1. Introduction

Combined cooling, heating, and power (CCHP) systems produce electricity and available heat from one generation site and the conversion efficiency of primary energy to useful energy is approximately 70–80% [

1,

2]. Due to the high conversion efficiency and greater environmental benefit, CCHP systems have attracted more attention in the past few decades [

3] and are widely used in buildings or regional energy systems [

4]. The CCHP system, also known as the tri-generation system, can be applied in a stand-alone microgrid (MG) or combined with the city power grid.

Recent research is focused on system management, operation, system optimization, size optimization, energy management, renewable energies, and more [

5]. Some renewable energies and technologies have been applied in the CCHP system, such as fuel cells, heat pumps [

6], photovoltaics (PV), wind turbines, and more [

7,

8]. Integrating renewable energy into the CCHP system can further improve the system’s energy efficiency and reduce carbon dioxide emissions; the renewable energies integrated into CCHP (RECCHP) systems can be used when the power grid is unavailable, for example, on islands, and in deserts [

9]. Chen et al. [

10] proposed a multi-objective optimization model of energy management for the integrated electrical and natural gas network with CCHP plants. Lo Basso et al. [

6] analyzed the thermal management and off-design operation of coupling of combined heat and power (CHP) and heat pump for the energy retrofitting of residential buildings. Wang et al. [

11] presented a comprehensive operation model to enhance the economic and environmental benefits through the improved CCHP strategy of MG. The main objective of optimization is to improve energy efficiency, maximize environmental benefits, and reduce the expense of the system. Some previous studies on system design and optimization of a CCHP system were often set to a constant, or assumed that the reliability and maintenance of the system were completely unfailing for operation [

12]. The cost of operation and maintenance of a system account for more than 50% of the total cost of the whole life cycle [

13] in fact. Thus, a reasonable maintenance strategy can improve the reliability of a system and reduce the maintenance cost.

Some articles on the operation, reliability, and maintenance of a CCHP system or microgrid are related to facilities’ distribution and system optimization design. Ou [

14] proposed an unsymmetrical faults analysis method to deal with the unsymmetrical faults of microgrid distribution systems adopting hybrid compensation. Ting-Chia Ou et al. studied the operation and control strategies for a microgrid which used renewable energies and fuel cells as power generators [

15]; a technology was developed to improve the transient stability in the hybrid power multi-system [

16]. Noussan et al. [

17] proposed an optimization tool to enhance the operation of a CHP system combined with a heat pump. Zamani-Gargari et al. [

18] proposed a method which combined the Monte Carlo Simulation (MCS) method to assess the reliability of a wind power system with energy storage. Yang et al. [

19] proposed an approach to analyzing how the wind farm electrical system influenced the system when the electrical system faulted. Wang [

20] presented a reliability and availability analysis of a redundant and non-redundant BCHP (building, cooling, heating, and power) system, but did not consider the component reliability of the system. Haghifam, and Manbachi [

21] proposed a reliability and availability modeling of CHP systems to analyze the impact of CHP system reliability with improved gas-delivery, water-delivery, and hot water-delivery subsystems but did not model the reliability of individual components. Frangopoulos [

22] analyzed the effect of optimization on the synthesis, design, and operation of a cogeneration system based on reliability considerations, but did not consider the effect of component reliability. El-Nashar [

23] presented an optimal design model of a cogeneration system using the thermoeconomic theory to carry out the design optimization.

Only a few articles to date have studied the component reliability of the power generation plant, cogeneration system, and CCHP system. Sabouhi et al. [

24] mentioned a reliability model to assess the combined cycle power generation plants and applied it to a reliability analysis for gas turbine power plants and steam turbine power plants. The reliability of components was used to compute the system availability and the study compared the availability, but did not mention the importance of maintenance regarding the components in one system. Carazas et al. [

25] presented an availability analysis for component maintenance policies of a gas turbine, but did not assess the reliability of the whole power generation system. A CCHP system is a complex system, however, containing a large number of components and a series of subsystems. When a failure occurs on one component, it might cause a failure of a subsystem or the whole system. The reliability of the whole system is dependent on the reliability of each component of the system.

Traditionally, the maintenance of components in a system is managed by specifying a fixed schedule. Each component of a system has its own maintenance schedule performed according to the manufacturer’s recommendations. It might lead to the waste of maintenance resources and a high cost of maintenance. To comprehensively evaluate the degree of maintenance importance regarding the components of a whole system and propose a reasonable maintenance strategy is a vital way to avoid the wastage of maintenance resources and reduce the total costs, therefore, the reliability and maintenance prioritization analysis of components of a whole system is necessary.

A reliability importance index is one of the methods to identify system weaknesses and provide a numerical value to determine which components are more important for the improvement of system reliability [

26]. The reliability importance index can be used to assess which components are needing maintenance and which components are needing more attention to reduce maintenance costs [

27]. It can provide a reference for system designers and managers to optimize the design plan and operation strategy for future design, redesign, and operation to reduce the total cost and improve reliability. Conventional reliability importance indices are a function of component reliability, however; they cannot be used directly to optimize maintenance costs.

Two new reliability importance indices are developed in this study based on the component failure cost for the identification of component maintenance priorities from the perspective of maintenance cost. A comparative analysis is performed between the new reliability importance indices and conventional reliability importance indices. Additionally, a Markov model based on the state–space method (SSM) is used to analyze the reliability and availability of components and subsystems of a CCHP System. This study is validated by actual survey reliability data of the CCHP system in Kitakyushu Science and Research Park (KSRP), Kitakyushu, Japan; the system has been operational since July 2001.

This paper is organized as follows:

Section 2 introduces the main components of a CCHP system and the CCHP system at Kitakyushu Science and Research Park, the applied objective;

Section 3 describes the methodologies of reliability analysis and reliability importance analysis;

Section 4 analyzes the reliability of a CCHP system;

Section 5 presents the numerical calculations and dissection of the case;

Section 6 outlines the conclusions.

2. Main Components of CCHP Systems

Several technologies have been applied to CCHP systems for power generation, waste heat recovery, thermal storage, and thermal energy conversion such as an Absorption chiller. The main components of technologies are the keys to system reliability. The main components and subsystem technologies of a CCHP system are listed in

Table 1 [

7,

28]. Some auxiliaries and components are not listed in this table, such as cooling pumps, cooling towers, control panels and so on, but these components also have an influence on the subsystem or system reliability. Hence, auxiliaries and components will be considered in the reliability analysis of the system.

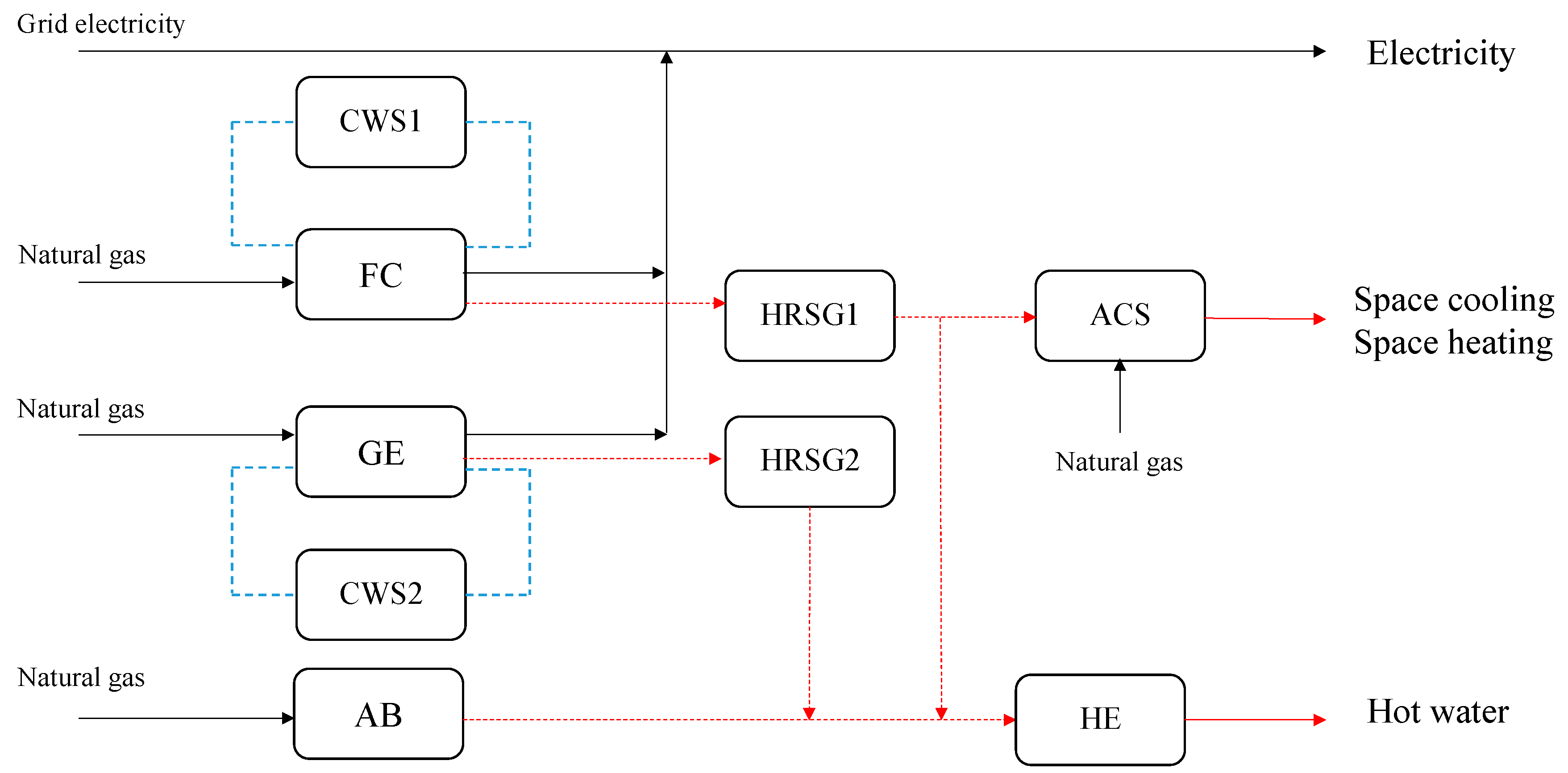

The CCHP system at Kitakyushu Science and Research Park (KSRP) [

29] is the analysis objective. The Kitakyushu Science and Research Park is located in Kitakyushu, Japan. The generation of electricity and thermal form of the CCHP system are used to meet the electricity load, space cooling load, space heating load, and hot water load of several buildings on the campus. The system scheme of the CCHP system at KSRP is shown in

Figure 1 [

30]. The fuel cells and gas engines fueled by natural gas are used to drive the power generation units to generate electricity. Every power generation unit has an independent cooling water system. The waste heat from the power generation unit is recovered by the heat recovery steam generator (HRSG), and the 50% recovered heat from the fuel cell is used to drive the absorption chiller to meet the space cooling load in summer and the space heating load in winter. The 50% recovered heat from the fuel cell and all recovered heat from the gas engine are used to drive the heat exchanger to meet the hot water load. Since the electricity generation of the system cannot meet the electricity load of the campus, it is necessary to purchase electricity from the electricity grid. The available gas-fired absorption chiller fueled by natural gas meets the shortage of space cooling and space heating. An auxiliary boiler fueled by natural gas is used to complement the shortage of hot water. Details of the power generation units of the CCHP system in KSRP is shown in

Table 2 [

30].

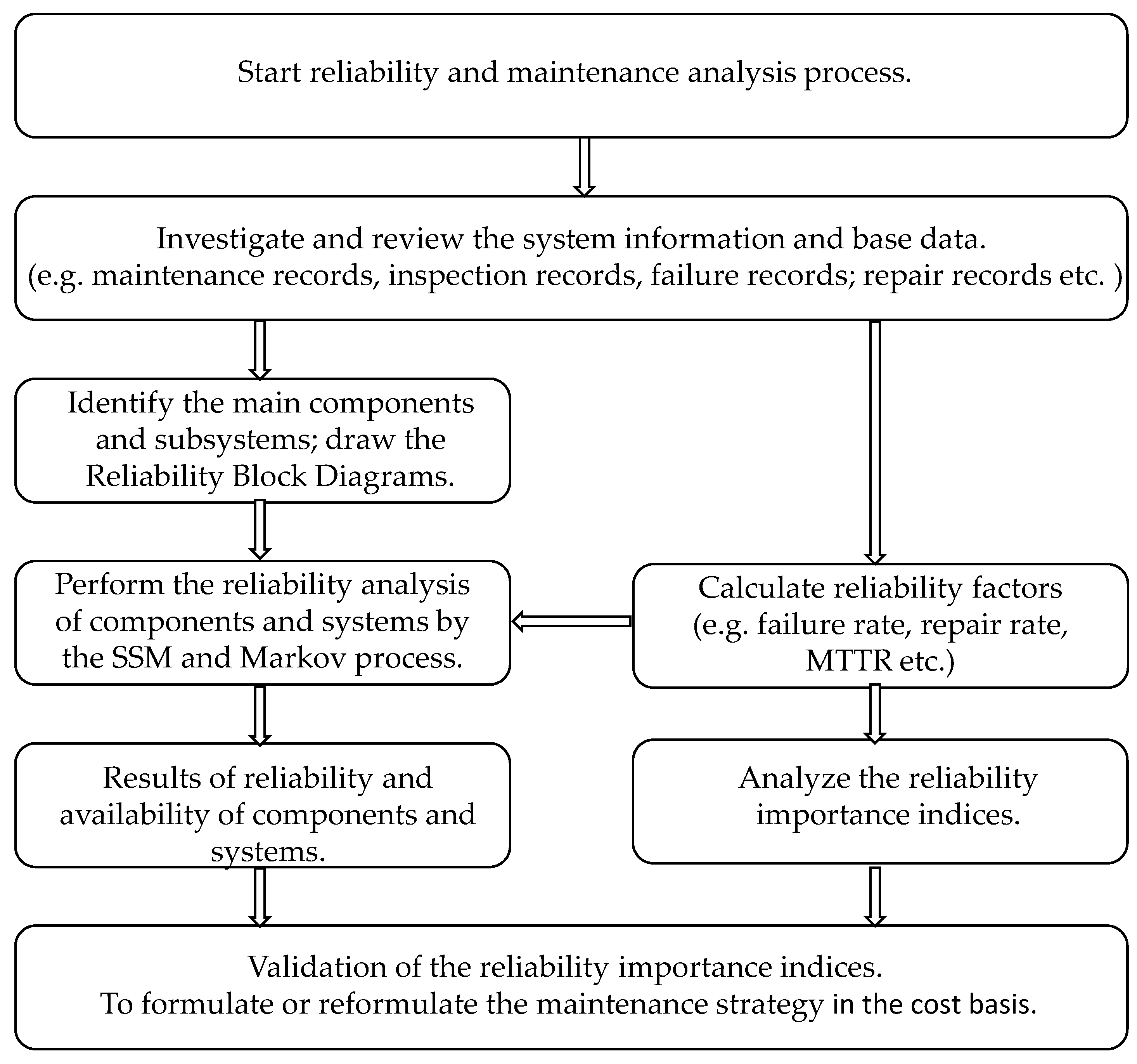

The research flow of reliability and maintenance prioritization analysis is shown in

Figure 2. Reliability and maintenance prioritization analyses will be applied to the components and subsystems of the CCHP system at KSRP. The following points of system reliability are assumed for the CCHP system at KSRP:

- (1)

The failure of a component or a subsystem is independent of each other. This analysis only considers one component failure and how it affects the system status and operation; multiple failures of components in the system will not be considered at this time.

- (2)

When a failure occurs in a power generation unit, the outage of electricity will be satisfied by the electricity grid and the failure of the electricity grid is not considered. Similarly, the outage of space cooling/heating, and hot water is considered satisfied when the corresponding system has failed.

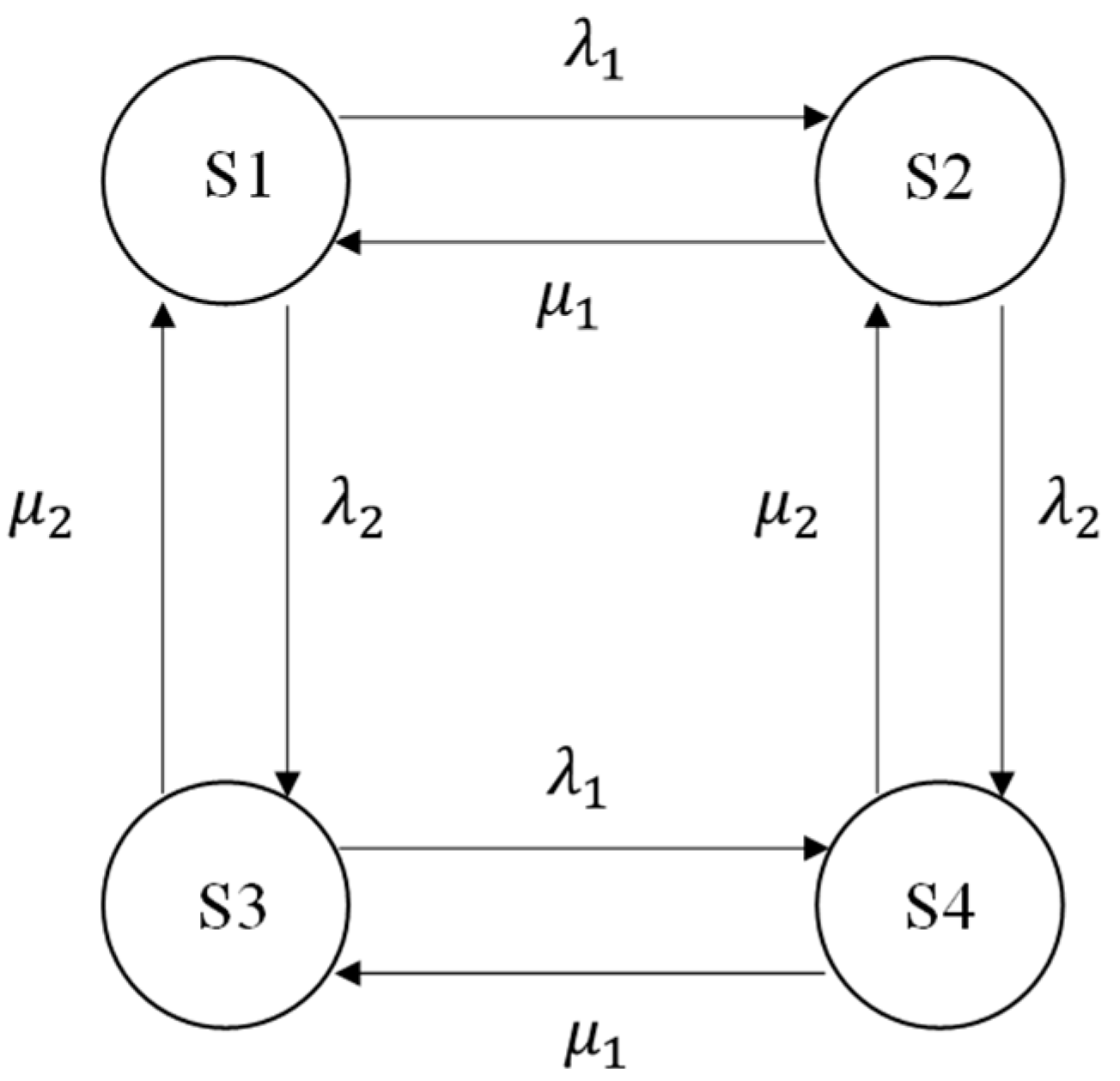

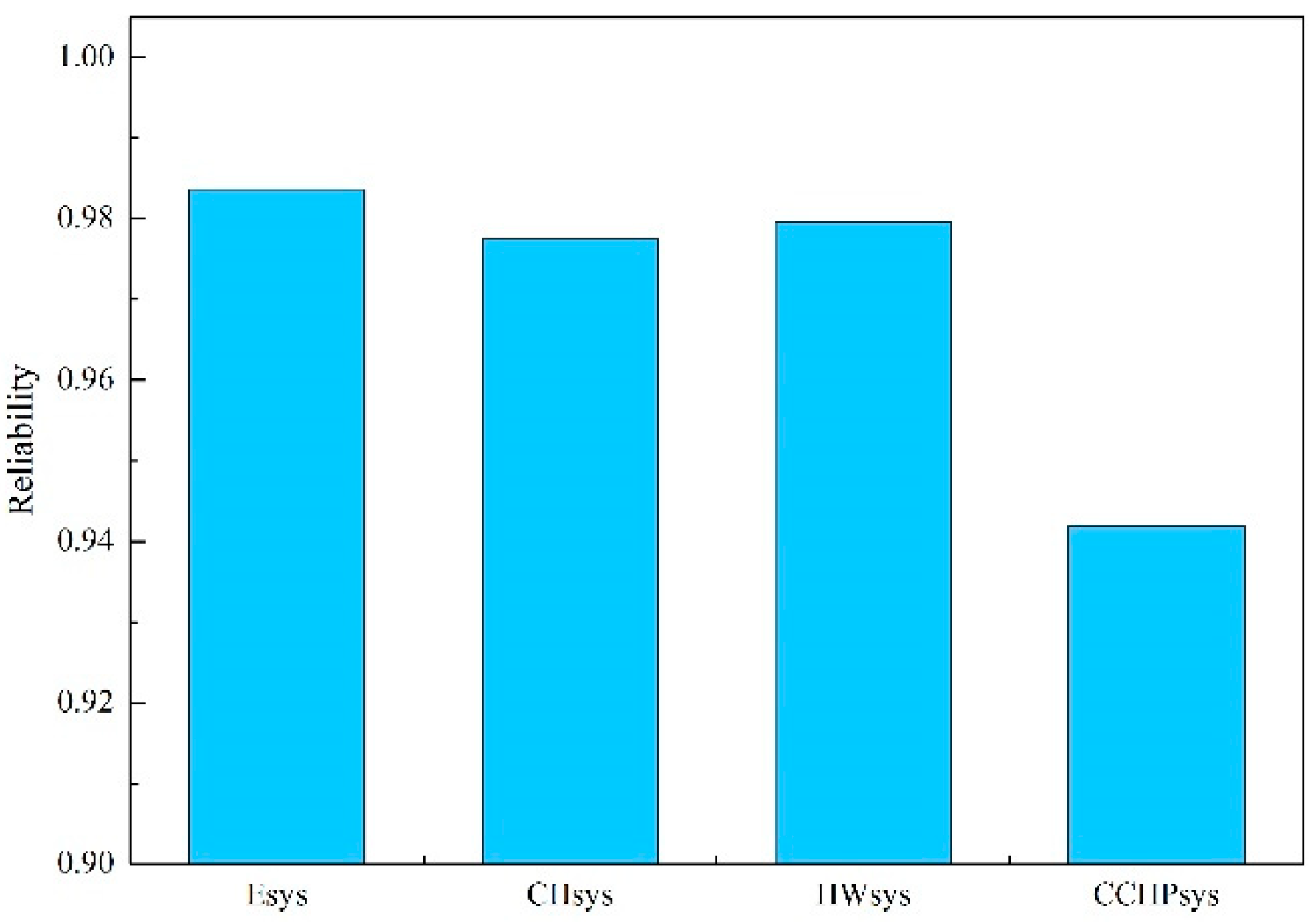

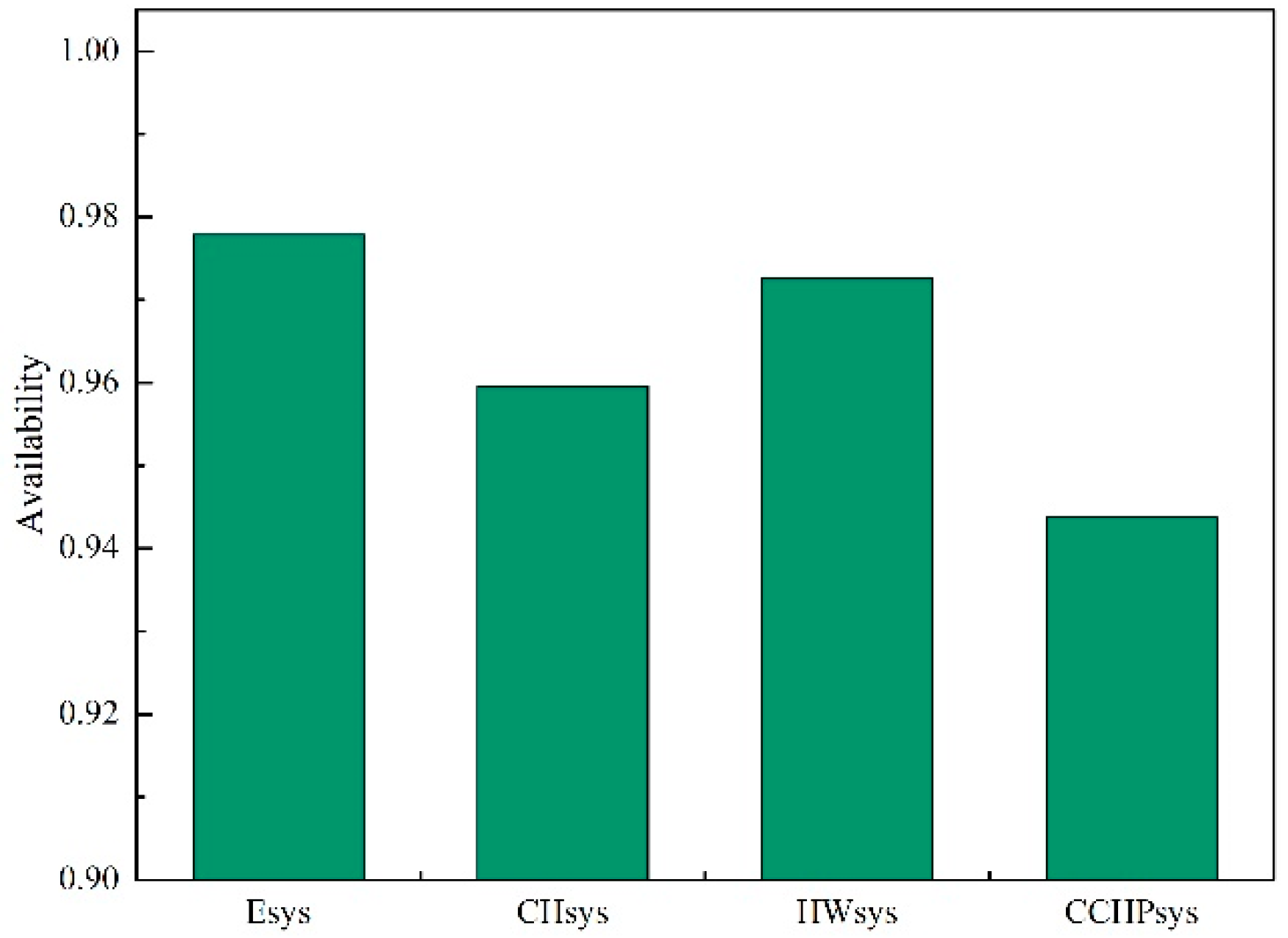

4. Reliability Analysis of CCHP System

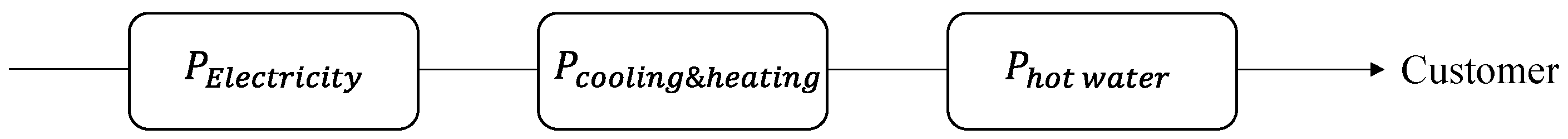

Reliability and availability analyses of components and subsystems are applied in the CCHP system at KSRP. The CCHP system is a complex system which can provide the electricity and thermal energies (cooling, heating, and hot water) to meet customer load, and is combined with a series of subsystems consisting of a power generation system, city gas supply system, water supply system, cooling water system, thermal supply system, and transfer system. Therefore, the reliability of this CCHP system must consider series subsystem reliability, which is too complex and difficult to be analyzed, hence, the reliability of this CCHP system was simplified as customer-oriented reliability; only the reliability of electricity, space cooling and heating, and hot water delivery to the customer were considered. The Markov processes and SSM were selected to analyze the reliability and availability of the electricity subsystem, space cooling and heating subsystem, hot water subsystem and the whole system.

A simple customer-oriented reliability model of the CCHP system is shown in

Figure 4. Based on this model, the electricity subsystem, space cooling and heating subsystem, and hot water subsystem are described as a series connection. This is because the whole system reliability should be considered from the perspective of the customer. Thus, the reliability of the whole system is written as:

When one of the subsystems fails but the other subsystems still function, it creates a situation of availability of the functioning subsystems but not the availability for the whole system. When a component or subsystem has stopped operating according to a schedule, its reliability is not cemented in the whole system’s reliability. According to the schedule, for instance, the space cooling and heating subsystem will stop in the spring or autumn due to lack of need resulting from temperature changes, therefore, the whole system’s reliability is only dependent on the electricity and hot water subsystem’s reliability. Even though parts of the system are no longer functioning, the rest of the system can continue to function.

4.1. Electricity Subsystem

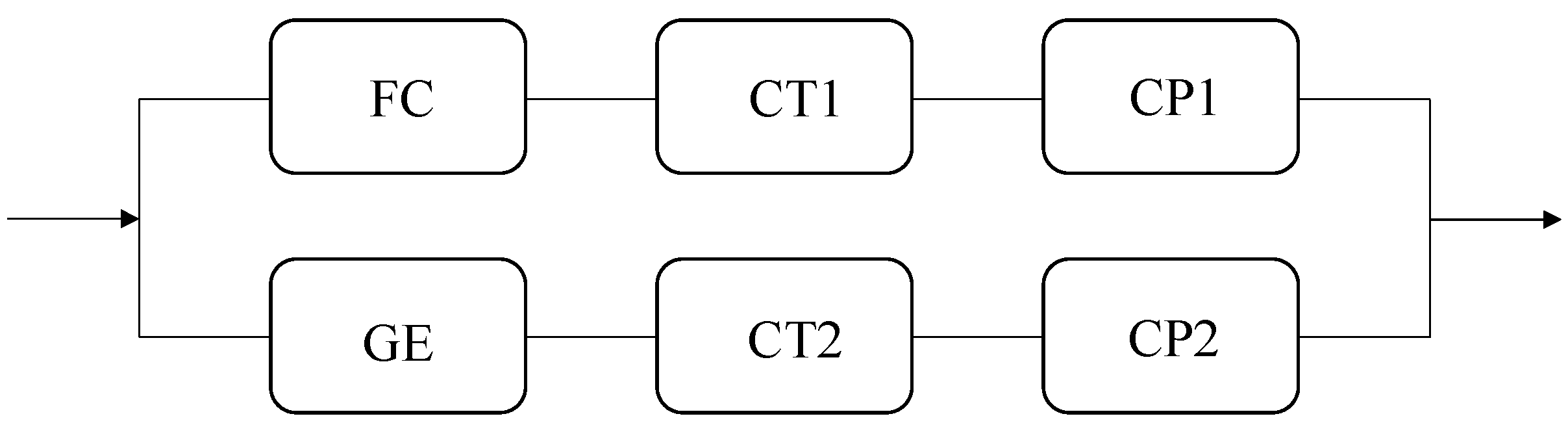

The subsystem of electricity generation of the CCHP system of KSRP consisted of two generation units, a fuel cell unit (E1) and a gas engine unit (E2). The main components of the electricity subsystem of the CCHP system are presented in

Table 5. The main components of the fuel cell unit included the fuel cell, cooling power1, and cooling pump1. The main components of the gas engine unit included the gas engine, cooling tower2, and cooling pump2.

A simplified reliability block diagram of the electricity subsystem of the CCHP system is shown in

Figure 5. Generally, the two generation units were regarded as having a parallel relationship, where at least one of them would be functioning, and the system was considered reliable and available. However, when one of the units failed, it caused the electricity supply to be in a lacking state. Thus, the situation where one of the units failed was considered as unavailable or partially available. The reliability of the whole system or a subsystem of the CCHP system was defined as all of the components of the system functioning under given conditions for the stated period. This system, considering customer-oriented reliability, could be described as all subsystems were reliable since the system can be viewed as a series system.

Based on reliability analysis methods introduced in

Section 3.1, the operation states and reliability data for the electricity subsystem of the CCHP system is shown in

Table 6. The operation states of the electricity subsystem included 4 states, the completely available state (State1), the partially available states (State2, State3), and the completely unavailable state (State4). The failure rate and repair rate of E1, E2, and the subsystems are symbolized in

Table 6. The reliability of the electricity subsystem was dependent on the reliability of State1, thus, the reliability of the electricity subsystem was determined by both E1 and E2.

A series system’s reliability was expressed by Equation (14), thus, the reliability of E1 is presented as follows:

A reliability can be expressed by the failure rate as in the following equation:

Therefore, if the failure rates are constant, then Equation (24) can be expressed as

Thus, the following equation is obtained from the above equation:

Similarly, the failure rate of E2 is obtained using

Moreover, the availability of the electricity subsystem is equal to the probability of State1, and it also is defined as

, therefore, the availability of the electricity subsystem is expressed as

Therefore, the repair rate of the electricity system is solved as

Let

,

,

, and then

Usually,

,

and then, Equation (32) is written as

Thus, the repair rate of the electricity subsystem is obtained by the following:

Hence, for a series system consisting of

n components, the failure rate and repair rate are presented as the following, respectively:

Thus, the main reliability parameters of E1, E2, and the electricity subsystem are expressed as the following:

Failure rate of electricity subsystem:

Repair rate of electricity subsystem:

The availability of the electricity subsystem:

The reliability of the electricity subsystem:

4.2. Space Cooling and Heating Subsystem

The space cooling and heating subsystem of the CCHP system at KSRP consisted of three space cooling and heating generation units, the generation units that used the waste heat from the fuel cell unit (CH1), and the generation units that assisted the absorption chiller fueled by natural gas (CH2 and CH3). More details of the space cooling and heating subsystem are shown in

Table 7. The main components of CH1 included the fuel cell unit (E1), the heat recovery steam generator1, and the absorption chiller1. CH2 and CH3 only had one component, an absorption chiller fueled by natural gas.

A simplified reliability block diagram of the space cooling and heating subsystem of the CCHP system is shown in

Figure 6. The space cooling and heating for customers came from three ways. The CH2 and CH3 each used the same component. The operation states and reliability data for the space cooling and heating subsystem of the CCHP system are presented in

Table 8. Due to CH2 and CH3 only having one component, the failure rate and repair rate of CH2 and CH3 units were expressed by the component’s failure rate and repair rate. The reliability and availability of the space cooling and heating subsystem were equal to the reliability and availability of State 1.

According to Equations (34) and (35), the main reliability parameters of the CH1 unit and space cooling and heating subsystem are expressed as the following:

Failure rate of the space cooling and heating subsystem:

Repair rate of the space cooling and heating subsystem:

The availability of the space cooling and heating subsystem:

The reliability of the space cooling and heating subsystem:

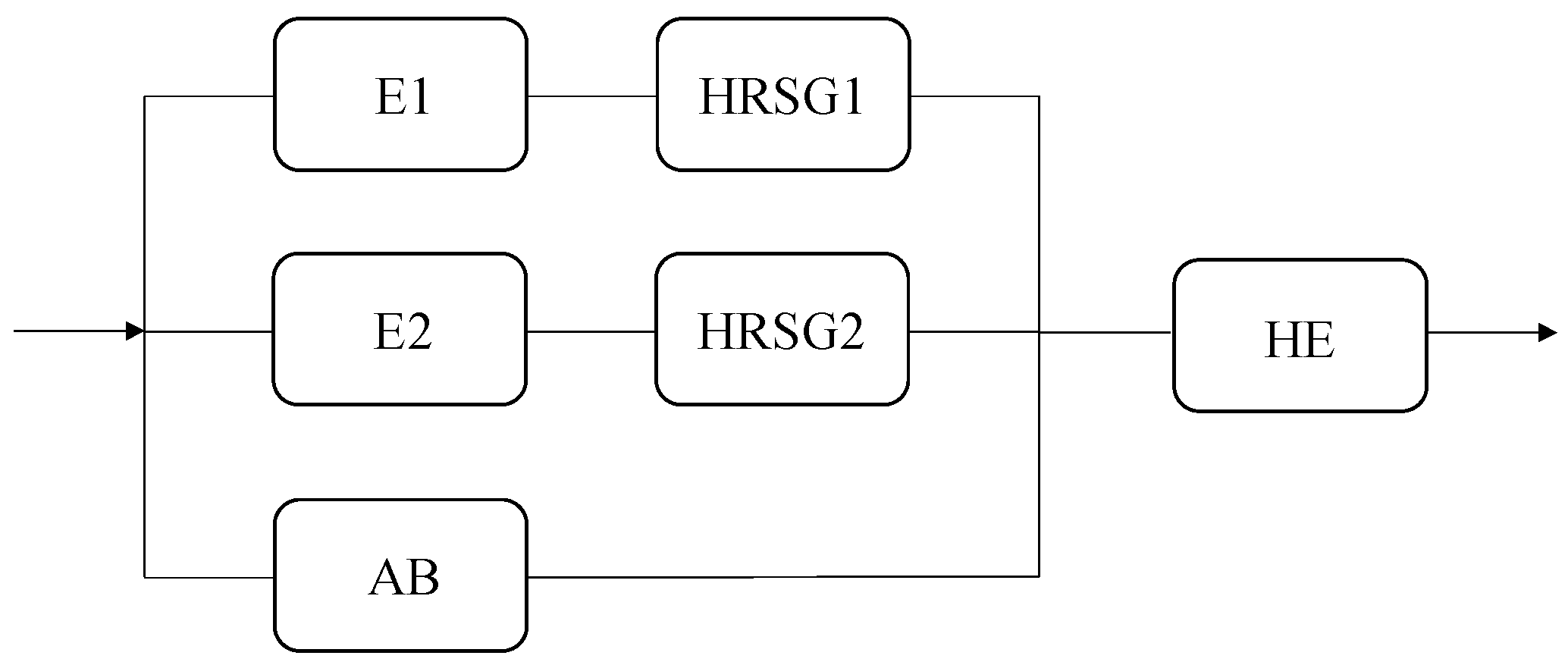

4.3. Hot Water Subsystem

The hot water subsystem of the CCHP system at KSRP consisted of three hot water generation units and a heat exchanger unit. The generation unit (HW1) used the recovery heat from E1, the generation unit (HW2) used the recovery heat from E2, and an auxiliary boiler (HW1) fueled by natural gas produced the hot water when the heat from HW1 and HW2 was not enough. A heat exchanger unit (HE) was used to exchange the heat to hot water. More details of the main components of the hot water subsystem are shown in

Table 9. The main components of HW1 included the fuel cell unit and heat recovery steam generator1. The main components of HW2 included the gas engine unit and heat recovery steam generator2, while HW3 had only one component, the auxiliary boiler.

A simplified reliability block diagram of the hot water subsystem of the CCHP system is shown in

Figure 7. The hot water subsystem was regarded as a series system consisting of the three hot water generation units and a heat exchanger unit. When the heat exchanger unit failed, the hot water supply was interrupted and the hot water subsystem was unavailable. The operation states and reliability data for the hot water subsystem of the CCHP system is shown in

Table 10. There were 9 states of the hot water subsystem. The reliability and availability of the hot water subsystem were equal to the reliability and availability of State1. Thus, the main reliability parameters of HW1, HW2, and the hot water subsystem were obtained as follows:

Failure rate of the hot water subsystem:

Repair rate of the hot water subsystem:

The availability of the hot water subsystem:

The reliability of the hot water subsystem:

6. Conclusions and Prospects

This paper focuses on the reliability and availability analysis and components maintenance prioritization analysis of the CCHP system. Failure cost importance index (FCI) and potential failure cost importance index (PI) were developed for the maintenance prioritization analysis of the CCHP system. A Markov model based on a state–space method was used to analyze the reliability and availability of the CCHP system. The reliability and availability of the components, subsystems, and whole system were deduced.

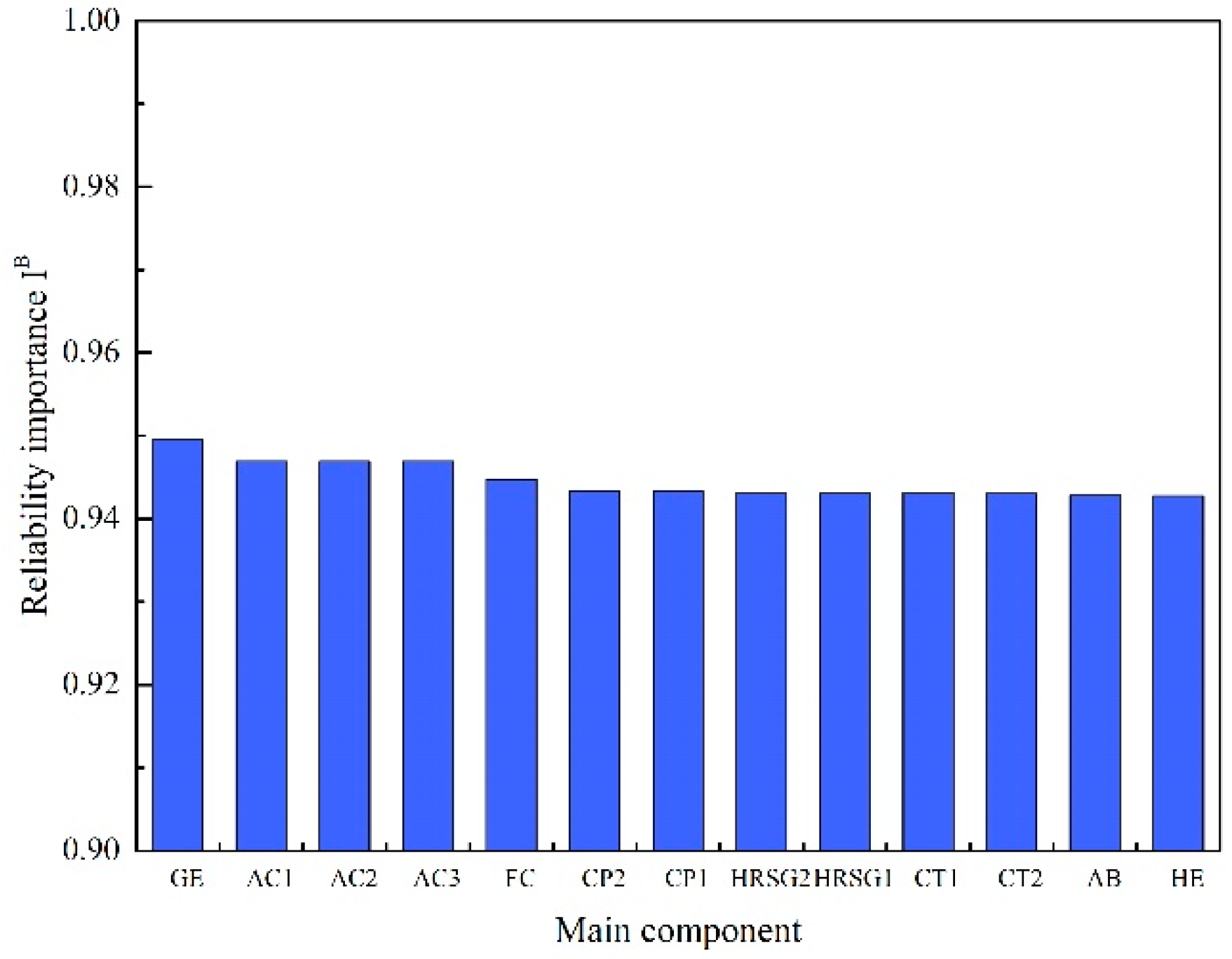

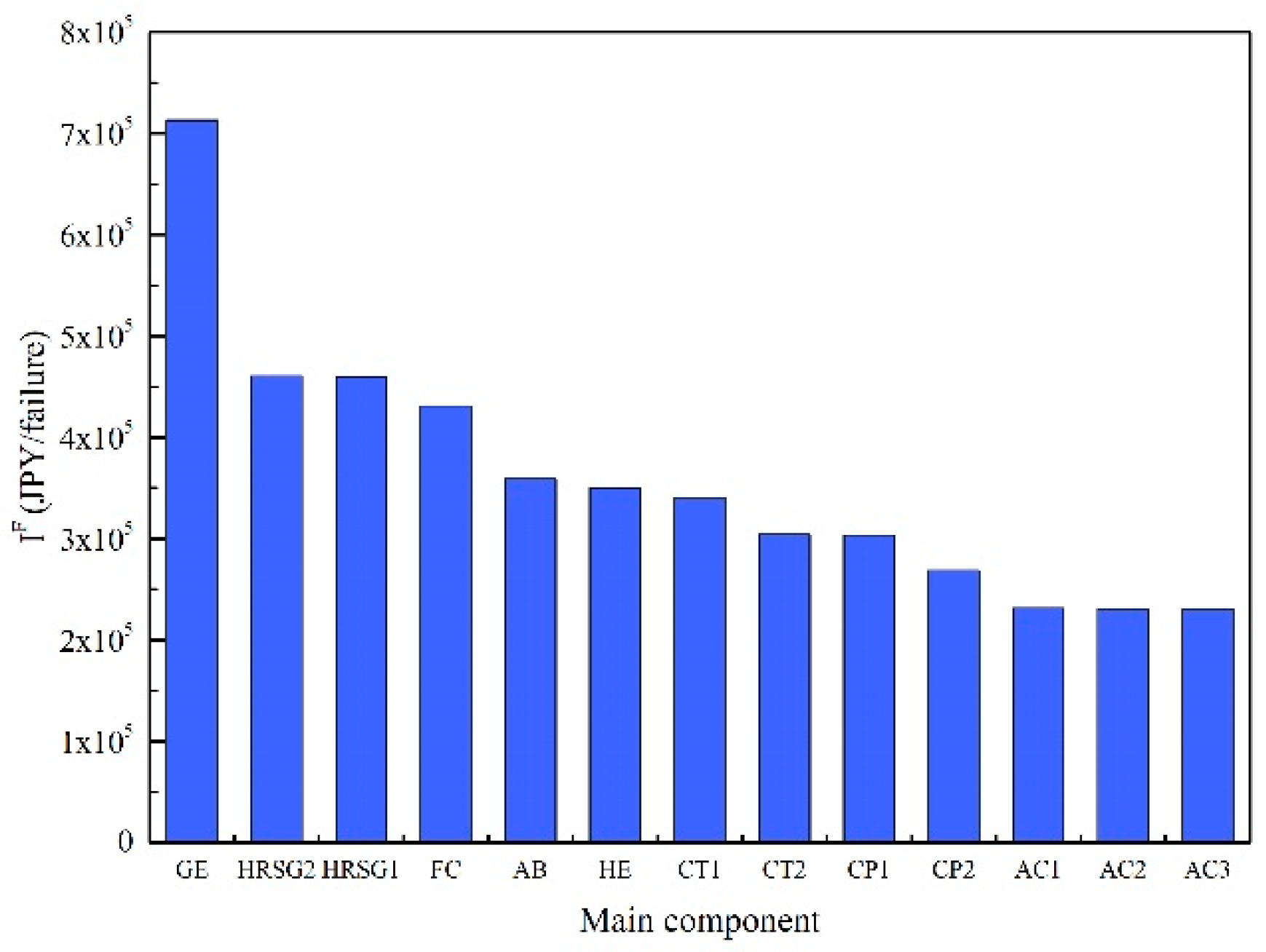

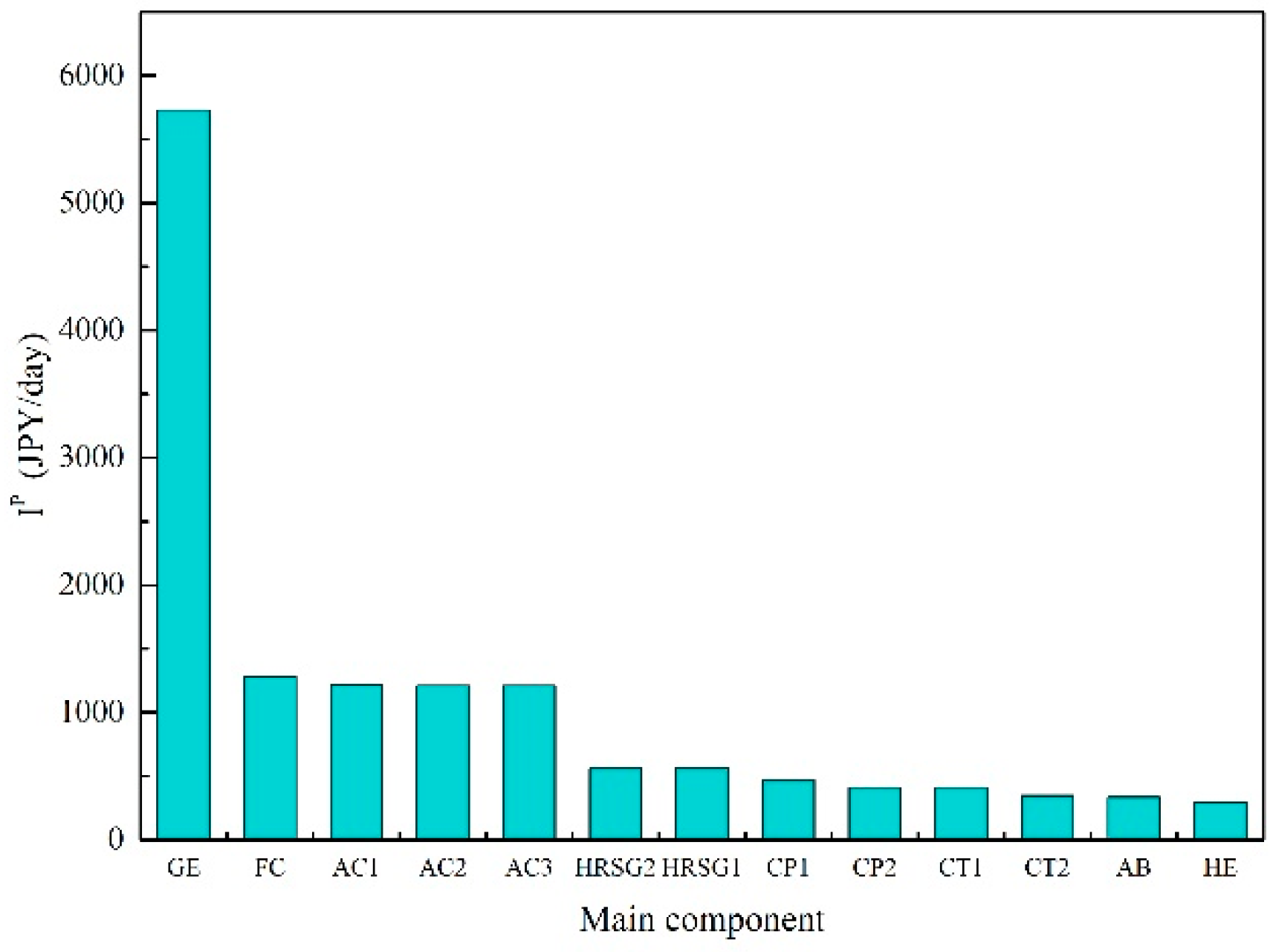

This paper aimed at selecting the component reliability importance indices to identify the priority of the component maintenance from the perspective of maintenance cost. The BI and CI were used to compare to FCI and PI. It was observed that the FCI and PI might lead to different rankings. FCI enabled the system managers to know the cost of a one-time failure of each component in a system. PI enabled the system managers to know the cost before the failure occurred for a one-time failure of each component in a system. The two indices would help managers to make a reasonable decision for maintenance on the cost basis, and also help designers to optimize the system on the cost basis.

The reliability of the CCHP system is the product of the reliability of each component when the reliability is considered the energy supply. The system reliability can be ensured by improving the components’ failure rates. The auxiliary boiler (low failure rate with high failure cost) can improve the reliability of the subsystem.

The reliability and availability analysis method is the only study on how one component failure can affect the system as a whole or in part; the reliability of multiple failure states and the time-variances were ignored. Moreover, the CCHP system is a complex and repairable system, generally with high maintenance and reliability, where failure data is difficult to obtain, thus, the degradation data can be used to optimize the maintenance strategy based on the component reliability importance indices.

The proposed component reliability importance indices of the maintenance prioritization analysis in this paper can be applied to other cogeneration systems or to other maintenance problems. The reliability importance indices will be further validated in CCHP systems which use renewable energies and other technologies like PV, wind power, or heat pumps.