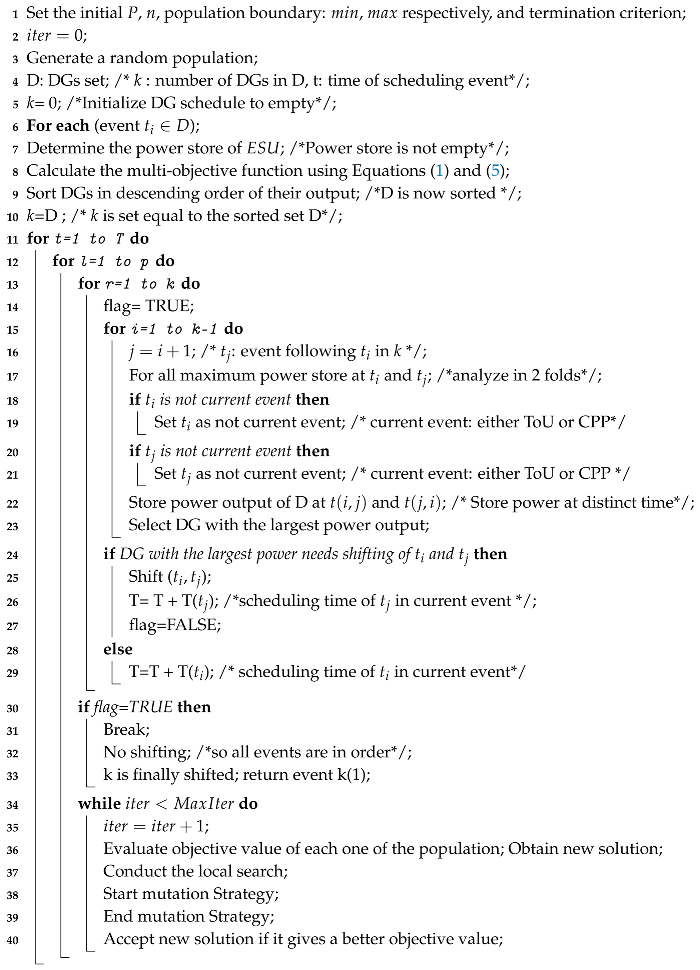

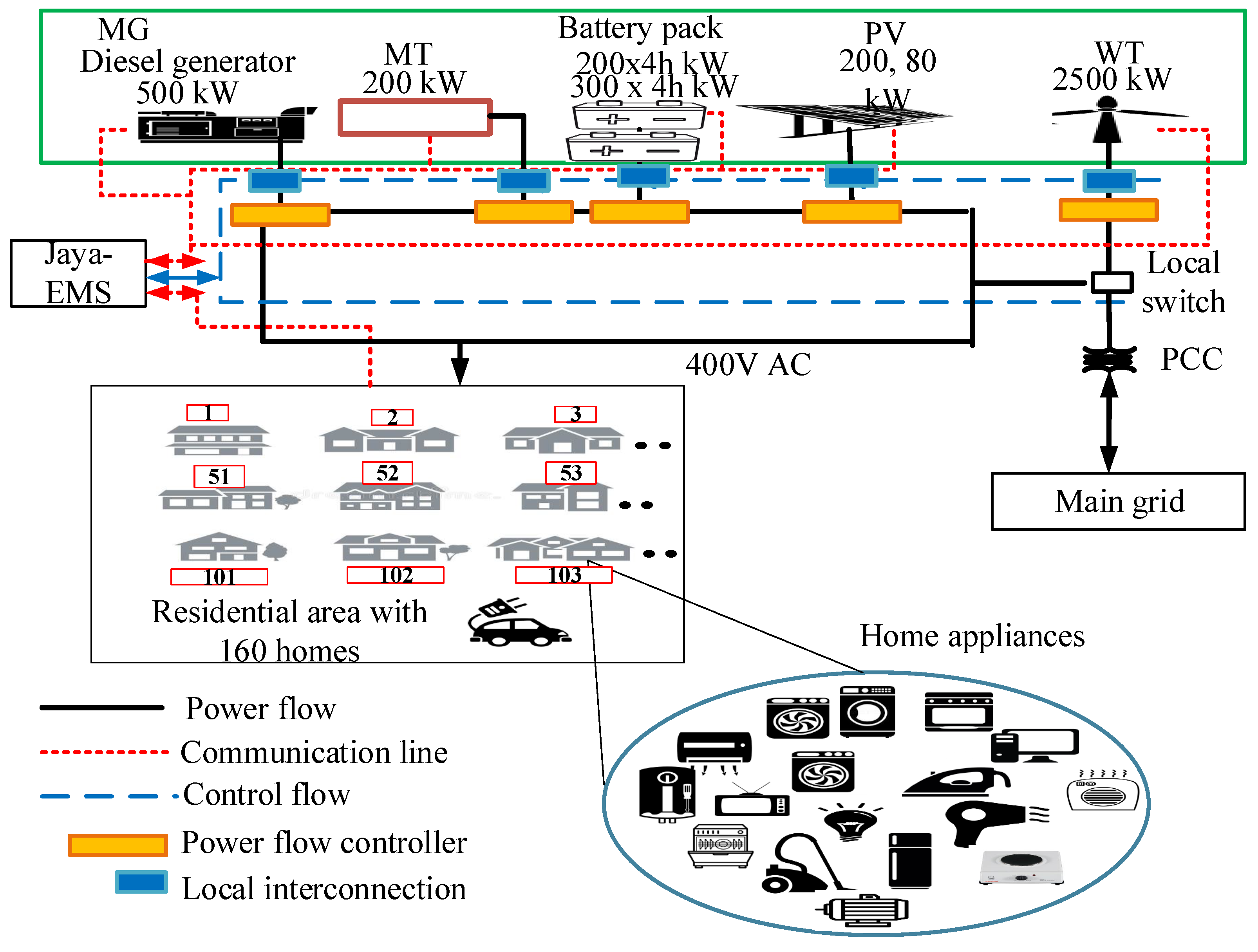

In this section, we illustrate the effectiveness of the proposed system model through two case studies: standalone and grid-connected operation modes. The proposed multi-objective optimization problem was simulated in MATLAB R2016a. Hourly time-dependent and event-based electricity prices are shown in

Table 3, and were used for energy exchange with the utility. The power ratings of WT, PV, MT, diesel generator, and ESS were chosen empirically based on the parameters shown in

Table 4,

Table 5,

Table 6 and

Table 7, respectively. The results of the proposed method were analyzed and compared with that of SBA and EDE respectively.

5.1. Operation in Standalone MG Mode

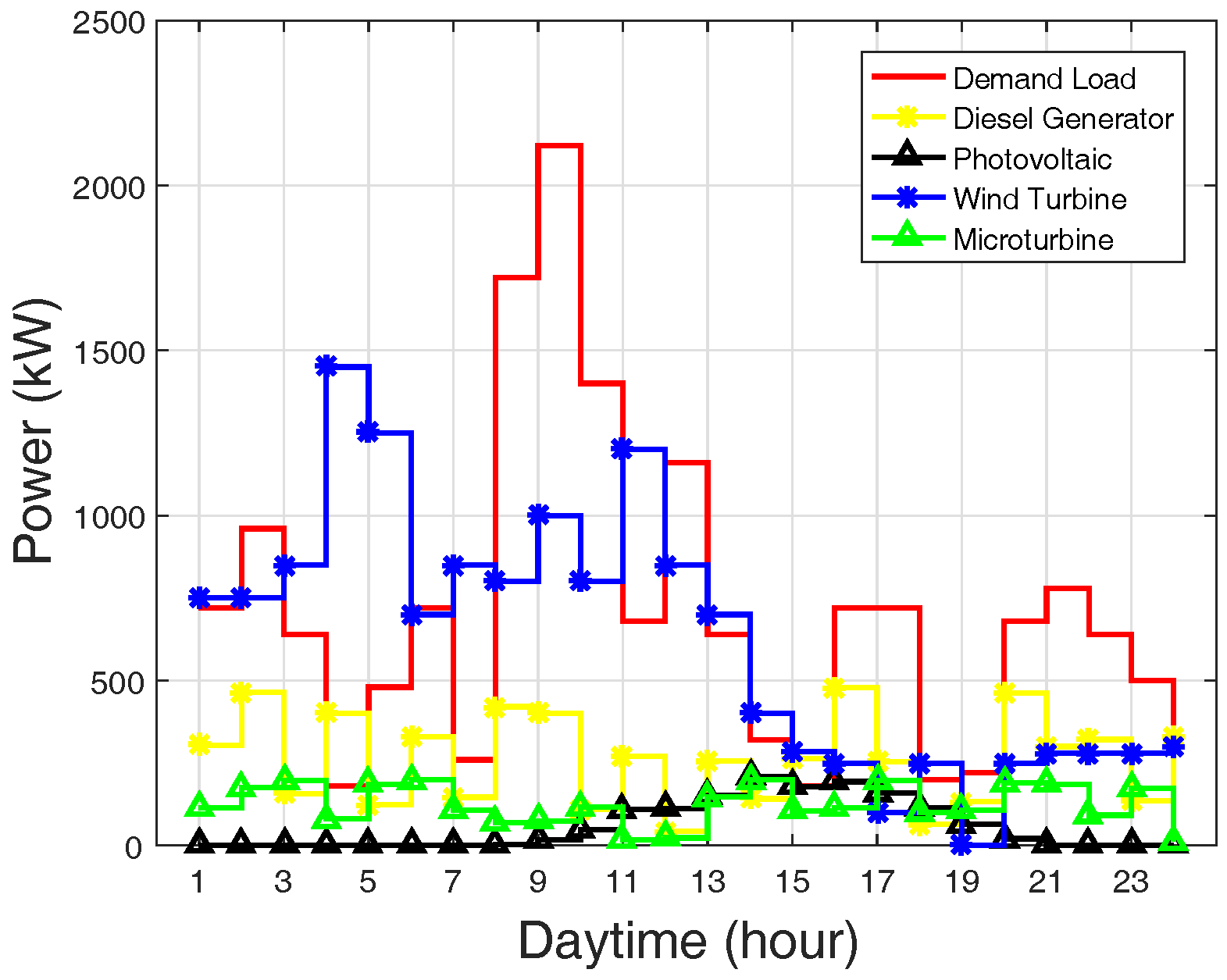

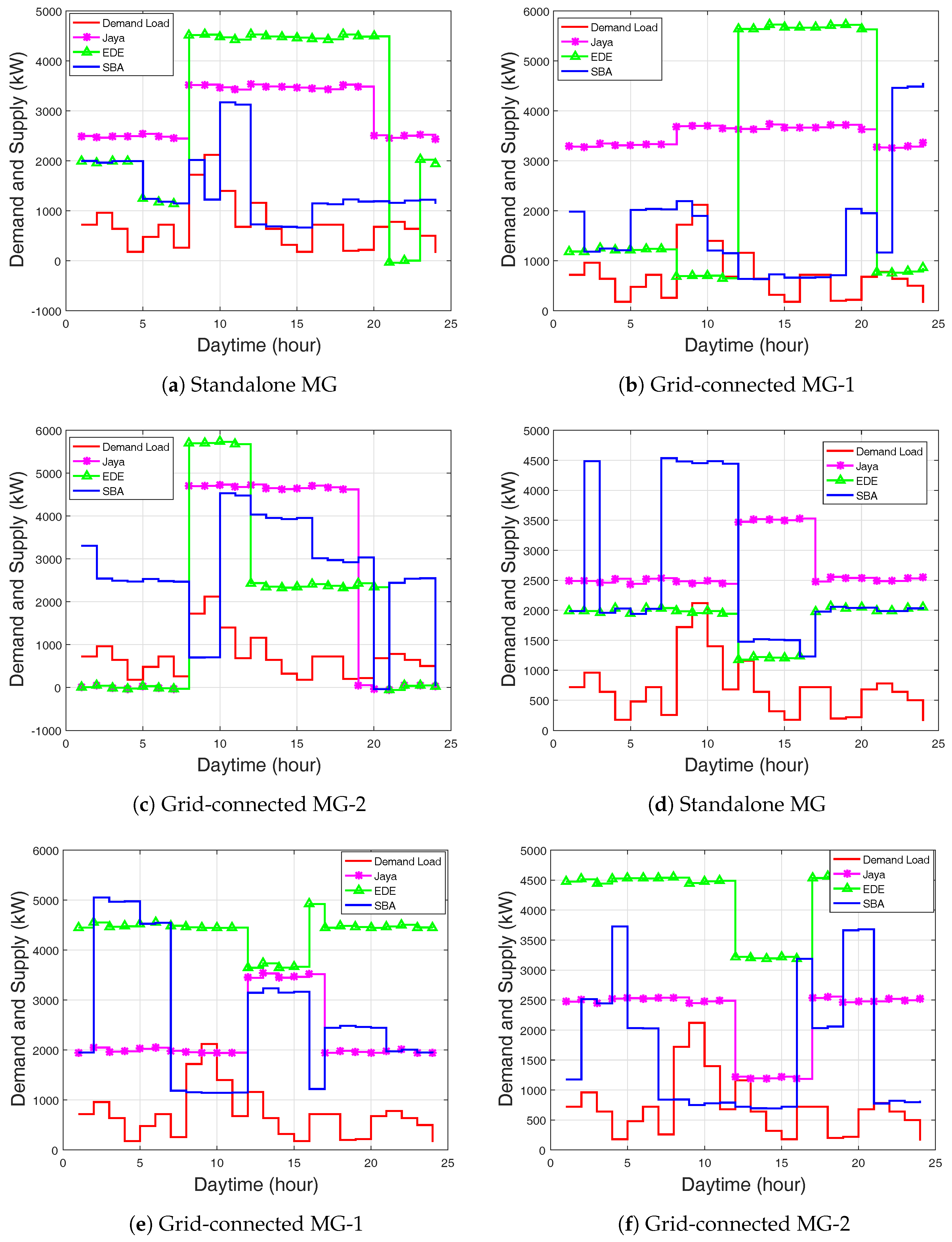

Figure 3 shows the hourly rating of DGs and the load demand. Load demand is the hourly aggregated operational loads of multiple homes. The figure shows that demand load is far greater than the initial power capacity of each distributed generation unit.

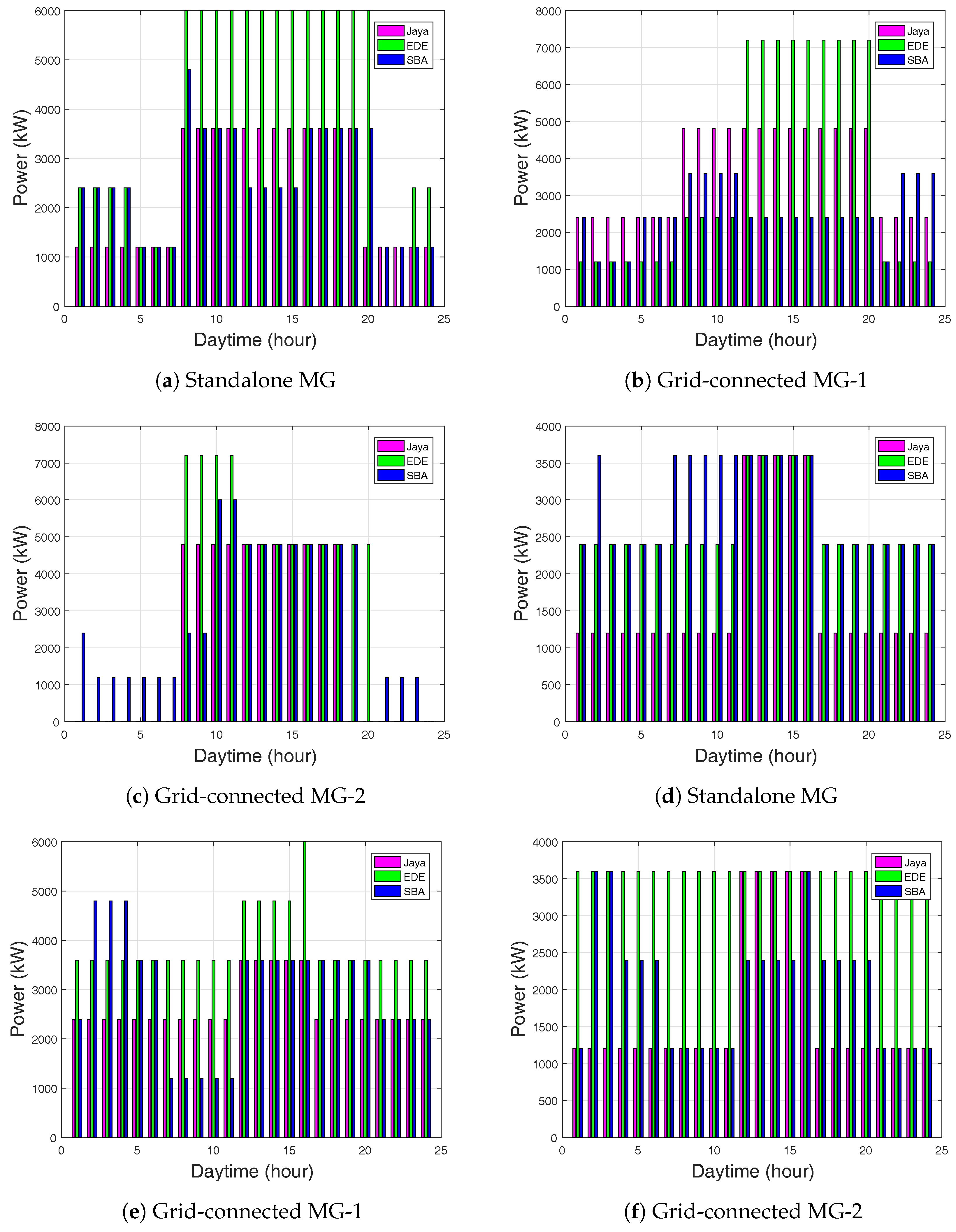

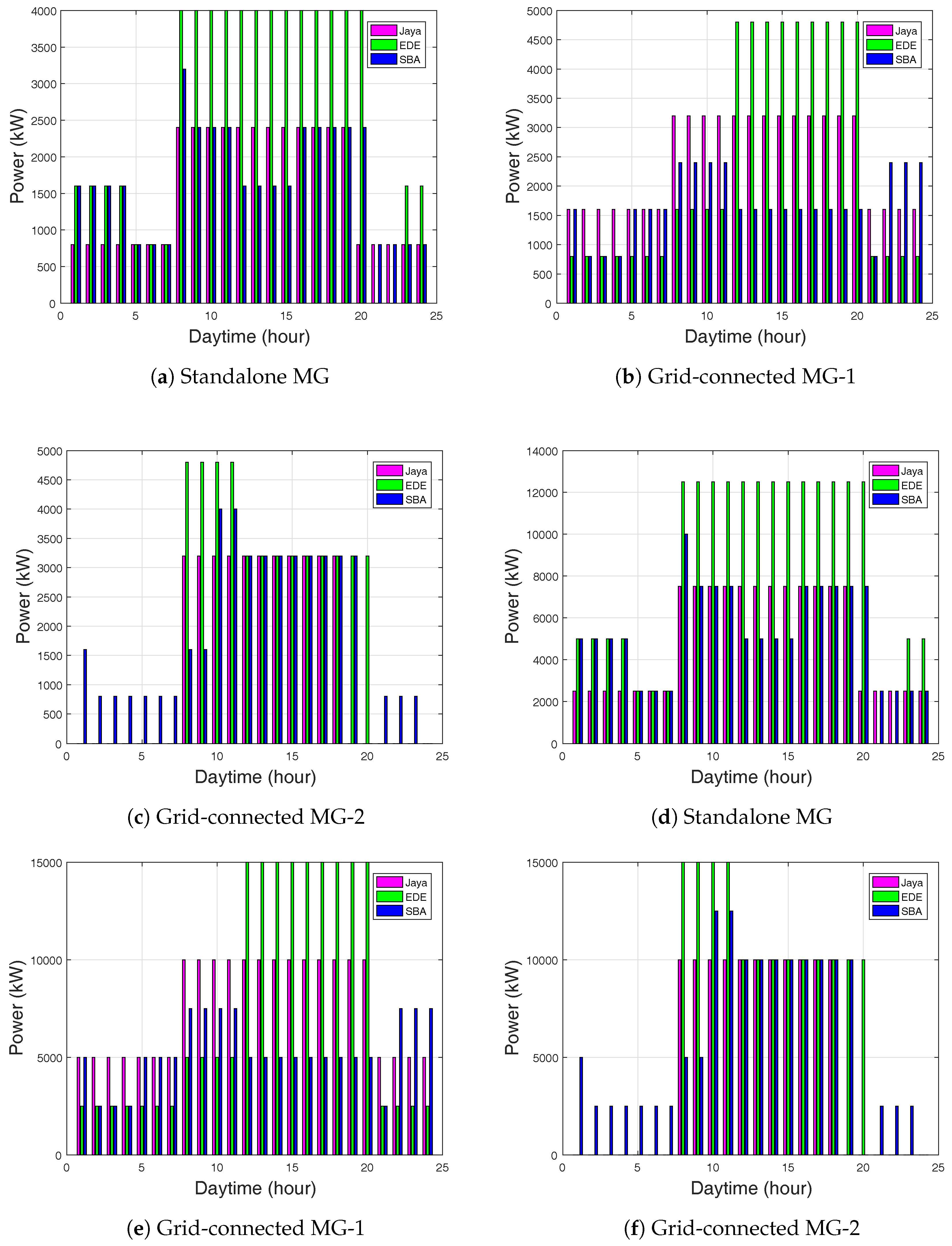

Optimal energy management for a MG with hourly ESU and SOC are shown in

Figure 4,

Figure 5 and

Figure 6. In the ToU case for battery-1: During the first 7 h (12 a.m.–6 a.m.) of the simulation period for the ESU, the Jaya-based EMS stored the power of 3500 kW for 9–19 h and reduced in subsequent hours. EDE stored the power of 7200 kW, whereas the SBA-based EMS stored 6000 kW, as shown in

Figure 4a for the standalone grid. The Jaya-based EMS stored the power of 4800 kW, whereas the EDE-based EMS stored 7200 kW and the SBA-based EMS stored 3200 kW, as shown in

Figure 4b for grid-connected MG-1. In

Figure 4c, the Jaya-based EMS stored the power of 4800 kW and EDE-based EMS stored 7200 kW, whereas, SBA-based EMS stored 6000 kW for grid-connected MG-2.

For the CPP case: 3500 kW was the stored power for Jaya, EDE, and SBA-based EMS, as shown in

Figure 4d for the standalone grid. The stored power for Jaya in grid-connected MG-1 was 3500 kW, it was 6000 kW for EDE, and was 4800 kW SBA-based EMS, as shown in

Figure 4e. Similarly, 3600 kW was the stored power of Jaya, EDE, and SBA-based EMS as shown in

Figure 4f for grid-connected MG-2.

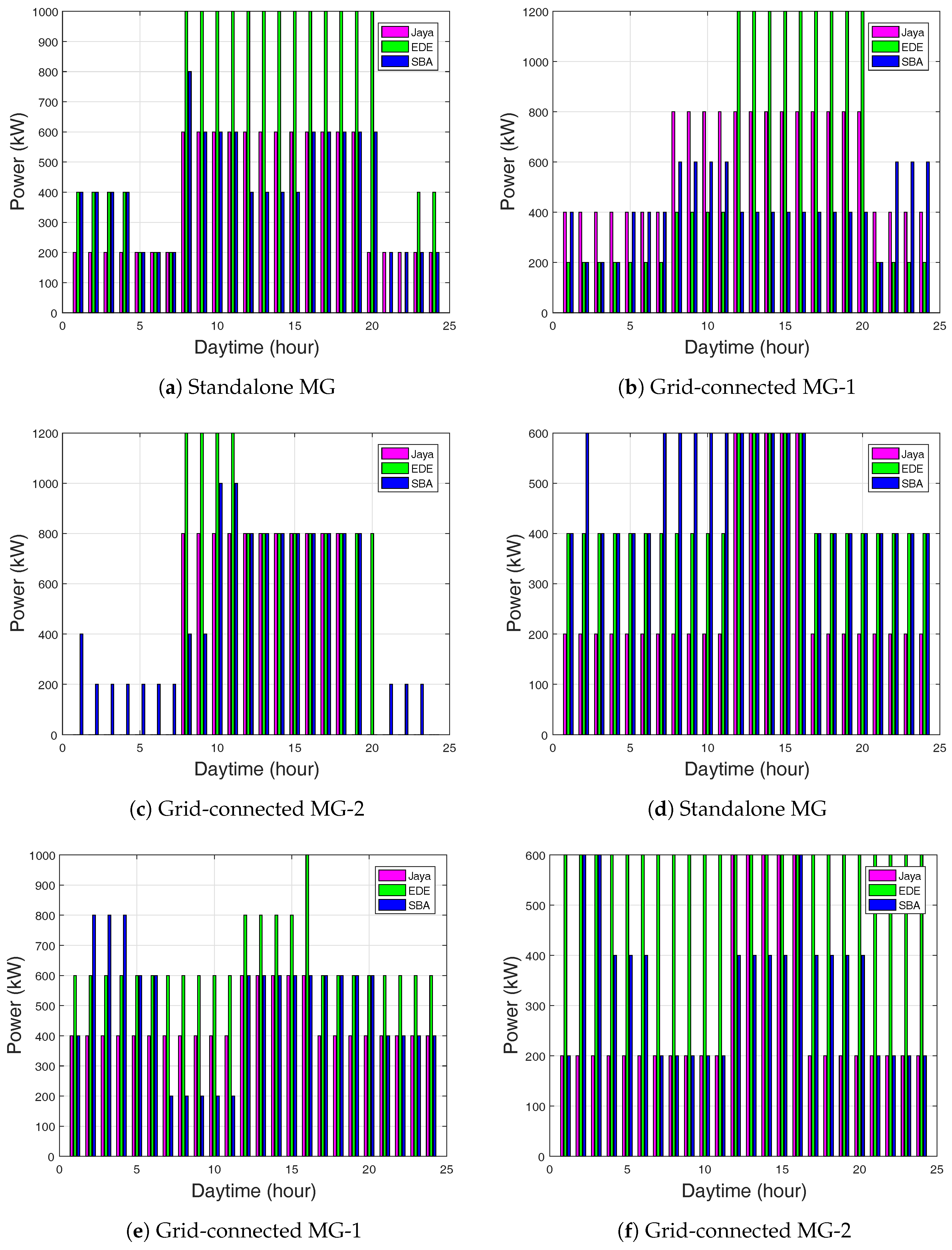

In battery-2, Jaya-based stored the power of 2800 kW, EDE-based stored 4000 kW, and SBA stored 3300 kW, as shown in

Figure 5a for the standalone grid. In

Figure 5b, Jaya-based stored the power of 3200 kW, EDE-based stored 4600 kW, and SBA-based EMS stored 2800 kW for for the grid-connected MG-1. Jaya-based EMS stored the power of 3200 kW, EDE-based stored 4700 kW, and SBA-based stored 4000 kW for the grid-connected MG-2. However, Jaya-based did not show stored power in some hours, because Jaya-based EMS sufficiently satisfied load demand.

In

Figure 5d, the diesel generator for the standalone showed that Jaya-based EMS reduced its power supply during the first 1–9 h as compared to EDE and SBA. The maximum power supply of the diesel generator for Jaya-based EMS was 6800 kW, as compared to 12,200 kW for EDE and SBA. The maximum diesel power generation was 10,000 kW, as compared to 15,000 kW for EDE and SBA, as shown in

Figure 5e. Similarly, for the Jaya-based EMS, the maximum diesel power generation was 10,000 kW, as compared to 15,000 kW for EDE and SBA (

Figure 5f). However, the Jaya-based EMS had no diesel power supply during first 1–9 h and 19–24 h respectively. This is because the stored power in the batteries was used to satisfy the demand load request during these hours.

The batteries had unstable charging behavior due to the high demand load request.

Figure 6a shows the SOC for the two MG operational modes. Meanwhile, the batteries maximum charging rates were 99% for SBA, 96% for Jaya, and 95% for EDE. There was no charging rate below the initially charged limit, and the MG could meet the load requirement even for the inactive state.

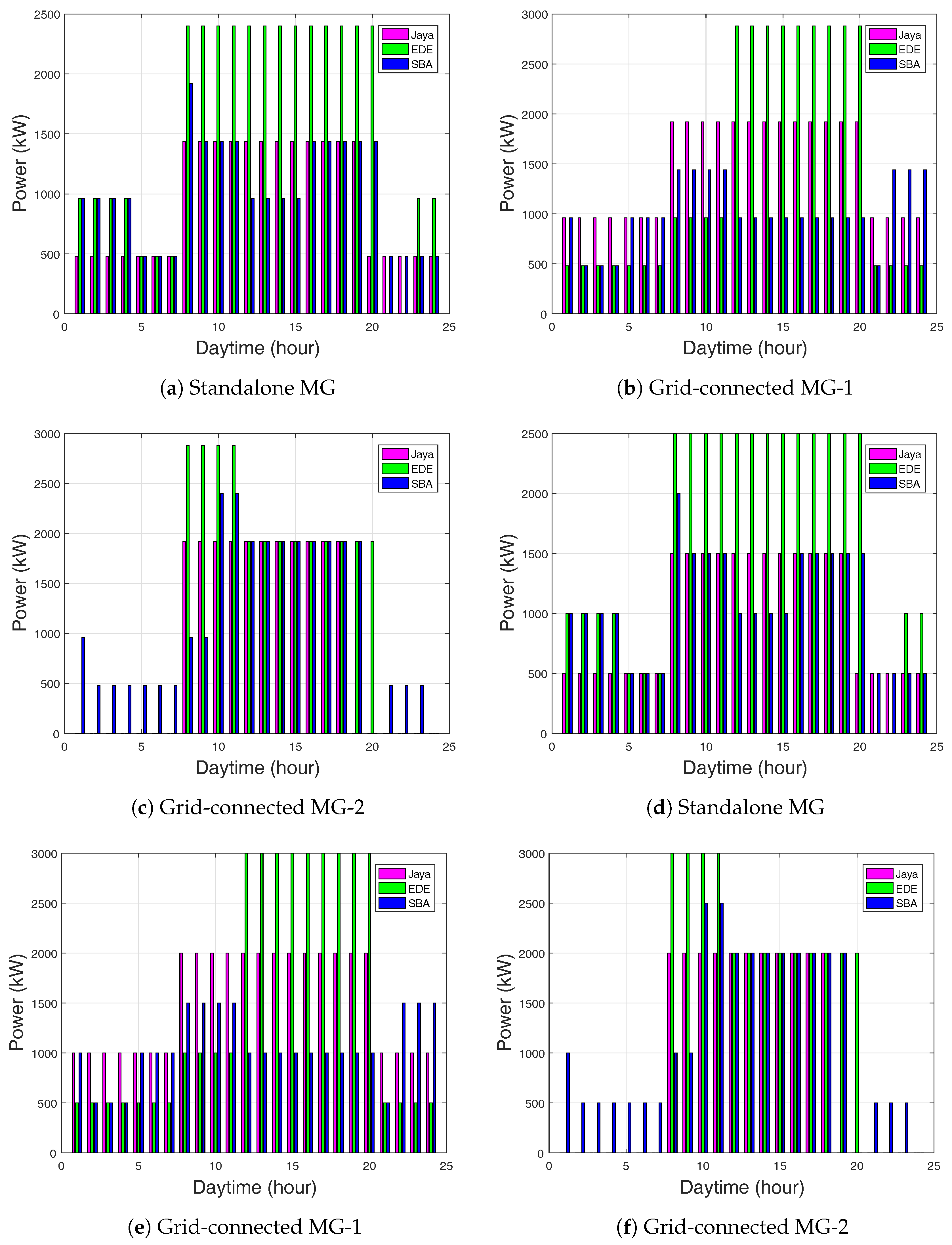

The PV unit significantly supplied 2500 kW power more than the 2400 kW of WT and 1000 kW of MT, as shown in

Figure 7a and

Figure 8a. SBA and EDE supplied more power in the WT unit than Jaya-based EMS.

Figure 8d shows the maximum power supply of 2000 kW, 2500 kW, and 1500 kW of PV for SBA, EDE, and Jaya-based EMS, respectively. In this period, the MG could satisfy the load requirement and charged the batteries. The diesel generator unit supplied power of 12,200 kW as compared to the 8000 kW of battery-1 and 4000 kW of battery-2. Thus, fuel cost increased.

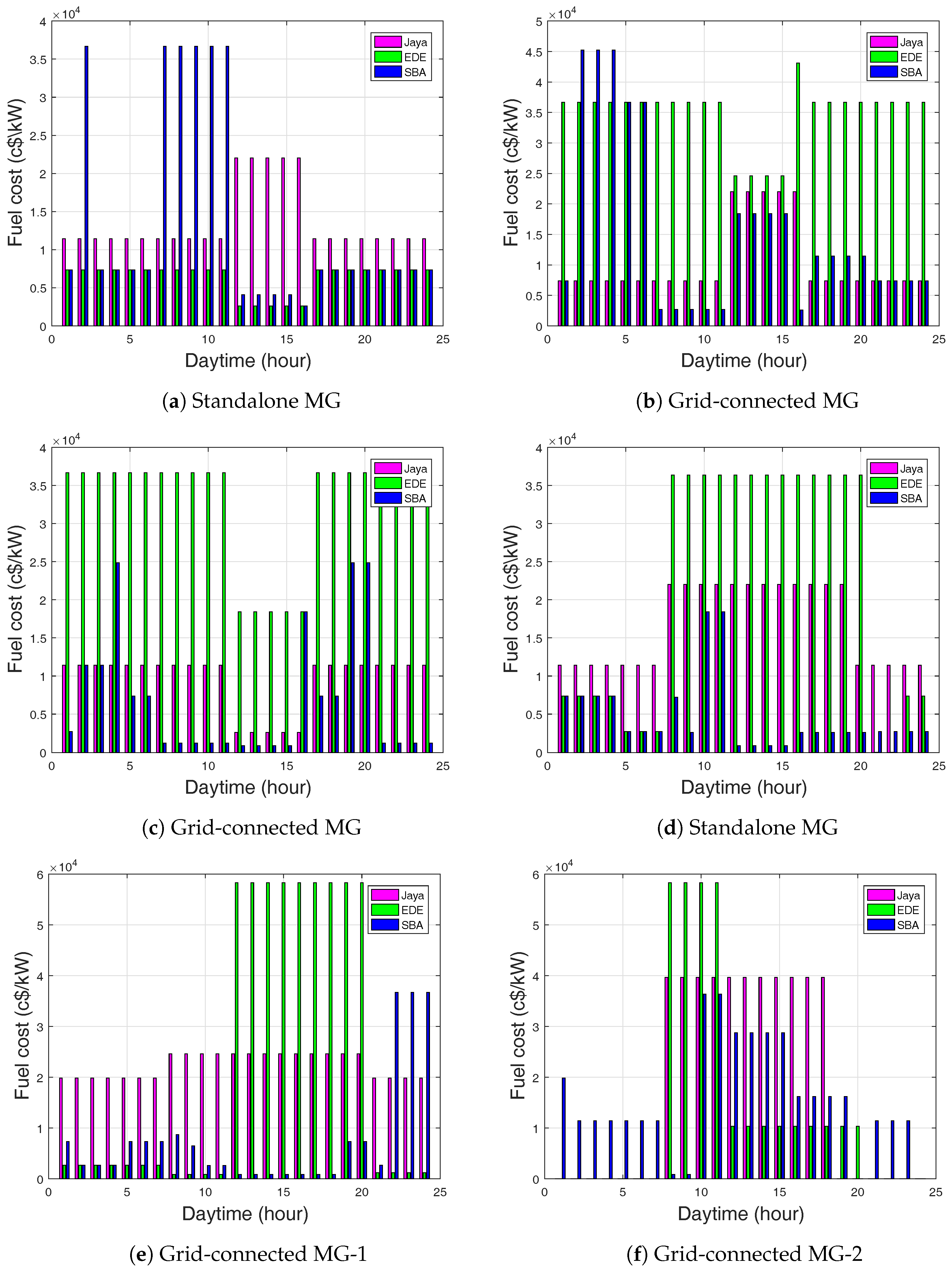

In

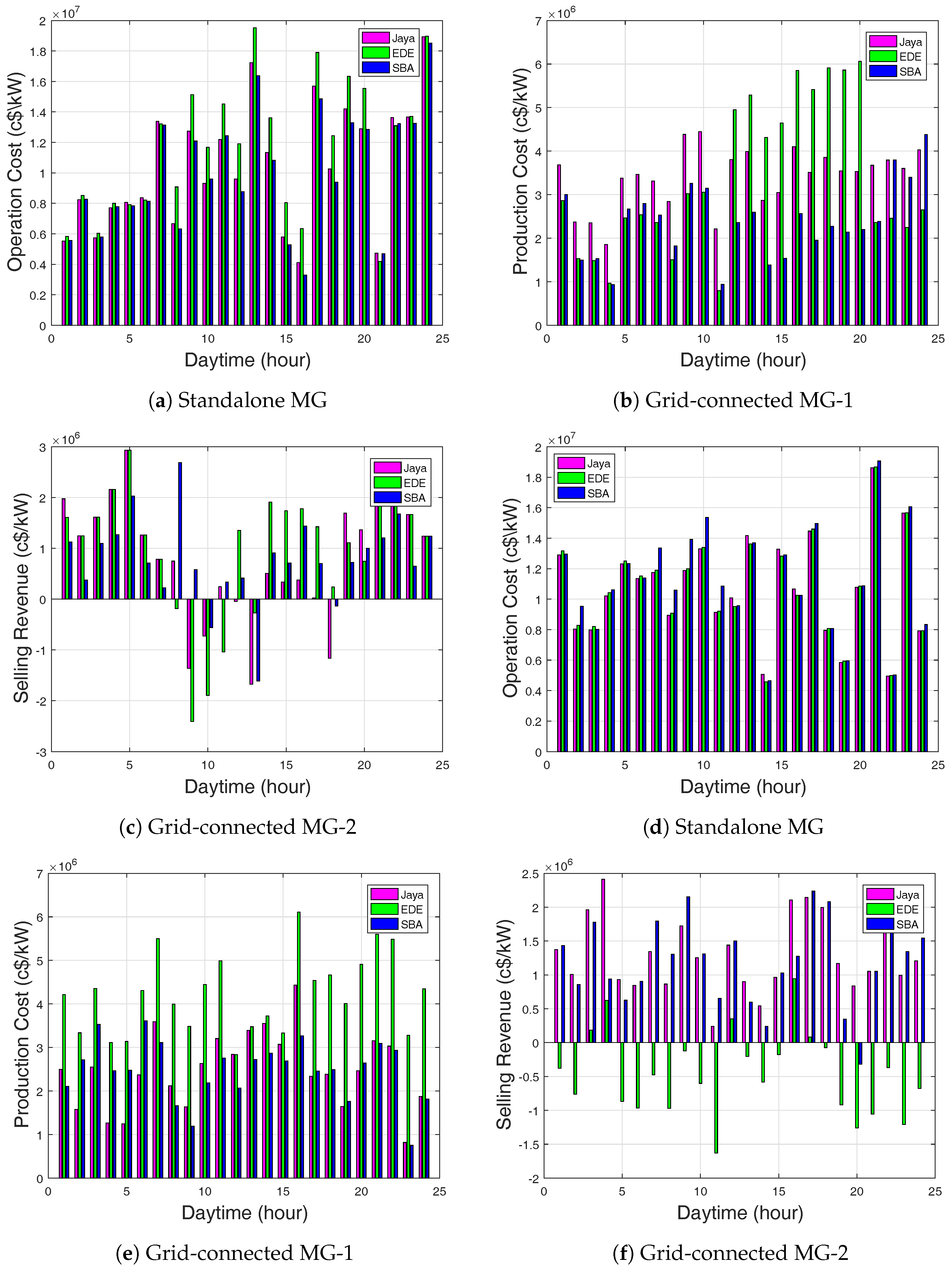

Figure 9a, EDE-based EMS generated a minimal fuel cost in the first 7 h and was then reduced in the 12–16 h of the day, whereas SBA-based EMS generated the greatest fuel cost. In

Table 8, EDE-based EMS produced a sales revenue that was greater than that of Jaya and SBA. This is due to the high power supply of MT and PV. EDE-based EMS had minimal production cost as compared to Jaya and SBA.

Figure 9d shows the hourly fuel cost. The figure shows the time period with minimal fuel cost generated by SBA and Jaya-based EMS. All algorithms generated a high fuel cost during the peak hours which then reduced in subsequent hours. This was due to the high amount of power supplied by the diesel generator.

Figure 10a illustrates that there was a fluctuating cost of operations during the period of simulation. The results indicate that the EMS was able to shift dispatchable DGs from on-peak to off-peak hours.

Table 8 and

Table 9 show the total daily fuel cost, production cost, and selling revenue for the ToU and CPP. In

Table 9, EDE-based EMS showed a high total daily fuel cost of 5,24,930 USD cents per kilowatt-hour (c

$/kWh) as compared to Jaya and SBA, meaning that there was a high production cost for Jaya and SBA. Jaya-based EMS showed better sales revenue than EDE and SBA. However, Jaya-based EMS showed minimum execution time as compared to SBA and EDE.

In

Figure 11a during the first 8 h for Jaya and EDE-based EMS, a constant amount of power was supplied which sufficiently satisfied the load requirement. There was no reduction in power supply except for EDE-based EMS during hours 21 and 22. Thus, the batteries started discharging to supply power. During the peak hours, a high amount of power was supplied to satisfy the load request, and thus the batteries started charging.

For the CPP case, during the time periods of 1–11 h, Jaya-based EMS had continuous power stored at 1200 kW for battery-1 and 550 kW for battery-2. EDE and SBA-based EMS showed better power stored than the Jaya-based EMS with the power stored at 2400 kW for battery-1 and 1600 kW for battery-2. The power stored for all proposed algorithms was 3600 kW and 2400 kW for battery-1 and battery-2, respectively. The batteries had unsteady charging behavior, and this was due to high demand load request from the residential area. However, batteries did not get complete charging; more so, the batteries’ discharging did not exceed the specified charged limit of 20%. Thus, the MG could meet the demand load requirement of the residential area for the inactive state. In

Figure 10d, SBA-based EMS produced the highest operating cost, greater than EDE and Jaya, respectively. The operation and maintenance costs were stable for the three algorithms, among which Jaya-based EMS had the minimal cost.

Operation in Grid-Connected Mode

In the grid-connected mode, energy exchange occurs between the MG and the main grid to meet the demand load requirement of the residential area. The EMS provides optimal scheduling of the DERs under grid-connected mode to minimize the production cost and maximize the sales revenue.

Figure 11b shows demand and supply. The batteries were at steady charging state with the power stored of 8000 kW and 4000 kW for both grid-connected MG-1 and MG-2, as shown in

Figure 4 and

Figure 5.

The batteries stored more power for EDE than Jaya and SBA-based EMS. In the WT unit in

Figure 8b,c, EDE-based EMS supplied more power than Jaya and SBA. The diesel generator power supply tended to reduce in Jaya and SBA, but was high for EDE-based EMS. In EDE-based EMS, the diesel generator incurred more fuel cost, since it generated 15,000 kW of power at 12–20 h and 15,000 kW at 8–12 h, as shown in

Figure 9e.

As soon as the MG is able to meet demand load requirement of the residential area, batteries stop discharging for subsequent use during peak demand load request. In

Figure 10c, SBA-based EMS did not show improvement in total daily production cost. If the power supplied is more from the MG than the power supplied by the main grid, then the preserved power from the ESSs can be used, especially when utility prices are high. The preferred performance of Jaya-based EMS over SBA and EDE in terms of sales revenues is clearly seen.

In the case of CPP, Jaya-based EMS in

Table 8 had a minimum total daily production cost as compared to EDE and SBA.

Figure 11e,f show the demand and supply for the grid-connected modes. From the figures, the MG supplied more power during the on-peak and off-peak hours. EDE-based EMS supplied more power as compared to Jaya and SBA. This is because EDE-based EMS scheduled the WT and MT at the same time. The negative selling revenue indicates the operation and maintenance costs were greater than the production cost.

5.2. Performance Trade-Off

To show the comparative analysis using CPP, the fuel cost without EMS was 403,850 c$/kWh. Jaya-based EMS reduced the daily fuel cost by up to 18.96% compared to the 62.16% of EDE and 17.14% of SBA for the standalone MG. Whereas, a daily fuel cost reduction of 38.13% was observed in the Jaya-based system compared to −107.63% in EDE and 5.57% in SBA for grid-connected MG-1. Additionally, Jaya-based EMS reduced fuel costs by up to 42.98% compared to −95.38% for EDE and 59.73% for SBA for the grid-connected MG-2. The total daily production cost without EMS was 42,495,000 c$/kWh; with Jaya-based EMS the total daily production cost was reduced by up to 93.89% compared to 92.90% with EDE and 93.67% with SBA for the standalone MG. Whereas, the daily production reduction with the Jaya-based EMS was 93.89% compared to 92.90% with EDE and 93.67% with SBA. In addition, Jaya-based EMS reduced the daily production cost by up to 93.89% compared to 92.90% for EDE and 93.84% of SBA for the grid-connected MG-1 and MG-2, respectively. The daily sales revenue without EMS was 13,325,000 c$/kWh; Jaya-based EMS achieved a maximum daily sales revenue above 100% (i.e., 132.84%) compared to 133.58% for EDE and −352.54% for SBA for the standalone MG. Whereas, the Jaya-based EMS maximized the daily sales revenue by up to 72.78% as compared to −38.67% for EDE and −389.52% for SBA. In addition, Jaya-based EMS maximized the daily sales revenue by up to 136.42% compared to −16.70% for EDE and −286.38% for SBA for grid-connected MG-1 and MG-2, respectively.

The following is a comparative analysis using ToU. The daily fuel cost without EMS was 403,850 c$/kWh; Jaya-based EMS reduced the daily fuel cost by up to 0.61% compared to −29.98% for EDE and 72.37% for SBA in the standalone MG. The Jaya-based EMS did not improve the daily fuel cost, with −33.15% compared to −36.70% with EDE and 52.53% with SBA. In a similar manner, Jaya-based EMS failed by −8.03% compared to 19.13% by EDE and 6.66% by SBA for the grid-connected MG-1 and MG-2 respectively. The total daily production costs without EMS were 42,593,000 c$/kWh; the total daily production cost with Jaya-based EMS was minimized by up to 41.30% compared to 34.32% with EDE and 43.28% with SBA for the standalone MG. Meanwhile, there was a 92.35% daily production cost reduction by Jaya-based EMS, compared to 92.38% by EDE and 92.82% by SBA. In addition, Jaya-based EMS reduced the daily production cost by up to 93.68% compared to 93.77% with EDE and 93.66% with SBA for the grid-connected MG-1 and MG-2 respectively. The daily sales revenue without EMS was 13,611,000 c$/kWh; Jaya-based EMS maximized the daily sales revenue by up to 64.39% compared to −45.85% with EDE and −236.56% with SBA for the standalone MG. Whereas, Jaya-based EMS maximized the daily sales revenue by up to 17.14% compared to 24.91% with EDE and −55.97% with SBA. Additionally, Jaya-based EMS maximized the daily sales revenue by up to 42.51% compared to 73.71% of EDE and −351.76% of SBA for grid-connected MG-1 and MG-2 respectively.

However, Jaya-based EMS outperformed the other methods in terms of execution time, having (0.4253, 0.0977, 0.0551) compared to (0.6791, 0.3641, 0.3725) with EDE and (0.5479, 0.2736, 0.3507) with SBA for standalone, grid-connected MG-1, and MG-2, respectively in the ToU case. Similarly, Jaya-based EMS showed better execution times of (0.4505, 0.0488, 0.0575) compared to (0.8126, 0.3275, 0.3371) for EDE and (0.5172, 0.2598, 0.2316) for SBA for standalone, grid-connected MG-1, and MG-2, respectively, in the CPP case.