A Pathway to Reduce Energy Consumption in the Thermal Stabilization Process of Carbon Fiber Production

Abstract

:1. Introduction

2. Experimental

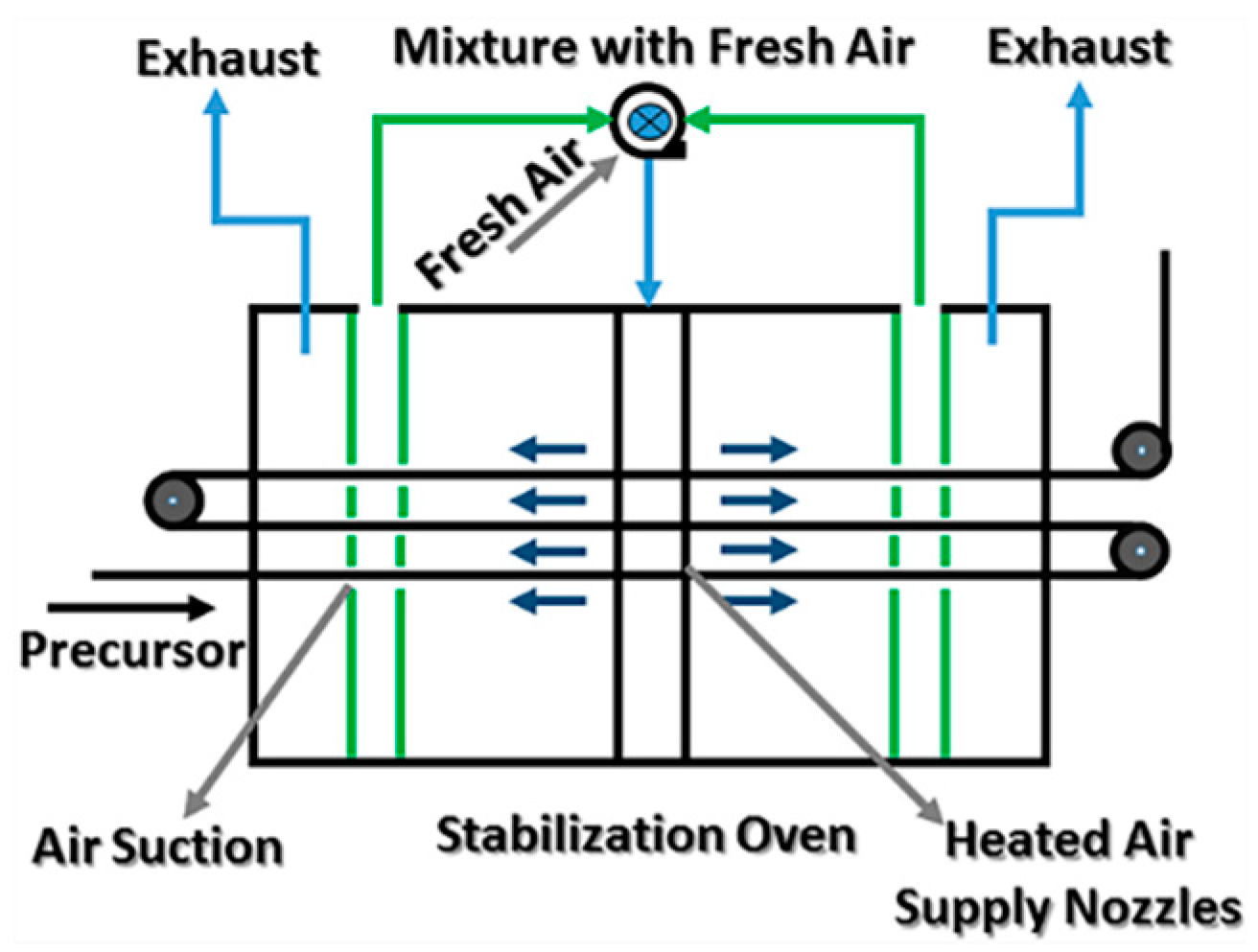

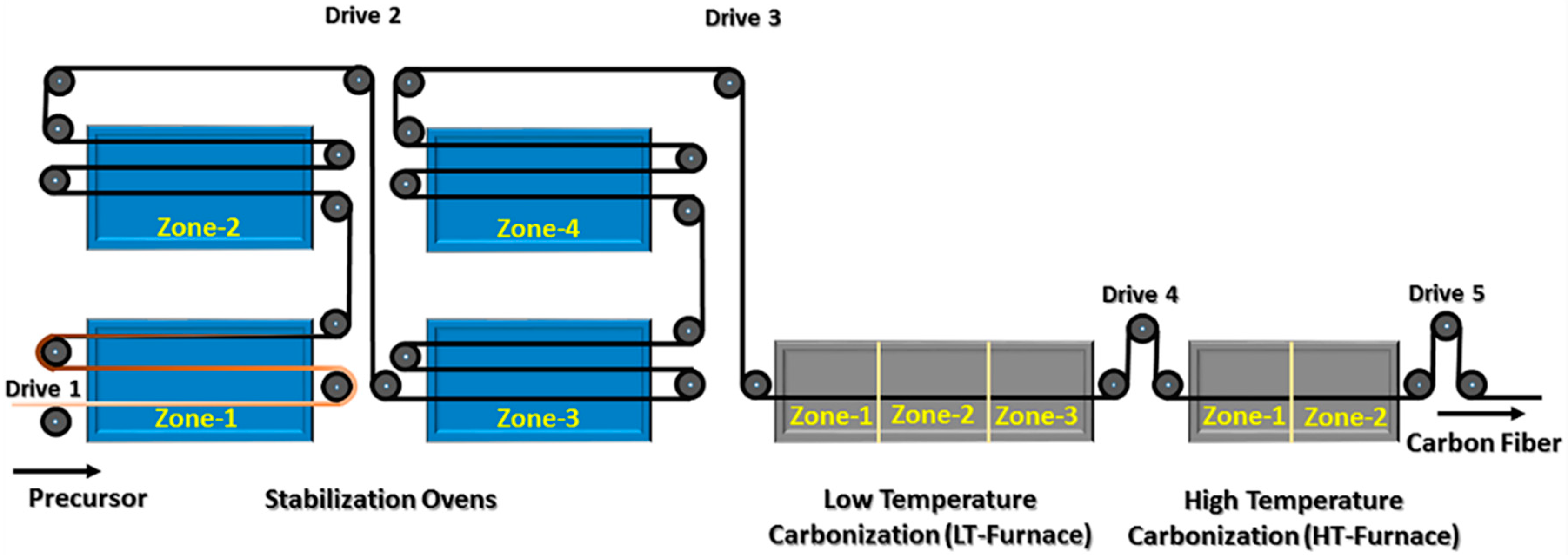

2.1. Sample Preparation

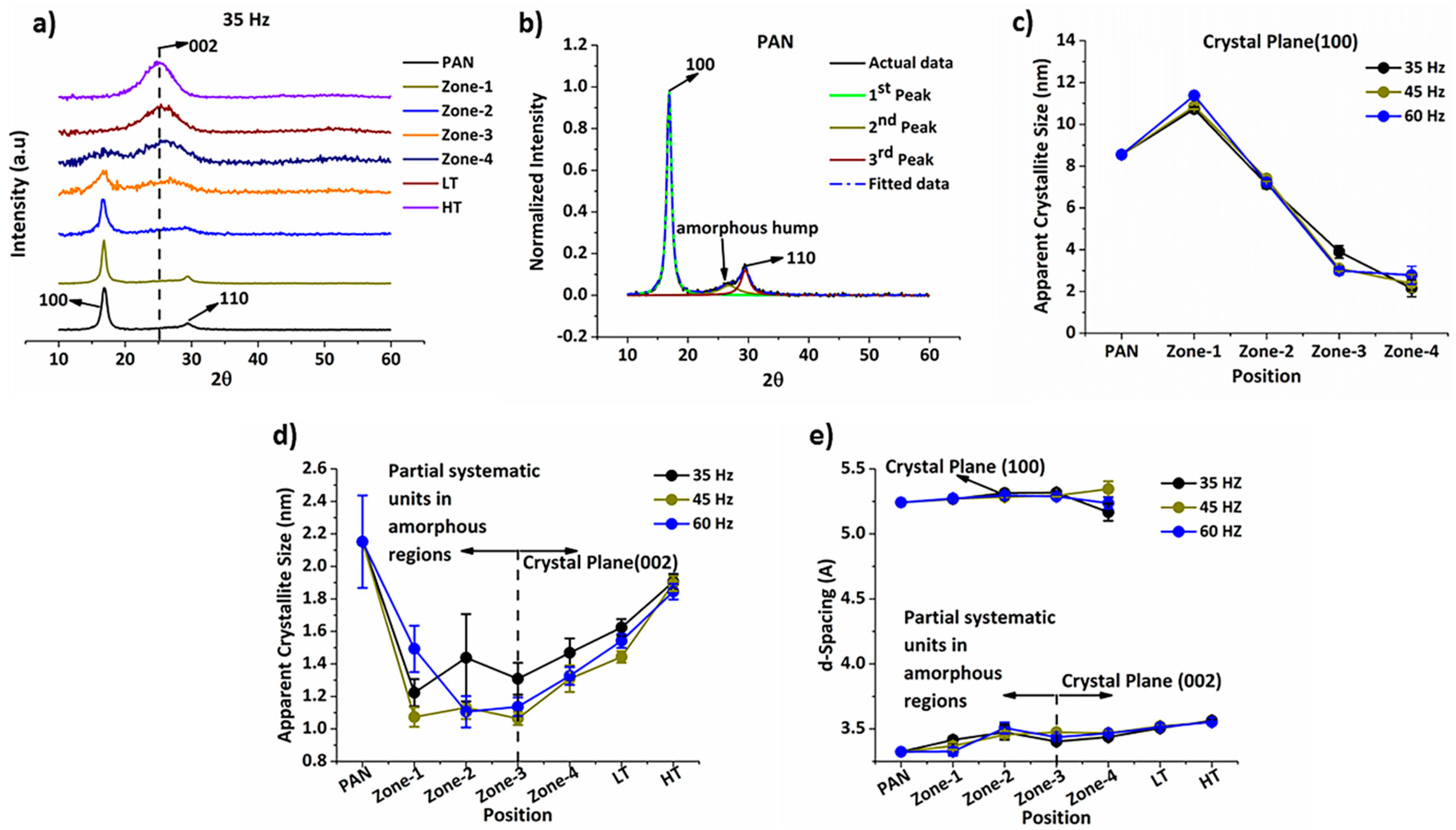

2.2. X-ray Diffraction Studies

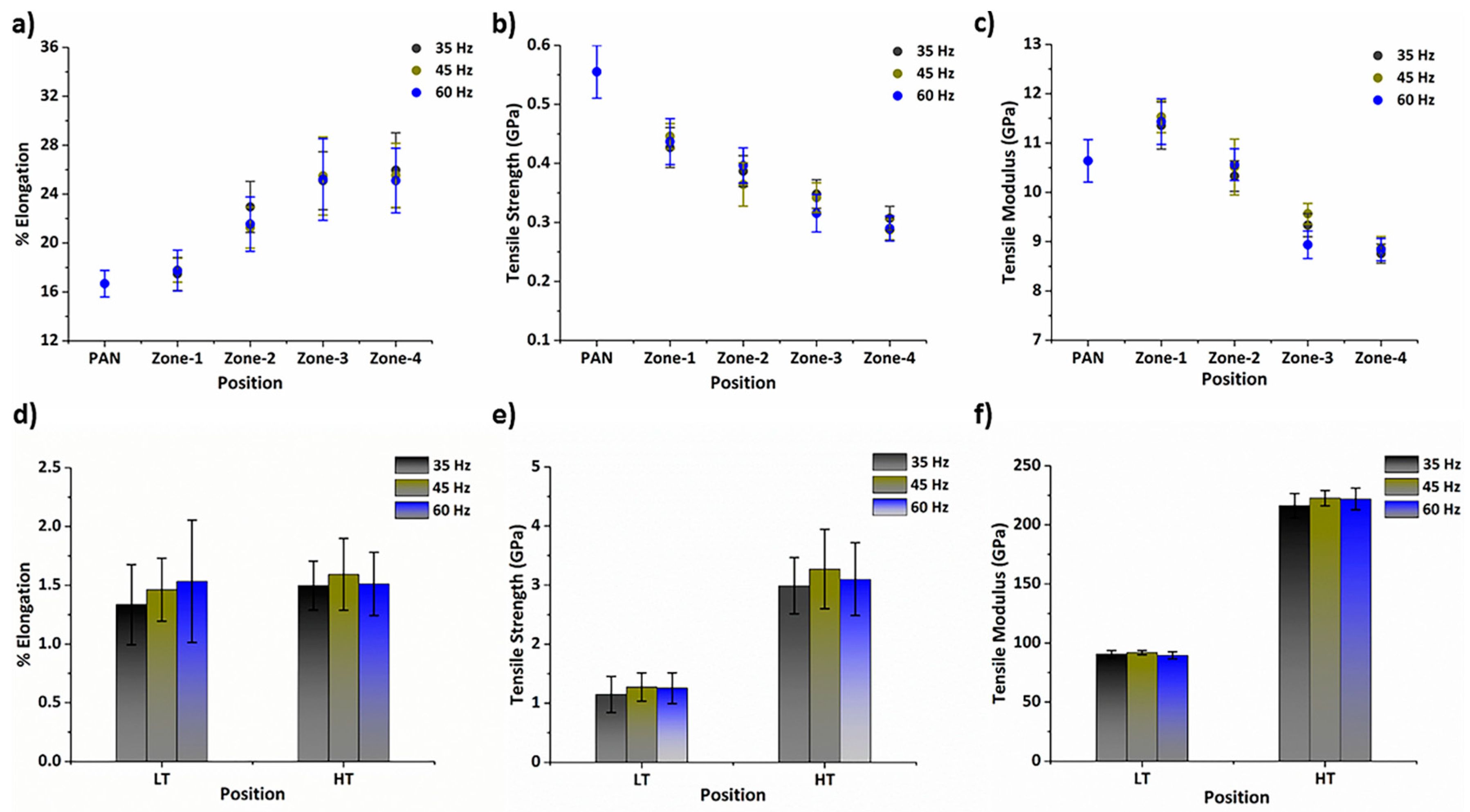

2.3. Tensile Testing

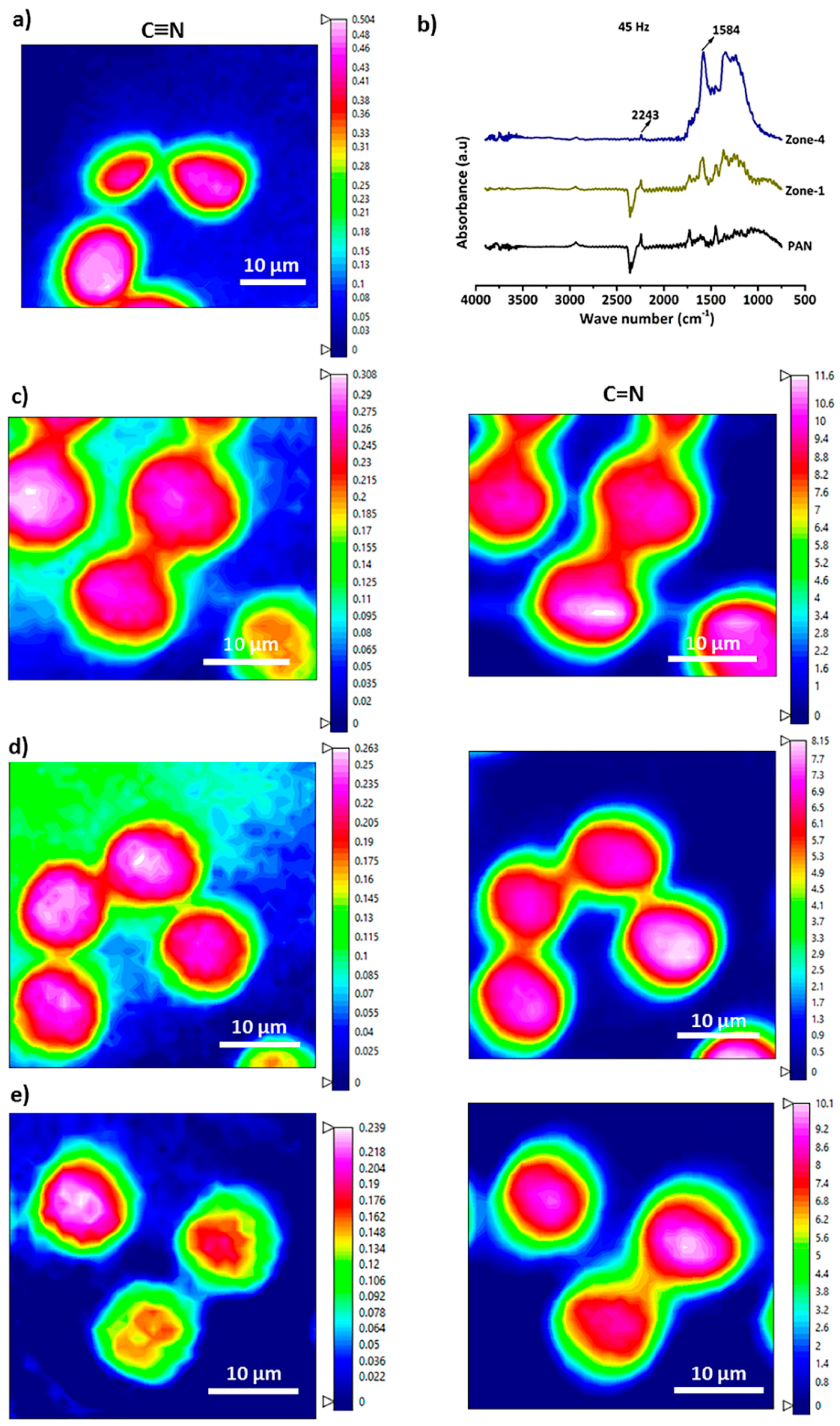

2.4. IR Studies

3. Results and Discussion

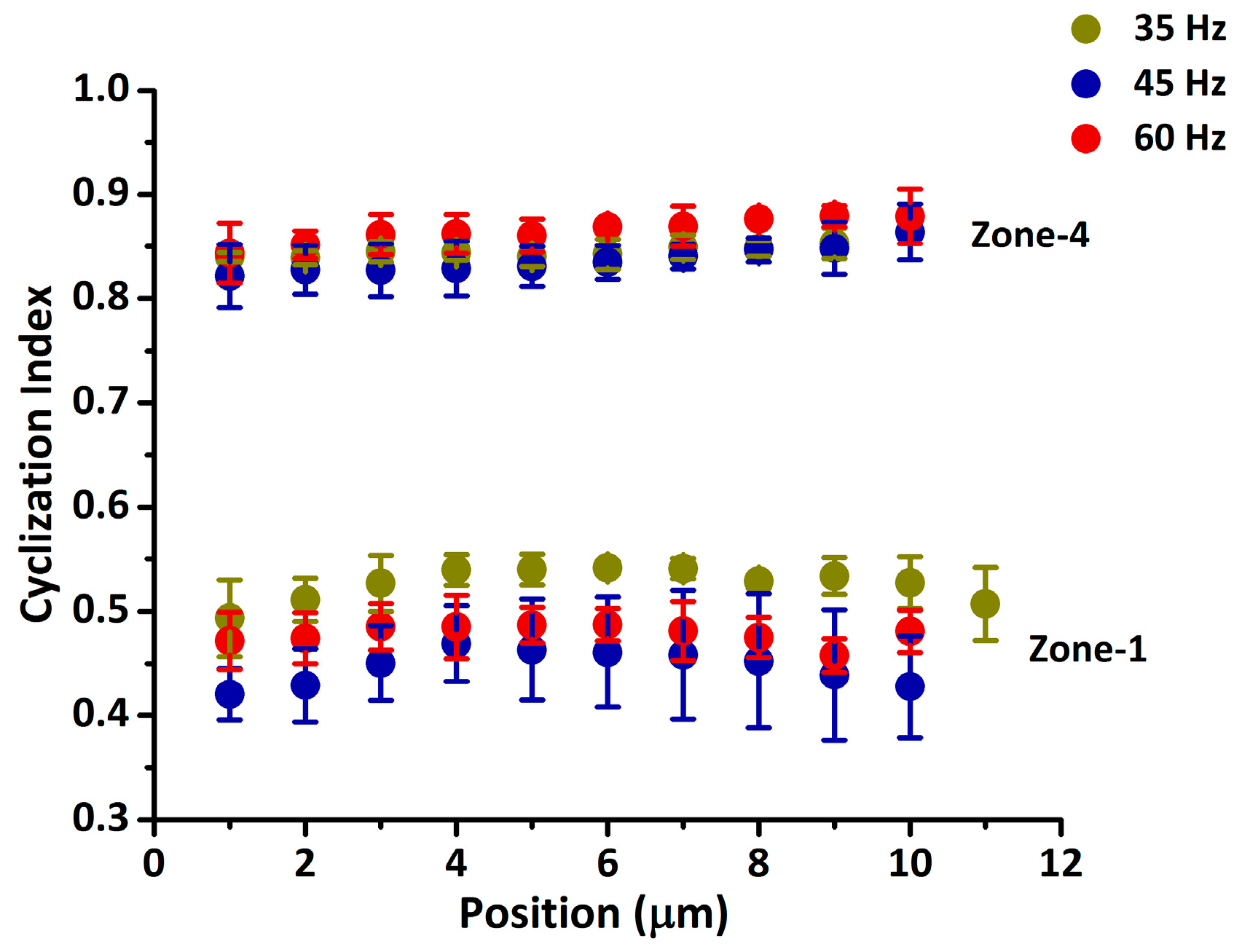

3.1. Chemical Structure Transformation during Thermal Stabilization

3.2. Microstructure and Property Variation in Fibers

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Jasjeet, K.; Keith, M.; Shaun, S. Producing high-quality precursor polymer and fibers to achieve theoretical strength in carbon fibers: A review. J. Appl. Polym. Sci. 2016, 133, 43963. [Google Scholar]

- Liu, J.; Yue, Z.; Fong, H. Continuous nanoscale carbon fibers with superior mechanical strength. Small 2009, 5, 536–542. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Lu, Y.; Zhou, L.; Jiang, J.; Wang, J.; Chen, Q.; Tian, F. Effects on the oriented structure and mechanical properties of carbon fibers by pre-irradiating polyacrylonitrile fibers with γ ray. J. Mater. Sci. 2016, 51, 7073–7084. [Google Scholar] [CrossRef]

- De Santis, V.; Campi, T.; Cruciani, S.; Laakso, I.; Feliziani, M. Assessment of the induced electric fields in a carbon-fiber electrical vehicle equipped with a wireless power transfer system. Energies 2018, 11, 684. [Google Scholar] [CrossRef]

- Ko, T.H. The influence of pyrolysis on physical properties and microstructure of modified PAN fibers during carbonization. J. Appl. Polym. Sci. 1991, 43, 589–600. [Google Scholar] [CrossRef]

- Nunna, S.; Naebe, M.; Hameed, N.; Fox, B.L.; Creighton, C. Evolution of radial heterogeneity in polyacrylonitrile fibres during thermal stabilization: An overview. Polym. Degrad. Stab. 2017, 136, 20–30. [Google Scholar] [CrossRef]

- Maghe, M.; Creighton, C.; Henderson, L.C.; Huson, M.G.; Nunna, S.; Atkiss, S.; Byrne, N.; Fox, B.L. Using ionic liquids to reduce energy consumption for carbon fibre production. J. Mater. Chem. A 2016, 4, 16619–16626. [Google Scholar] [CrossRef]

- Khayyam, H.; Naebe, M.; Bab-Hadiashar, A.; Jamshidi, F.; Li, Q.; Atkiss, S.; Buckmaster, D.; Fox, B. Stochastic optimization models for energy management in carbonization process of carbon fiber production. Appl. Energy 2015, 158, 643–655. [Google Scholar] [CrossRef]

- Golkarnarenji, G.; Naebe, M.; Badii, K.; Milani, A.S.; Jazar, R.N.; Khayyam, H. Production of Low Cost Carbon-Fiber through Energy Optimization of Stabilization Process. Materials 2018, 11, 385. [Google Scholar] [CrossRef] [PubMed]

- Golkarnarenji, G.; Naebe, M.; Badii, K.; Milani, A.S.; Jazar, R.N.; Khayyam, H. Support vector regression modelling and optimization of energy consumption in carbon fiber production line. Comp. Chem. Eng. 2018, 109, 276–288. [Google Scholar] [CrossRef]

- Ko, T.H.; Li, C.H.; Hu, C.H. The characterization of high-performance PAN-based carbon fibers developed by continuous carbonization and air oxidation. J. Mater. Res. 1995, 10, 1529–1538. [Google Scholar] [CrossRef]

- Fitzer, E.; Frohs, W.; Heine, M. Optimization of stabilization and carbonization treatment of PAN fibres and structural characterization of the resulting carbon fibres. Carbon 1986, 24, 387–395. [Google Scholar] [CrossRef]

- Khayyam, H.; Fakhrhoseini, S.M.; Church, J.S.; Milani, A.S.; Bab-Hadiashar, A.; Jazar, R.N.; Naebe, M. Predictive modelling and optimization of carbon fiber mechanical properties through high temperature furnace. Appl. Therm. Eng. 2017, 125, 1539–1554. [Google Scholar] [CrossRef]

- Wang, L.; Lu, W.; Zhang, L.; Xue, L.; Ryu, S.K.; Jin, R.G. Effects of positive and negative stretching on the structure and properties of polyacrylonitrile fibers in the pre-oxidation process. Carbon Lett. 2011, 12, 107–111. [Google Scholar] [CrossRef]

- Nunna, S.; Naebe, M.; Hameed, N.; Creighton, C.; Naghashian, S.; Jennings, M.J.; Atkiss, S.; Setty, M.; Fox, B.L. Investigation of progress of reactions and evolution of radial heterogeneity in the initial stage of thermal stabilization of PAN precursor fibres. Polym. Degrad. Stab. 2016, 125, 105–114. [Google Scholar] [CrossRef]

- Badii, K.; Naebe, M.; Golkarnarenji, G.; Dhami, N.; Atkiss, S.; Buckmaster, D.; Fox, B.; Khayyam, H. Energy Saving in Electric Heater of Carbon Fiber Stabilization Oven. In Proceedings of the 2014 4th International Conference on Artificial Intelligence with Applications in Engineering and Technology (ICAIET), Kota Kinabalu, Malaysia, 3–5 December 2014; pp. 109–114. [Google Scholar]

- Dunham, M.G.; Edie, D.D. Model of stabilization for pan-based carbon fiber precursor bundles. Carbon 1992, 30, 435–450. [Google Scholar] [CrossRef]

- Nunna, S.; Creighton, C.; Fox, B.L.; Naebe, M.; Maghe, M.; Tobin, M.J.; Bambery, K.; Vongsvivut, J.; Hameed, N. The effect of thermally induced chemical transformations on the structure and properties of carbon fibre precursors. J. Mater. Chem. A 2017, 5, 7372–7382. [Google Scholar] [CrossRef]

- Liu, F.; Wang, H.; Xue, L.; Fan, L.; Zhu, Z. Effect of microstructure on the mechanical properties of PAN-based carbon fibers during high-temperature graphitization. J. Mater. Sci. 2008, 43, 4316–4322. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, J.; Zhou, T.; Liu, X.; Yuan, Q.; Zhang, A. New understanding on the reaction pathways of the polyacrylonitrile copolymer fiber pre-oxidation: Online tracking by two-dimensional correlation FTIR spectroscopy. RSC Adv. 2016, 6, 4397–4409. [Google Scholar] [CrossRef]

- Khayyam, H.; Naebe, M.; Zabihi, O.; Zamani, R.; Atkiss, S.; Fox, B. Dynamic Prediction Models and Optimization of Polyacrylonitrile (PAN) Stabilization Processes for Production of Carbon Fiber. IEEE Trans. Ind. Inform. 2015, 11, 887–895. [Google Scholar] [CrossRef]

- Layden, G.K. Retrograde core formation during oxidation of polyacrylonitrile filaments. Carbon 1972, 10, 59–63. [Google Scholar] [CrossRef]

- Arbab, S.; Mirbaha, H.; Zeinolebadi, A.; Nourpanah, P. Indicators for evaluation of progress in thermal stabilization reactions of polyacrylonitrile fibers. J. Appl. Polym. Sci. 2014, 131, 40343. [Google Scholar] [CrossRef]

- Kikuma, J.; Warwick, T.; Shin, H.J.; Zhang, J.; Tonner, B.P. Chemical state analysis of heat-treated polyacrylonitrile fiber using soft X-ray spectromicroscopy. J. Electron Spectrosc. Relat. Phenom. 1998, 94, 271–278. [Google Scholar] [CrossRef]

- Hameed, N.; Sharp, J.; Nunna, S.; Creighton, C.; Magniez, K.; Jyotishkumar, P.; Salim, N.V.; Fox, B. Structural transformation of polyacrylonitrile fibers during stabilization and low temperature carbonization. Polym. Degrad. Stab. 2016, 128, 39–45. [Google Scholar] [CrossRef]

- Yu, M.J.; Bai, Y.J.; Wang, C.G.; Xu, Y.; Guo, P.Z. A new method for the evaluation of stabilization index of polyacrylonitrile fibers. Mater. Lett. 2007, 61, 2292–2294. [Google Scholar] [CrossRef]

- Karacan, I.; Erdoğan, G. The role of thermal stabilization on the structure and mechanical properties of polyacrylonitrile precursor fibers. Fibers Polym. 2012, 13, 855–863. [Google Scholar] [CrossRef]

- Wang, B.; Xiao, S.; Cao, W.; Shi, X.; Xu, L. Evolution of aggregation structure of polyacrylonitrile fibers in the cyclization reaction. J. Appl. Polym. Sci. 2012, 124, 3413–3418. [Google Scholar] [CrossRef]

- Ko, T.H.; Lin, C.H.; Ting, H.Y. Structural changes and molecular motion of polyacrylonitrile fibers during pyrolysis. J. Appl. Polym. Sci. 1989, 37, 553–566. [Google Scholar] [CrossRef]

- Gupta, A.; Harrison, I.R. New aspects in the oxidative stabilization of PAN-based carbon fibers: II. Carbon 1997, 35, 809–818. [Google Scholar] [CrossRef]

| Stage | Position | Constant Process Parameters | Variable Process Parameter | ||||

|---|---|---|---|---|---|---|---|

| Temperature (°C) | Time (Min) | Tension (cN) | Recirculation Fan Frequency (Hz)-1 | Recirculation Fan Frequency (Hz)-2 | Recirculation Fan Frequency (Hz)-3 | ||

| Stabilization | Zone-1 | 227 | 20 | 2650 ± 50 | 35 | 45 | 60 |

| Zone-2 | 237 | 20 | 2650 ± 50 | 35 | 45 | 60 | |

| Zone-3 | 248 | 20 | 2850 ± 250 | 35 | 45 | 60 | |

| Zone-4 | 258 | 20 | 2850 ± 250 | 35 | 45 | 60 | |

| Low Temperature (LT) | Zone-3 | ~850 | ~6 | ~2000 | |||

| High Temperature (HT) | Zone-2 | ~1400 | ~4 | ~3200 | |||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nunna, S.; Maghe, M.; Fakhrhoseini, S.M.; Polisetti, B.; Naebe, M. A Pathway to Reduce Energy Consumption in the Thermal Stabilization Process of Carbon Fiber Production. Energies 2018, 11, 1145. https://doi.org/10.3390/en11051145

Nunna S, Maghe M, Fakhrhoseini SM, Polisetti B, Naebe M. A Pathway to Reduce Energy Consumption in the Thermal Stabilization Process of Carbon Fiber Production. Energies. 2018; 11(5):1145. https://doi.org/10.3390/en11051145

Chicago/Turabian StyleNunna, Srinivas, Maxime Maghe, Seyed Mousa Fakhrhoseini, Bhargav Polisetti, and Minoo Naebe. 2018. "A Pathway to Reduce Energy Consumption in the Thermal Stabilization Process of Carbon Fiber Production" Energies 11, no. 5: 1145. https://doi.org/10.3390/en11051145

APA StyleNunna, S., Maghe, M., Fakhrhoseini, S. M., Polisetti, B., & Naebe, M. (2018). A Pathway to Reduce Energy Consumption in the Thermal Stabilization Process of Carbon Fiber Production. Energies, 11(5), 1145. https://doi.org/10.3390/en11051145