Hybrid Solar-Geothermal Energy Absorption Air-Conditioning System Operating with NaOH-H2O—Las Tres Vírgenes (Baja California Sur), “La Reforma” Case

Abstract

1. Introduction

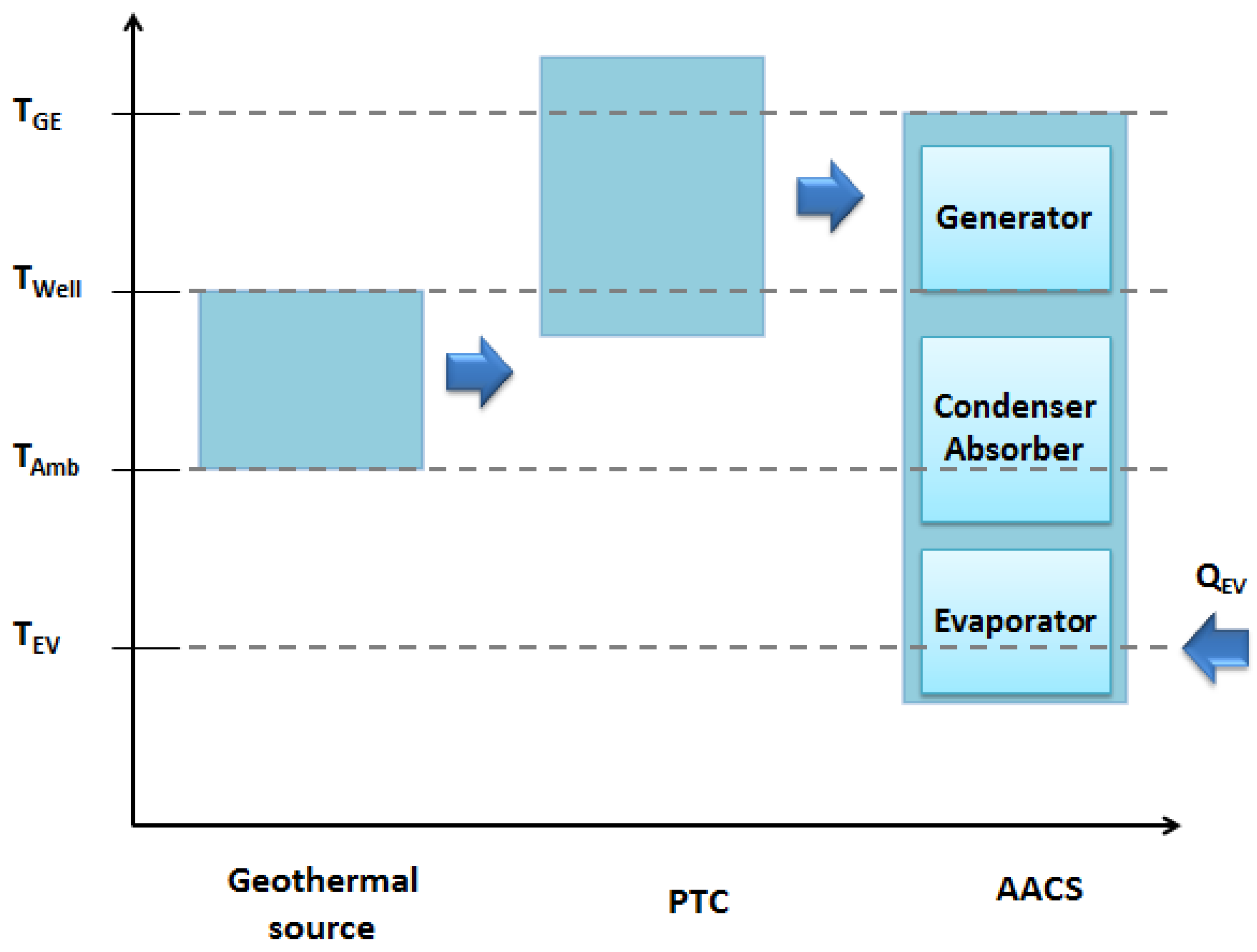

2. Description of the System

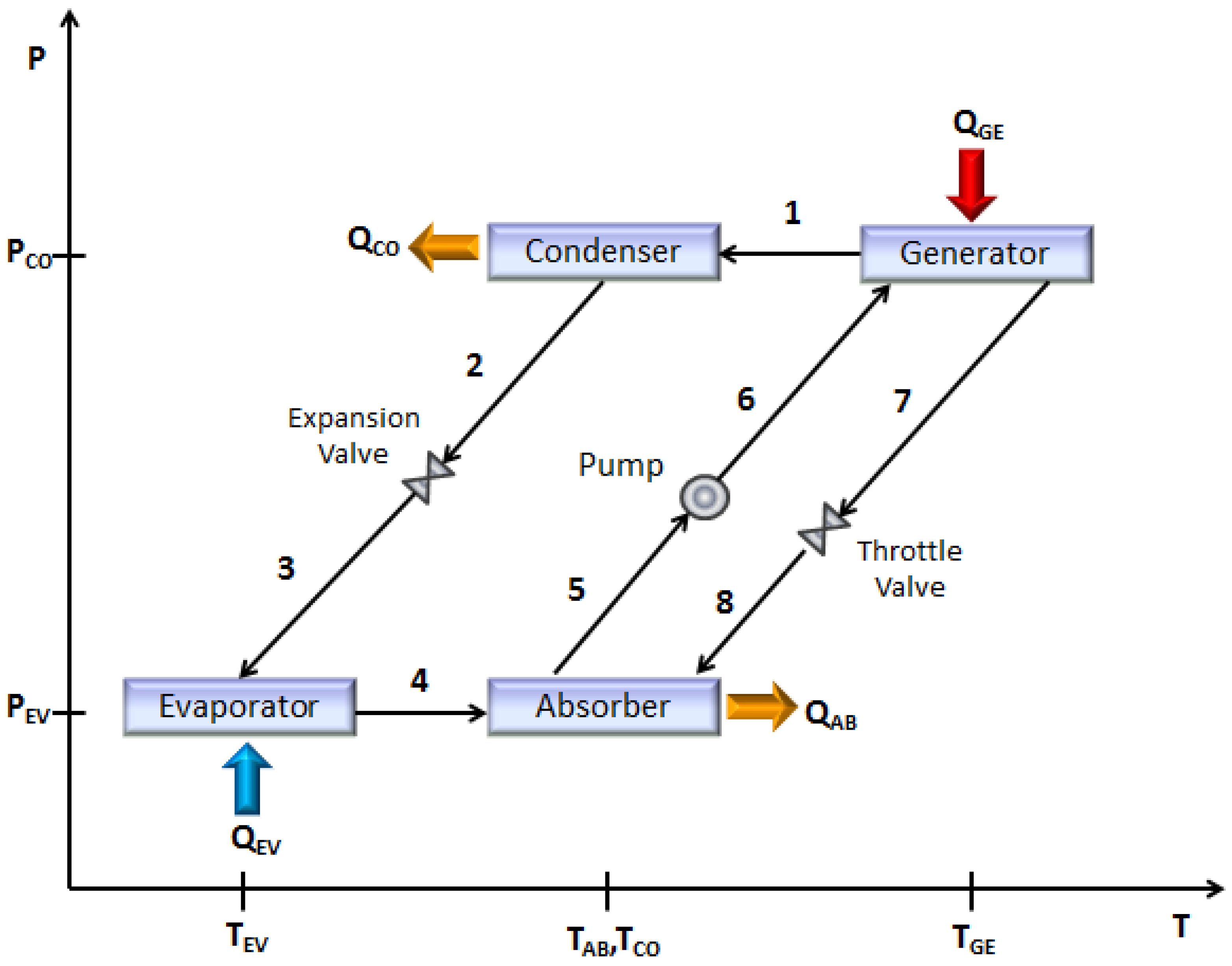

2.1. Absorption Air-Conditioning System (AACS)

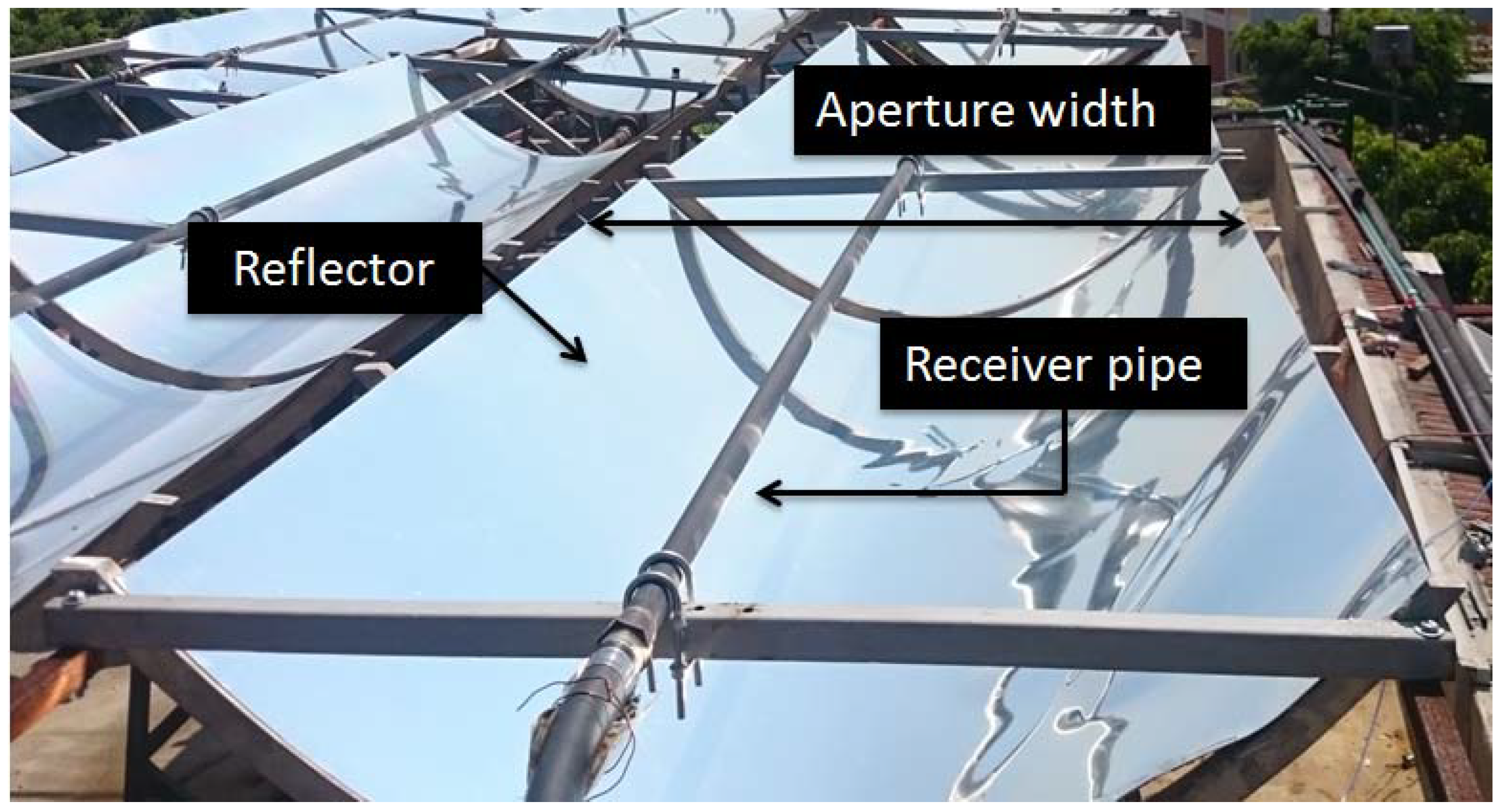

2.2. Parabolic trough Collectors

2.3. Shallow Geothermal Wells

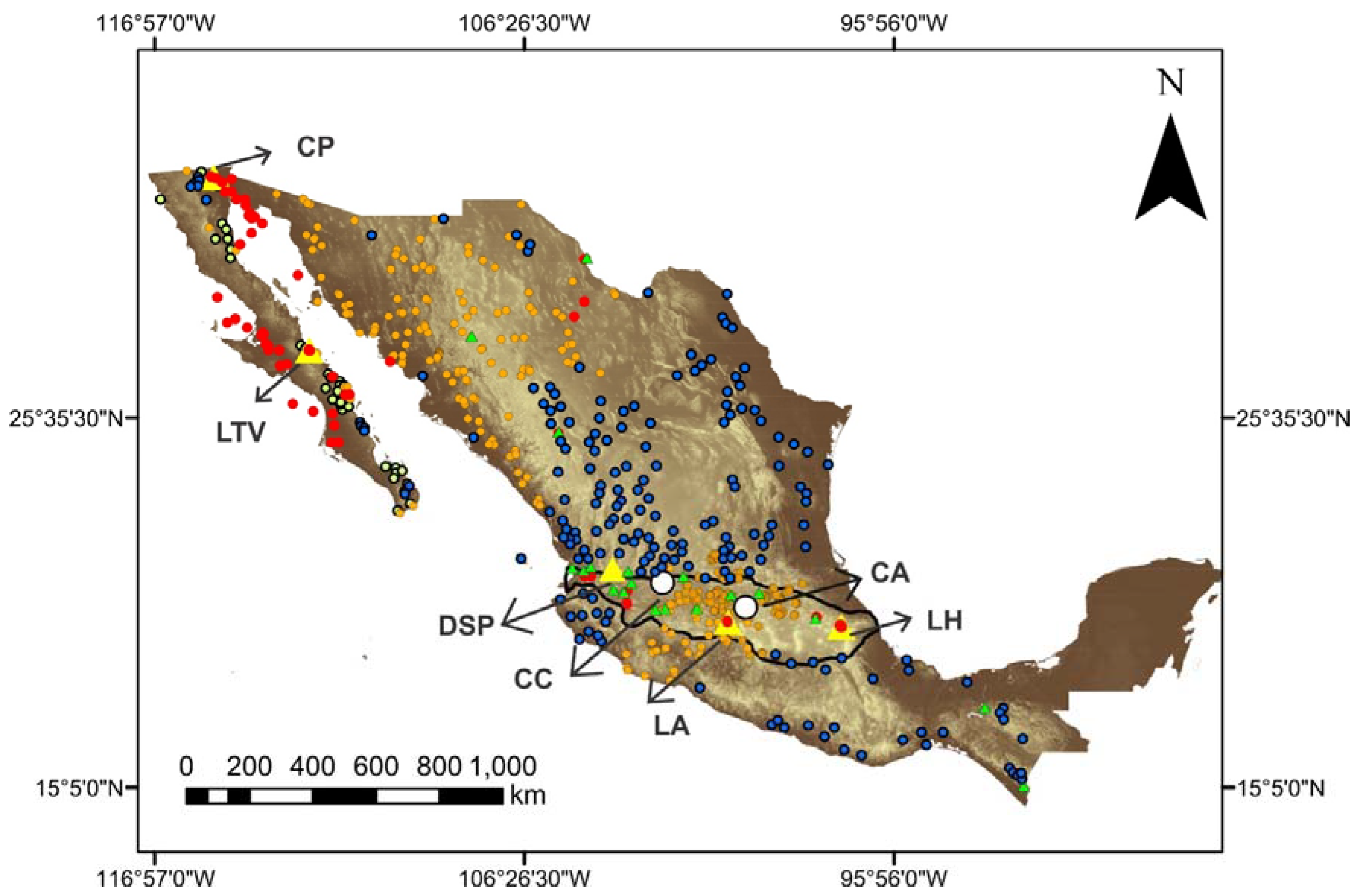

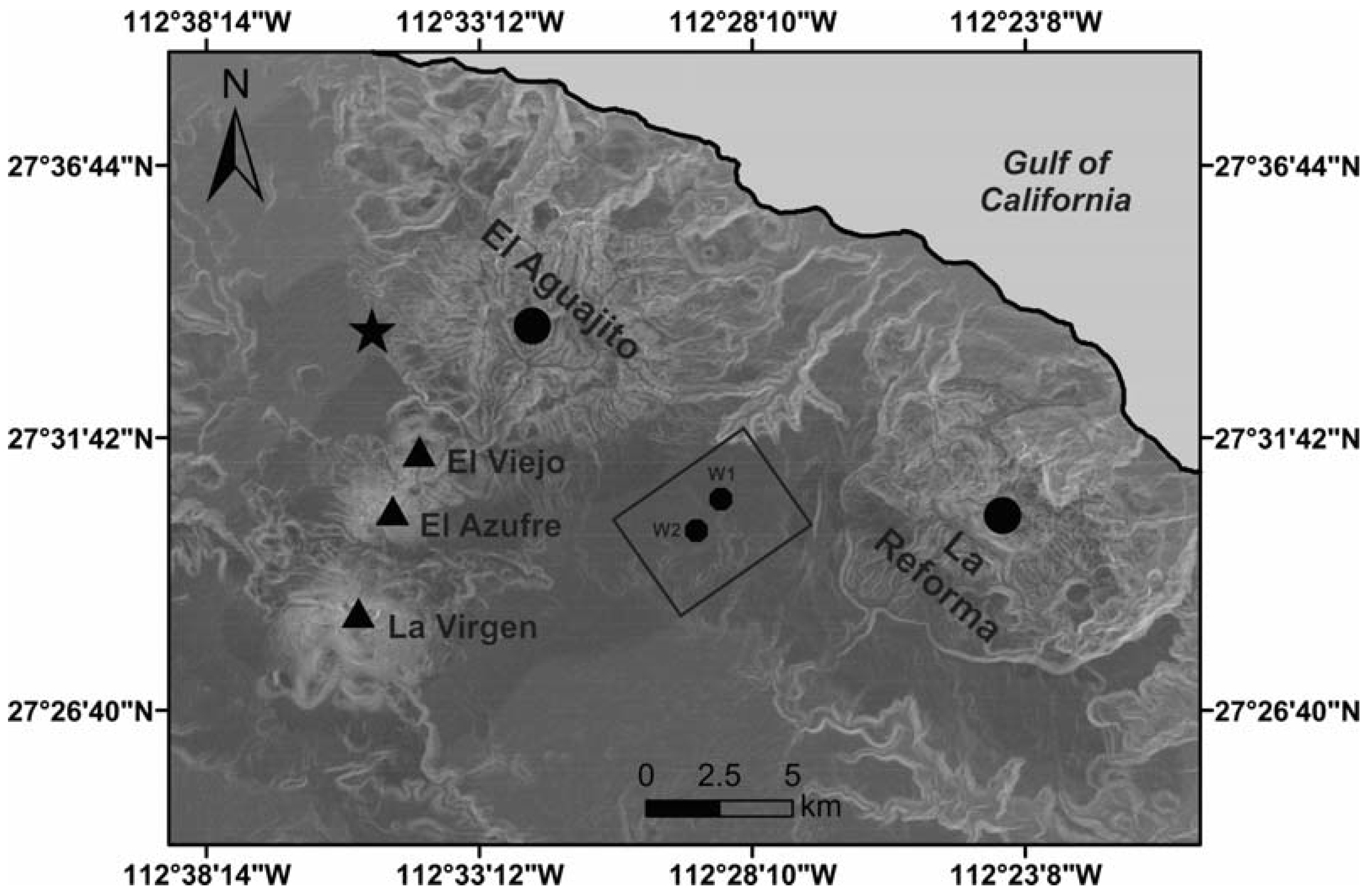

2.3.1. Study Area

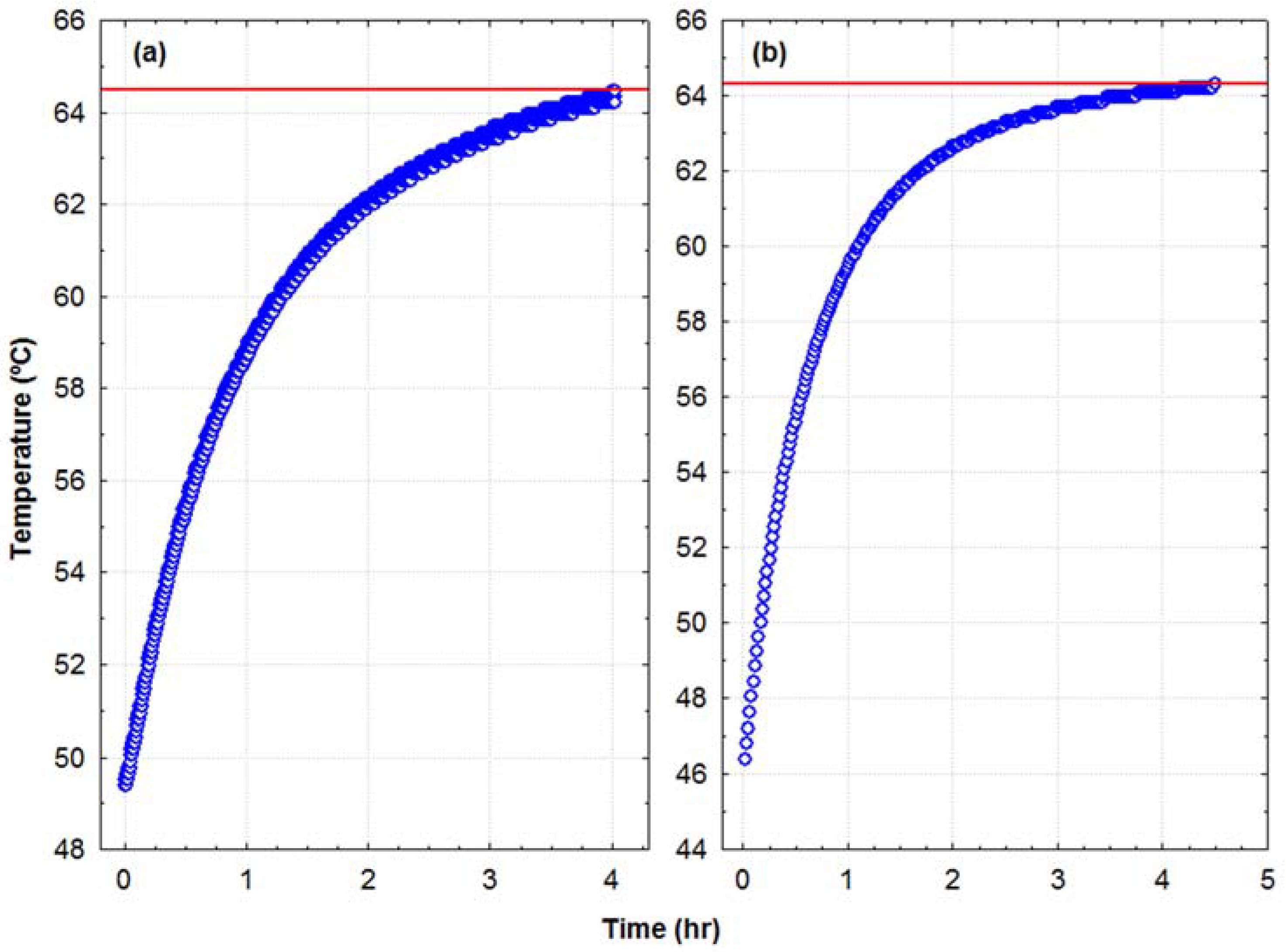

2.3.2. Drilling Wells and Log Temperatures

3. Methodology

3.1. Simulation of Single Stage Absorption Air-Conditioning System

3.2. PTC Model

3.3. Seasonal Variation in Ground Temperature

3.4. Convective Heat Transfer (Water Heating in the Well)

4. Results

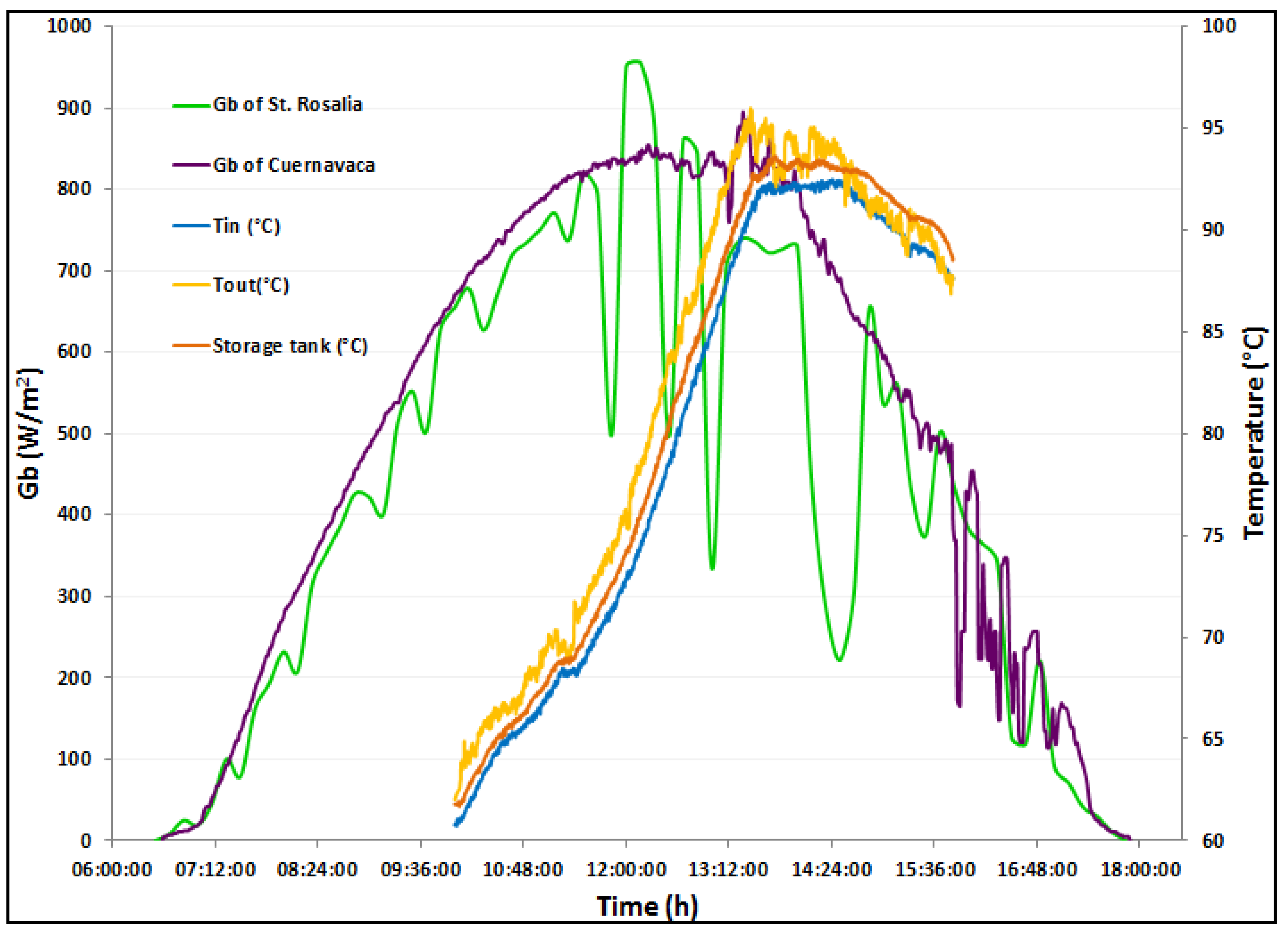

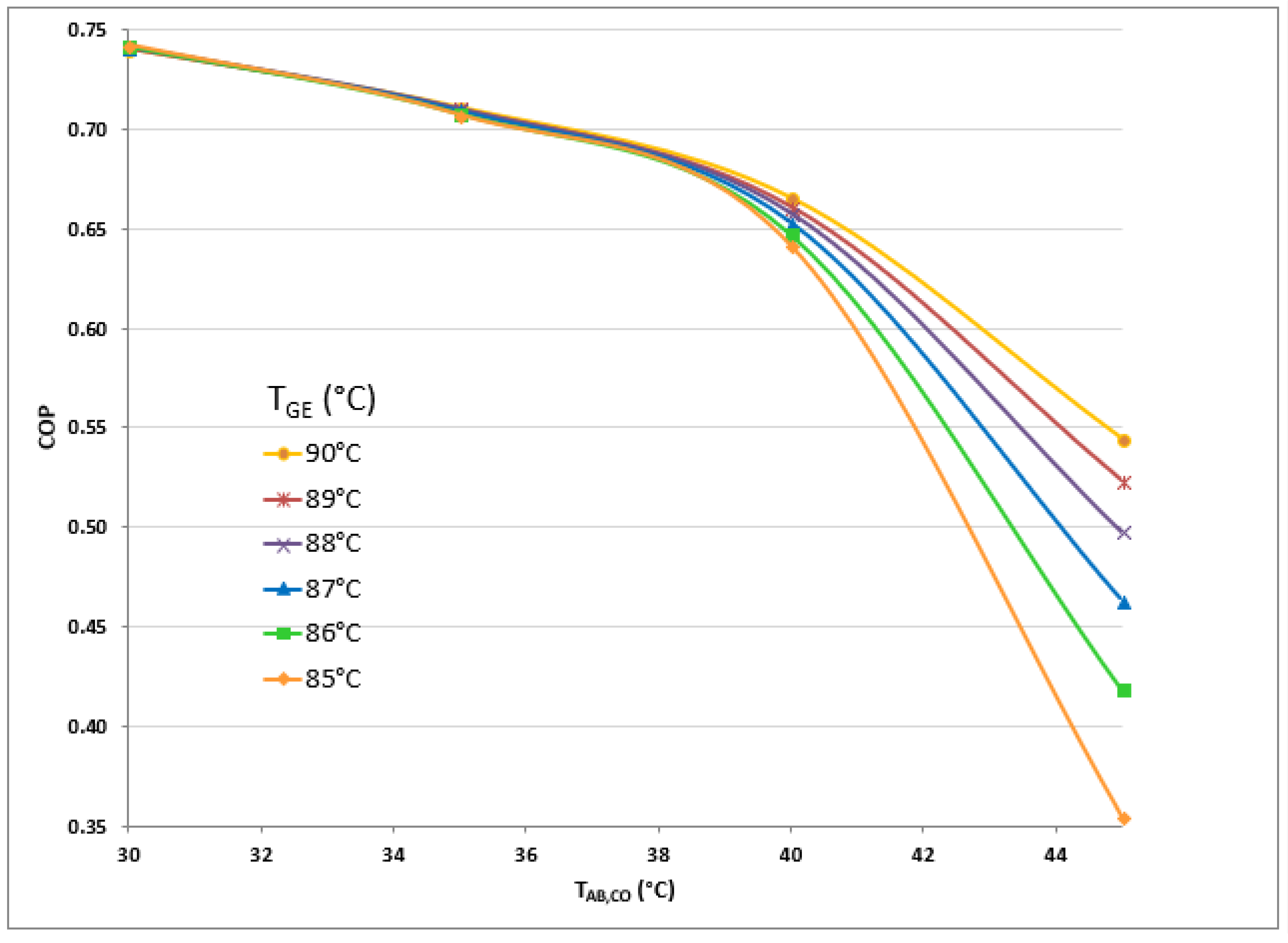

4.1. Solar-Geothermal System Evaluation

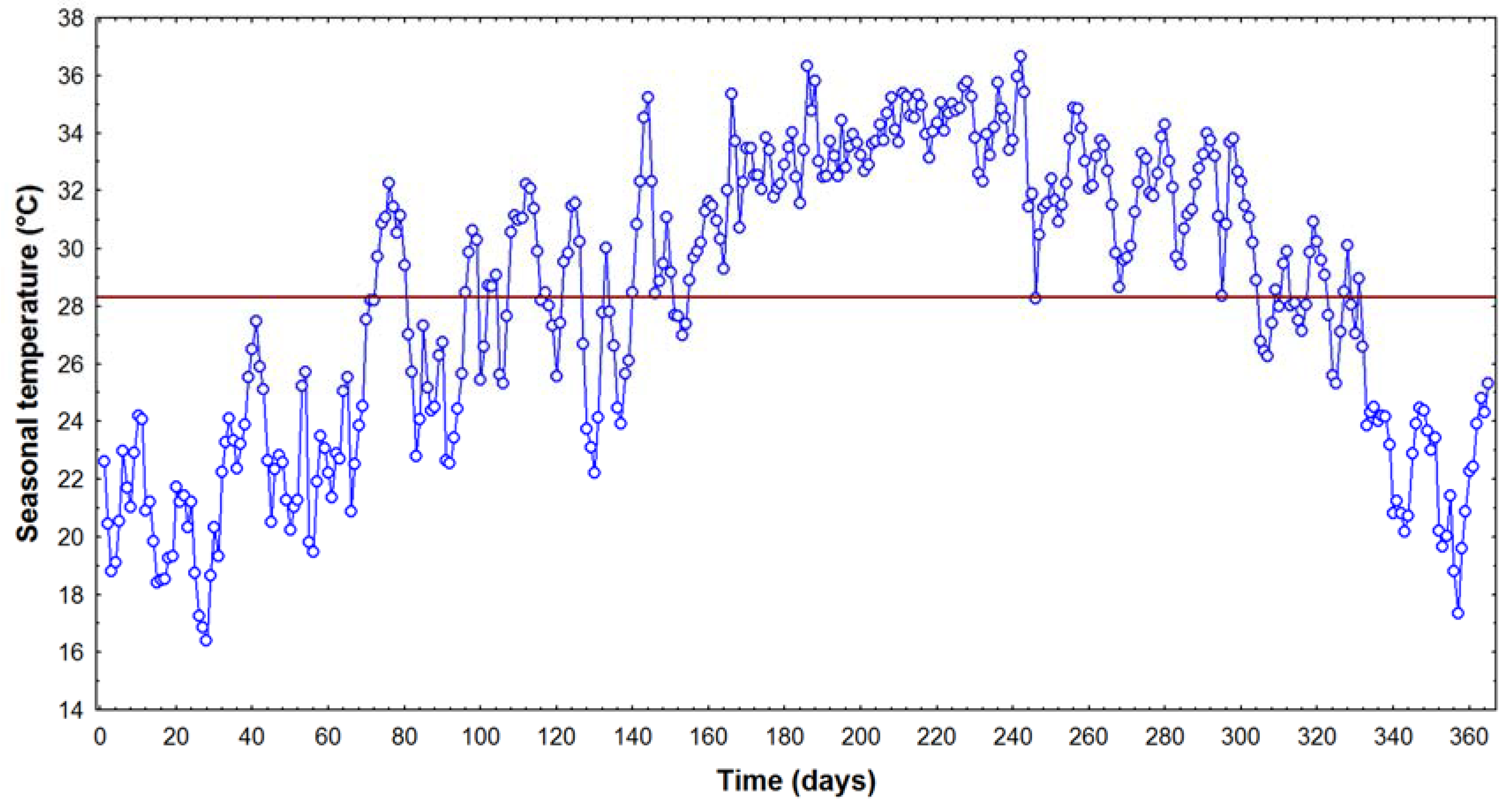

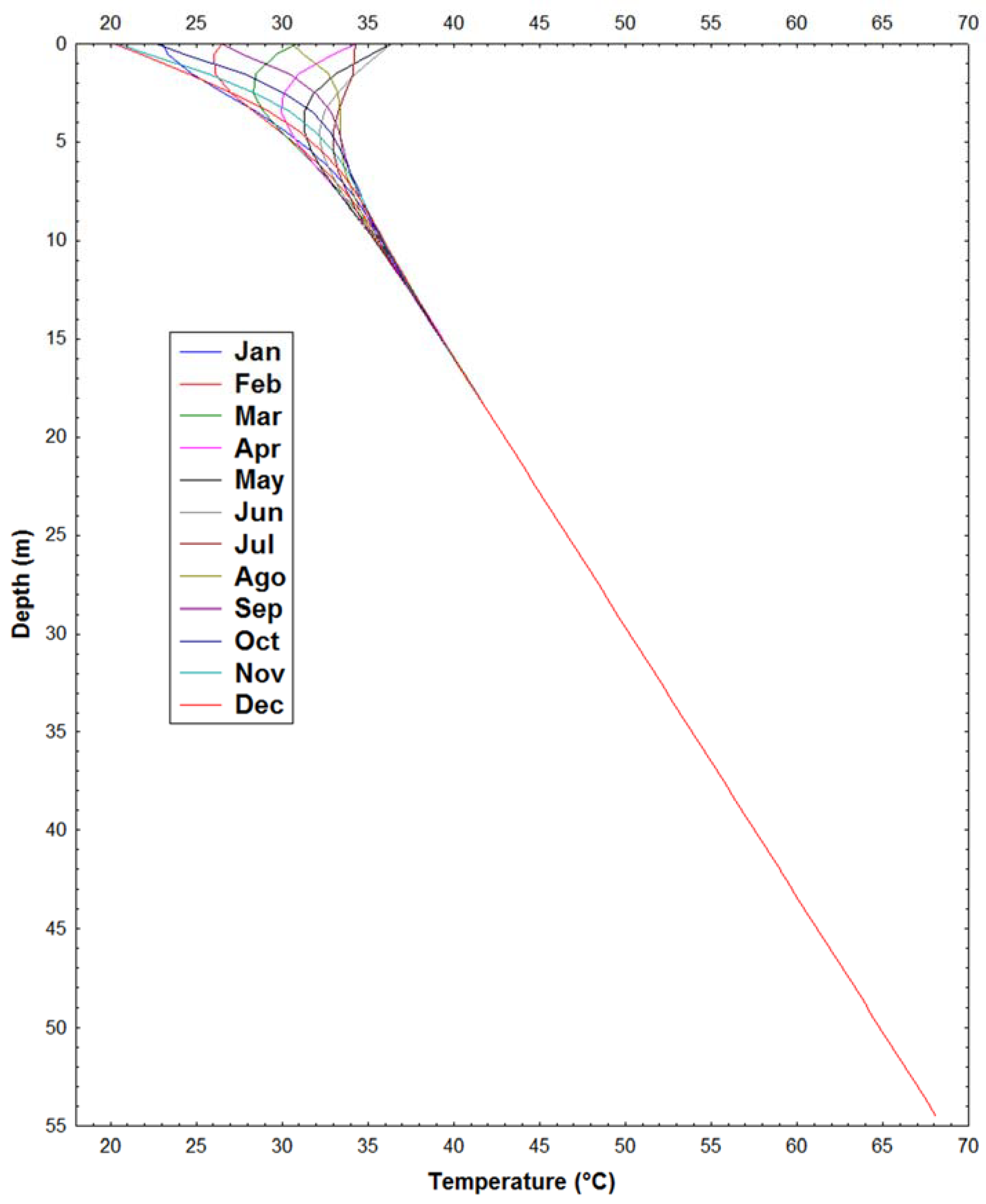

4.2. Ground Temperature Variation Results

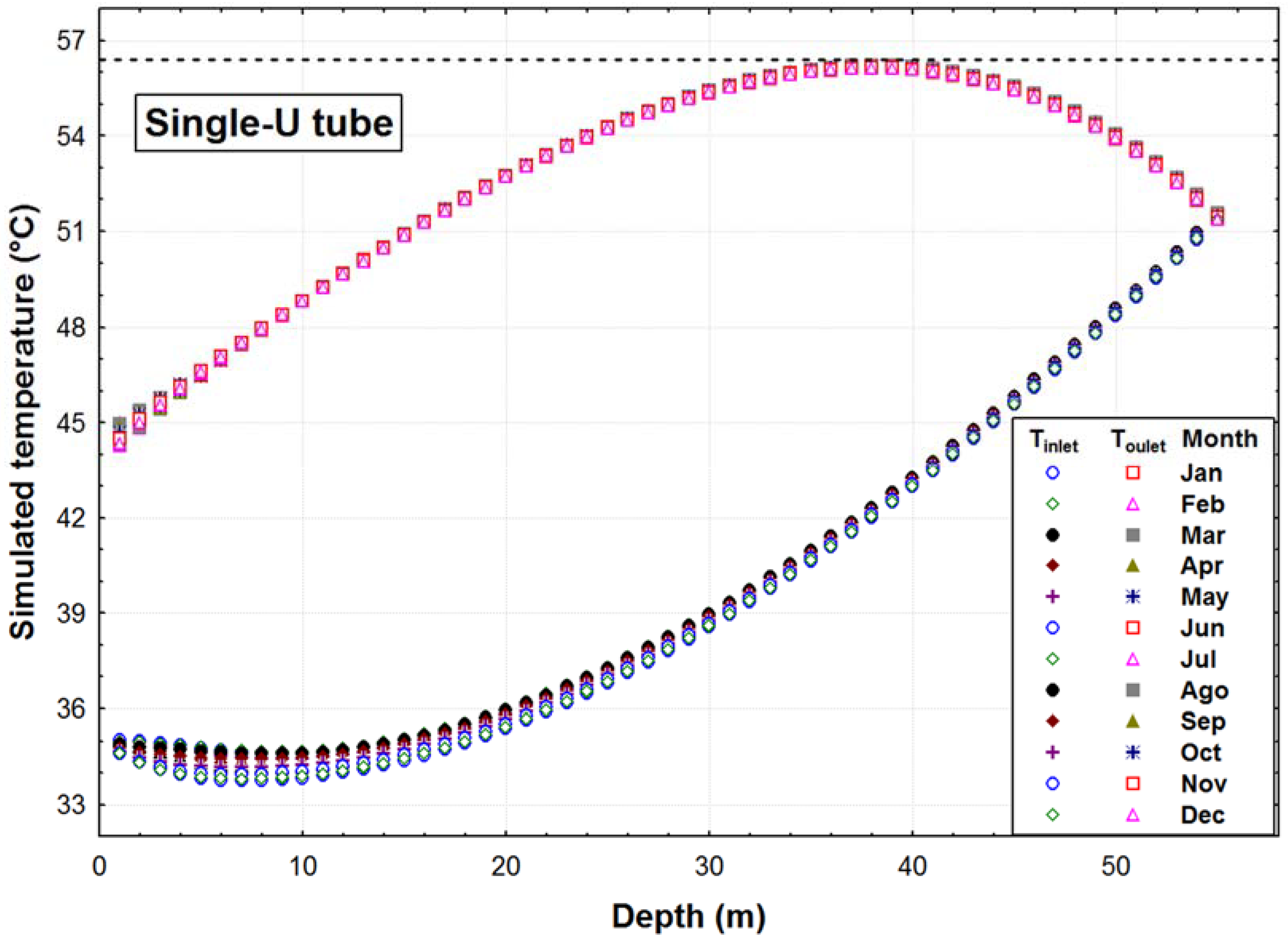

4.3 Numerical Heat Transfer

4.4. Single Stage Absorption Air-Conditioning System Evaluation

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Cabrera, F.J.; Fernández-García, A.; Silva, R.M.P.; Pérez-García, M. Use of parabolic trough solar collector for solar refrigeration and air-conditioning applications. Renew. Sustain. Energy Rev. 2013, 20, 103–118. [Google Scholar] [CrossRef]

- Shen, X.; Han, Y.; Zhu, S.; Zheng, J.; Li, Q.; Nong, J. Comprehensive power-supply planning for active distribution system considering cooling, heating and power load balance. J. Mod. Power Syst. Clean Energy 2015, 3, 485–493. [Google Scholar] [CrossRef]

- Miao, L.; Huanan, L. Analysis and assessments of combined cooling, heating and power systems in various operation modes for a building in China, Dalian. Energies 2013, 6, 2446–2467. [Google Scholar]

- Ghafoor, A.; Munir, A. Worldwide overview of solar thermal cooling technologies. Renew. Sustain. Energy Rev. 2015, 43, 763–774. [Google Scholar] [CrossRef]

- Suddiqui, M.U.; Said, S.A.M. A review of solar powered absorption system. Renew. Sustain. Energy Rev. 2015, 42, 93–115. [Google Scholar] [CrossRef]

- Kalogirou Soteris, A. Solar thermal collectors and applications. Prog. Energy Combust. 2014, 30, 231–295. [Google Scholar] [CrossRef]

- Lin, W.-M.; Tu, C.S.; Tsai, M.-T.; Lo, C.-C. Optimal energy reduction schedules for ice storage air-conditioning systems. Energies 2015, 8, 10504–10521. [Google Scholar] [CrossRef]

- Pavan Kumar, Y.V.; Bhimasingu, R. Renewable energy based microgrid system sizing energy management for green buildings. J. Mod. Power Syst. Clean Energy 2015, 3, 1–13. [Google Scholar] [CrossRef]

- Nchelatebe Nkwetta, D.; Smyth, M. The potential applications and advantages of powering solar air-conditioning systems using concentrator augmented solar collectors. Appl. Energy 2012, 89, 380–386. [Google Scholar] [CrossRef]

- Fernández-García, A.; Zarza, E.; Valenzuela, L.; Pérez, M. Parabolic-trough solar collector and their applications. Renew. Sustain. Energy Rev. 2010, 14, 1695–1721. [Google Scholar] [CrossRef]

- Ziuku, S.; Seyitini, L.; Mapurisa, B.; Chikodzi, D.; van Kuijk, K. Potential of concentrated solar power (CSP) in Zimbabwe. Energy Sustain. Dev. 2014, 23, 220–227. [Google Scholar] [CrossRef]

- Jaramillo, O.A.; Venegas-Reyes, E.; Aguilar, J.O.; Castrejón-García, R. Parabolic trough concentrator for low enthalpy processes. Renew. Energy 2013, 60, 529–539. [Google Scholar] [CrossRef]

- Reddy, K.S.; Kumar, K.R. Solar collector field design and viability analysis of stand-alone parabolic trough power plants for Indian conditions. Energy Sustain. Dev. 2012, 16, 456–470. [Google Scholar] [CrossRef]

- Rosado Hau, N.; Escalante Soberanis, M.A. Efficiency of parabolic trough collector as a water heater system in Yucatán, Mexico. J. Renew. Sustain. Energy 2011. [Google Scholar] [CrossRef]

- Venegas-Reyes, E.; Jaramillo, O.A.; Castrejón-García, R.; Sosa-Montemayor, F. Design, construction, and testing of a parabolic trough solar concentrator for hot water and low enthalpy steam generation. J. Renew. Sustain. Energy 2012, 4, 53–103. [Google Scholar] [CrossRef]

- Mazloumi, M.; Naghashzadegan, M.; Javaherdeh, K. Simulation of solar lithium bromide-water absorption cooling system with parabolic trough collector. Energy Convers. Manag. 2008, 49, 2820–2832. [Google Scholar] [CrossRef]

- Ghaddar, N.K.; Shihab, M.; Bdeir, F. Modeling and simulation of solar absorption system performance in Beirut. Renew. Energy 1997, 10, 539–558. [Google Scholar] [CrossRef]

- Baniyounes, A.M.; Rasul, M.G.; Khan, M.M.K. Assessment of solar assisted air conditioning in Central Queensland’s subtropical climate. Renew. Energy 2013, 50, 334–341. [Google Scholar] [CrossRef]

- Mujahid Rafique, M.; Rehman, S.; Lashing, A.; Arifi, A.N. Analysis of a solar cooling system for climatic conditions of five different cities of Saudi Arabia. Energies 2016, 9. [Google Scholar] [CrossRef]

- Florides, G.A.; Kalogirou, S.A.; Tassou, S.A.; Wrobel, L.C. Modelling and simulation of an absorption solar cooling system for Cyprus. Sol. Energy 2002, 72, 43–51. [Google Scholar] [CrossRef]

- Syed, A.; Izquierdo, M.; Rodríguez, P.; Maidment, G.; Missenden, J.; Lecuona, A.; Tozer, R. A novel experimental investigation of a solar cooling system in Madrid. Int. J. Refrig. 2005, 28, 859–871. [Google Scholar] [CrossRef]

- Li, Z.F.; Sumathy, K. Experimental studies on a solar powered air conditioning system with partitioned hot water storage tank. Sol. Energy 2001, 71, 285–297. [Google Scholar] [CrossRef]

- Zhai, X.; Li, Y.; Cheng, X.; Wang, R. Experimental investigation on a solar-powered absorption radiant cooling system. Energy Procedia 2015, 70, 552–559. [Google Scholar] [CrossRef]

- Bertani, R. Geothermal power generation in the world 2010–2014 updates report. Geothermics 2016, 60, 31–43. [Google Scholar] [CrossRef]

- Lund, J.W.; Boyd, T.L. Direct utilization of geothermal energy 2015 worldwide review. Geothermics 2016, 60, 66–93. [Google Scholar] [CrossRef]

- Rosiek, S.; Batlles, F.J. Shallow geothermal energy applied to a solar-assisted air-conditioning system in southern Spain: Two-year experience. Appl. Energy 2012, 100, 267–276. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; Palombo, A.; Vicidomini, M. Energy and economic analysis of geothermal-solar trigeneration systems: A case study for a hotel building in Ischia. Appl. Energy 2015, 138, 224–241. [Google Scholar] [CrossRef]

- Calise, F.; Dentice dÁccadia, M.; Macaluso, A.; Piacentino, A.; Vanoli, L. Exergetic and exergoeconomic analysis of a novel hybrid solar-geothermal polygeneration system producing energy and water. Energy Convers. Manag. 2016, 115, 200–220. [Google Scholar] [CrossRef]

- Ahmadi Boyaghchi, F.; Chavoshi, M. Multi-criteria optimization of a micro solar-geothermal CCHP system applying water/CuO nanofluid based on exergy, exergoeconomic and exergoenvironmental concepts. Appl. Therm. Eng. 2017, 112, 660–675. [Google Scholar] [CrossRef]

- Romo-Jones, J.M.; Gutiérrez-Negrín, L.C.; Sánchez-Cornejo, C.; González-Alcántar, N.; García-Gutiérrez, A. 2017 Mexico Country Report; IEA-Geothermal: Paris, France, 2018. [Google Scholar]

- Tsai, J.-H.; Wu, C.-P.; Chang, H.-C. An investigation of geothermal energy applications and assisted air-conditioning system for energy conservation analysis. Geothermics 2014, 50, 220–226. [Google Scholar] [CrossRef]

- Abtullah, T.; Oguz, A. Optimization of geothermal energy aided absorption refrigeration system-GAARS: A novel ANN-based approach. Geothermics 2017, 65, 210–221. [Google Scholar]

- Pingye, G.; Manchao, H.; Liange, Z.; Na, Z. A geothermal recycling system for cooling and heating in deep mines. Appl. Therm. Eng. 2017, 116, 833–839. [Google Scholar]

- Farabi-Asl, H.; Fujii, H.; Kosukegawa, H. Cooling tests, numerical modeling and economic analysis of semi-open loop ground source heat pump system. Geothermics 2018, 71, 34–45. [Google Scholar] [CrossRef]

- Maya-González, R.; Guitiérrez-Negrín, L. Recursos geotérmicos para generar electricidad en México. Rev. Digit. Univ. 2007, 8, 1–13. [Google Scholar]

- Santoyo-Gutiérrez, E.; Torres-Alvarado, I.S. Escenario futuro de explotación de la energía geotérmica: Hacia un desarrollo sustentable. Rev. Digit. Univ. 2010, 11, 1–26. Available online: http://www.revista.unam.mx/vol.11/num10/art95/index.html (accessed on 9 April 2018).

- González-Ruiz, L.E.; González-Partida, E.; Garduño-Monroy, V.; Martínez, L.; Pironon, J.; Díaz-Carreño, E.H.; Yáñez-Dávila, D.; Romero-Rojas, W.; Romero-Rojas, M.C. Distribución de anomalías geotérmicas en México: Una guía útil en la prospección geotérmica. Rev. Int. Investig. Innov. Technol. 2015, 1–31. Available online: http://riiit.com.mx/apps/site/idem.php?module=Catalog&action=ViewItem&id=6216&item_id=74910 (accessed on 9 April 2018).

- Sigma Aldrich. Available online: https://www.sigmaaldrich.com/catalog/search?term=LiBr&interface=All&N=0&mode=match%20partialmax&lang=es®ion=MX&focus=product (accessed on 9 April 2018).

- Domínguez Patiño, J.A.; Rodríguez Martínez, A.; Romero, R.J.; Ibarra Bahena, J.; Domínguez Patiño, M.L. Environmental impact assessment for an absorption heat transformer. OJAppS 2016, 6, 409–415. [Google Scholar] [CrossRef][Green Version]

- Ibarra-Bahena, J.; Romero Rosenberg, J. Performance of different experimental absorber designs in absorption heat pump cycle technologies: A review. Energies 2014, 7, 751–766. [Google Scholar] [CrossRef]

- Garduño-Monroy, V.H.; Vargas-Ledezma, H.; Campos-Enriquez, J.O. Preliminary geologic studies of Sierra El Aguajito (Baja California, Mexico): A resurgent-type caldera. J. Volcanol. Geotherm. Res. 1993, 59, 47–58. [Google Scholar] [CrossRef]

- Verma, S.P.; Pandarinath, K.; Santoyo, E.; González-Partida, E.; Torres-Alvarado, I.S.; Tello-Hinojosa, E. Fluid chemistry and temperatures prior to exploitation at the Las Tres Vírgenes geothermal field, Mexico. Geothermics 2006, 35, 156–180. [Google Scholar] [CrossRef]

- Romo, J.J.M.; Wong-Ortega, V.; Vázquez-González, R.; Flores-Luna, C. Conductividad eléctrica y atenuación de ondas de coda en el campo geotérmico Las Tres Vírgenes en Baja California Sur. Unión Geofís. Mex. 2000, 20, 21–29. [Google Scholar]

- Antayhua-Vera, Y.; Lermo-Samaniego, J.; Quintanar-Robles, L.; Campos-Enríquez, O. Seismic activity and stress tensor inversion at Las Tres Vírgenes Volcanic and Geothermal Field (México). J. Volcanol. Geotherm. Res. 2015, 305, 19–29. [Google Scholar] [CrossRef]

- Espinoza-Ojeda, O.M.; Santoyo, E.; Andaverde, J. A new look at the statistical assessment of approximate and rigorous methods for the estimation of stabilized formation temperatures in geothermal and petroleum wells. J. Geophys. Eng. 2011, 8, 233–258. [Google Scholar] [CrossRef]

- Liu, C.; Li, K.; Chen, Y.; Jia, L.; Ma, D. Static formation temperature prediction based on bottom hole temperature. Energies 2016, 9, 646. [Google Scholar] [CrossRef]

- Kurevija, T.; Strpic, K.; Koscak-Kolin, S. Applying petroleum the pressure buildup well test procedure on thermal response test—A novel method for analyzing temperature recovery period. Energies 2018, 11, 366. [Google Scholar]

- Alexey, A. The equations for thermophysical properties of aqueous solutions of sodium hydroxide. In Proceedings of the 14th International Conference on the Properties of Water and Steam, Kyoto, Japan, 29 August–3 September 2004. [Google Scholar]

- Olsson, J.; Jernqvist, A.; Aly, G. Thermophysical properties of aqueous NaOH-H2O solutions at high concentration. Int. J. Thermophys. 1997, 18, 779–793. [Google Scholar] [CrossRef]

- Ibarra-Bahena, J.; Romero, R.J.; Velazquez-Avelar, L.; Valdez-Morales, C.V.; Galindo-Luna, Y.R. Evaluation of the thermodynamic effectiveness of a plate heat exchanger integrated into an experimental single stage heat transformer operating with Water/Carrol mixture. Exp. Therm. Fluid Sci. 2013, 51, 257–263. [Google Scholar] [CrossRef]

- Jaramillo, O.A.; Aguilar, O.; Castrejón-García, R.; Venegas-Reyes, E.; Sosa-Montemayor, F. Parabolic trough concentrators for hot water generation: Comparison of the levelized cost production. J. Renew. Sustain. Energy 2013, 5. [Google Scholar] [CrossRef]

- Garcia-Gutiérrez, A.; Barragan-Reyes, R.M.; Arellano-Gómez, V.M. Research and development on heat pump systems in Mexico using geothermal energy. Curr. Appl. Phys. 2010, 10, S123–S127. [Google Scholar] [CrossRef]

- Ioan Sarbu, I.; Sebarchievici, C. General review of ground-source heat pump systems for heating and cooling of buildings. Energy Build. 2014, 70, 441–454. [Google Scholar] [CrossRef]

- Jensen-Page, L.; Narsilio, G.A.; Bidarmaghz, A.; Johnston, I.W. Investigation of the effect of seasonal variation in ground temperature on thermal response tests. Renew. Energy 2018, 125, 609–619. [Google Scholar] [CrossRef]

- Liebel, H.T.; Huber, K.; Frengstad, B.S.; Ramstad, R.K.; Brattli, B. Temperature footprint of a thermal response test can help to reveal thermogeological information. Nor. Geol. Unders. Bull. 2011, 451, 20–31. [Google Scholar]

- Ozgener, O.; Ozgener, L.; Tester, J.W. A practical method to predict soil temperature variations for geothermal (ground) heat exchangers applications. Int. J. Heat Mass Transf. 2013, 62, 473–480. [Google Scholar] [CrossRef]

- Mihalakakou, G.; Santamouris, M.; Lewis, J.O.; Asimakopoulos, D.N. On the applications of the energy balance equation to predict ground temperature profile. Sol. Energy 1997, 60, 181–190. [Google Scholar] [CrossRef]

- Bandos, T.V.; Montero, Á.; Fernández de Córdoba, P.; Urchueguía, J.F. Improving parameter estimates obtained from thermal response tests: Effect of ambient air temperature variations. Geothermics 2011, 40, 136–143. [Google Scholar] [CrossRef]

- Li, M.; Lai, A.C.K. Review of analytical models for heat transfer by vertical ground heat exchangers (GHE’s): A perspective of time and space scales. Appl. Energy 2015, 151, 178–191. [Google Scholar] [CrossRef]

- Lucia, U.; Simonetti, M.; Chiesa, G.; Grisolia, G. Ground-source pump system for heating and cooling: Review and thermodynamic approach. Renew. Sustain. Energy Rev. 2017, 70, 867–874. [Google Scholar] [CrossRef]

- Bandos, T.V.; Montero, Á.; Fernández, E.; Santander, J.L.G.; Isidro, J.M.; Pérez, J.; Fernández de Córdoba, P.J.; Urchueguía, J.F. Finite line-source model for borehole heat exchangers: Effect of vertical temperature variation. Geothermics 2009, 38, 263–270. [Google Scholar] [CrossRef]

- Kim, M.; Baik, Y.J.; Park, S.R.; Chang, K.C.; Ra, H.S. Design of a high temperature production heat pump system using geothermal water at moderate temperature. Curr. Appl. Phys. 2010, 10, S117–S122. [Google Scholar] [CrossRef]

- Holman, J.P. Heat Transfer, 6th ed.; McGraw-Hill Book Co.: Singapore, 1986. [Google Scholar]

- Sieder, E.N.; Tate, C.R. Heat transfer and pressure drop pf liquids in tubes. Ind. Eng. Chem. 1936, 28, 1429–1435. [Google Scholar] [CrossRef]

- Eppelbaum, L.; Kutasov, I.; Pilchin, A. Lecture Notes in Earth System Sciences; Springer: Berlin, Germany, 2014. [Google Scholar]

| Parameter | Symbol | Value | |

|---|---|---|---|

| Length | L | 4.88 | m |

| Width | w | 1.05 | m |

| Aperture area | Aa | 5.124 | m2 |

| Rim angle | β | 90 | degrees |

| Exterior diameter | D | 0.0254 | m |

| Inner diameter | d | 0.019 | m |

| Recommended flow rate | 0.1 | l/s | |

| Focal length | Lf | 0.26 | m |

| PTC thermal removal factor (ΔT/Gb) | FR | 0.569–2.049 | dimensionless |

| Overal collector heat loss coefficient | UL | 32.193 | W/m2 K |

| Number of PTC | No. | 9 | (units) |

| Parameter | Value |

|---|---|

| Country | Mexico |

| City | Cuernavaca |

| Latitude | 18°55′7′′ |

| Longitude | 99°14′3′′ |

| Required temperature | 90 °C |

| Temperature outlet | 80 °C |

| Daily required volume | 2735 L |

| Required mass flow | 455.8 kg/h |

| Design operation time | 10:00–16:00 h |

| Storage tank volume | 2500 L |

| UT of storage tank | 1 W/m2 K |

| Cp,water | 4196 J/kg K |

| Rock | Thermal Conductivity (W/m·°C) | Heat Capacity (J/kg·°C) | Density (kg/m3) |

|---|---|---|---|

| Pumice (0–12 m) | 1.768 | 885 | 2360 |

| Ash (12–43 m) | 1.535 | 920 | 2180 |

| Basalt (43–53 m) | 2.200 | 880 | 2700 |

| Rhyolite (53–55 m) | 3.520 | 1074 | 2550 |

| Stream | T (°C) | (g/s) | hNaOH-H2O (kJ/kg) | x (%) * |

|---|---|---|---|---|

| 1 | 90.0 | 2.97 | 2659.56 | 0 |

| 2 | 35.0 | 2.97 | 146.65 | 0 |

| 3 | 10.0 | 2.97 | 146.65 | 0 |

| 4 | 10.0 | 2.97 | 2519.22 | 0 |

| 5 | 35.0 | 8.90 | 211.36 | 40.3 |

| 6 | 35.0 | 8.90 | 211.36 | 40.3 |

| 7 | 90.0 | 5.93 | 656.63 | 60.5 |

| 8 | 90.0 | 5.93 | 656.63 | 60.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galindo-Luna, Y.R.; Gómez-Arias, E.; Romero, R.J.; Venegas-Reyes, E.; Montiel-González, M.; Unland-Weiss, H.E.K.; Pacheco-Hernández, P.; González-Fernández, A.; Díaz-Salgado, J. Hybrid Solar-Geothermal Energy Absorption Air-Conditioning System Operating with NaOH-H2O—Las Tres Vírgenes (Baja California Sur), “La Reforma” Case. Energies 2018, 11, 1268. https://doi.org/10.3390/en11051268

Galindo-Luna YR, Gómez-Arias E, Romero RJ, Venegas-Reyes E, Montiel-González M, Unland-Weiss HEK, Pacheco-Hernández P, González-Fernández A, Díaz-Salgado J. Hybrid Solar-Geothermal Energy Absorption Air-Conditioning System Operating with NaOH-H2O—Las Tres Vírgenes (Baja California Sur), “La Reforma” Case. Energies. 2018; 11(5):1268. https://doi.org/10.3390/en11051268

Chicago/Turabian StyleGalindo-Luna, Yuridiana Rocio, Efraín Gómez-Arias, Rosenberg J. Romero, Eduardo Venegas-Reyes, Moisés Montiel-González, Helene Emmi Karin Unland-Weiss, Pedro Pacheco-Hernández, Antonio González-Fernández, and Jorge Díaz-Salgado. 2018. "Hybrid Solar-Geothermal Energy Absorption Air-Conditioning System Operating with NaOH-H2O—Las Tres Vírgenes (Baja California Sur), “La Reforma” Case" Energies 11, no. 5: 1268. https://doi.org/10.3390/en11051268

APA StyleGalindo-Luna, Y. R., Gómez-Arias, E., Romero, R. J., Venegas-Reyes, E., Montiel-González, M., Unland-Weiss, H. E. K., Pacheco-Hernández, P., González-Fernández, A., & Díaz-Salgado, J. (2018). Hybrid Solar-Geothermal Energy Absorption Air-Conditioning System Operating with NaOH-H2O—Las Tres Vírgenes (Baja California Sur), “La Reforma” Case. Energies, 11(5), 1268. https://doi.org/10.3390/en11051268