On the Heat Transfer Enhancement of Plate Fin Heat Exchanger

Abstract

:1. Introduction

2. Physical and Mathematic Model

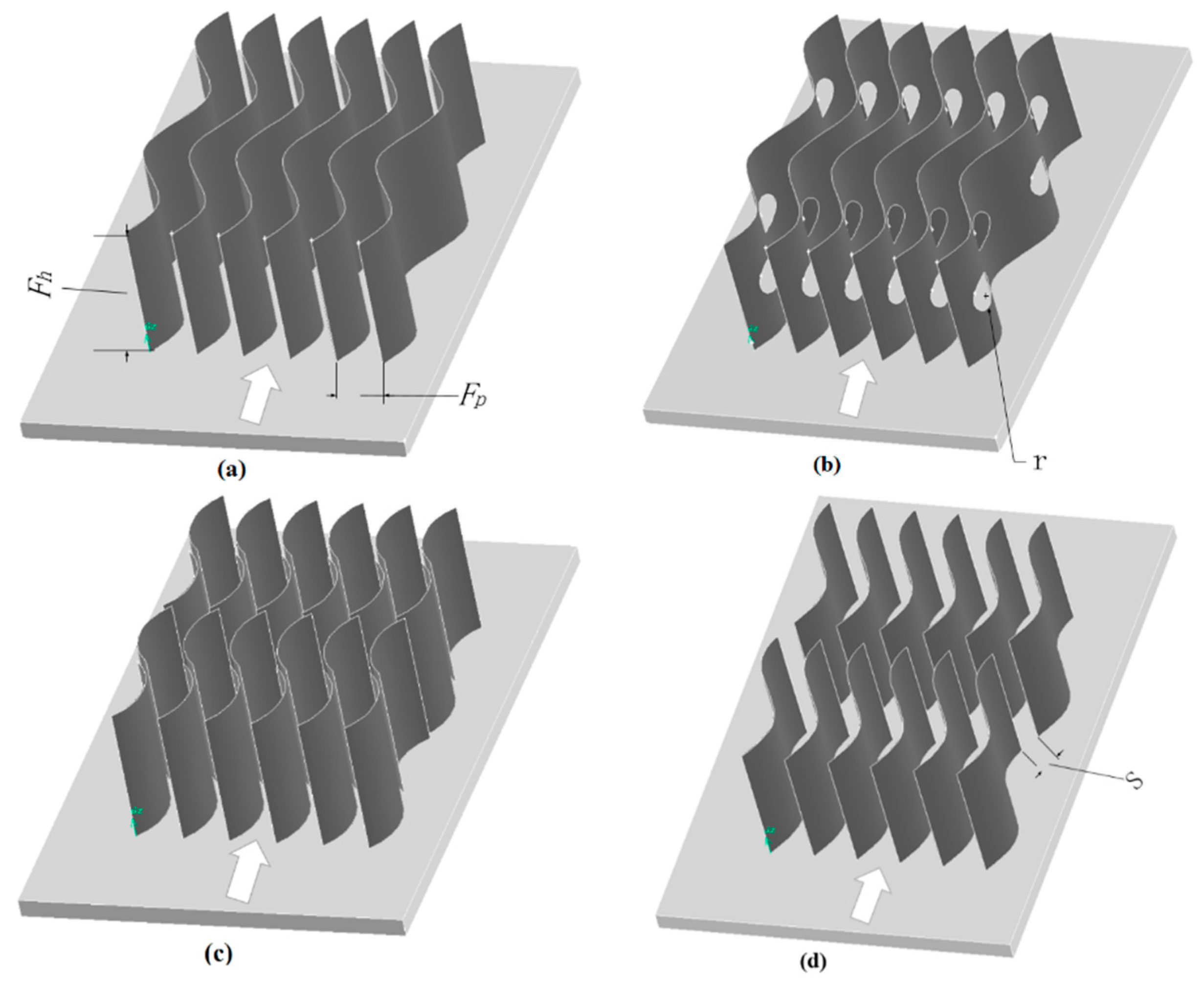

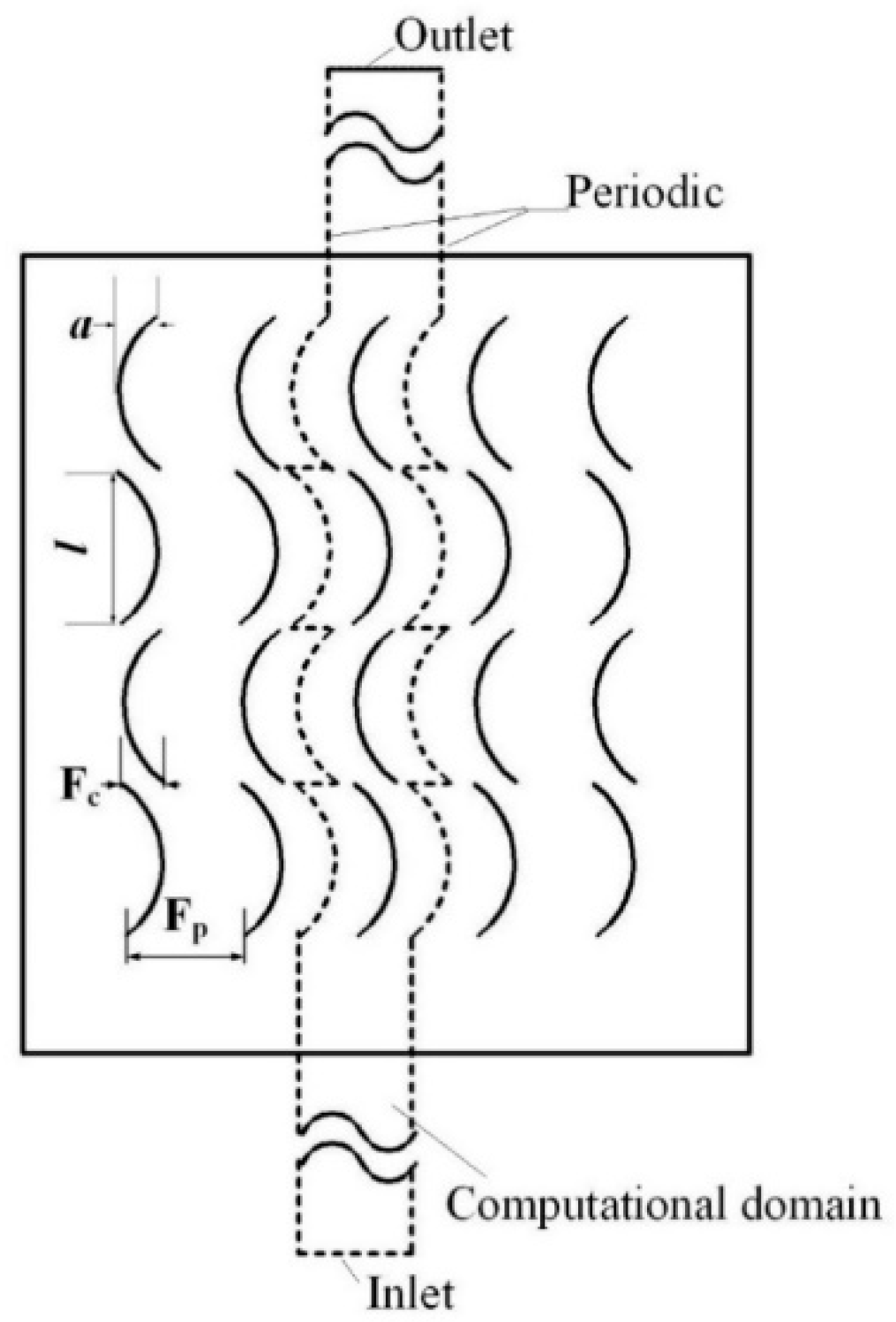

2.1. Physical Model

2.2. Governing Equations

2.3. Parameter Definitions

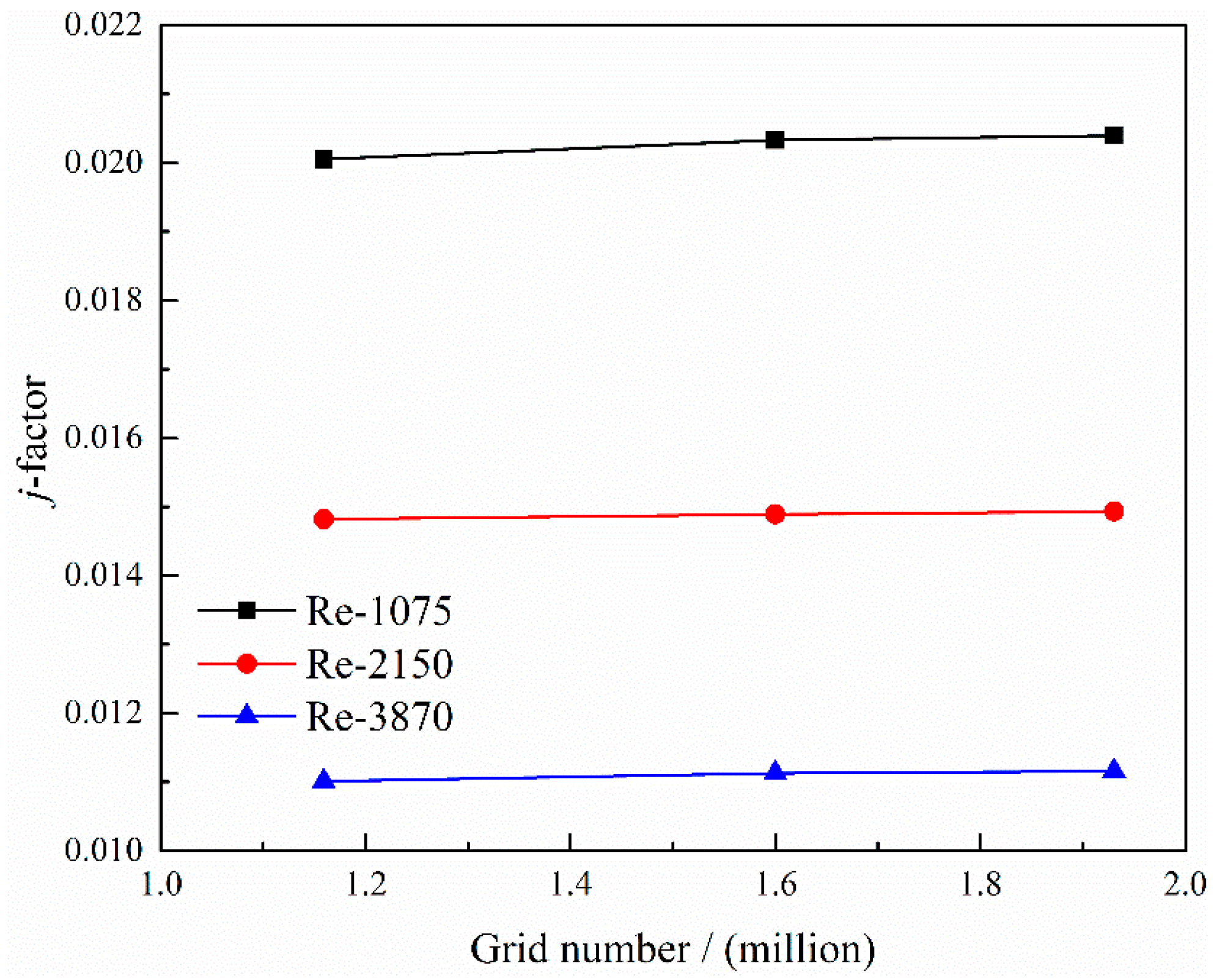

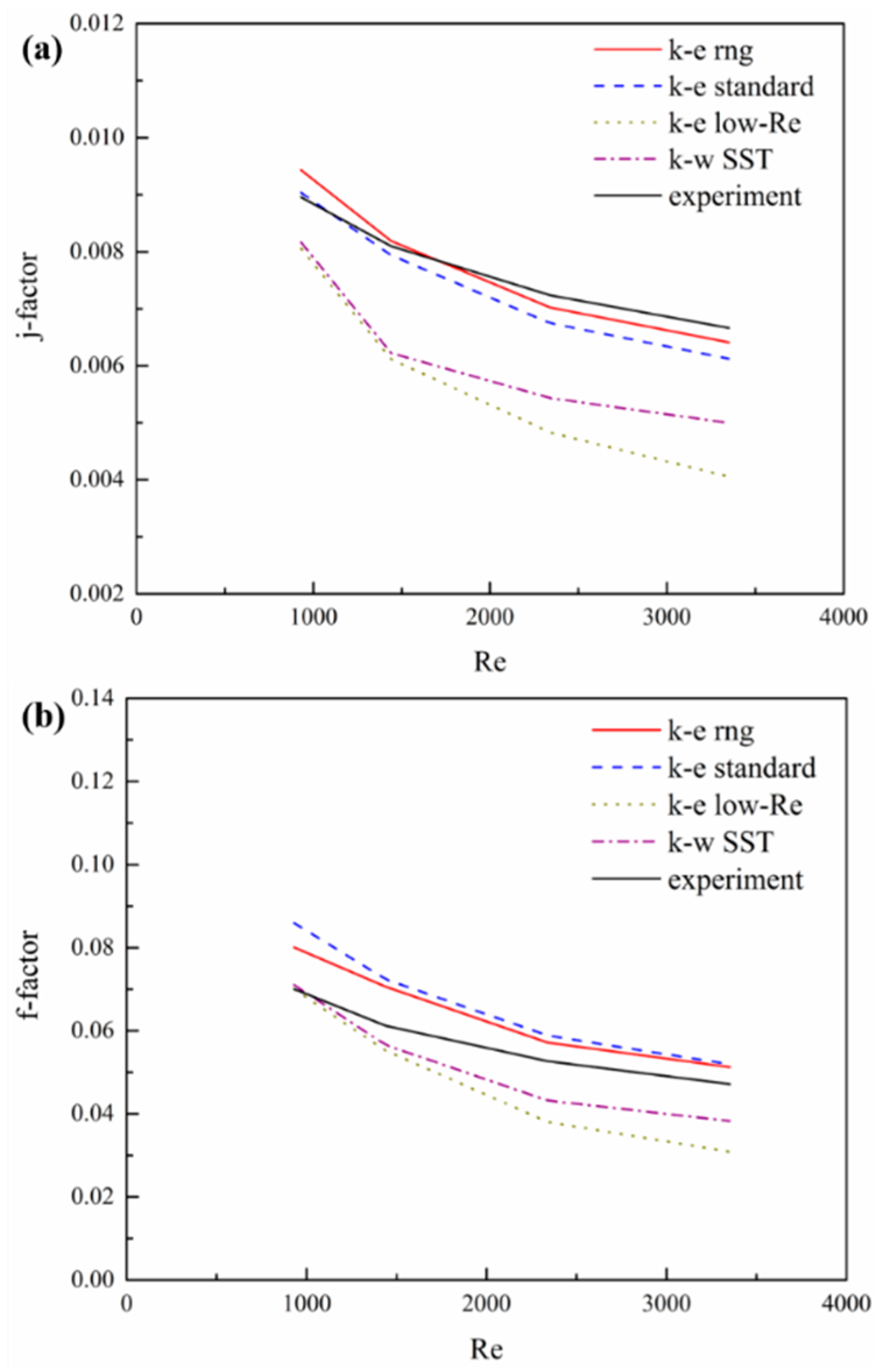

2.4. Grid Independence Tests and Verification of CFD Model

3. Results with Analysis

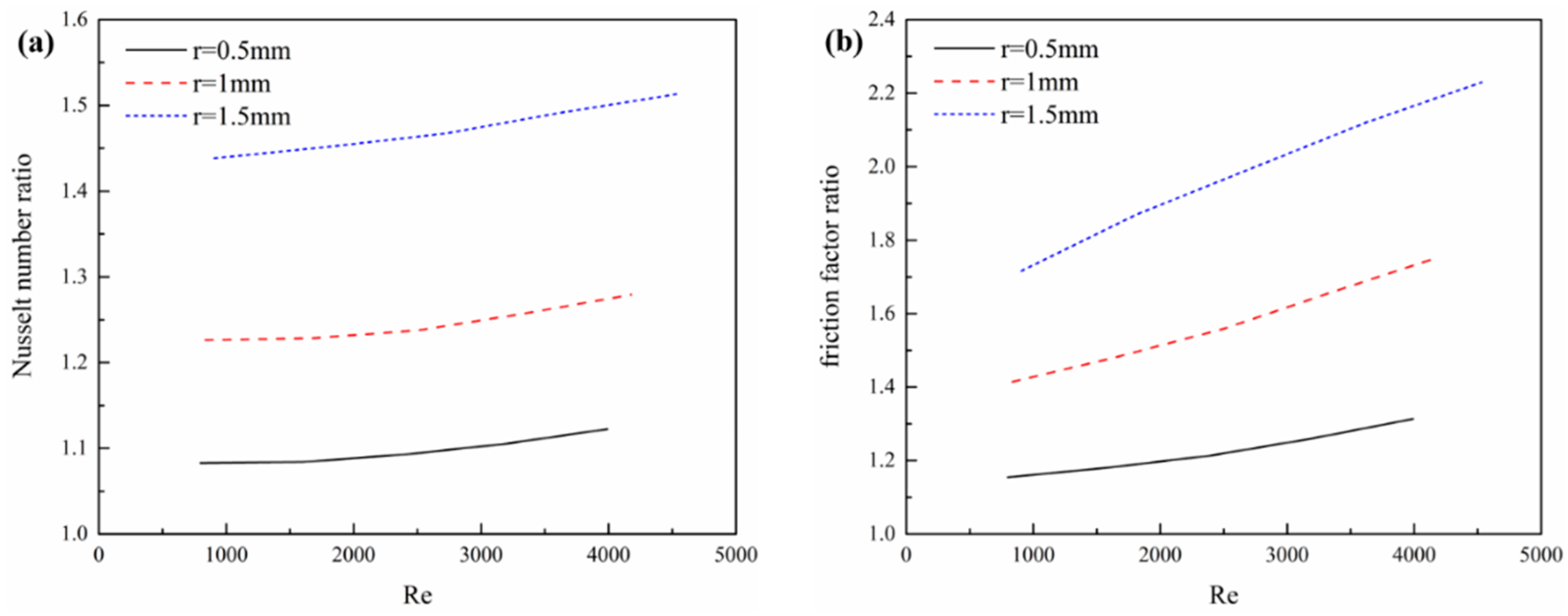

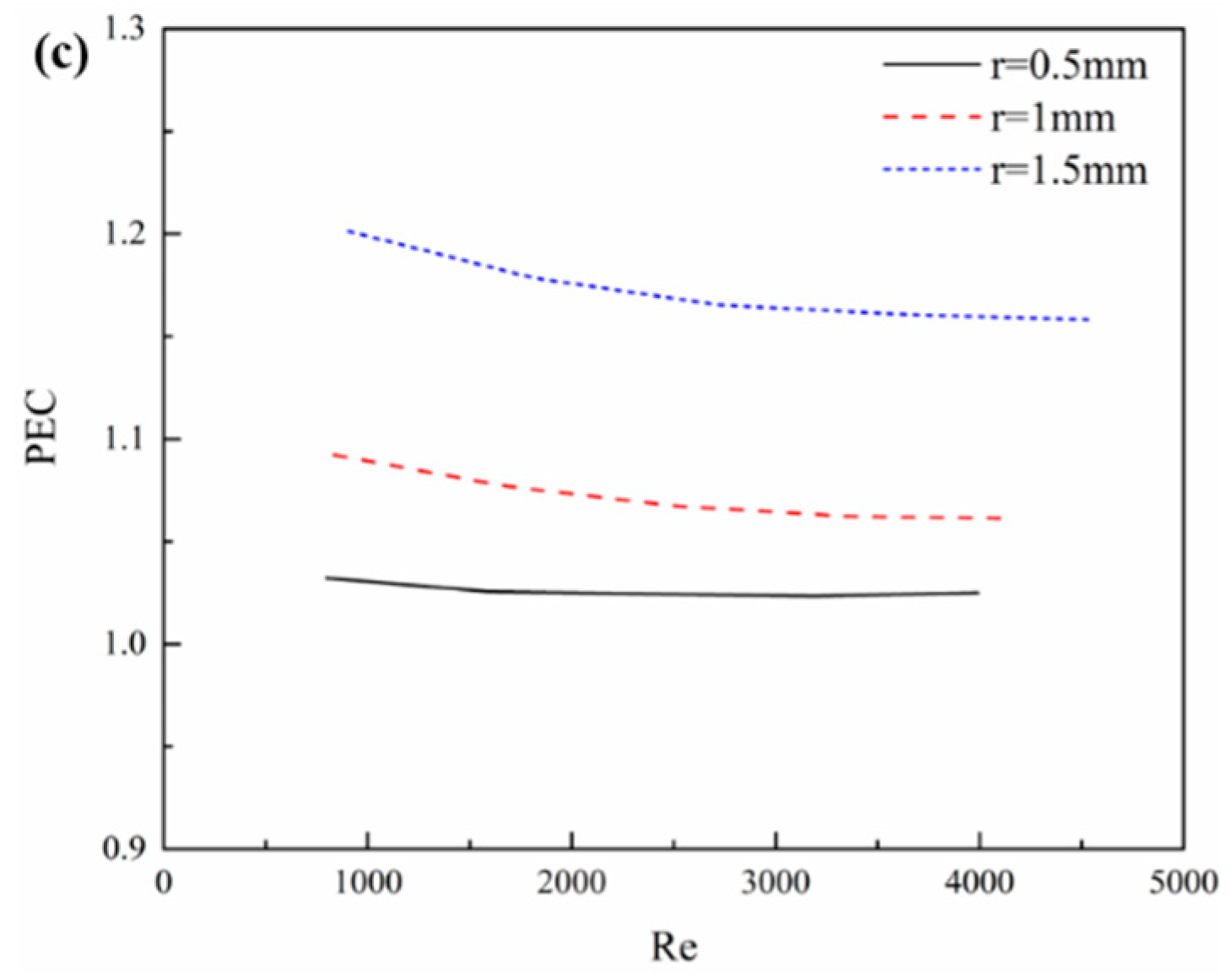

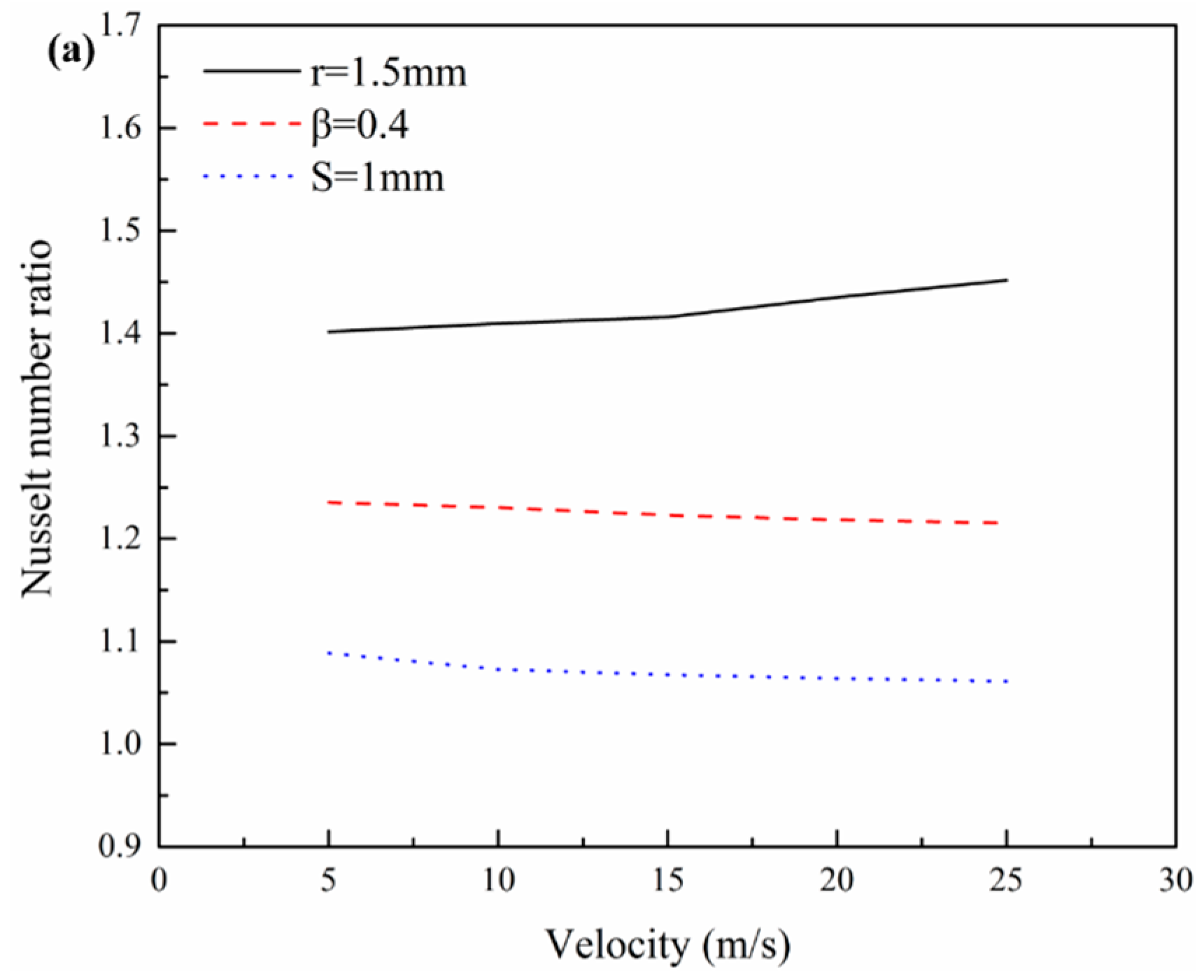

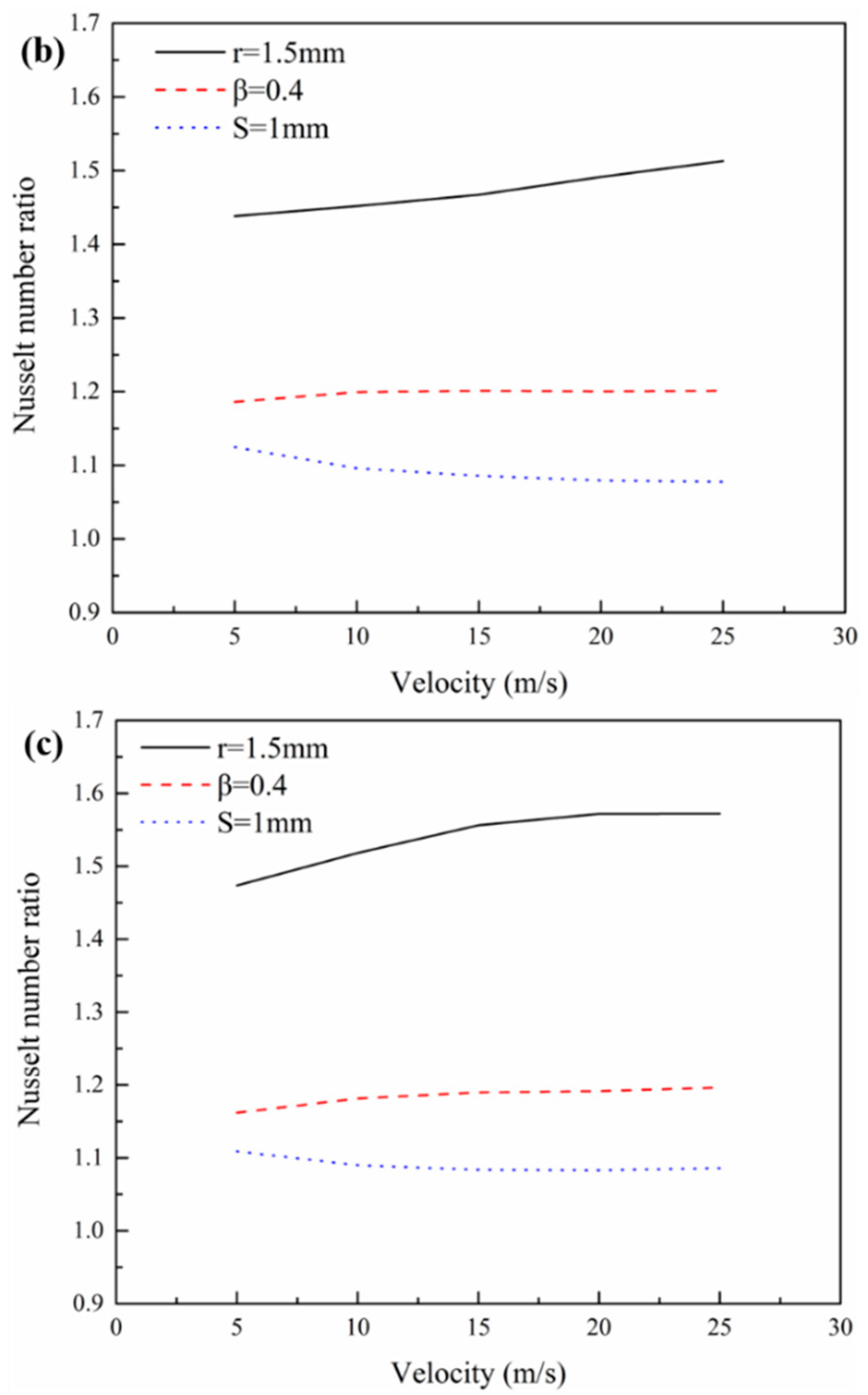

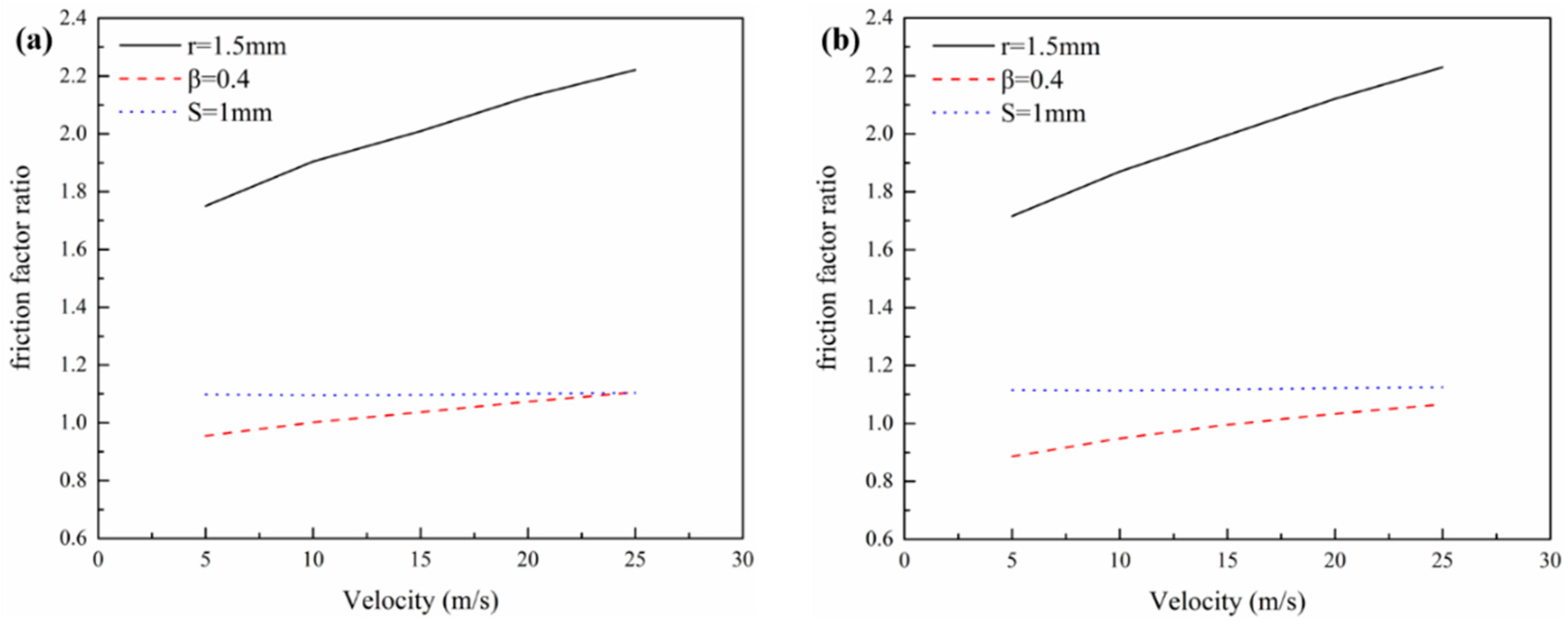

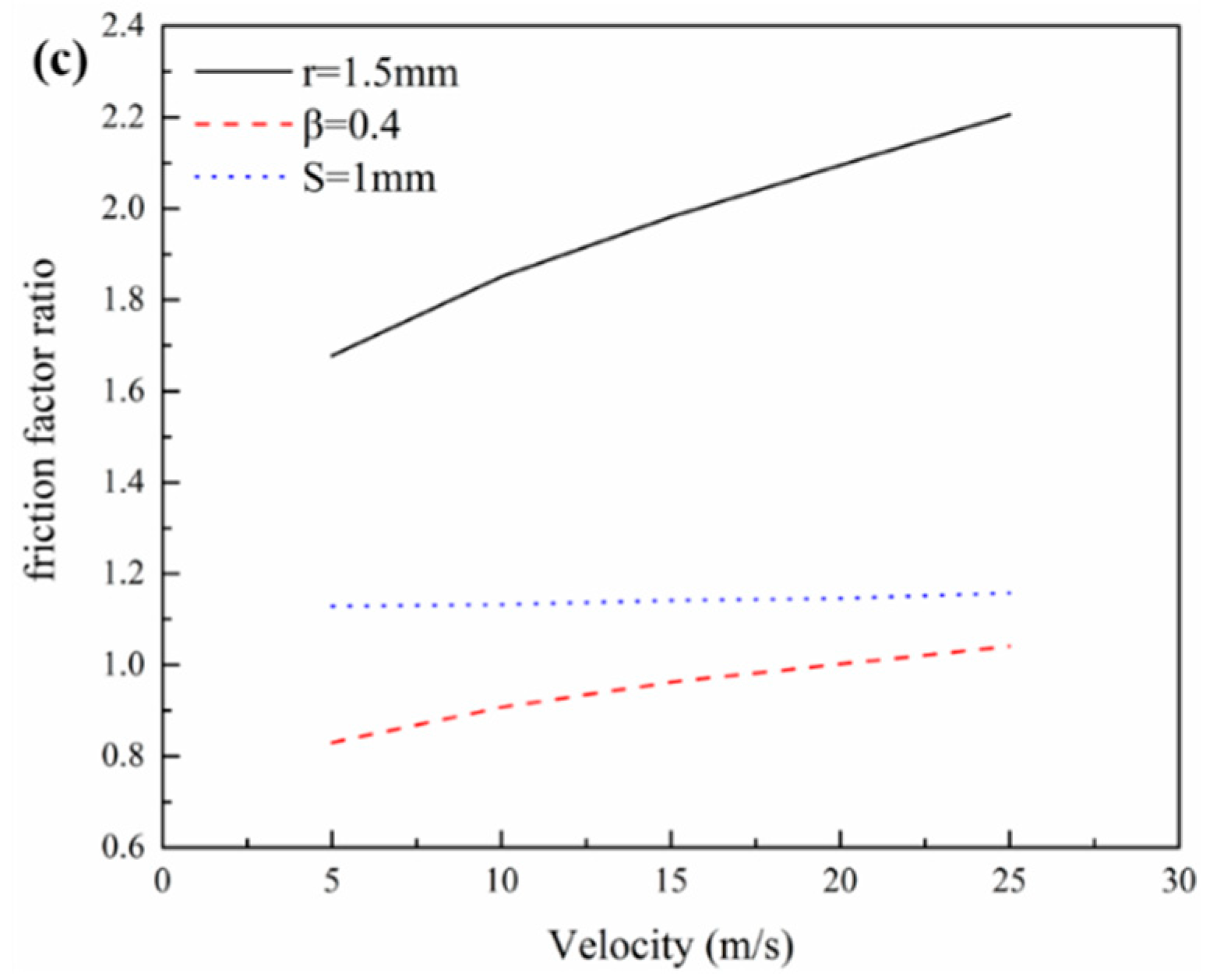

3.1. Influence of Different Perforated Radius

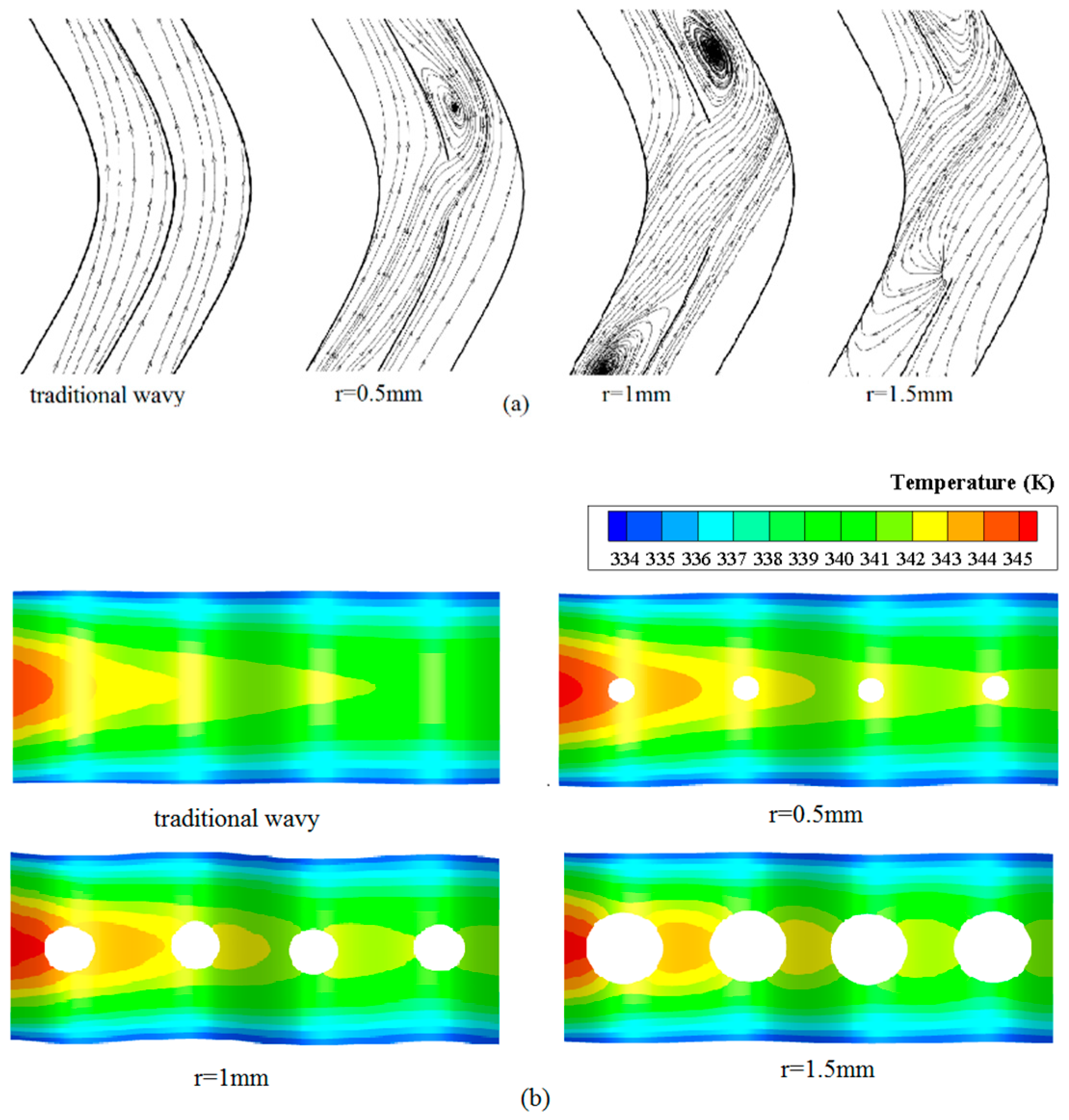

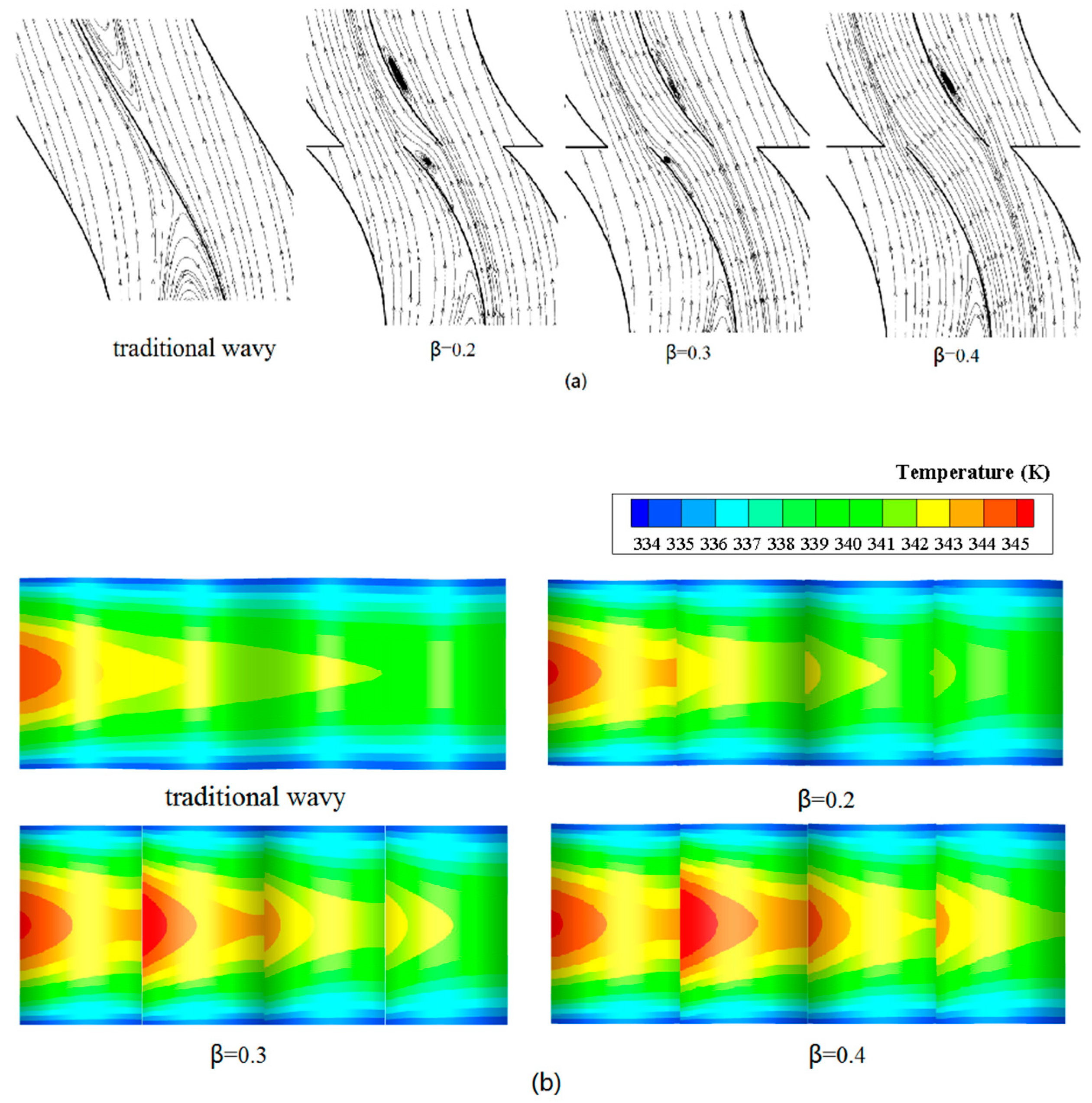

3.2. Influence of Different Staggered Ratio

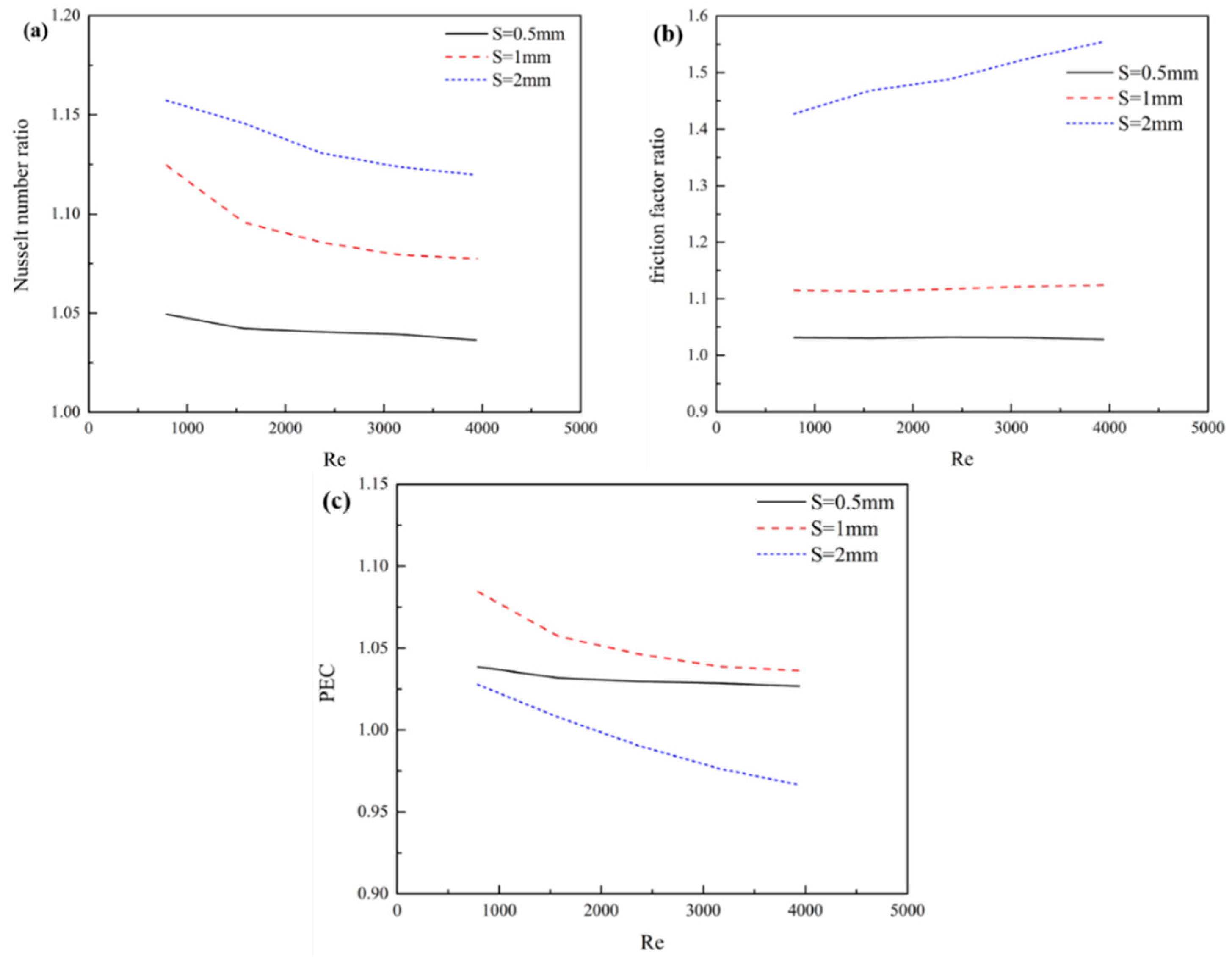

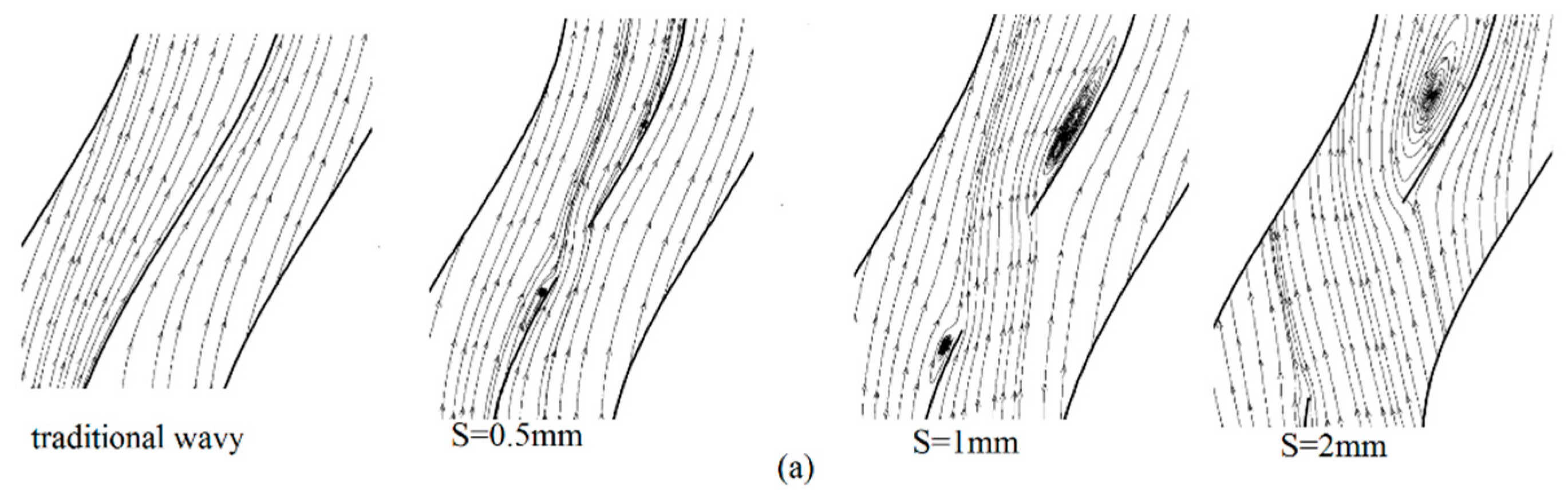

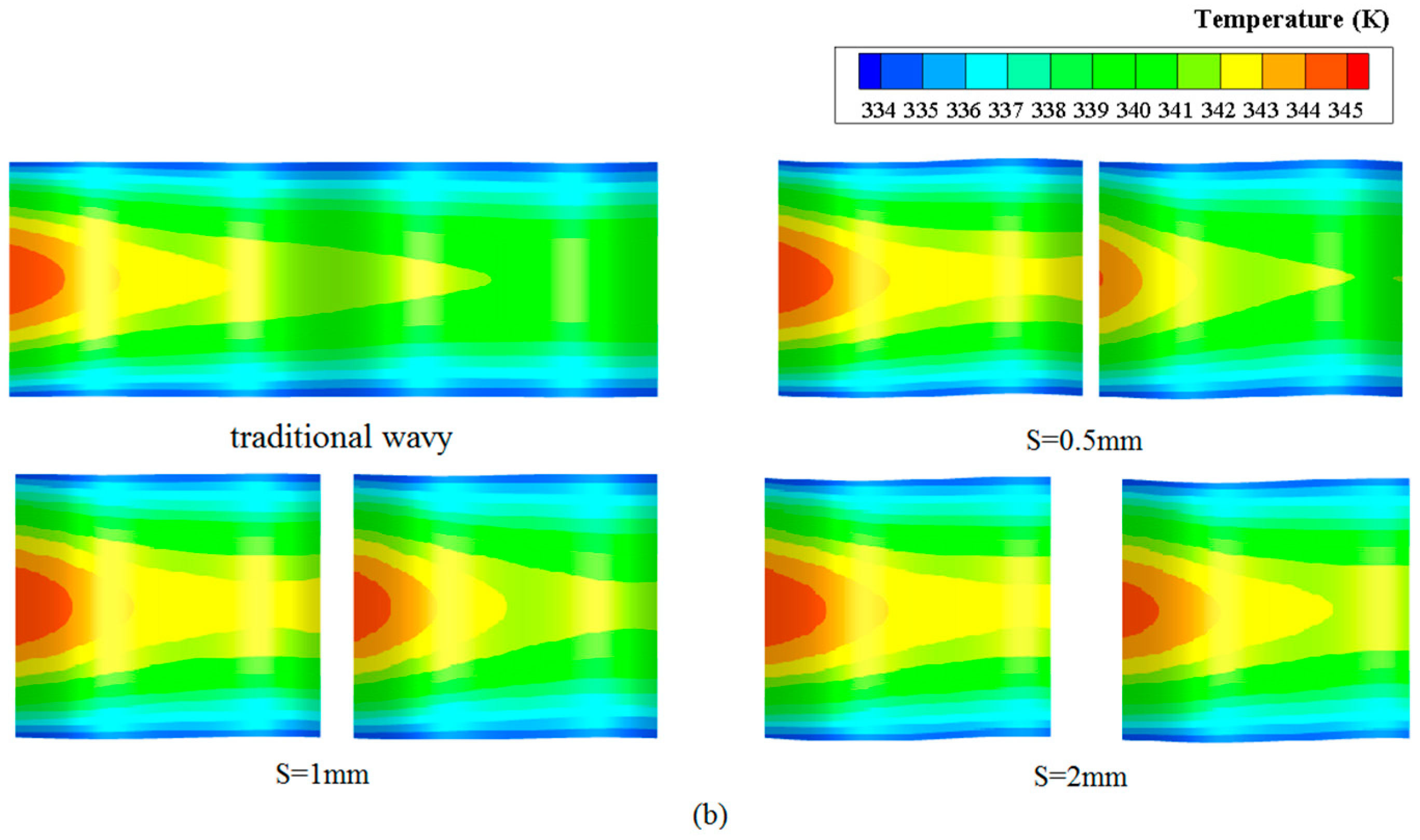

3.3. Influence of Different Breaking Distance for Discontinuous Wavy Fin

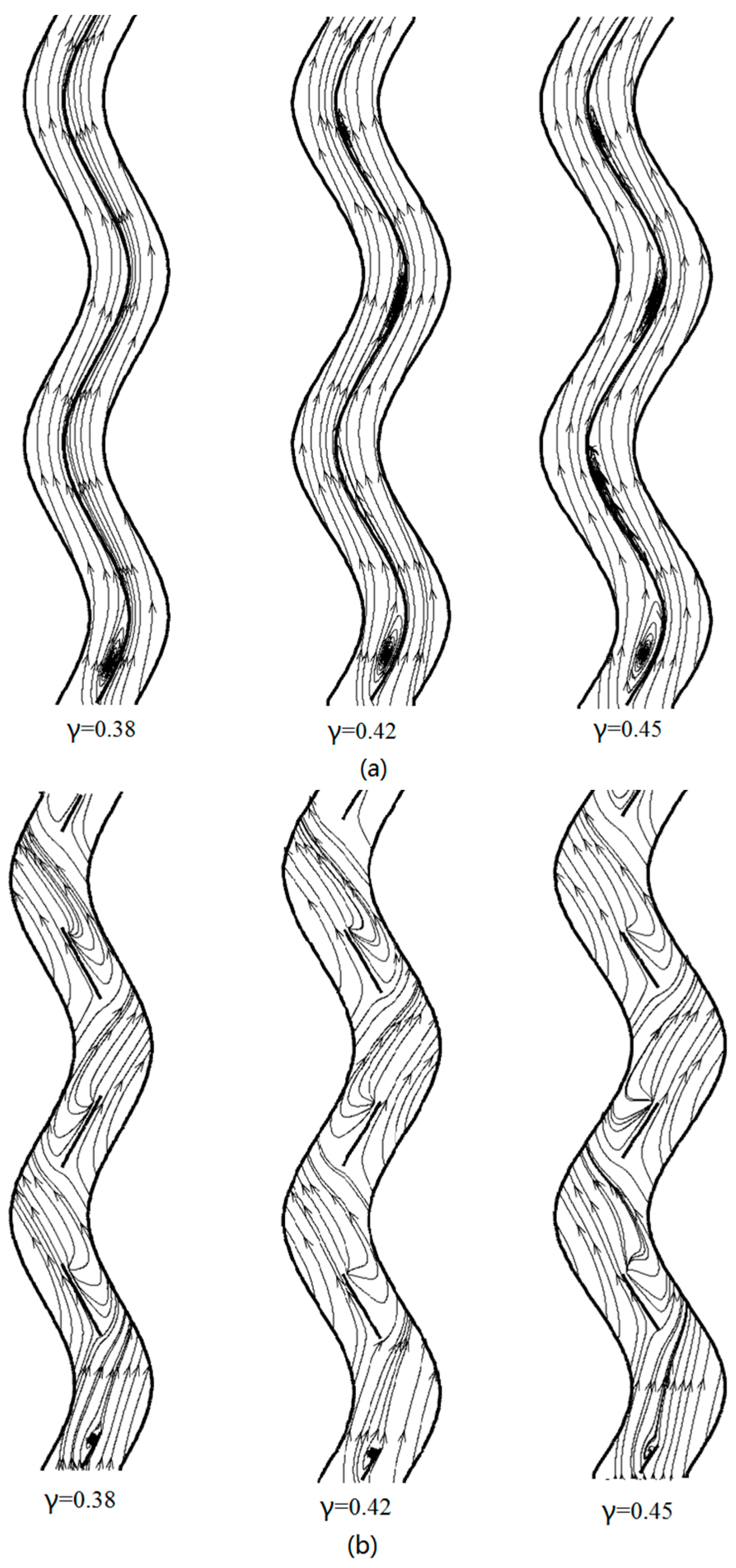

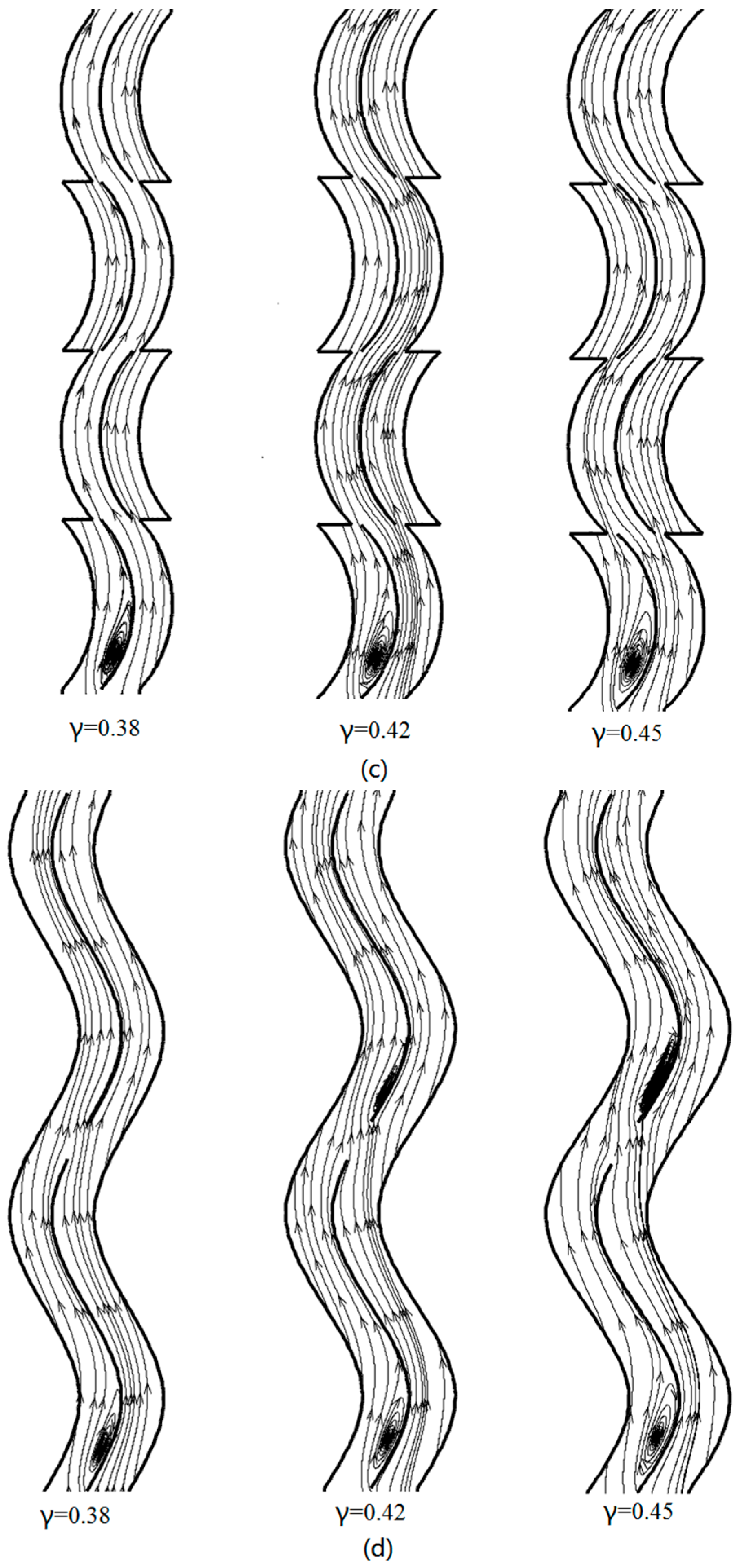

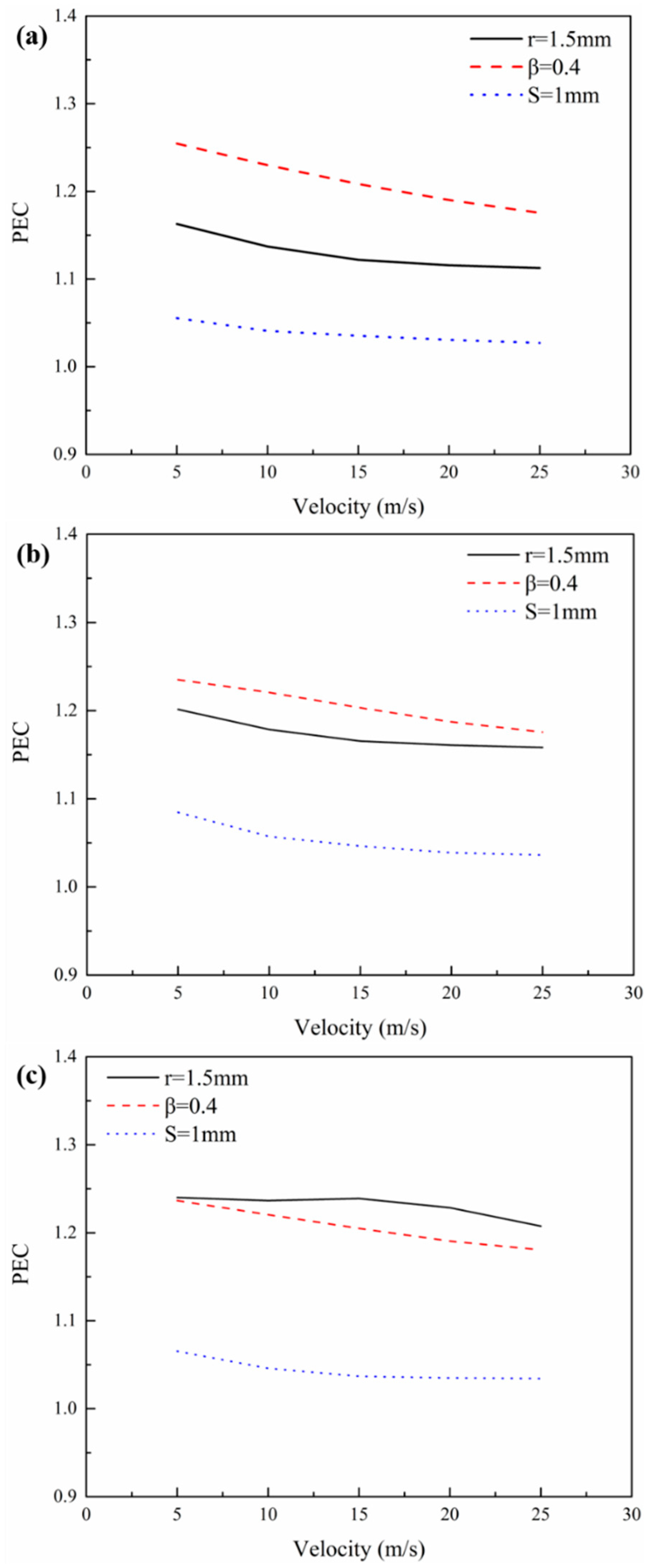

3.4. Influence of Waviness Aspect Ratio of Different Wavy Fin

4. Conclusions

- For perforated wavy fin, the enlarged hole can strengthen the flow turbulence, causing rapid mixing between the core and the fluid near the fin surface. The bigger the holes, the better the thermal-hydraulic performance. For staggered wavy fin, the greater staggered ratio, the less flow turbulence at the staggered section. Then, the larger the staggered ratio, the better the thermal-hydraulic performance. For discontinuous wavy fin, the larger the distance between the discontinuous wavy fins, the better the mixing of fluid on both sides of the fin, thereby enhancing the heat transfer performance. At the same time, the friction factor has increased dramatically when the breaking distance is 2 mm.

- The Nusselt number and friction factor of the perforated wavy fin are all higher than that of the traditional wavy fin. The serration technology is beneficial to reduce the friction factor compared to the traditional wavy fin. Using the serration technique in the smaller aspect ratio can obviously improve the thermal-hydraulic performance of the wavy fin.

- At a given inlet velocity, Nusselt number and the PEC for the three proposed new wavy fins are higher than that of the traditional wavy fin, and it tends to almost invariable with increasing waviness aspect ratio for the discontinuous wavy fin. At the same time, with increasing of waviness aspect ratio, the PEC for the perforated wavy fin and staggered wavy fin increases. In addition, the predominance of the staggered wavy fin is gradually surpassed by the perforated wavy fin.

- The present research shows that the proposed heat transfer enhancement techniques all have advantages over the traditional wavy fin. Perforation is beneficial to the enhancement of the heat transfer and the improvement of the Nusselt number. Serration is beneficial to reduce the friction factor, and the breaking technique can reduce heat transfer area while enhancing heat transfer performance.

Author Contributions

Acknowledgments

Conflicts of Interest

Nomenclature

| A | Total heat transfer area, m2 |

| Ac | Minimum free flow area, m2 |

| a | wave amplitude, mm |

| Cp | specific heat at constant pressure, kJ/(kg·K) |

| Dh | hydraulic diameter, mm |

| Fc | Staggered spacing, mm |

| Fh | Fin height, mm |

| Fp | Fin pitch, mm |

| f | friction factor |

| G | mass velocity, kg/(m2·s) |

| h | heat transfer coefficient, W/(m2·K) |

| j | Colburn factor |

| k | The turbulence kinetic energy |

| L | Flow length, mm |

| Lz | Wavy fin passage length, mm |

| l | wavy length, mm |

| m | Mass flow rate, kg/s |

| Nu | Nusselt number |

| Pr | Prandtl number |

| p | pressure, Pa |

| PEC | Performance evaluation criteria |

| Q | Heat flow, W |

| r | Perforation radius, mm |

| Re | Reynolds number |

| S | Breaking distance in discontinuous wavy fin, mm; mean rate of strain tensor. |

| T | temperature, K |

| V | Air inlet velocity, m/s |

| ui | Velocity in the direction, m/s |

| uj | Velocity in the direction, m/s |

| xi | Coordinate, m |

| Greek Letters | |

| β | Staggered ratio |

| γ | waviness aspect ratio |

| δ | Fin thickness, mm |

| δij | Kronecker delta |

| η | Fin efficiency |

| λ | Thermal conductivity, W/(m·K) |

| μ | dynamic viscosity, Pa·s |

| μt | turbulent viscosity, Pa·s |

| ρ | Fluid density, kg/m3 |

| τ | Shear stress, Pa |

| Subscripts | |

| f | fin |

| in | inlet |

| out | outlet |

| p | plate |

| w | wall |

References

- Tinaut, F.V.; Melgar, A.; Ali, A.A.R. Correlations for heat transfer and flow friction characteristics of compact plate-type heat exchangers. Int. J. Heat Mass Transf. 1992, 35, 1659–1665. [Google Scholar] [CrossRef]

- Ismail, L.S.; Velraj, R.; Ranganayakulu, C. Studies on pumping power in terms of pressure drop and heat transfer characteristics of compact plate-fin heat exchangers&mdash—A review. Renew. Sustain. Energy Rev. 2010, 14, 478–485. [Google Scholar]

- Yousefi, M.; Enayatifar, R.; Darus, A.N. Optimal design of plate-fin heat exchangers by a hybrid evolutionary algorithm. Int. Commun. Heat Mass Transf. 2011, 38, 258–263. [Google Scholar] [CrossRef]

- T’Joen, C.; Jacobi, A.; Paepe, M.D. Flow visualisation in inclined louvered fins. Exp. Therm. Fluid Sci. 2009, 33, 664–674. [Google Scholar] [CrossRef]

- Vaisi, A.; Esmaeilpour, M.; Taherian, H. Experimental investigation of geometry effects on the performance of a compact louvered heat exchanger. Appl. Therm. Eng. 2011, 31, 3337–3346. [Google Scholar] [CrossRef]

- Kays, W.M.; London, A.L. Compact heat exchangers. J. Appl. Mech. 1984, 27, 460–470. [Google Scholar] [CrossRef]

- Khoshvaght-Aliabadi, M.; Hormozi, F.; Zamzamian, A. Role of channel shape on performance of plate-fin heat exchangers: Experimental assessment. Int. J. Therm. Sci. 2014, 79, 183–193. [Google Scholar] [CrossRef]

- Du, J.; Qian, Z.Q.; Dai, Z.Y. Experimental study and numerical simulation of flow and heat transfer performance on an offset plate-fin heat exchanger. Heat Mass Transf. 2016, 52, 1–16. [Google Scholar] [CrossRef]

- Dong, J.; Chen, J.; Zhang, W.; Hu, J. Experimental and numerical investigation of thermal-hydraulic performance in wavy fin-and-flat tube heat exchangers. Appl. Therm. Eng. 2010, 30, 1377–1386. [Google Scholar] [CrossRef]

- Joardar, A.; Jacobi, A.M. Impact of leading edge delta-wing vortex generators on the thermal performance of a flat tube, louvered-fin compact heat exchanger. Int. J. Heat Mass Transf. 2005, 48, 1480–1493. [Google Scholar] [CrossRef]

- Lotfi, B.; Sundén, B.; Wang, Q. An investigation of the thermo-hydraulic performance of the smooth wavy fin-and-elliptical tube heat exchangers utilizing new type vortex generators. Appl. Energy 2016, 162, 1282–1302. [Google Scholar] [CrossRef]

- Tang, L.H.; Chu, W.X.; Ahmed, N.; Zeng, M. A new configuration of winglet longitudinal vortex generator to enhance heat transfer in a rectangular channel. Appl. Therm. Eng. 2016, 104, 74–84. [Google Scholar] [CrossRef]

- Peng, H.; Xiang, L.; Li, J. Performance investigation of an innovative offset strip fin arrays in compact heat exchangers. Energy Convers. Manag. 2014, 80, 287–297. [Google Scholar] [CrossRef]

- Alessa, A.H.; Maqableh, A.M.; Ammourah, S. Enhancement of natural convection heat transfer from a fin by rectangular perforations with aspect ratio of two. Int. J. Phys. Sci. 2009, 4, 540–547. [Google Scholar]

- Shaeri, M.R.; Yaghoubi, M.; Jafarpur, K. Heat transfer analysis of lateral perforated fin heat sinks. Appl. Energy 2009, 86, 2019–2029. [Google Scholar] [CrossRef]

- Ridouane, E.H.; Campo, A. Heat Transfer Enhancement of Air Flowing Across Grooved Channels: Joint Effects of Channel Height and Groove Depth. J. Heat Transf. 2008, 130, 281–293. [Google Scholar] [CrossRef]

- Tian, L.; Liu, B.; Min, C.; Wang, J.; He, Y. Study on the effect of punched holes on flow structure and heat transfer of the plain fin with multi-row delta winglets. Heat Mass Transf. 2015, 51, 1523–1536. [Google Scholar] [CrossRef]

- Du, X.; Feng, L.; Yang, Y.; Yang, L. Experimental study on heat transfer enhancement of wavy finned flat tube with longitudinal vortex generators. Appl. Therm. Eng. 2013, 50, 55–62. [Google Scholar] [CrossRef]

- Lu, G.; Zhou, G. Numerical simulation on performances of plane and curved winglet type vortex generator pairs with punched holes. Int. J. Heat Mass Transf. 2016, 102, 679–690. [Google Scholar] [CrossRef]

- Jeong, C.H.; Kim, H.R.; Ha, M.Y.; Son, S.W.; Lee, J.S.; Kim, P.Y. Numerical investigation of thermal enhancement of plate fin type heat exchanger with creases and holes in construction machinery. Appl. Therm. Eng. 2014, 62, 529–544. [Google Scholar] [CrossRef]

- Ahn, H.S.; Lee, S.W.; Lau, S.C. Heat Transfer Enhancement for Turbulent Flow Through Blockages with Round and Elongated Holes in a Rectangular Channel. J. Heat Transf. 2007, 129, 1611–1615. [Google Scholar] [CrossRef]

- Kays, W.M.; London, A.L. Compact Heat Exchangers, 3rd ed.; McGraw-Hill Book Company: New York, NY, USA, 1984. [Google Scholar]

- Junqi, D.; Jiangping, C.; Zhijiu, C.; Yimin, Z.; Wenfeng, Z. Heat transfer and pressure drop correlations for the wavy fin and flat tube heat exchangers. Appl. Therm. Eng. 2007, 27, 2066–2073. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, Y.; Ge, Z.; Du, X.; Yang, L. On the Heat Transfer Enhancement of Plate Fin Heat Exchanger. Energies 2018, 11, 1398. https://doi.org/10.3390/en11061398

Xue Y, Ge Z, Du X, Yang L. On the Heat Transfer Enhancement of Plate Fin Heat Exchanger. Energies. 2018; 11(6):1398. https://doi.org/10.3390/en11061398

Chicago/Turabian StyleXue, Yuan, Zhihua Ge, Xiaoze Du, and Lijun Yang. 2018. "On the Heat Transfer Enhancement of Plate Fin Heat Exchanger" Energies 11, no. 6: 1398. https://doi.org/10.3390/en11061398

APA StyleXue, Y., Ge, Z., Du, X., & Yang, L. (2018). On the Heat Transfer Enhancement of Plate Fin Heat Exchanger. Energies, 11(6), 1398. https://doi.org/10.3390/en11061398