Physiochemical and Electrical Properties of Refined, Bleached and Deodorized Palm Oil under High Temperature Ageing for Application in Transformers

Abstract

1. Introduction

2. Materials and Methods

2.1. Thermal Ageing Procedure

2.2. Measurement of Properties

2.2.1. Moisture Content

2.2.2. Acidity

2.2.3. Viscosity

2.2.4. AC breakdown Voltage

2.2.5. Dielectric Dissipation Factor, Relative Permittivity and Resistivity

3. Results

3.1. Physicochemical Properties

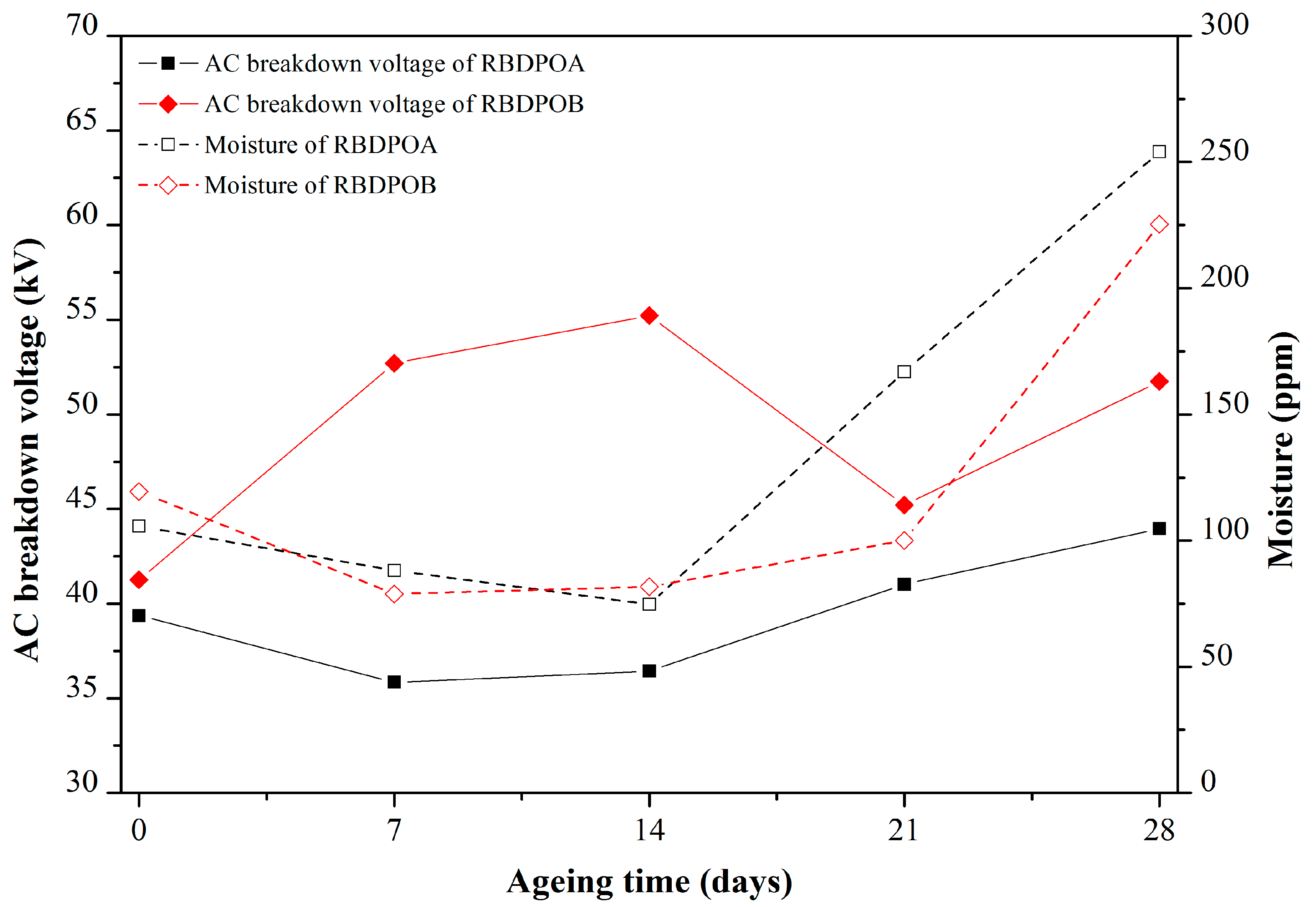

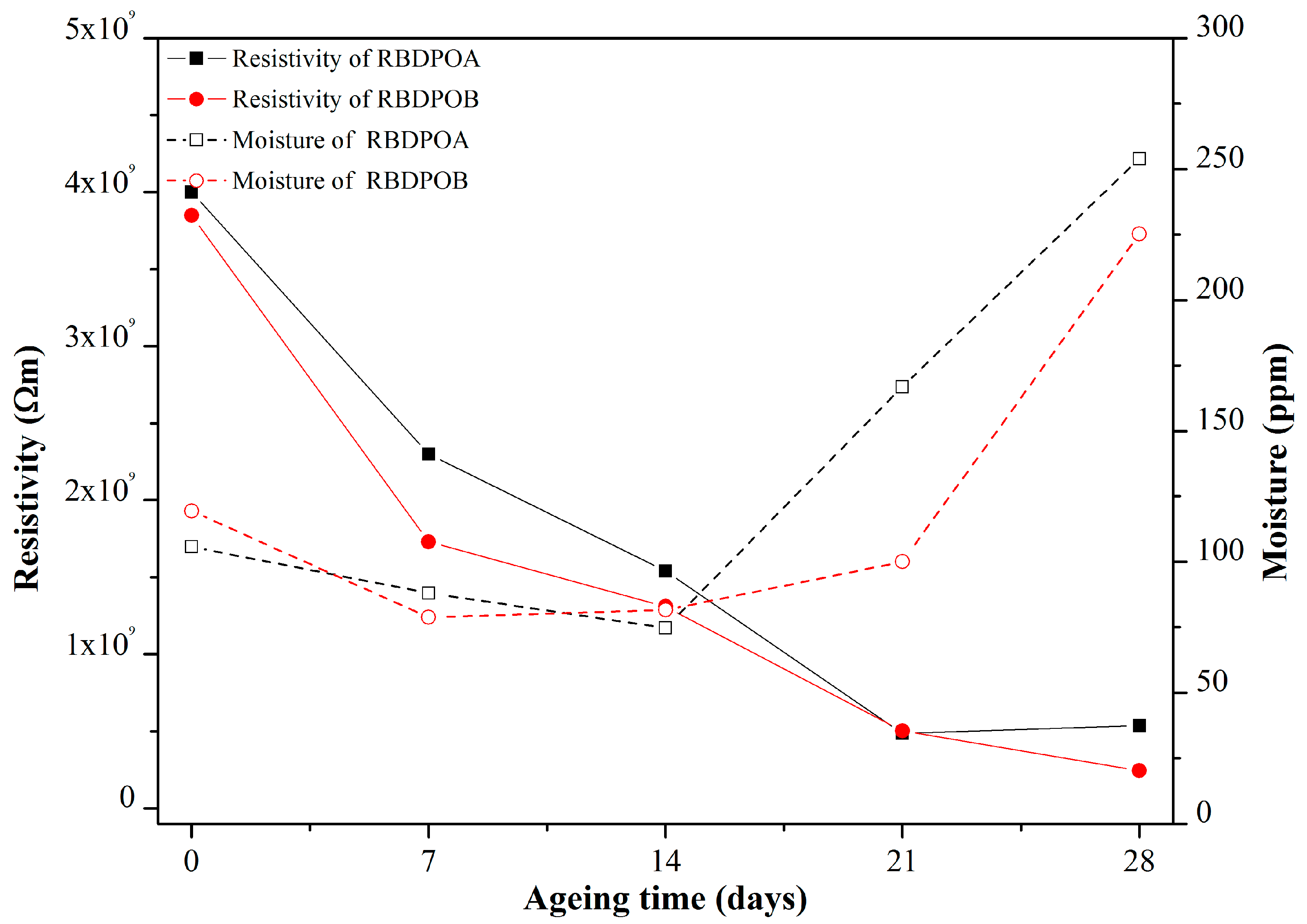

3.1.1. Moisture

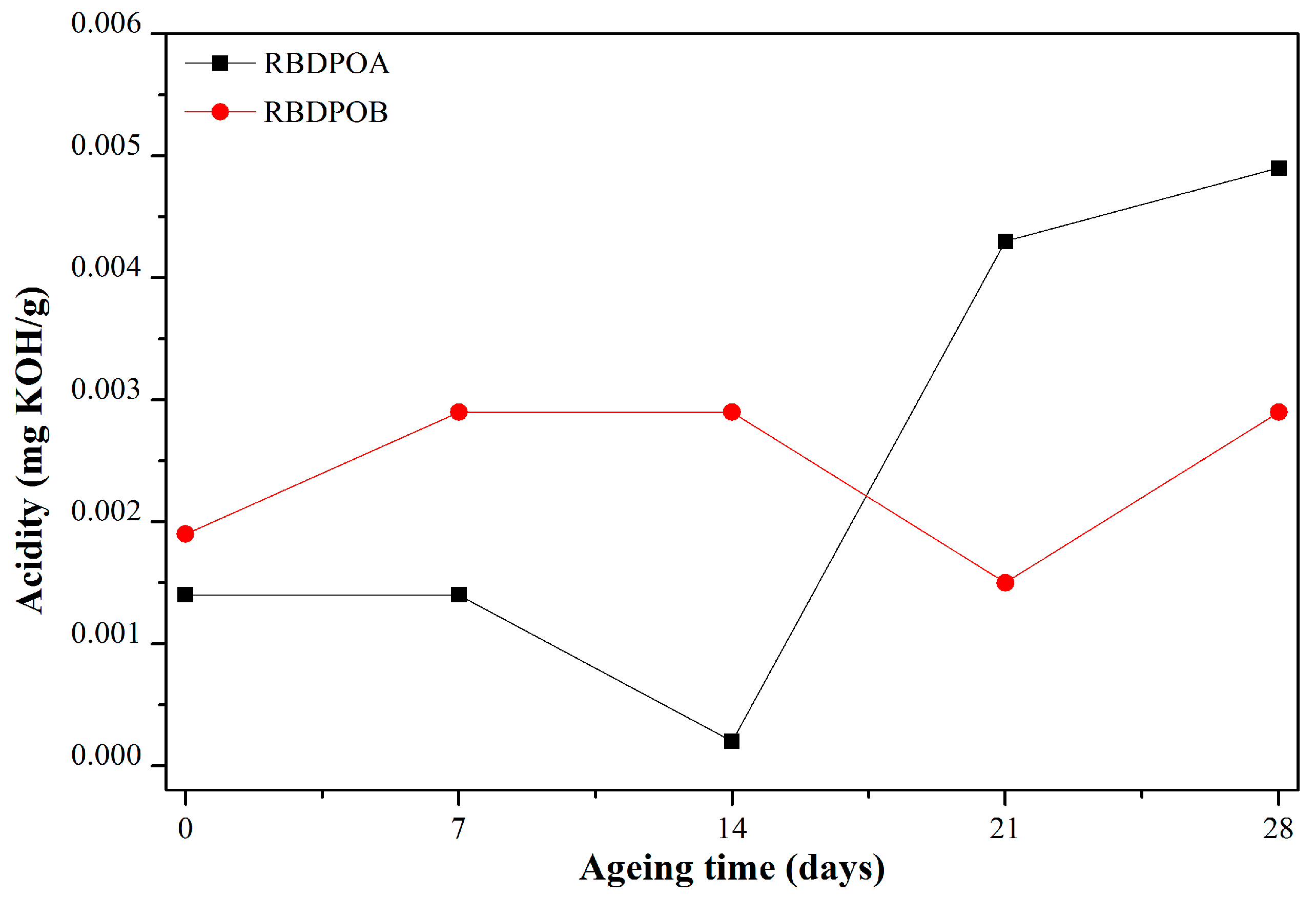

3.1.2. Acidity

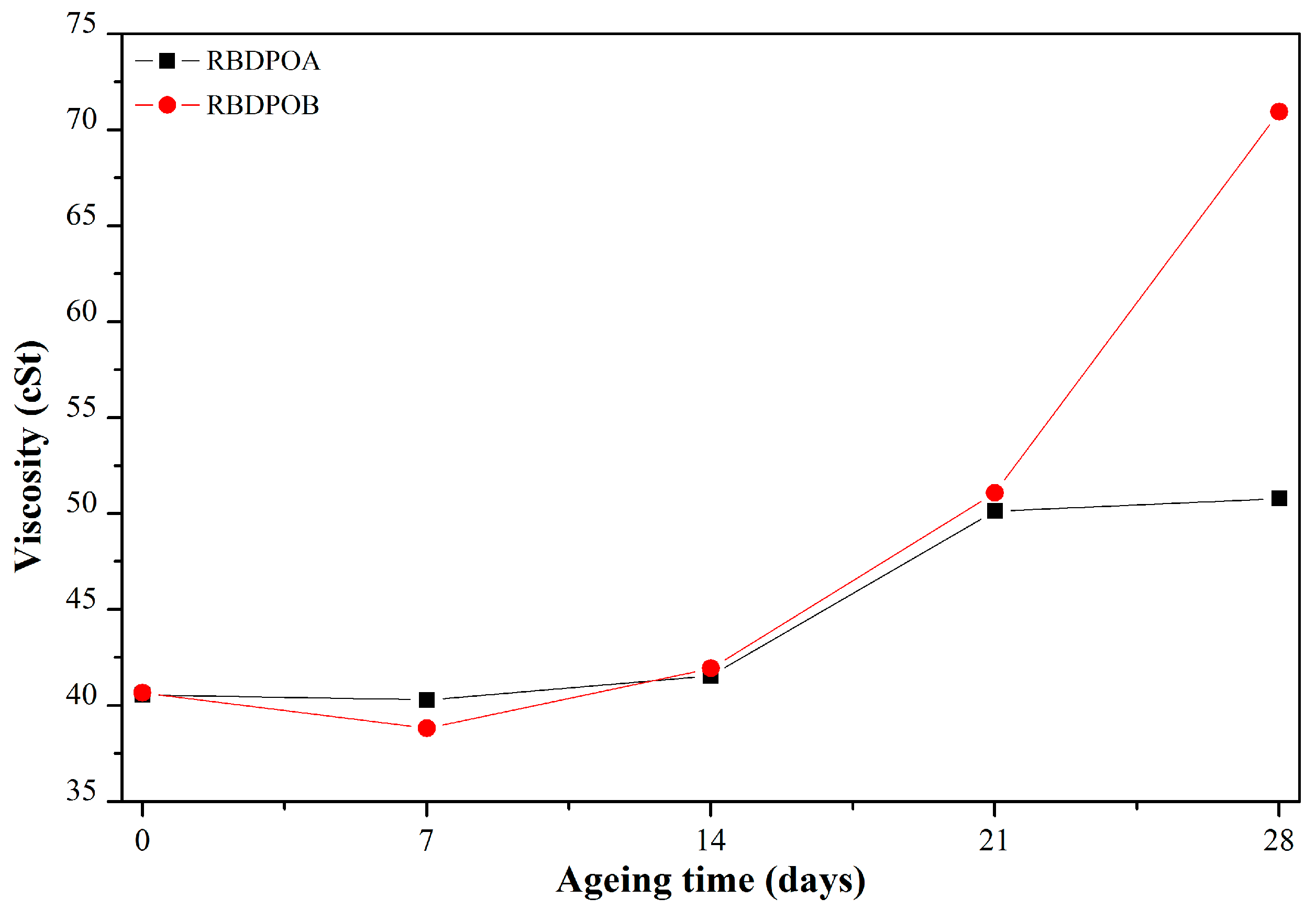

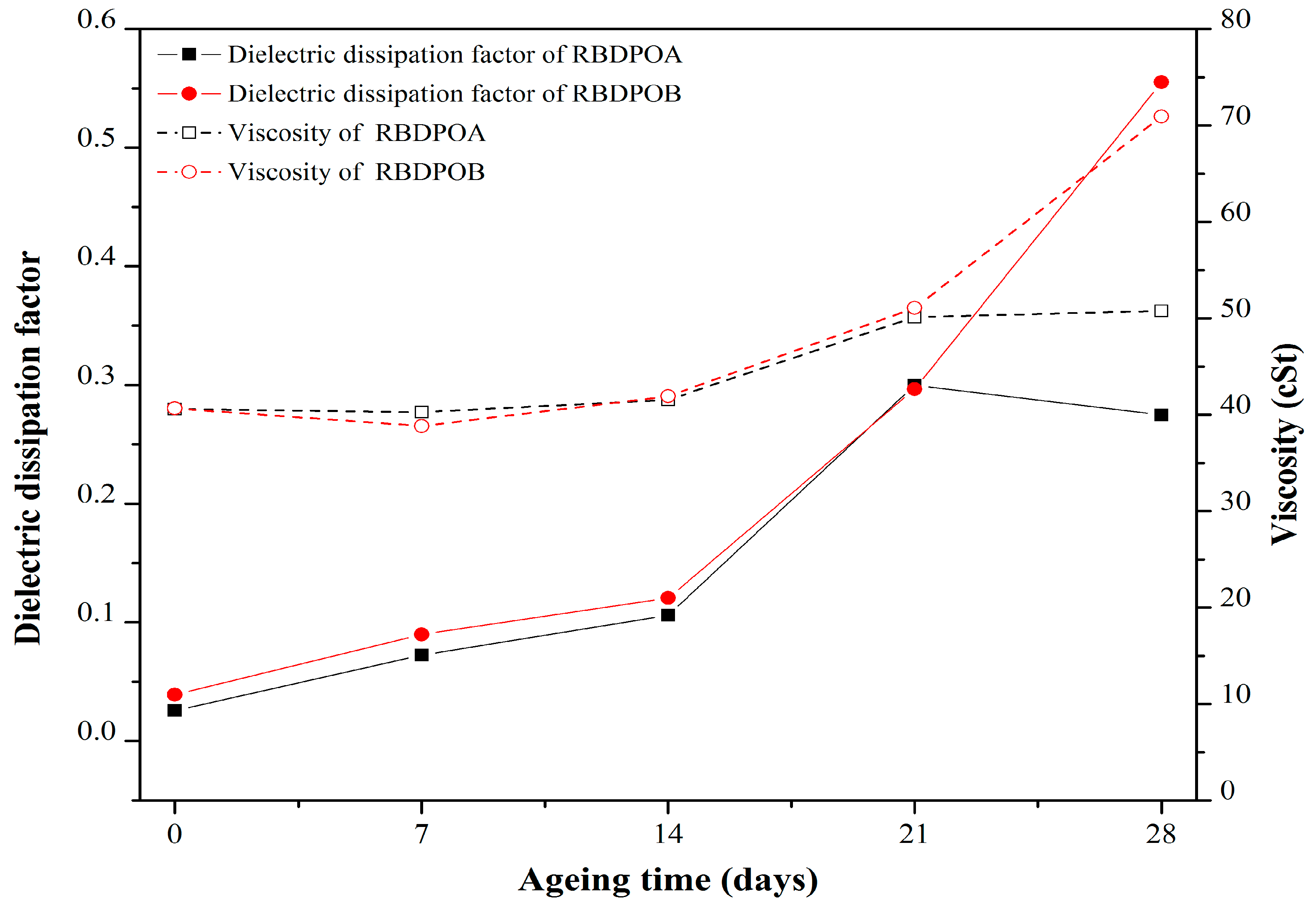

3.1.3. Viscosity

3.2. Electrical Properties

3.2.1. AC Breakdown Voltage

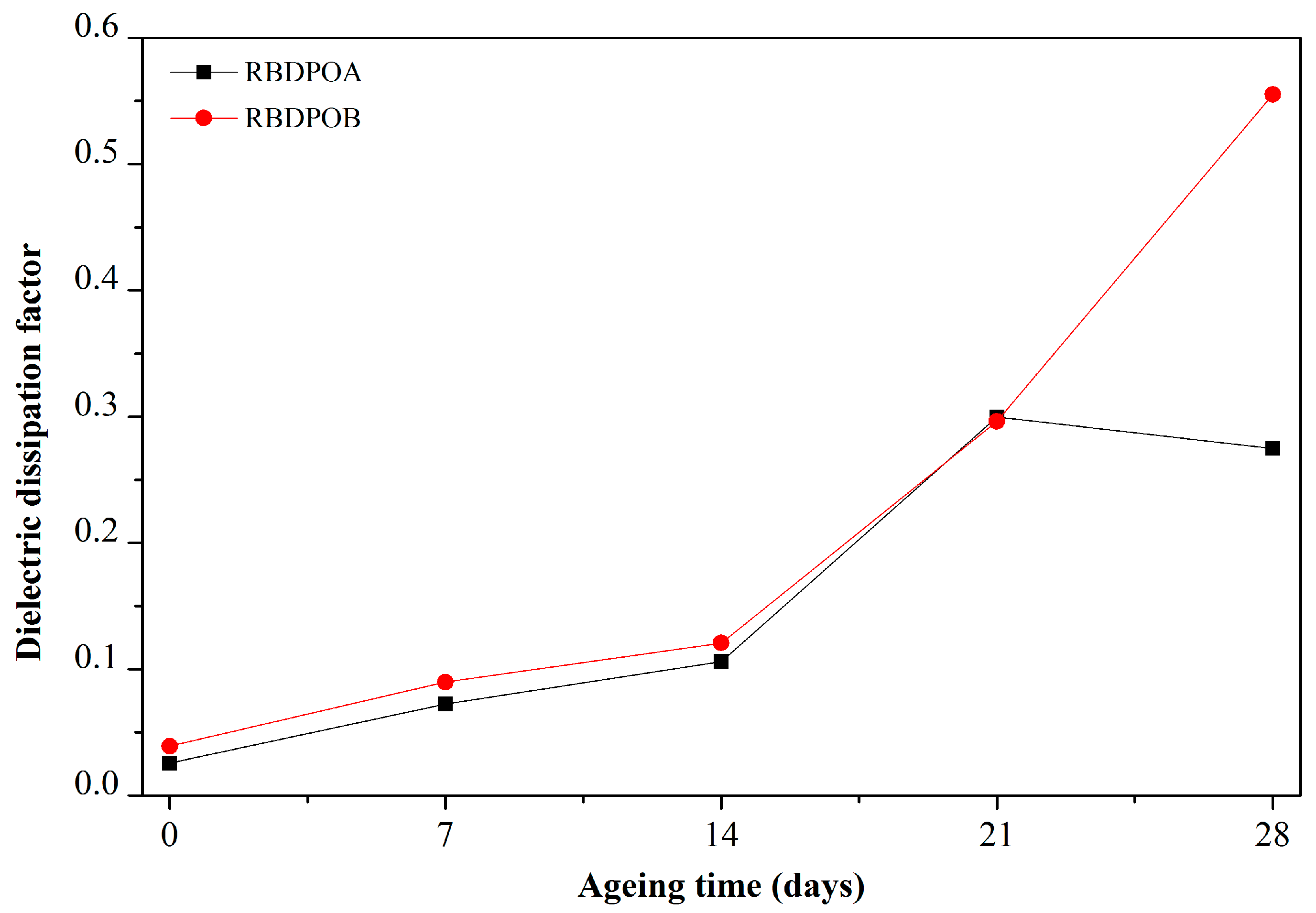

3.2.2. Dielectric Dissipation Factor

3.2.3. Resistivity

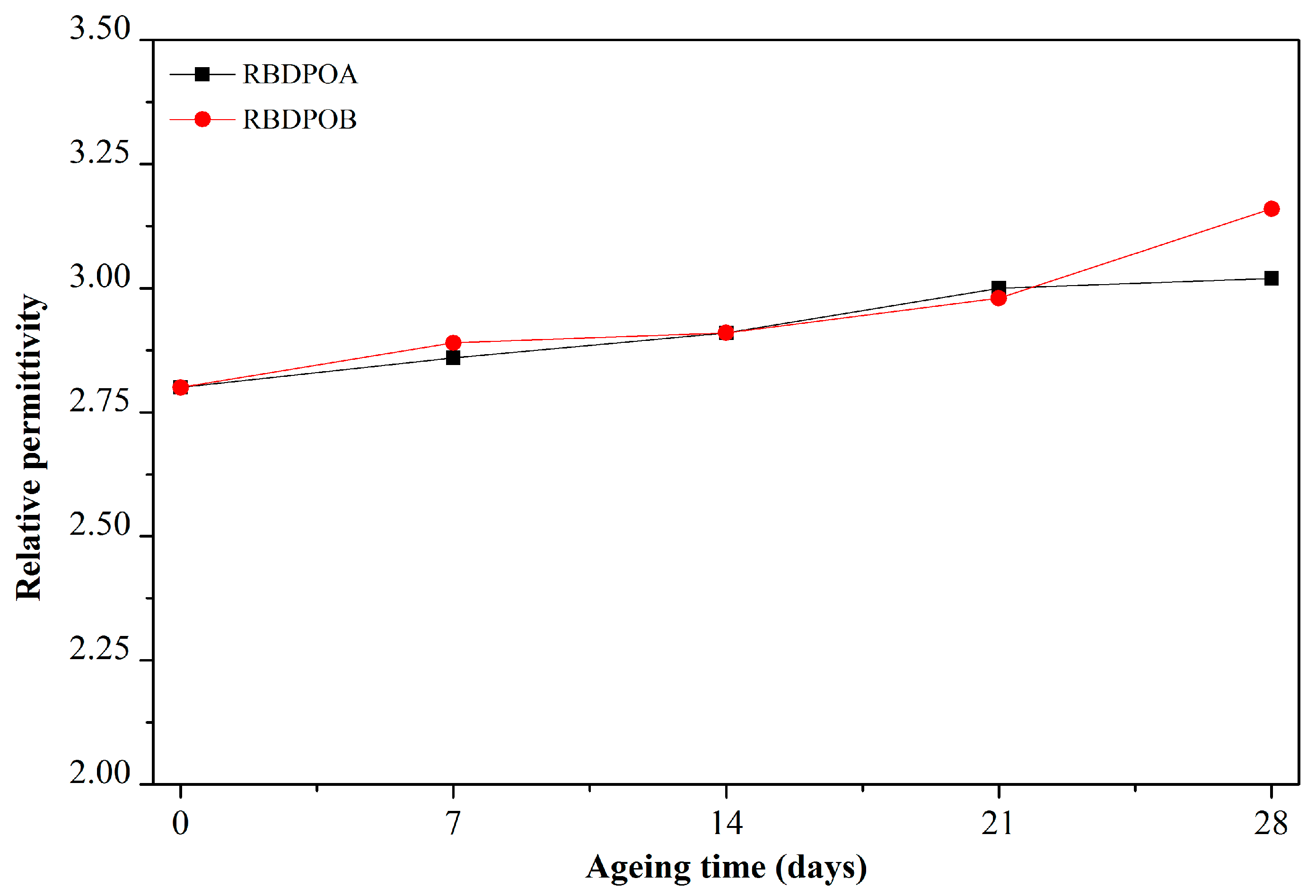

3.2.4. Relative Permittivity

4. Discussion

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Abdullahi, U.U.; Bashi, S.M.; Yunus, R.; Mohibullah; Nurdin, H.A. The Potentials of Palm Oil as a Dielectric Fluid. In Proceedings of the IEEE International Conference on National Power and Energy (PECon), Kuala Lumpur, Malaysia, 29–30 November 2004; pp. 224–228. [Google Scholar]

- Azis, N.; Jasni, J.; Kadir, M.Z.A.A.; Mohtar, M.N. Suitability of Palm Based Oil as Dielectric Insulating Fluid in Transformers. J. Electr. Eng. Technol. 2014, 9, 662–669. [Google Scholar] [CrossRef]

- Azmi, K.; Ahmad, A.; Kamarol, M. Study of Dielectric Properties of a Potential RBD Palm Oil and RBD Soybean Oil Mixture as Insulating Liquid in Transformer. J. Electr. Eng. Technol. 2015, 10, 709–718. [Google Scholar] [CrossRef]

- Thien, Y.V.; Azis, N.; Jasni, J.; Kadir, M.Z.A.A.; Yunus, R.; Ishak, M.T.; Yaakub, Z. The Effect of Polarity on the Lightning Breakdown Voltages of Palm Oil and Coconut Oil under a Non-uniform Field for Transformers Application. Ind. Crops Prod. 2016, 89, 250–256. [Google Scholar] [CrossRef]

- Raof, N.A.; Rashid, U.; Yunus, R.; Azis, N.; Yaakub, Z. Development of Palm-based Neopentyl Glycol Diester as Dielectric Fluid and Its Thermal Aging Performance. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2051–2058. [Google Scholar] [CrossRef]

- Jonathan, O.O.; Agber, D.J.U. Palm Oil as an Alternative Dielectric Transformer Coolant. Int. J. Res. Eng. Sci. 2014, 2, 8–13. [Google Scholar]

- Munajad, A.; Subroto, C.; Suwarno. Study on the effects of thermal aging on insulating paper for high voltage transformer composite with natural ester from palm oil using fourier transform infrared spectroscopy (FTIR) and energy dispersive X-ray spectroscopy (EDS). Energies 2017, 10, 1857. [Google Scholar] [CrossRef]

- Mohamad, N.A.; Azis, N.; Jasni, J.; Kadir, M.Z.A.A.; Yunus, R.; Ishak, M.T.; Yaakub, Z. Investigation on the dielectric, physical and chemical properties of palm oil and coconut oil under open thermal ageing condition. J. Electr. Eng. Technol. 2016, 11, 690–698. [Google Scholar] [CrossRef]

- Senthilkumar, S.; Karthik, B.; Chandrasekar, S. Investigations on PD Characteristics of Thermal Aged Palm and Corn Oil for Power Transfomers Insulation Application. J. Electr. Eng. Technol. 2014, 9, 742–751. [Google Scholar] [CrossRef]

- Suwarno, S.A. Investigation on thermal aging of ester from palm oil and kraft paper composite insulation system for high voltage transformer. WSEAS Trans. Environ. Dev. 2017, 13, 75–84. [Google Scholar]

- Suwarno, S.A. Thermal aging of ester from palm oil and kraft paper composite insulation. Int. J. Appl. Phys. 2016, 1, 77–84. [Google Scholar]

- Carcedo, J.; Fernandez, I.; Ortiz, A.; Delgado, F.; Renedo, C.J.; Pesquera, C. Aging assessment of dielectric vegetable oils. IEEE Electr. Insul. Mag. 2015, 31, 13–21. [Google Scholar] [CrossRef]

- Bandara, K.; Ekanayake, C.; Saha, T.; Ma, H. Performance of natural ester as a transformer oil in moisture-rich environments. Energies 2016, 9, 258. [Google Scholar] [CrossRef]

- Duart, J.-C.; Bates, L.C. Aging of high temperature insulation systems with alternative fluids. In Proceedings of the IEEE International Symposium on Electrical Insulation (ISEI), San Diego, CA, USA, 6–9 June 2010; pp. 1–5. [Google Scholar]

- Azis, N.; Wang, Z.D. Acid generation study of natural ester. In Proceedings of the XVII International Symposium on High Voltage Engineering, Hannover, Germany, 22–26 August 2011; pp. 1–6. [Google Scholar]

- Borsi, H. Dielectric behavior of silicone and ester fluids for use in distribution transformers. IEEE Trans. Dielectr. Electr. Insul. 1991, 26, 755–762. [Google Scholar] [CrossRef]

- Perrier, C.; Beroual, A. Experimental investigation on insulating liquids for power transformer: Mineral, ester and silicone oils. IEEE Electr. Insul. Mag. 2009, 25, 6–13. [Google Scholar] [CrossRef]

- Liao, R.; Guo, C.; Wang, K.; Yang, L. Investigation on thermal aging characteristics of vegetable oil-paper insulation with flowing dry air. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 1649–1658. [Google Scholar] [CrossRef]

- International Electrotechnical Commission. Specific Standard for Unused Natural Esters Liquids for Transformers and Similar Electrical Equipment; IEC 62770; International Electrotechnical Commission: Geneva, Switzerland, 2013. [Google Scholar]

- Wilhelm, H.M.; Tulio, L.; Jasinski, R.; Almeida, G. Aging markers for in-service natural ester-based insulating fluids. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 714–719. [Google Scholar] [CrossRef]

- Sherwin, E.R. Oxidation and antioxidants in fat and oil processing. J. Am. Oil Chem. Soc. 1978, 55, 809–814. [Google Scholar] [CrossRef]

- Fox, N.J.; Stachowiak, G.W. Vegetable oil-based lubricants—A review of oxidation. Tribol. Int. 2007, 40, 1035–1046. [Google Scholar] [CrossRef]

- Snyder, J.M.; Frankel, E.N.; Selke, E. Capillary gas chromatographic analyses of headspace volatiles from vegetable oils. J. Am. Oil Chem. Soc. 1985, 62, 1675–1679. [Google Scholar] [CrossRef]

- Neff, W.E.; El-Agaimy, M.A.; Mounts, T.L. Oxidative stability of blends and interesterified blends of soybean oil and palm olein. J. Am. Oil Chem. Soc. 1994, 71, 1111–1116. [Google Scholar] [CrossRef]

- Rooney, D.; Weatherley, L.R. The effect of reaction conditions upon lipase catalysed hydrolysis of high oleate sunflower oil in a stirred liquid—Liquid reactor. Process Biochem. 2001, 36, 947–953. [Google Scholar] [CrossRef]

- ISO 5508:1990. Animal and Vegetable Fats and Oils—Analysis by Gas Chromatography (GC) of Methyl-Esters of Fatty Acids; International Organization for Standardization: Geneva, Switzerland, 1990. [Google Scholar]

- ASTM D6304. Standard Test Method for Determination of Water in Petroleum Products, Lubricating Oils and Additives by Coulometric Karl Fischer Titration; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM D974. Standard Test Method for Acid and Base Number by Color-Indicator Titration; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM D445. Standard Method of Test for Viscosity of Transparent and Opaque Liquids (Kinematic and Dynamic Viscosities); ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM D1816. Standard Test Method for Dielectric Breakdown Voltage of Insulating Liquids Using VDE Electrodes; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- IEC 60247. Measurement of Relative Permittivity, Dielectric Dissipation Factor and D.C. Resistivity of Insulating Liquids; International Electrotechnical Commission: Geneva, Switzerland, 2004. [Google Scholar]

- Rapp, K.J.; McShane, C.P.; Luksich, J. Interaction mechanisms of natural ester dielectric fluid and kraft paper. In Proceedings of the IEEE International Conference on Dielectric Liquids (ICDL), Coimbra, Portugal, 26 June–1 July 2005; pp. 393–396. [Google Scholar]

- Viertel, J.; Ohlsson, K.; Singha, S. Thermal aging and degradation of thin films of natural ester dielectric liquids. In Proceedings of the IEEE International Conference on Dielectric Liquids (ICDL), Trondheim, Norway, 26–30 June 2011; pp. 1–4. [Google Scholar]

- IEEE Power and Energy Society. IEEE Guide for Acceptance of Silicone Insulating Fluid and Its Maintenance in Transformers; IEEE: Piscataway, NJ, USA, 1989. [Google Scholar]

- Xu, Y.; Qian, S.; Liu, Q.; Wang, Z.D. Oxidation stability assessment of a vegetable transformer oil under thermal aging. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 683–692. [Google Scholar] [CrossRef]

| Types of Fats | Types of Fatty Acids | Sample (%) | |

|---|---|---|---|

| RBDPO A | RBDPO B | ||

| Saturated | C6: Caproic | - | - |

| C8: Caprylic | - | - | |

| C10: Capric | - | - | |

| C12: Lauric | 0.3 | 0.3 | |

| C14: Myristic | 1.1 | 0.9 | |

| C16: Palmitic | 37.7 | 39.0 | |

| C18: Stearic | 3.9 | 4.2 | |

| Mono-unsaturated | C18: Oleic | 42.3 | 43.0 |

| Poly-unsaturated | C18: Linoleic | 12.4 | 10.4 |

| C18: Linolenic | 0.3 | 0.2 | |

| Others | 0.1 | 0.1 | |

| Samples | Ageing Time (Days) | Normal Distribution | Weibull Distribution | ||

|---|---|---|---|---|---|

| 1% | 50% | 1% | 50% | ||

| RBDPO A | 0 | 23.56 | 39.37 | 21.6 | 39.97 |

| 7 | 21.94 | 35.84 | 19.95 | 36.41 | |

| 14 | 24.18 | 36.43 | 22.22 | 36.98 | |

| 21 | 23.8 | 41.02 | 22.35 | 41.71 | |

| 28 | 28.23 | 43.96 | 25.86 | 44.63 | |

| RBDPO B | 0 | 29.2 | 41.27 | 19.80 | 40.9 |

| 7 | 37.38 | 52.71 | 37.14 | 53.51 | |

| 14 | 37.4 | 55.22 | 35.86 | 56.08 | |

| 21 | 26.23 | 45.19 | 23.90 | 45.86 | |

| 28 | 35.06 | 51.74 | 32.29 | 52.5 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohamad, N.A.; Azis, N.; Jasni, J.; Ab Kadir, M.Z.A.; Yunus, R.; Yaakub, Z. Physiochemical and Electrical Properties of Refined, Bleached and Deodorized Palm Oil under High Temperature Ageing for Application in Transformers. Energies 2018, 11, 1583. https://doi.org/10.3390/en11061583

Mohamad NA, Azis N, Jasni J, Ab Kadir MZA, Yunus R, Yaakub Z. Physiochemical and Electrical Properties of Refined, Bleached and Deodorized Palm Oil under High Temperature Ageing for Application in Transformers. Energies. 2018; 11(6):1583. https://doi.org/10.3390/en11061583

Chicago/Turabian StyleMohamad, Nur Aqilah, Norhafiz Azis, Jasronita Jasni, Mohd Zainal Abidin Ab Kadir, Robiah Yunus, and Zaini Yaakub. 2018. "Physiochemical and Electrical Properties of Refined, Bleached and Deodorized Palm Oil under High Temperature Ageing for Application in Transformers" Energies 11, no. 6: 1583. https://doi.org/10.3390/en11061583

APA StyleMohamad, N. A., Azis, N., Jasni, J., Ab Kadir, M. Z. A., Yunus, R., & Yaakub, Z. (2018). Physiochemical and Electrical Properties of Refined, Bleached and Deodorized Palm Oil under High Temperature Ageing for Application in Transformers. Energies, 11(6), 1583. https://doi.org/10.3390/en11061583