Natural Ventilation Effectiveness of Round Wall-Mounted Vent Caps in Residential Kitchens

Abstract

1. Introduction

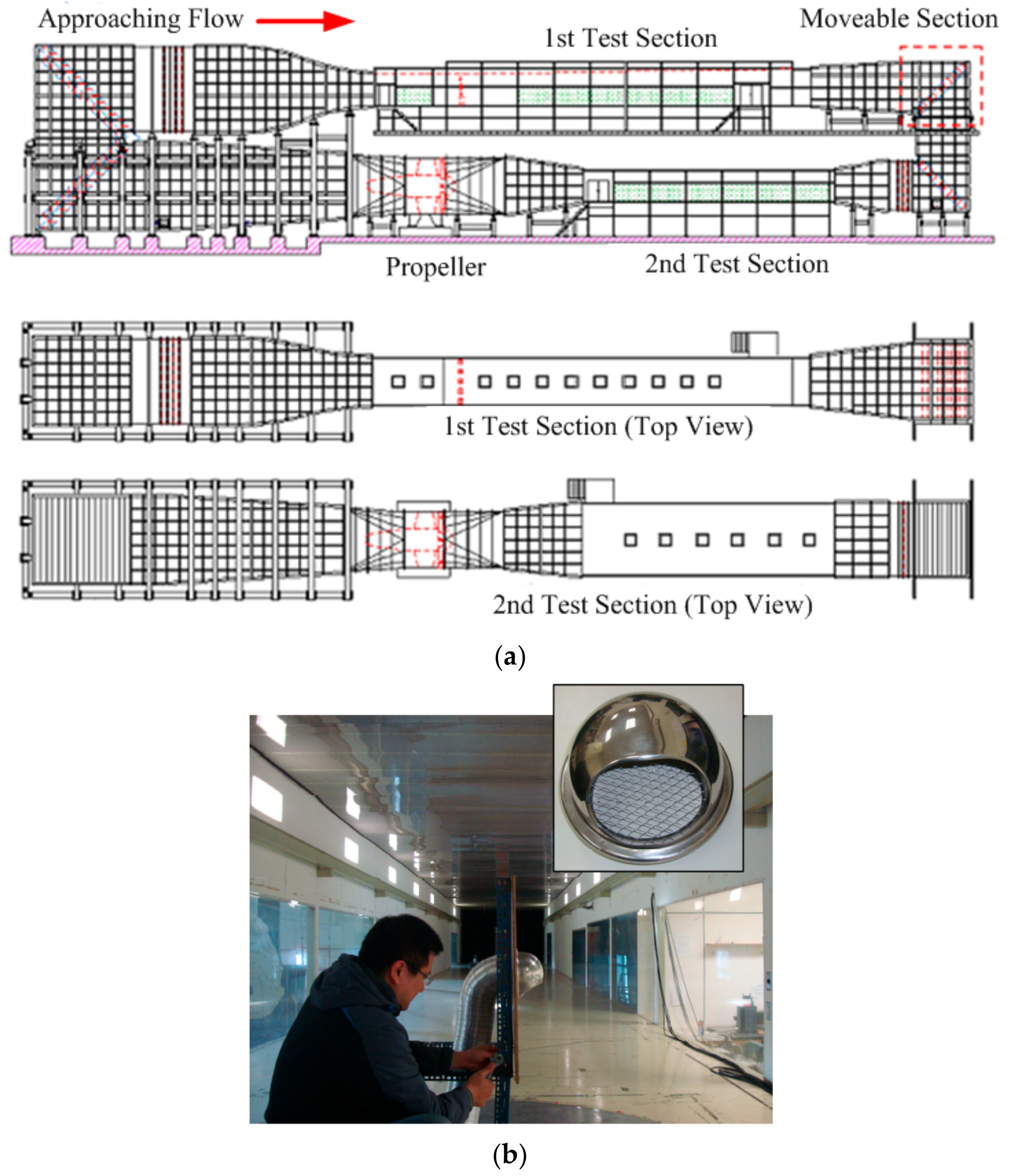

2. Wind Tunnel Tests of the Induced Ventilation Rates of Round Wall-Mounted Vent Caps

2.1. The Tested Vent Cap

2.2. Test Setup

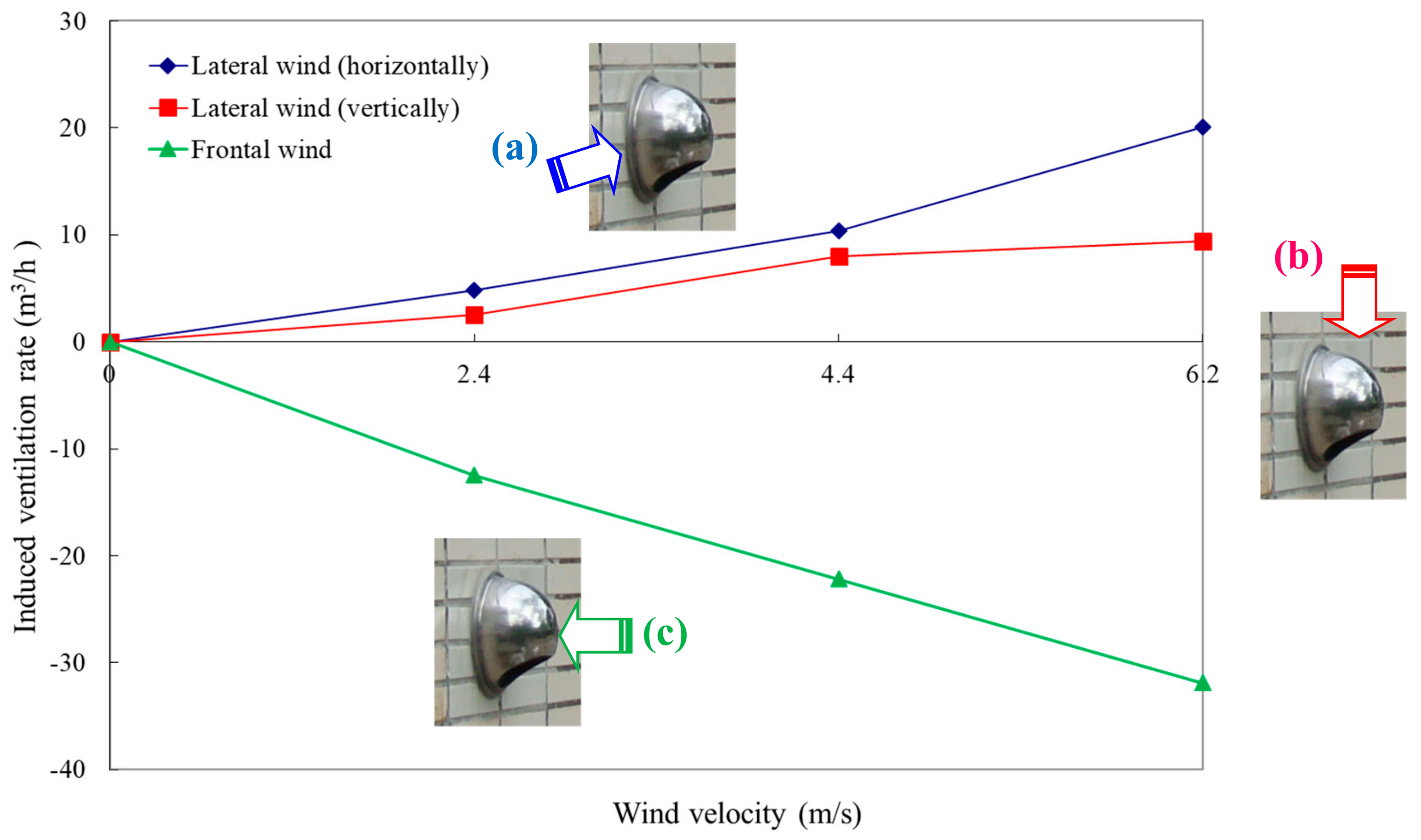

2.3. Test Results and Discussion

3. Application to Residential Kitchen Ventilation

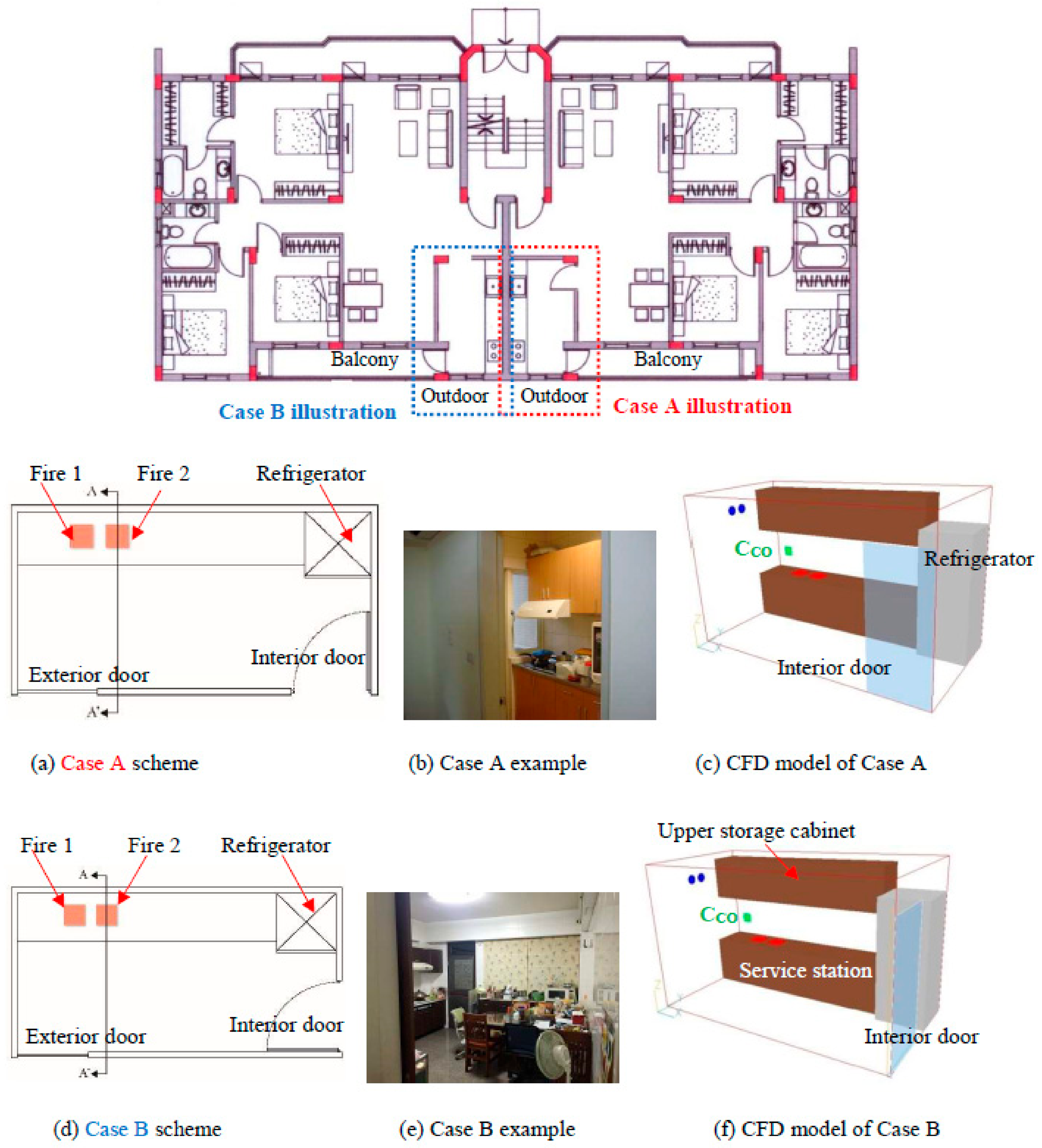

3.1. Investigated Model Kitchens

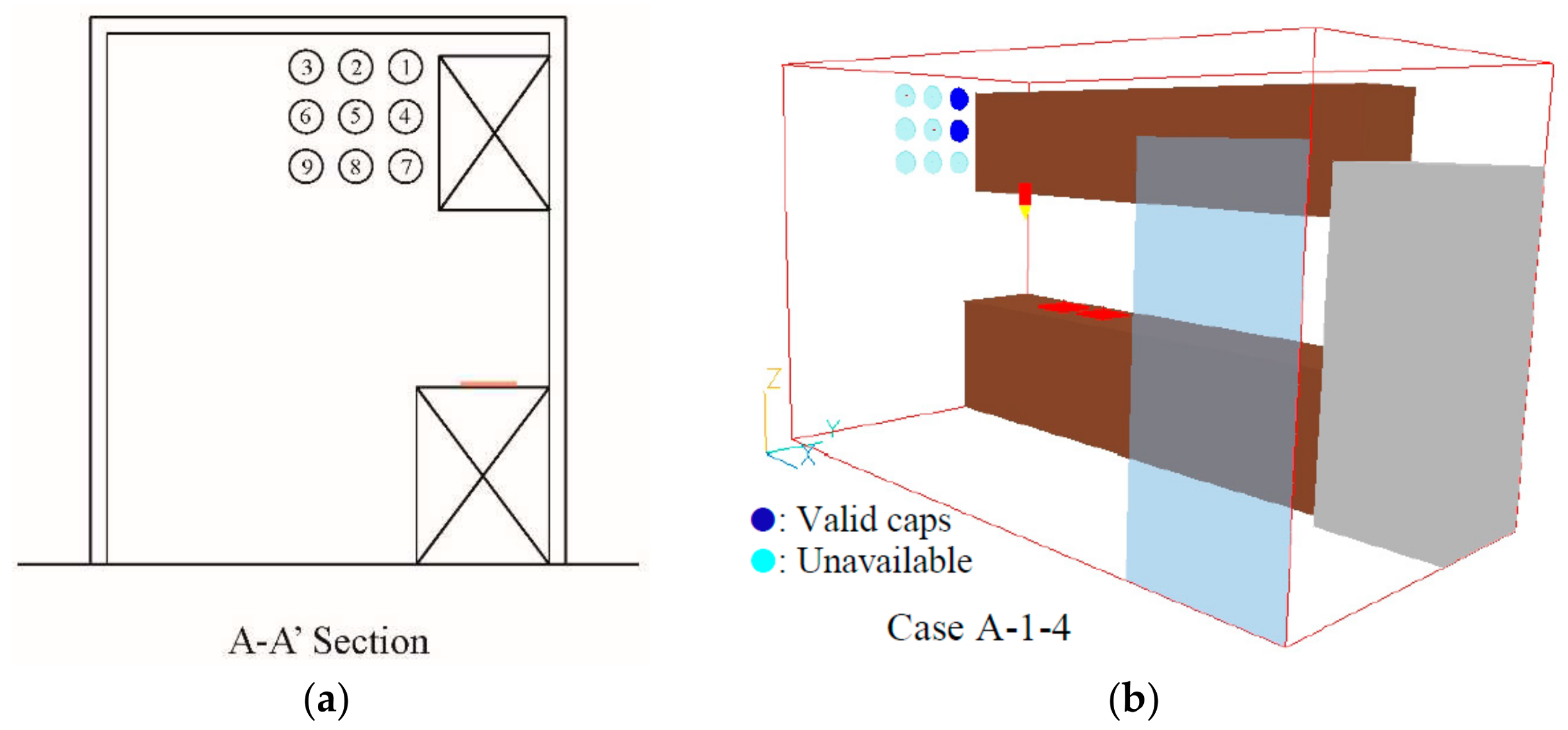

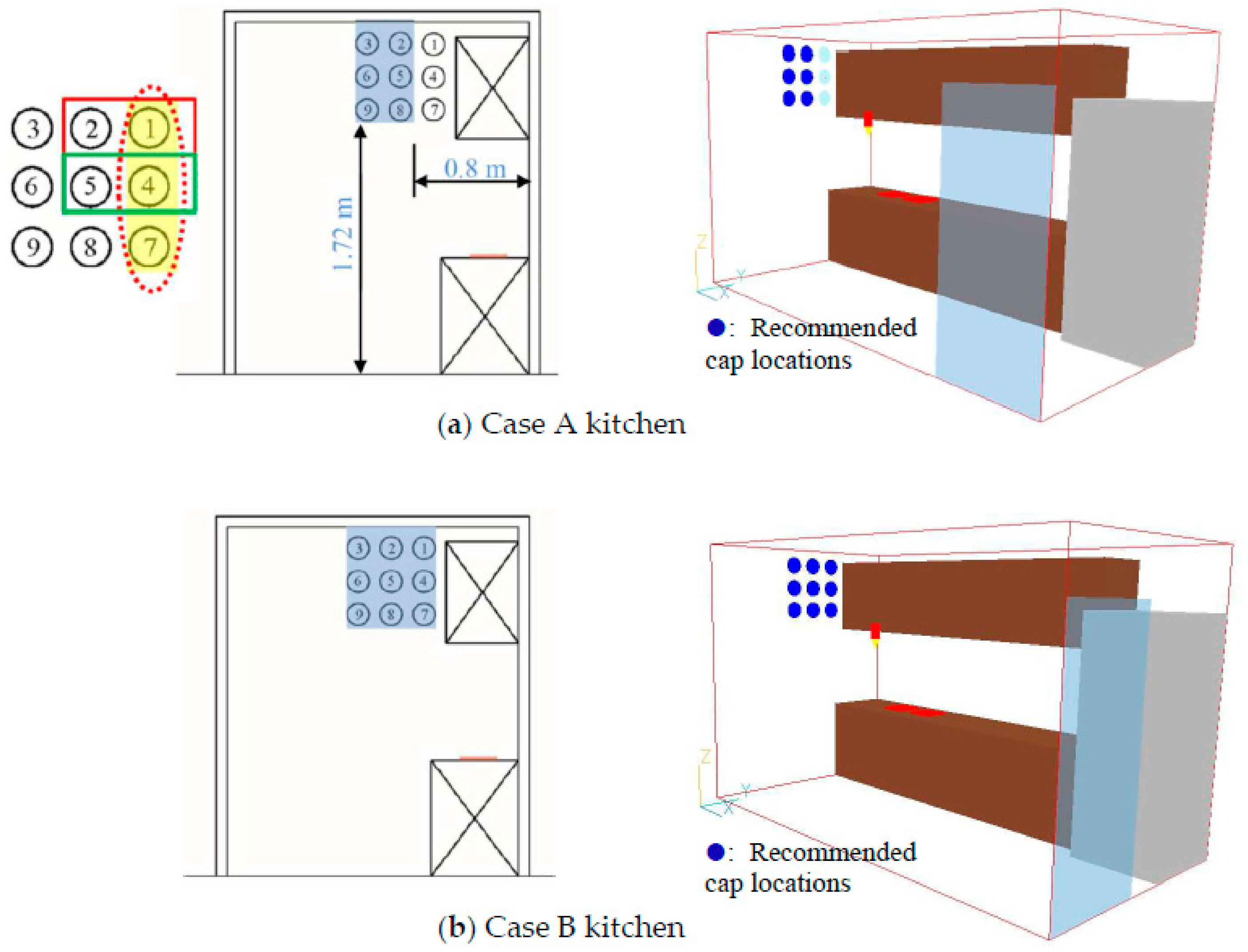

3.2. Configurations and Effectiveness Assessment of Vent Cap Installation

- Installation of one vent cap: nine locations (①–⑨);

- Installation of two vent caps: nine horizontal layouts (①②, ②③, ①③, ④⑤, ⑤⑥, ④⑥, ⑦⑧, ⑧⑨, and ⑦⑨) and nine vertical layouts (①④, ④⑦, ①⑦, ②⑤, ⑤⑧, ②⑧, ③⑥, ⑥⑨, and ③⑨);

- Installation of three vent caps: three horizontal layouts (①②③, ④⑤⑥, and ⑦⑧⑨) and three vertical layouts (①④⑦, ②⑤⑧, and ③⑥⑨).

3.3. Numerical Methods

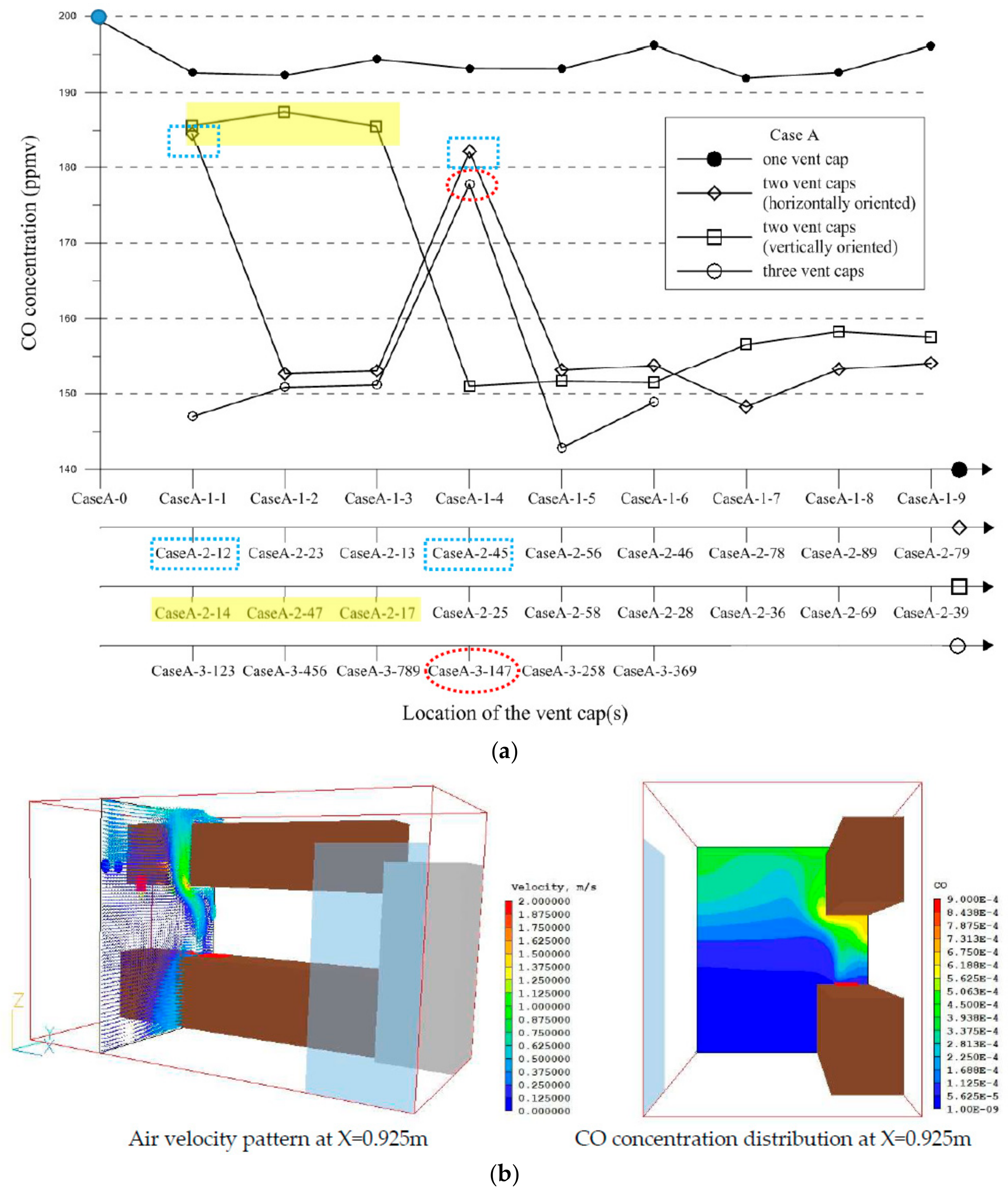

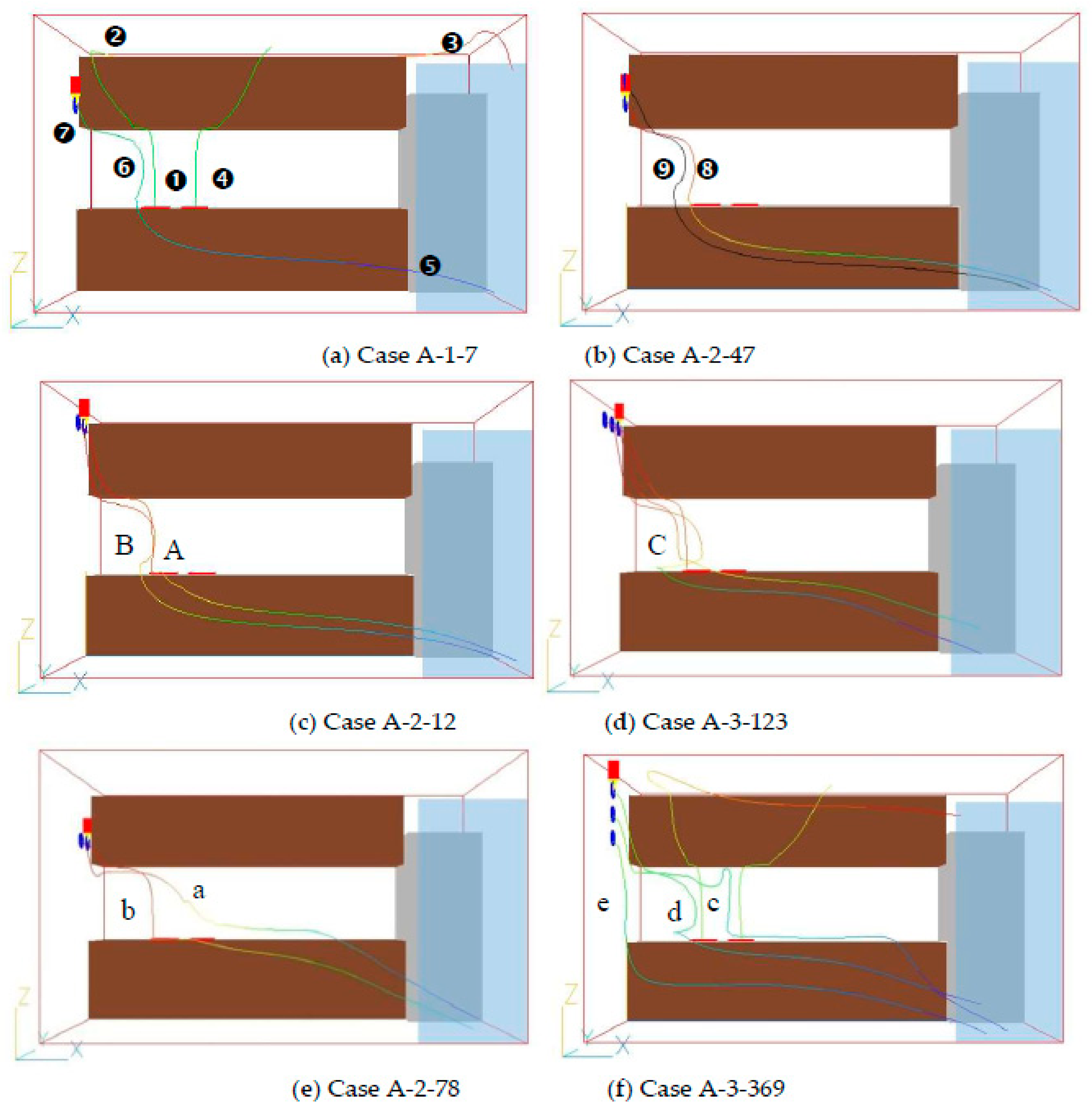

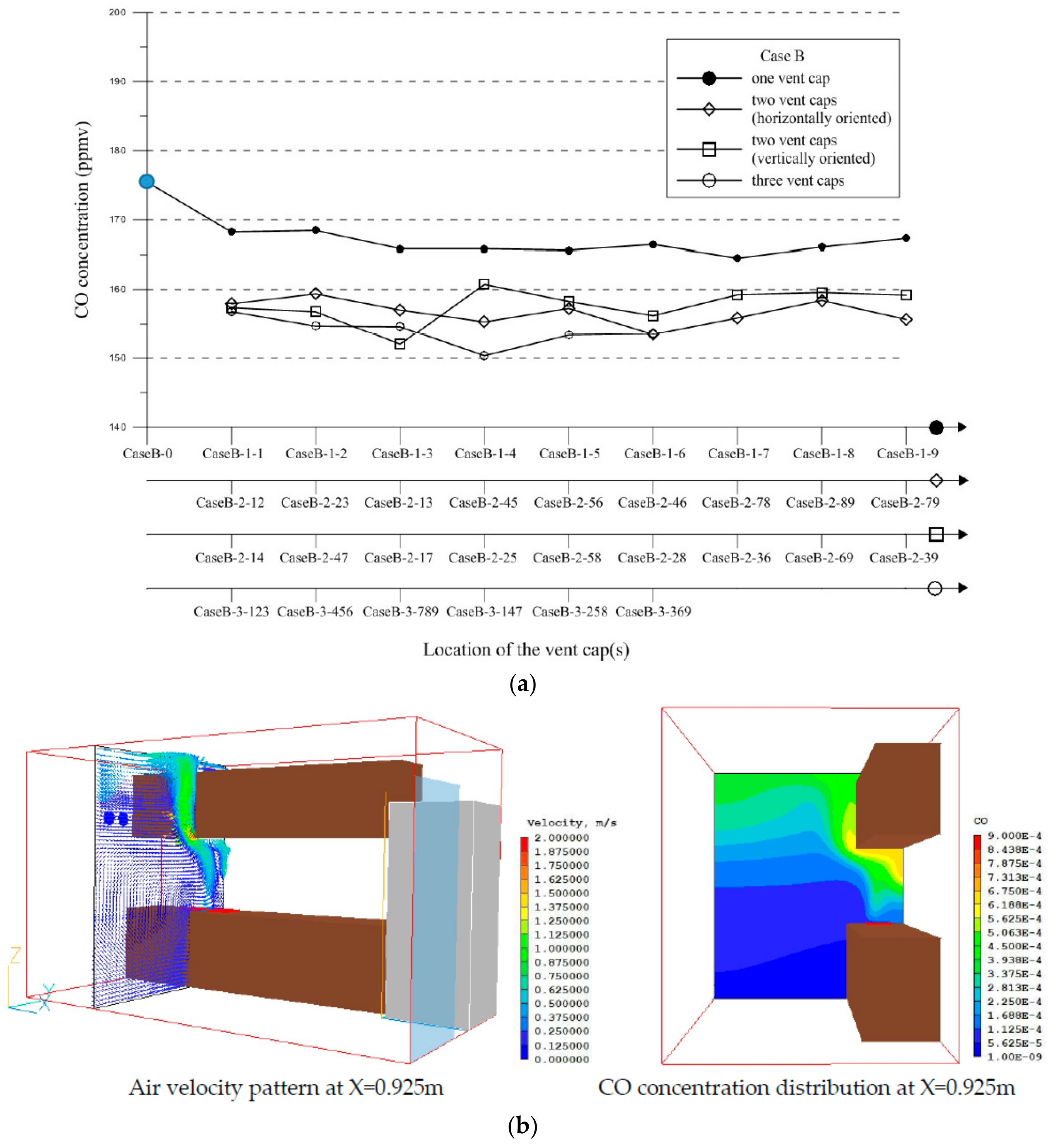

3.4. CFD Simulation Results and Discussion

4. Conclusions

- Winds with speeds of 0–6 m/s that flow parallel to the wall with a vent cap cause ventilation rates of 0–20 m3/h to exit through the vent cap. When the wind blows perpendicular to the wall at speeds of 0–6 m/s, outdoor air flow indoors with the ventilation rates of 0–31.9 m3/h.

- After the vent cap(s) is (are) installed on the exterior wall of the Case A kitchen (Figure 4a,c), the average CO concentrations of the cook are lower than the average CO concentrations prior to the installation. However, when one vent cap is installed, the average CO concentration remains high, regardless of its location. When two vent caps are installed near the upper storage cabinet, the average CO concentration remains fairly high. When three vent caps are installed, only the vertical layout closest to the storage cabinet produces a high CO concentration.

- When one vent cap is installed on the exterior wall in the Case B kitchen (Figure 4d,f), the average CO concentration remains high, regardless of the installation location. When two or three vent caps are installed, the number and location of the vent caps do not have a significant effect on the CO concentration.

- The direction of the typically opened interior door can influence the ventilation efficiency of the vent cap.

- The recommended installation locations for round wall-mounted vent caps (blue areas in Figure 10) are provided.

Author Contributions

Conflicts of Interest

References

- Ko, Y.C.; Cheng, L.S.; Lee, C.H.; Huang, J.J.; Huang, M.S.; Kao, E.L.; Wang, H.Z.; Lin, H.J. Chinese food cooking and lung cancer in women nonsmokers. Am. J. Epidemiol. 2000, 151, 140–147. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.H.; Lee, Y.S.; Chen, K.S. Carbonyl compounds in dining areas, kitchens and exhaust streams in restaurants with varying cooking methods in Kaohsiung, Taiwan. J. Environ. Sci. 2016, 41, 218–226. [Google Scholar] [CrossRef] [PubMed]

- Wan, M.-P.; Wu, C.-L.; To, G.-N.S.; Chan, T.-C.; Chao, C.Y.H. Ultrafine particles, and PM2.5 generated from cooking in homes. Atmos. Environ. 2011, 45, 6141–6148. [Google Scholar] [CrossRef]

- Kosonen, R. The effect of supply air systems on the efficiency of a ventilated ceiling. Build. Environ. 2007, 42, 1613–1623. [Google Scholar] [CrossRef]

- Li, A.; Zhao, Y.; Jiang, D.; Hou, X. Measurement of temperature, relative humidity, concentration distribution and flow field in four typical Chinese commercial kitchens. Build. Environ. 2012, 56, 139–150. [Google Scholar] [CrossRef]

- Gao, J.; Cao, C.; Xiao, Q.; Xu, B.; Zhou, X.; Zhang, X. Determination of dynamic intake fraction of cooking-generated particles in the kitchen. Build. Environ. 2013, 65, 146–153. [Google Scholar] [CrossRef]

- Smith, K.M.; Svendsen, S. The effect of a rotary heat exchanger in room-based ventilation on indoor humidity in existing apartments in temperate climates. Energy Build. 2016, 116, 349–361. [Google Scholar] [CrossRef]

- Pinto, M.; Viegas, J. The influence of ventilation systems on domestic gas appliances: An experimental study. Build. Environ. 2013, 69, 1–13. [Google Scholar] [CrossRef]

- Zhou, B.; Chen, F.; Dong, Z.; Nielsen, P.V. Study on pollution control in residential kitchen based on the push-pull ventilation system. Build. Environ. 2016, 107, 99–112. [Google Scholar] [CrossRef]

- Li, A.; Zhang, W.; Gao, M. Field test and CFD modeling for flow characteristics in central cooking exhaust shaft of a high-rise residential building. Energy Build. 2017, 147, 210–223. [Google Scholar] [CrossRef]

- Singer, B.C.; Pass, R.Z.; Delp, W.W.; Lorenzetti, D.M.; Maddalena, R.L. Pollutant concentrations and emission rates from natural gas cooking burners without and with range hood exhaust in nine California homes. Build. Environ. 2017, 122, 215–229. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, Y.; Liu, L.; Nielsen, P.V.; Jensen, R.L.; Yang, X. Performance of constant exhaust ventilation for removal of transient high-temperature contaminated airflows and ventilation-performance comparison between two local exhaust hoods. Energy Build. 2017, 154, 207–216. [Google Scholar] [CrossRef]

- Dobbin, N.A.; Sun, L.; Wallace, L.; Kulka, R.; Singer, B.C. The benefit of kitchen exhaust fan use after cooking—An experimental assessment. Build. Environ. 2018, 135, 286–296. [Google Scholar] [CrossRef]

- Cao, G.; Awbi, H.; Yao, R.; Fan, Y.; Sirén, K.; Kosonen, R.; Zhang, J. A review of the performance of different ventilation and airflow distribution systems in buildings. Build. Environ. 2014, 73, 171–186. [Google Scholar] [CrossRef]

- Chiang, C.-M.; Lai, C.-M.; Chou, P.-C.; Li, Y.-Y. The influence of an architectural design alternative (transoms) on indoor air environment in conventional kitchens in Taiwan. Build. Environ. 2000, 35, 579–585. [Google Scholar] [CrossRef]

- D’Ambrosio Alfano, F.R.; Ficco, G.; Palella, B.I.; Riccio, G.; Ranesi, A. An Experimental Investigation on the Air Permeability of Passive Ventilation Grilles. Energy Procedia 2015, 78, 2869–2874. [Google Scholar] [CrossRef]

- Wang, H.; Lin, H.; Ng, V.C.Y.; Yang, T.; Guan, L.Y. Failure of natural ventilation strategy in a sustainable house in China. Int. J. Low Carbon Technol. 2015, 10, 216–228. [Google Scholar] [CrossRef]

- Elshafei, G.; Negm, A.; Bady, M.; Suzuki, M.; Ibrahim, M.G. Numerical and experimental investigations of the impacts of window parameters on indoor natural ventilation in a residential building. Energy Build. 2017, 141, 321–332. [Google Scholar] [CrossRef]

- Southall, R.G. An assessment of the potential of supply-side ventilation demand control to regulate natural ventilation flow patterns and reduce domestic space heating consumption. Energy Build. 2018, 168, 201–214. [Google Scholar] [CrossRef]

- Li, B.; Du, C.; Yao, R.; Yu, W.; Costanzo, V. Indoor thermal environments in Chinese residential buildings responding to the diversity of climates. Appl. Therm. Eng. 2018, 129, 693–708. [Google Scholar] [CrossRef]

- Spalding, D.B. The PHOENICS Encyclopedia; CHAM: London, UK, 1994. [Google Scholar]

| Parts of the Model | Geometric Data |

|---|---|

| Model kitchen | 4 m (X) × 2 m (Y) × 2.4 m (Z) |

| Net ceiling height | 2.4 m (Z) |

| Interior doors (normally open) | 0.8 m × 2 m (Z) |

| Exterior doors (normally closed) | 0.8 m × 2 m (H) |

| Service station | 3.25 m × 0.6 m × 0.8 m |

| Upper storage cabinet | 3.25 m × 0.5 m × 0.7 m |

| Refrigerator | 0.75 m × 0.75 m × 1.9 m |

| Gas stove | 0.25 m (X) × 0.25 m (Y) |

| The circular opening on the exterior wall for installing the vent cup | Diameter = 15 cm |

| Walls, Doors, Service Station, Upper Storage Cabinet, Refrigerator | Adiabatic |

|---|---|

| Gas stove | Gas flow rate = 6.56 × 10−2 m3/s Heat release rate = 7.2 × 105 W/m2 Carbon monoxide emission rate = 1.1 g/m2s |

| Vent cap | Induced airflow velocity = 1 m/s |

| Ambient air temperature | 25 °C |

| Ambient CO concentration | 1 PPMV |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Y.-P.; Iba, C.; Lai, C.-M. Natural Ventilation Effectiveness of Round Wall-Mounted Vent Caps in Residential Kitchens. Energies 2018, 11, 1230. https://doi.org/10.3390/en11051230

Lin Y-P, Iba C, Lai C-M. Natural Ventilation Effectiveness of Round Wall-Mounted Vent Caps in Residential Kitchens. Energies. 2018; 11(5):1230. https://doi.org/10.3390/en11051230

Chicago/Turabian StyleLin, Yi-Pin, Chiemi Iba, and Chi-Ming Lai. 2018. "Natural Ventilation Effectiveness of Round Wall-Mounted Vent Caps in Residential Kitchens" Energies 11, no. 5: 1230. https://doi.org/10.3390/en11051230

APA StyleLin, Y.-P., Iba, C., & Lai, C.-M. (2018). Natural Ventilation Effectiveness of Round Wall-Mounted Vent Caps in Residential Kitchens. Energies, 11(5), 1230. https://doi.org/10.3390/en11051230