Estimation of Thermal Performance and Heat Loss in Plastic Greenhouses with and without Thermal Curtains

Abstract

:1. Introduction

2. Material and Methods

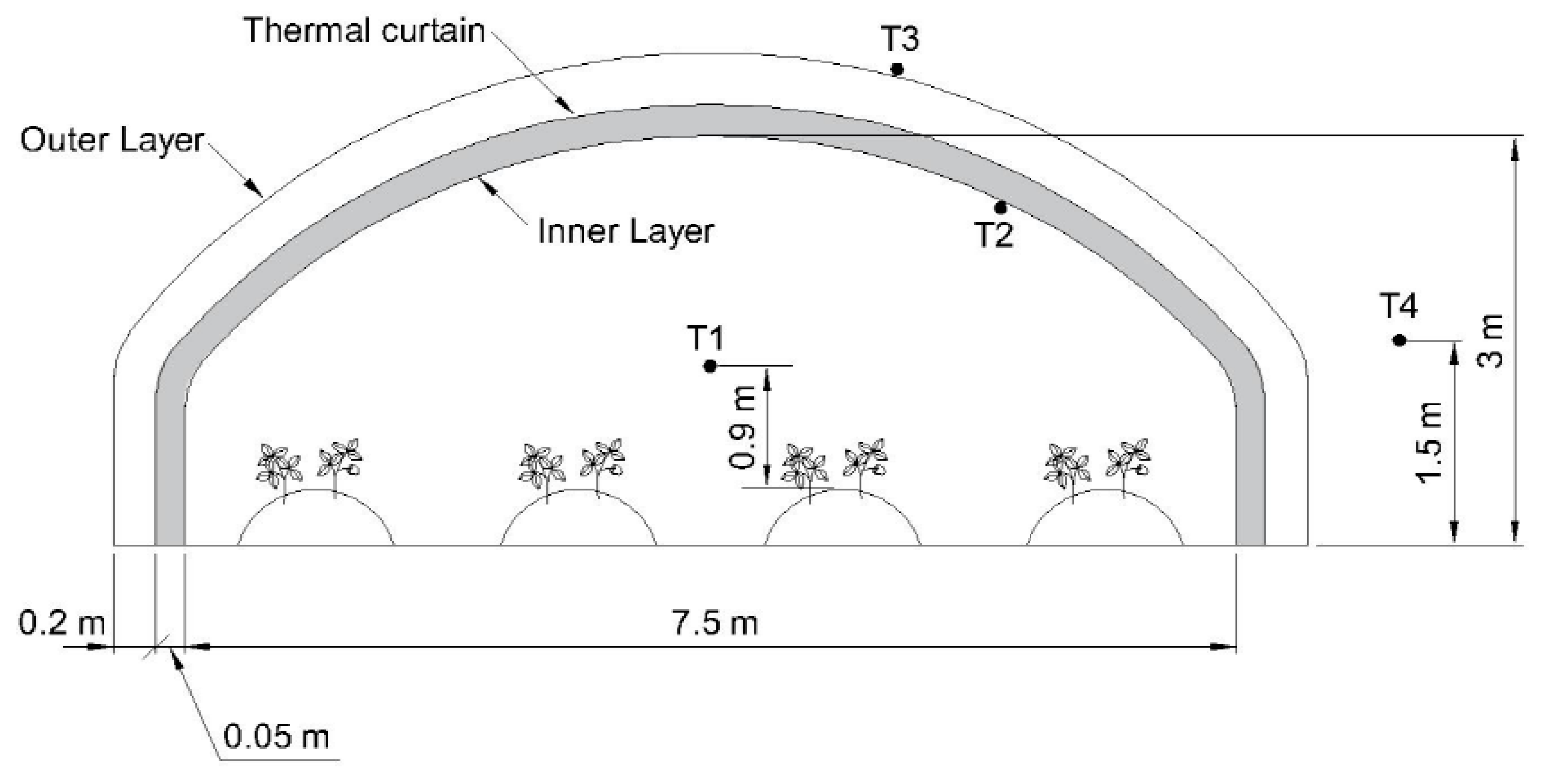

2.1. Experimental Greenhouse and System Description

2.2. Measurements

2.3. Energy Analysis Methodology

3. Results and Discussion

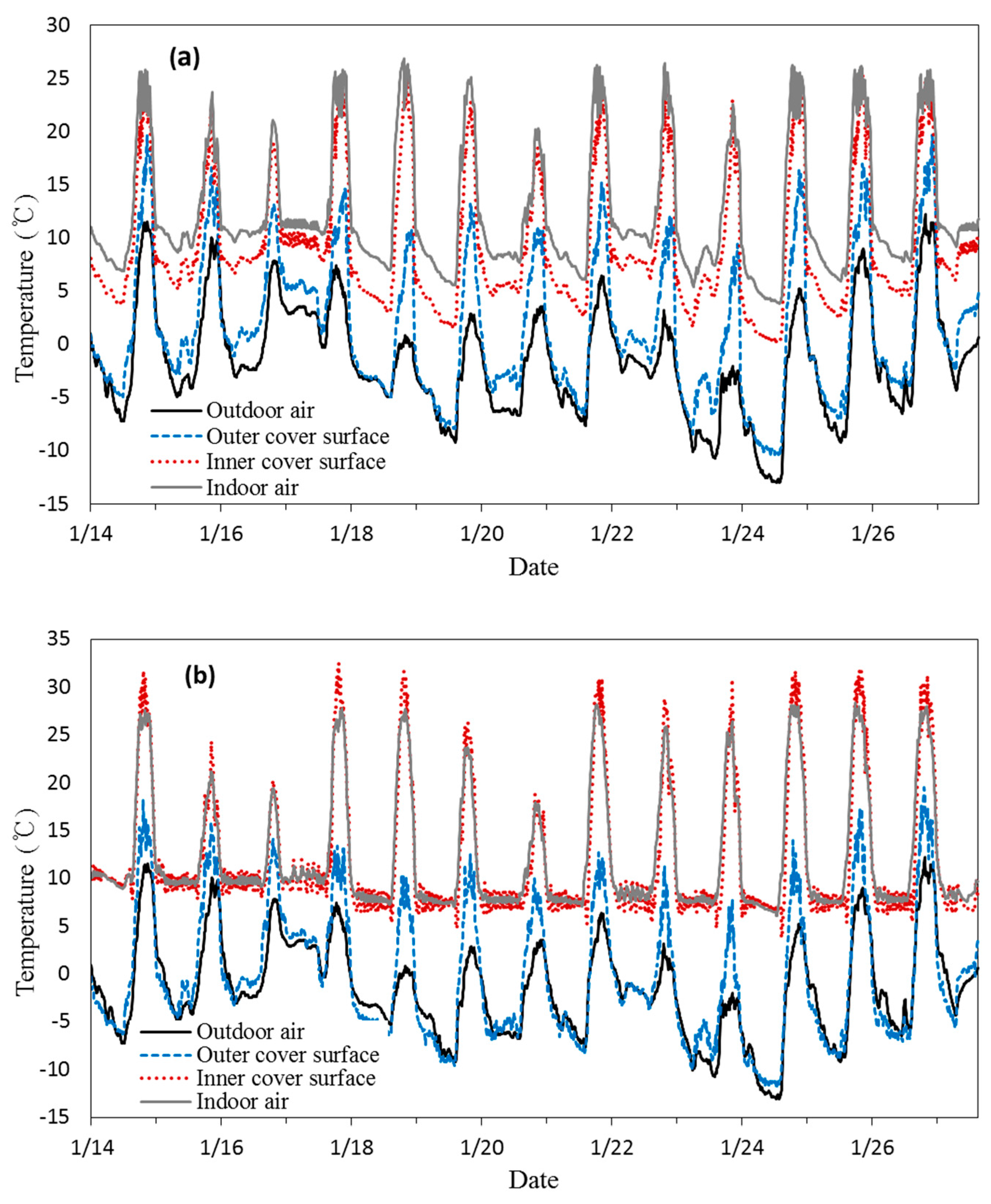

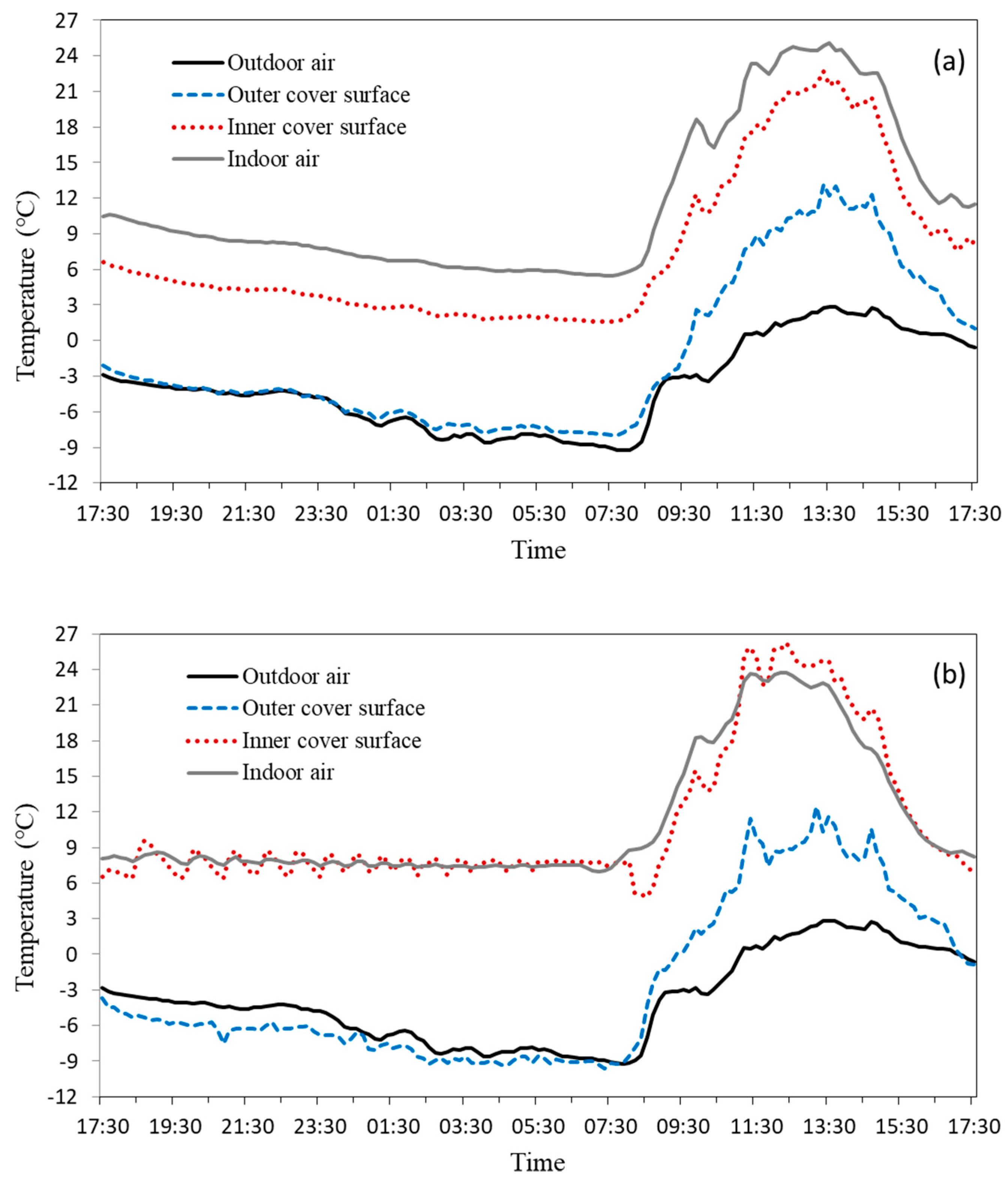

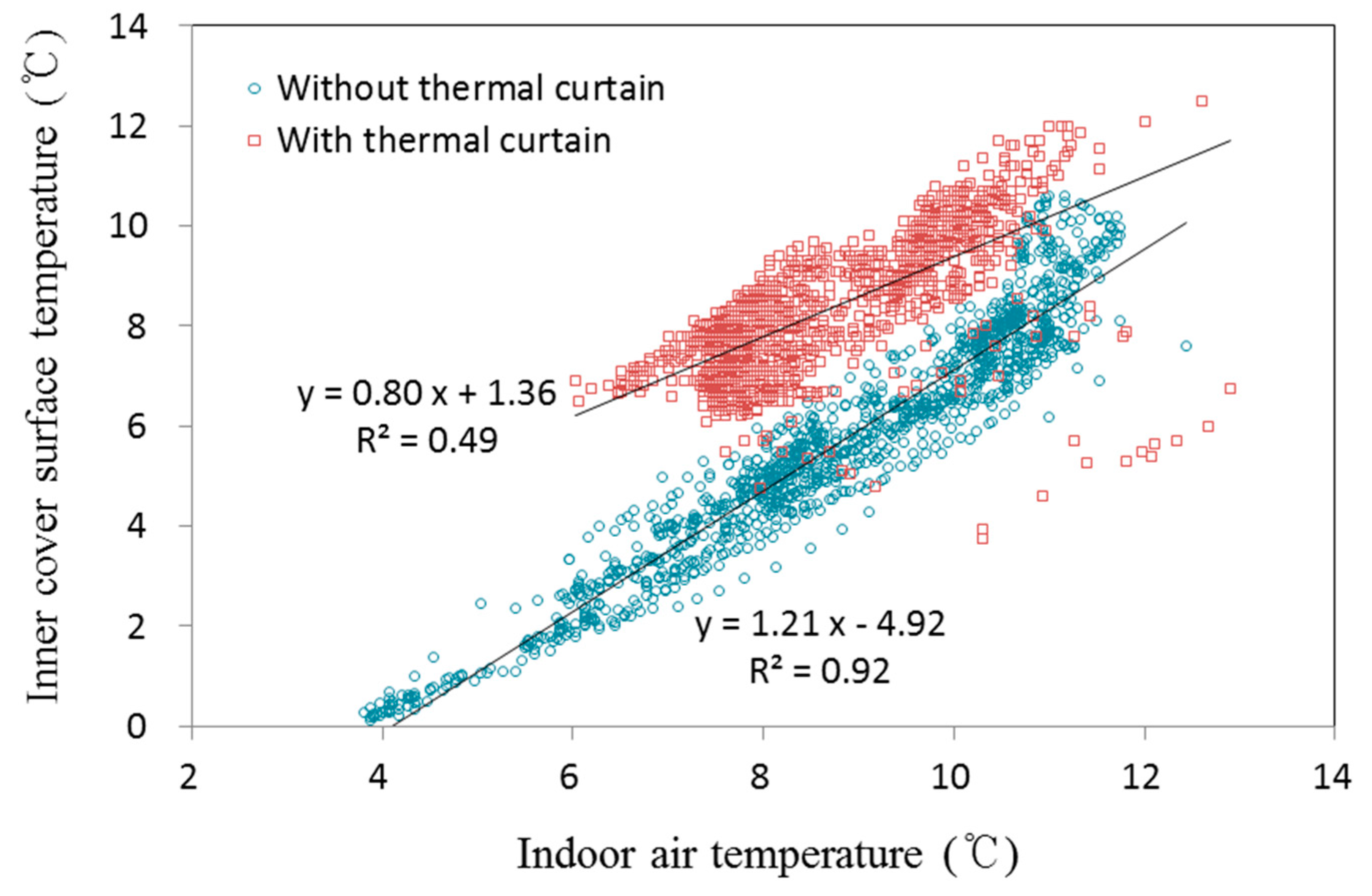

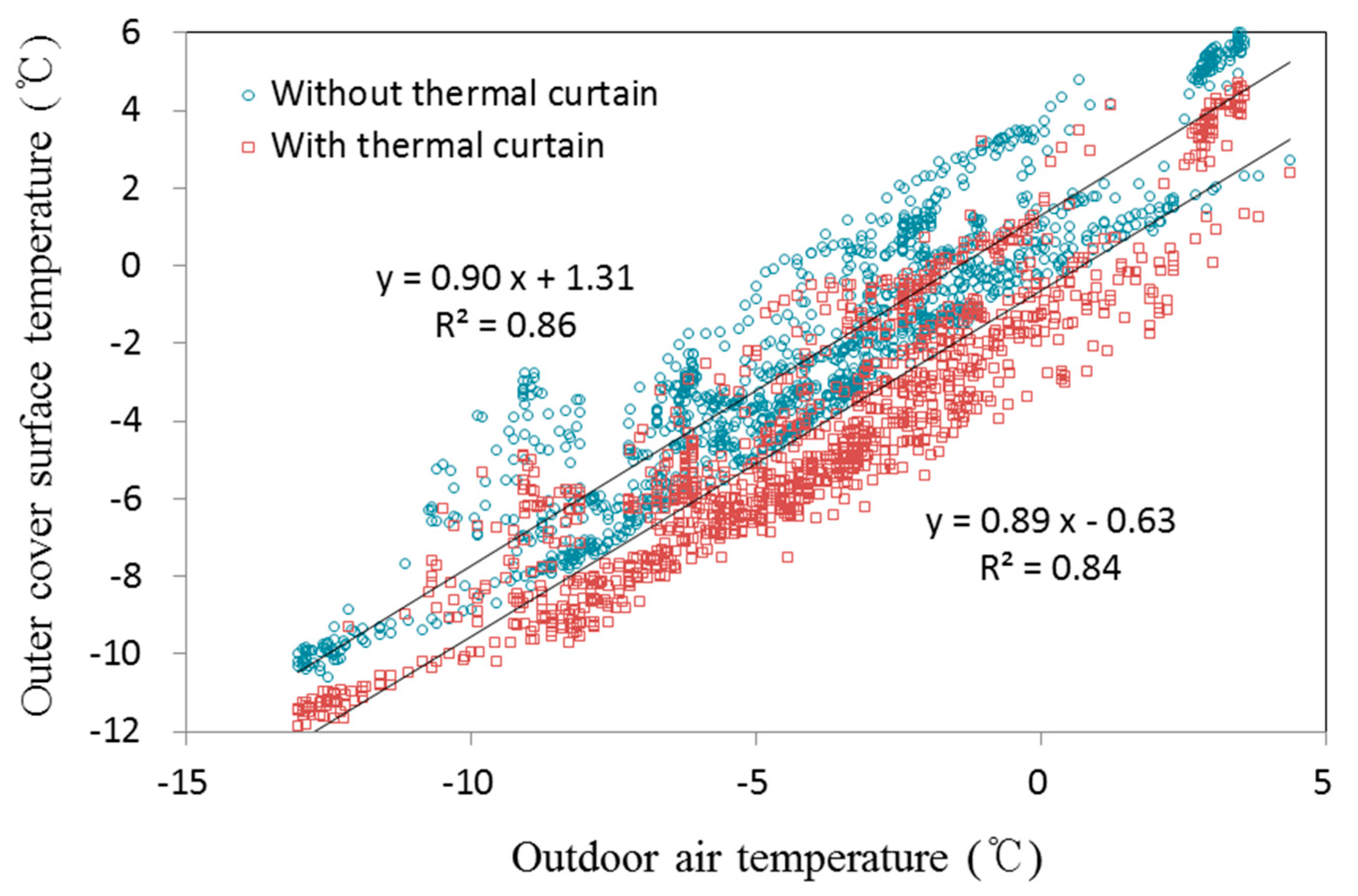

3.1. Greenhouse Temperature

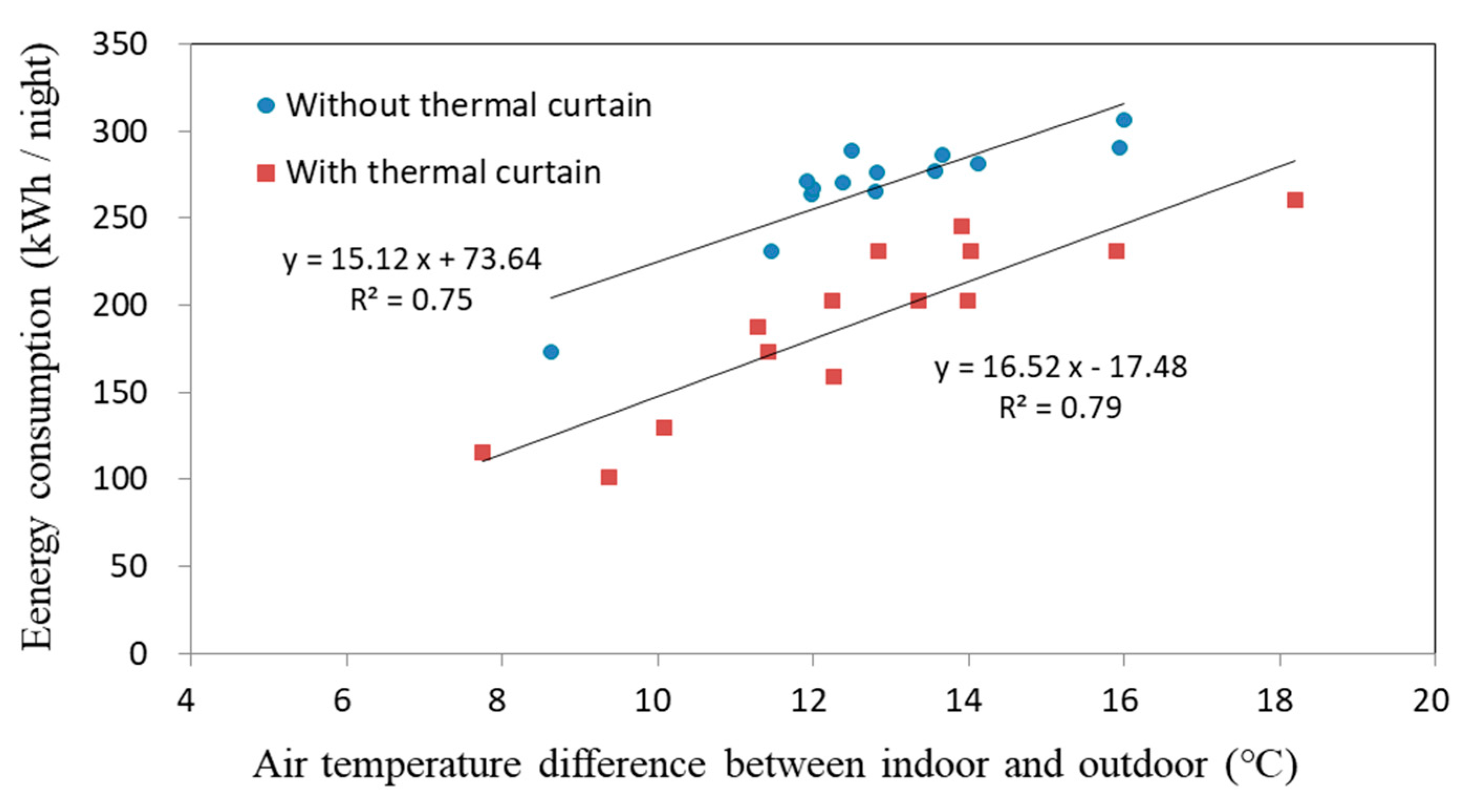

3.2. Assessment of Energy Consumption and U Values

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ministry of Agriculture, Food and Rural Affairs (MAFRA). The Status of Vegetable Greenhouse Facilities and Vegetables Production in 2014; MAFRA: Sejong, Korea, 2015. Available online: http://ebook.mafra.go.kr/preview/viewer/main.php?site=2&menuno=2&previewno=7548&iframe=0&dlbt=80 (accessed on 8 September 2017).

- Salwa, B.; Sami, K.; Safa, S.; Mariem, L.; Abdelhamid, F. Improvement of the greenhouse climate using a solar air heater with latent storage energy. Energy 2014, 64, 663–672. [Google Scholar]

- Yang, S.H.; Rhee, J.Y. Utilization and performance evaluation of a surplus air heat pump system for greenhouse cooling and heating. Appl. Energy 2013, 105, 244–251. [Google Scholar] [CrossRef]

- Teitel, M.; Barak, M.; Antler, A. Effect of cyclic heating and a thermal screen on the nocturnal heat loss and microclimate of a greenhouse. Biosyst. Eng. 2009, 102, 162–170. [Google Scholar] [CrossRef]

- Rural Development Administration (RDA). Energy Saving Technology for Protected Horticulture (Guide for Agricultural Techniques); RDA: Jeonju, Korea, 2014.

- Rural Development Administration (RDA). Guidebook of Energy Saving for Overcoming High Oil Price in Protected Horticulture; RDA: Suwon, Korea, 2008.

- García, J.L.; Plaza, S.S.L.; Navas, L.M.; Benevente, R.M.; Luna, L. Evaluation of the feasibility of alternative energy sources for greenhouse heating. J. Agric. Eng. Res. 1998, 69, 107–114. [Google Scholar] [CrossRef]

- Berroug, F.; Lakhal, E.K.; EI Omari, M.; Faraji, M.; EI Qarnia, H. Thermal performance of a greenhouse with a phase change material north wall. Energy Build. 2011, 43, 3027–3035. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.; Wang, R.Z.; Liu, W. Performance investigation of a solar heating system with underground seasonal energy storage for greenhouse application. Energy 2014, 67, 63–73. [Google Scholar] [CrossRef]

- Alkilani, M.M.; Sopian, K.; Alghoul, M.A.; Sohif, M.; Ruslan, M.H. Review of solar air collectors with thermal storage units. Renew. Sustain. Energy Rev. 2011, 15, 1476–1490. [Google Scholar] [CrossRef]

- Ghosal, M.K.; Tiwari, G.N. Mathematical modeling for greenhouse heating by using thermal curtain and geothermal energy. Sol. Energy 2004, 76, 603–613. [Google Scholar] [CrossRef]

- Zhang, Y.; Gauthier, L.; de Halleux, D.; Dansereau, B.; Gosselin, A. Effect of covering materials on energy consumption and greenhouse microclimate. Agric. For. Meteorol. 1996, 82, 227–244. [Google Scholar] [CrossRef]

- Kittas, C.; Katsoulas, N.; Baille, A. Influence of an aluminized thermal screen on greenhouse microclimate and canopy energy balance. Trans. ASAE 2003, 46, 1653–1663. [Google Scholar] [CrossRef]

- Arinze, E.A.; Schoenau, G.J.; Besant, R.W. Experimental and computer performance evaluation of a movable thermal insulation for energy conservation in greenhouses. J. Agric. Eng. Res. 1986, 34, 97–113. [Google Scholar] [CrossRef]

- Huseyin Ozturk, H. Experimental determination of the overall heat loss coefficient for energy requirement of greenhouse heating. Int. J. Energy Res. 2005, 29, 937–944. [Google Scholar] [CrossRef]

- Perdigones, A.; García, J.L.; Pastor, M.; Benavente, R.M.; Luna, L.; Chaya, C.; de la Plaza, S. Effect of heating control strategies on greenhouse energy efficiency: Experimental results and modeling. Trans. ASABE 2006, 49, 143–155. [Google Scholar] [CrossRef]

- Suleiman, B.M. Estimation of U-value of traditional North African houses. Appl. Therm. Eng. 2011, 31, 1923–1928. [Google Scholar] [CrossRef]

- Papadakis, G.; Briassoulis, D.; Scarascia Mungnozza, G.; Vox, G.; Feuilloley, P.; Stoffers, J.A. Radiometric and thermal properties of, and testing methods for, greenhouse covering materials. J. Agric. Eng. Res. 2000, 77, 7–38. [Google Scholar] [CrossRef]

- Japan Greenhouse Horticulture Association (JGHA). Handbook of Protected Horticulture, 5th ed.; JGHA: Tokyo, Japan, 2015. [Google Scholar]

- Seginer, I.; Kantz, D.; Peiper, U.M.; Levav, N. Transfer coefficients of several polyethylene greenhouse covers. J. Agric. Eng. Res. 1988, 39, 19–37. [Google Scholar] [CrossRef]

- Nijskens, J.; Deltour, J.; Coutisse, S.; Nisen, A. Heat transfer through covering materials of greenhouses. Agric. For. Meteorol. 1984, 33, 193–214. [Google Scholar] [CrossRef]

- Baille, A.; López, J.C.; Bonachela, S.; González-Real, M.M.; Montero, J.L. Night energy balance in a heated low-cost plastic greenhouse. Agric. For. Meteorol. 2006, 137, 107–118. [Google Scholar] [CrossRef]

- Rural Development Administration (RDA). Strawberry Cultivation (Guide for Agricultural Techniques); RDA: Suwon, Korea, 2013.

- Al-Helal, I.M.; Waheeb, S.A.; Ibrahim, A.A.; Shady, M.R.; Abdel-Ghany, A.M. Modified thermal model to predict the natural ventilation of greenhouses. Energy Build. 2015, 99, 1–8. [Google Scholar] [CrossRef]

- Montero, J.L.; Castilla, N.; Gutiérrez de Ravé, E.; Bretones, F. Climate under plastic in the Almería area. Acta Hortic. 1985, 170, 227–234. [Google Scholar] [CrossRef]

- Papadakis, G.; Frangoudakis, A.; Kyritsis, S. Theoretical and experimental investigation of thermal radiation transfer in polyethylene covered greenhouses. J. Agric. Eng. Res. 1989, 44, 97–111. [Google Scholar] [CrossRef]

- Korean Standards Association (KSA). Thermal Performance of Buildings—Quantitative Detection of Thermal Irregularities in Building Envelops–Infrared Method; KSA: Seoul, Korea, 2005. [Google Scholar]

| Condition | U Value (W m−2 °C−1) | Energy Consumption (kWh) | ∆T (°C) |

|---|---|---|---|

| With thermal curtain | 2.76 | 191.0 | 12.6 |

| Without thermal curtain | 3.85 | 267.8 | 12.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-K.; Kang, G.-C.; Moon, J.-P.; Lee, T.-S.; Oh, S.-S. Estimation of Thermal Performance and Heat Loss in Plastic Greenhouses with and without Thermal Curtains. Energies 2018, 11, 578. https://doi.org/10.3390/en11030578

Kim H-K, Kang G-C, Moon J-P, Lee T-S, Oh S-S. Estimation of Thermal Performance and Heat Loss in Plastic Greenhouses with and without Thermal Curtains. Energies. 2018; 11(3):578. https://doi.org/10.3390/en11030578

Chicago/Turabian StyleKim, Hyung-Kweon, Geum-Choon Kang, Jong-Pil Moon, Tae-Seok Lee, and Sung-Sik Oh. 2018. "Estimation of Thermal Performance and Heat Loss in Plastic Greenhouses with and without Thermal Curtains" Energies 11, no. 3: 578. https://doi.org/10.3390/en11030578

APA StyleKim, H.-K., Kang, G.-C., Moon, J.-P., Lee, T.-S., & Oh, S.-S. (2018). Estimation of Thermal Performance and Heat Loss in Plastic Greenhouses with and without Thermal Curtains. Energies, 11(3), 578. https://doi.org/10.3390/en11030578