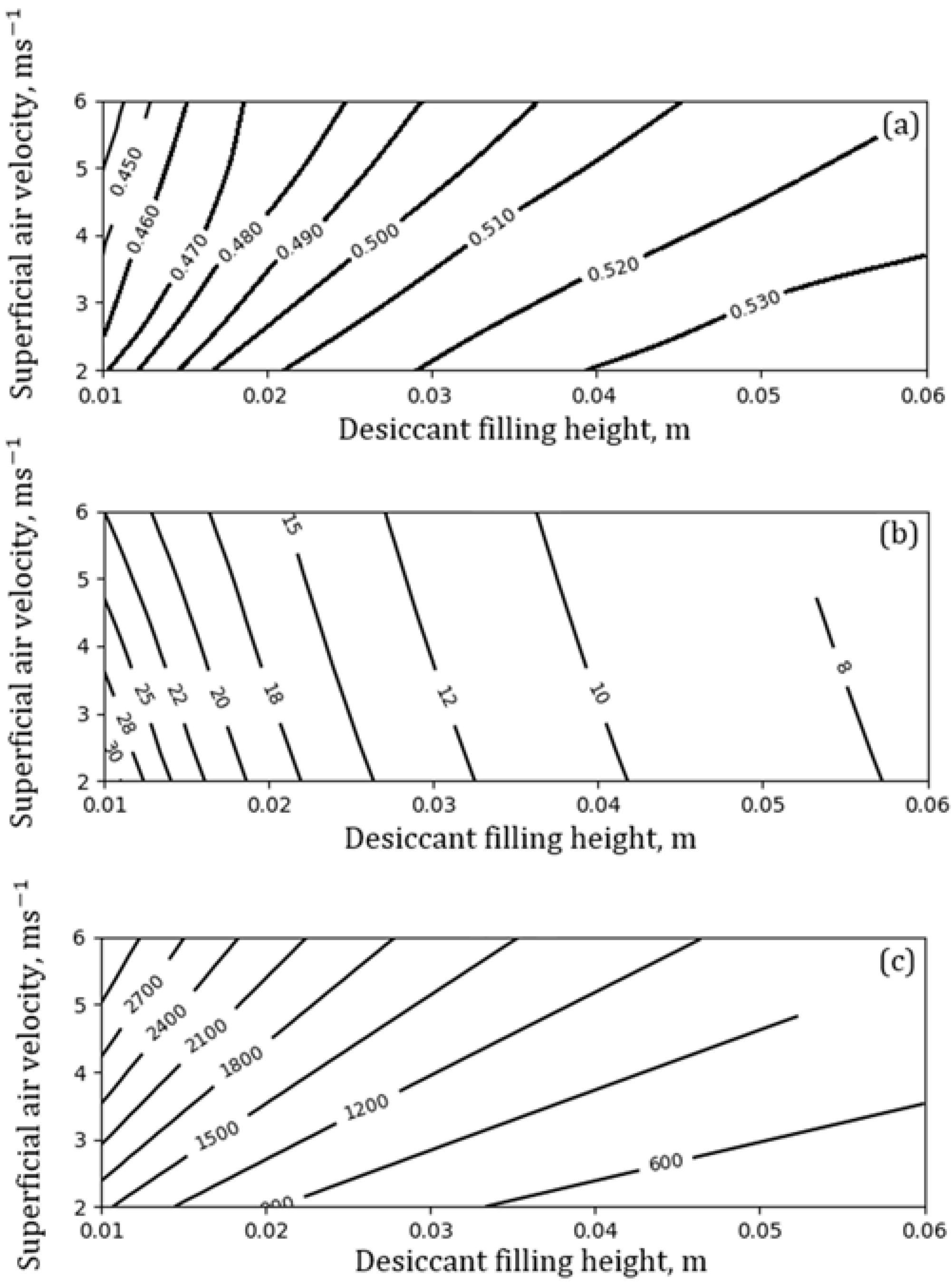

3.4. The Effect of Desiccant Filling Height

4. Conclusions

- A decrease of the desiccant particle diameter improves the performance of FDC, mainly by reducing the intraparticle mass transfer resistance and thereby enhancing the sorption kinetics. Nevertheless, the particle diameter affects the minimum and the maximum fluidisation velocity, which puts significant limitations on FDC operation. In the case of desiccant particle diameters smaller than 1 mm, fluidisation maintenance can be problematic because of the very narrow fluidisation regime.

- A FDC should operate with a optimum switching time that maximizes the electric COP and SCP. On the other hand, increasing the switching time above the optimum value will result in an increased thermal COP, but at the expense of the electric COP and SCP. Operating the FDC with the switching time below optimum is not recommended, as it deteriorates the performance of the FDC.

- Optimum electric COP can be achieved with similar superficial air velocities. The increase of the superficial air velocity during the adsorption over desorption allows for the mitigation of the differences of the adsorption and desorption kinetics, and can be applied as an alternative method for increasing COP in multibed systems, for example.

- The cooling power, which is provided with the air stream, is proportional to the superficial air velocity. In turn, the superficial air velocity is limited by the minimum and the maximum fluidisation velocities. The amount of desiccant in the fluidised bed has to be matched to the provided cooling power. Therefore, decreasing the desiccant filling height results in the significant increase of SCP and electric COP. The desiccant filling height has a significant impact on the performance of a FDC, especially on the electric COP. A desiccant filling height of below 4 cm has been recommended. This essentially affects the scalability of the FDC systems.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| cg | Specific heat of air J/(kg K) |

| COPel | electric COP |

| COPth | thermal COP |

| A | cross section area of the fluidised bed, m2 |

| g | gravitational acceleration m/s2 |

| Hd | desiccant filling height m |

| air mass flow during adsorption, kg/s | |

| air mass flow during desorption, kg/s | |

| Md | desiccant mass in the bed kg |

| electric power W | |

| cooling power W | |

| heating power W | |

| SCP | specific cooling power W/kg |

| tsw | switching time s |

| Uads | superficial air velocity during adsorption m/s |

| Udes | superficial air velocity during desorption m/s |

| ∆Hev | heat of evaporation J/kg |

| ∆p | pressure drop on fluidised bed Pa |

| ∆Tmean | mean air temperature drop during regeneration K |

| ∆w | change of desiccant water uptake kg/kg |

| ε | void fraction |

| ρd | desiccant bulk density kg/m3 |

| ρg | air density kg/m3 |

| ρp | desiccant particle density kg/m3 |

References

- Wang, D.; Zhang, J.; Tian, X.; Liu, D.; Sumathy, K. Progress in silica gel-water adsorption refrigeration technology. Renew. Sustain. Energy Rev. 2014, 30, 85–104. [Google Scholar] [CrossRef]

- Chorowski, M.; Rogala, Z.; Pyrka, P. System options for cooling of buildings making use of district heating heat. Int. J. Refrig. 2016, 70, 183–195. [Google Scholar] [CrossRef]

- Chen, C.H.; Schmid, G.; Chan, C.T.; Chiang, Y.C.; Chen, S.L. Application of silica gel fluidised bed for air-conditioning systems. Appl. Therm. Eng. 2015, 89, 229–238. [Google Scholar] [CrossRef]

- Chen, C.H.; Ma, S.S.; Wu, P.H.; Chiang, Y.C.; Chen, S.L. Adsorption and desorption of silica gel circulating fluidized beds for air conditioning systems. Appl. Energy 2015, 155, 708–718. [Google Scholar] [CrossRef]

- Chiang, Y.C.; Chen, C.H.; Chiang, Y.C.; Chen, S.L. Circulating inclined fluidized beds with application for desiccant dehumidification systems. Appl. Energy 2016, 175, 199–211. [Google Scholar] [CrossRef]

- Rogala, Z.; Kolasiński, P.; Gnutek, Z. Effect of operating conditions on performance of silica gel-water air-fluidised desiccant cooler. In Proceedings of the International Conference on Advances in Energy Systems and Environmental Engineering (ASEE17), Wrocław, Poland, 2–5 July 2017; Volume 22. [Google Scholar]

- Rogala, Z.; Gnutek, Z.; Kolasiński, P. Modelling and experimental analyzes on air-fluidised silica gel-water adsorption and desorption. Appl. Therm. Eng. 2017, 127, 950–962. [Google Scholar] [CrossRef]

- Nunes, T.K.; Vargas, J.V.C.; Ordonez, J.C.; Shah, D.; Martinho, L.C.S. Modeling, simulation and optimization of a vapor compression refrigeration system dynamic and steady state response. Appl. Energy 2015, 158, 540–555. [Google Scholar] [CrossRef]

- Ibrahim, N.I.; Al-farayedhi, A.A.; Gandhidasan, P. Experimental investigation of a vapor compression system with condenser air pre-cooling by condensate. Appl. Therm. Eng. 2017, 110, 1255–1263. [Google Scholar] [CrossRef]

- Chorowski, M.; Pyrka, P. Modelling and experimental investigation of an adsorption chiller using low-temperature heat from cogeneration. Energy 2015, 92, 221–229. [Google Scholar] [CrossRef]

- Rogala, Z. Adsorption chiller using flat-tube adsorbers—Performance assessment and optimization. Appl. Therm. Eng. 2017, 121, 431–442. [Google Scholar] [CrossRef]

- Brancato, V.; Gordeeva, L.; Sapienza, A.; Freni, A.; Frazzica, A. Dynamics study of ethanol adsorption on microporous activated carbon for adsorptive cooling applications. Appl. Therm. Eng. 2016, 105, 28–38. [Google Scholar] [CrossRef]

- Santamaria, S.; Sapienza, A.; Frazzica, A.; Freni, A.; Girnik, I.S.; Aristov, Y.I. Water adsorption dynamics on representative pieces of real adsorbers for adsorptive chillers. Appl. Energy 2014, 134, 11–19. [Google Scholar] [CrossRef]

- Wen-Ching, Y. Handbook of Fluidization and Fluid-Particle Systems; Taylor & Francis Group LLC: New York, NY, USA, 2003. [Google Scholar]

| Operating Parameter | dp, mm | tsw, s | Uads, m/s | Udes, m/s | Hd, cm |

|---|---|---|---|---|---|

| Desiccant particle diameter (see Figure 4) | 1, 3, 5 | 3000 | 2 | 2 | 5 |

| Desiccant particle diameter (see Figure 5) | 1, 3, 5 | 2000 | 2 | 2 | 5 |

| Desiccant particle diameter (see Figure 6) | 1–5 | optimum | 2 | 2 | 5 |

| Switching time (see Figure 7) | 1, 3, 5 | 200–1500 | 2 | 2 | 4 |

| Switching time (see Figure 8) | 1 | 200, 350, 650 | 2 | 2 | 4 |

| Superficial air velocity during adsorption (see Figure 9) | 1 | 2000 | 2, 4, 6 | - | 4 |

| Superficial air velocity during desorption (see Figure 10) | 1 | 1500 | - | 2, 4, 6 | 4 |

| Superficial air velocities (see Figure 11) | 1 | optimum | 1–6 | 1–6 | 4 |

| Desiccant filling height (see Figure 12) | 1 | 3000 | 2 | - | 1, 5, 10 |

| Desiccant filling height (see Figure 6) | 1 | optimum | 2 | - | 1, 5, 10 |

| Superficial air velocities and desiccant filling height (see Figure 14) | 1 | optimum | 2–6 | 2 | 1–6 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rogala, Z.; Kolasiński, P.; Błasiak, P. The Influence of Operating Parameters on Adsorption/Desorption Characteristics and Performance of the Fluidised Desiccant Cooler. Energies 2018, 11, 1597. https://doi.org/10.3390/en11061597

Rogala Z, Kolasiński P, Błasiak P. The Influence of Operating Parameters on Adsorption/Desorption Characteristics and Performance of the Fluidised Desiccant Cooler. Energies. 2018; 11(6):1597. https://doi.org/10.3390/en11061597

Chicago/Turabian StyleRogala, Zbigniew, Piotr Kolasiński, and Przemysław Błasiak. 2018. "The Influence of Operating Parameters on Adsorption/Desorption Characteristics and Performance of the Fluidised Desiccant Cooler" Energies 11, no. 6: 1597. https://doi.org/10.3390/en11061597

APA StyleRogala, Z., Kolasiński, P., & Błasiak, P. (2018). The Influence of Operating Parameters on Adsorption/Desorption Characteristics and Performance of the Fluidised Desiccant Cooler. Energies, 11(6), 1597. https://doi.org/10.3390/en11061597