Area-Saving and High-Efficiency RGB LED Driver with Adaptive Driving Voltage and Energy-Saving Technique

Abstract

1. Introduction

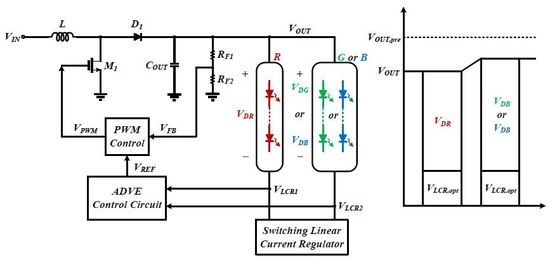

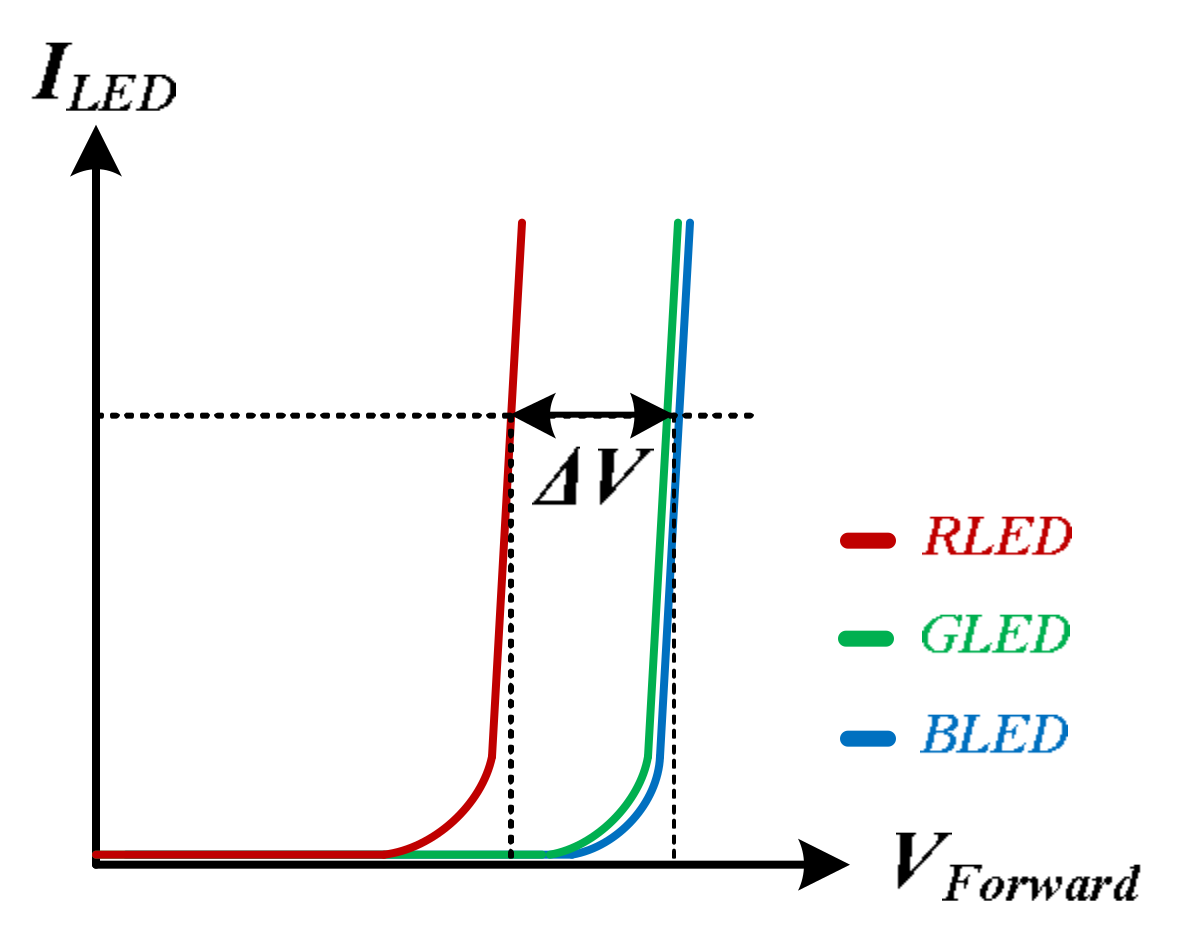

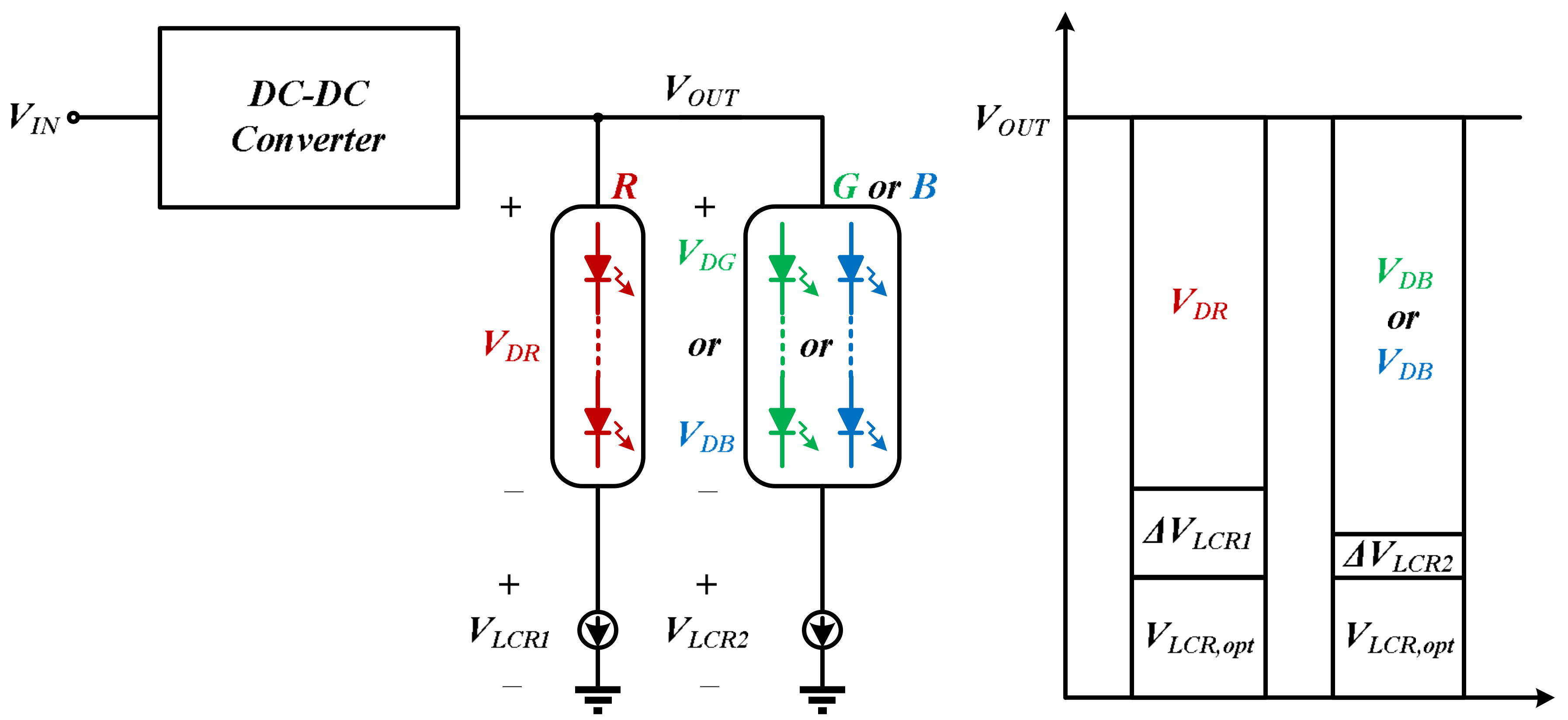

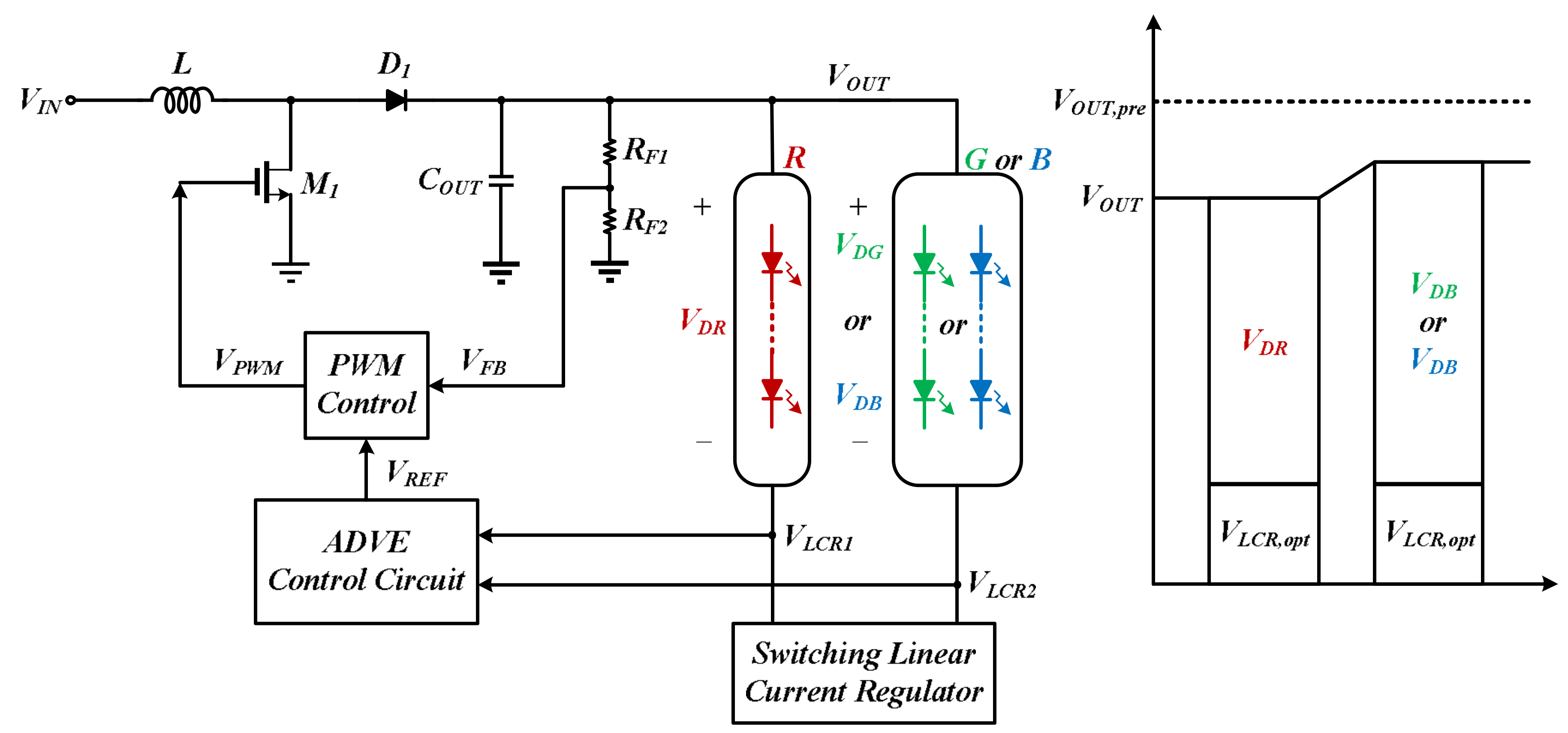

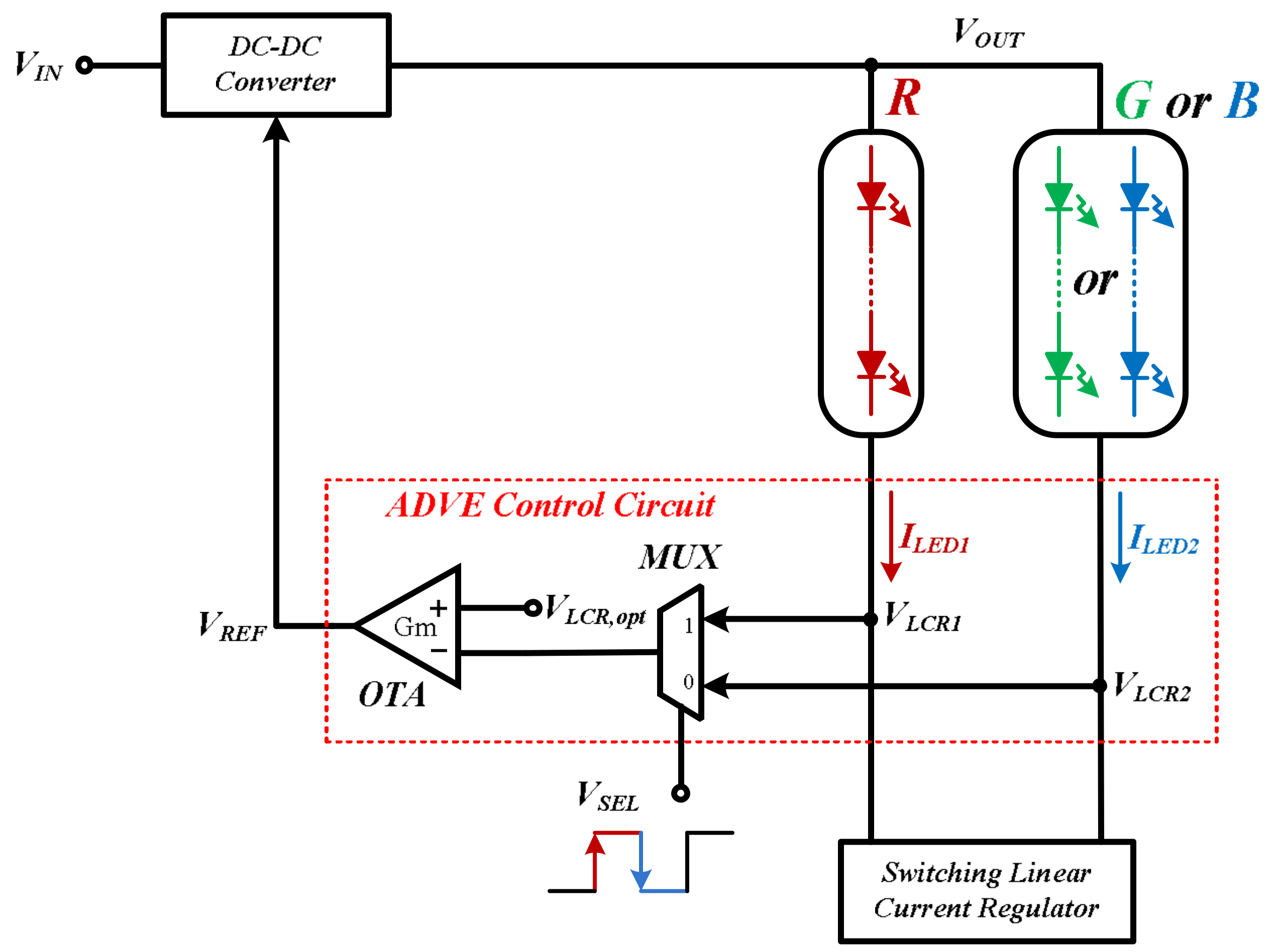

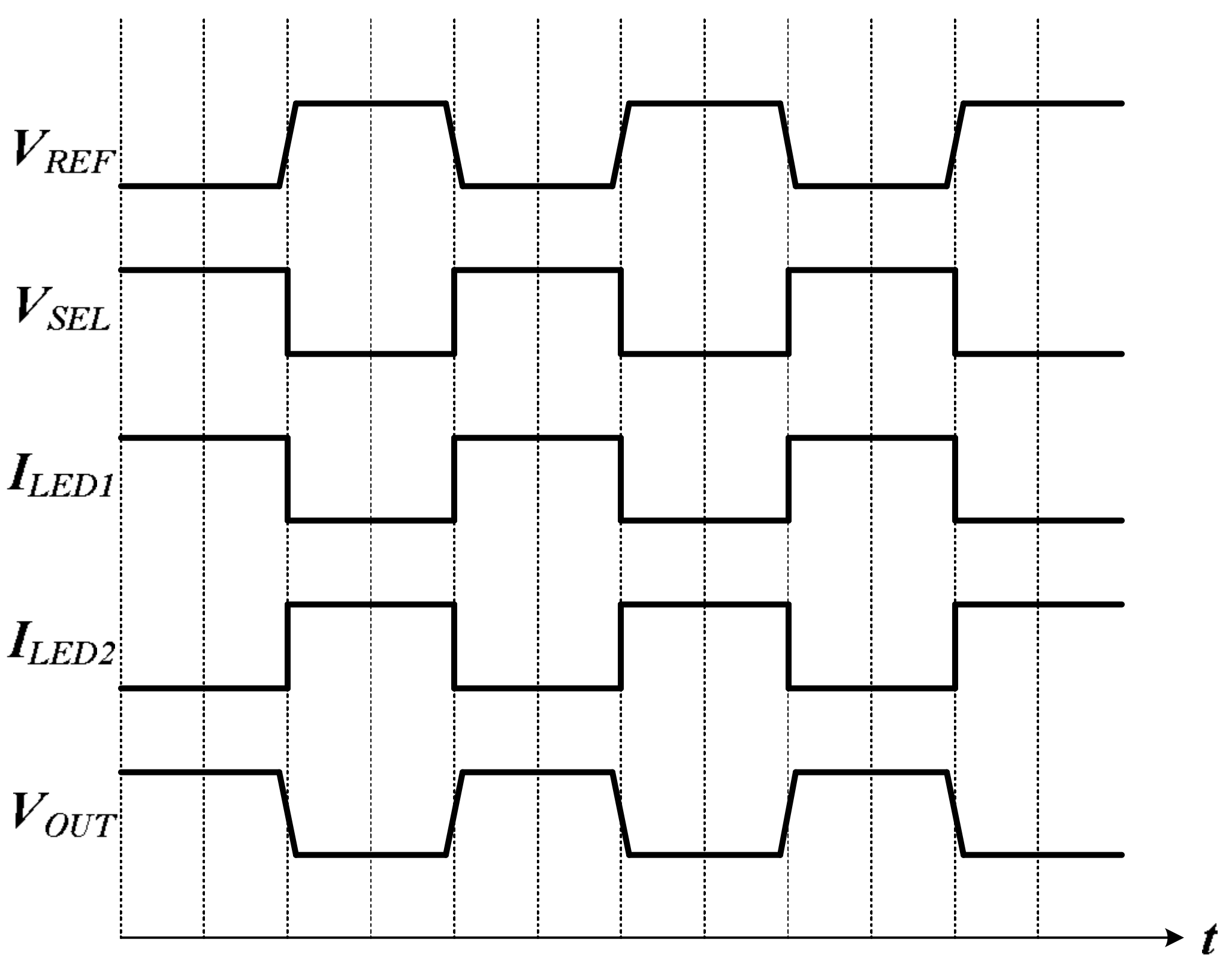

2. Proposed Adaptive Driving Voltage and Energy-Saving Technique

3. Circuit Implementation

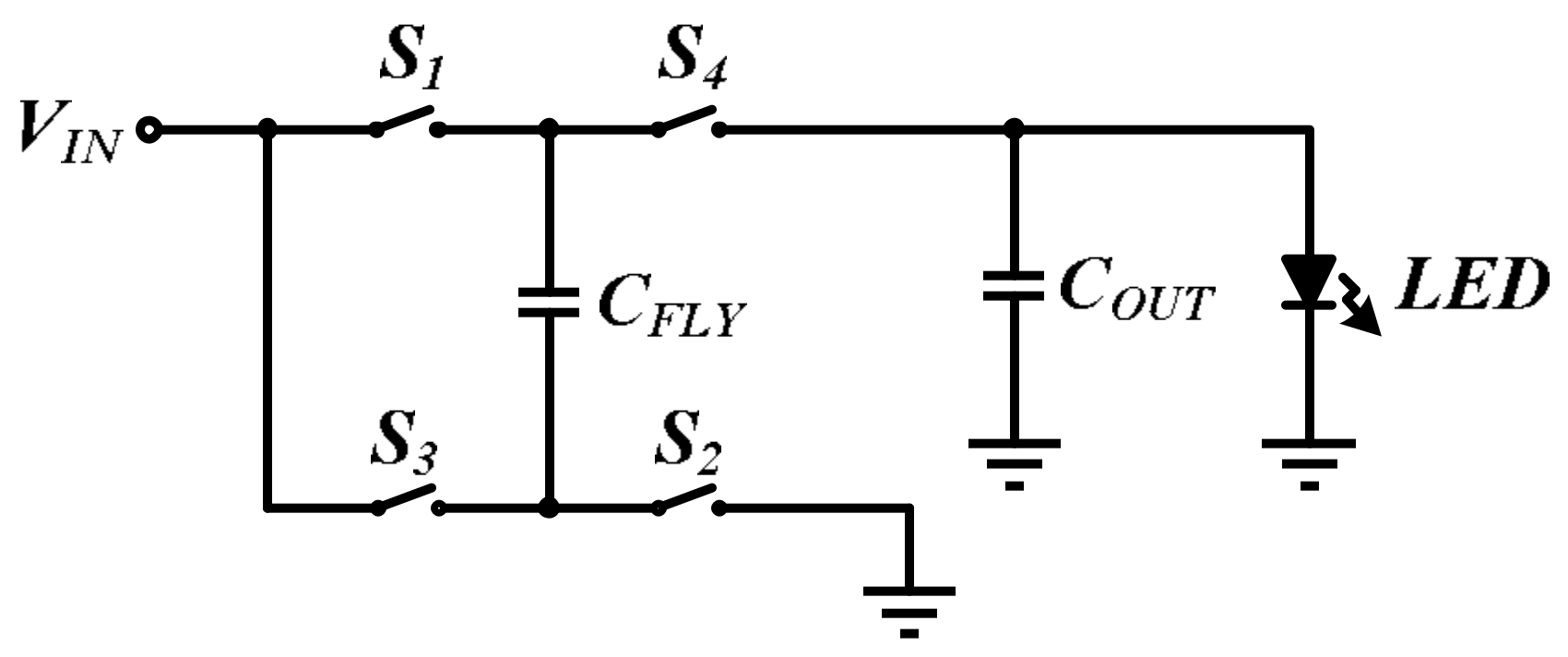

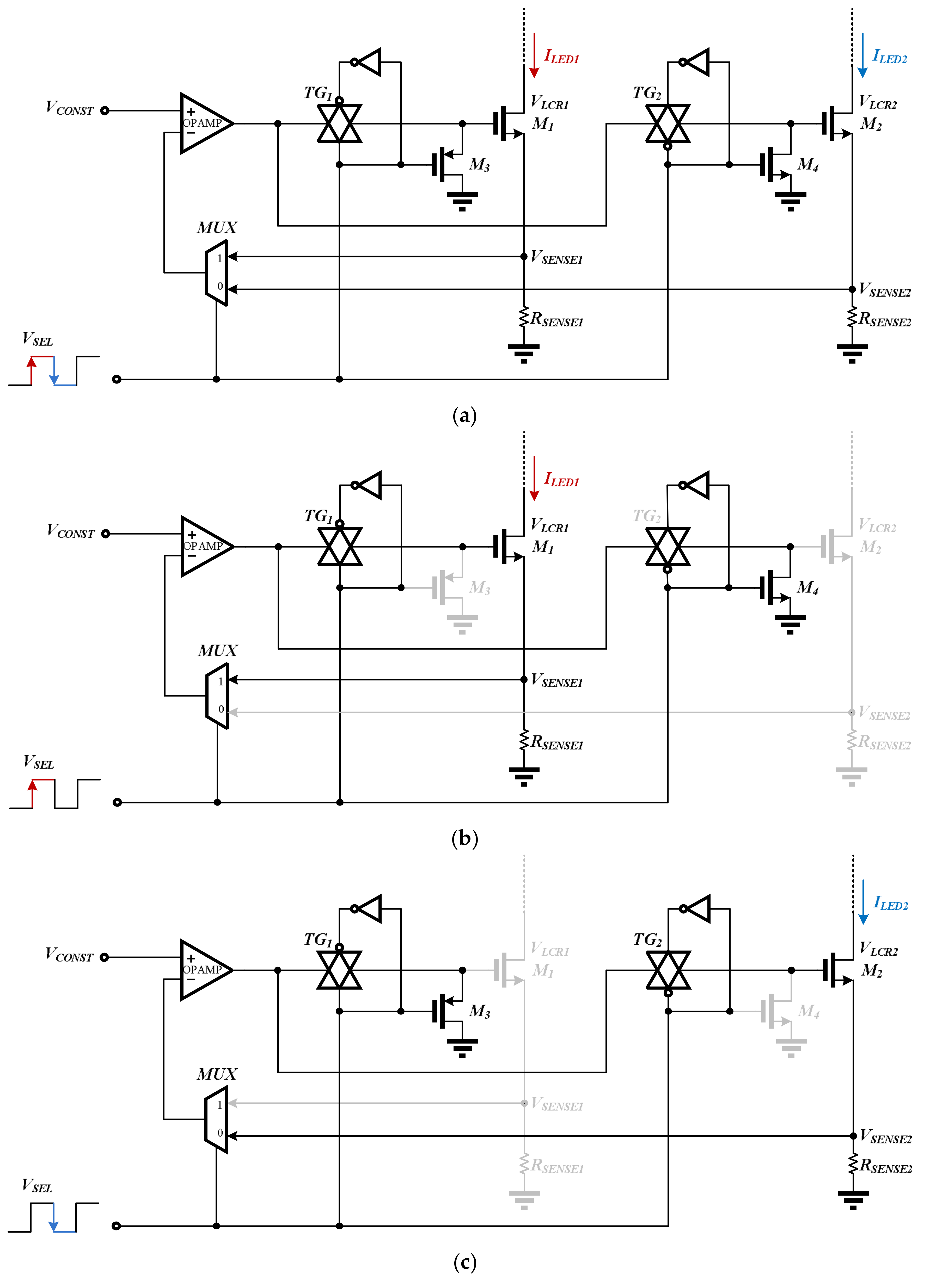

3.1. Switching Linear Current Regulators

3.2. Adaptive Driving Voltage and Energy-Saving Control Circuit

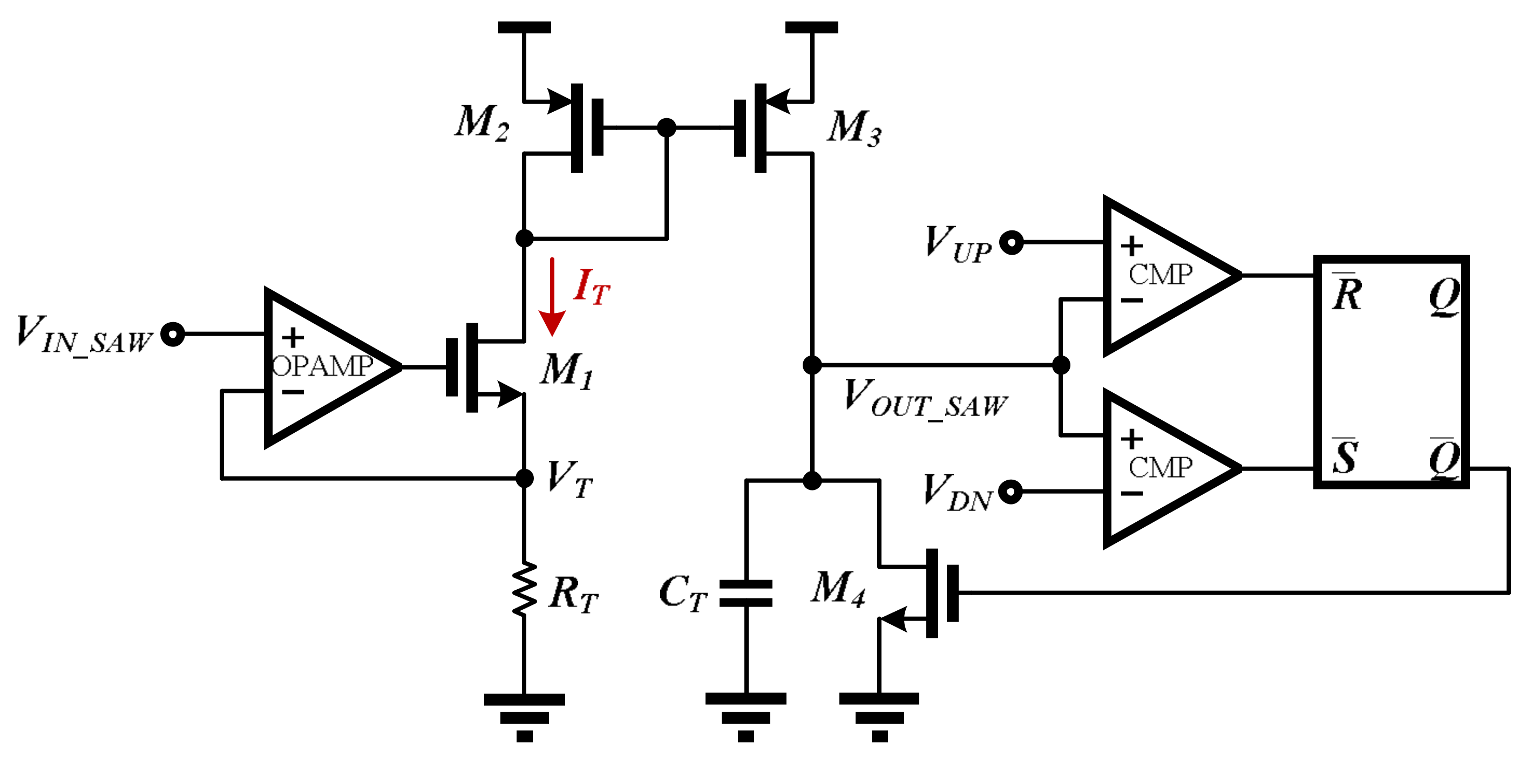

3.3. Sawtooth Generator

3.4. PWM Control Circuit

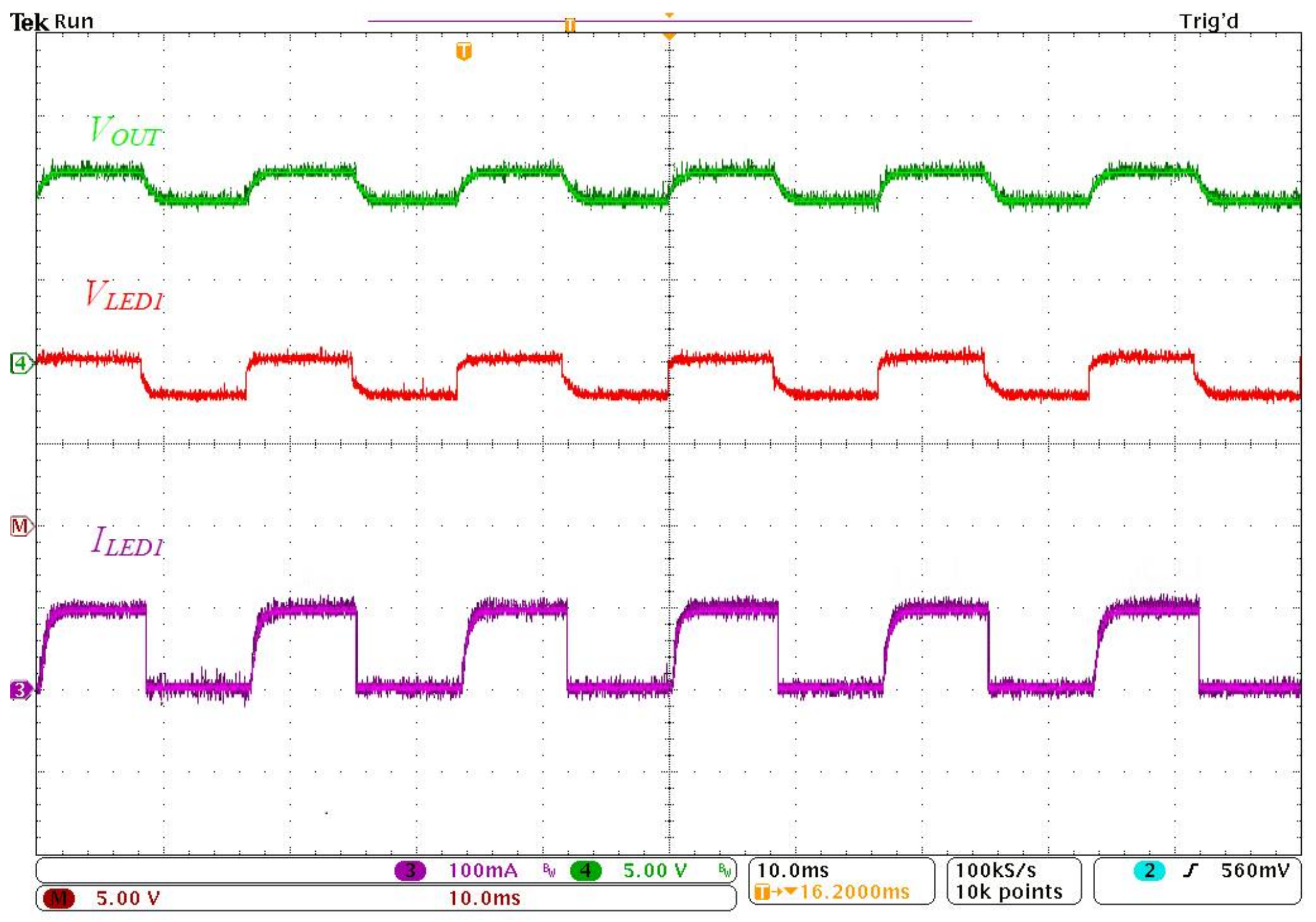

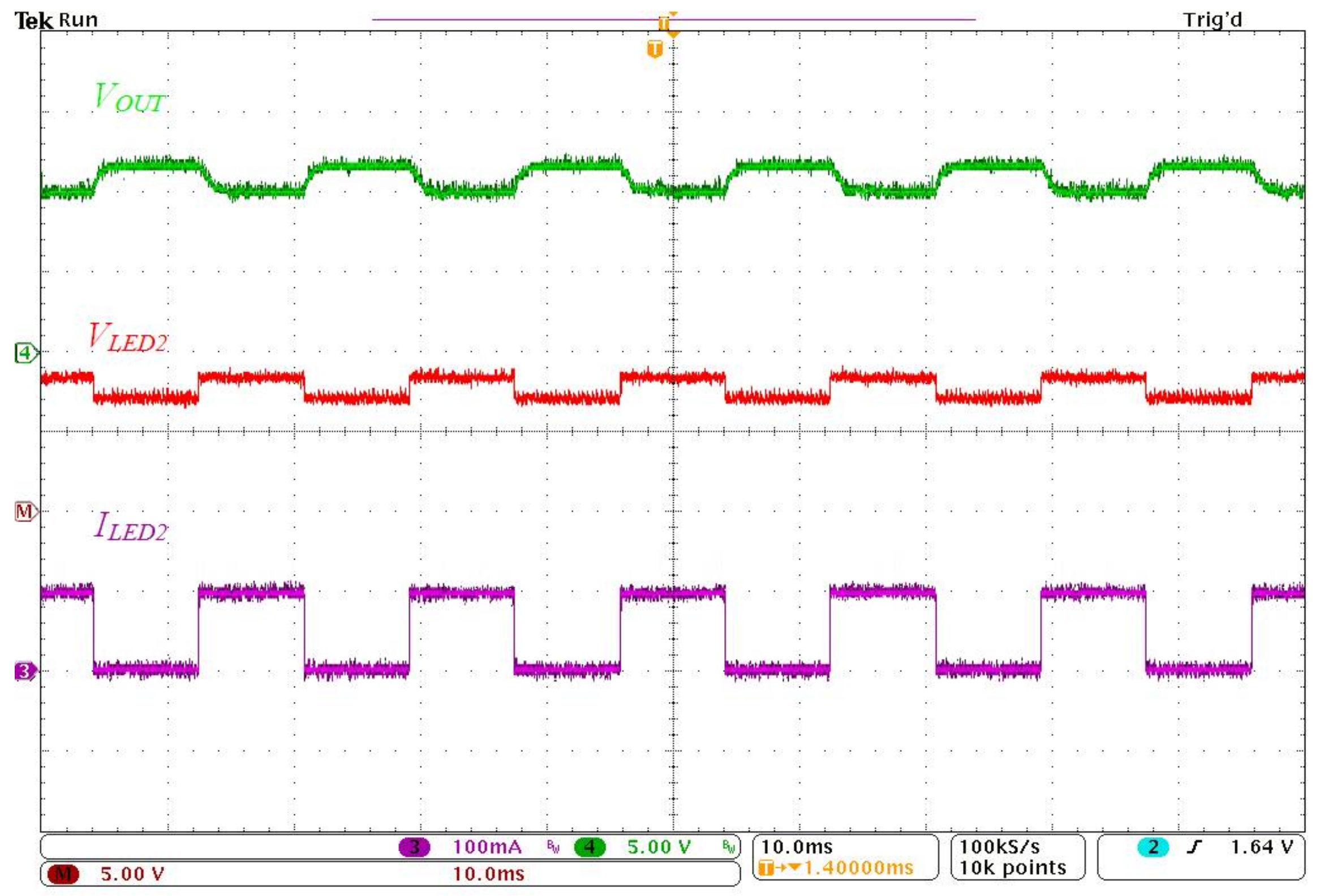

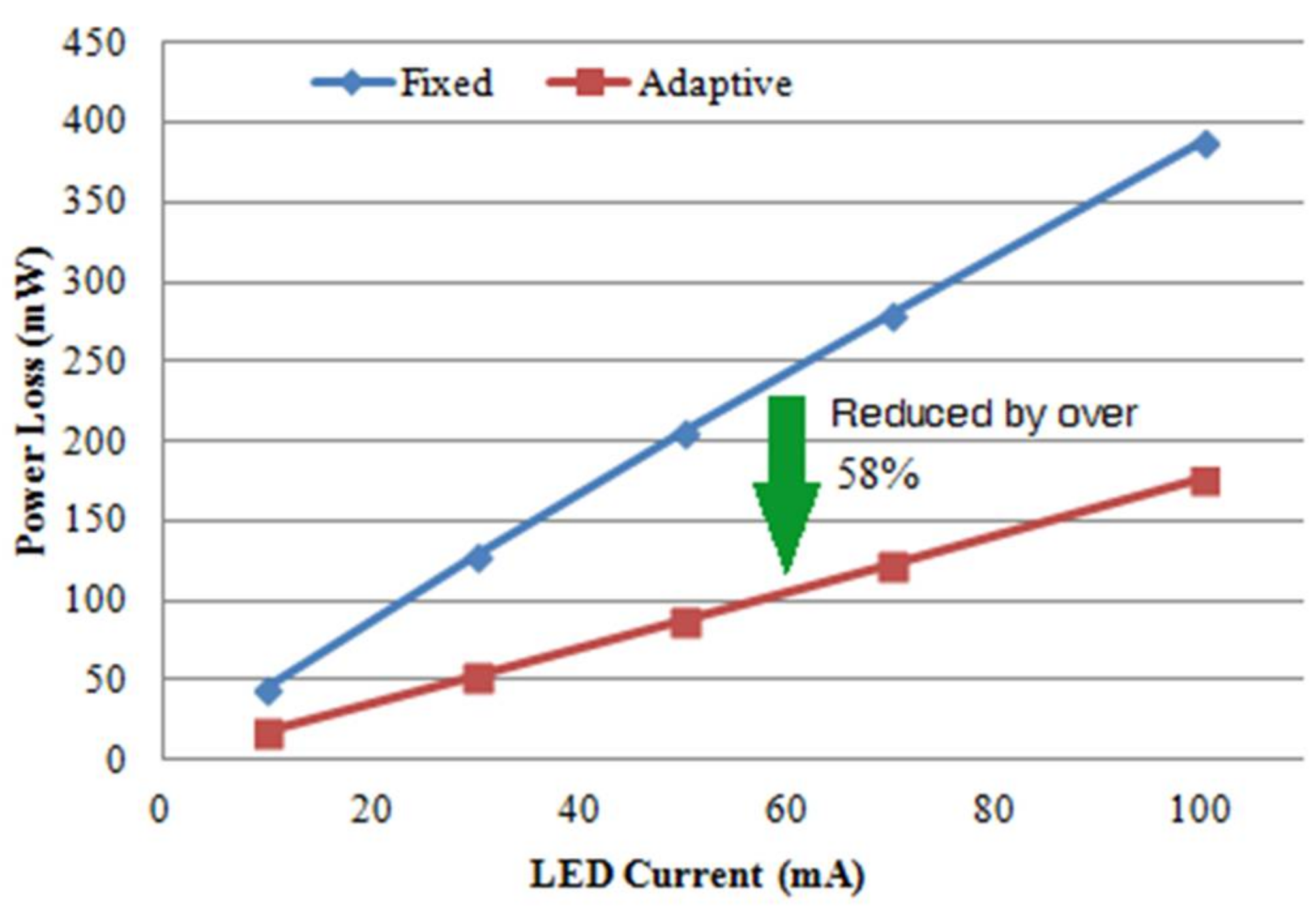

4. Experimental Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Thielemans, S.; Zenobio, D.D.; Touhafi, A.; Lataire, P.; Steenhaut, K. DC Grids for Smart LED-Based Lighting: The EDISON Solution. Energies 2017, 10, 1454. [Google Scholar] [CrossRef]

- Vu, N.H.; Pham, T.T.; Shin, S. LED Uniform Illumination Using Double Linear Fresnel Lenses for Energy Saving. Energies 2017, 10, 2091. [Google Scholar] [CrossRef]

- Lin, Y.-L.; Chiu, H.-J.; Lo, Y.-K.; Leng, C.-M. LED Backlight Driver Circuit With Dual-Mode Dimming Control and Current-Balancing Design. IEEE Trans. Ind. Electron. 2014, 61, 4632–4639. [Google Scholar] [CrossRef]

- Ahn, Y.D.; Bae, S.; Kang, S.-J. Power Controllable LED System with Increased Energy Efficiency Using Multi-Sensors for Plant Cultivation. Energies 2017, 10, 1607. [Google Scholar] [CrossRef]

- Lin, M.-S.; Chen, C.-L. An LED Driver with Pulse Current Driving Technique. IEEE Trans. Power Electron. 2012, 27, 4594–4601. [Google Scholar] [CrossRef]

- Hsieh, C.-Y.; Chen, K.-H. Boost DC–DC Converter with Fast Reference Tracking (FRT) and Charge-Recycling (CR) Techniques for High-Efficiency and Low-Cost LED Driver. IEEE J. SolidState Circuits 2009, 44, 2568–2580. [Google Scholar] [CrossRef]

- Crawford, M. LEDs for Solid-State Lighting: Performance Challenges and Recent Advances. IEEE J. Sel. Top. Quantum Electron. 2009, 15, 1028–1040. [Google Scholar] [CrossRef]

- Tansu, N.; Zhao, H.; Liu, G.; Li, X.-H.; Tong, J.-Z.; Tong, H.; Ee, Y.-K. III-Nitride Photonics. IEEE Photonics J. 2010, 2, 241–248. [Google Scholar] [CrossRef]

- DenBaars, S.; Feezell, D.; Kelchner, K.; Pimputkar, S.; Pan, C.-C.; Yen, C.-C.; Tanaka, S.; Zhao, Y.; Pfaff, N.; Farrell, R.; et al. Development of Gallium-nitride-based Light-emitting diodes (LEDs) and Laser Diodes for Energy-efficient Lighting and Displays. Acta Mater. 2013, 61, 945–951. [Google Scholar] [CrossRef]

- Arif, R.A.; Ee, Y.-K.; Tansu, N. Polarization Engineering via Staggered InGaN Quantum Wells for Radiative Efficiency Enhancement of Light Emitting Diodes. Appl. Phys. Lett. 2007, 91, 091110. [Google Scholar] [CrossRef]

- Tan, C.-K.; Tansu, N. Nanostructured Lasers: Electrons and Goles Get Closer. Nat. Nanotechnol. 2015, 10, 107–109. [Google Scholar] [CrossRef] [PubMed]

- Park, H.-H.; Zhang, X.; Cho, Y.; Kim, D.-W.; Kim, J.; Lee, K.-W.; Choi, J.; Lee, H.-K.; Jung, S.-H.; Her, E.-J.; et al. Wafer-scale Surface Roughening for Enhanced Light Extraction of High Power AlGaInP-based Light-emitting Diodes. Opt. Express 2014, 22, A723–A734. [Google Scholar] [CrossRef] [PubMed]

- Zhu, P.-F.; Tansu, N. Effect of Packing Density and Packing Geometry on Light Extraction of III-Nitride Light-Emitting Diodes with Microsphere Arrays. Photonics Res. 2015, 3, 184–191. [Google Scholar] [CrossRef]

- Li, X.-H.; Zhu, P.-F.; Liu, G.-Y.; Zhang, J.; Song, R.-B.; Ee, Y.-K.; Kumnorkaew, P.; Gilchrist, J.-F.; Tansu, N. Light Extraction Efficiency Enhancement of III-Nitride Light-Emitting Diodes by using 2-D Close-Packed TiO2 Microsphere Arrays. IEEE J. Disp. Technol. 2013, 9, 324–332. [Google Scholar] [CrossRef]

- Yamada, F.; Nakamura, H.; Sakaguchi, Y.; Taira, Y. Sequentialcolor LCD based on OCB with an LED backlight. J. SID 2002, 10, 81–85. [Google Scholar]

- Chen, C.-C.; Wu, C.-Y.; Chen, Y.-M.; Wu, T.-F. Sequential Color LED Backlight Driving System for LCD Panels. IEEE Trans. Power Electron. 2007, 22, 919–925. [Google Scholar] [CrossRef]

- Wu, C.-H.; Chen, C.-L. High-Efficiency Current-Regulated Charge Pump for a White LED Driver. IEEE Trans. Circuits Syst. II Exp. Briefs 2009, 56, 763–767. [Google Scholar]

- Fu, L.; Wang, Y.; Wang, Q.; Yang, S.; Yang, Y.; Huo, Z. A High Efficiency All-PMOS Charge Pump for 3D NAND Flash Memory. In Proceedings of the IEEE 11th International Conference on ASIC (ASICON), Chengdu, China, 3–6 November 2015; pp. 1–4. [Google Scholar]

- Hsieh, C.-Y.; Yang, C.-Y.; Chen, K.-H. A Charge-Recycling Buck-Store and Boost-Restore (BSBR) Technique with Dual Outputs for RGB LED Backlight and Flashlight Module. IEEE Trans. Power Electron. 2009, 24, 1914–1925. [Google Scholar] [CrossRef]

- Lun, W.-K.; Loo, K.-H.; Tan, S.-C.; Lai, Y.-M.; Tse, C.-K. Bilevel Current Driving Technique for LEDs. IEEE Trans. Power Electron. 2009, 24, 2920–2932. [Google Scholar]

- Liu, C.-H.; Hsieh, C.-Y.; Hsieh, Y.-C.; Tai, T.-J.; Chen, K.-H. SAR-Controlled Adaptive Off-Time Technique Without Sensing Resistor for Achieving High Efficiency and Accuracy LED Lighting System. IEEE Trans. Circuits Syst. I Reg. Pap. 2010, 57, 1384–1394. [Google Scholar]

- Van der Broeck, H.; Sauerlander, G.; Wendt, M. Power Driver Topologies and Control Schemes for LEDs. In Proceedings of the IEEE Applied Power Electronics Conference and Exposition (APEC), Anaheim, CA, USA, 25 February–1 March 2007; pp. 1319–1325. [Google Scholar]

- Seoul Semiconductor Co. Ltd. SZX05A0A Z-Power LED, SSC-SZX05A0A Datasheet. Available online: https://docs-emea.rs-online.com/webdocs/1009/0900766b810099d0.pdf (accessed on April 2017).

- Hu, Y.; Jovanovic, M. LED Driver with Self-Adaptive Drive Voltage. IEEE Trans. Power Electron. 2008, 23, 3116–3125. [Google Scholar] [CrossRef]

- Chiu, H.-J.; Lo, Y.-K.; Chen, J.-T.; Cheng, S.-J.; Lin, C.-Y.; Mou, S.-C. A High-Efficiency Dimmable LED Driver for Low-Power Lighting Applications. IEEE Trans. Ind. Electron. 2010, 57, 735–743. [Google Scholar] [CrossRef]

- Liu, P.-J.; Hsu, S.-R.; Chang, C.-W.; Chien, L.-H. Dimmable White LED Driver with Adaptive Voltage Feedback Control. In Proceedings of the IEEE International Future Energy Electronics Conference (IFEEC), Taipei, Taiwan, 1–4 November 2015; pp. 1–4. [Google Scholar]

- Hong, S.-I.; Han, J.-W.; Kim, D.-H.; Kwon, O.-K. A Double-loop Control LED Backlight Driver IC for Medium-sized LCDs. In Proceedings of the IEEE ISSCC, San Francisco, CA, USA, 7–11 February 2010; pp. 116–117. [Google Scholar]

- Sun, Y.-M.; Wu, X.-B. High Efficiency LED Driver Featuring Auto Output-voltage Tuning. In Proceedings of the 2010 IEEE International Conference of Electron Devices and Solid-State Circuits (EDSSC), Hong Kong, China, 15–17 December 2010; pp. 1–4. [Google Scholar]

- Hsieh, Y.-T.; Liu, B.-D.; Wu, J.-F.; Fang, C.-L.; Tsai, H.-H.; Juang, Y.-Z. A High-dimming-ratio LED Driver for LCD Backlights. IEEE Trans. Power Electron. 2012, 27, 4562–4570. [Google Scholar] [CrossRef]

- Allen, P.E.; Holberg, D.R. CMOS Analog Circuit Design, 2nd ed.; Oxford University Press: New York, NY, USA, 2002; p. 157. ISBN 0195392469. [Google Scholar]

- Baker, R.J. CMOS Circuit Design, Layout, and Simulation, 2nd ed.; IEEE Press: Piscataway, NJ, USA, 2005; p. 645. ISBN 047170055X. [Google Scholar]

- Lee, C.-F.; Mok, P.-K.-T. A Monolithic Current-Mode CMOS DC-DC Converter with on-Chip Current-Sensing Technique. IEEE J. SolidState Circuits 2004, 39, 3–14. [Google Scholar] [CrossRef]

| Specifications | [5] | [17] | [26] | [27] | This Work |

|---|---|---|---|---|---|

| Technology | 0.35 μm CMOS | 0.5 μm CMOS | 0.35 μm CMOS | 0.35 μm BCD | 0.35 μm CMOS |

| Active Area (mm2) | 0.89 | 0.403 | N/A | N/A | 0.3 |

| Input Voltage (V) | 4.5~5 | 2.8~4.2 | 7 | 6~27 | 5~7 |

| Output Voltage (V) | N/A | 2.8~4.2 | 10~14 | 60 | 8~14 |

| Driving Capability | 1 LED | 1 LED | N/A | 24 LEDs | 6~8 LEDs |

| Driving Current (mA) | 220 | 20 | 200 | 30 | 100 |

| Operating Freq. (kHz) | 500 | 200 | 100 | 39 | 100 |

| Adaptive Control | No | No | Yes | Yes | Yes |

| Energy-Saving Control | No | No | No | No | Yes |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsu, Y.-C.; Lin, J.-Y.; Chen, C.C.-P. Area-Saving and High-Efficiency RGB LED Driver with Adaptive Driving Voltage and Energy-Saving Technique. Energies 2018, 11, 1422. https://doi.org/10.3390/en11061422

Hsu Y-C, Lin J-Y, Chen CC-P. Area-Saving and High-Efficiency RGB LED Driver with Adaptive Driving Voltage and Energy-Saving Technique. Energies. 2018; 11(6):1422. https://doi.org/10.3390/en11061422

Chicago/Turabian StyleHsu, Yi-Chieh, Jing-Yuan Lin, and Charlie Chung-Ping Chen. 2018. "Area-Saving and High-Efficiency RGB LED Driver with Adaptive Driving Voltage and Energy-Saving Technique" Energies 11, no. 6: 1422. https://doi.org/10.3390/en11061422

APA StyleHsu, Y.-C., Lin, J.-Y., & Chen, C. C.-P. (2018). Area-Saving and High-Efficiency RGB LED Driver with Adaptive Driving Voltage and Energy-Saving Technique. Energies, 11(6), 1422. https://doi.org/10.3390/en11061422