Enhancing the Performance of Evacuated and Non-Evacuated Parabolic Trough Collectors Using Twisted Tape Inserts, Perforated Plate Inserts and Internally Finned Absorber

Abstract

:1. Introduction

2. Material and Methods

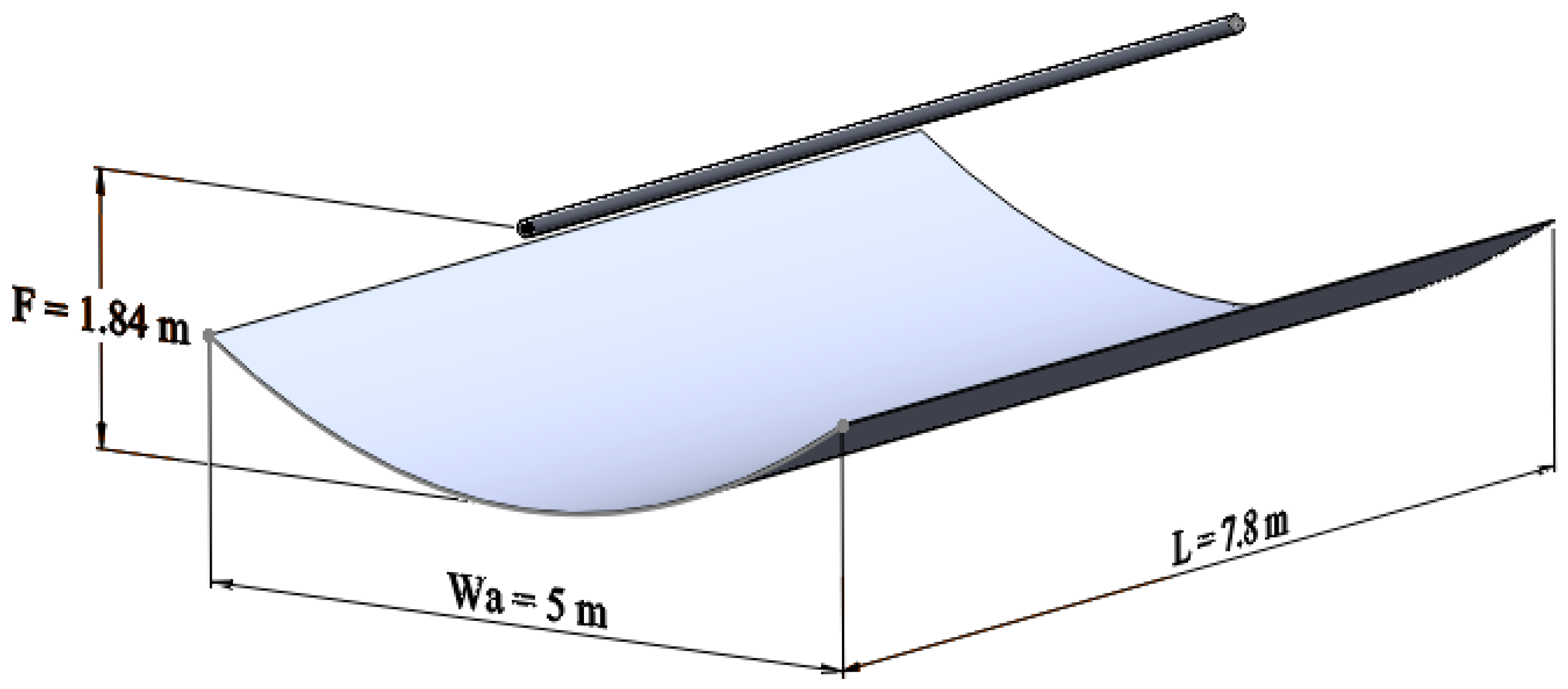

2.1. The Examined Solar Collector

2.2. Basic Mathematical Formulation

2.2.1. Thermal Model

2.2.2. Hydraulic Model

2.2.3. Evaluation Criteria of the Thermal Enhancement Techniques

2.3. The Examined Thermal Enhancement Techniques

- (a)

- Smooth case

- (b)

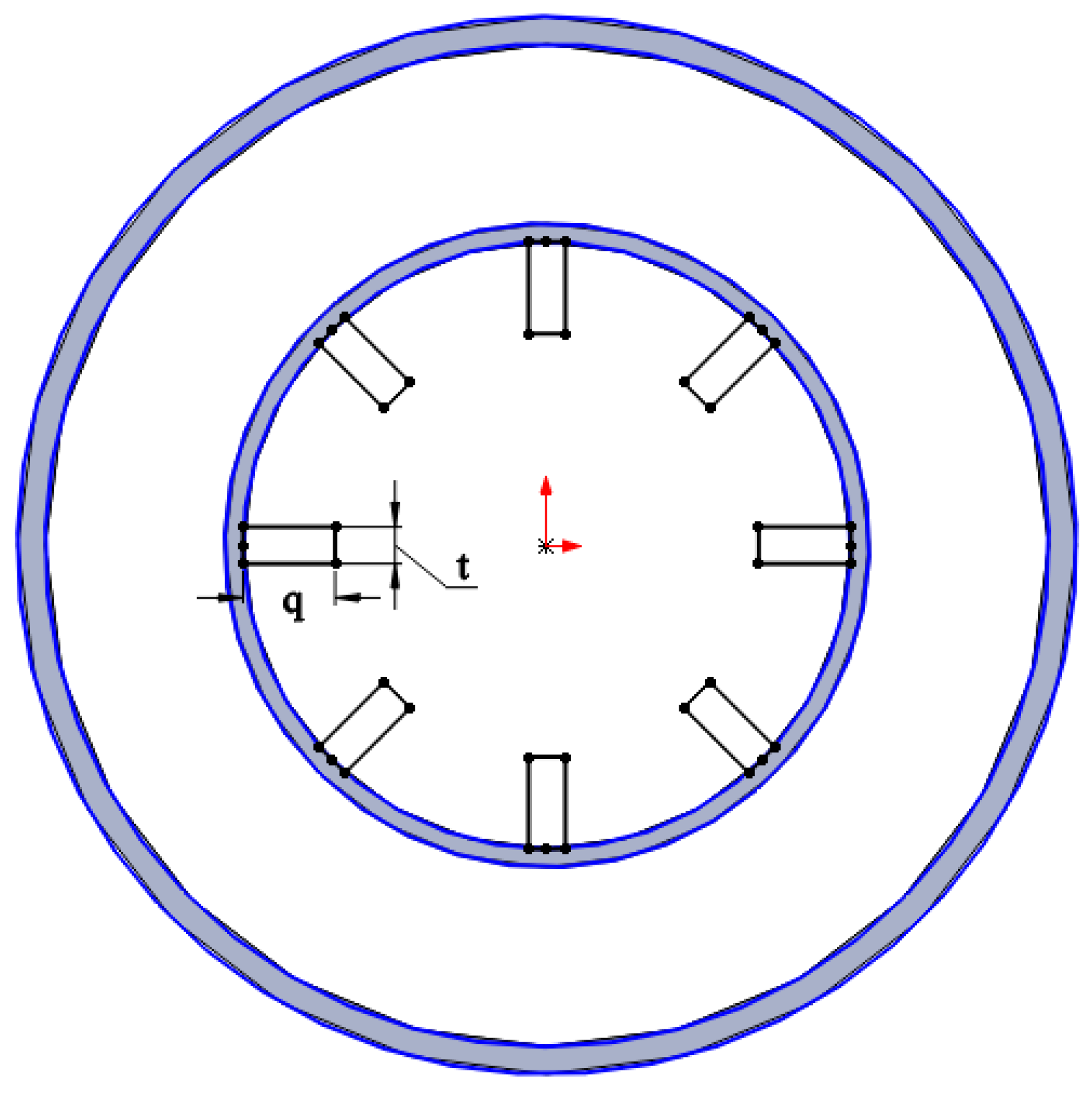

- Internally finned absorber

- (c)

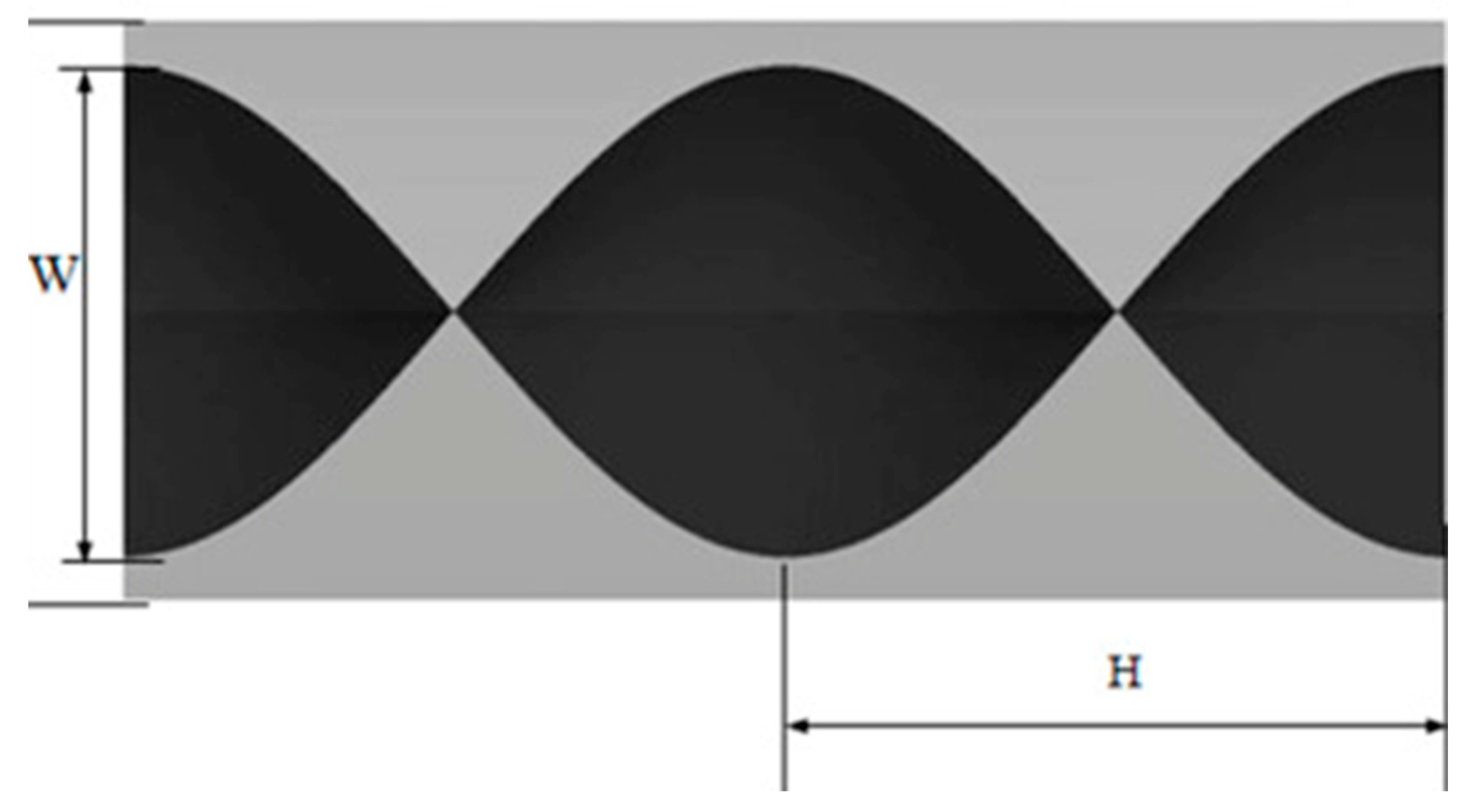

- Twisted tape inserts

- (d)

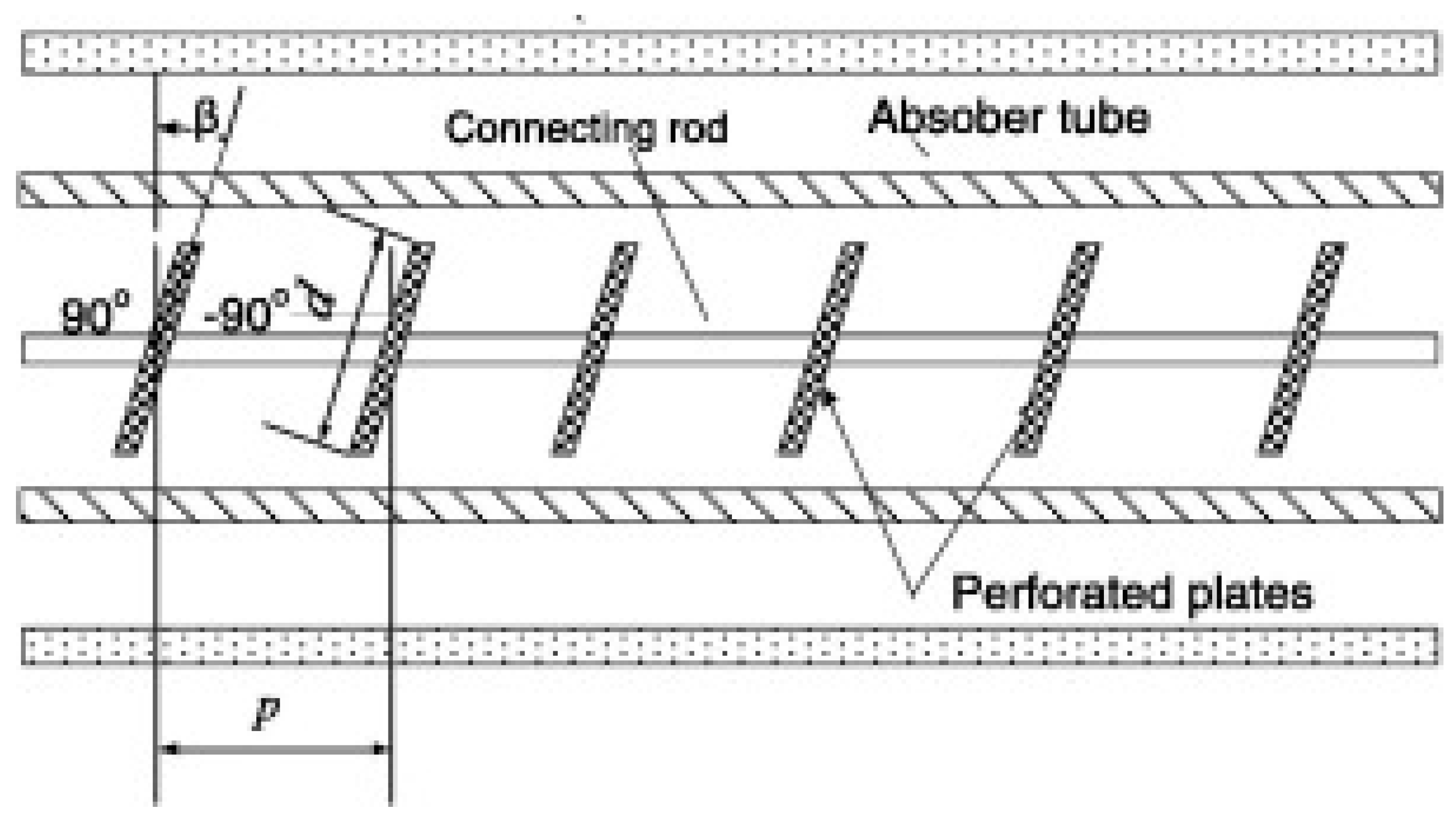

- Perforated tape insert

2.4. The Developed Model in EES

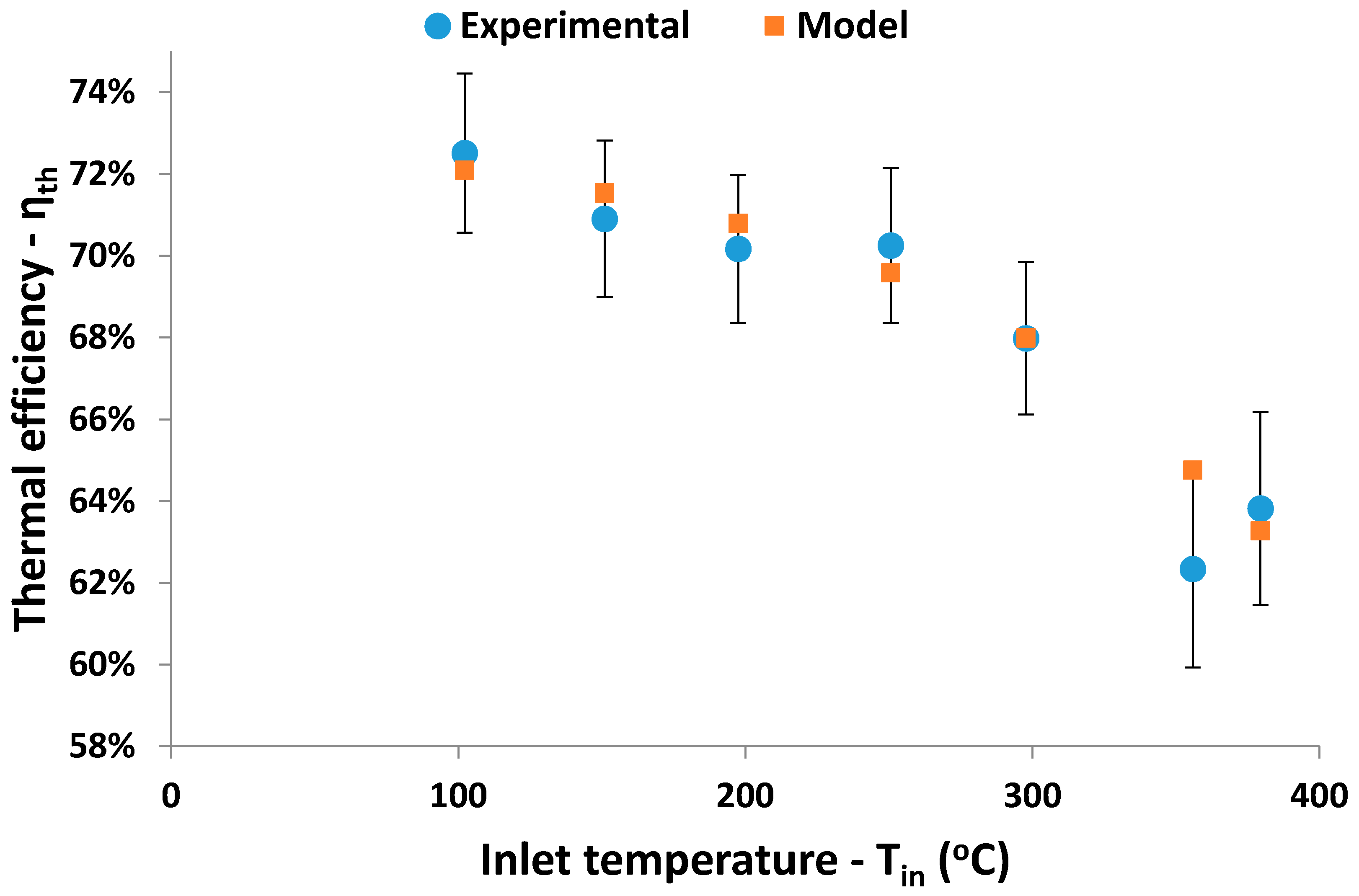

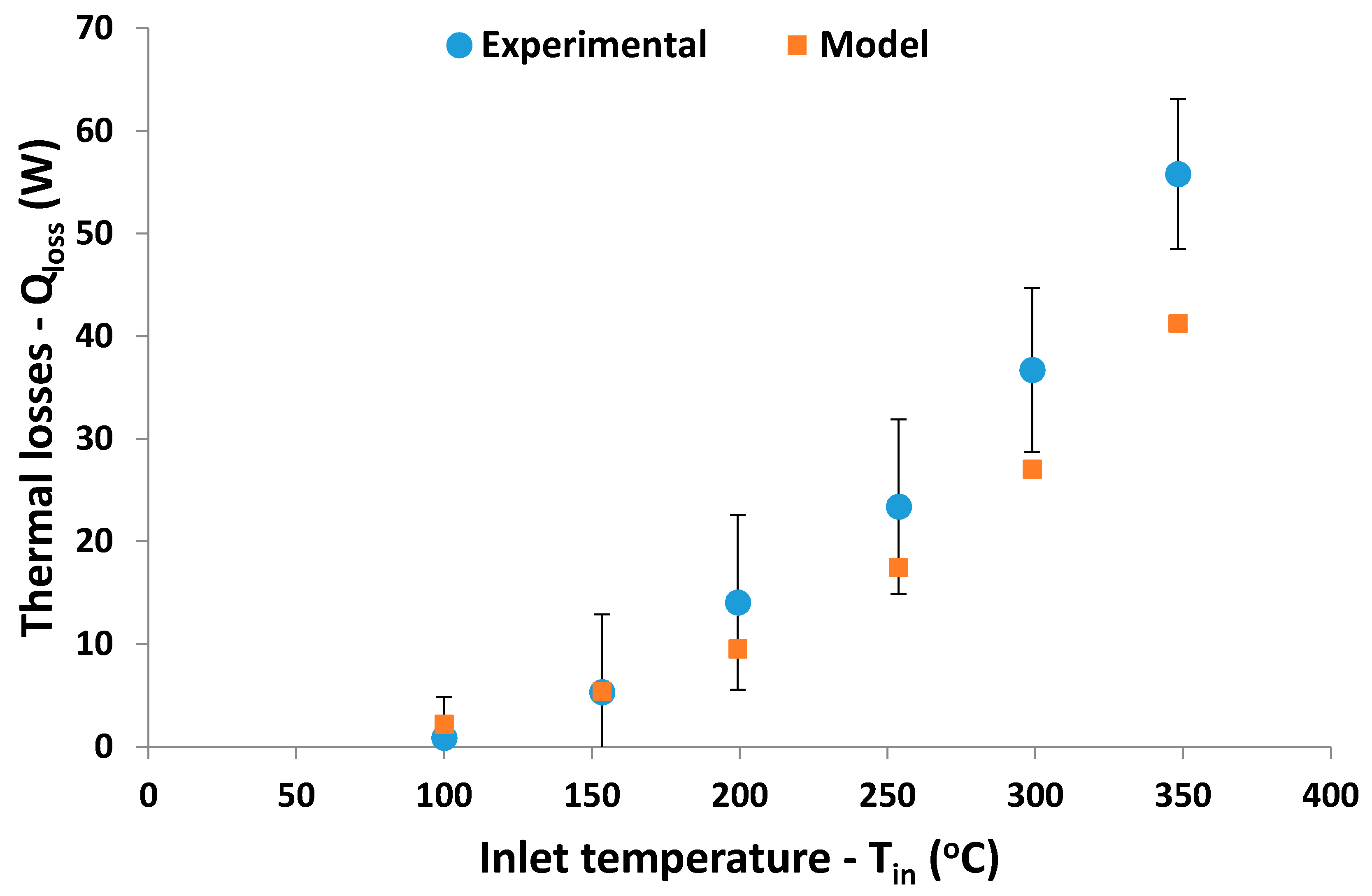

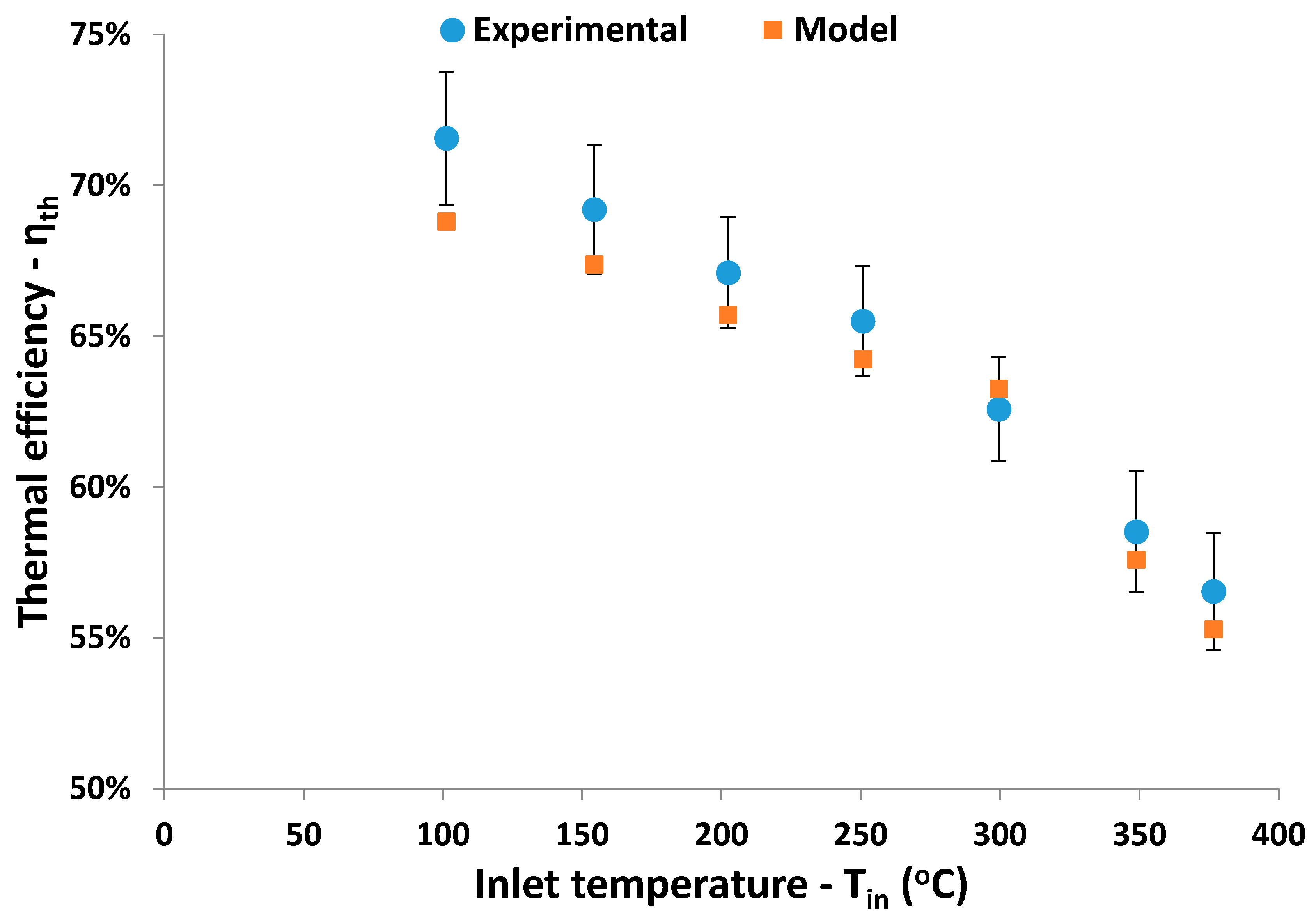

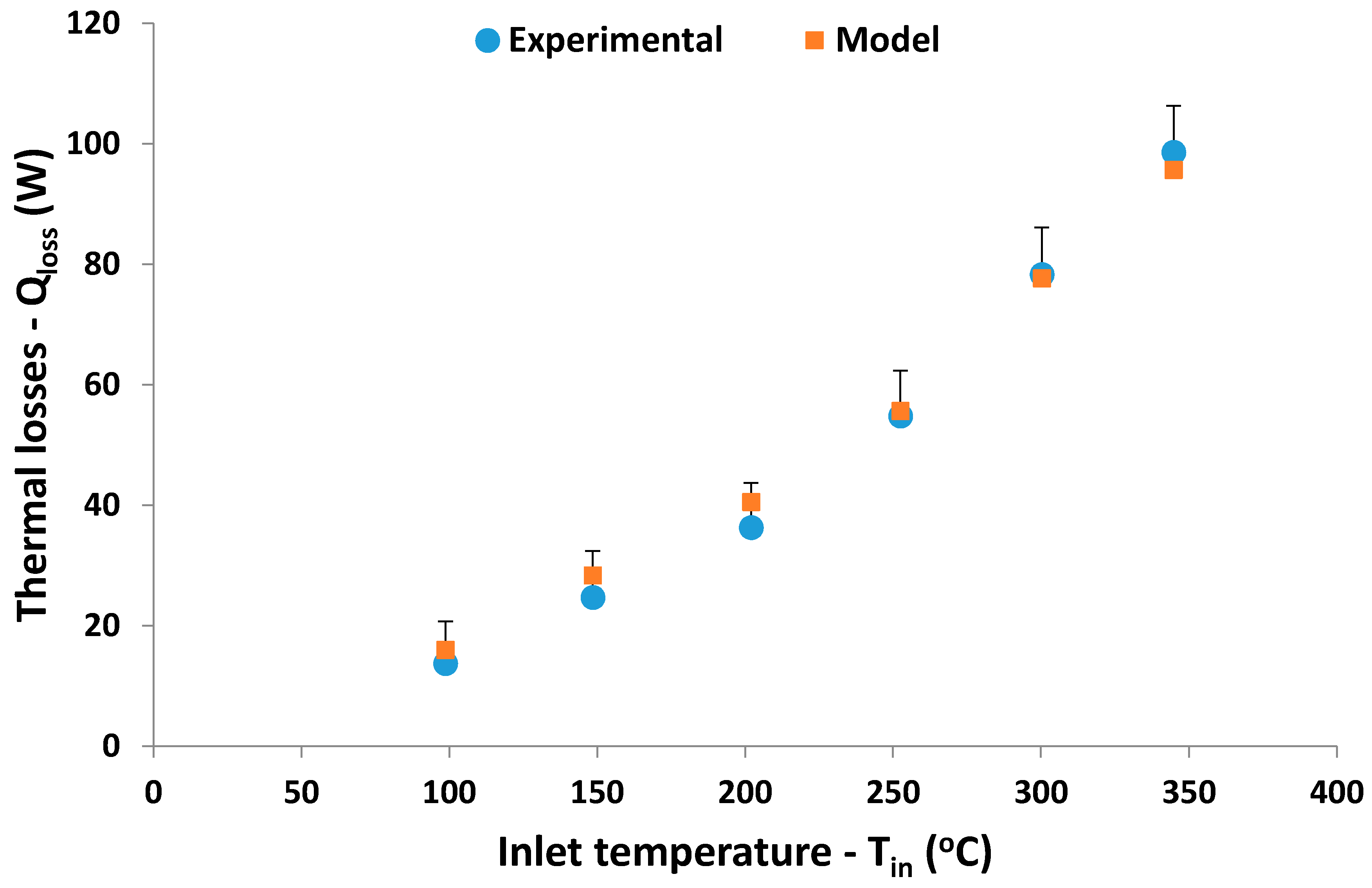

2.5. Model Validation

3. Results and Discussion

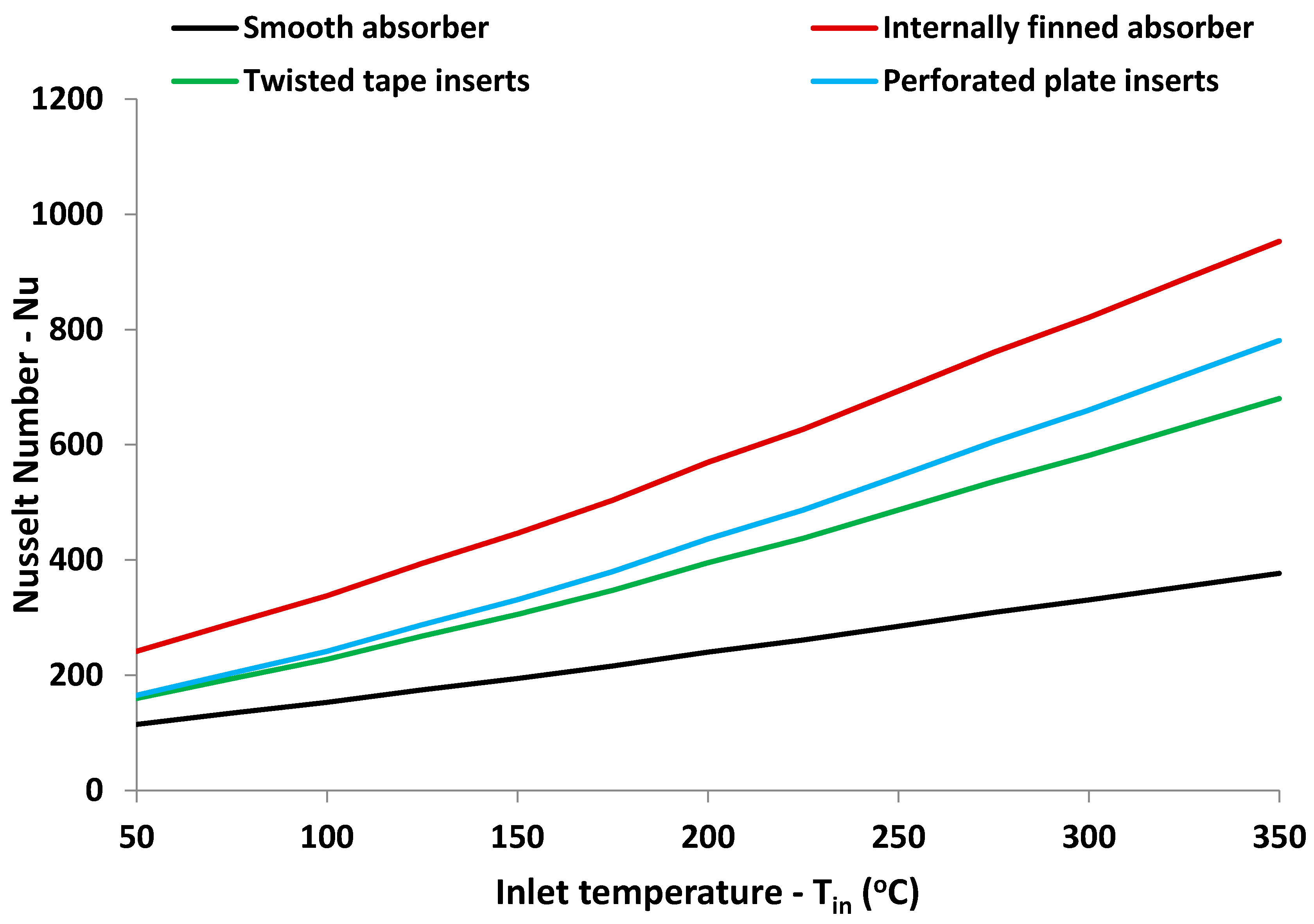

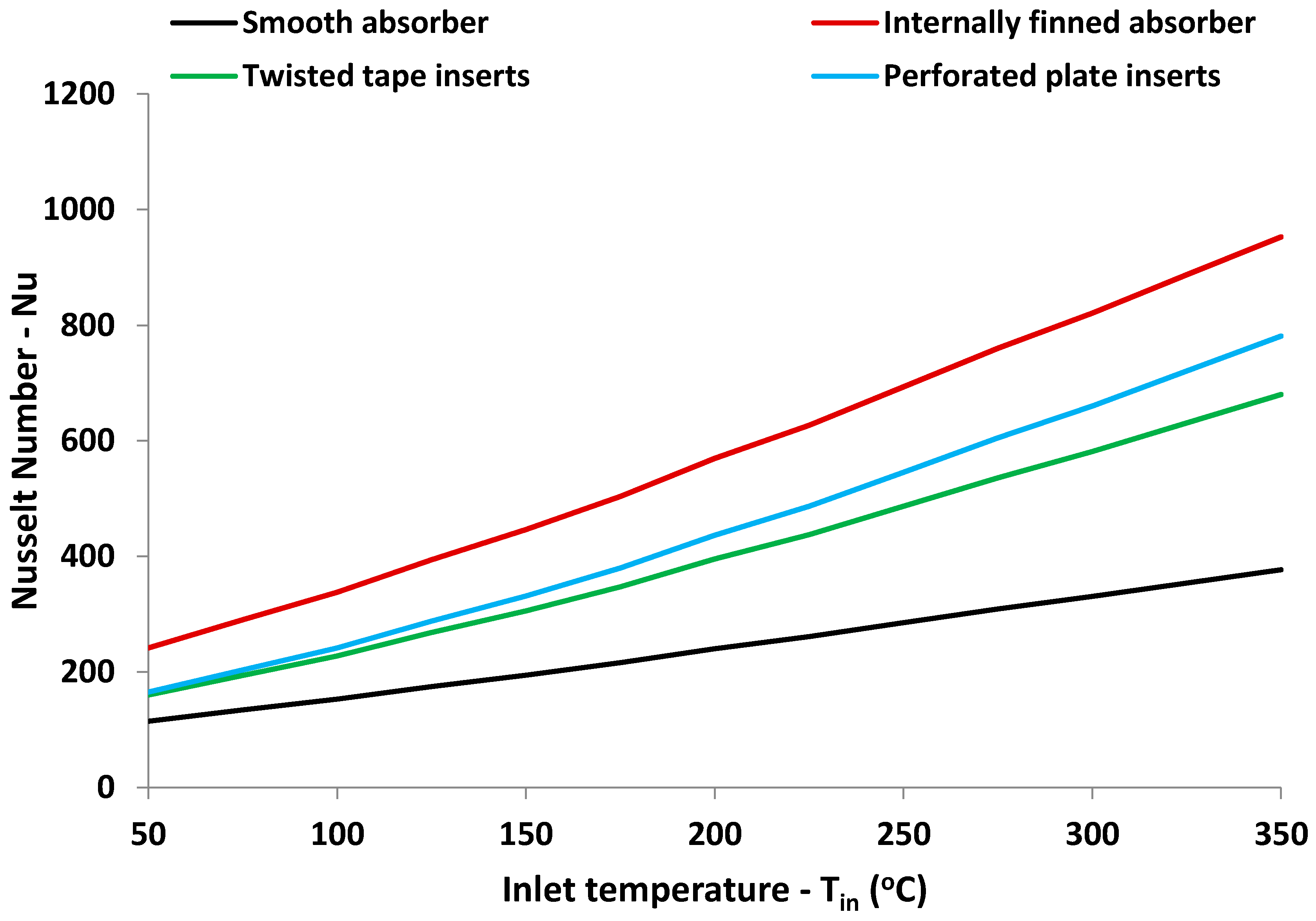

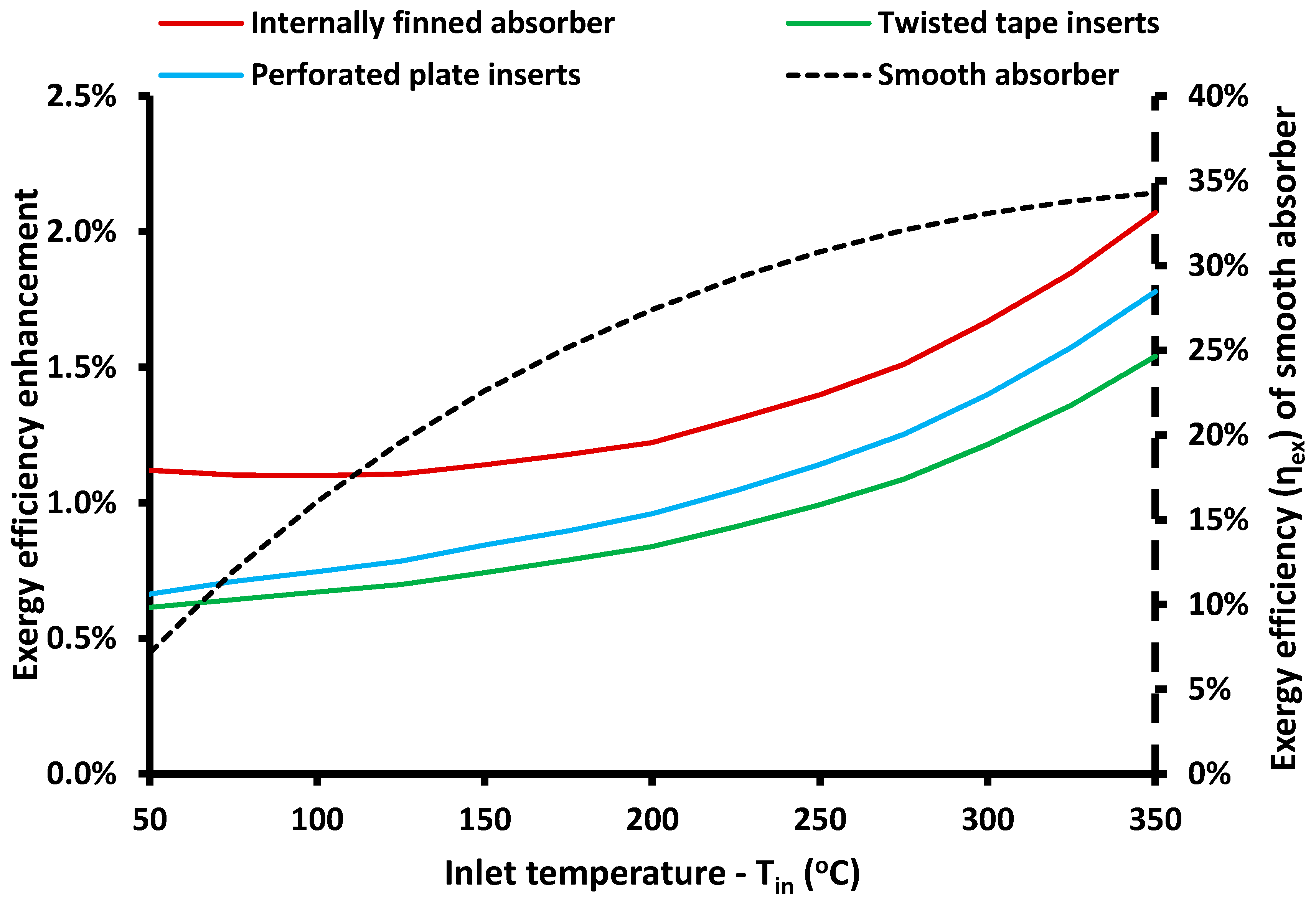

3.1. Evacuated Tube Receiver Performance

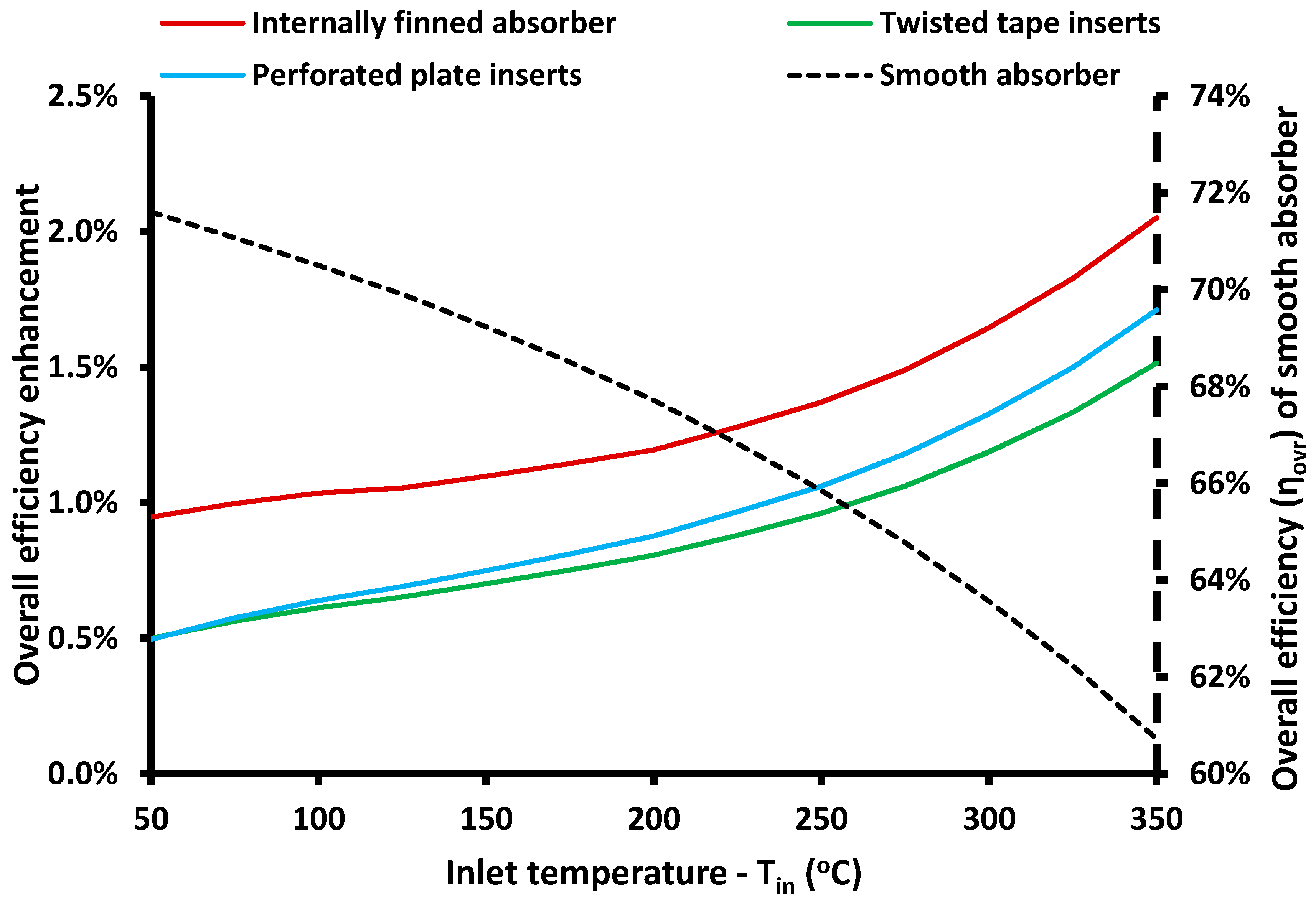

3.2. Non-Evacuated tube Receiver Performance

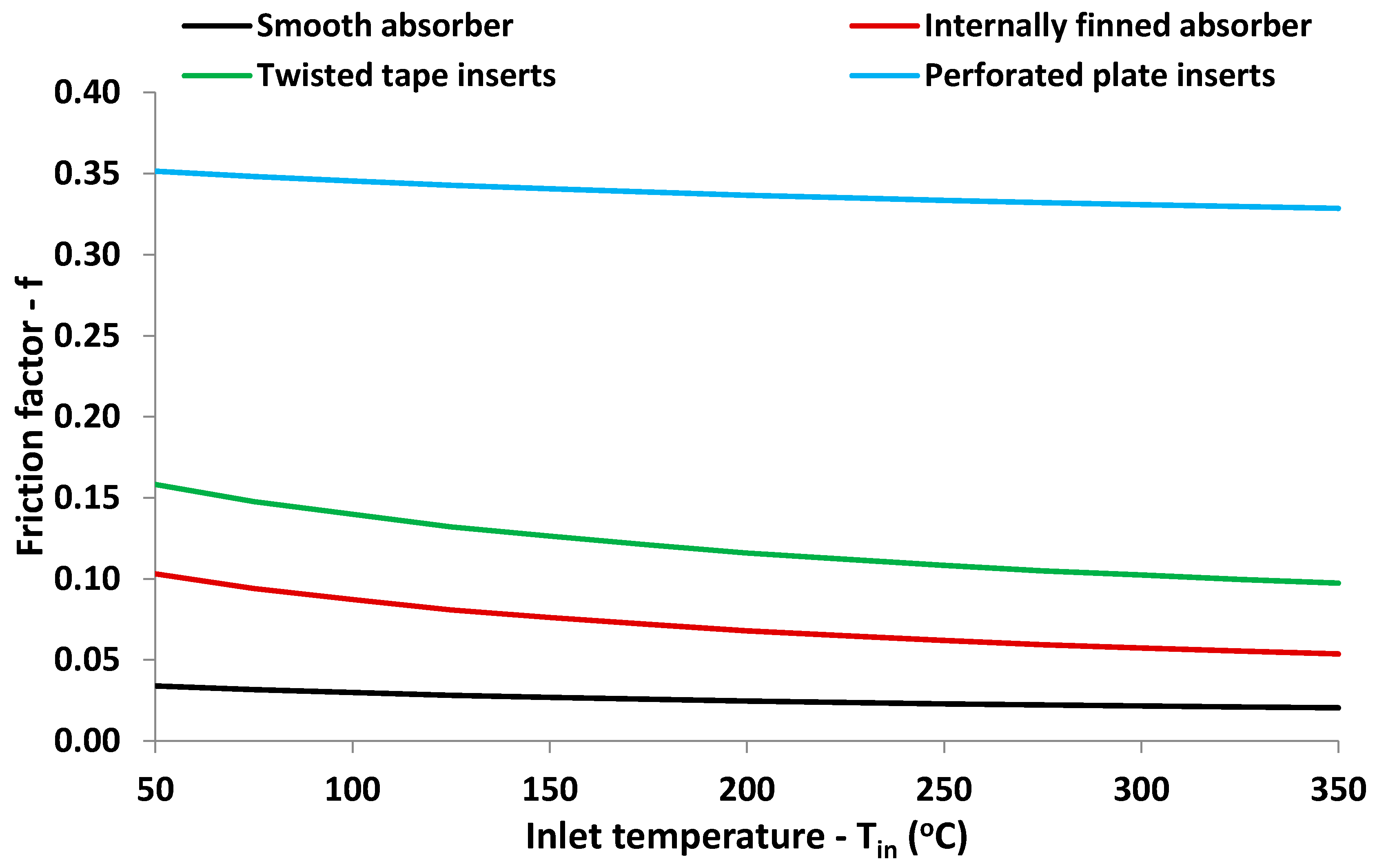

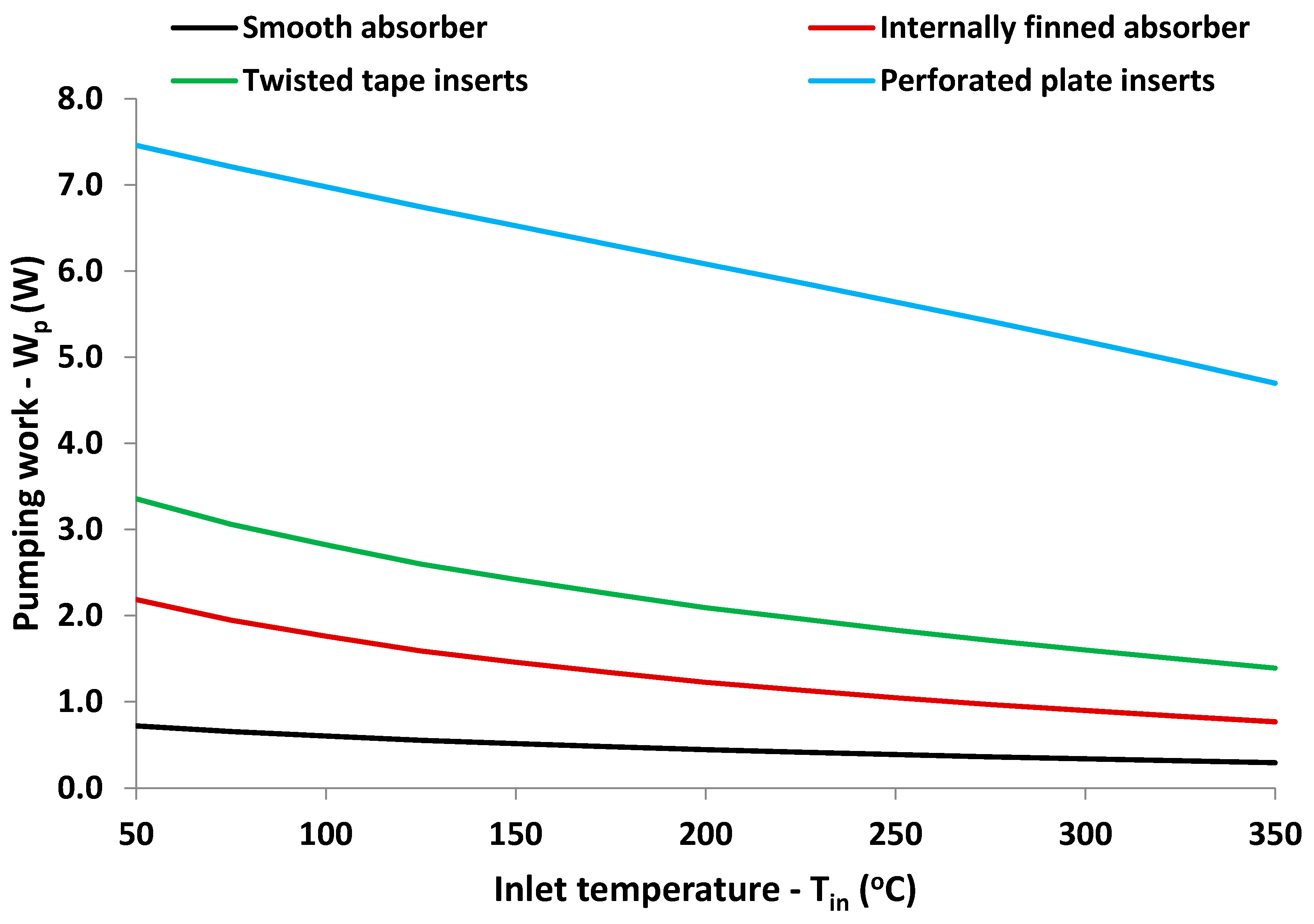

3.3. Hydraulic Performance of the Collector

3.4. Thermal Enhancement Comparison of Evacuated and Not Evacuated Receiver

4. Conclusions

- -

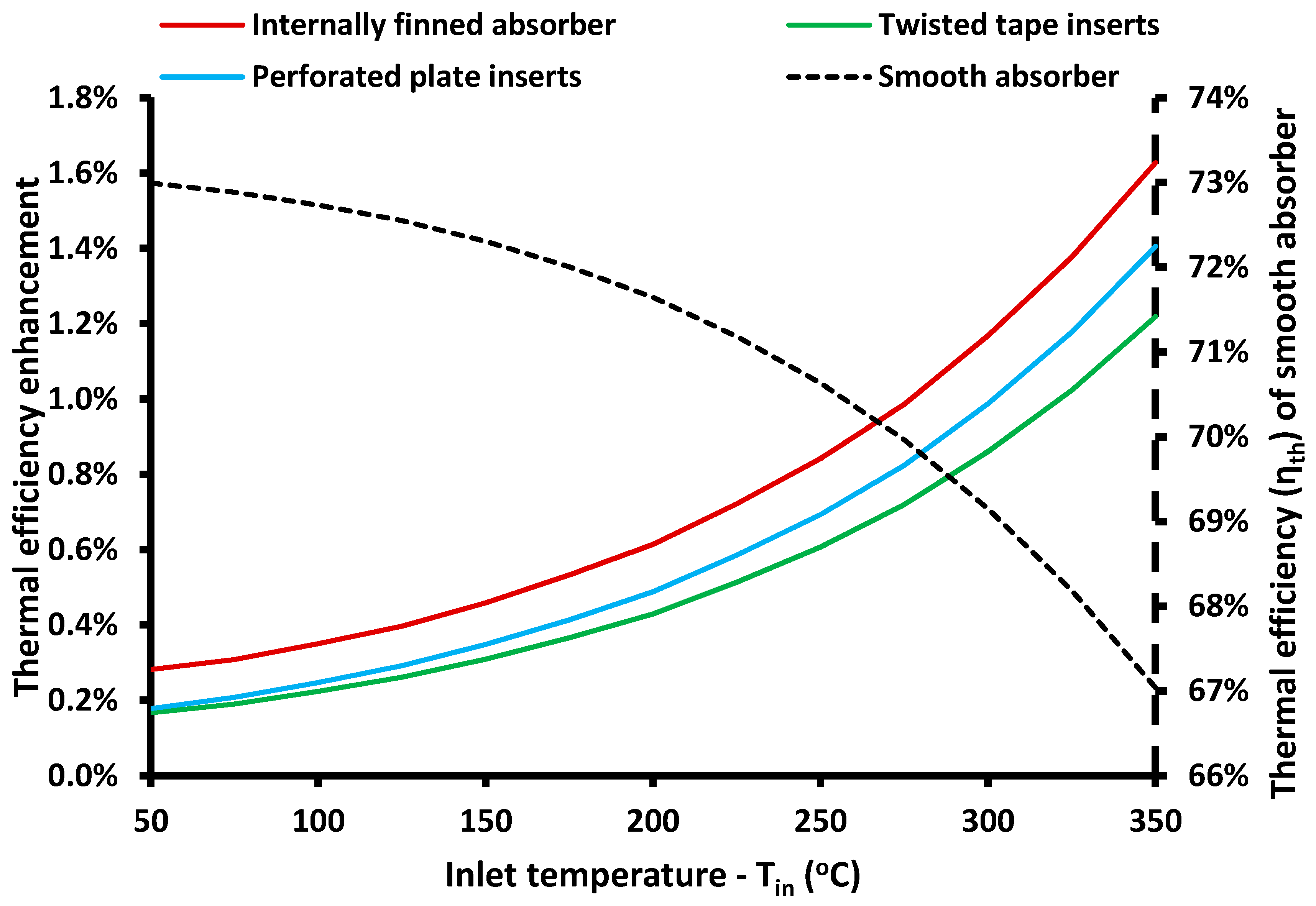

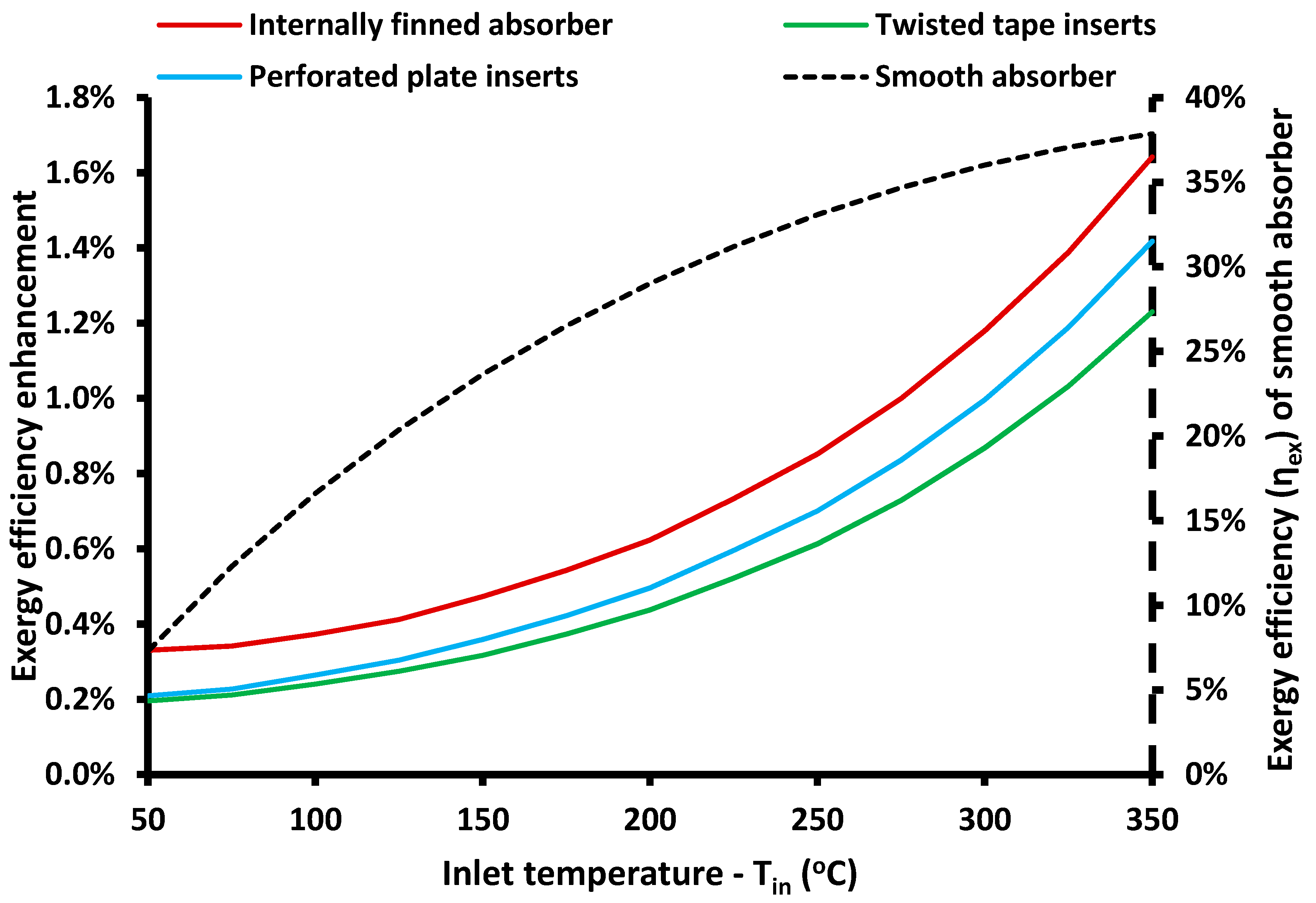

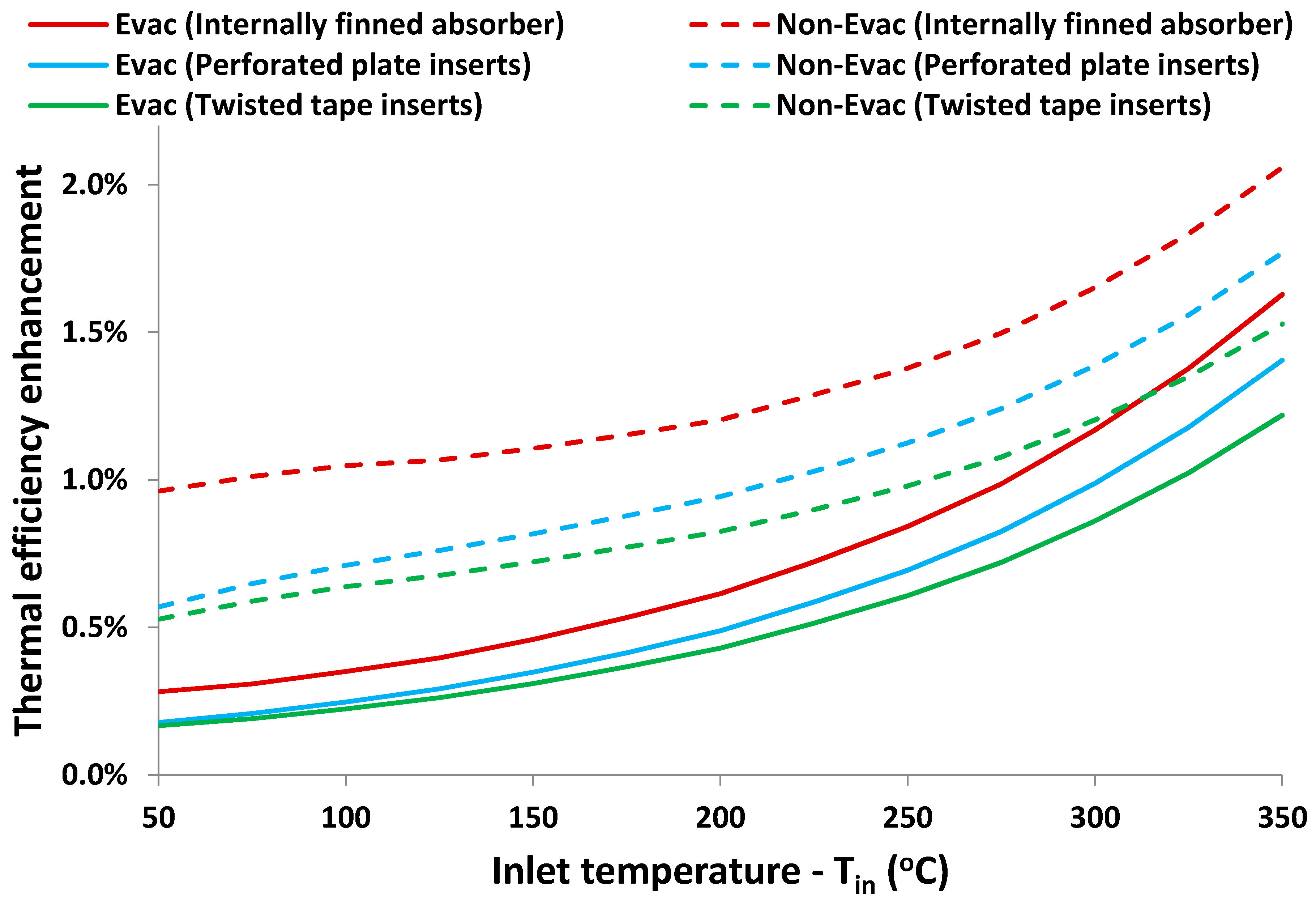

- All of the examined thermal efficiency enhancement methods are found to be effective and they enhance the thermal efficiency of the solar collector. Moreover, the exergy efficiency and the overall efficiency are also enhanced. The obtained enhancements are greater at higher inlet temperature levels.

- -

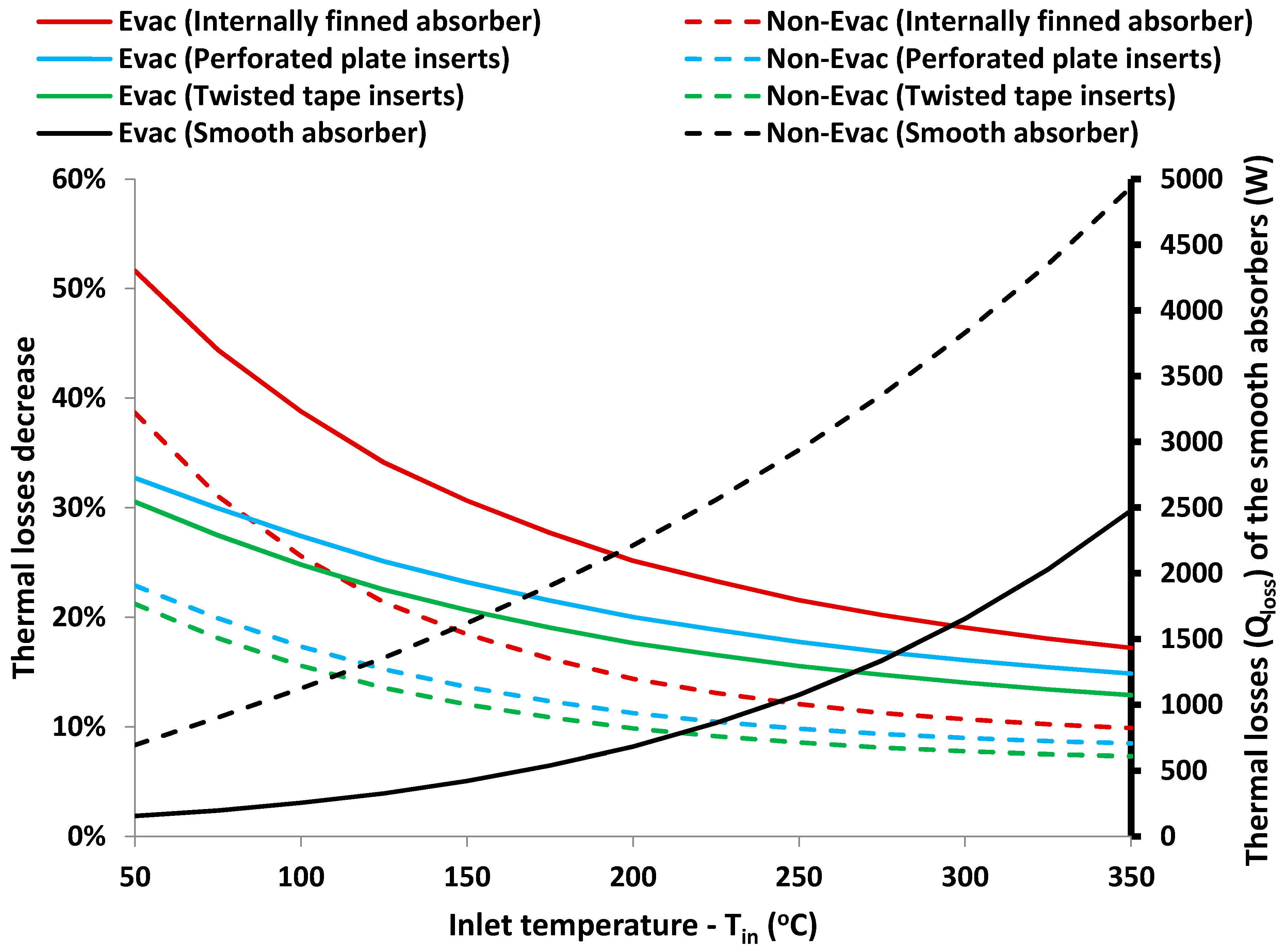

- The enhancements are higher for the non-evacuated tube cases, because in these cases, there are higher thermal losses and a higher thermal enhancement margin.

- -

- The highest enhancements are found with the use of internal fins, while the use of perforated inserts is the second choice and the use of twisted tape inserts leads to the lowest enhancements.

- -

- The mean thermal efficiency enhancement with the internal fins is 0.7% for the evacuated tube and 1.3% for the non-evacuated tube, while the maximum enhancements are 1.6% and 2.1%, respectively. It is important to state that these small thermal enhancements are explained by the low thermal losses of the PTC.

- -

- Furthermore, it is important to state that these small thermal enhancements are close to the possible errors from the uncertainties that are associated with the Nusselt number calculation from the used literature formula. However, there is a thermal enhancement in all of the cases, but there is uncertainty about the values of the enhancement.

- -

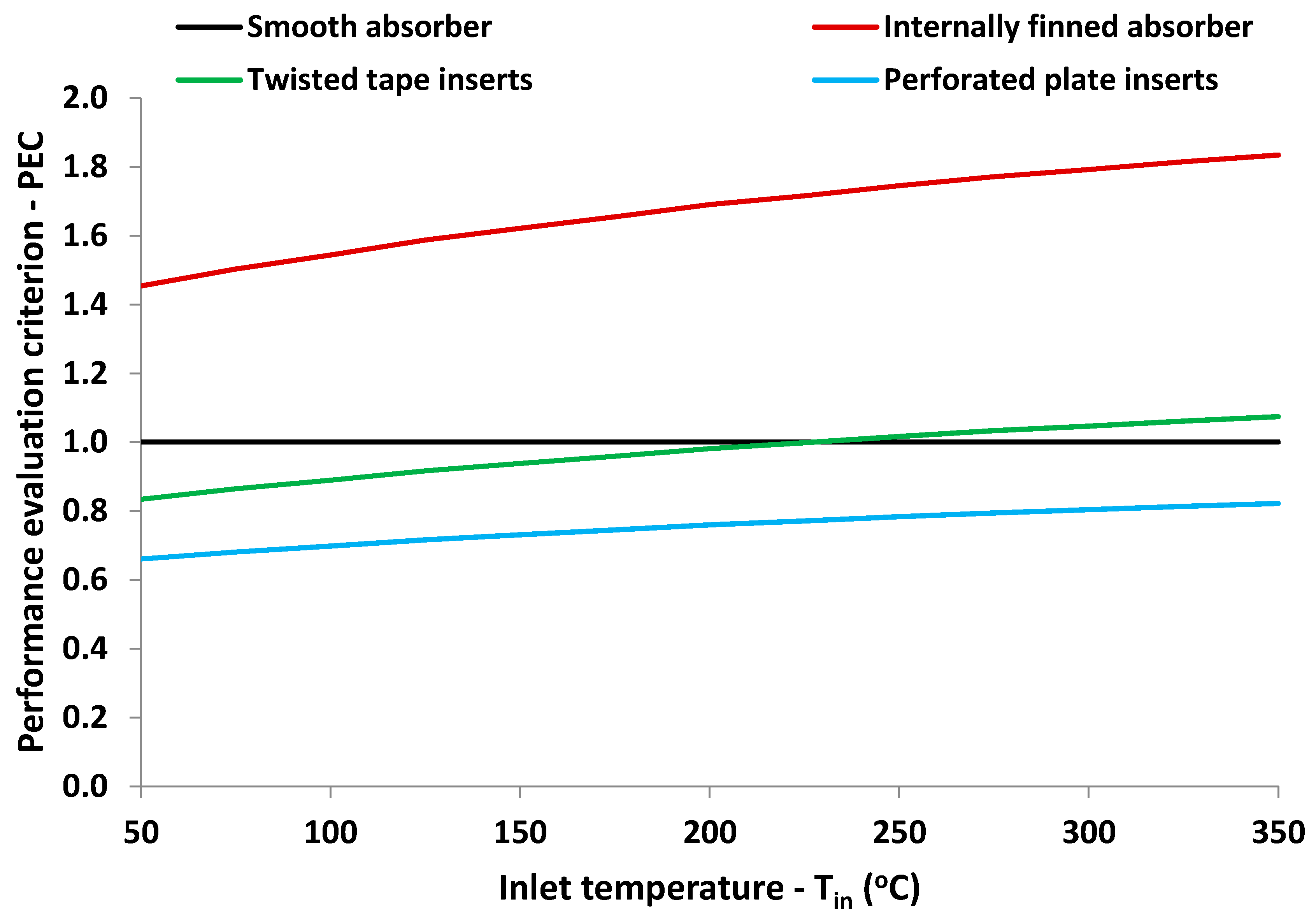

- The thermal enhancements methods lead to a higher friction factor and pumping work demand. The highest pressure drop was found for perforated tape inserts, while the other methods lead to lower pressure drop increases. The exergy and the overall efficiency criteria proved that the increase of the pumping work is not adequate to eliminate the thermal enhancement, and so all of the enhancement methods are effective. On the other hand, the performance evaluation criterion (PEC) showed that the use of internal fins for all the inlet temperatures and the use of twisted tape inserts for inlet temperatures over 225 °C leads to flow enhancement.

Author Contributions

Acknowledgments

Conflicts of Interest

Nomenclature

| A | Area | m2 |

| C | Concentration ratio | - |

| cp | Specific heat capacity under constant pressure | J/kg K |

| D | Diameter | m |

| d | Perforated plate diameter | m |

| E | Exergy rate | W |

| F | Focal distance | m |

| f | Friction factor | - |

| Fg | Geometric parameter | - |

| Gb | Solar direct beam irradiation | W/m2 |

| H | Twisted tape half pitch | m |

| h | Heat transfer coefficient of the flow | W/m2K |

| hin | Convection coefficient between absorber and cover | W/m2K |

| hout | Convection coefficient between cover and ambient | W/m2K |

| K | Incident angle modifier | - |

| keff | Effective thermal conductivity | W/mK |

| k | Thermal conductivity | W/mK |

| L | Tube length | m |

| m | Mass flow rate | kg/s |

| Nu | Nusselt number | - |

| p | Perforated plate spacing | m |

| Pr | Prandtl number | - |

| Q | Heat rate | W |

| q | Fin length | m |

| Ra | Rayleigh number | - |

| Re | Reynolds number | - |

| r | Reflectance | - |

| T | Temperature | oC or K |

| t | Fin thickness | m |

| Tsky | Sky temperature | K |

| Tsun | Sun temperature | K |

| T0 | Reference temperature | K |

| u | Fluid velocity | m/s |

| V | Volumetric flow rate | L/min |

| Vwind | Ambient air velocity | m/s |

| W | Twisted tape width | m |

| Wa | Width | m |

| Wp | Pumping work | W |

Greek Symbols

| α | Absorbance | - |

| β | Slope of the perforated plate | ° |

| ε | Emittance | - |

| ΔP | Pressure drop | Pa |

| ηel | equivalent electrical efficiency | - |

| ηex | Exergy efficiency | - |

| ηopt | Optical efficiency | - |

| ηovr | Overall efficiency | - |

| ηth | Thermal efficiency | - |

| θ | Incident angle | ° |

| μ | Dynamic viscosity | Pa s |

| ρ | Density | kg/m3 |

| σ | Stefan-Boltzmann constant | [=5.67 × 10−8 W/m2K4] |

| τ | Transmittance | - |

Subscripts and Superscripts

| a | aperture |

| air | air inside the receiver |

| am | ambient |

| c | cover |

| ci | cover inner |

| co | outer cover |

| fm | mean fluid |

| in | inlet |

| max | maximum |

| o | reference case |

| out | outlet |

| r | receiver |

| ri | inner receiver |

| ro | receiver outer |

| s | solar |

| u | useful |

Abbreviations

| EES | Engineering equation solver |

| PEC | Performance evaluation criterion |

| PTC | Parabolic trough collector |

References

- Rogada, J.R.; Barcia, L.A.; Martinez, J.A.; Menendez, M.; Juez, F.J.D. Comparative Modeling of a Parabolic Trough Collectors Solar Power Plant with MARS Models. Energies 2018, 11, 37. [Google Scholar] [CrossRef]

- Praveen, R.P.; Baseer, M.A.; Awan, A.B.; Zubair, M. Performance Analysis and Optimization of a Parabolic Trough Solar Power Plant in the Middle East Region. Energies 2018, 11, 741. [Google Scholar] [CrossRef]

- Calise, F.; Capuano, D.; Vanoli, L. Dynamic Simulation and Exergo-Economic Optimization of a Hybrid Solar-Geothermal Cogeneration Plant. Energies 2015, 8, 2606–2646. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Optimization of a Solar-Driven Trigeneration System with Nanofluid-Based Parabolic Trough Collectors. Energies 2017, 10, 848. [Google Scholar] [CrossRef]

- Buonomano, A.; Calise, F.; Palombo, A. Solar heating and cooling systems by absorption and adsorption chillers driven by stationary and concentrating photovoltaic/thermal solar collectors: Modelling and simulation. Renew. Sustain. Energy Rev. 2018, 82, 1874–1908. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Tsimpoukis, D. Thermal, hydraulic and exergetic evaluation of a parabolic trough collector operating with thermal oil and molten salt based nanofluids. Energy Convers. Manag. 2018, 156, 388–402. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. A review of concentrating solar thermal collectors with and without Nanofluids. J. Therm. Anal. Calorim. 2018. [Google Scholar] [CrossRef]

- Kasaeian, A.; Daneshazarian, R.; Mahian, O.; Kolsi, L.; Chamkha, A.J.; Wongwises, S.; Pop, I. Nanofluid flow and heat transfer in porous media: A review of the latest developments. Int. J. Heat Mass Transf. 2017, 107, 778–791. [Google Scholar] [CrossRef]

- Gupta, M.; Singh, V.; Kumar, R.; Said, Z. A review on thermophysical properties of nanofluids and heat transfer applications. Renew. Sustain. Energy Rev. 2017, 74, 638–670. [Google Scholar] [CrossRef]

- Bhakta, A.K.; Panday, N.K.; Singh, S.N. Performance Study of a Cylindrical Parabolic Concentrating Solar Water Heater with Nail Type Twisted Tape Inserts in the Copper Absorber Tube. Energies 2018, 11, 204. [Google Scholar] [CrossRef]

- Too, Y.C.S.; Benito, R. Enhancing heat transfer in air tubular absorbers for concentrated solar thermal applications. Appl. Therm. Eng. 2013, 50, 1076–1083. [Google Scholar] [CrossRef]

- Jaramillo, O.A.; Borunda, M.; Velazquez-Lucho, K.M.; Robles, M. Parabolic trough solar collector for low enthalpy processes: An analysis of the efficiency enhancement by using twisted tape inserts. Renew. Energy 2016, 93, 125–141. [Google Scholar] [CrossRef]

- Mwesigye, A.; Bello-Ochende, T.; Meyer, J.P. Heat transfer and entropy generation in a parabolic trough receiver with wall-detached twisted tape inserts. Int. J. Therm. Sci. 2016, 99, 238–257. [Google Scholar] [CrossRef]

- Ghadirijafarbeigloo, S.H.; Zamzamian, A.H.; Yaghoubi, M. 3-D Numerical Simulation of Heat Transfer and Turbulent Flow in a Receiver Tube of Solar Parabolic Trough Concentrator with Louvered Twisted-tape Inserts. Energy Procedia 2014, 49, 373–380. [Google Scholar] [CrossRef]

- Zhu, X.; Zhu, L.; Zhao, J. Wavy-tape insert designed for managing highly concentrated solar energy on absorber tube of parabolic trough receiver. Energy 2017. [Google Scholar] [CrossRef]

- Chang, C.; Xu, C.; Wu, Z.Y.; Li, X.; Zhang, Q.Q.; Wang, Z.F. Heat Transfer Enhancement and Performance of Solar Thermal Absorber Tubes with Circumferentially Non-uniform Heat Flux. Energy Procedia 2015, 69, 320–327. [Google Scholar] [CrossRef]

- Rawani, A.; Sharma, S.P.; Singh, K.D.P. Enhancement in Performance of Parabolic Trough Collector with Serrated Twisted-tape Inserts. Int. J. Thermodyn. 2017, 20, 111–119. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, Q.; Hu, K.; Hao, J.-H. Flow field optimization for the solar parabolic trough receivers in direct steam generation systems by the variational principle. Int. J. Heat Mass Transf. 2016, 102, 1073–1081. [Google Scholar] [CrossRef]

- Song, X.; Dong, G.; Gao, F.; Diao, X.; Zheng, L.; Zhou, F. A numerical study of parabolic trough receiver with nonuniform heat flux and helical screw-tape inserts. Energy 2014, 77, 771–782. [Google Scholar] [CrossRef]

- Diwan, K.; Soni, M.S. Heat Transfer Enhancement in Absorber Tube of Parabolic Trough Concentrators Using Wire-Coils Inserts. Univers. J. Mech. Eng. 2015, 3, 107–112. [Google Scholar] [CrossRef]

- Şahin, H.M.; Baysal, E.; Dal, A.R.; Şahin, N. Investigation of heat transfer enhancement in a new type heat exchanger using solar parabolic trough systems. Int. J. Hydrog. Energy 2015, 40, 15254–15266. [Google Scholar] [CrossRef]

- Jamal-Abad, M.T.; Saedodin, S.; Aminy, M. Experimental investigation on a solar parabolic trough collector for absorber tube filled with porous media. Renew. Energy 2017, 107, 156–163. [Google Scholar] [CrossRef]

- Wang, P.; Liu, D.Y.; Xu, C. Numerical study of heat transfer enhancement in the receiver tube of direct steam generation with parabolic trough by inserting metal foams. Appl. Energy 2013, 102, 449–460. [Google Scholar] [CrossRef]

- Mwesigye, A.; Bello-Ochende, T.; Meyer, J.P. Heat transfer and thermodynamic performance of a parabolic trough receiver with centrally placed perforated plate inserts. Appl. Energy 2014, 136, 989–1003. [Google Scholar] [CrossRef]

- Mwesigye, A.; Bello-Ochende, T.; Meyer, J.P. Multi-objective and thermodynamic optimisation of a parabolic trough receiver with perforated plate inserts. Appl. Therm. Eng. 2015, 77, 42–56. [Google Scholar] [CrossRef]

- Chang, C.; Sciacovelli, A.; Wu, Z.; Li, X.; Li, Y.; Zhao, M.; Deng, J.; Wang, Z.; Ding, Y. Enhanced heat transfer in a parabolic trough solar receiver by inserting rods and using molten salt as heat transfer fluid. Appl. Energy 2018, 220, 337–350. [Google Scholar] [CrossRef]

- Ghasemi, S.E.; Ranjbar, A.A. Numerical thermal study on effect of porous rings on performance of solar parabolic trough collector. Appl. Therm. Eng. 2017, 118, 807–816. [Google Scholar] [CrossRef]

- Kumar, K.R.; Reddy, K.S. Thermal analysis of solar parabolic trough with porous disc receiver. Appl. Energy 2009, 86, 1804–1812. [Google Scholar] [CrossRef]

- Reddy, K.S.; Kumar, K.R.; Ajay, C.S. Experimental investigation of porous disc enhanced receiver for solar parabolic trough collector. Renew. Energy 2015, 77, 308–319. [Google Scholar] [CrossRef]

- Kumar, K.R.; Reddy, K.S. Effect of porous disc receiver configurations on performance of solar parabolic trough concentrator. Heat Mass Transf. 2012, 48, 555–571. [Google Scholar] [CrossRef]

- Zheng, Z.; Xu, Y.; He, Y.-L. Thermal analysis of a solar parabolic trough receiver tube with porous insert optimized by coupling genetic algorithm and CFD. Sci. China Tech. Sci. 2016, 59, 1475–1485. [Google Scholar] [CrossRef]

- Cheng, Z.D.; He, Y.L.; Cui, F.Q. Numerical study of heat transfer enhancement by unilateral longitudinal vortex generators inside parabolic trough solar receivers. Int. J. Heat Mass Transf. 2012, 55, 5631–5641. [Google Scholar] [CrossRef]

- Gong, X.; Wang, F.; Wang, H.; Tan, J.; Lai, Q.; Han, H. Heat transfer enhancement analysis of tube receiver for parabolic trough solar collector with pin fin arrays inserting. Solar Energy 2017, 144, 185–202. [Google Scholar] [CrossRef]

- Benabderrahmane, A.; Aminallah, M.; Laouedj, S.; Benazza, A.; Solano, J.P. Heat Transfer Enhancement in a Parabolic Trough Solar Receiver using Longitudinal Fins and Nanofluids. J. Therm. Sci. 2016, 25, 410–417. [Google Scholar]

- Reddy, K.S.; Satyanarayana, G.V. Numerical Study of Porous Finned Receiver for Solar Parabolic Trough Concentrator. Eng. Appl. Comput. Fluid Mech. 2008, 2, 172–184. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Daniil, I.; Antonopoulos, K.A. The impact of internal longitudinal fins in parabolic trough collectors operating with gases. Energy Convers. Manag. 2017, 135, 35–54. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Daniil, I. Energetic and exergetic investigation of a parabolic trough collector with internal fins operating with carbon dioxide. Int. J. Energy Environ. Eng. 2017, 8, 109–122. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Daniil, I. Thermal and exergetic evaluation of parabolic trough collectors with finned absorbers operating with air. Proc. Inst. Mech. Eng. Part J. Power Energy 2017. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Tsimpoukis, D. Thermal enhancement of parabolic trough collector with internally finned absorbers. Solar Energy 2017, 157, 514–531. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Tsimpoukis, D. Multi-criteria evaluation of parabolic trough collector with internally finned absorbers. Appl. Energy 2017, 205, 540–561. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Tsimpoukis, D. Optimum number of internal fins in parabolic trough collectors. Appl. Therm. Eng. 2018, 137, 669–677. [Google Scholar] [CrossRef]

- Muñoz, J.; Abánades, A. A technical note on application of internally finned tubes in solar parabolic trough absorber pipes. Solar Energy 2011, 85, 609–612. [Google Scholar] [CrossRef] [Green Version]

- Muñoz, J.; Abánades, A. Analysis of internal helically finned tubes for parabolic trough design by CFD tools. Appl. Energy 2011, 88, 4139–4149. [Google Scholar] [CrossRef] [Green Version]

- Wang, F.; Tang, Z.; Gong, X.; Tan, J.; Han, H.; Li, B. Heat transfer performance enhancement and thermal strain restrain of tube receiver for parabolic trough solar collector by using asymmetric outward convex corrugated tube. Energy 2016, 114, 275–292. [Google Scholar]

- Huang, Z.; Li, Z.-Y.; Yu, G.-L.; Tao, W.-Q. Numerical investigations on fully-developed mixed turbulent convection in dimpled parabolic trough receiver tubes. Appl. Therm. Eng. 2017, 114, 1287–1299. [Google Scholar] [CrossRef]

- Bitam, E.W.; Demagh, Y.; Hachicha, A.A.; Benmoussa, H.; Kabar, Y. Numerical investigation of a novel sinusoidal tube receiver for parabolic trough technology. Appl. Energy 2018, 218, 494–510. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Antonopoulos, K.A.; Gkinis, G. Thermal enhancement of solar parabolic trough collectors by using nanofluids and converging-diverging absorber tube. Renew. Energy 2016, 94, 213–222. [Google Scholar] [CrossRef]

- Huang, Z.; Yu, G.L.; Li, Z.Y.; Tao, W.Q. Numerical study on heat transfer enhancement in a receiver tube of parabolic trough solar collector with dimples, protrusions and helical fins. Energy Procedia 2015, 69, 1306–1316. [Google Scholar] [CrossRef]

- F-Chart Software, Engineering Equation Solver (EES), 2015. Available online: http://www.fchart.com/ees (accessed on 1 February 2018).

- Bellos, E.; Tzivanidis, C.; Antonopoulos, K.A. A detailed working fluid investigation for solar parabolic trough collectors. Appl. Therm. Eng. 2017, 114, 374–386. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. A detailed exergetic analysis of parabolic trough collectors. Energy Convers. Manag. 2017, 149, 275–292. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Antonopoulos, K.A.; Daniil, I. The use of gas working fluids in parabolic trough collectors—An energetic and exergetic analysis. Appl. Therm. Eng. 2016, 109, 1–14. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Thermal efficiency enhancement of nanofluid-based parabolic trough collectors. J. Therm. Anal. Calorim. 2018. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Assessment of the thermal enhancement methods in parabolic trough collectors. Int. J. Energy Environ. Eng. 2017, 9, 59–70. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Thermal analysis of parabolic trough collector operating with mono and hybrid nanofluids. Sustain. Energy Technol. Assess. 2018, 26, 105–115. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Parametric investigation of supercritical carbon dioxide utilization in parabolic trough collectors. Appl. Therm. Eng. 2017, 127, 736–747. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Parametric investigation of nanofluids utilization in parabolic trough collectors. Therm. Sci. Eng. Progress 2017, 2, 71–79. [Google Scholar] [CrossRef]

- Dudley, V.; Kolb, G.; Sloan, M.; Kearney, D. SEGS LS2 solar collector-test results. In Report of Sandia National Laboratories; SAN94-1884; Philogiston Press: Cambridge, MA, USA, 1994. [Google Scholar]

- Forristall, R. Heat Transfer Analysis and Modeling of a Parabolic trough Solar Receiver Implemented in Engineering Equation Solver; National Renewable Energy Laboratory (NREL): Golden, CO, USA; Springfield, VA, USA, 2003.

- Behar, O.; Khellaf, A.; Mohammedi, K. A novel parabolic trough solar collector model—Validation with experimental data and comparison to Engineering Equation Solver (EES). Energy Convers. Manag. 2015, 106, 268–281. [Google Scholar] [CrossRef]

- Available online: https://www.loikitsdistribution.com/files/syltherm-800-technical-data-sheet.pdf (accessed on 1 February 2018).

- Raithby, G.D.; Hollands, K. A general method of obtaining approximate solutions to laminar and turbulent free convection problems. Adv. Heat Transf. 1975, 11, 265–315. [Google Scholar]

- Qiu, Y.; Li, M.-J.; He, Y.-L.; Tao, W.-Q. Thermal performance analysis of a parabolic trough solar collector using supercritical CO2 as heat transfer fluid under non-uniform solar flux. Appl. Therm. Eng. 2017, 115, 1255–1265. [Google Scholar] [CrossRef]

- Bhowmik, N.C.; Mullick, S.C. Calculation of tubular absorber heat loss factor. Solar Energy 1985, 35, 219–225. [Google Scholar] [CrossRef]

- Swinbank, W.C. Long-wave radiation from clear skies. QJR Meteorol. Soc. 1963, 89, 339–340. [Google Scholar] [CrossRef]

- Petela, R. Exergy of undiluted thermal radiation. Solar Energy 2003, 74, 469–488. [Google Scholar] [CrossRef]

- Wirz, M.; Petit, J.; Haselbacher, A.; Steinfeld, A. Potential improvements in the optical and thermal efficiencies of parabolic trough concentrators. Solar Energy 2014, 107, 398–414. [Google Scholar] [CrossRef]

- Hasanpour, A.; Farhadi, M.; Sedighi, K. A review study on twisted tape inserts on turbulent flow heat exchangers: The overall enhancement ratio criteria. Int. Commun. Heat Mass Transf. 2014, 55, 53–62. [Google Scholar] [CrossRef]

- Leinhard, J., IV; Leinhard, J., V. A Heat Tranfer Textbook, 4th ed.; Philogiston Press: Cambridge, MA, USA, 2012. [Google Scholar]

- Moody, L.F. Friction factors for pipe flow. Trans. ASME 1944, 66, 671–684. [Google Scholar]

| Parameter | Symbol | Value |

|---|---|---|

| Module width | Wa | 5.0 m |

| Module length | L | 7.8 m |

| Module focal distance | F | 1.71 m |

| Module aperture | Aa | 39.0 m2 |

| Concentration ratio | C | 22.74 |

| Receiver inner diameter | Dri | 66 × 10−3 m |

| Receiver outer diameter | Dro | 70 × 10−3 m |

| Cover inner diameter | Dci | 109 × 10−3 m |

| Cover outer diameter | Dco | 115 × 10−3 m |

| Cover emittance | εc | 0.860 |

| Maximum optical efficiency | ηopt,max | 0.753 |

| Cover transmittance | τ | 0.935 |

| Absorber absorbance | α | 0.960 |

| Equivalent reflectance | r | 0.826 |

| Parameter | Symbol | Value |

|---|---|---|

| Direct beam irradiation | Gb | 1000 W/m2 |

| Incident angle | θ | 0° |

| Ambient temperature | Tam | 25 °C |

| Wind speed | Vwind | 1 m/s |

| Volumetric flow rate | V | 100 L/min |

| Inlet temperature | Tin | 50 °C–350 °C |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bellos, E.; Tzivanidis, C. Enhancing the Performance of Evacuated and Non-Evacuated Parabolic Trough Collectors Using Twisted Tape Inserts, Perforated Plate Inserts and Internally Finned Absorber. Energies 2018, 11, 1129. https://doi.org/10.3390/en11051129

Bellos E, Tzivanidis C. Enhancing the Performance of Evacuated and Non-Evacuated Parabolic Trough Collectors Using Twisted Tape Inserts, Perforated Plate Inserts and Internally Finned Absorber. Energies. 2018; 11(5):1129. https://doi.org/10.3390/en11051129

Chicago/Turabian StyleBellos, Evangelos, and Christos Tzivanidis. 2018. "Enhancing the Performance of Evacuated and Non-Evacuated Parabolic Trough Collectors Using Twisted Tape Inserts, Perforated Plate Inserts and Internally Finned Absorber" Energies 11, no. 5: 1129. https://doi.org/10.3390/en11051129

APA StyleBellos, E., & Tzivanidis, C. (2018). Enhancing the Performance of Evacuated and Non-Evacuated Parabolic Trough Collectors Using Twisted Tape Inserts, Perforated Plate Inserts and Internally Finned Absorber. Energies, 11(5), 1129. https://doi.org/10.3390/en11051129