The Biodiesel of Microalgae as a Solution for Diesel Demand in Iran

Abstract

1. Introduction

2. Overview of Diesel Status

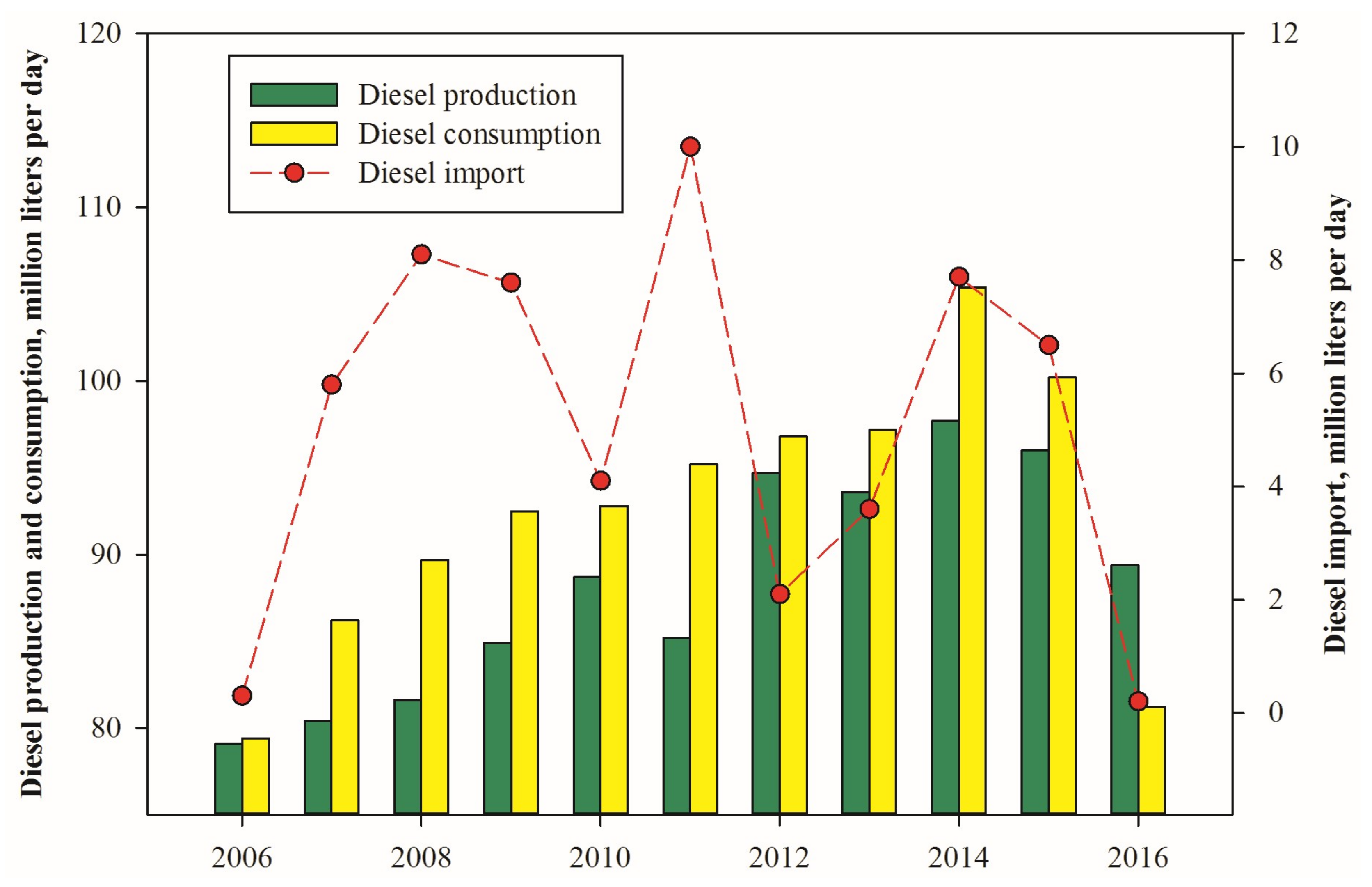

Diesel Consumption, Production, and Import

3. Policy Solutions of Diesel Demand

3.1. Rationing

3.2. Targeted Subsidy Plan

4. Biodiesel as Alternative Fuel

4.1. Oil Seeds Production in Iran

4.1.1. Corn and Walnut Seeds

4.1.2. Cotton and Sesame Seed

4.1.3. Soybean and Canola Seed

4.1.4. Other Oil Seeds

4.2. Microalgae Production Potential in Iran

4.2.1. Algae in Iran

4.2.2. Cultivation of Indigenous Microalgae, Dunaliella salina

4.3. Biodiesel Production Potential in Iran

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rehman, S.A.U.; Cai, Y.; Fazal, R.; Das Walasai, G.; Mirjat, N.H. An integrated modeling approach for forecasting long-term energy demand in Pakistan. Energies 2017, 10, 1868. [Google Scholar] [CrossRef]

- Balatsky, A.V.; Balatsky, G.I.; Borysov, S.S. Resource demand growth and sustainability due to increased world consumption. Sustainability 2015, 7, 3430–3440. [Google Scholar] [CrossRef]

- Tvaronavičienė, M. Contemporary perceptions of energy security: Policy implications. J. Secur. Sustain. Issues 2012, 1, 235–247. [Google Scholar] [CrossRef]

- Baublys, J.; Miškinis, V.; Konstantinavičiūtė, I.; Lekavičius, V. Energy efficiency as precondition of energy security. J. Secur. Sustain. Issues 2015, 4, 197–208. [Google Scholar] [CrossRef][Green Version]

- Hassanzadeh, E. Recent Developments in Iran’s Energy Subsidy Reforms. Policy Brief. International Institute for Sustainable Development, 2012. Available online: www.iisd.org/gsi/sites/default/files/pb14_iran.pdf (accessed on 28 March 2018).

- Mirzahosseini, A.H.; Taheri, T. Environmental, technical and financial feasibility study of solar power plants by retscreen, according to the targeting of energy subsidies in Iran. Renew. Sustain. Energy Rev. 2012, 16, 2806–2811. [Google Scholar] [CrossRef]

- Kalghatgi, G.T. The outlook for fuels for internal combustion engines. Int. J. Engine Res. 2014, 15, 383–398. [Google Scholar] [CrossRef]

- Ghobadian, B.; Najafi, G.; Rahimi, H.; Yusaf, T. Future of renewable energies in Iran. Renew. Sustain. Energy Rev. 2009, 13, 689–695. [Google Scholar] [CrossRef]

- Aghaii Tabrizi, M. Exiting constraints on Iran's gasoline supply and contributing factors. J. Energy Econ. Rev. 2006, 6, 16–21. [Google Scholar]

- Aghaii Tabrizi, M. Iran’s Gasoline Challenges & Solutions; Institute for International Energy Studies: Tehran, Iran, 2006. [Google Scholar]

- Ahmadian, M.; Chitnis, M.; Hunt, L.C. Gasoline Demand, Pricing Policy and Social Welfare in IRAN; Surrey Energy Economics Centre (SEEC), School of Economics, University of Surrey: Guildford, UK, 2007. [Google Scholar]

- Norman, M.E. Reducing gasoline use: A multipronged approach. Energy Policy 1994, 22, 37–39. [Google Scholar] [CrossRef]

- Timilsina, G.R.; Shrestha, A. How much hope should we have for biofuels? Energy 2011, 36, 2055–2069. [Google Scholar] [CrossRef]

- Shah, S.H.; Raja, I.A.; Rizwan, M.; Rashid, N.; Mahmood, Q.; Shah, F.A.; Pervez, A. Potential of microalgal biodiesel production and its sustainability perspectives in Pakistan. Renew. Sustain. Energy Rev. 2018, 81, 76–92. [Google Scholar] [CrossRef]

- Russo, D.; Dassisti, M.; Lawlor, V.; Olabi, A. State of the art of biofuels from pure plant oil. Renew. Sustain. Energy Rev. 2012, 16, 4056–4070. [Google Scholar] [CrossRef]

- Bezergianni, S.; Dimitriadis, A. Comparison between different types of renewable diesel. Renew. Sustain. Energy Rev. 2013, 21, 110–116. [Google Scholar] [CrossRef]

- Najafi, G.; Ghobadian, B.; Yusaf, T.F. Algae as a sustainable energy source for biofuel production in Iran: A case study. Renew. Sustain. Energy Rev. 2011, 15, 3870–3876. [Google Scholar] [CrossRef]

- Zhu, L.; Nugroho, Y.; Shakeel, S.; Li, Z.; Martinkauppi, B.; Hiltunen, E. Using microalgae to produce liquid transportation biodiesel: What is next? Renew. Sustain. Energy Rev. 2017, 78, 391–400. [Google Scholar] [CrossRef]

- Mata, T.M.; Martins, A.A.; Caetano, N.S. Microalgae for biodiesel production and other applications: A review. Renew. Sustain. Energy Rev. 2010, 14, 217–232. [Google Scholar] [CrossRef]

- Show, K.-Y.; Lee, D.-J.; Tay, J.-H.; Lee, T.-M.; Chang, J.-S. Microalgal drying and cell disruption–recent advances. Bioresour. Technol. 2015, 184, 258–266. [Google Scholar] [CrossRef] [PubMed]

- Aziz, M.; Oda, T.; Kashiwagi, T. Enhanced high energy efficient steam drying of algae. Appl. Energy 2013, 109, 163–170. [Google Scholar] [CrossRef]

- Pan, J.; Muppaneni, T.; Sun, Y.; Reddy, H.K.; Fu, J.; Lu, X.; Deng, S. Microwave-assisted extraction of lipids from microalgae using an ionic liquid solvent [BMIM][HSO4]. Fuel 2016, 178, 49–55. [Google Scholar] [CrossRef]

- Lee, I.; Park, J.-Y.; Choi, S.-A.; Oh, Y.-K.; Han, J.-I. Hydrothermal nitric acid treatment for effectual lipid extraction from wet microalgae biomass. Bioresour. Technol. 2014, 172, 138–142. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.; Watson, I.A. Microwave treatment of wet algal paste for enhanced solvent extraction of lipids for biodiesel production. Renew. Energy 2015, 76, 470–477. [Google Scholar] [CrossRef]

- Milano, J.; Ong, H.C.; Masjuki, H.; Chong, W.; Lam, M.K.; Loh, P.K.; Vellayan, V. Microalgae biofuels as an alternative to fossil fuel for power generation. Renew. Sustain. Energy Rev. 2016, 58, 180–197. [Google Scholar] [CrossRef]

- Griffiths, M.J.; Harrison, S.T. Lipid productivity as a key characteristic for choosing algal species for biodiesel production. J. Appl. Phycol. 2009, 21, 493–507. [Google Scholar] [CrossRef]

- Weldy, C.S.; Huesemann, M. Lipid production by Dunaliella salina in batch culture: Effects of nitrogen limitation and light intensity. J. Undergrad. Res. 2007, 7, 115–122. [Google Scholar]

- Milledge, J.J. Commercial application of microalgae other than as biofuels: A brief review. Rev. Environ. Sci. Bio/Technol. 2011, 10, 31–41. [Google Scholar] [CrossRef]

- Yilancioglu, K.; Cokol, M.; Pastirmaci, I.; Erman, B.; Cetiner, S. Oxidative stress is a mediator for increased lipid accumulation in a newly isolated Dunaliella salina strain. PLoS ONE 2014, 9, e91957. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Mukherjee, J.; Hawkes, J.J.; Wilkinson, S.J. Optimization of lipid production for algal biodiesel in nitrogen stressed cells of Dunaliella salina using FTIR analysis. J. Chem. Technol. Biotechnol. 2013, 88, 1807–1814. [Google Scholar] [CrossRef]

- Yang, C.; Jia, L.; Chen, C.; Liu, G.; Fang, W. Bio-oil from hydro-liquefaction of Dunaliella salina over Ni/REHY catalyst. Bioresour. Technol. 2011, 102, 4580–4584. [Google Scholar] [CrossRef] [PubMed]

- Lamers, P.P.; Janssen, M.; De Vos, R.C.; Bino, R.J.; Wijffels, R.H. Carotenoid and fatty acid metabolism in nitrogen-starved dunaliella salina, a unicellular green microalga. J. Biotechnol. 2012, 162, 21–27. [Google Scholar] [CrossRef] [PubMed]

- Shenbaga Devi, A.; Santhanam, P.; Rekha, V.; Ananth, S.; Prasath, B.B.; Nandakumar, R.; Jeyanthi, S.; Kumar, S.D. Culture and biofuel producing efficacy of marine microalgae Dunaliella salina and nannochloropsis sp. J. Algal Biomass Util. 2012, 3, 38–44. [Google Scholar]

- Abd El Baky, H.; El-Baroty, G.; Bouaid, A. Lipid induction in dunaliella salina culture aerated with various levels CO2 and its biodiesel production. J. Aquacult. Res. Dev. 2014, 5, 1–6. [Google Scholar]

- Giordano, M. Interactions between c and n metabolism in Dunaliella salina cells cultured at elevated CO2 and high N concentrations. J. Plant Physiol. 2001, 158, 577–581. [Google Scholar] [CrossRef]

- Giordano, M.; Davis, J.S.; Bowes, G. Organic carbon release by Dunaliella salina (chlorophyta) under different growth conditions of CO2, nitrogen, and salinity. J. Phycol. 1994, 30, 249–257. [Google Scholar] [CrossRef]

- Herrmann, H.; HÄDER, D.P.; Ghetti, F. Inhibition of photosynthesis by solar radiation in Dunaliella salina: Relative efficiencies of UV-B, UV-A and PAR. Plant Cell Environ. 1997, 20, 359–365. [Google Scholar] [CrossRef]

- Dutta, S.; Neto, F.; Coelho, M.C. Microalgae biofuels: A comparative study on techno-economic analysis & life-cycle assessment. Algal Res. 2016, 20, 44–52. [Google Scholar]

- Ghorbani, A.; Rahimpour, H.R.; Ghasemi, Y.; Zoughi, S.; Rahimpour, M.R. A review of carbon capture and sequestration in Iran: Microalgal biofixation potential in Iran. Renew. Sustain. Energy Rev. 2014, 35, 73–100. [Google Scholar] [CrossRef]

- Montazeri-Najafabady, N.; Negahdaripour, M.; Salehi, M.H.; Morowvat, M.H.; Shaker, S.; Ghasemi, Y. Effects of osmotic shock on production of β-carotene and glycerol in a naturally isolated strain of Dunaliella salina. J. Pharm. Sci. 2016, 6, 160–163. [Google Scholar] [CrossRef]

- Morowvat, M.H.; Ghasemi, Y. Culture medium optimization for enhanced β-carotene and biomass production by Dunaliella salina in mixotrophic culture. Biocatal. Agric. Biotechnol. 2016, 7, 217–223. [Google Scholar] [CrossRef]

- Morowvat, M.H.; Ghasemi, Y. Evaluation of antioxidant properties of some naturally isolated microalgae: Identification and characterization of the most efficient strain. Biocatal. Agric. Biotechnol. 2016, 8, 263–269. [Google Scholar] [CrossRef]

- Zarei, M.; Mobasher, M.A.; Morowvat, M.H.; Mousavi, P.; Montazeri-Najafabady, N.; Hajighahramani, N.; Ghasemi, Y. Effects of menthone and piperitone on growth, chlorophyll a and β-carotene production in Dunaliella salina. J. Appl. Pharm. Sci. 2016, 6, 215–219. [Google Scholar] [CrossRef][Green Version]

- Jafari, H.H.; Baratimalayeri, A. The crisis of gasoline consumption in the Iran’s transportation sector. Energy Policy 2008, 36, 2536–2543. [Google Scholar] [CrossRef]

- Taheri, M.M. The study of supportive policies of Iran’s government in energy sector considering the plan of targeted subsidies. Int. J. Bus. Soc. Sci. 2012, 3, 1–4. [Google Scholar]

- Maghsoudi, N.; Tohidy Ardahaey, F. Targeting subsidies considering the applied models in Iran. Int. J. Bus. Soc. Sci. 2012, 3, 1–7. [Google Scholar]

- Mohammadi-Nasrabadi, F. Impact of cash transfer on food security: A review. Nutr. Food Sci. Res. 2016, 3, 3–10. [Google Scholar] [CrossRef]

- Demirbas, A. Importance of biodiesel as transportation fuel. Energy Policy 2007, 35, 4661–4670. [Google Scholar] [CrossRef]

- Borowitzka, M.A.; Moheimani, N.R. Sustainable biofuels from algae. Mitig. Adapt. Strateg. Glob. Chang. 2013, 18, 13–25. [Google Scholar] [CrossRef]

- Zarei-Darki, B. Cyanoprokaryota from differentwater bodies of Iran. Int. J. Algae 2011, 13, 52–62. [Google Scholar] [CrossRef]

- Jafari, N. Using algae to assess environmental conditions in river. Int. J. Algae 2009, 11, 246–259. [Google Scholar] [CrossRef]

- Dogadina, T.; Zarei, D.B.; Gorbulin, O. Algae of enzeli swamp (Iran). Int. J. Algae 2002, 4, 81–87. [Google Scholar] [CrossRef]

- Noroozi, M.; Naqunezhad, A.; Mehrvarz, S.S. Algal flora in first Iranian land-marine the boujagh national park. Int. J. Algae 2009, 11, 276–288. [Google Scholar]

- Morowvat, M.H.; Rasoul-Amini, S.; Ghasemi, Y. Chlamydomonas as a “new” organism for biodiesel production. Bioresour. Technol. 2010, 101, 2059–2062. [Google Scholar]

- Tabatabaei, M.; Tohidfar, M.; Jouzani, G.S.; Safarnejad, M.; Pazouki, M. Biodiesel production from genetically engineered microalgae: Future of bioenergy in Iran. Renew. Sustain. Energy Rev. 2011, 15, 1918–1927. [Google Scholar] [CrossRef]

- Van Stappen, G.; Fayazi, G.; Sorgeloos, P. International study on Artemia LXIII. Field study of the Artemia urmiana (Günther, 1890) population in Lake Urmiah, Iran. In Saline Lakes; Springer: London, UK, 2001; pp. 133–143. [Google Scholar]

- Saberi, A. A Survey on the Physical, Chemical, Biological and Pharmaceutical Characteristics of Urmia Lake Water and Mud. Ph.D. Thesis, Tehran University, Tehran, Iran, 1978. [Google Scholar]

- Ryahi, H.; Soltani, N. Shokravi sh: Study of Urmia lake algae flora. Sci. J. Padjuhesh Sazandegi 1994, 25, 23–25. [Google Scholar]

- Mohebbi, F.; Asadpour, Y.; Esmaeili, L.; Javan, S. Phytoplankton population dynamics in Urmia Lake. In Proceedings of the 14th National & 2nd International Conference of Biology, Tarbiat Modares University, Tehran, Iran, 29–31 August 2006. [Google Scholar]

- Eimanifar, A.; Mohebbi, F. Urmia Lake (Northwest Iran): A brief review. Saline Syst. 2007, 3, 5. [Google Scholar] [CrossRef] [PubMed]

- John, D.M.; Whitton, B.A.; Brook, A.J. The Freshwater Algal Flora of the British Isles: An Identification Guide to Freshwater and Terrestrial Algae; Cambridge University Press: Cambridge, UK, 2002; Volume 1. [Google Scholar]

- Eaton, A.; Clesceri, L.; Greenberg, A. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 1995. [Google Scholar]

- Mooney, B.D.; Nichols, P.D.; De Salas, M.F.; Hallegraeff, G.M. Lipid, fatty acid, and sterol composition of eight species of Kareniaceae (Dinophyta): Chemotaxonomy and putative lipid phycotoxins. J. Phycol. 2007, 43, 101–111. [Google Scholar] [CrossRef]

- Rasoul-Amini, S.; Ghasemi, Y.; Morowvat, M.H.; Mohagheghzadeh, A. PCR amplification of 18S rRNA, single cell protein production and fatty acid evaluation of some naturally isolated microalgae. Food Chem. 2009, 116, 129–136. [Google Scholar] [CrossRef]

- De Morais, M.G.; Costa, J.A.V. Carbon dioxide fixation by Chlorella kessleri, C. vulgaris, Scenedesmus obliquus and Spirulina sp. Cultivated in flasks and vertical tubular photobioreactors. Biotechnol. Lett. 2007, 29, 1349–1352. [Google Scholar] [CrossRef] [PubMed]

- Talebi, A.F.; Mohtashami, S.K.; Tabatabaei, M.; Tohidfar, M.; Bagheri, A.; Zeinalabedini, M.; Mirzaei, H.H.; Mirzajanzadeh, M.; Shafaroudi, S.M.; Bakhtiari, S. Fatty acids profiling: A selective criterion for screening microalgae strains for biodiesel production. Algal Res. 2013, 2, 258–267. [Google Scholar] [CrossRef]

- Radakovits, R.; Jinkerson, R.E.; Darzins, A.; Posewitz, M.C. Genetic engineering of algae for enhanced biofuel production. Eukaryotic Cell 2010, 9, 486–501. [Google Scholar] [CrossRef] [PubMed]

- Altun, Ş.; Yaşar, F.; Öner, C. The fuel properties of methyl esters produced from canola oil-animal tallow blends by basecatalyzed transesterification. Int. J. Eng. Res. Dev. 2010, 2, 2–5. [Google Scholar]

- Gismondi, A.; Pippo, F.D.; Bruno, L.; Antonaroli, S.; Congestri, R. Phosphorus removal coupled to bioenergy production by three cyanobacterial isolates in a biofilm dynamic growth system. Int. J. Phytoremed. 2016, 18, 869–876. [Google Scholar] [CrossRef] [PubMed]

- Mandal, S.; Mallick, N. Microalga Scenedesmus obliquus as a potential source for biodiesel production. Appl. Microbiol. Biotechnol. 2009, 84, 281–291. [Google Scholar] [CrossRef] [PubMed]

- Chisti, Y. Biodiesel from microalgae. Biotechnol. Adv. 2007, 25, 294–306. [Google Scholar] [CrossRef] [PubMed]

- Doan, T.T.Y.; Sivaloganathan, B.; Obbard, J.P. Screening of marine microalgae for biodiesel feedstock. Biomass Bioenergy 2011, 35, 2534–2544. [Google Scholar] [CrossRef]

- Rugnini, L.; Costa, G.; Congestri, R.; Antonaroli, S.; di Toppi, L.S.; Bruno, L. Phosphorus and metal removal combined with lipid production by the green microalga Desmodesmus sp.: An integrated approach. Plant Physiol. Biochem. 2018, 125, 45–51. [Google Scholar] [CrossRef] [PubMed]

- Gouveia, L.; Oliveira, A.; Congestri, R.; Bruno, L.; Soares, A.; Menezes, R.; Tzovenis, I. Biodiesel from microalgae. In Microalgae-Based Biofuels and Bioproducts; Elsevier: Amsterdam, The Netherlands, 2018; pp. 235–258. [Google Scholar]

- Ullah, K.; Ahmad, M.; Sharma, V.K.; Lu, P.; Harvey, A.; Zafar, M.; Sultana, S.; Anyanwu, C. Algal biomass as a global source of transport fuels: Overview and development perspectives. Prog. Nat. Sci. Mater. Int. 2014, 24, 329–339. [Google Scholar] [CrossRef]

- Ghasemi, Y.; Rasoul-Amini, S.; Fotooh-Abadi, E. The biotransformation, biodegradation, and bioremediation of organic compounds by microalgae. J. Phycol. 2011, 47, 969–980. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Xu, M.; Zhang, X.; Hu, Q.; Sommerfeld, M.; Chen, Y. Life-cycle analysis on biodiesel production from microalgae: Water footprint and nutrients balance. Bioresour. Technol. 2011, 102, 159–165. [Google Scholar] [CrossRef] [PubMed]

| Year | LPG | Gasoline | Kerosene | Diesel | Fuel oil | Total |

|---|---|---|---|---|---|---|

| 2006 | 6.1 | 67 | 20.5 | 79.4 | 40.7 | 213.7 |

| 2007 | 6.1 | 73.6 | 19.7 | 86.2 | 42.8 | 228.4 |

| 2008 | 6.1 | 64.5 | 20.2 | 89.7 | 45.3 | 225.8 |

| 2009 | 6.1 | 67 | 18.4 | 92.5 | 47.2 | 231.2 |

| 2010 | 6.8 | 64.8 | 17.8 | 92.8 | 45.0 | 227.2 |

| 2011 | 6.7 | 61.3 | 13.8 | 95.2 | 40.3 | 217.3 |

| 2012 | 6.1 | 59.9 | 13.5 | 96.8 | 42.9 | 219.2 |

| 2013 | 6.0 | 63.5 | 12.3 | 97.2 | 51.7 | 230.7 |

| 2014 | 5.6 | 68.4 | 11.9 | 105.4 | 50.7 | 242 |

| 2015 | 5.6 | 69.6 | 10.1 | 100.1 | 36.7 | 222.1 |

| 2016 | 5.6 | 71.0 | 9.1 | 81.2 | 24.5 | 191.4 |

| Transport | Power Plant | Agriculture | Industry | Domestic | Others |

|---|---|---|---|---|---|

| 53 | 26 | 9 | 7 | 0 | 5 |

| 56 | 19 | 11 | 8 | 0 | 6 |

| Year | Domestic Price (USD/Liter) | Import Price, FOB Persian Gulf (USD/Liter) | |

|---|---|---|---|

| 2007 | 0.018 | 0.575 | |

| 2008 | 0.017 | 0.652 | |

| 2009 | 0.017 | 0.435 | |

| 2010 | Before TSL | 0.015 | 0.592 |

| After TSL | 0.136, 0.318 | ||

| 2011 | 0.076, 0.177 | 0.787 | |

| Systematic Name | Common Name | Formula | No. of Double Bond(s) | Fatty Acid Content (% Total) | Family |

|---|---|---|---|---|---|

| N-Hexadecanoic acid | Palmitic acid | C16H32O2 | 0 | 43.00 | Saturated FA |

| Octadeca-10,13-dienoate acid | - | C18H34O2 | 2 | 9.60 | Monounsaturated FA |

| Octadeca-9,12,15-trienoic acid | α-Linoleic acid | C18H32O2 | 3 | 10.98 | Monounsaturated FA |

| N-Octadecanoic acid | Stearophanic acid | C18H36O2 | 0 | 23.72 | Saturated FA |

| N-Heneicosanoic acid | Heneicosylic acid | C21H42O2 | 0 | 3.80 | Saturated FA |

| N-Docosanoic acid methyl ester | Methyl behenate | C23H46O2 | 0 | 8.90 | Saturated FA |

| Oil Seeds | Oil Content (%) | Oil Yield (L ha−1 year−1) | Percent of Iran Cropping area to Displace Diesel Import in 2015–2016 | Percent of Iran Cropping Area to Displace Diesel Consumption in 2016 |

|---|---|---|---|---|

| Walnut | 60 | 2108.1 | 6.5 | 119.4 |

| Corn | 10 | 738.4 | 18.6 | 341.0 |

| Cotton | 40 | 1469.2 | 9.29 | 171.4 |

| Almond | 54 | 905.6 | 15.1 | 278.1 |

| Canola | 30 | 709.2 | 19.2 | 355.1 |

| Soybean | 18 | 900.4 | 15.2 | 279.7 |

| Olive | 20 | 542.8 | 25.1 | 463.9 |

| Hazelnut | 62 | 1265.3 | 10.8 | 199.0 |

| Sesame | 50 | 618.5 | 22.1 | 407.1 |

| Microalgae (10 g·m−2·day−1) | 30 | 12,000 | 1.1 | 21.0 |

| Microalgae (50 g·m−2·day−1) | 50 | 98,500 | 0.1 | 2.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghorbani, A.; Rahimpour, M.R.; Ghasemi, Y.; Raeissi, S. The Biodiesel of Microalgae as a Solution for Diesel Demand in Iran. Energies 2018, 11, 950. https://doi.org/10.3390/en11040950

Ghorbani A, Rahimpour MR, Ghasemi Y, Raeissi S. The Biodiesel of Microalgae as a Solution for Diesel Demand in Iran. Energies. 2018; 11(4):950. https://doi.org/10.3390/en11040950

Chicago/Turabian StyleGhorbani, Afshin, Mohammad Reza Rahimpour, Younes Ghasemi, and Sona Raeissi. 2018. "The Biodiesel of Microalgae as a Solution for Diesel Demand in Iran" Energies 11, no. 4: 950. https://doi.org/10.3390/en11040950

APA StyleGhorbani, A., Rahimpour, M. R., Ghasemi, Y., & Raeissi, S. (2018). The Biodiesel of Microalgae as a Solution for Diesel Demand in Iran. Energies, 11(4), 950. https://doi.org/10.3390/en11040950