Mechanism and Prevention of a Chock Support Failure in the Longwall Top-Coal Caving Faces: A Case Study in Datong Coalfield, China

Abstract

1. Introduction

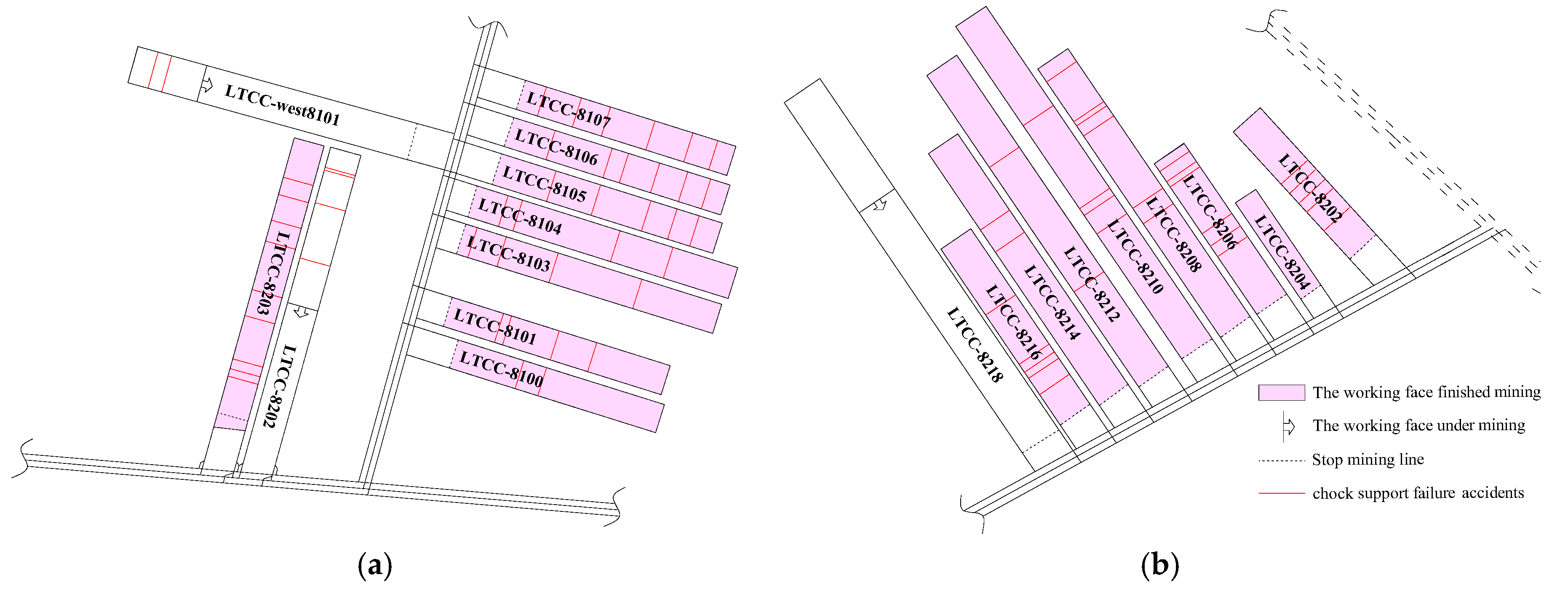

2. Case Summary and Analysis

2.1. Case Study1: LTCC-West8101 of Tongxin Mine

2.2. Case Study2: LTCC 8202 of Tongxin Mine

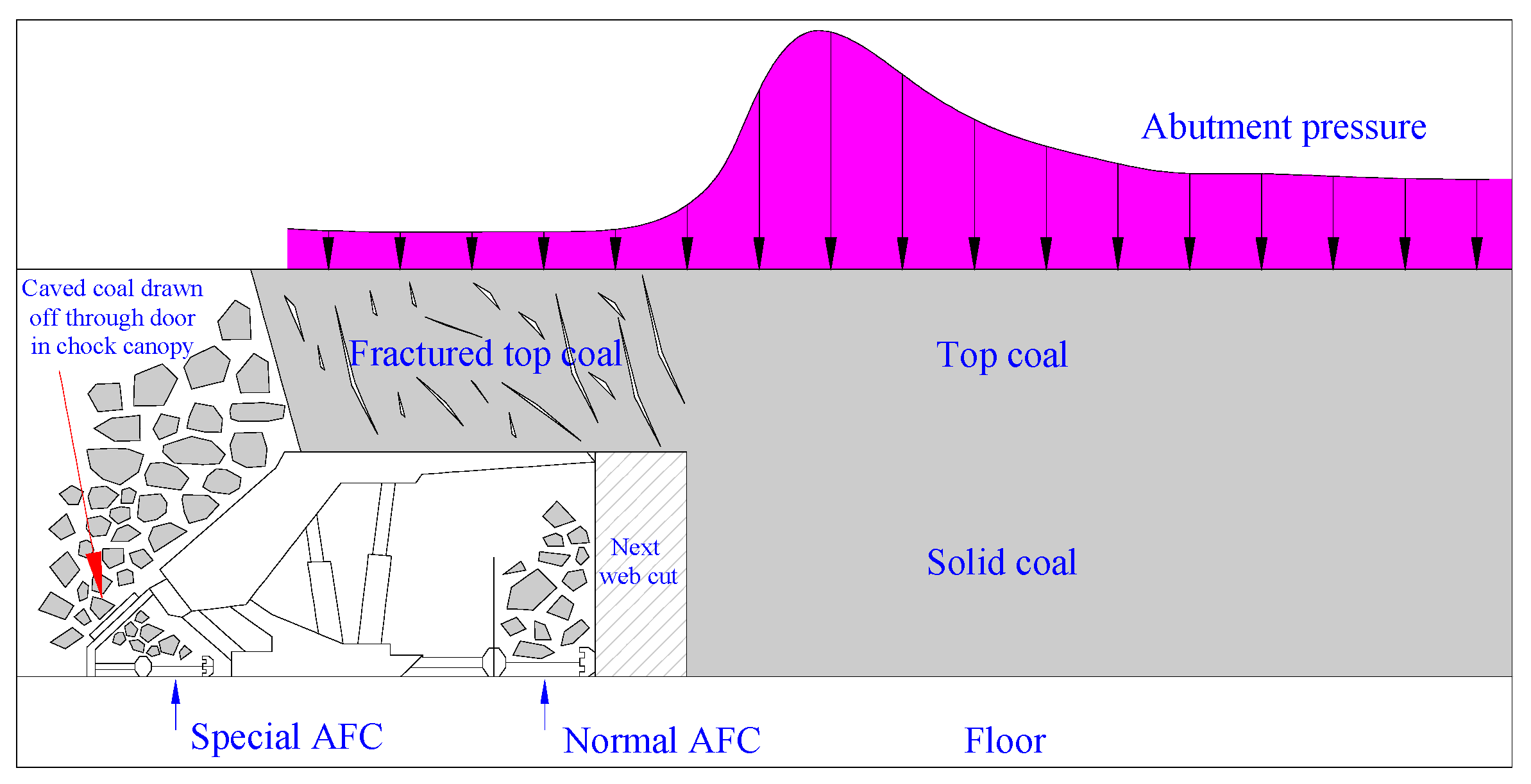

3. Mechanism of Support Failure Accidents

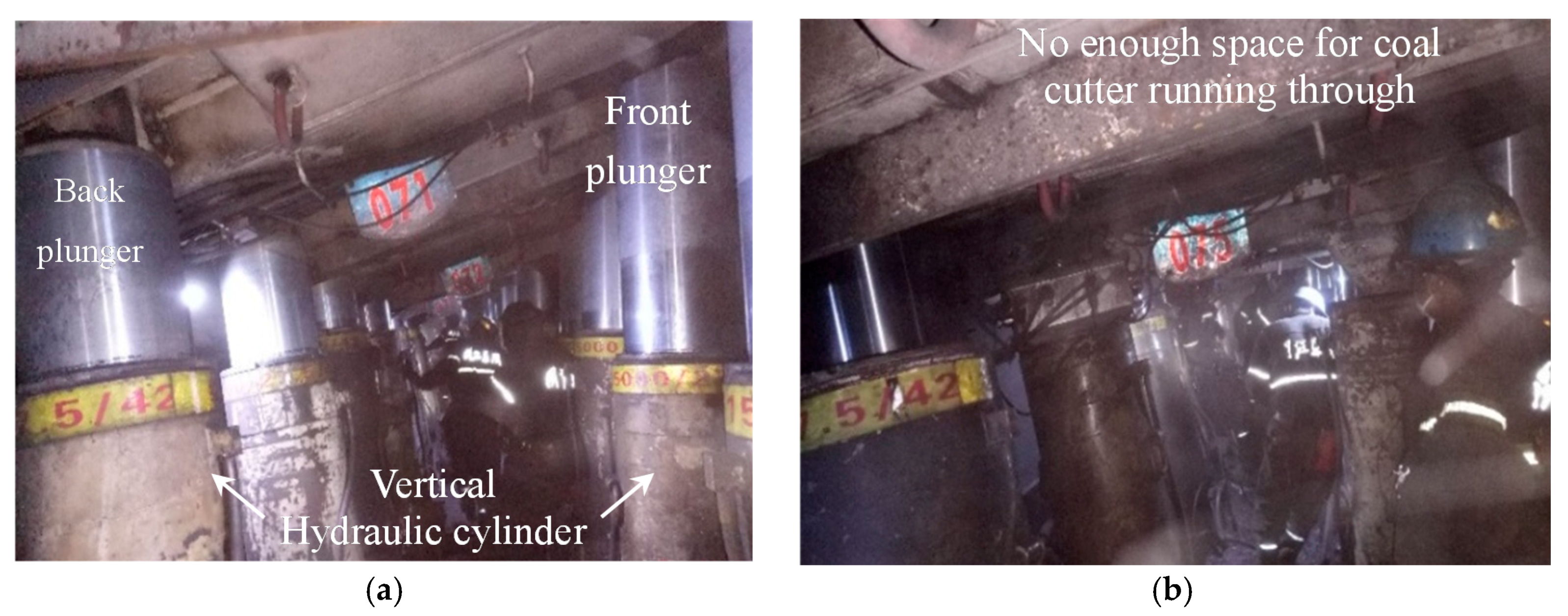

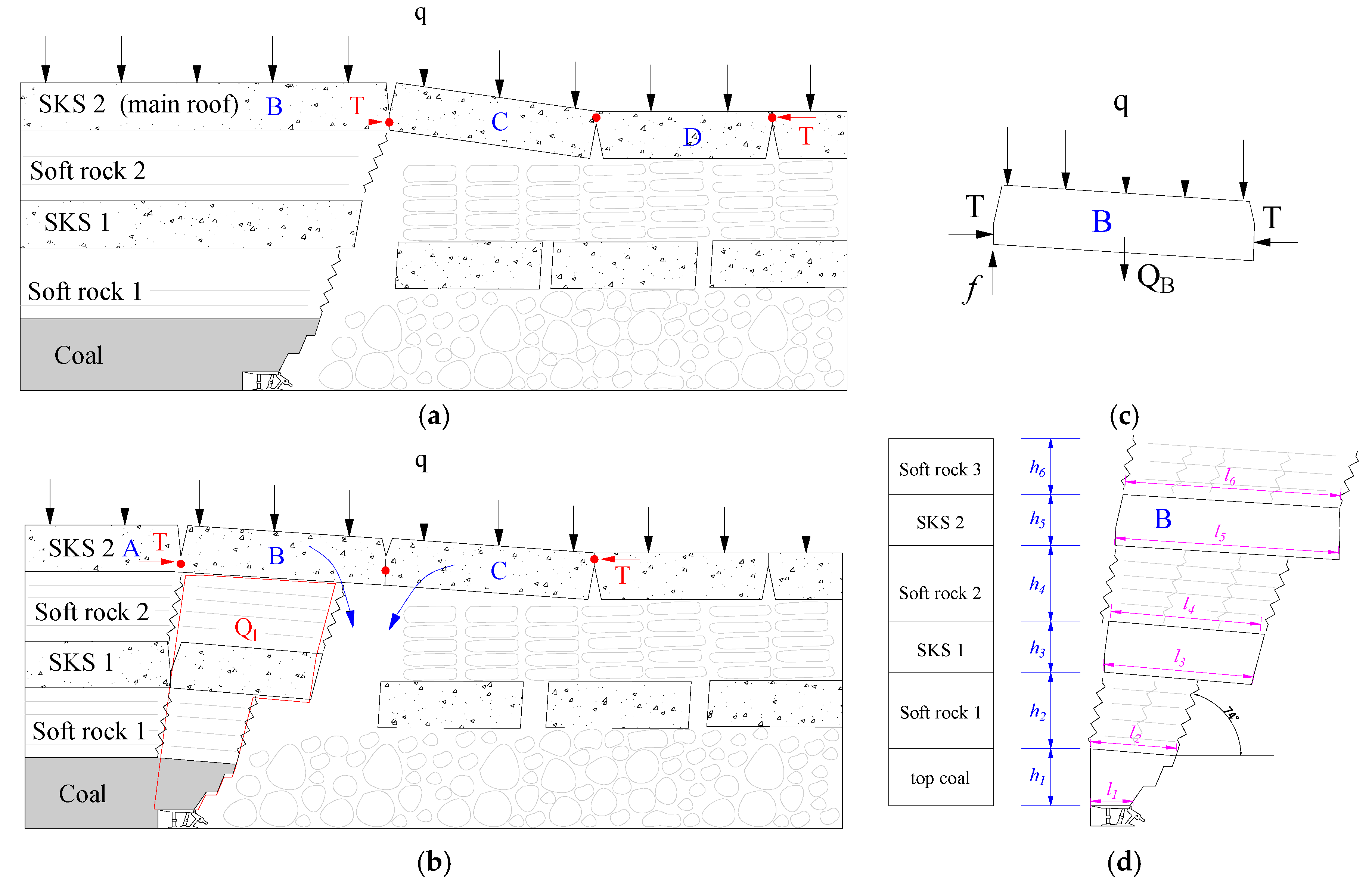

3.1. The Insufficient Capacity of Chock Supports

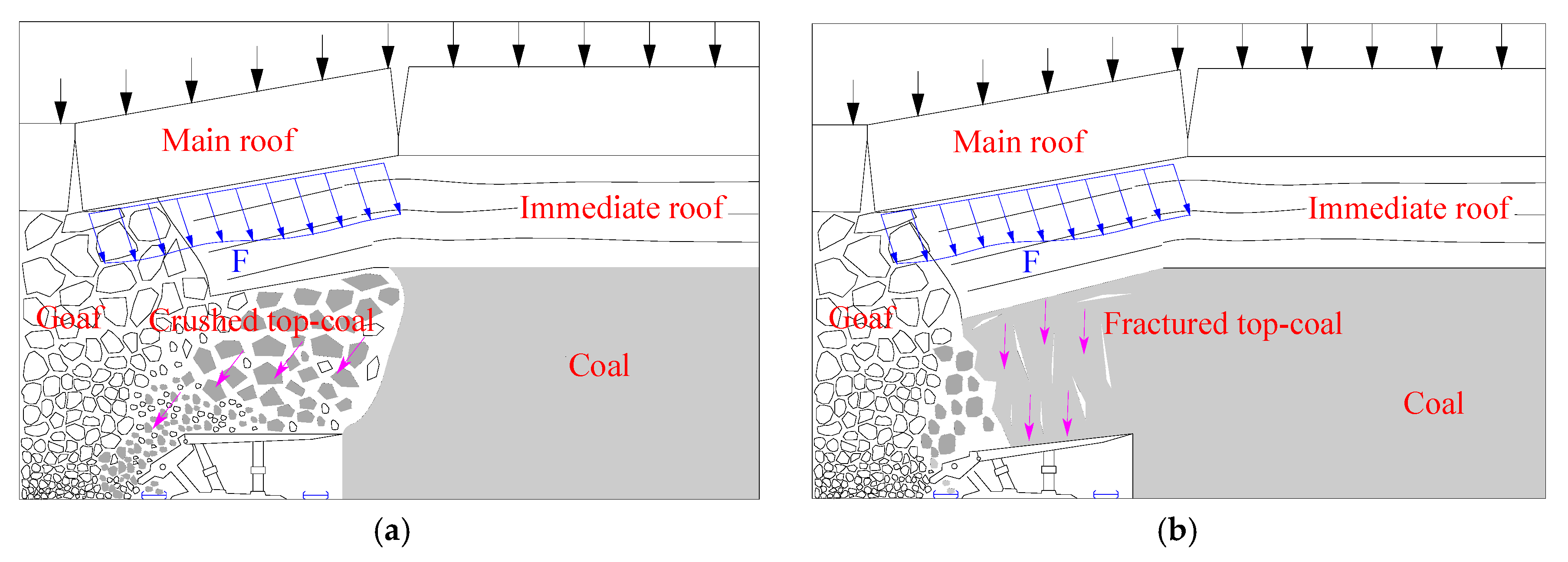

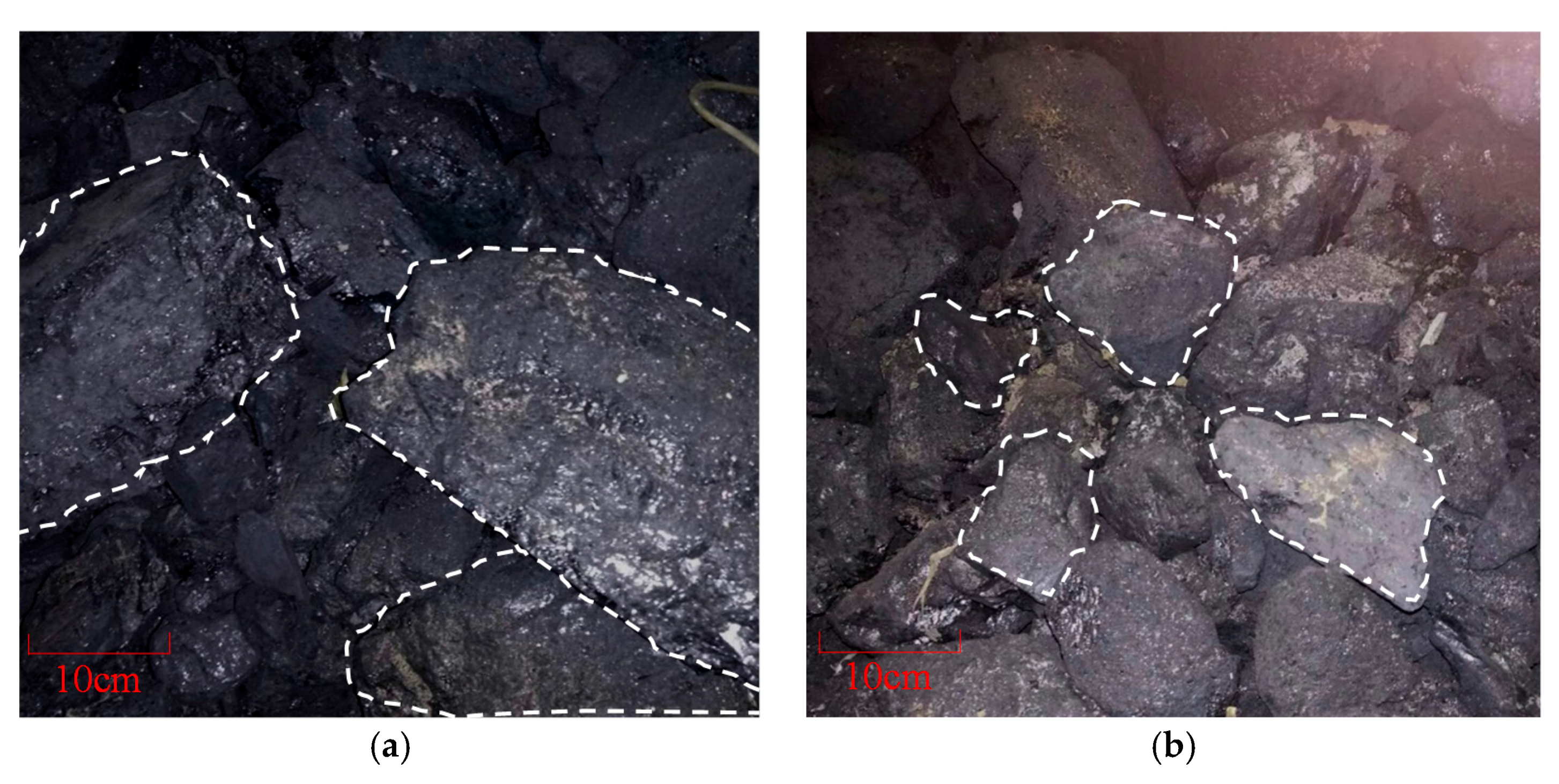

3.2. The Overhanging of Hard Top-Coal

4. Analysis and Discussion on Preventive Measures

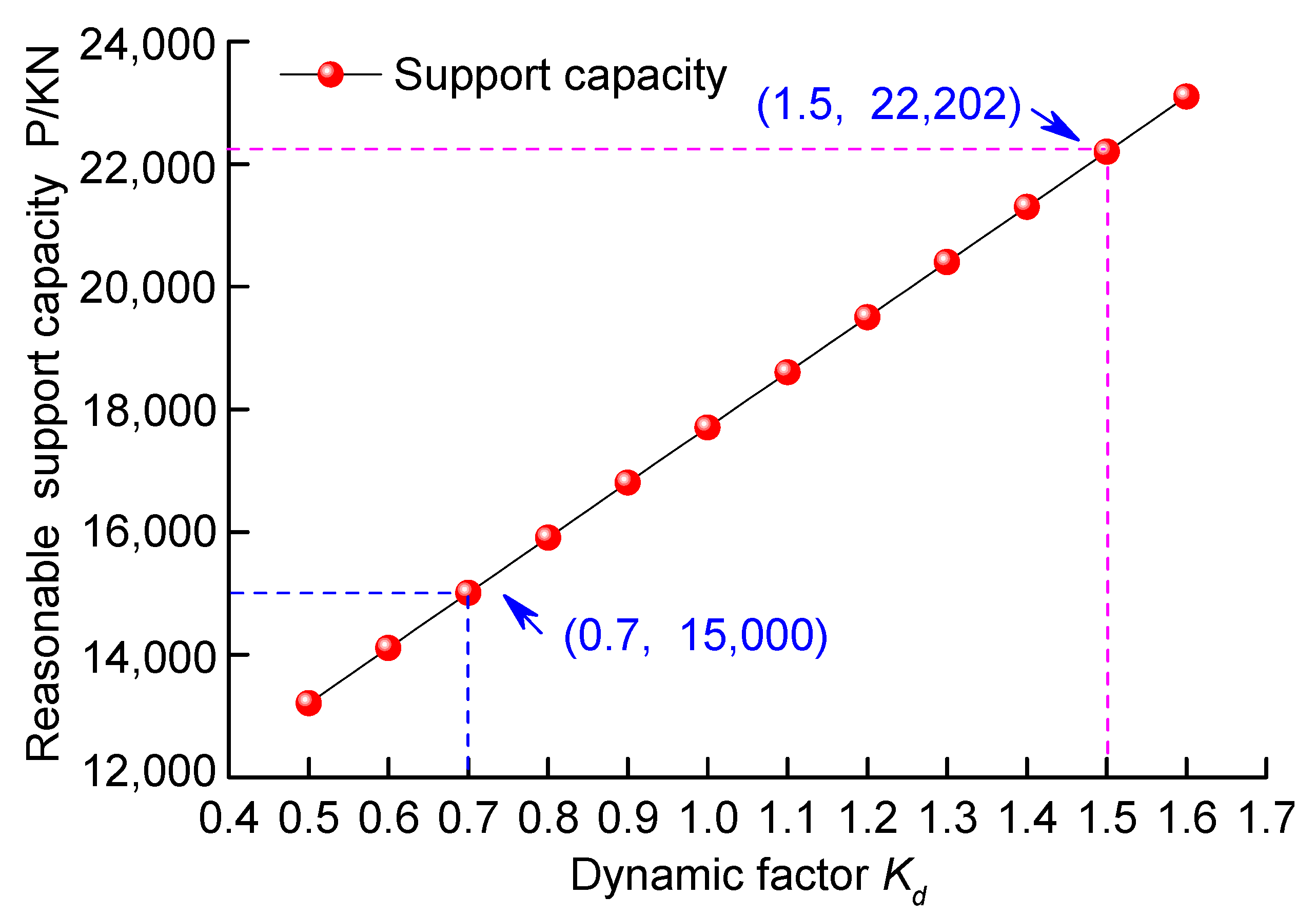

4.1. Determination of Reasonable Support Capacity

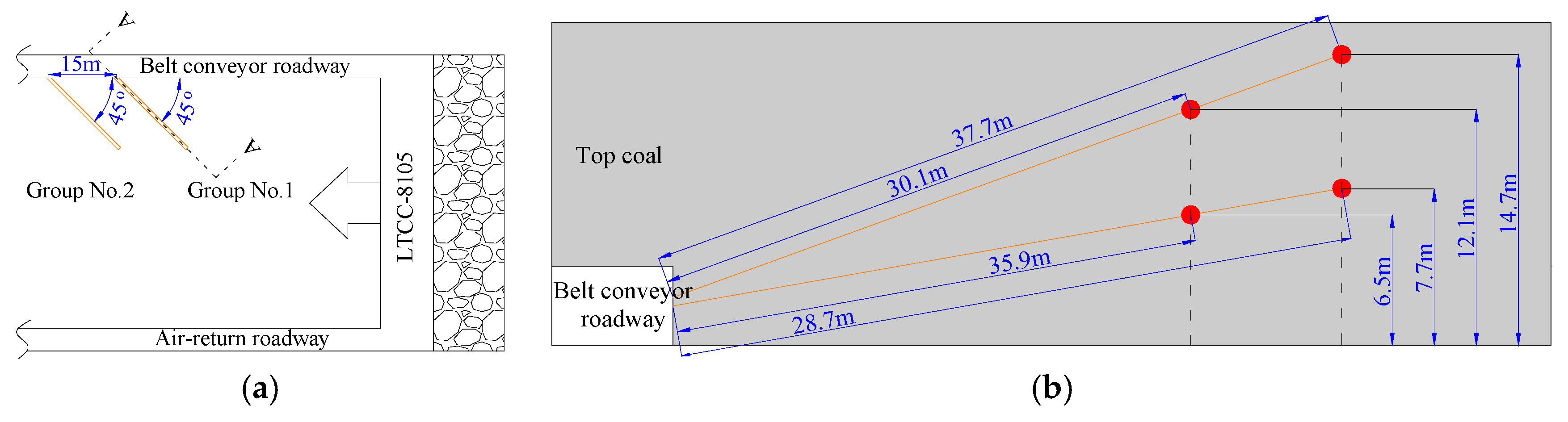

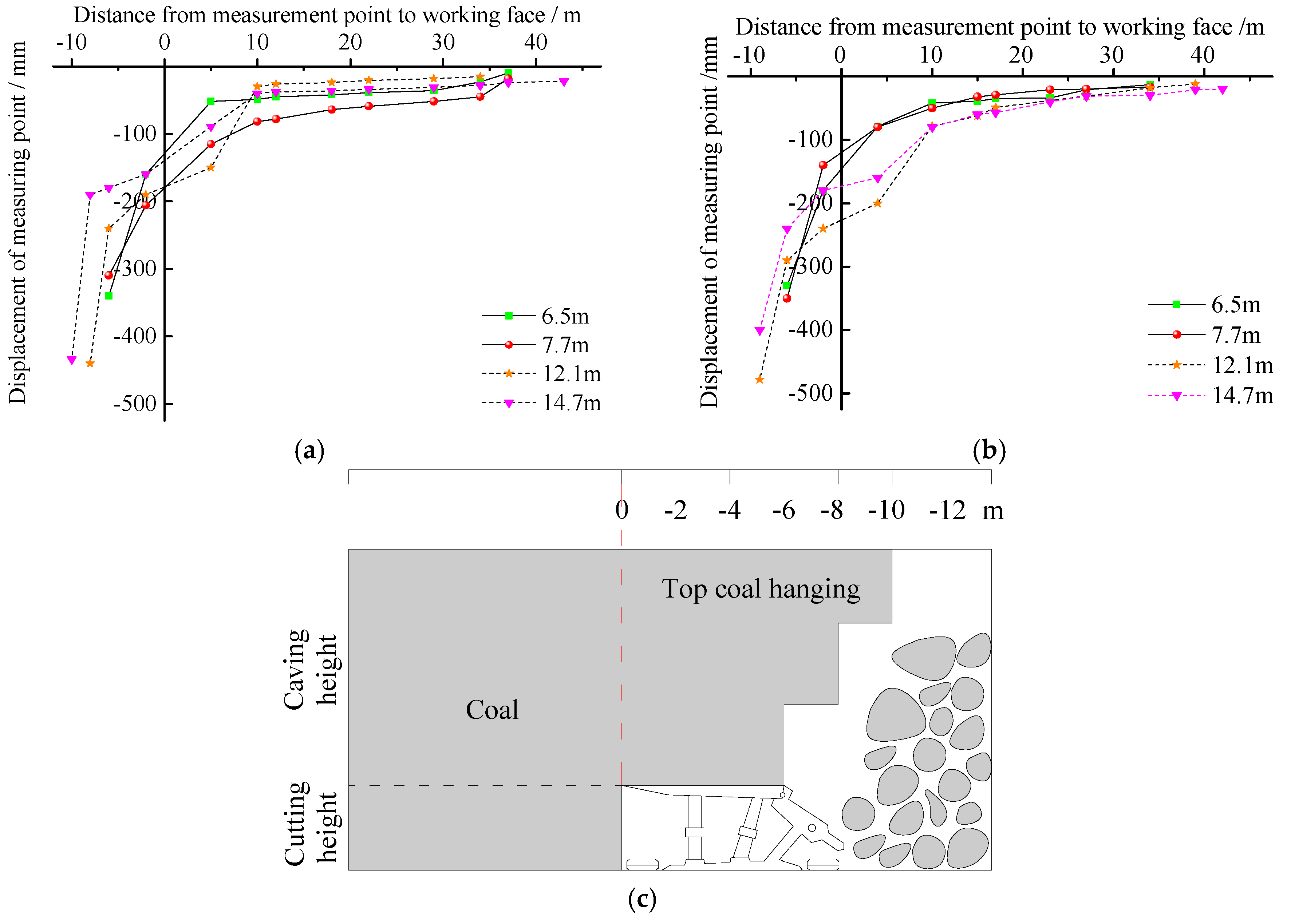

4.2. Hydraulic Fracturing for Hard Top-Coal

4.3. Optimization of Caving Process

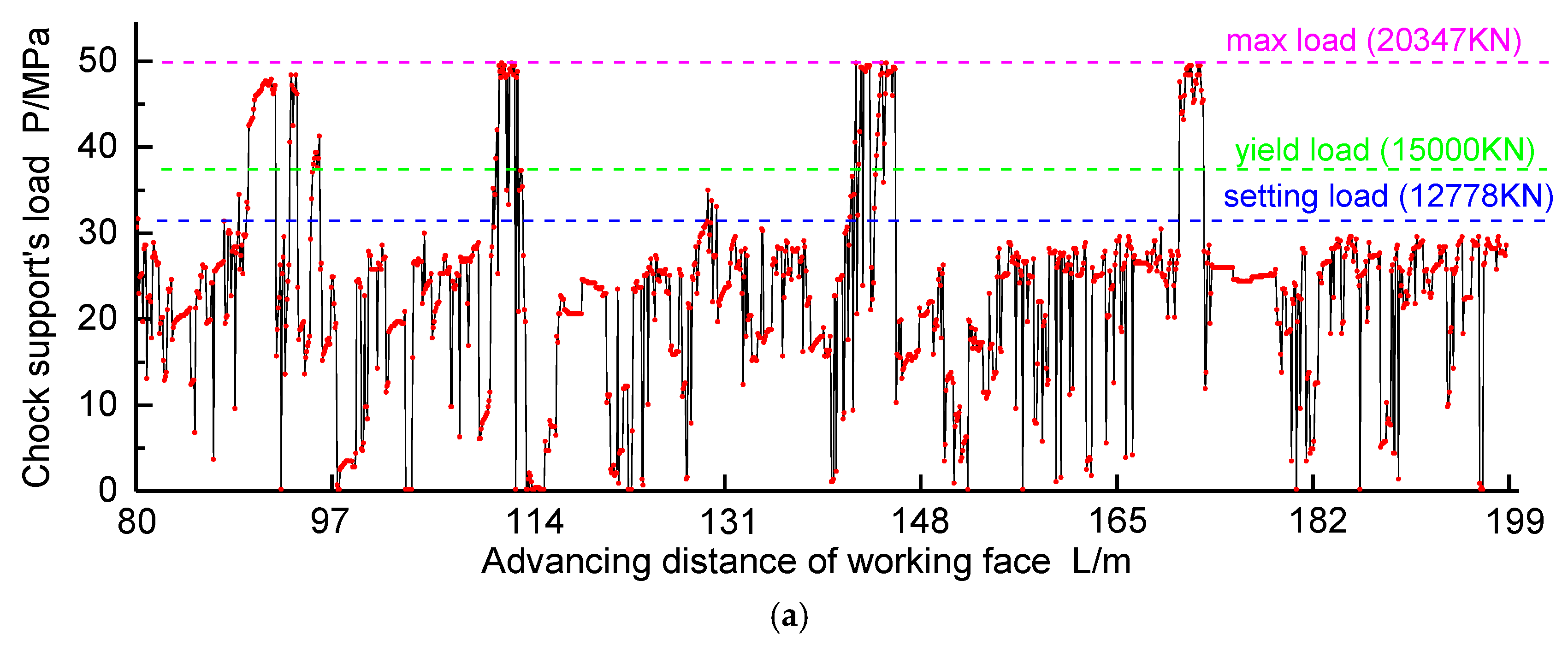

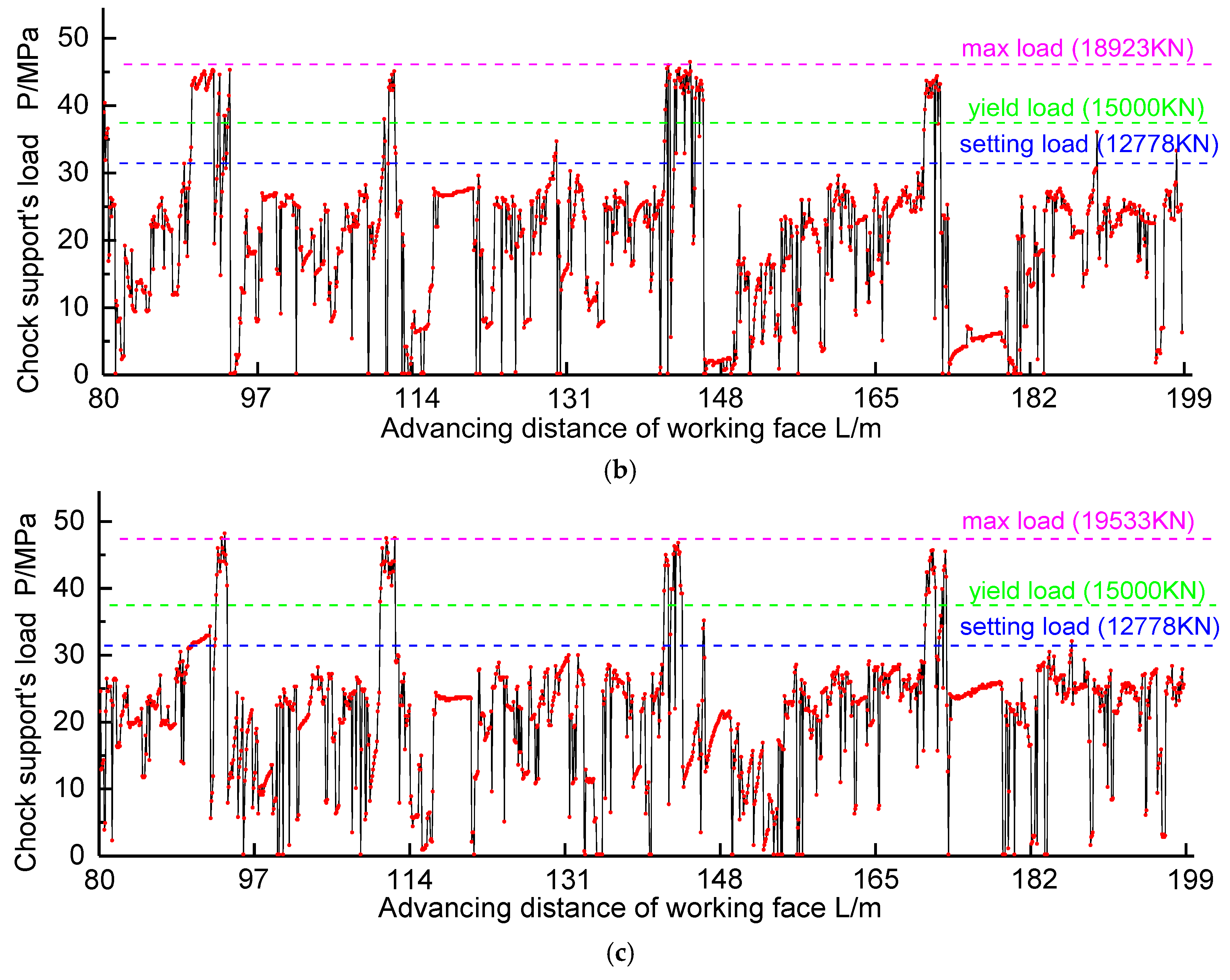

5. Engineering Implementation Effect

6. Conclusions

- (1)

- The intense strata behavior is a typical problem in hard coal seams with the LTCC method, and the harder the top-coal is, the stronger the strata behavior appears, even leading to chock support failure accidents, which has been confirmed by mining practices in the Datong coal field in recent years. Therefore, top-coal can no longer be regarded as a soft cushion for alleviating the strata behavior and the chock support load. This is a good addition to a more comprehensive understanding of the relationship between the top-coal and the strata behavior in the longwall top-coal caving face.

- (2)

- The results of this study show that the insufficient capacity of supports and the overhanging of hard top-coal were the primary reasons for the chock support failure accidents in the LTCC face in the Datong coalfield. A reasonable support capacity was determined based on a mechanical model. Meanwhile, the measures of weakening top-coal by hydraulic fracturing and upgrading the crushing degree of top-coal by raising supports up and down repeatedly through manual operation were proposed for relieving strata behavior and avoiding chock support failure accidents.

- (3)

- Through field measurement, the proposed measures proved to be effective. After these measures had been applied, the maximum chock support load decreased from 18,000~20,000 KN to 14,400~16,000 KN and the shrinkage of the plunger of vertical hydraulic cylinders is less than 300 mm during the roof weighting. Most importantly, chock support failure accidents were largely eliminated in the LTCC face in subsequent production of the extra-thick hard coal seams in the Datong coalfield.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Xie, H.P.; Zhou, H.W. Application of fractal theory to top-coal caving. Chaos Solitons Fractals 2008, 36, 797–807. [Google Scholar] [CrossRef]

- Yu, B.; Zhao, J.; Kuang, T.J.; Meng, X.B. In situ investigations into overburden failures of a super-thick coal seam for longwall top coal caving. Int. J. Rock Mech. Min. Sci. 2015, 78, 155–162. [Google Scholar] [CrossRef]

- Yu, B. Study on Strong Pressure Behavior Mechanism and Roof Control of Fully Mechanized Top Coal Caving in Extra Thickness Seam in Datong Coal Mine. Doctoral Dissertation, China University of Mining and Technology, Xuzhou, China, 2014. (In Chinese). [Google Scholar]

- Yasitli, N.E.; Unver, B. 3D numerical modeling of longwall mining with top-coal caving. Int. J. Rock Mech. Min. Sci. 2005, 42, 219–235. [Google Scholar] [CrossRef]

- Qian, M.G.; Shi, P.W.; Xu, J.L. Ground Pressure and Strata Control, 2rd ed.; China University of Mining and Technology Press: Xuzhou, China, 2010; pp. 271–275. [Google Scholar]

- Ju, J.F.; Xu, J.L. Longwall chock sudden closure incident below coal pillar of adjacent upper mined coal seam under shallow cover in the Shendong coal field. Int. J. Rock Mech. Min. Sci. 2015, 77, 192–201. [Google Scholar] [CrossRef]

- Xu, J.L.; Zhu, W.B.; Ju, J.F. Supports crushing types in the longwall mining of shallow seams. J. China Coal Soc. 2014, 39, 1625–1634. (In Chinese) [Google Scholar]

- Xie, Y.S.; Zhao, Y.S. Numerical simulation of the top coal caving process using the discrete element method. Int. J. Rock Mech. Min. Sci. 2009, 46, 983–991. [Google Scholar] [CrossRef]

- Yang, S.L.; Wang, J.C.; Chen, Y.; Song, Z.Y. Effect of upward angle on the drawing mechanism in longwall top-coal caving mining. Int. J. Rock Mech. Min. Sci. 2016, 85, 92–101. [Google Scholar] [CrossRef]

- Vakili, A.; Hebblewhite, B.K. A new cavability assessment criterion for longwall top coal caving. Int. J. Rock Mech. Min. Sci. 2010, 47, 1317–1329. [Google Scholar] [CrossRef]

- Wang, J.C.; Zhang, J.W.; Li, Z.L. A new research system for caving mechanism analysis and its application to sublevel top-coal caving mining. Int. J. Rock Mech. Min. Sci. 2016, 88, 273–285. [Google Scholar] [CrossRef]

- Alehossein, H.; Poulsen, B.A. Stress analysis of longwall top coal caving. Int. J. Rock Mech. Min. Sci. 2010, 47, 30–41. [Google Scholar] [CrossRef]

- Xie, J.; Gao, M.Z.; Zhang, R.; Li, S.W.; Tan, Q.; Qiu, Z.Q. Lessons learnt from measurements of vertical pressure at a top coal mining face at Datong Tashan mines, China. Rock Mech. Eng. 2016, 49, 2977–2983. [Google Scholar] [CrossRef]

- Unver, B.; Yasitli, N.E. Modelling of strata movement with a special reference to caving. Int. J. Rock Mech. Min. Sci. 2006, 66, 227–252. [Google Scholar]

- Zhang, N.B.; Liu, C.Y. Arch structure effect of the coal gangue flow of the fully mechanized caving in special thick coal seam and its impact on the loss of top coal. Int. J. Min. Sci. Technol. 2016, 26, 593–599. [Google Scholar] [CrossRef]

- Huang, P.; Ju, F.; Jessu, K.V.; Xiao, M.; Guo, S. Optimization and Practice of Support Working Resistance in Fully-Mechanized Top Coal Caving in Shallow Thick Seam. Energies 2017, 10, 1046. [Google Scholar] [CrossRef]

- Zhao, Y.S.; Xie, Y.S.; Guo, J.G.; Huo, L.J. Technical principle of top coal caving with vibration and its practice. Chin. J. Mech. Eng. 2008, 27, 187–192. (In Chinese) [Google Scholar]

- Yu, B.; Xia, H.C.; Meng, X.B. Top coal arching mechanism and arch removal strategies in fully mechanized top coal caving mining of ultra-thick coal seam. J. China Coal Soc. 2016, 41, 1617–1623. (In Chinese) [Google Scholar]

- Gao, F.Q.; Stead, D.; Coggan, J. Evaluation of coal longwall caving characteristics using an innovative UDEC trigon approach. Comput. Geotech. 2014, 55, 448–460. [Google Scholar] [CrossRef]

- Huang, B.X.; Wang, Y.Z.; Cao, S.G. Cavability control by hydraulic fracturing for top coal caving in hard thick coal seams. Int. J. Rock Mech. Min. Sci. 2015, 74, 45–57. [Google Scholar] [CrossRef]

- Zhang, H.W.; Zhu, Z.J.; Huo, L.J.; Chen, Y.; Huo, B.J. Overburden failure height of superhigh seam by fully mechanized caving method. J. China Coal Soc. 2014, 39, 816–821. (In Chinese) [Google Scholar]

- Huo, B.J.; Yu, B.; Zhang, H.W.; Lu, Y.B. Study on formation mechanism of arch shell large structure of overburden in coal mining face with multi layer hard roof. Coal Sci. Technol. 2016, 44, 18–23. (In Chinese) [Google Scholar]

- Wang, J.H.; Yu, B.; Kang, H.P.; Wang, G.F.; Mao, D.B.; Liang, Y.T.; Jiang, P.F. Key technologies and equipment for a fully mechanized top-coal caving operation with a large mining height at ultra-thick coal seams. Int. J. Coal Sci. Technol. 2015, 2, 97–161. [Google Scholar] [CrossRef]

- Ju, J.F.; Xu, J.L. Structural characteristics of key strata and strata behaviour of a fully mechanized longwall face with 7.0 m height chocks. Int. J. Rock Mech. Min. Sci. 2013, 58, 46–54. [Google Scholar]

- Ju, J.F.; Xu, J.L. Surface stepped subsidence related to top-coal caving longwall mining of extremely thick coal seam under shallow cover. Int. J. Rock Mech. Min. Sci. 2015, 78, 27–35. [Google Scholar] [CrossRef]

- Wang, J.C.; Yang, S.L.; Li, Y.; Wang, Z.H. A dynamic method to determine the supports capacity in longwall coal mining. Int. J. Min. Reclam. Environ. 2015, 29, 277–288. [Google Scholar] [CrossRef]

- Lu, Y.Y.; Cheng, Y.G.; Ge, Z.L.; Cheng, L.; Zuo, S.J.; Zhong, J.Y. Determination of Fracture Initiation Locations during Cross-Measure Drilling for Hydraulic Fracturing of Coal Seams. Energies 2016, 9, 358. [Google Scholar] [CrossRef]

| Coal Mine | Working Face | Face Width/Mining Height/(m) | Support Resistance (KN) | Accidents Position/Advancing Distance (m) | Support Shrinkage (mm) |

|---|---|---|---|---|---|

| Tongxin | LTCC-8101 | 205/13.5 | 15,000 | 502(45#~66#), 761(55#~80#), 1088(65#~82#), 1435(40#~66#) | 1000–1200 |

| LTCC-8100 | 205/13.5 | 15,000 | 808(30#~50#), 964(45#~58#) | 900–1100 | |

| LTCC-8106 | 212/12.8 | 15,000 | 143(65#~75#), 300(65#~78#), 482(67#~83#), 706(50#~70#), 817(39#~79#), 1208(50#~76#) | 800–1100 | |

| LTCC-8107 | 240/14.3 | 15,000 | 114(70#~85#), 295(50#~65#), 545(72#~88#), 850(45#~70#), 1049(60#~75#), 1309(50#~80#) | 800–1200 | |

| LTCC-8105 | 200/14.5 | 15,000 | 158(35#~50#), 310(47#~80#), 490(59#~79#), 844(47#~98#), 1140(67#~83#) | 800–1000 | |

| LTCC-8104 | 206/14 | 15,000 | 434(45#~65#), 796(52#~74#), 1476(38#~67#), 1567(62#~90#) | 800–1100 | |

| LTCC-8103 | 200/14 | 15,000 | 538(47#~59#), 1121(60#~70#), 1481(82#~97#), 1677(40#~60#) | 700–1100 | |

| LTCC-8203 | 203/14.5 | 15,000 | 269(47#~67#), 386(30#~45#), 561(40#~60#), 703(25#~55#), 1033(50#~75#), 1210(30#~45#), 1505(40#~60#), 1571(35#~58#), 1622(37#~65#) | 800–1200 | |

| LTCC-west8101 | 245/14 | 15,000 | 98(45#~60#), 115(60#~87#) | 800–1000 | |

| LTCC-8202 | 200/14 | 15,000 | 137(37#~54#), 156(35#~63#), 378(60#~82#), 754(56#~88#), | 700–900 | |

| Tashan | LTCC-8202 | 236/12 | 10,000 | 460(50#~60#), 539(70#~82#), 629(47#~62#), 706(82#~94#), 872(56#~67#) | 500–1000 |

| LTCC-8206 | 237/12.5 | 13,000 | 62(42#~55#), 142(24#~82#), 184(54#~70#), 551(55#~78#), 649(46#~75#), 732(43#~68#) | 600–900 | |

| LTCC-8208 | 236/13 | 13,000 | 102(61#~76#), 415(60#~80#), 450(72#~95#), 529(61#~80#), 1098(47#~72#), 1219(77#~98#) | 800–1000 | |

| LTCC-8210 | 236/12.8 | 13,000 | 780(54#~72#), 1431(37#~85#), 1485(45#~62#), 1630(52#~79#) | 600–900 | |

| LTCC-8212 | 235/13.5 | 13,000 | 713(35#~49#), 1702(63#~82#) | 700–1000 | |

| LTCC-8214 | 230/13 | 13,000 | 590(55#~75#), 763(63#~87#) | 600–900 | |

| LTCC-8216 | 236/13.8 | 15,000 | 518(40#~56#), 906(47#~69#), 967(62#~83#), 1016(34#~70#), 1133(50#~92#) | 700–1000 | |

| Cumulative number of regional support-crushing accidents | 76 | ||||

| Strata | Bulk Density /N × m−3 | Thickness /m | Length /m |

|---|---|---|---|

| Top-coal | = 14,000 | h1 = 11 | l1 = 6.5 |

| Soft rock 1 | = 25,000 | h2 = 25 | l2 = 10 |

| SKS 1 | = 25,000 | h3 = 10 | l3 = 20 |

| Soft rock 2 | = 25,000 | h4 = 6 | l4 = l3 = 20 |

| SKS 2 (main roof) | = 25,000 | h5 = 13 | l5 = 30 |

| Soft rock 3 | = 25,000 | h6 = 10 | l6 = l5 = 30 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Xu, J.; Yu, S.; Ju, J.; Xu, J. Mechanism and Prevention of a Chock Support Failure in the Longwall Top-Coal Caving Faces: A Case Study in Datong Coalfield, China. Energies 2018, 11, 288. https://doi.org/10.3390/en11020288

Li Z, Xu J, Yu S, Ju J, Xu J. Mechanism and Prevention of a Chock Support Failure in the Longwall Top-Coal Caving Faces: A Case Study in Datong Coalfield, China. Energies. 2018; 11(2):288. https://doi.org/10.3390/en11020288

Chicago/Turabian StyleLi, Zhu, Jialin Xu, Shengchao Yu, Jinfeng Ju, and Jingmin Xu. 2018. "Mechanism and Prevention of a Chock Support Failure in the Longwall Top-Coal Caving Faces: A Case Study in Datong Coalfield, China" Energies 11, no. 2: 288. https://doi.org/10.3390/en11020288

APA StyleLi, Z., Xu, J., Yu, S., Ju, J., & Xu, J. (2018). Mechanism and Prevention of a Chock Support Failure in the Longwall Top-Coal Caving Faces: A Case Study in Datong Coalfield, China. Energies, 11(2), 288. https://doi.org/10.3390/en11020288