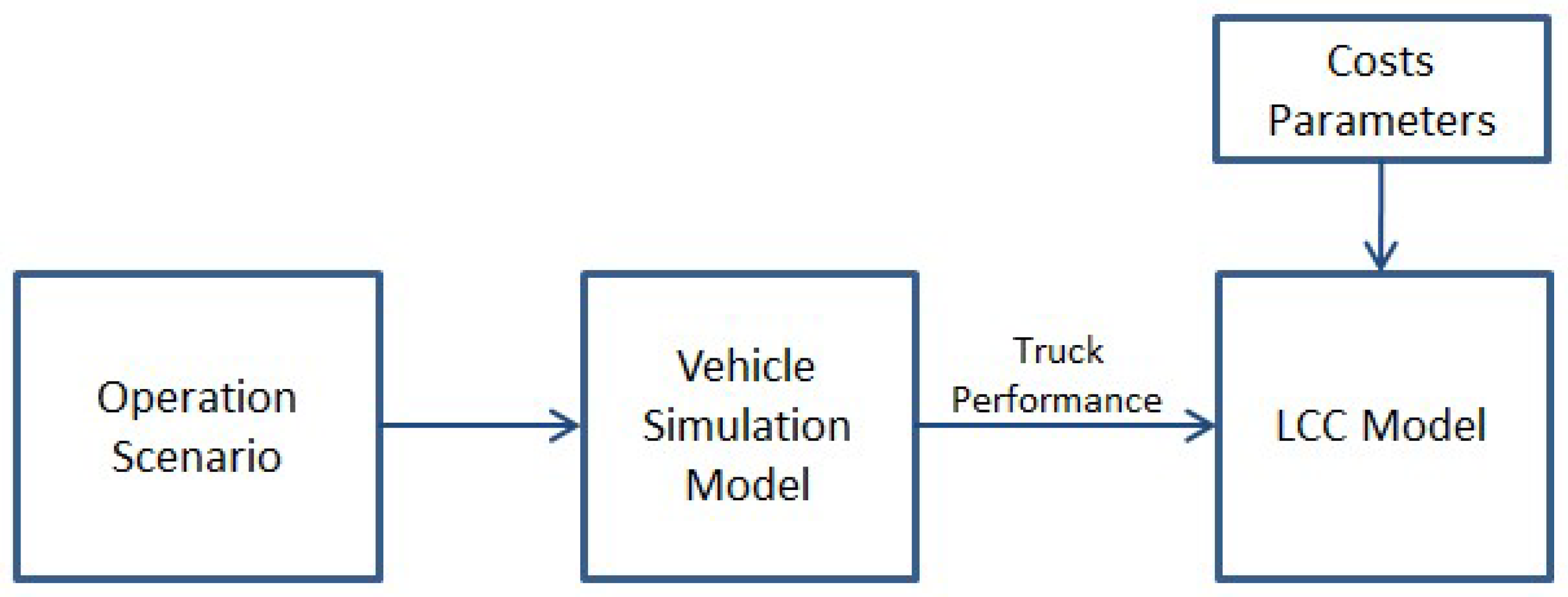

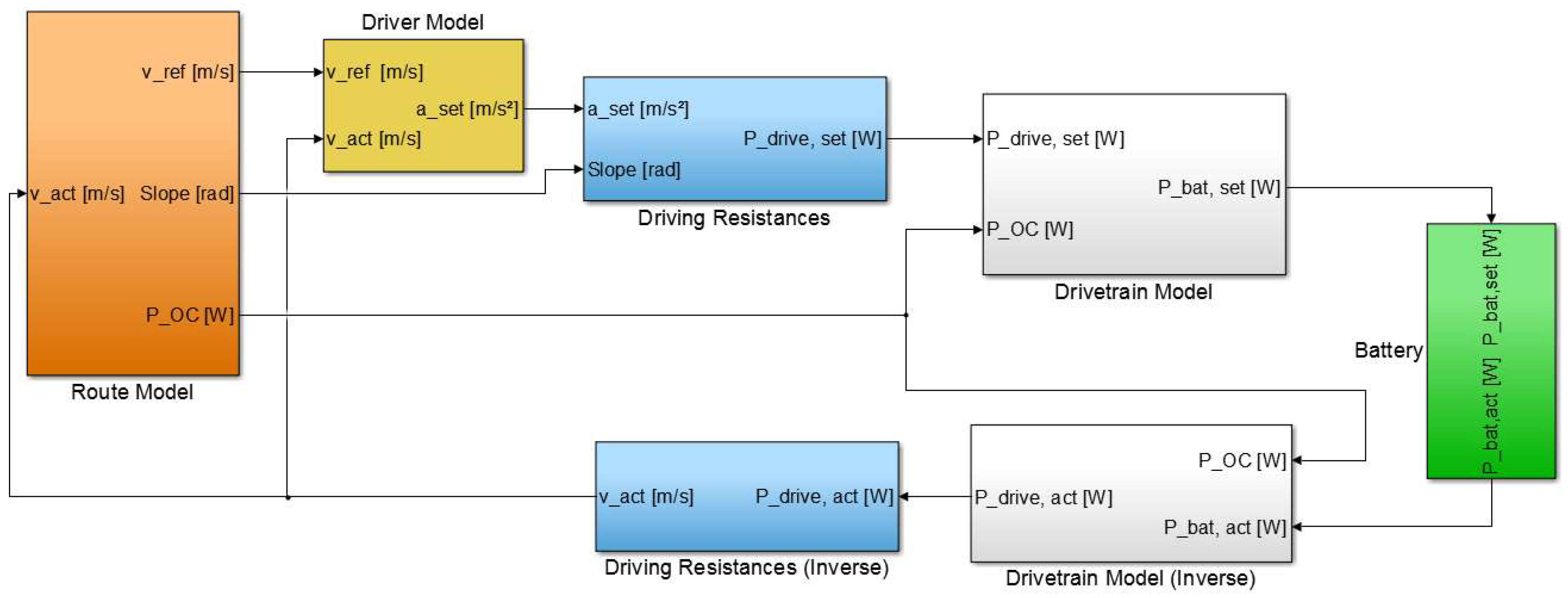

As mentioned in the previous chapter, the vehicle simulation model is used to simulate an overhead catenary truck on the specified driving profile and to obtain the truck performance data as input for the LCC model. The vehicle simulation model itself is implemented in Matlab/Simulink R2015b and its schematic structure is shown in

Figure 2. It consists of route model, driver model, driving resistances model, drivetrain model, and battery model. These are described in the following subchapters.

2.2.3. Driving Resistances Model

The driving resistances model gets the set acceleration

aset, the slope, and the actual velocity

vact and calculates the set drivetrain power

Pdrive,set to overcome the actual driving resistance. The actual driving resistance is the sum of air resistance, rolling resistance, slope resistance, and acceleration resistance. The driving resistances model is described in detail in the previous study [

4].

The driving resistances model was parameterized for a heavy-duty semi-trailer truck with a gross vehicle weight of up to 40 t. The air drag coefficient and the rolling drag coefficient were set to 0.63 resp. 0.007 that corresponds to the average values in the range given in [

11,

12] for European semi-trailer truck.

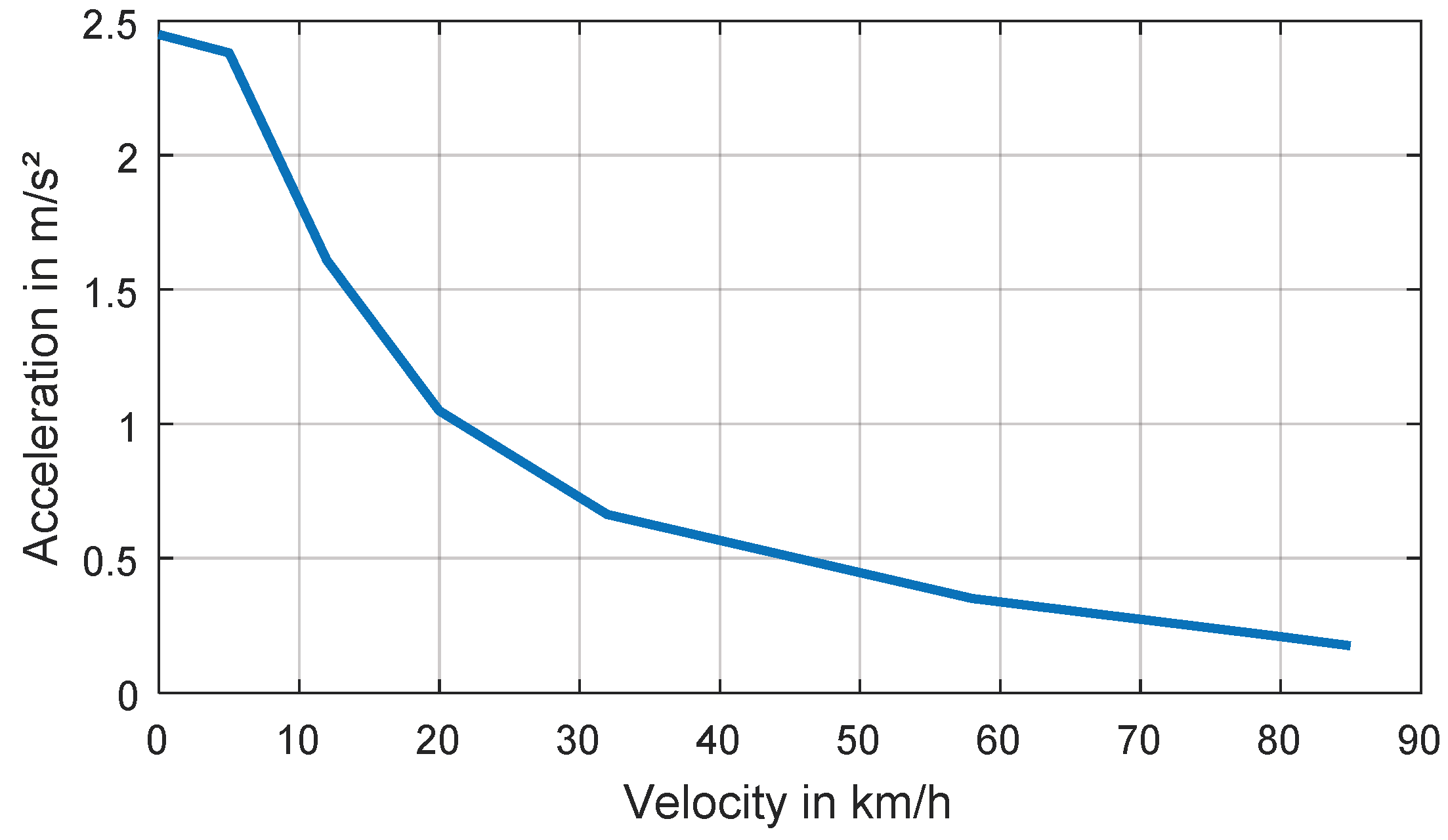

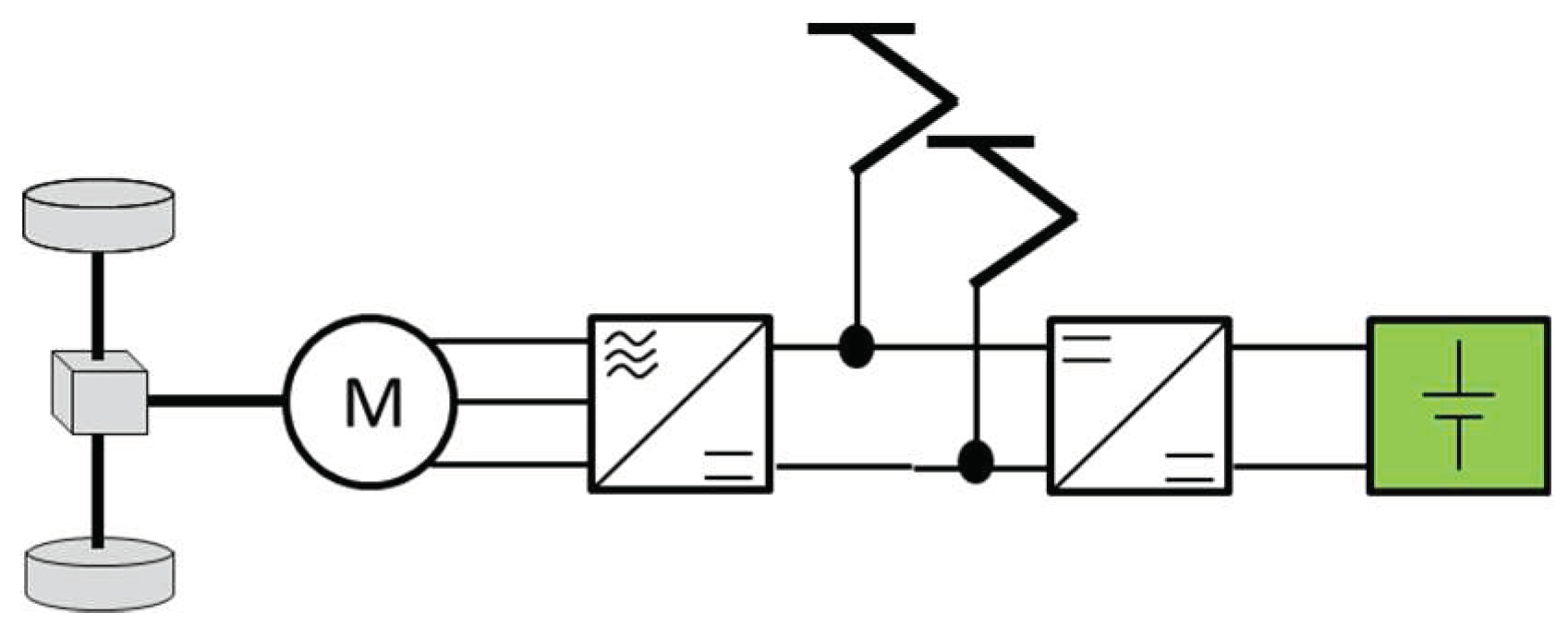

2.2.4. Drivetrain Model

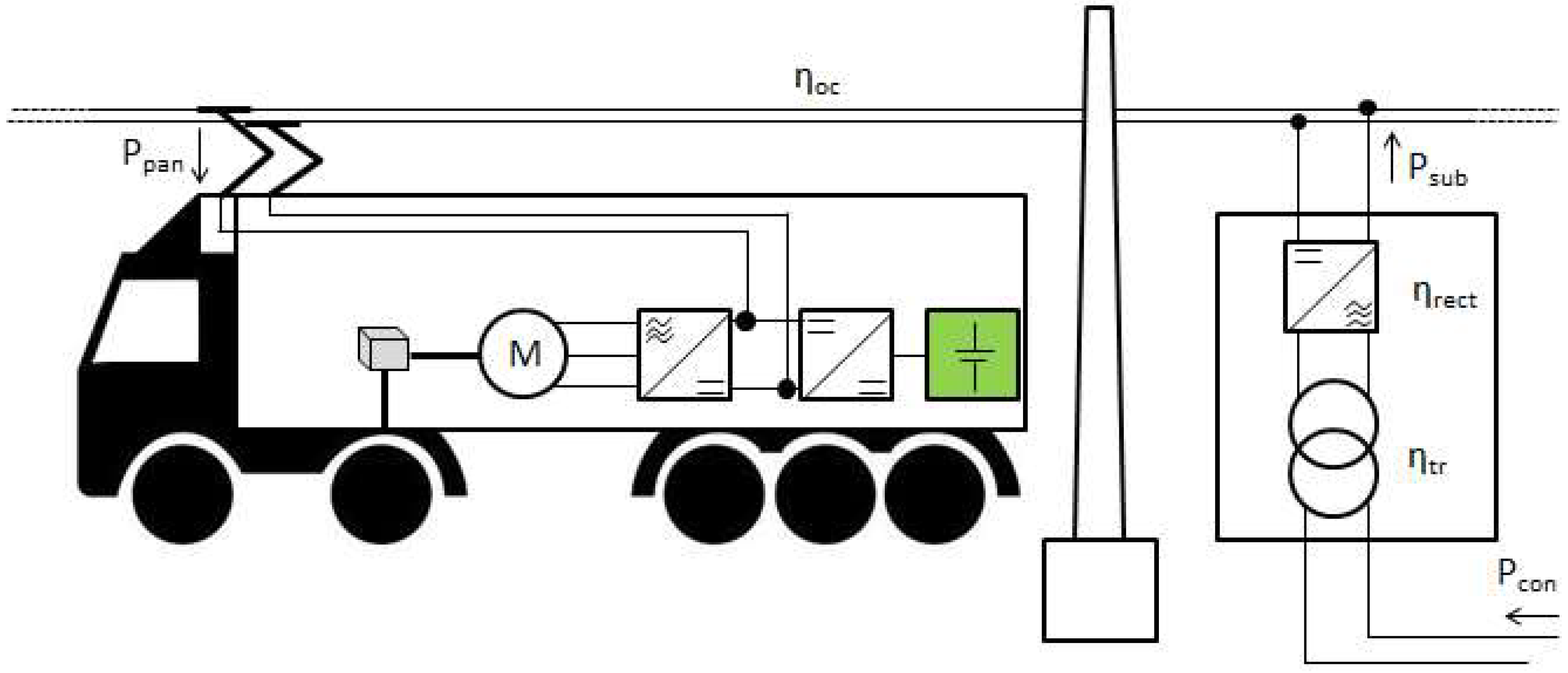

The drivetrain model simulates the drivetrain topology of an overhead catenary truck shown in

Figure 4. It includes electric converters for the traction motor and the battery, pantographs, and an electric motor connected to the drive shaft via a gearbox. The pantographs are connected to the vehicle’s direct current link without a dedicated converter as the voltage in the catenary power systems is controlled to hold a constant value. The battery is connected to the direct current link via a converter to account for the variable battery voltage.

Considering the overhead catenary power

POC, the battery power

Pbat, the power

Pdrive to overcome the driving resistances and the power

Paux for auxiliary consumers, the following power balance at the direct current link results:

where

ηpan is the pantograph efficiency,

ηBC is the efficiency of the battery converter,

ηgearbox is the gearbox efficiency, and

ηmot&conv is the efficiency of the electric motor and its converter. The pantograph efficiency

ηpan is set to 0.99 according to the measurement results of a prototype overhead catenary truck in the project ENUBA 2 [

8]. The efficiency

ηBC of the battery converter is assumed in this study to 0.95. According to the gearbox efficiencies for heavy-duty trucks given in [

13], the gearbox efficiency

ηgearbox is assumed as 0.94. The electric machine and the traction converter were implemented as an efficiency map [

14]. Their efficiency

ηmot&conv depends on the shaft speed and torque. As the implemented three-phase permanent magnet electric motor has a nominal power of 188 kW, two these motors were implemented, providing a total power of 376 kW that is suitable for a heavy-duty truck. The auxiliary power

Paux is assumed constant as 5 kW.

For providing the requested power to the electric motor and auxiliary from the traction battery or the catenary, an energy management system was implemented. In case the catenary is not available, the requested power is completely provided by the traction battery. In case the catenary is available, the requested power is provided by the catenary. The excess catenary power is used to charge the battery. If the catenary power is not sufficient to cover the requested power by the electric motor and the auxiliaries, the battery power is used.

During braking, the regenerated power from the electric motor is provided to auxiliaries and to the traction battery. If the battery is completely charged, the regenerated power is provided to the catenary grid. As the catenary power systems are designated for highway sections with high truck numbers, it is assumed in this study that the catenary grid is always able to receive power from regenerative braking and to provide it to other electric trucks.

First, the drivetrain model calculates the set battery power Pbat,set using Equation (1), the set drivetrain power Pdrive,set to overcome the actual driving resistance, and the overhead catenary power POC. Afterwards, the battery power Pbat,act is simulated by a separate block that is described in the next subsection. Finally, the inverse drivetrain model calculates the actual available drivetrain power Pdrive,act to overcome the driving resistances.

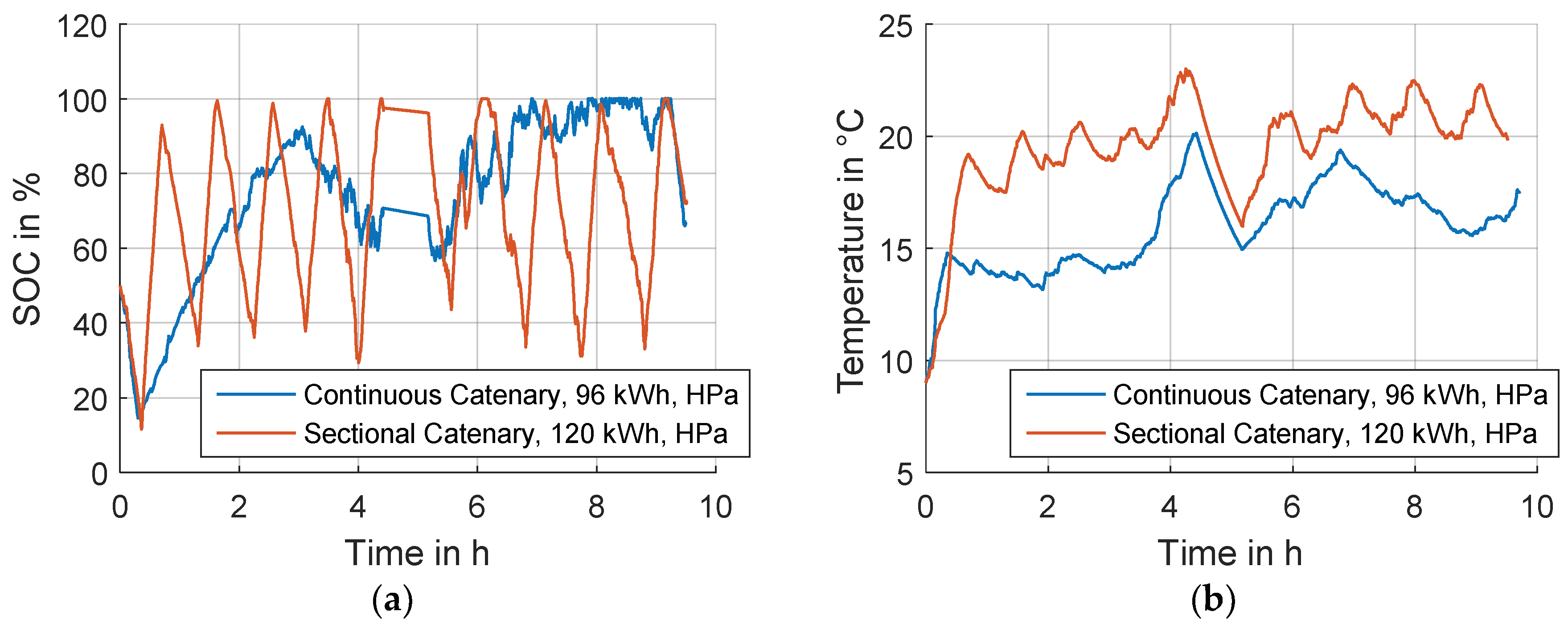

2.2.5. Battery Model

The battery model uses a holistic battery cell model described in [

13] which consists of the impedance-based electric model, thermal model, and aging model. The impedance-based model calculates the cell voltage depending on the current, state of charge, and temperature. The results of the impedance model are passed to the thermal model that calculates the cell temperature due to ohmic losses inside the cell. Afterwards, the cell aging model calculates the cyclic aging and the calendar aging that are added to get the total cell aging.

In this study, the parameterizations for two cell types with data according to

Table 1 [

14,

15] are used. Though the considered cells have the same chemistry, their application fields, capacities, current rates, and cyclic lifetimes are different. The first cell is designed as a cell with high energy density used in automotive applications like fully electric cars [

14]. In contrast to the first cell, the second cell is designed as a high-power cell that can accept high charging and discharging currents but has a smaller energy density. In automotive applications, this cell is typically used in hybrid cars [

15].

The current rate is useful to understand the magnitude of a current value compared to the cell capacity. It is calculated as the current divided by the cell capacity. High power cells usually have higher values of maximum charging and discharging current rates as it is the case for the cells in

Table 1. Using the mathematical cell aging model [

15], the maximum number of full cycles was calculated at the current rate of 1 C and the ambient temperature of 15 °C. The cell’s end of life is reached at 20% capacity loss or at doubled internal resistance. The battery pack costs given in

Table 1 are assumed for battery packs using cells and considering the full cycles number of the cell and actual battery prices [

16].

After running the vehicle simulation model including the battery model for a specified operation period, the cell data is passed to the cell aging model [

13]. The cell aging model calculates the actual residual capacity and the actual internal resistance of the cell after operation in the simulated scenario period. After the aging calculation, the actual capacity and internal resistance are passed back to the vehicle simulation model to calculate the truck performance for the next operation period. The end of life of a battery cell is usually defined by reaching 80% of the initial capacity or by doubling the initial internal resistance of the cell. After reaching one of these conditions, LCC calculation is executed.