Assessment of Collective Production of Biomethane from Livestock Waste for Urban Transportation Mobility in Brazil and the United States

Abstract

:1. Introduction

2. Motivation and Problem Formulation

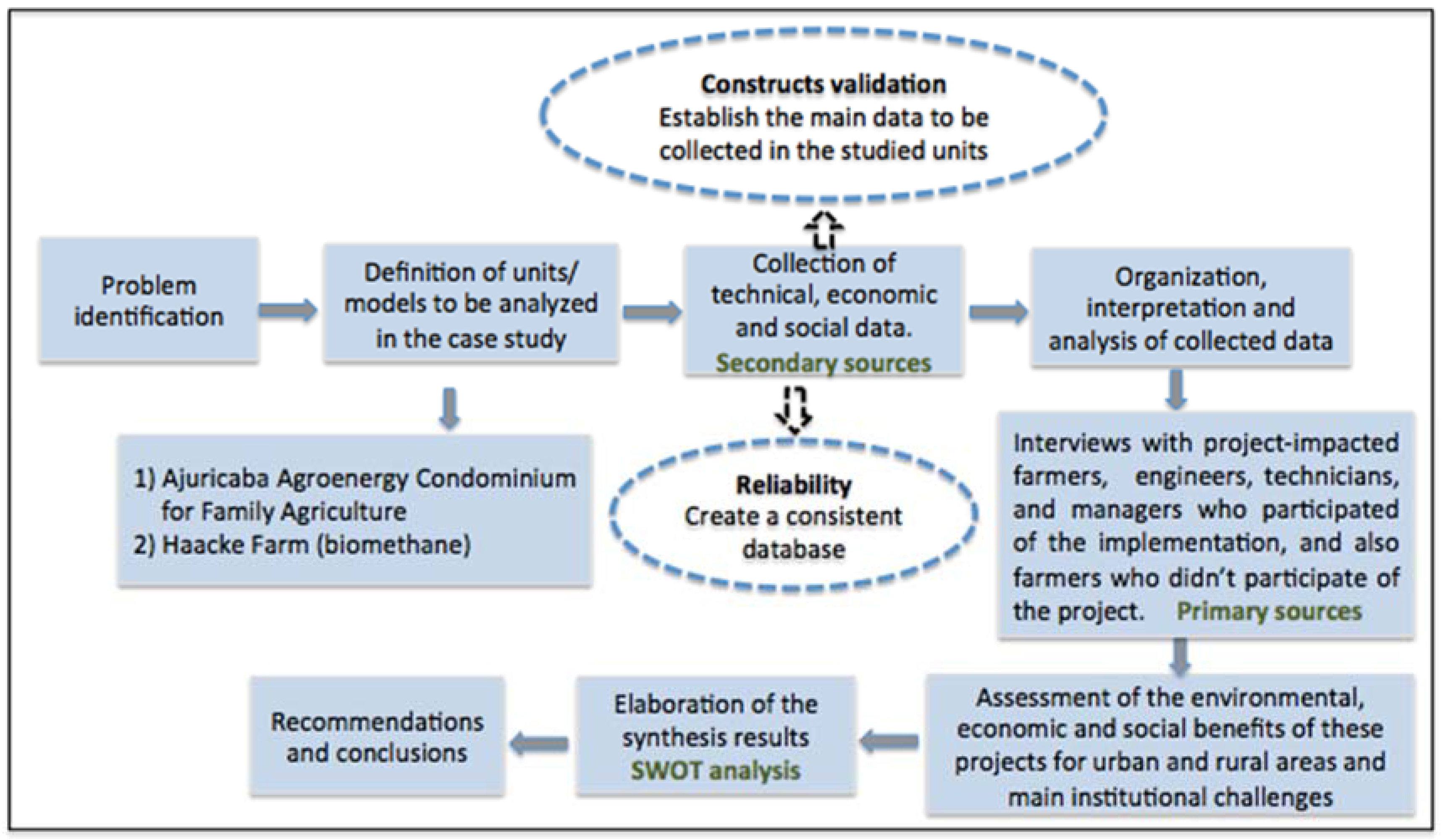

3. Methods and Materials

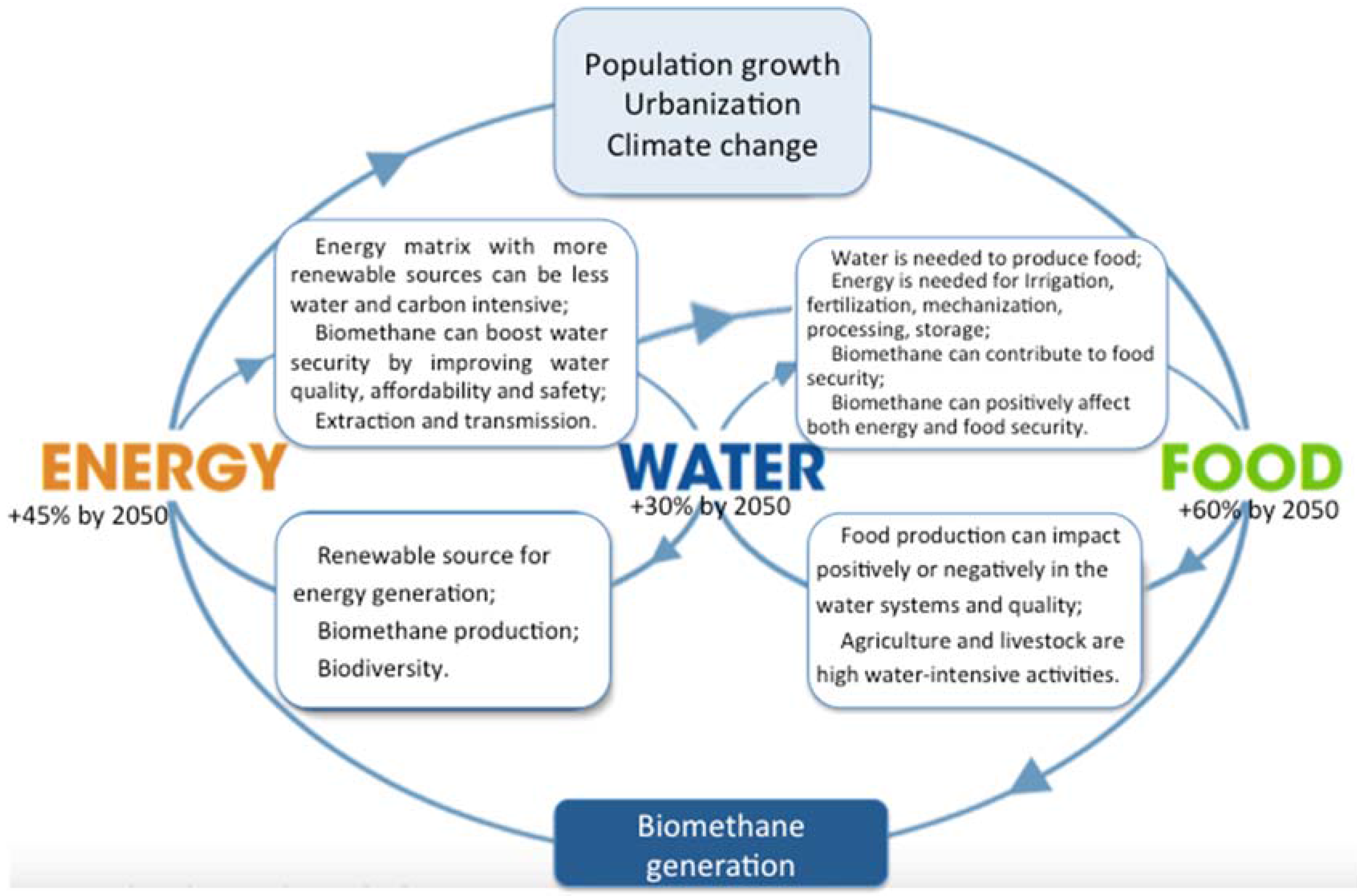

4. Water–Energy–Food Trade-Offs and Synergies of Biomethane

4.1. Biomethane Potential for Brazil and the U.S.

4.2. Collective Production of Biomethane Perspectives and Applications for Brazil and the U.S.

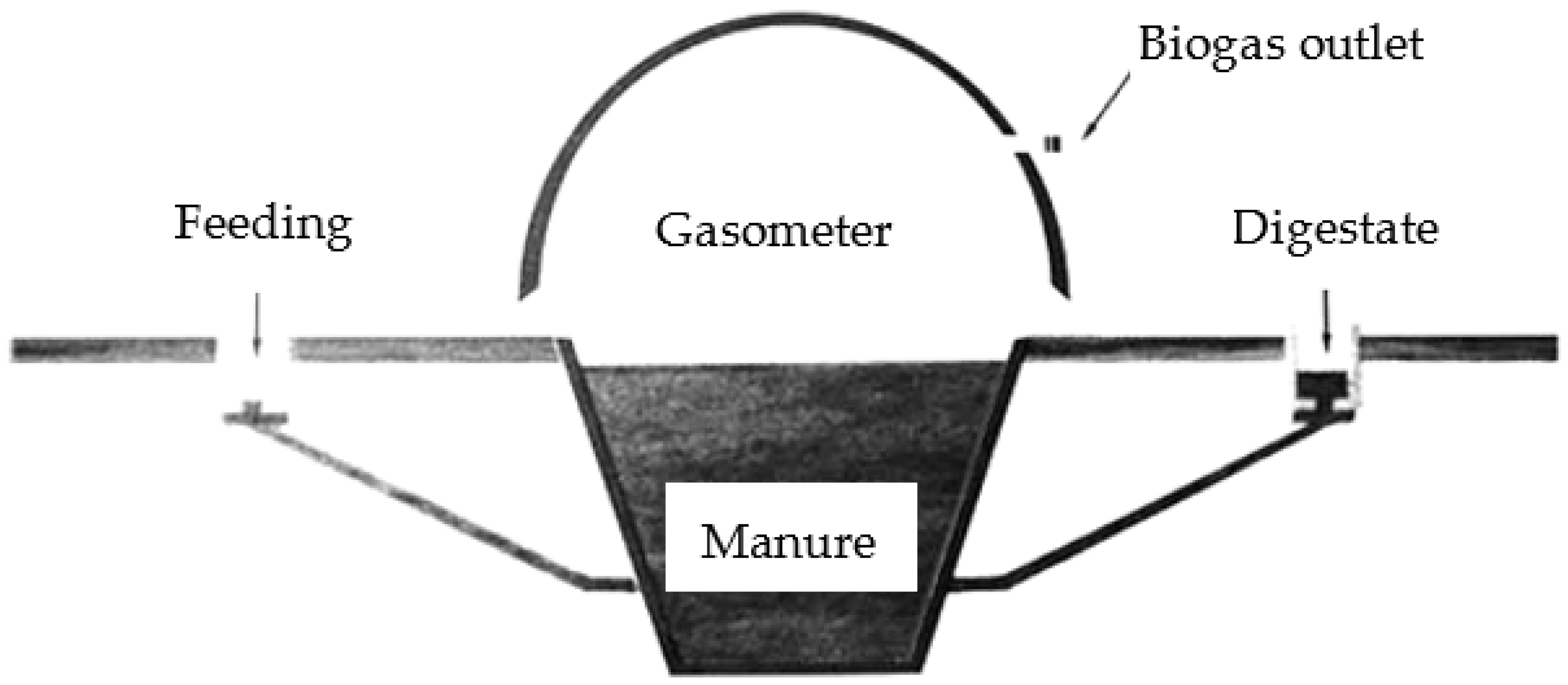

4.3. Ajuricaba Case Study: Agroenergy Condominium as a Technical and Social Innovation

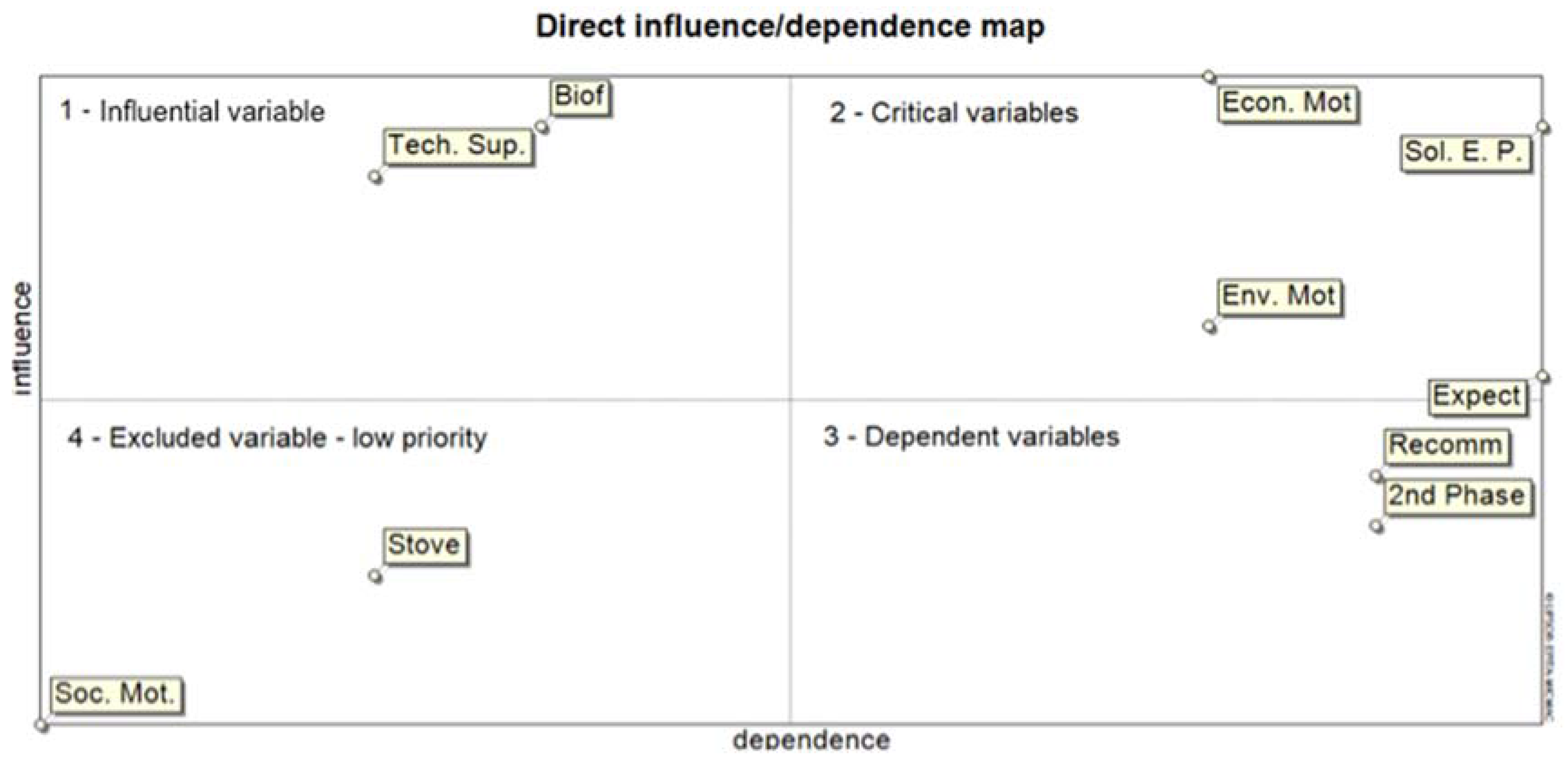

- Environmental motivation to participate in the project (Env. Mot.)

- Social motivation to participate (Social Mot.)

- Economic motivation to participate (Econ. Mot.)

- Willingness to participate in the second phase of the project and commercialize biogas (2nd Phase)

- Possibility to solve environmental problems (Sol. E.P.)

- Possibility to use biogas to cook (Stove)

- Possibility to produce a biofertilizer (Biof.)

- Possibility to have specialized technical support (Tech. Sup.)

- Possibility to meet your expectations and needs (Expec.)

- Recommendation to your neighbor to participate of the project (Recomm.).

5. Findings and Results Discussion

- (1)

- Opportunities

- (a)

- Environmental: With projections of livestock production increases in the coming years, the proper treatment of waste is essential, strengthening the need to use biogas and biomethane systems; promotion of synergies between the water–energy–food nexus; water and soil quality enhance though anaerobic digestion; environmental sanitation in the properties that compose the condominium and the region where it is located; reduction of pathogenic vectors; better spatial organization of the farms and cleanliness; reduction of GHG emissions with the biogas system and also with the optimized logistics proposed in agroenergy condominiums; stimulate the less dependence on fossil fuels and vulnerability to depend only in few sources of energy; and environmental awareness and better joint action of communities.

- (b)

- Economic: This type of arrangement boosts the importance of family farming, that is very representative in Brazil and the U.S., augmenting their financial health and perspectives for new investments in the property; use of electric, thermic and vehicular energies for self consumption in the farms and sale of the surplus for local companies; use of biofertilizer for increasing agricultural production, increasing the project’s viability, since is produced more with less investment; economy with the use of biogas stove, replacing the use of LPG; and development and creation of national technologies to replace imported ones, strengthening national companies. This issue is linked to the circular economy concept, which means that resource input and waste, emission, and energy leakage are minimized by slowing, closing, and narrowing material and energy loops; valuing waste, through biogas and biomethane generation processes, raises investments in this source of energy.

- (c)

- Social: It strengthenx family farming production and attractiveness of farmers to stay in the field due to the project. The inclusion of biogas technologies creates changes in the routine and attracts discovery and technological innovation, favoring the inclusion of new generations (children) in the routine of family agriculture, including, encouraging entrepreneurship in the specialized biogas services sector; associative work; creation of a biogas association; adding importance to women’s role to convince their husbands to participate actively in the project; better quality of life in their properties; reduction of bad smell and pathogenic vectors, such as flies and insects; and introduction of biogas management in the farmer’s routine, increasing their awareness about the environment.

- (d)

- Institutional: Alliance of expert companies that act in inter-related sectors of biogas production chain develop the most suitable management, based on their knowledge and expertise; biomethane management solutions to implement in future condominiums or projects; learning about managing different interests of people and companies; management challenges and solutions for being an innovative project; and the technologies implemented have known limits now, facilitating the replication of the condominium in other places and providing more credibility to the involved companies. Repetition of experiences even creates elements and validations for creating credit lines and financing family farming.

- (e)

- Technological: During the implementation of the agroenergy condominium, many technologies and processes were improved and even created, such as the small-scale fiberglass biodigestor that was installed according to the specific situation and type of manure of the properties; the installation of an extensive low pressure biogas collection network (25.5 km) was a new technology in Brazil and worldwide; development of national technology to replace imported ones; and the technologies implemented have known limits now, facilitating the replication in other places and improving the products even more. Among these bottlenecks are the cost of volume measurement and biogas and biomethane compression technologies. Biogas and biomethane is the renewable source that most closely resembles hydraulic energy, as it can be stored and dispatched continuously and, unlike solar and wind sources, they provide uninterrupted input into the grid. In recent years, some regulations for biomethane were stablished in Brazil and the U.S., stimulating the use of this source of energy. The development of the project encourages the public discussion of the solution and creation of standards and parameters of quality and safety.

- (2)

- Challenges

- (a)

- Environmental: A very detailed study of the types and quantities of waste generated in each property at the design stage of the agroenergy condominium is necessary, so that the project is implemented under the right conditions and without significative estimate variations; need of efficient corrective and preventive maintenance of the biogas system to avoid environmental problems and impacts; and importance of daily monitoring procedures to evaluate the results and detect possible disruptions.

- (b)

- Economic: The farmers who participated in the pilot project recommended a small financial involvement of farmers for future projects, so they can valorize the project and be more responsible for their results. As a Research and Development funded project, it was designed to develop new technologies, not to generate profit, but for future condominiums a profit forecast is necessary. The challenge is to find the relationship between investment and results; the main driver of biomethane penetration in the fuel market is the fuel cost, compared to fossil fuels, which requires incentives and public polices; cheap and abundant natural gas has made it difficult for biomethane and other renewable technologies to compete with fossil fuels; and the cost of equipment and their service life need to be seriously taking into account, as some of them did not work as expected and needed to be replaced, such as the compressors.

- (c)

- Social: At the outreach and promotion phase of the project, it is recommended to deeply evaluate the farmer’s vocation to participate in this kind of arrangement—some farmer’s actions and commitment were below expectation in the pilot project and some of them did not understand their important role to obtain results for the collective. The communication with farmers need to be frequent and clear, so they can trust in the project. It is advisable to develop contracts or terms of commitment after the promotion phase. The key of this phase is that the expectations of the participants are adequately managed. Another important point is that there should be a timetable to be disseminated and respected, and if changes are needed, these should be widely disseminated among all farmers. Social gains (such as collaborative work and increasing knowledge) are not so valorized as economic gains, so this appeal must be reinforced. Farmers nee training and motivation to obtain better results and encourage them to work as a team. It was difficult for producers to act in an associative way.

- (d)

- Institutional: Diffuse interests of the partners are a crucial point in the project, so the involved companies need to clearly establish their role and responsibilities and create a good synergy; it is essential that suppliers are as close as possible to the condominium, as it strengthens the local economy and gives a better application of regional development; efficient technical assistance is necessary, demanding organization and commitment from the involved staff; the high turnover of technicians and involved suppliers ends up weakening the farmer’s reliability; the lack of specific regulations for rural biogas collection networks added difficulty to the project operation, as today it only exists for large scale; and the lack of state-level mechanisms, for example “feed-in tariff,” which is a policy mechanism designed to accelerate investment in renewable energy technologies.

- (e)

- Technological: During the project implementation, technological limitations were identified, such as difficulties to operate the micro thermoelectric central and low performance of the original moto-generator for electricity generation; some materials did not correspond to their purposes, needing to be replaced; importance of a detailed project design, as biogas production was overestimated at the beginning, not considering temperature variations and sanitary void. Regarding the anaerobic reactors, it is necessary to incorporate technological devices to keep temperature in the optimal mesophilic conditions (35 °C) during the entire year. A mixing strategy needs to be added to improve hydraulic flow and, thus, increase the methane production and reduce the necessity of periodic sludge removal. Moreover, frequent scientific investigations about new types of biomass, including agricultural waste, need to be developed to take advantage of the existing facilities and, thus, improve the biogas yield of the farm.

Use of Biomethane for Urban Mobility and Reduction of Fossil Fuel Dependence

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- United Nations. Department of Economic and Social Affairs, Population Division (UNDESA). World Population Prospects: The 2015 Revision, Key Findings and Advance Tables; Working Paper No. ESA/P/WP.241; United Nations: New York, NY, USA, 2015.

- Akhbari, M.; Grigg, N.S.; Waskom, R. Water-Energy-Food Nexus: Compelling Issues for Geophysical Research; Abstract #H23T-07; American Geophysical Union: Washington, DC, USA, 2014. [Google Scholar]

- United Nations Water. Water for Food. 2015. Available online: http://www.un.org/waterforlifedecade/food_security.shtml (accessed on 13 October 2017).

- World Bank. Population 2015. 2015. Available online: http://databank.worldbank.org/data/download/POP.pdf (accessed on 22 September 2017).

- Food and Agriculture Organization of the United Nations (FAO). The Water-Energy-Food Nexus: A New Approach in Support of Food Security and Sustainable Agriculture. 2014. Available online: http://www.fao.org/nr/water/docs/FAO_nexus_concept.pdf (accessed on 26 September 2017).

- United States Energy Information Administration (EIA). USA Energy in Brief. 2015. Available online: http://www.eia.gov/energy_in_brief/article/major_energy_sources_and_users.cfm (accessed on 28 October 2017).

- Central Intelligence Agency. Total Renewable Water Resources. 2011. Available online: https://www.cia.gov/library/publications/the-world-factbook/fields/2201.html (accessed on 5 October 2017).

- Kunz, A.; de Oliveira, P.A.V. Aproveitamento de dejetos de animais para geração de biogás. J. Polít. Agríc. 2006, 15, 28–35. [Google Scholar]

- Ministry of Agriculture Livestock and Food Supply. Suinocultura de Baixa Emissão de Carbono. Available online: http://www.agricultura.gov.br/assuntos/sustentabilidade/plano-abc/suinocultura-abc/publicacoes-de-suinocultura/levantamento-de-tecnologias-de-tratamento-de-dejetos-para-suinocultura-de-pequeno-porte.pdf (accessed on 5 November 2017).

- Souza, M.; Schneider, A.H. Opportunities of the Biogas Production Chain for the State of Paraná. 2016. Available online: http://www.fiepr.org.br/observatorios/download-Oportunidades-da-cadeia-produtiva-de-biogas-para-o-estado-do-parana-1-19295-319478.shtml (accessed on 10 November 2017).

- Kish, L. Survey Sampling; Wiley Classics Library: New York, NY, USA, 1995. [Google Scholar]

- Polacinski, E. Godet Strategic Foresight: Application Process for Local Productive Arrangements. Ph.D. Thesis, Federal University of Santa Catarina, Florianópolis, Brazil, 2011. [Google Scholar]

- Godet, M. From Antecipation to Action: A Handbook of Strategic Prospective; UNESCO: Paris, France, 1993. [Google Scholar]

- Humphrey, A. SWOT Analysis for Management Consulting. SRI Alumni Newsletter, 2005. Available online: https://www.sri.com/sites/default/files/brochures/dec-05.pdf (accessed on 15 May 2017).

- Water, Food and Energy. Available online: http://www.unwater.org/water-facts/water-food-and-energy/ (accessed on 7 November 2017).

- U.S. Energy Information Administration (EIA). Different Types of Energy Sources (or Fuels) Are Used for Transportation in the United States. 2016. Available online: http://www.eia.gov/energyexplained/?page=us_energy_transportation (accessed on 4 May 2017).

- United States Environmental Protection Agency (USEPA). Greenhouse Gas Equivalencies Calculator. 2017. Available online: https://www.epa.gov/energy/greenhouse-gas-equivalencies-calculator (accessed on 20 October 2017).

- Curitiba Urbanization Company (URBS). Transporte Coletivo Urbano. 2017. Available online: https://www.urbs.curitiba.pr.gov.br/institucional/urbs-em-numeros (accessed on 22 November 2017).

- Iniciativa Verde. Emissions Calculator. 2017. Available online: http://www.iniciativaverde.org.br/calculadora/index.php#coletivo (accessed on 22 November 2017).

- Pasqual, J.C.; Bollmann, H.A.; Scott, C.A. Biogas Perspectives in Livestock Sector in Brazil and the United States: Electric, Thermal and Vehicular Energy Use. J. Agric. Sci. Technol. 2017, 7, 258–273. [Google Scholar] [CrossRef]

- Brazilian Company of Energy Research (EPE). Statistical Yearbook of Electricity 2015. 2015. Available online: http://www.epe.gov.br/AnuarioEstatisticodeEnergiaEletrica/Forms/Anurio.aspx (accessed on 12 May 2017).

- Organization for Economic Co-Operation and Development (OECD). Carbon Dioxide Equivalent. 2016. Available online: https://stats.oecd.org/glossary/detail.asp?ID=285 (accessed on 19 September 2017).

- Energy Research Company (EPE). National Energy Balance 2016. Available online: https://ben.epe.gov.br/downloads/S%C3%ADntese%20do%20Relatório%20Final_2016_Web.pdf (accessed on 10 August 2017).

- American Gas Foundation. The Potential for Renewable Natural Gas: Biogas Derived from Biomass Feedstocks. 2011. Available online: http://www.gasfoundation.org/researchstudies/agf-renewable-gas-assessment-report-110901.pdf (accessed on 10 November 2017).

- United States Department of Agriculture (USDA). 2012 Census of Agriculture. 2012. Available online: https://www.agcensus.usda.gov/Publications/2012/ (accessed on 10 November 2017).

- Ministry of Agriculture Livestock and Food Supply. Agribusiness Projections until 2026. 2017. Available online: http://www.agricultura.gov.br/assuntos/politica-agricola/todas-publicacoes-de-politica-agricola/projecoes-do-agronegocio/projecoes-do-agronegocio-2017-a-2027-versao-preliminar-25-07-17.pdf (accessed on 15 November 2017).

- Ministry of Mines and Energy (MME). RenovaBio. 2017. Available online: http://www.mme.gov.br/web/guest/secretarias/petroleo-gas-natural-e-combustiveis-renovaveis/programas/renovabio/diretrizes (accessed on 24 November 2017).

- National Agency of Petroleum, Natural Gas and Biofuels (ANP). Resolution No. 8 from ANP. 2015. Available online: https://www.legisweb.com.br/legislacao/?id=280722 (accessed on 25 November 2017).

- Ministry of the Environment. Sustainable Mobility. 2017. Available online: http://www.mma.gov.br/cidades-sustentaveis/urbanismo-sustentavel/mobilidade-sustentável (accessed on 10 September 2017).

- United States Environmental Protection Agency (EPA). The Energy Independence and Security Act (EISA) of 2007. 2007. Available online: https://www.epa.gov/laws-regulations/summary-energy-independence-and-security-act (accessed on 19 December 2017).

- California Legislative Information. AB-1900 Renewable Energy Resources: Biomethane. 2012. Available online: https://leginfo.legislature.ca.gov/faces/billTextClient.xhtml?bill_id=201120120AB1900 (accessed on 7 October 2017).

- University of California. Renewable Energy Resource, Technology, and Economic Assessments. 2017. Available online: http://www.energy.ca.gov/2017publications/CEC-500-2017-007/CEC-500-2017-007-APH.pdf (accessed on 25 September 2017).

- California Energy Commission. Renewable Energy Program: Overall Program Guidebook—Seventh Edition. 2013. Available online: http://www.energy.ca.gov/2013publications/CEC-300-2013-008/CEC-300-2013-008-ED6-CMF.pdf (accessed on 12 October 2017).

- California Energy Commission. Renewable Energy Program: Overall Program Guidebook—Eighth Edition. 2015. Available online: http://www.energy.ca.gov/2015publications/CEC-300-2015-001/CEC-300-2015-001-ED8-CMF.pdf (accessed on 15 October 2017).

- Brazilian Institute of Geography and Statistics (IBGE). Censo Agro 2006: IBGE Revela Retrato do Brasil Agrário. 2006. Available online: https://agenciadenoticias.ibge.gov.br/agencia-sala-de-imprensa/2013-agencia-de-noticias/releases/13719-asi-censo-agro-2006-ibge-revela-retrato-do-brasil-agrario.html (accessed on 10 November 2017).

- Brazilian Agricultural Research Corporation (EMBRAPA). Swine Treatment System. Available online: http://www.cnpsa.embrapa.br/invtec/09.html (accessed on 26 March 2018).

- Ferrer, P.; Cambra-López, M.; Cerisuelo, A.; Peñaranda, D.; Moset, V. The use of agricultural substrates to improve methane yield in anaerobic co-digestion with pig slurry: Effect of substrate type and inclusion level. Waste Manag. 2014, 34, 196–203. [Google Scholar] [CrossRef] [PubMed]

- Yin, F.; Dong, H.; Ji, C.; Tao, X.; Chen, Y. Effects of anaerobic digestion on chlortetracycline and oxytetracycline degradation efficiency for swine manure. Waste Manag. 2016, 56, 540–546. [Google Scholar] [CrossRef] [PubMed]

- Borowski, S.; Domanski, J.; Weatherley, L. Anaerobic co-digestion of swine and poultry manure with municipal sewage sludge. Waste Manag. 2008, 34, 513–521. [Google Scholar] [CrossRef] [PubMed]

- Sánchez, M.; Gomez, X.; Barriocanal, G.; Cuetos, M.J.; Morán, A. Assessment of the stability of livestock farm wastes treated by anaerobic digestion. Int. Biodeterior. Biodegrad. 2008, 62, 421–426. [Google Scholar] [CrossRef]

- Kafle, G.K.; Chen, L. Comparison on batch anaerobic digestion of five different livestock manures and prediction of biochemical methane potential (BMP) using different statistical models. Waste Manag. 2016, 48, 492–502. [Google Scholar] [CrossRef] [PubMed]

- Luste, S.; Loustarinen, S. Enhanced methane production from ultrasound pre-treated and hygienized dairy cattle slurry. Waste Manag. 2011, 31, 2174–2179. [Google Scholar] [CrossRef] [PubMed]

- Bujoczek, G.; Oleszkiewicz, J.; Cenkowski, S. High solid anaerobic digestion of chicken manure. J. Agric. Eng. Res. 2000, 76, 51–60. [Google Scholar] [CrossRef]

- International Center of Biogas (CIBIOGÁS). The First Brazilian Family Farming Community Producing Electric and Thermal Energies, and Biofertizers with Biogas. 2016. Available online: https://cibiogas.org/en/ajuricaba_unit (accessed on 14 June 2017).

- Vega, R.P. Ciudadanía ambiental global: Un recorte analítico para el estudio de la sociedad civil transnacional. J. Espiral. 2006, 12, 149–172. Available online: http://www.scielo.org.mx/scielo.php?pid=S1665-05652006000100006&script=sci_abstract (accessed on 27 May 2017).

- Energy Research Company (EPE). National Energy Balance 2017. Available online: https://ben.epe.gov.br/downloads/Relatorio_Final_BEN_2017.pdf (accessed on 8 January 2018).

- ENGIE. Natural Gas, LNG, Biomethane: How do They Differ? 2017. Available online: http://www.engie.com/en/news/natural-gas-lng-biomethane-hydrogen/ (accessed on 23 August 2017).

- European Union. Well-to-Wheels Report Version 4.a. 2014. Available online: http://iet.jrc.ec.europa.eu/about-jec/sites/iet.jrc.ec.europa.eu.about-jec/files/documents/wtw_report_v4a_march_2014_final.pdf (accessed on 20 August 2017).

- National Renewable Energy Laboratory (NREL). Emissions Associated with Electric Vehicle Charging: Impact of Electricity Generation Mix, Charging Infrastructure Availability, and Vehicle Type. 2016. Available online: https://www.afdc.energy.gov/uploads/publication/ev_emissions_impact.pdf (accessed on 18 May 2017).

- International Center of Biogas (CIBiogás). Biogas Projects. 2017. Available online: https://cibiogas.org/quem_somos (accessed on 26 May 2017).

| Description | Brazil | US |

|---|---|---|

| Biogas production (million m3/year) 1,2 | 11,421.3 | 29,866.0 |

| Biomethane potential (million gallons/year) 3 | 1,961,171.9 | 5,128,344.6 |

| Diesel potential (million gallons/year) | 1667.42 | 4360.21 |

| Gasoline potential (million gallons/year) | 1848.34 | 4883.29 |

| Passenger-miles driven per year with biomethane [17] | 3,516,740 | 9,197,189 |

| Total passenger-miles driven by passenger vehicle [17] | 40,252,882,353 | 105,271,742,642 |

| Number of buses powered per year 4 [18] | 147,363 | 385,347 |

| Number of people transported per year 5 | 63,033,521,206 | 164,829,130,933 |

| CO2 emissions reduction per year (kg of CO2 eq) [19] 6 | 28,423,983 | 74,327,145 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pasqual, J.C.; Bollmann, H.A.; Scott, C.A.; Edwiges, T.; Baptista, T.C. Assessment of Collective Production of Biomethane from Livestock Waste for Urban Transportation Mobility in Brazil and the United States. Energies 2018, 11, 997. https://doi.org/10.3390/en11040997

Pasqual JC, Bollmann HA, Scott CA, Edwiges T, Baptista TC. Assessment of Collective Production of Biomethane from Livestock Waste for Urban Transportation Mobility in Brazil and the United States. Energies. 2018; 11(4):997. https://doi.org/10.3390/en11040997

Chicago/Turabian StylePasqual, Janaina Camile, Harry Alberto Bollmann, Christopher A. Scott, Thiago Edwiges, and Thais Carlini Baptista. 2018. "Assessment of Collective Production of Biomethane from Livestock Waste for Urban Transportation Mobility in Brazil and the United States" Energies 11, no. 4: 997. https://doi.org/10.3390/en11040997

APA StylePasqual, J. C., Bollmann, H. A., Scott, C. A., Edwiges, T., & Baptista, T. C. (2018). Assessment of Collective Production of Biomethane from Livestock Waste for Urban Transportation Mobility in Brazil and the United States. Energies, 11(4), 997. https://doi.org/10.3390/en11040997