Vacuum Exhaust Process in Pilot-Scale Vacuum Pressure Swing Adsorption for Coal Mine Ventilation Air Methane Enrichment

Abstract

1. Introduction

2. Experiment Section

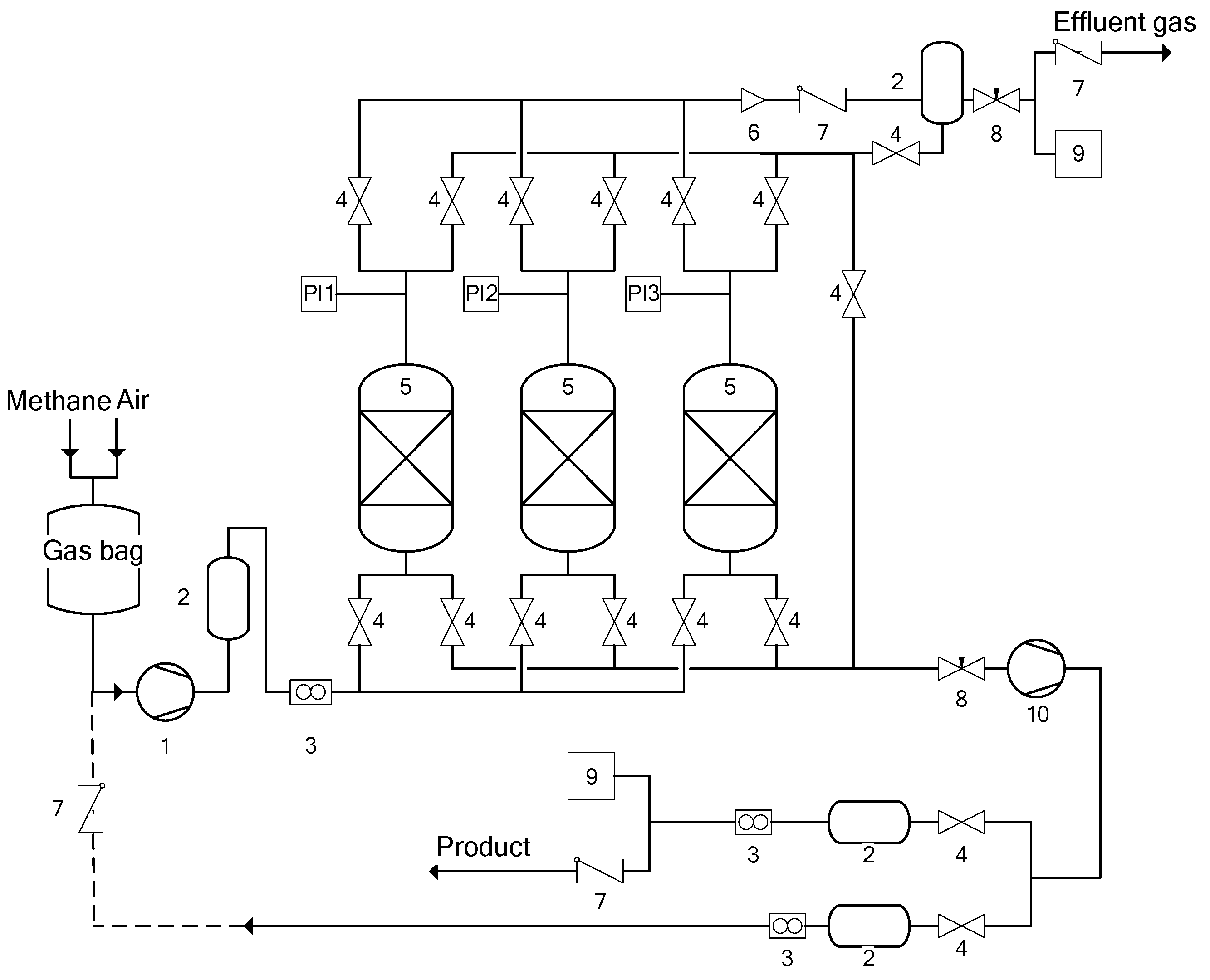

2.1. Experimental Facility

2.2. VPSA Process Cycle

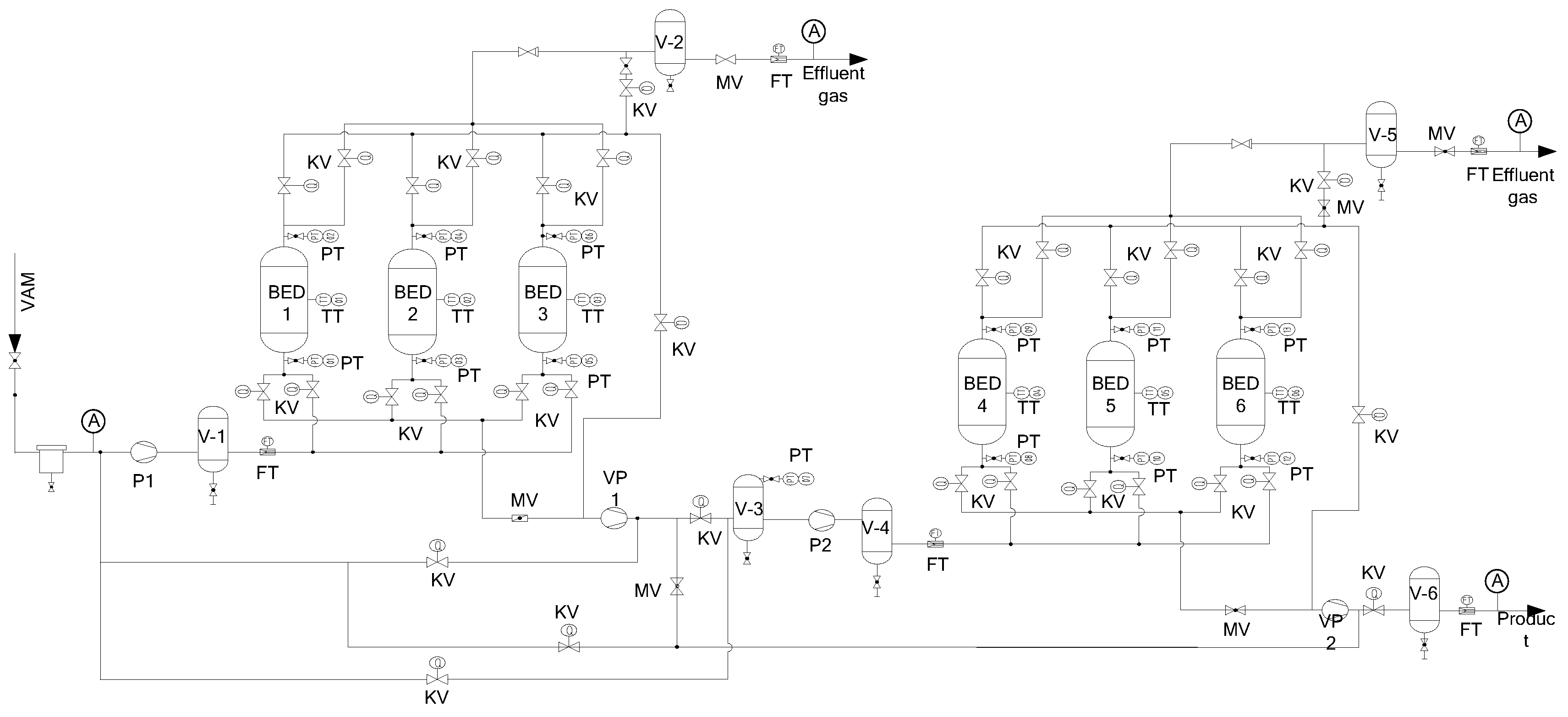

2.3. Pilot Separation Device

2.4. Adsorbent Isotherm Measurement

3. Results and Discussion

3.1. Adsorbent Analyses

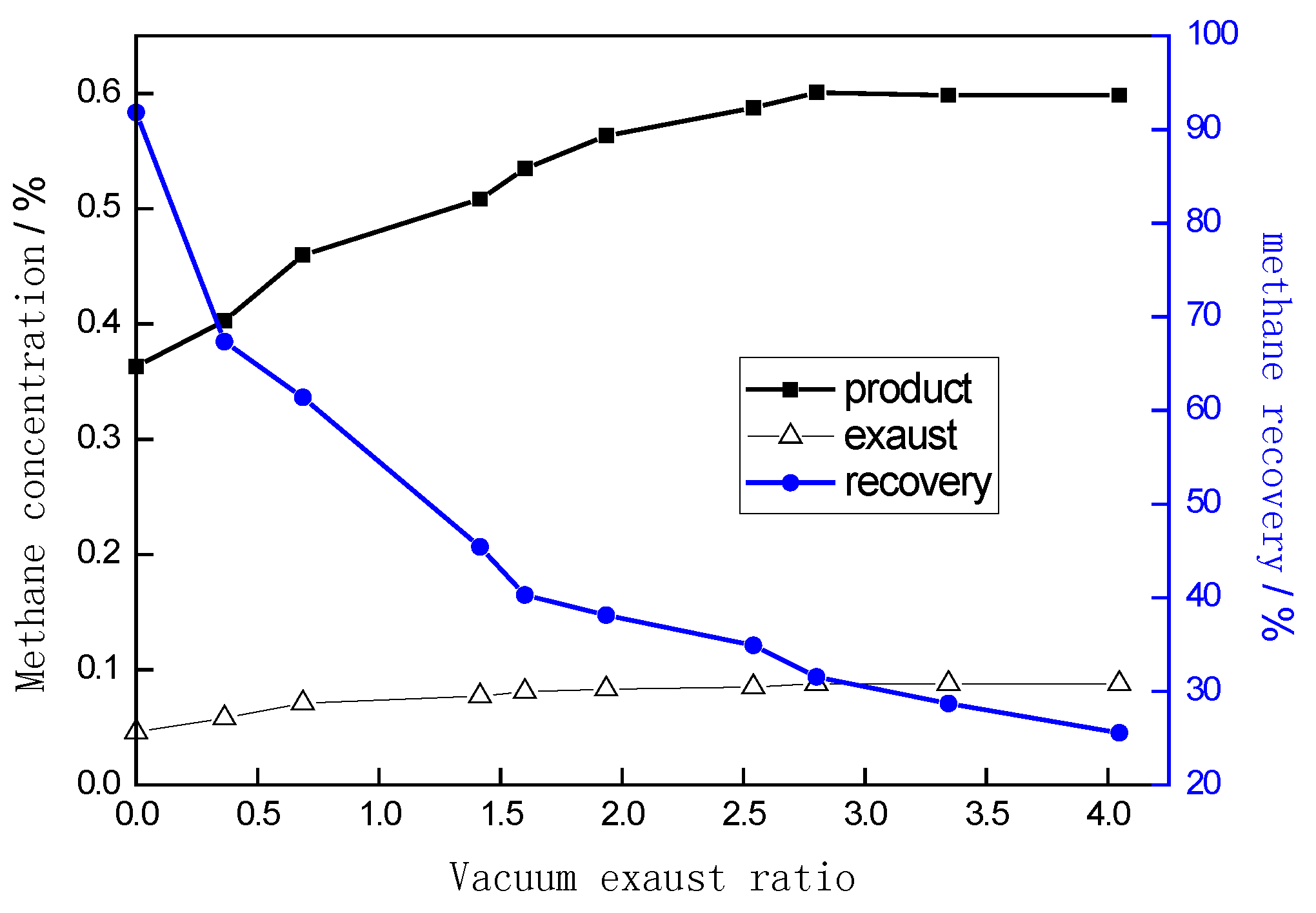

3.2. Effect of Vacuum Exhaust Process on Vacuum Pressure Swing Adsorption Performance

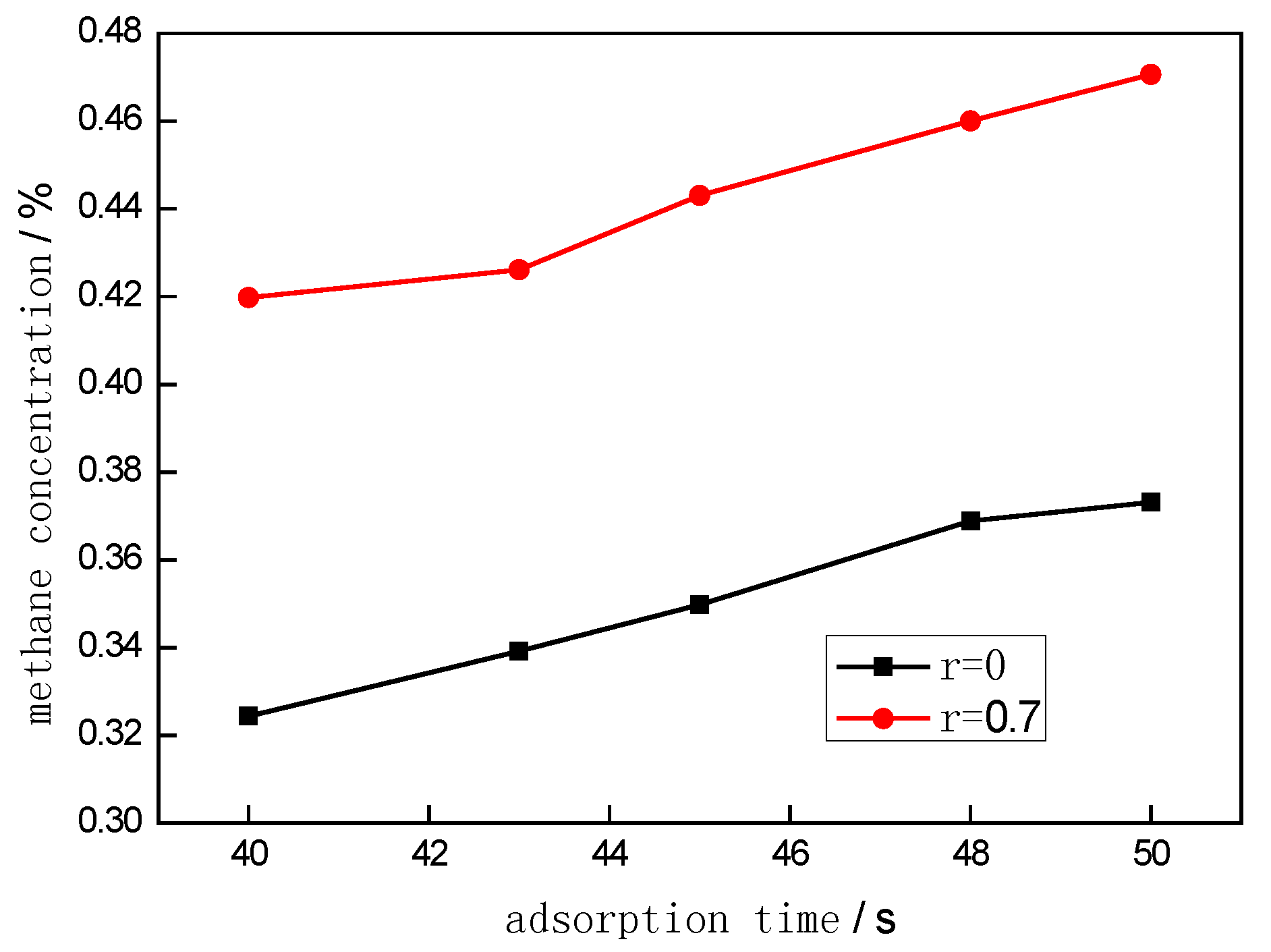

3.3. Effect of Reflow of Exhausted Gas in the Vacuuming Process on Separation Effect

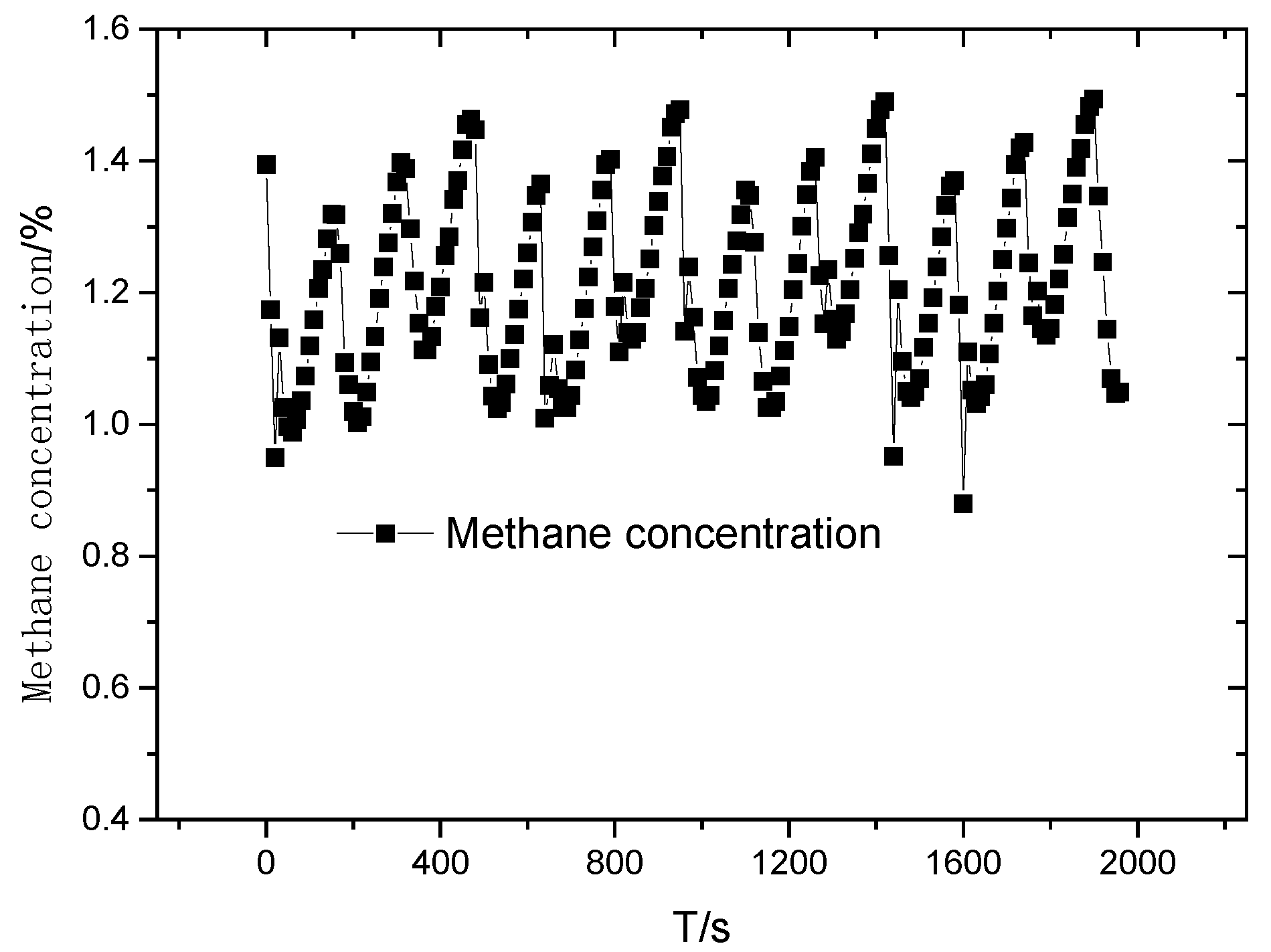

3.4. Application of Vacuum Exhaust Procedure in Pilot-Scale VAM Recovery System

4. Conclusions

- (1).

- The coconut shell activated carbon with equilibrium selectivity of 5.12 was used as the sorbent for VAM recovery. A vacuum exhaust step introduced into the three-bed vacuum pressure swing adsorption (VPSA) process enhanced the methane product purity by 2–3.45 times without changing adsorption and desorption pressure. The concentration of methane in the product increased (from 0.4% to 0.69%) with an increase in the vacuum exhaust ratio (from 0 to 3.1), when the feed gas was 0.2%.

- (2).

- A critical vacuum exhaust ratio may exist and was determined to be 0.7 for this work, below which the product purity was lower in cycle b than in cycle a, and above which, the product purity was enhanced.

- (3).

- A pilot-scale system for VAM enrichment was built and gave results that correlated well with the laboratory results regarding the effects of the vacuum exhaust on gas separation. Practically, VAM with a flow rate of 500 m3/h and concentration of 0.2% can be enriched to more than 1.2%. This could be a reference for VAM utilization by lean-burn combustion turbines technologies.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Tutak, M. Analysis of varying levels of methane emissions from coal mines in Poland. In Proceedings of the SGEM 2017 Vienna GREEN Conference, Vienna, Austria, 27–29 November 2017; Volume 17, pp. 301–308. [Google Scholar]

- Isaksen, I.S.A.; Berntsen, T.K.; Dalsøren, S.B.; Eleftheratos, K.; Orsolini, Y.; Rognerud, B.; Stordal, F.; Søvde, O.A.; Zerefos, C.; Holmes, C.D. Atmospheric ozone and methane in a changing climate. Atmosphere 2014, 5, 518–535. [Google Scholar] [CrossRef]

- Brodny, J.; Tutak, M. Analysis of methane emission into the atmosphere as a result of mining activity. In Proceedings of the SGEM 2016 International Multidisciplinary Scientific Geo Conference: SGEM: Surveying Geology & mining Ecology Management, Sofia, Bulgaria, 28 June–7 July 2016; pp. 83–90. [Google Scholar]

- Su, S.; Agnew, J. Catalytic combustion of coal mine ventilation air methane. Fuel 2006, 85, 1201–1210. [Google Scholar] [CrossRef]

- US EPA. Assessment of the Worldwide Market Potential for Oxidising Coal Mine Ventilation Air Methane; EPA 430-R-03-002; United States Environmental Protection Agency: Washington, DC, USA, 2003. [Google Scholar]

- Cheng, Y.P.; Wang, L.; Zhang, X.L. Environmental impact of coal mine methane emissions and responding strategies in China. Int. J. Greenh. Gas Control 2011, 5, 157–166. [Google Scholar] [CrossRef]

- Kosmack, D. Capture and Use of Coal Mine Ventilation Air Methane; CONSOL Energy Inc. Research & Development: Pittsburgh, PA, USA, 2003. [Google Scholar]

- Kosmack, D.A.; Winschel, R.A.; Zak, K.P.; First, U.S. field trial of oxidation technology for ventilation air methane. In Proceedings of the 1st Annual US Coal Mine Methane Conference, St. Louis, MI, USA, 25–27 September 2007. [Google Scholar]

- Mattus, R. Full Operation—The World’s First VAM Power Plant; MEGTEC Systems Inc.: De Pere, WI, USA, 2008. [Google Scholar]

- Gosiewski, K.; Warmuzinski, K. Effect of the mode of heat withdrawal on the asymmetry of temperature profiles in reverse-flow reactors. Catalytic combustion of methane as a test case. Chem. Eng. Sci. 2007, 62, 2679–2689. [Google Scholar] [CrossRef]

- Warmuzinski, K. Harnessing methane emissions from coal mining. Process Saf. Environ. Prot. 2008, 86, 315–320. [Google Scholar] [CrossRef]

- Su, S.; Yu, X. A 25 kWe low concentration methane catalytic combustion gas turbine prototype unit. Energy 2015, 79, 428–438. [Google Scholar] [CrossRef]

- Su, S.; Beath, A.; Guo, H.; Mallett, C. An assessment of mine methane mitigation and utilization technologies. Prog. Energy Combust. Sci. 2005, 31, 123–170. [Google Scholar] [CrossRef]

- Baris, K. Assessing ventilation air methane (VAM) mitigation and utilization opportunities: A case study at Kozlu Mine, Turkey. Energy Sustain. Dev. 2013, 17, 13–23. [Google Scholar] [CrossRef]

- Olajossy, A.; Gawdzik, A.; Budner, Z.; Dula, J. Methane separation from coal mine methane gas by vacuum pressure swing adsorption. Chem. Eng. Res. Des. 2003, 81, 474–482. [Google Scholar] [CrossRef]

- Olajossy, A. Effective recovery of methane from coal mine methane gas by vacuum pressure swing adsorption: A pilot scale case study. Chem. Eng. Sci. 2013, 1, 46–54. [Google Scholar] [CrossRef]

- Yang, X.; Liu, Y.; Li, Y.; Meng, Y.; Zhang, C.; Yan, J. Safe separation of the low-concentration and oxygen-bearing coal mine methane by vacuum pressure swing adsorption. Adsorpt. Sci. Technol. 2014, 32, 667–679. [Google Scholar] [CrossRef]

- Yang, H.; Yin, C.; Jiang, B.; Zhang, D. Optimization and analysis of a VPSA process for N2/CH4 separation. Sep. Purif. Technol. 2014, 134, 232–240. [Google Scholar] [CrossRef]

- Zhou, Y.; Fu, Q.; Shen, Y.; Sun, W.; Zhang, D.; Li, D.; Yan, H. Upgrade of low-concentration oxygen-bearing coal bed methane by a vacuum pressure swing adsorption process: Performance study and safety analysis. Energy Fuels 2016, 30, 1496–1509. [Google Scholar] [CrossRef]

- Gomes, V.G.; Hassan, M.M. Coalseam methane recovery by vacuum swing adsorption. Sep. Purif. Technol. 2001, 24, 189–196. [Google Scholar] [CrossRef]

- Jayaraman, A.; Hernandez-Maldonado, A.J.; Yang, R.T.; Chinn, D.; Munson, C.L.; Mohr, D.H. Clinoptilolites for nitrogen/methane separation. Chem. Eng. Sci. 2004, 59, 2407–2417. [Google Scholar] [CrossRef]

- Delgado, J.A.; Uguina, M.A.; Sotelo, J.L.; Ruíz, B. Modelling of the fixed-bed adsorption of methane/nitrogen mixtures on silicalite pellets. Sep. Purif. Technol. 2006, 50, 192–203. [Google Scholar] [CrossRef]

- Grande, C.A.; Cavenati, S.; Da Silva, F.A.; Rodrigues, A.E. Carbon molecular sieves for hydrocarbon separations by adsorption. Ind. Eng. Chem. Res. 2005, 44, 7218–7227. [Google Scholar] [CrossRef]

- Thiruvenkatachari, R.; Su, S.; Yu, X.X. Carbon fibre composite for ventilation air methane (VAM) capture. J. Hazard. Mater. 2009, 172, 1505–1511. [Google Scholar] [CrossRef] [PubMed]

- Bae, J.S.; Su, S.; Yu, X.X. Enrichment of ventilation air methane (VAM) with carbon fiber composites. Environ. Sci. Technol. 2014, 48, 6043–6049. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, S.; Xu, S.; Song, N.; Jiao, S. Coconut shell-based carbon adsorbents for ventilation air methane enrichment. Fuel 2013, 113, 420–425. [Google Scholar] [CrossRef]

- Li, Z.; Liu, Y.; Zhang, C.; Yang, X.; Ren, J.; Jiang, L. Methane recovery from coal bed gas using modified activated carbons: A combined method for assessing the role of functional groups. Energy Fuels 2015, 29, 6858–6865. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, X.; Li, Y.; Yang, H.; Zhang, C.; Meng, Y. The experiment study on ventilation air methane enrichment by vacuum pressure swing adsorption. Energy Educ. Sci. Technol. Part A-Energy Sci. Res. 2012, 29, 217–226. [Google Scholar]

- Li, Z.; Liu, Y.; Yang, X.; Xing, Y.; Wang, Z.; Yang, Q.; Yang, R.T. Desorption kinetics of naphthalene and acenaphthene over two activated carbons via thermogravimetric analysis. Energy Fuels 2015, 29, 5303–5310. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Kikkinides, E.S.; Yang, R.T. Response to Comments on Concentration and Recovery of CO2 from Flue-Gas by Pressure Swing Adsorption. Ind. Eng. Chem. Res. 1994, 33, 2881. [Google Scholar] [CrossRef]

- Zhang, J.; Webley, P.A.; Xiao, P. Effect of process parameters on power requirements of vacuum swing adsorption technology for CO2 capture from flue gas. Energy Conver. Manag. 2008, 49, 346–356. [Google Scholar] [CrossRef]

- Ruthven, D.M.; Farooq, S.; Knaebel, K.S. Pressure Swing Adsorption; VCH Publishers Inc.: New York, NY, USA, 1994. [Google Scholar]

- Yang, R.T. Adsorbents: Fundamentals and Applications; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003. [Google Scholar]

- Sircar, S.; Kumar, R. Column dynamics for adsorption of bulk binary gas mixtures on activated carbon. Sep. Sci. Technol. 1986, 21, 919–939. [Google Scholar] [CrossRef]

| Bed A | AD | PE↓ | VE | VA | PE↑ | PR | |||

| Bed B | PE↑ | PR | AD | PE↓ | VE | VA | |||

| Bed C | PE↓ | VE | VA | PE↑ | PR | AD | |||

| Sorbate | 298 K | 308 K | 318 K | |||

|---|---|---|---|---|---|---|

| qm (mmol/g) | b (mmhg−1) | qm (mmol/g) | b (mmhg−1) | qm (mmol/g) | b (mmhg−1) | |

| CH4 | 1.99 | 0.001 | 1.916 | 9.342 × 10−4 | 1.824 | 7.894 × 10−4 |

| N2 | 1.697 | 2.746 × 10−4 | 1.709 | 2.328 × 10−4 | 1.975 | 1.635 × 10−4 |

| Adsorbent | BET Surface/(m2/g) | Pore Volume/(cc/g) |

|---|---|---|

| AC | 1155 | 0.67 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Liu, Y.; Li, Z.; Zhang, C.; Xing, Y. Vacuum Exhaust Process in Pilot-Scale Vacuum Pressure Swing Adsorption for Coal Mine Ventilation Air Methane Enrichment. Energies 2018, 11, 1030. https://doi.org/10.3390/en11051030

Yang X, Liu Y, Li Z, Zhang C, Xing Y. Vacuum Exhaust Process in Pilot-Scale Vacuum Pressure Swing Adsorption for Coal Mine Ventilation Air Methane Enrichment. Energies. 2018; 11(5):1030. https://doi.org/10.3390/en11051030

Chicago/Turabian StyleYang, Xiong, Yingshu Liu, Ziyi Li, Chuanzhao Zhang, and Yi Xing. 2018. "Vacuum Exhaust Process in Pilot-Scale Vacuum Pressure Swing Adsorption for Coal Mine Ventilation Air Methane Enrichment" Energies 11, no. 5: 1030. https://doi.org/10.3390/en11051030

APA StyleYang, X., Liu, Y., Li, Z., Zhang, C., & Xing, Y. (2018). Vacuum Exhaust Process in Pilot-Scale Vacuum Pressure Swing Adsorption for Coal Mine Ventilation Air Methane Enrichment. Energies, 11(5), 1030. https://doi.org/10.3390/en11051030