Abstract

Bio-organic greenhouses that are based on alternative resources for producing heat and electricity stand out as an efficient option for the sustainable development of agriculture, thus ensuring good growth and development of plants in all seasons, especially during the cold season. Greenhouses can be used with maximum efficiency in various agricultural lands, providing ideal conditions of temperature and humidity for short-term plant growing, thereby increasing the local production of fruit and vegetables. This paper presents the development of a durable greenhouse concept that is based on complex energy system integrating fuel cells and solar panels. Approaching this innovative concept encountered a major problem in terms of local implementation of this type of greenhouses because of the difficulty in providing electrical and thermal energy from conventional sources to ensure an optimal climate for plant growing. The project result consists in the design and implementation of a sustainable greenhouse energy system that is based on fuel cells and solar panels.

1. Introduction

Development of renewable energy as a primary global resource of clean energy is one of the main objectives of energy policies worldwide, which, in the general framework of sustainable development, aimed at reducing energy consumption, increasing security of supply, environmental protection, and friendly and sustainable energy technology development [1].

Renewable sources represent good alternatives to fossil resources, which are limited in quantity and are prone to exhaustion.

In this context, the use of the proposed hybrid system can be successfully used in areas where the connection to the grid is not possible or where the development of the electrical infrastructure is not technically feasible or in terms of investment costs. The area of greenhouses in Romania is 922 hectares, of which, about 450 hectares are heated greenhouses.

Agriculture is one of the most important sectors, which is characterized by the greatest potential for sustainable economic development [1,2].

In order to reduce production costs, it is necessary to implement a hybrid thermal power that is based on renewable energy designed and dimensioned according to local demand, so that the production costs to be reduced significantly, while considering that heating accounts for about 30% of the total energy used in the greenhouse [3,4]. Integration of renewable sources-based hybrid system in the greenhouses to provide heat and electricity is an important objective for sustainability and efficiency of commercial systems in order to increase the production and reduce costs that are associated to heat production in order to ensure an optimal climate for plant growing [5,6].

The concept of this project came as a result of the demand of a farming company that is specialized in greenhouse vegetable-growing, which has shown interest in developing a new greenhouse concept based on sustainable sources of energy-combustion piles and solar power. Major disadvantages for vegetable farmers occur in winter when it is necessary to provide specific environmental conditions: temperature (min 15 °C), humidity, sun exposure, water, and fertilizers. In this context, the design of a sustainable energy system is the first Romanian initiative to implement renewable energy sources in the agricultural field [7].

A combination of renewable sources by creating a mixed system is a sustainable and economic solution that could address these issues [8,9,10].

Reducing fossil fuel consumption by using solar energy can contribute to global climate change as a result of reducing greenhouse gas emissions and the impact of energy use on the environment [11].

Photovoltaic energy is a valuable energy source that comes from renewable sources that are inexhaustible and non-polluting. To be used in a wide range of applications and to meet cost constraints, the implemented energy system must feature a good optimization of photovoltaic cells with a practical validation [12].

The total amount of solar energy received at ground level for one week exceeds the energy that is produced by oil, coal, natural gas, and uranium in the world.

In most cases, it is necessary to convert solar energy into electricity [13].

Solar energy is a source of green and inexhaustible energy and its production cost is zero, thus successfully replacing the conventional energy that we buy, and, consequently, reducing the production costs considerably [14]. These initiatives were adopted in some Smart Island north European [15].

Photovoltaic energy is the product of direct conversion of solar light into electricity using solar cells that are connected to produce the desired electrical energy [16].

Using solar energy that is provided through solar panels and solar collectors is an efficient and environmentally friendly way that can help to reduce production costs in stand-alone greenhouses [17,18,19].

Free energy of the sun can be used to heat greenhouses by collecting and storing heat during the hot summer season and using it during the cold season.

Moreover, solar energy can be used to generate electricity by integrating a system of photovoltaic panels that are mowing on the roof of the greenhouse [19].

As an alternative to fossil fuels that are expensive, farmers use renewable energy sources, such as solar heat pumps [20], geothermal heating systems, thermo-solar and photovoltaic panels, and biomass-derived fuels for greenhouse heating.

Greenhouses are covered with transparent materials since they mainly use solar energy, being designed to provide optimum growth conditions for plants [21].

There are two types of greenhouses that use solar energy for heating.

First, passive greenhouses are designed to maximize solar heat gains by using special coating and structural materials that are used as solar collectors [22].

Secondly, there are active greenhouses that are equipped with solar systems using an independent heat collection and storage system, supplying the greenhouse with additional thermal energy when compared to the heat that is generated by direct heating [23,24].

The main objective of the research partnership made up of Stefan cel Mare University of Suceava and National Research and Development Institute for Cryogenic and Isotopic Technologies (ICSI) Ramnicu Valcea is to develop a functional and durable energy system that is aimed at greenhouse bio-organic farming.

2. Hybrid Energy System: A Case Study

This paper identifies specific elements of a case study on the concept of sustainable development of organic greenhouses by integrating a hybrid energy system that is based on renewable sources [25].

In the warmer months, the excess energy that is produced by photovoltaic panels is stored in a hydrogen tank using an electrolyzer, and in the cold season, hydrogen is used by the fuel cell to generate energy when the photovoltaic panels are unable to cover the demand energy.

This concept of hybrid energy system based greenhouse was designed, built, and implemented in a research project having ICSI as partner. The project beneficiary provided a greenhouse having the parameters that are specified in Table 1.

Table 1.

Calculation of greenhouse heat demand.

Table 1 shows the calculation of heat demand of a modular greenhouse.

The hybrid energy system is able to produce cost efficient heat and electricity at any time, having good efficiency and a low level of environmental pollution.

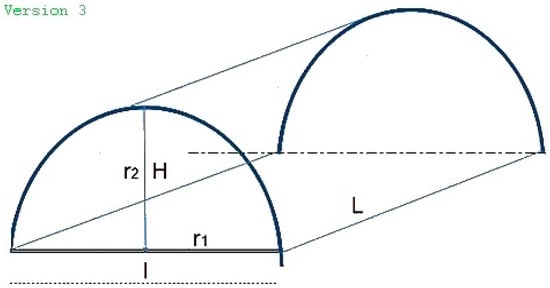

An important requirement is to investigate the feasibility of the equipment installed in experimental greenhouse, and to evaluate the mutual benefits that are arising from this integration. The case study refers to a modular greenhouse with an area of 90 m2, airfoil shaped tunnel with steel structure and round arches.

Gauge dimensions of the greenhouse are: L = 10 m, l = 9 m, H = 4 m.

Figure 1 shows the concept and design of the greenhouse and Figure 2 shows a functional greenhouse [26].

Figure 1.

Elliptic design of the greenhouse.

Figure 2.

Functional greenhouse.

This greenhouse model was selected because it displays good strength and durability, being able to resist winds of 90 km/h and snow layer (80 kg/m2 + 25 kg/m2 internal load) [27].

According to Romanian standard SR 1907-3, the energy for heating the greenhouses was calculated, while considering the type of material that I sused for insulation and coatings [28].

Efforts to decrease energy consumption have led the researchers to use alternative energy sources for greenhouse heating.

Several types of passive solar systems and techniques have been proposed and used for the substitution of conventional fuels with solar energy as available low-cost technology [29,30].

Because the sunlight may be insufficient in winter, then a combination of renewable energy sources is very useful to be used in this situation.

Table 2 shows the calculation of greenhouse heat loss.

Table 2.

Calculation of greenhouse heat loss.

Collecting solar radiation is more efficient when the greenhouse is oriented East-West, which may be performed both in summer and winter [31,32,33,34,35,36].

3. Hybrid Energy System Components

The project research team identified the following components of the hybrid energy system, in accordance with the specific technical requirements of the beneficiary.

The use of the fuel cell in the proposed hybrid system will have a high economic profitability, as it will be implemented by as many users as possible, thus reducing the cost of fuel cell production.

In the next level of this research, a multicriterial analyse taking into account economic criteria for all equipment from hybrid energy will be realized.

3.1. Thermal Energy Production System

- -

- Thermal heating generator that is based on fuel wood and biomass is used to produce heat for the greenhouse needs. This equipment has a nominal heat output of 38 kW, it works very efficiently, gasification has low fuel consumption, and it shows superior performance, which is up to 93%.

From thermal calculation performed, it results that this model of power with thermal power of 38 kW is sufficient to provide the energy requirements of the greenhouse at a rate of up to 70%, when considering that its use is done mainly in winter.

- -

- Thermal solar collector panels with vacuum tubes are a great alternative to produce hot water using solar energy in summer.

The total area is 3.5 m2, Pmax = 1260 kWh, 666.34 kWh/m2 (63 kWh/tube), 67% optical efficiency, maximum temperature 239 °C.

Using thermal solar panels for a period of 4–6 months per year in the greenhouse can bring in significant savings on heat production.

Mixed hybrid heating system based on solar-hydrogen energy and biomass allows for a saving of up to 30% of annual fuel that is used for heating and domestic hot water [37].

3.2. Electricity Generation System

- -

- The assembly of photovoltaic panels, Off Grid.

- -

- Polymer electrolyte membrane fuel cells (PEMFC), Pmax = 9 kW, T = 14.4 V, I = 35 A, hydrogen consumption 6.5 L/min.

- -

- Proton excenge membrane (PEM) electrolyzer, with capacity of 1.05 Nm3H2/h at a pressure up to 30 bar, U = 230 V, Pmax = 2 kW.

The hydrogen produced by the electrolyzer is very efficient when it is converted into electricity using fuel cells with proton exchange membrane, which are actually electrochemical energy converters [38].

This equipment has the advantage that it can be used to produce electricity at any time using stored hydrogen, but only when it is necessary.

PEM fuel cells are the most promising type of power generation, due to its advantages, such as simplicity, low operating temperature, and easy maintenance [39,40].

PEM fuel cells are the future of generators that provide electricity and portable station types, using renewable energy sources for this purpose.

The implementation of a combined electrolysis fuel system for the production and storage of hydrogen in a demonstration greenhouse is a good alternative to traditional power solutions, given that it provides reliable equipment and it generates electricity at all times [41].

3.3. Electrical and Thermal Energy Storage System

- -

- Mixed boiler for hot water heating and storage, with a capacity of 500 L and thermal energy storage power up to 42 kWh.

- -

- Pressure hydrogen storage cylinders, with a capacity of 50 L and volume of 10 m3.

- -

- Solar batteries with gel solution, U = 12 V, I = 200 Ah, are designed for photovoltaic systems and kits, and they are used to store electricity.

This type of battery uses innovative technology “Absorbent Glass Mat”, which gives them the property to provide significant energy reserves that can feed many electrical consumers throughout its service life [42].

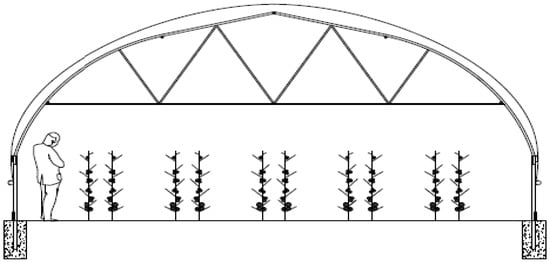

A schematic diagram of the constructed experimental system is illustrated in Figure 3.

Figure 3.

Schematic diagram of the hybrid greenhouse system.

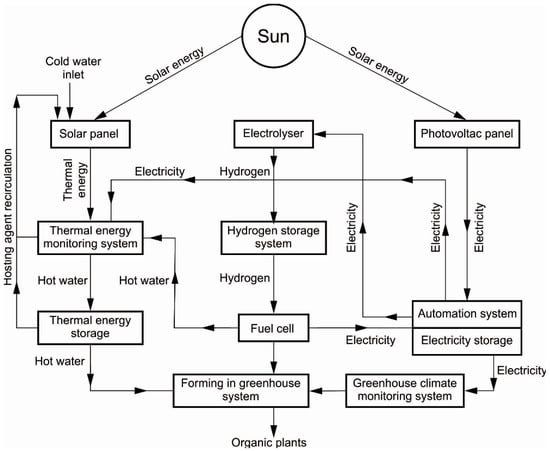

The output power of a solar PV panel changes in accordance with change in solar radiation and temperature level.

This makes it impossible to use the direct-coupled method to automatically track the maximum power point.

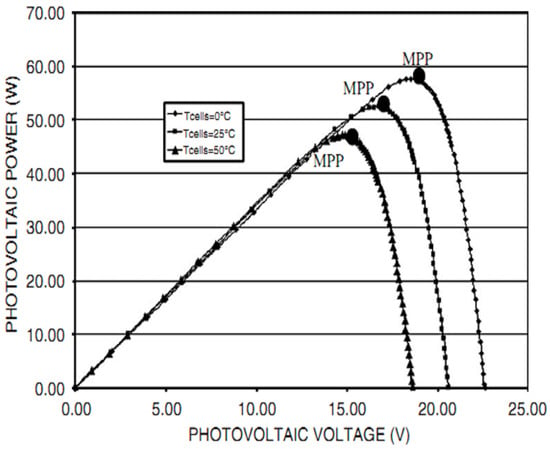

These changes in weather conditions are shown by the P-V curves that are displayed in Figure 4 and Figure 5, respectively.

Figure 4.

Characteristic curves at four different irradiances.

Figure 5.

Characteristic curves at different temperatures.

Figure 4 shows the characteristic curves at four different irradiances.

A Maximum Power Point Tracking (MPPT) system needs to be implemented in order to extract maximum power during the operation of solar panel and to be able to track the changes in power due to changes in the atmospheric conditions [43].

Figure 5 presents the characteristic curves at different temperatures.

Modularity is one major advantage of this sustainable type of renewable sources based greenhouse. Once the hybrid system is sized and implemented by resizing individual components, an unlimited number of various constructive structural elements can be added: photovoltaic panels, thermal solar modules, fuel cells heating systems, ventilation systems, etc. [44].

In the event that there are conditions for biogas production to complement the energy requirement of the greenhouse, a small system to produce the fuel gas by decomposing organic matter can also be integrated.

Renewable energy resources, such as wind, sunlight, geothermal, and biomass are mostly used.

They are working together and their integration into the energy market can improve the sustainability and the reliability of the power systems [45].

A microgrid is an autonomous electric distribution system that combines one or more energy resources with the loads, having its own management and control system, and working as an independent controllable entity [46].

The communication and control responsible device collects the data from the microgrid and manages the system.

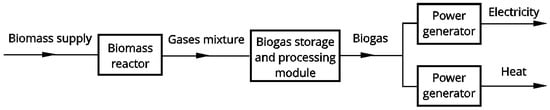

In Figure 6 is represented the functional scheme of biogas system.

Figure 6.

Schematic diagram of the biogas system.

The algorithm that is used to test the system is based on the state of charge of the batteries. The read values are the following: BatSoc, PacSI, ExtPwrAt, GnManStr, PacSB, and Pbio (power of the biomass generator).

The microgrid setup has emulators for the geothermal and biomass generators and a photovoltaic system with storage capability and two inverters, a grid forming capable, and a grid follower.

That proper energy production of the microgrids is also a substantial issue.

The balance between the energy flow and the load demands is their basic rule considering the availability of the resources.

A properly functioning energy management system can ensure the best solution and meet the load requirements continuously and in short time.

The gradient-based systems are too slow to be used in real-time energy management systems, so the articles from this area focus on the off-line application [47].

The use of biogas to produce heat and electricity in the case of greenhouses is one of the most effective solutions to ensure their sustainability.

Heating and cooling systems are major costs involved in plant production in greenhouses.

Normally, heat-generating generators that imply the high consumption of energy are normally used to heat greenhouses, which are usually supplied by combustion of fossil fuels (diesel fuel, oil, oil, gas).

In view of the above, an effective solution for the sustainable development of greenhouse farming is the replacement of fossil fuels with alternative energy sources [48].

The main alternative energy sources to be implemented in the greenhouse for the supply of heat and power are the following:

- -

- thermo-solar energy;

- -

- energy from biomass and solid wood; and,

- -

- energy from hydrogen energy.

The innovative combination of these renewable sources and the use of local air conditioning systems [49,50] will create an energy system that can meet the energy needs of an agricultural greenhouse, thus achieving an optimal climate for plant growing [51].

4. Development and Perspectives

The greenhouse systems that are provided with heating systems which are usually used during cold nights and during the winter season have a significant advantage over the quality of the products that are obtained, as well as a significant reduction in the planting and harvesting time.

In order to maintain the ambient temperature at optimal parameters for plant growing, it is necessary to consume large amounts of heat, which is usually supplied by fossil fuel energy systems [52].

As a result, the average temperature difference between the inlet and outlet of the earth-air heat exchanger (EAHE) was 8.29 °C.

The total electricity consumption of this system was 8.10 kWh, operating approximately 11 h/day, when 34.55% of this energy demand was provided by photovoltaic cells [53].

An Indian study [54] analyzed and modeled an integrated energy system for a greenhouse consisting of solar PV, a PEM polymeric membrane electrolyzer, and fuel cell assemblies. This study demonstrated that 51 PV modules, each modulus with a power of about 75 W together with a 3.3 kW electrolyzer and two PEM fuel cell assemblies, each 480 W power unit can cover the energy requirement of a flower greenhouse of 90 m2.

Solar radiation in the greenhouse depends on its orientation and positioning, but East-West orientation is more effective in collecting solar radiation in winter than in summer collection [31,40].

A key factor in the proper functioning of the greenhouses is the implementation of an efficient irrigation system to ensure the effective hydration of the plants.

In this respect, ensuring the supply of electricity for pumping, transport, and water storage equipment is one of the most important objectives.

A solar water pumping system has many important advantages, for example, besides any fuel and maintenance costs; there is no environmental pollution hazard.

There are very frequent cases where rural settlements, which are made up of villages and communes, are not connected to the conventional power distribution lines because they are not located near them, being located at considerable and relatively isolated distances, so that it is almost impossible to connect them to classic energy distribution systems due to huge costs.

In this respect, the best solution to solve these problems is the use of small-scale energy applications consisting of combinations of photovoltaic panels with thermo-solar panels, which ensures the supply of greenhouses with heat, electricity, and water, representing an efficient and cost-effective solution for these isolated areas [55].

5. Conclusions

This paper presents the case study of a research project that had as the main objective the development and implementation of an experimental model of functional greenhouse, an integrated energy system for the production of thermal and electric energy using low-pollution renewable sources.

The case study that was analyzed in this paper shows that the development of a sustainable greenhouse concept that implements an integrated hydraulic energy system, based exclusively on renewable sources, such as solar energy, hydrogen energy, biomass with possible applicability in the future, along with the development of production technologies and the development of the production capacities of fuel cells.

The amount of additional energy that was produced by photovoltaic panels during the period 20 March–10 November, exceeding of technological consumption and lighting is 6775.84 kW, of this amount of energy between 20 March and 10 November, from using the electrolyzer we produce 203.28 kg of hydrogen. During 11 November–19 March, from 203.28 kg of hydrogen using fuel cell, we produce 3374.44 kW, which we provide 3 kW of energy for lighting and technology per day, with a total consumption of 387 kW and the difference of 2997.44 kW is used for heating the greenhouse as an additional energy, to the thermal energy produced by the wood, covering the peak load in the days with temperatures lower than −3 °C, with an average of 31 days per year.

New energy generation systems use all of the systems at renewable sources contribute to reducing overall energy consumption, increasing energy supply security, and protecting the environment, thus reducing the polluting emission [56,57].

In recent years, the use of food, water, and energy resources has become an essential issue, especially in rural areas, with some being unable to connect to electricity, water or gas networks but having very high potential for solar, wind and biomass renewable sources.

Due to different socio-economic obstacles, these renewable sources are under exploited and are poorly used by mankind.

Globally, due to population growth, and, implicitly, food and water needs, significant increases in energy consumption in agriculture are estimated.

The implementation of renewable energy sources, especially solar energy and biomass, will solve these problems by ensuring the provision of cheap and environmentally-friendly energy, especially for greenhouses, which use an appreciable amount of energy for the proper functioning of the cooling systems, heating, lighting, and irrigation.

Moreover, the use of green energy will lead to the sustainability of greenhouses, increased energy efficiency, increased food production, and the provision of cheap and clean energy.

Author Contributions

Conceptualization, I.A. and M.S.R.; Methodology, C.F.; Software, I.A.; Validation, I.A., C.F. and M.C.; Formal Analysis, G.R.; Investigation, M.S.R.; Resources, G.R.; Data Curation, I.A.; Writing-Original Draft Preparation, M.S.R.; Writing-Review & Editing, I.A. and C.F.; Visualization, G.R.; Supervision, I.A.; Project Administration, C.F.; Funding Acquisition, G.R.

Acknowledgments

This work was supported by a grant of the Romanian Ministery of Research and Innovation, CCCDI-UEFISCDI, project number PN-III-P1-1.2-PCCDI-2017-0776/No. 36 PCCDI/15.03.2018, within PNCDI III.

Conflicts of Interest

The authors declare no conflict of interest.

References

- The Institute for Diversification and Saving of Energy (IDAE). Renewable Energy Plan 2011–2020; IDAE; Spanish Ministry of Industry, Energy and Tourism: Madrid, Spain, 2010; Volume 1, p. 542.

- Odeim, F.; Roes, J.; Heinzel, A. Power Management Optimization of an Experimental Fuel Cell/Battery/Supercapacitor Hybrid System. Energies 2015, 8, 6302–6327. [Google Scholar] [CrossRef]

- Boulard, T.; Baille, A. Analysis of thermal performance of a greenhouse as a solar collector. Energy Agric. 1987, 6, 17–26. [Google Scholar] [CrossRef]

- Kim, M.; Kim, J.; Bae, S. Design of a Sustainable and Efficient Transportation Station (SETS) Based on Renewable Sources and Efficient Electric Drives. Symmetry 2016, 8, 146. [Google Scholar] [CrossRef]

- Nachidi, M.; Rodriguez, F.; Tadeo, F.; Guzman, J.L. Takagi-Sugeno control of nocturnal temperature in greenhouses using air heating. ISA Trans. 2011, 50, 315–320. [Google Scholar] [CrossRef] [PubMed]

- Lopez, J.C.; Baille, A.; Bonachela, S.; Perez-Parra, J. Analysis and prediction of greenhouse green bean (Phaseolus vulgaris L.) production in a Mediterranean climate. Biosyst. Eng. 2008, 100, 86–95. [Google Scholar] [CrossRef]

- Palander, T.; Kärhä, K. Adaptive Procurement Guidelines for Automatic Selection of Renewable Forest Energy Sources within a Sustainable Energy Production System. Energies 2016, 9, 155. [Google Scholar] [CrossRef]

- Erdinc, O.; Uzunoglu, M. Optimum design of hybrid renewable energy systems: Overview of different approaches. Renew. Sustain. Energy Rev. 2012, 16, 1412–1425. [Google Scholar] [CrossRef]

- Deshmukh, M.K.; Deshmukh, S.S. Modeling of hybrid renewable energy systems. Renew. Sustain. Energy Rev. 2008, 12, 235–249. [Google Scholar] [CrossRef]

- Nema, P.; Nema, R.K.; Rangnekar, S. A current and future state of art development of hybrid energy system using wind and PV-solar: A review. Renew. Sustain. Energy Rev. 2009, 13, 2096–2103. [Google Scholar] [CrossRef]

- Ozgener, O.; Hepbasli, A. Experimental Performance Analysis of a Solar Assisted Ground-Source Heat Pump Greenhouse Heating System. Energy Build. 2005, 37, 101–110. [Google Scholar] [CrossRef]

- Zerhouni, F.Z.; Zegrar, M.; Benmessaoud, M.T.; Stambouli, A.B.; Midoun, A. A novel method to optimize photovoltaic generator operation. Int. J. Energy Res. 2008, 32, 1444–1453. [Google Scholar] [CrossRef]

- Torres-Morenzo, J.L.; Gimenez-Fernandez, A.; Perez-Garcia, M.; Rodriquez, F. Energy Management Strategy for Micro-Grids with PV-Battery Systems and Electric Vehicles. Energies 2018, 11, 522. [Google Scholar] [CrossRef]

- Ibrahim, H.; Ilinca, A.; Perronv, J. Energy storage systems—Characteristics and comparisons. Renew. Sustain. Energy Rev. 2008, 12, 1221–1250. [Google Scholar] [CrossRef]

- Cannistraro, G.; Cannistraro, M.; Trovato, G. Islands “Smart Energy” for eco-sustainable energy a case study “Favignana Island”. Int. J. Heat Technol. 2017, 35, 87–95. [Google Scholar] [CrossRef]

- Rosa, C.B.; Rediske, G.; Rigo, P.D.; Wendt, J.F.M.; Michels, L.; Siluk, J.C.M. Development of a Computational Tool for Measuring Organizational Competitiveness in the Photovoltaic Power Plants. Energies 2018, 11, 867. [Google Scholar] [CrossRef]

- Von Zabeltitz, C. Integrated Greenhouse Systems for Mild Climates; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Sethi, V.P.; Sharma, S.K. Survey and evaluation of heating technologies for worldwide agricultural greenhouse applications. Sol. Energy 2008, 82, 832–859. [Google Scholar] [CrossRef]

- Carreno-Ortega, A.; Galdeano-Gomez, E.; Perez-Mesa, J.C.; Galera-Quiles, M.C. Policy and Environmental Implications of Photovoltaic Systems in Farming in Southeast Spain: Can Greenhouses Reduce the Greenhouse Effect? Energies 2017, 10, 761. [Google Scholar] [CrossRef]

- Esen, M.; Yuksel, T. Experimental evaluation of using various renewable energy sources for heating a greenhouse. Energy Build. 2013, 65, 340–351. [Google Scholar] [CrossRef]

- Panwar, N.L.; Kaushik, S.C.; Kothari, S. Solar greenhouse an option for renewable and sustainable farming. Renew. Sustain. Energy Rev. 2011, 15, 3934–3945. [Google Scholar] [CrossRef]

- Bot, G.P.A.; van de Braak, N.J.; Challa, H.; Hemming, S.; Rieswijk, T.; van Straten, G.; Verlodt, I. The solar greenhouse: State of the art in energy saving and sustainable energy supply. Acta Horticult. 2005, 691, 501–508. [Google Scholar] [CrossRef]

- Sethi, V.P.; Sumathy, K.; Lee, C.; Pal, D.S. Thermal modeling aspects of solar greenhouse microclimate control: A review on heating technologies. Sol. Energy 2013, 96, 56–82. [Google Scholar] [CrossRef]

- Santamouris, M.; Balaras, C.A.; Dascalaki, E.; Vallindras, M. Passive solar agricultural greenhouses: A worldwide classification and evaluation of technologies and systems used for heating purposes. Sol. Energy 1994, 53, 411–426. [Google Scholar] [CrossRef]

- Nižetić, S.; Papadopulos, A.M.; Tina, G.M.; Rosa-Clot, M. Hybrid energy scenarios for residential applications based on the heat pump split air-conditioning units for operation in the Mediterranean climate conditions. Energy Build. 2017, 140, 110–120. [Google Scholar] [CrossRef]

- Available online: www.seretransilvania.com (accessed on 17 November 2017).

- Short, G.D. Proiectarea si Constructia Serelor-Manual Tehnologic; United States Agency for International Development (USAID); Agricultural Competitiveness and Enterprise Development (ACED); Millennium Challenge Corporation: Chisinau, Moldova, 2013.

- Shen, Y.; Wei, R.; Xu, L. Energy Consumption Prediction of a Greenhouse and Optimization of Daily Average Temperature. Energies 2018, 11, 65. [Google Scholar] [CrossRef]

- Fabrizio, E. Energy reduction measures in agricultural greenhouses heating: Envelope, systems and solar energy collection. Energy Build. 2012, 53, 57–63. [Google Scholar] [CrossRef]

- Bargach, M.N.; Tadili, R.; Dahman, A.S.; Boukallouch, M. Survey of thermal performances of a solar system used for the heating of agricultural greenhouses in Morocco. Renew. Energy 2000, 20, 415–433. [Google Scholar] [CrossRef]

- Abdel-Ghany, A.M. Solar energy conversions in the greenhouses. Sustain. Cities Soc. 2011, 1, 219–226. [Google Scholar] [CrossRef]

- Castilla, N.; Hernandez, J. Greenhouse technological packages for high-quality production. Acta Horticul. 2007, 761, 285–297. [Google Scholar] [CrossRef]

- Barbir, F. PEM Fuel Cells: Theory and Practice; Academic Press: Cambridge, MA, USA, 2005; ISBN 978-0-12-078142-3. [Google Scholar]

- Larminie, J.; Dicks, A. Fuel Cell Systems Explained, 2nd ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2003; ISBN 978-0-47-084857-9. [Google Scholar]

- Nižetić, S.; Grubišić-Čabo, F.; Marinić-Kragić, I.; Papadopoulos, A.M. Experimental and numerical investigation of a backside convective cooling mechanism on photovoltaic panels. Energy 2016, 111, 211–225. [Google Scholar] [CrossRef]

- Ay, M.; Midilli, A.; Dincer, I. Exergetic performance analysis of a PEM fuel Cell. Int. J. Energy Res. 2006, 30, 307–321. [Google Scholar] [CrossRef]

- Available online: www.esolar.ro (accessed on 29 October 2017).

- Pascuzzi, S.; Anifantis, A.S.; Blanco, I.; Scarascia Mugnozza, G. Electrolyzer Performance Analysis of an Integrated Hydrogen Power System for Greenhouse Heating. A Case Study. Sustainability 2016, 8, 629. [Google Scholar] [CrossRef]

- González, I.; Calderón, A.J.; Andújar, J.M. Novel remote monitoring platform for RES-hydrogen based smart microgrid. Energy Convers. Manag. 2017, 148, 489–505. [Google Scholar] [CrossRef]

- Rosa, R.; Silva, A.M.; Miguel, A. Solar irradiation inside a single span greenhouse. J. Agric. Eng. Res. 1989, 43, 221–229. [Google Scholar] [CrossRef]

- Mengelkamp, E.; Gärttner, J.; Rock, K.; Kessler, S.; Orsini, L.; Weinhardt, C. Designing microgrid energy markets: A case study: The Brooklyn Microgrid. Appl. Energy 2017, 210, 870–880. [Google Scholar] [CrossRef]

- Smaoui, M.; Krichen, L. Control, energy management and performance evaluation of desalination unit based renewable energies using a graphical user interface. Energy 2016, 114, 1187–1206. [Google Scholar] [CrossRef]

- Abbasi, M.A.; Zia, M.F. Novel TPPO Based Maximum Power Point Method for Photovoltaic System. Adv. Electr. Comput. Eng. 2017, 17, 95–100. [Google Scholar] [CrossRef]

- Luque, A.; Hegedus, S. Handbook of Photovoltaic Science and Engineering, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar] [CrossRef]

- Whiteman, Z.S.; Bubna, P.; Prasad, A.K.; Ogunnaike, B.A. Design, Operation, Control, and Economics of a Photovoltaic/Fuel Cell/Battery Hybrid Renewable Energy System for Automotive Applications. Processes 2015, 3, 452–470. [Google Scholar] [CrossRef]

- Ahmadi, H.; Marti, J.R.; Dommel, H.W. A Framework for Volt-VAR Optimization in Distribution Systems. IEEE Trans. Smart Grid 2014, 6, 1473–1483. [Google Scholar] [CrossRef]

- Lazar, E.; Petreus, D.; Etz, R.; Patarau, T. Software Solution for a Renewable Energy Microgrid Emulator. Adv. Electr. Comput. Eng. 2018, 18, 89–94. [Google Scholar] [CrossRef]

- Jaramillo-Nieves, L.; Del Río, P. Contribution of Renewable Energy Sources to the Sustainable Development of Islands: An Overview of the Literature and a Research Agenda. Sustainability 2010, 2, 783–811. [Google Scholar] [CrossRef]

- Cannistraro, G.; Cannistraro, M.; Restivo, R. The local media radiant temperature for the calculation of comfort in areas characterized by radiant surfaces. Int. J. Heat Technol. 2015, 38, 111–118. [Google Scholar] [CrossRef]

- Cannistraro, G.; Cannistraro, M.; Restivo, R. Smart Control of Air Climatization System in Function on the Values of Mean Local Radiant Temperature. Smart Sci. 2015, 3, 157–163. [Google Scholar] [CrossRef]

- Chai, L.; Ma, C.; Ni, J.Q. Performance evaluation of ground source heat pump system for greenhouse heating in northern China. Biosyst. Eng. 2012, 111, 107–117. [Google Scholar] [CrossRef]

- Chinese, D.; Meneghetti, A.; Nardin, G. Waste-to-energy based greenhouse heating: Exploring viability conditions through optimisation models. Renew. Energy 2005, 30, 1573–1586. [Google Scholar] [CrossRef]

- Yıldız, A.; Ozgener, O.; Ozgener, L. Energetic performance analysis of a solar photovoltaic cell (PV) assisted closed loop earth-to-air heat exchanger for solar greenhouse cooling: An experimental study for low energy architecture in Aegean Region. Renew. Energy 2012, 44, 281–287. [Google Scholar] [CrossRef]

- Ganguly, A.; Misra, D.; Ghosh, S. Modeling and analysis of solar photovoltaic-electrolyzer-fuel cell hybrid power system integrated with a floriculture greenhouse. Energy Build. 2010, 42, 2036–2043. [Google Scholar] [CrossRef]

- Meah, K.; Fletcher, S.; Ula, S. Solar photovoltaic water pumping for remote locations. Renew. Sustain. Energy Rev. 2008, 12, 472–487. [Google Scholar] [CrossRef]

- Cannistraro, G.; Cannistraro, M.; Cannistraro, A.; Galvagno, A. Analysis of Air Pollution in the Urban Center of Four Cities Sicilian. Int. J. Heat Technol. 2016, 2, 219–225. [Google Scholar] [CrossRef]

- Cannistraro, G.; Cannistraro, M.; Galvagno, A.; Trovato, G. Technical and Economic Evaluations about the Integration of CoTrigeneration Systems in the Dairy Industry. Int. J. Heat Technol. 2016, 34, 332–336. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).